- Water intake when the supply is turned off

- Instructions for connecting and starting the system

- Features of piping an indirect heating boiler

- What pipes are suitable for tying

- Design features of an indirect boiler

- The principle of operation of the boiler

- What is an indirect heating boiler and what are they

- Kinds

- Which boilers can be connected to

- Tank shapes and installation methods

- Operation and mode of operation

- In private

- In a multistory

- How to choose an indirect heating boiler

- Calculation of the volume of the storage tank

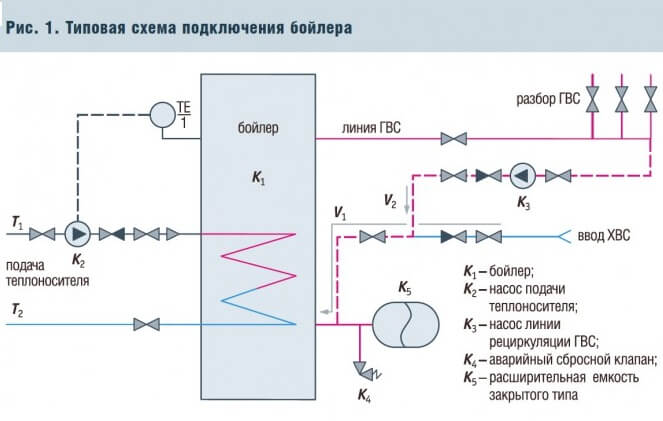

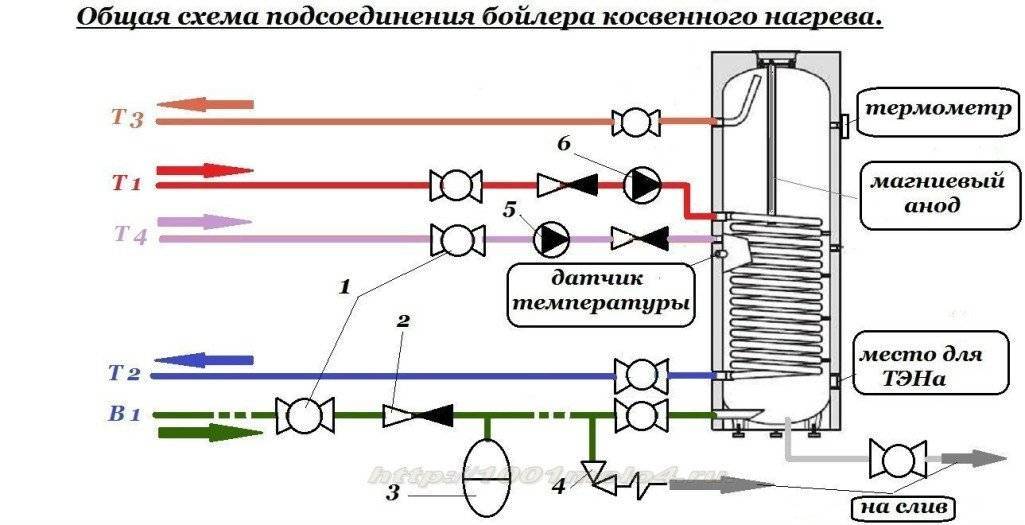

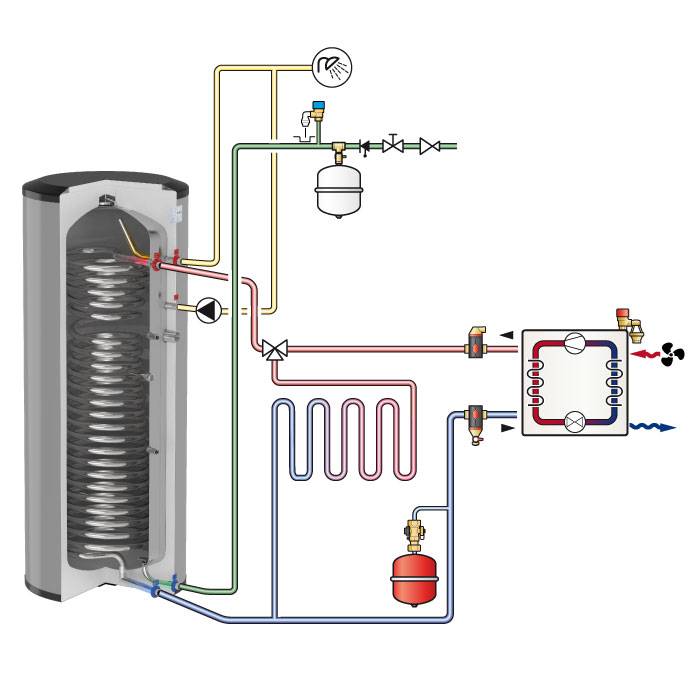

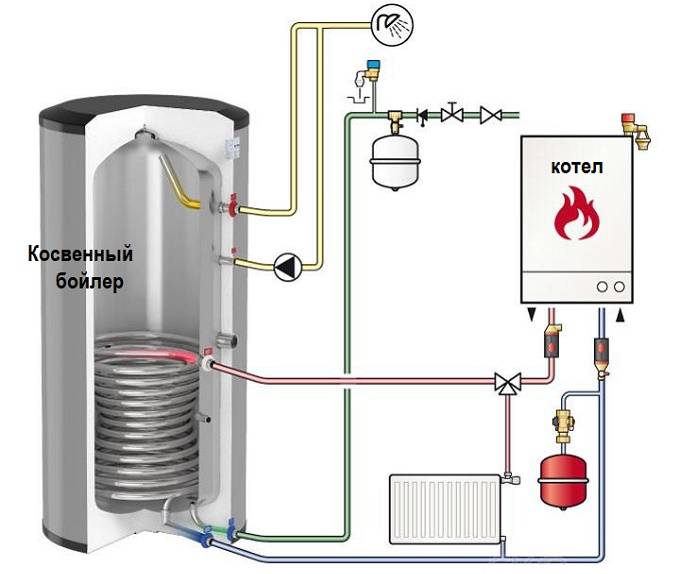

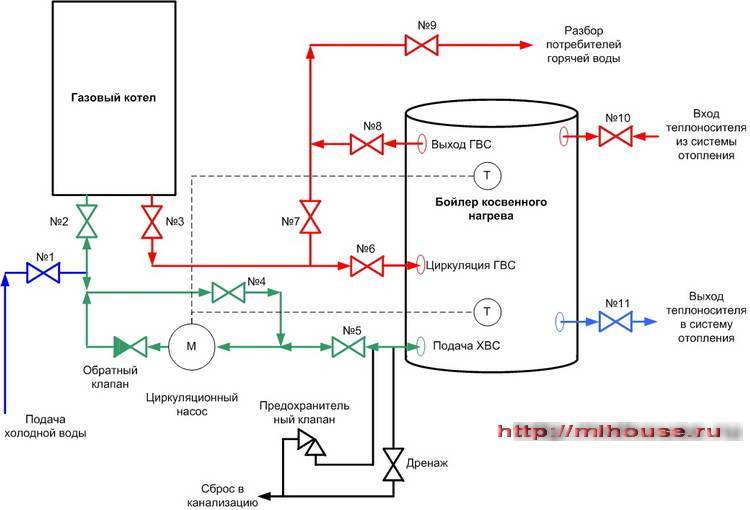

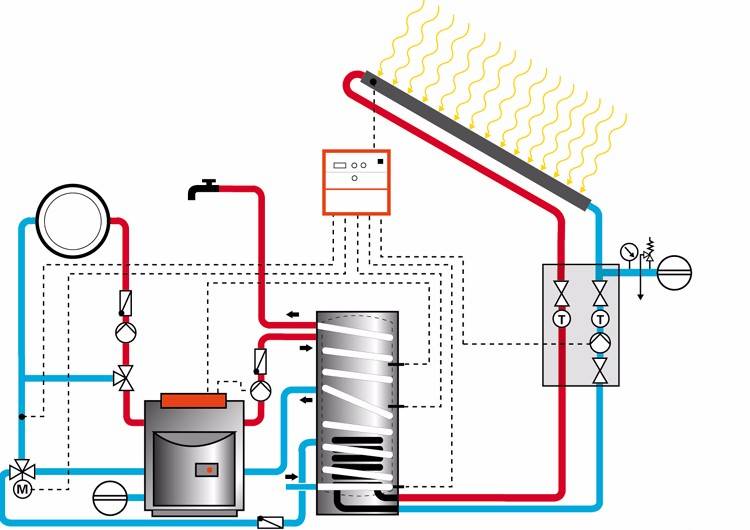

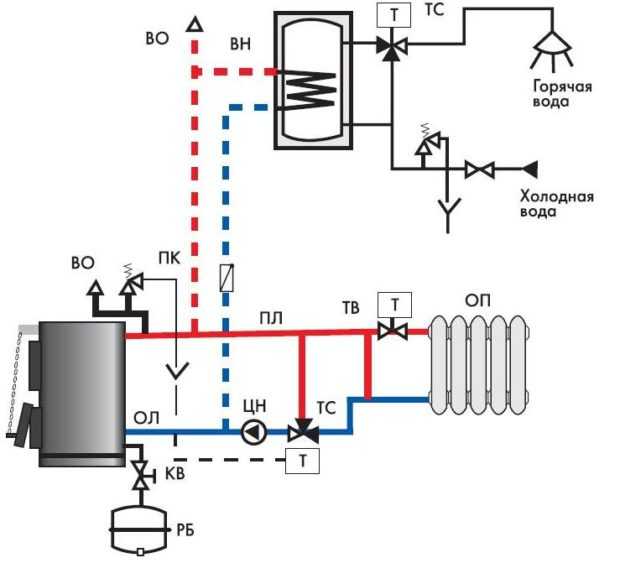

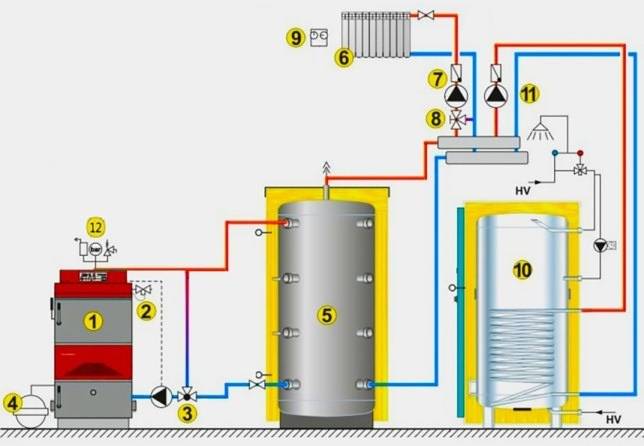

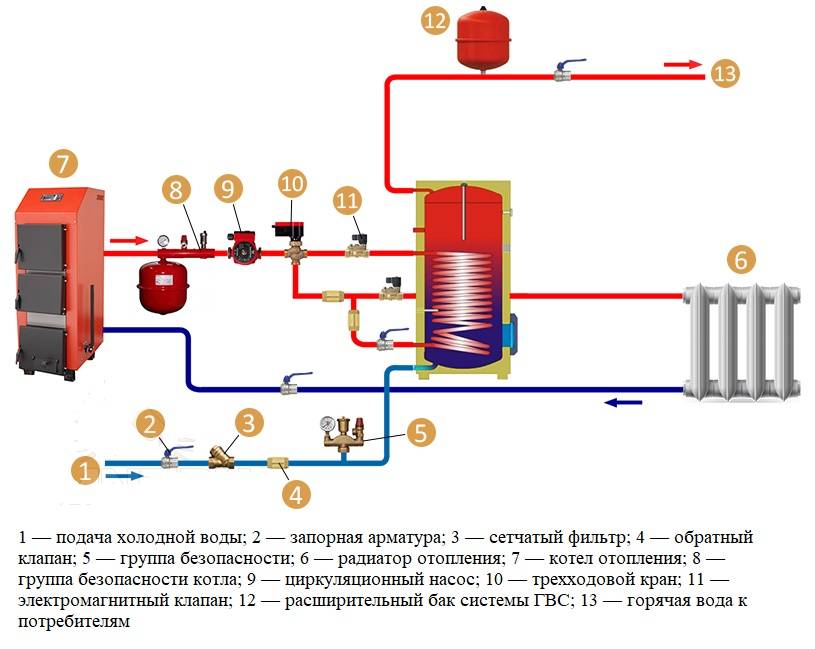

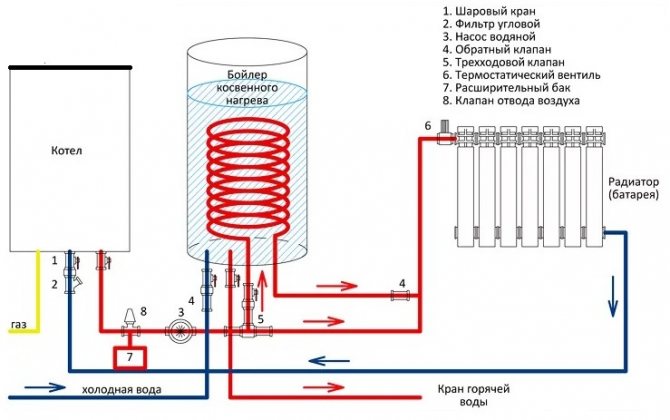

- Connection diagrams for the heating system

- Indirect heating boiler pros and cons

- Connecting the boiler to the water supply from different materials

- Polypropylene pipelines

- Insertion into a metal pipeline

- metal-plastic

Water intake when the supply is turned off

Most storage water heaters have a closed type device and do not drain water by gravity. However, there are a number of strapping additions that make it possible to draw water in the absence of pressure. These same additions make it easier to empty the tank if it is removed for maintenance.

First of all, the theory: the hot tank pipe reaches the very top of the tank, the cold one is located below under the diffuser cap. Water is drained precisely through the cold pipe, and air is sucked into the tank through a long hot outlet pipe.

The simplest solution is to embed a tee into the hot outlet up to the ball valve installation site. Using these two taps, you can provide the tank with air leakage and use hot water from the "cold" pipeline. But this approach is not entirely safe: forgetting to turn off the air suction valve, you risk flooding your home when pressure appears in the cold water supply system.

The problem is solved in two ways. The first is to install a check valve on the air suction valve at the hot inlet. The problem is that there is almost always a small amount of water in the high tube of a filled tank, so the system does not work very stably - the water column prevents the valve from opening even if there is a relative vacuum in the tank. You have to bleed the water from the tube manually when you first open the system.

1 - tee; 2 - check valve; 3 - valve for air suction

1 - tee; 2 - check valve; 3 - valve for air suction

It is also possible to install a check valve bypassing the cold supply shut-off valve. In this case, the valve is installed opposite to the normal flow of water, blocking its entry into the tank when pressure is applied. As before, this task can be solved with even fewer three-way valves.

Instructions for connecting and starting the system

When preparing the boiler for operation, it is first connected to the heating system. It can be a network of a home autonomous boiler or a central highway. During the connection process, the lid of the water heater tank must be open. When all the pipes are connected to each other in the right order, open the shut-off valve of the return pipe to make sure that there are no leaks at the joints and the pipes themselves.

If no leaks are found, you can open the coolant supply valve to the coil.After the spiral warms up to normal temperature, the structure is once again inspected for leaks.

If everything is in order, close the tank lid and draw water into it, and also open the hot water supply tap to the water supply. Now you can evaluate the quality of heating.

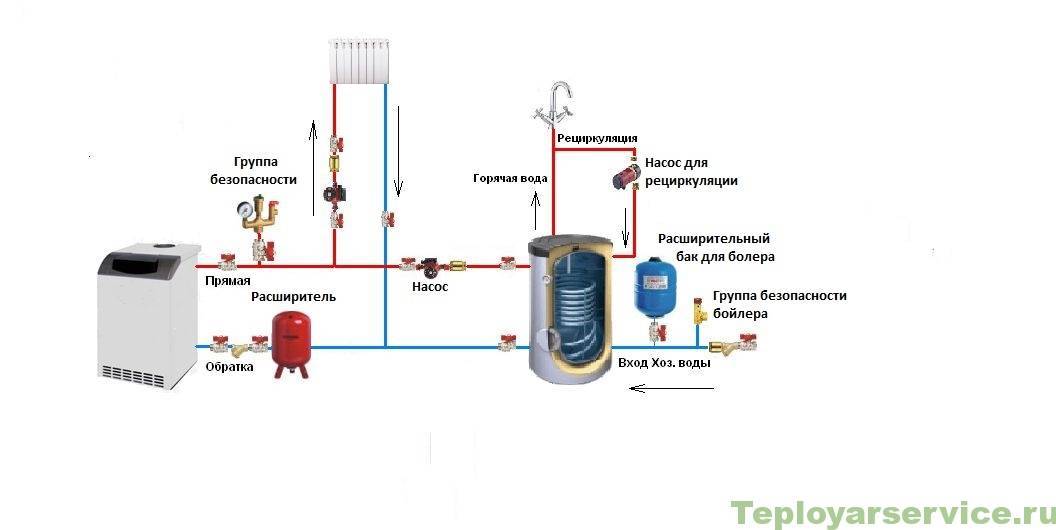

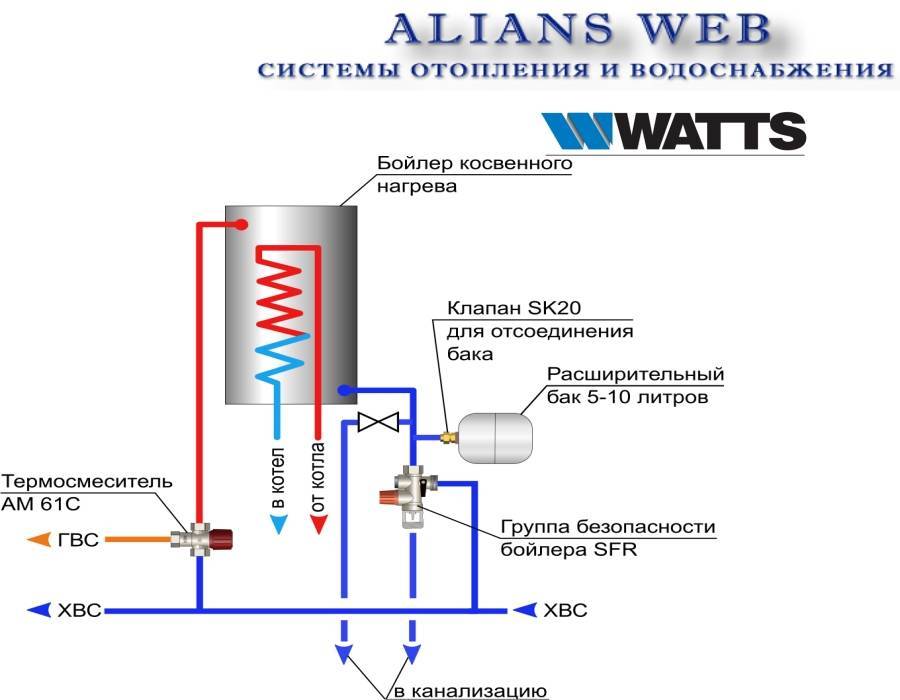

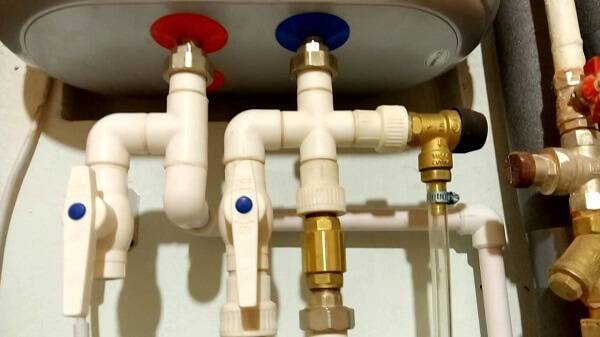

Features of piping an indirect heating boiler

It is easier to do wiring and piping if the KN boiler is installed together with the boiler, pumps and other equipment involved in the assembly of the DHW system. Embedding an additional device into an already existing network is much more difficult.

In any case, for the normal operation of the devices, you will have to follow a number of rules:

- choose the right place for installation - as close as possible to the boiler;

- provide a flat surface for mounting the boiler;

- to protect against thermal expansion, install a membrane accumulator (at the outlet of heated water), the volume of which is at least 1/10 of the volume of the BKN;

- equip each circuit with a ball valve - for convenient and safe maintenance of devices (for example, a three-way valve, a pump or the boiler itself);

- to protect against backflow, install check valves on the water supply pipes;

- improve water quality by inserting filters;

- correctly position the pump (or several pumps) - the motor axis must be in a horizontal position.

For safety reasons, do not attempt to mount heavy devices on plasterboard or thin wooden partitions. Concrete and brick walls are suitable. Brackets or other types of holders are fixed with brackets, anchors, dowels.

Regardless of the type of device - floor or wall - if possible, it is mounted above the level at which the boiler is installed, or at the same level.For outdoor, you can make a pedestal or a solid stand up to 1 m high

When installing, the nozzles are directed towards the boiler (even if they are masked in the back or behind a false wall). Do not use unreliable equipment, such as corrugated hoses that cannot withstand the pressure and pressure of water.

For normal operation of the storage water heater of indirect heating, the following functional devices must be included in the piping:

- A complex technical system must be equipped with pumps that supply hot sanitary water to the taps and stimulate the movement of the coolant along the heating branch, as well as along the water heating circuit in the boiler

- Cold water coming from a public or autonomous water supply must be cleaned through a sump or filter system that destroys lime salts before being supplied to the boiler. Filtration will prevent the formation of mineral sediment

- After the sump or water filtration system, there must be a pressure reducer. However, it is only needed if the pressure in the branch exceeds 6 bar

- Before entering cold water into the boiler, a check valve is required to prevent reverse flow.

- In order for the heating water to have a reserve for expansion during the period when it is not used, an expansion tank and a pressure relief valve are included in the piping

- To prevent excessively hot water from entering the taps, threatening burns, a three-way mixing valve must be installed in the circuit. It will mix portions of cold water with hot water, as a result, there will be water at the required temperature for the user

- In order for the heat carrier from the heating to enter the "jacket" heating the sanitary water only when it is needed, a two-way thermostat is installed. Its server is connected to the water heater temperature sensor

- If the hot water consumption in the house is large enough, it is advisable to purchase a boiler with a built-in additional instantaneous water heater or buy a separate device and include it in the hot water supply branch. In case of its shortage, a miniature protochnik will turn on and save the situation.

What pipes are suitable for tying

To connect the boiler and heating wiring, it is better to take metal-plastic or polypropylene pipes. They will cost less than galvanized or copper counterparts.

Sequential wiring of radiators is carried out using metal-plastic pipes on press fittings or polypropylene pipes with aluminum reinforcement. However, each of these options has its drawback. Press fittings are sensitive to the quality of installation and leakage can occur at the slightest displacement. Polypropylene, on the other hand, has a high coefficient of elongation when heated to more than 50°C. For wiring the "warm floor" system, metal-plastic on press fittings, polyethylene or thermomodified polyethylene are used.

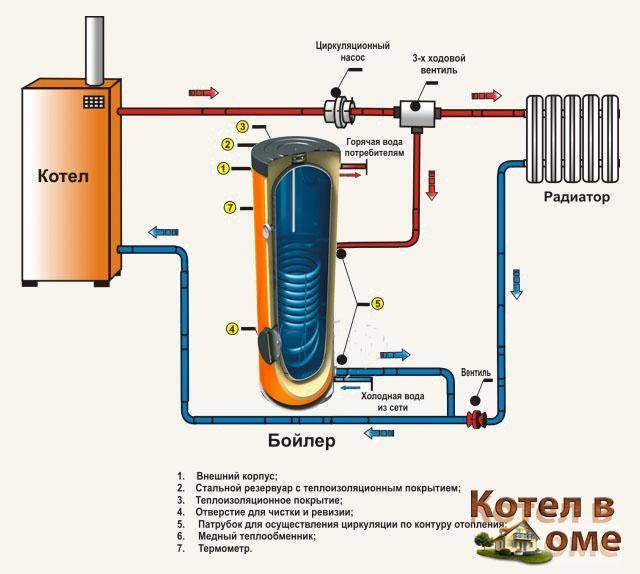

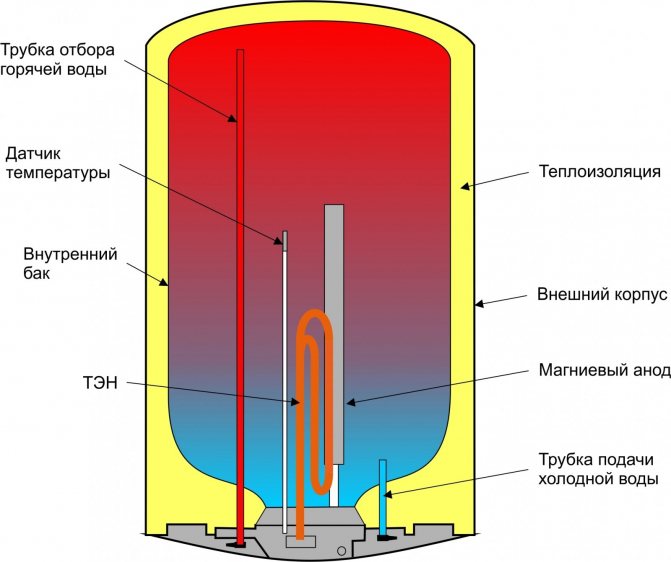

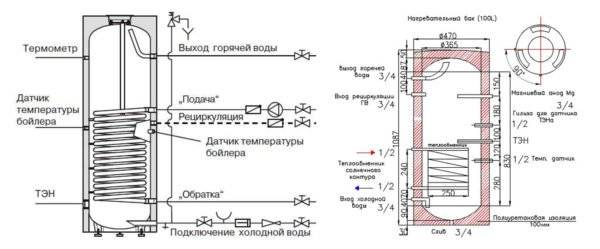

Design features of an indirect boiler

The indirect type boiler is a tank made of stainless steel. The inner walls of the tank are covered with a special material, which not only protects the surface of the water heater from corrosion processes, but also reduces the concentration of harmful bacteria and microorganisms.

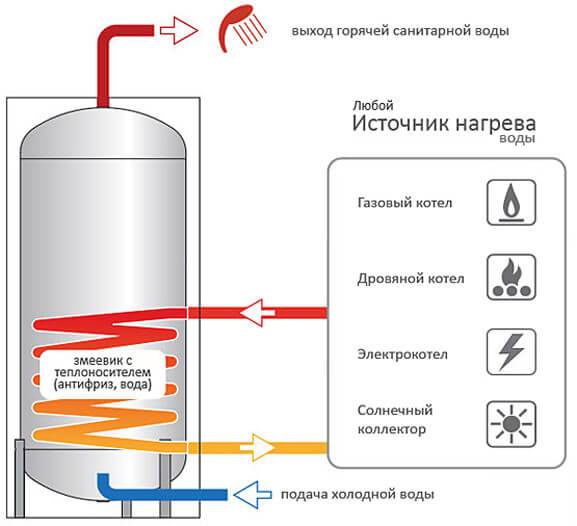

Scheme of the device of an indirect type boiler with a single-circuit coil

The rest of the boiler of the simplest design consists of the following components:

- the heat exchanger is a coiled tube or smaller tank. Depending on the volume of the tank, it can be located in its upper and lower parts;

- inlet pipe - a fitting at the bottom of the device for supplying a pipe with cold running water;

- outlet pipe - fitting for connecting the hot water outlet pipe;

- magnesium anode - additional protection of the tank walls from corrosion processes;

- internal thermometer - a device for measuring the temperature of water heating;

- thermostat - a device that prevents equipment from overheating;

- control unit - rotary knob with divisions for setting the heating temperature;

- thermal insulation - a layer of insulating material that helps maintain a given temperature of heated water;

- outlet - valve for draining stagnant water;

- revision - a large diameter hole designed for maintenance, repair and modernization of the boiler.

The design of new tank models may differ slightly and have a number of improvements from manufacturers, but in general, any indirect type boiler consists of the listed elements.

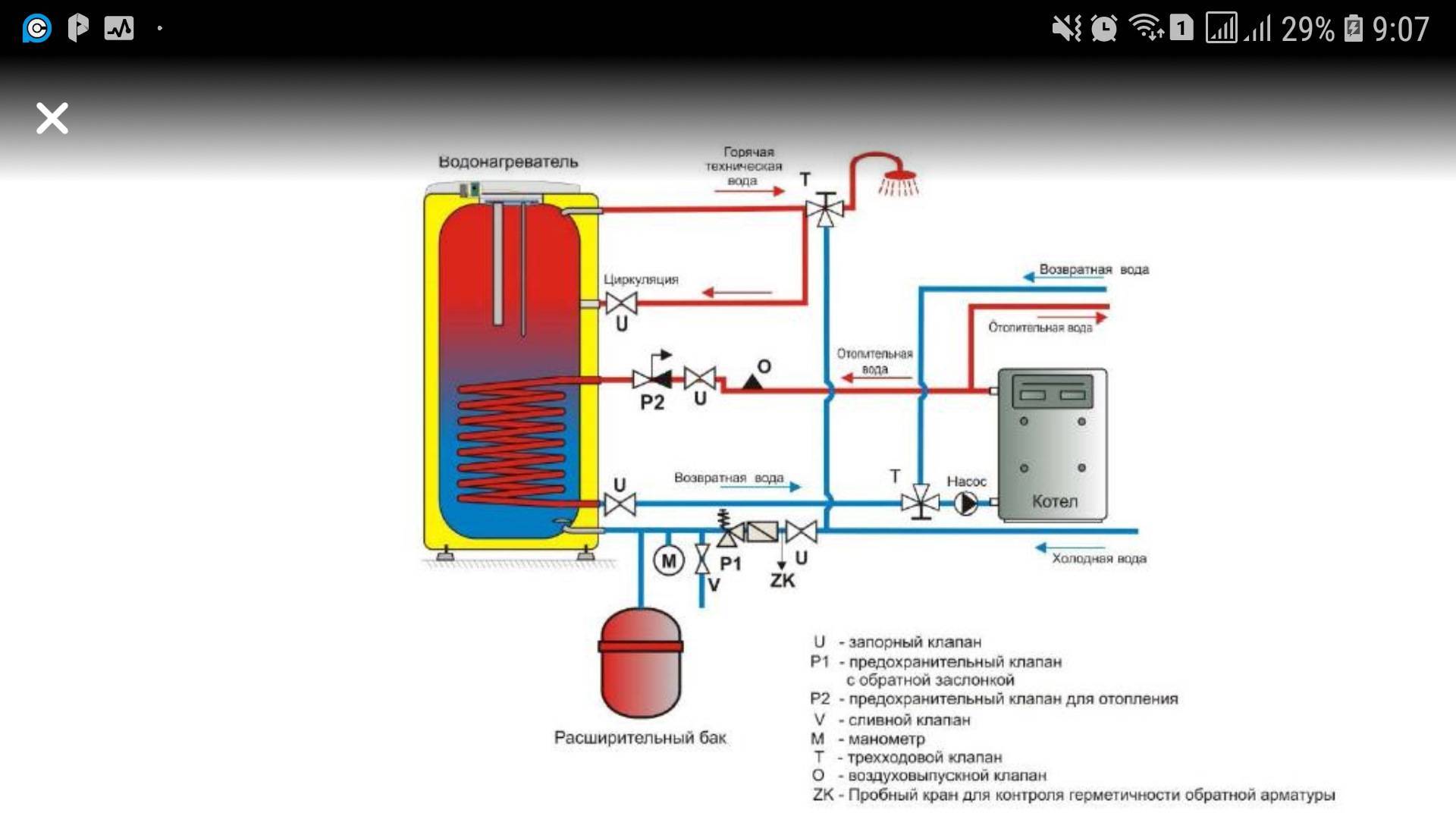

The principle of operation of the boiler

An indirect type boiler is part of the heating system and is connected directly to a gas, electric or solid fuel boiler, which heats the coolant using the energy released during fuel combustion.

The heat carrier circulates through the DHW system and passes through the heat exchanger located in the indirect heating boiler. Due to the release of thermal energy from the hot coolant, cold water is heated, which fills the device tank.From it, heated water is transported through the outlet through the pipe to the bathroom, to the kitchen and to other rooms with sanitary equipment.

An indirect type boiler can work with any type of heating boiler

When the heating boiler is turned off or it switches to an economical mode of operation, the coolant cools down quickly. Thanks to the design, which provides for the insulation of the walls of the tank with urethane foam, the water in the tank cools very slowly. This allows you to use the entire volume of warm water for several more hours.

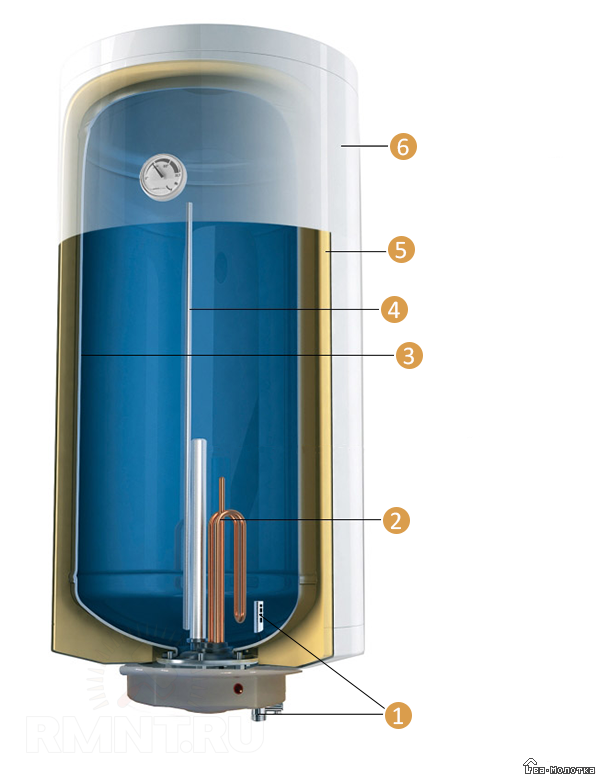

What is an indirect heating boiler and what are they

A water heater or an indirect exchange boiler is a tank with water in which a heat exchanger is located (a coil or, according to the type of water jacket, a cylinder in a cylinder). The heat exchanger is connected to a heating boiler or to any other system in which hot water or other coolant circulates.

Heating is simple: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the tank. Since the heating does not occur directly, then such a water heater is called "indirect heating". The heated water is used for household needs as needed.

Indirect heating boiler device

One of the important details in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

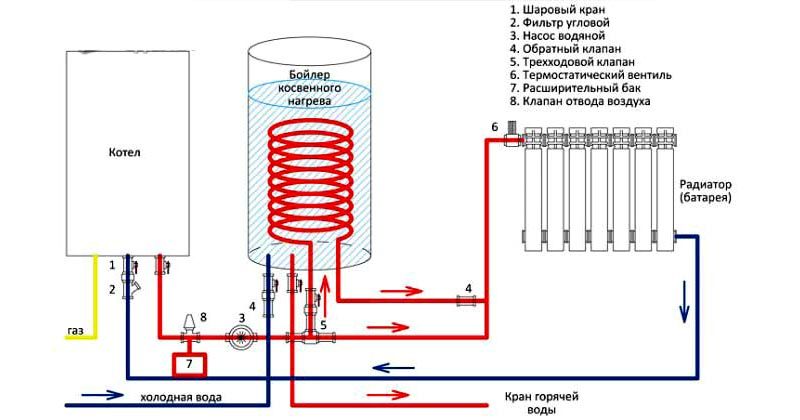

Kinds

There are two types of indirect heating boilers: with built-in control and without. Indirect heating boilers with built-in control are connected to a heating system powered by boilers without control.They have a built-in temperature sensor, their own control that turns on / off the supply of hot water to the coil. When connecting this type of equipment, all that is needed is to connect the heating supply and return to the corresponding inputs, connect the cold water supply and connect the hot water distribution comb to the upper outlet. That's all, you can fill the tank and start heating it.

Conventional indirect heating boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the body) and connect it to a certain boiler inlet. Next, they make the piping of the indirect heating boiler in accordance with one of the schemes. You can also connect them to non-volatile boilers, but this requires special schemes (see below).

What you need to remember is that the water in the indirect heating boiler can be heated just below the temperature of the coolant circulating in the coil. So if your boiler works in low-temperature mode and produces, say, + 40 ° C, then the maximum temperature of the water in the tank will be just that. You can't heat it up anymore. To get around this limitation, there are combined water heaters. They have a coil and a built-in heating element. The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good in tandem with solid fuel boilers - the water will be warm even when the fuel has burned out.

What else can be said about the design features? Several heat exchangers are installed in large-volume indirect systems - this reduces the time for heating water. To reduce the time of heating water and for slower cooling of the tank, it is better to choose models with thermal insulation.

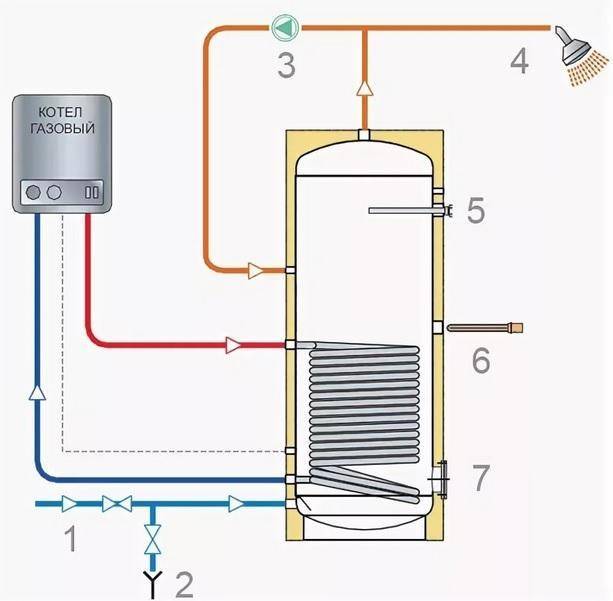

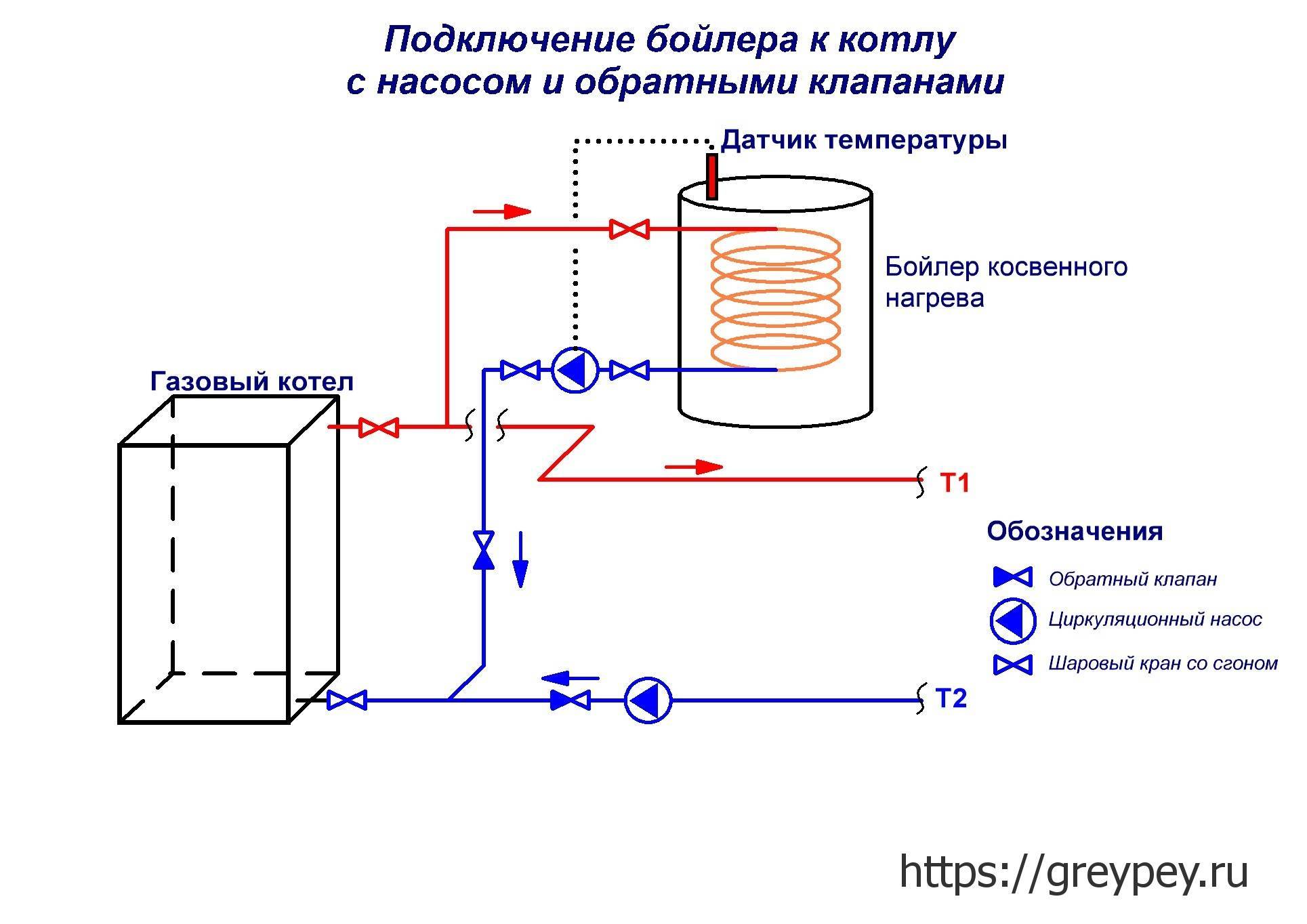

Which boilers can be connected to

Boilers of indirect heating can work with any source of hot water. Any hot water boiler is suitable - solid fuel - on wood, coal, briquettes, pellets. It can be connected to any type of gas boiler, electric or oil-fired.

Scheme of connection to a gas boiler with a special outlet for an indirect heating boiler

It’s just that, as already mentioned above, there are models with their own control, and then installing and tying them is a simpler task. If the model is simple, it is necessary to think over a system for controlling the temperature and switching the boiler from heating radiators to heating hot water.

Tank shapes and installation methods

The indirect heating boiler can be installed on the floor, it can be hung on the wall. Wall-mounted options have a capacity of no more than 200 liters, and floor options can hold up to 1500 liters. In both cases, there are horizontal and vertical models. When installing the wall-mounted version, the mount is standard - brackets that are mounted on dowels of the appropriate type.

If we talk about the shape, then most often these devices are made in the form of a cylinder. In almost all models, all working outputs (pipes for connection) are brought out at the back. It is easier to connect, and the appearance is better.On the front of the panel there are places for installing a temperature sensor or a thermal relay, in some models it is possible to install a heating element - for additional heating of water in case of a lack of heating power.

By type of installation, they are wall-mounted and floor-mounted, capacity - from 50 liters to 1500 liters

When installing the system, it is worth remembering that the system will work effectively only if the boiler capacity is sufficient.

Operation and mode of operation

After assembly and performance testing, the recirculation system is put into operation. It works continuously.

Some users, trying to save energy and equipment life, turn off the system at night or during a long absence.

This is a very effective solution, but you will have to get up early in the morning to start the movement of water and raise its temperature. However, you can spend a little money and install a control unit. It will automatically stop the circulation and restart it according to the set program.

In private

For a private house, a continuous circulation mode is recommended.

This is especially important if the house uses an autonomous sewer.

Dumping excess water will necessitate frequent evacuation of the receiving tank, which will add cost and hassle.

In a multistory

DHW recycling in multi-storey buildings works automatically, without the participation of residents. The system is configured so that all control is located in the basement (in the boiler room), and does not require outside intervention.

All maintenance, repairs and other works are carried out by employees of the management company. This is convenient for apartment residents, as it relieves them of concern about the condition of the equipment.

How to choose an indirect heating boiler

Making the right choice of a suitable indirect heating boiler model is a difficult task for a beginner. However, there is nothing overwhelming here, you just need to take into account a few important nuances:

When choosing a water heater with indirect heating for an apartment or a private house, the first step is to determine the optimal volume of the storage tank. In order for all family members to have enough hot water, they calculate taking into account the approximate consumption of 100 liters per day by one person.

Cost-effective indirect water heating boiler for a family of four or more people

With this number of people, the approximate consumption of hot water is 1.5 l / min.

Paying attention to the volume of the tank, take into account the heating time. Large capacity will take longer to heat up. It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system.

The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off.

Cheap water heaters come with foam. Porous material poorly retains heat and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam.

To make the right choice, you need to compare the power of the indirect water heater and the heating boiler. If the latter is characterized by weak parameters, the boiler will become an unbearable load.

When buying any model, be sure to pay attention to the presence of a thermostat, valve and other security elements.

It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system.

The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off. Cheap water heaters come with foam.Porous material poorly retains heat and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam.

To make the right choice, you need to compare the power of the indirect water heater and the heating boiler

If the latter is characterized by weak parameters, the boiler will become an unbearable load.

When buying any model, be sure to pay attention to the presence of a thermostat, valve and other security elements.

When the issue is resolved with all the important nuances, you can pay attention to the form, design, manufacturer and other details.

Calculation of the volume of the storage tank

To make an approximate calculation of the volume of the storage tank, you can use a simple reading of the water meter. When the same number of people constantly arrive at the house, the daily consumption will have the same data.

A more accurate calculation of the volume is based on counting the water points, taking into account their purpose and the number of living family members. In order not to go into complex formulas, the hot water consumption is taken from the table.

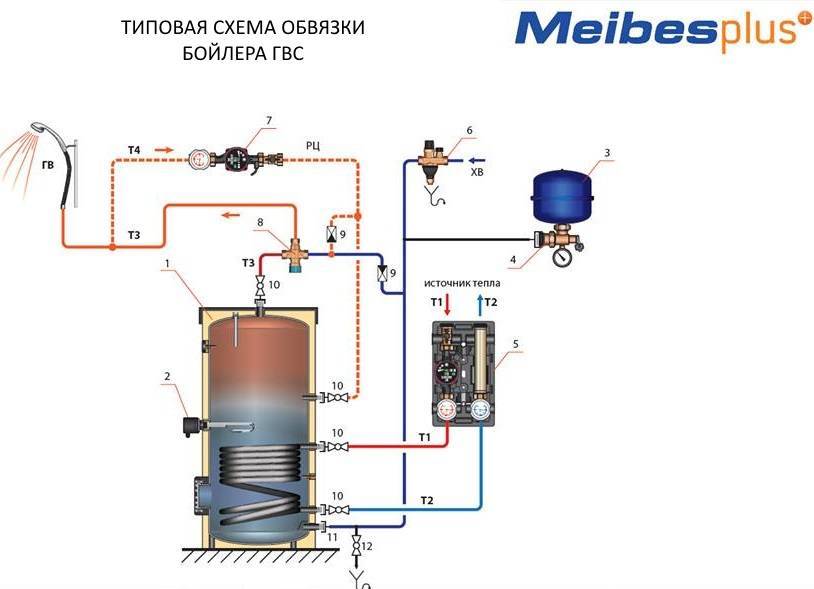

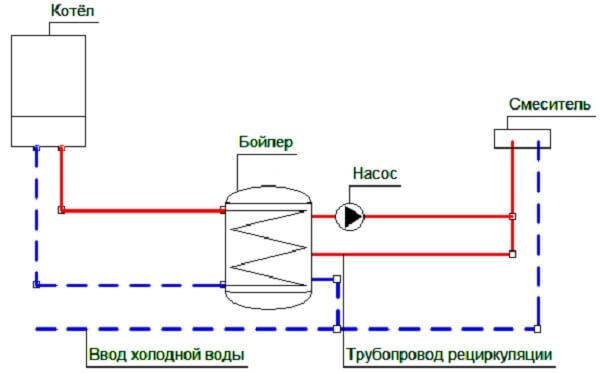

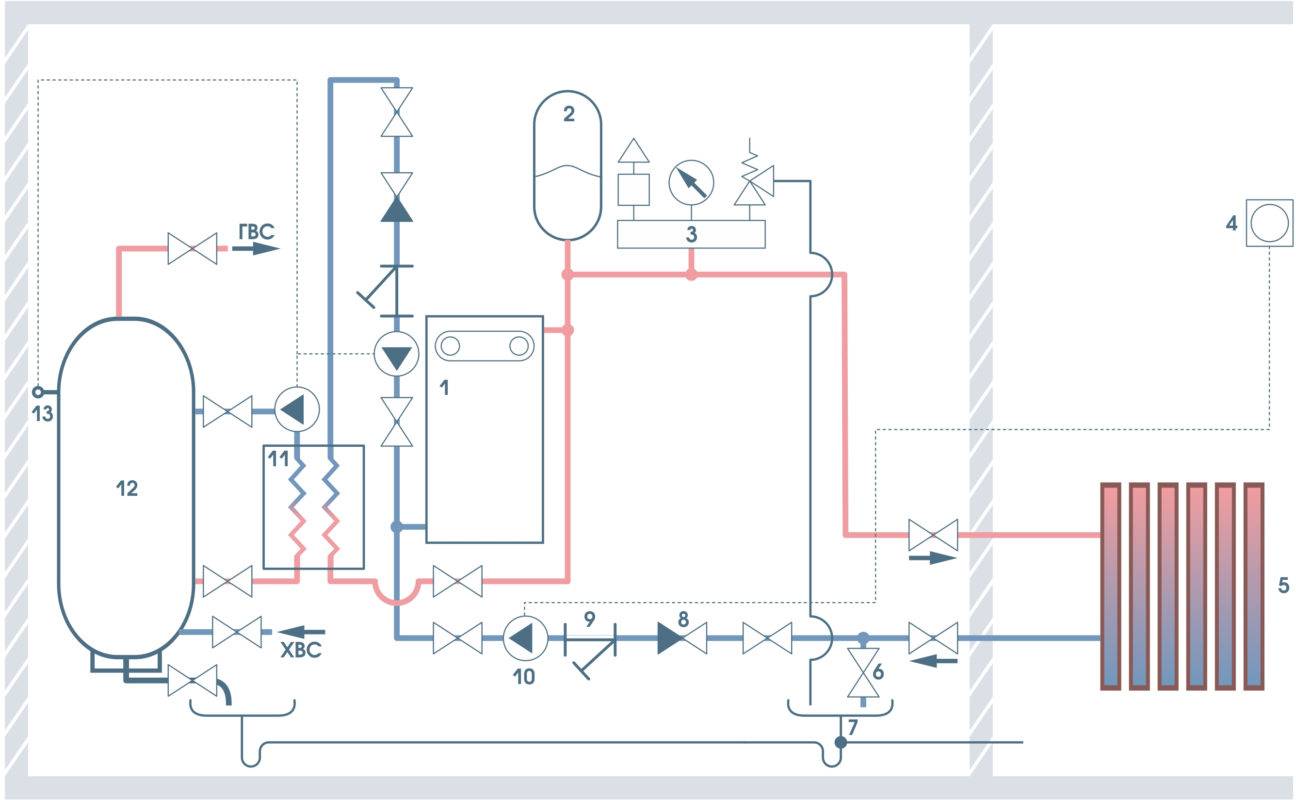

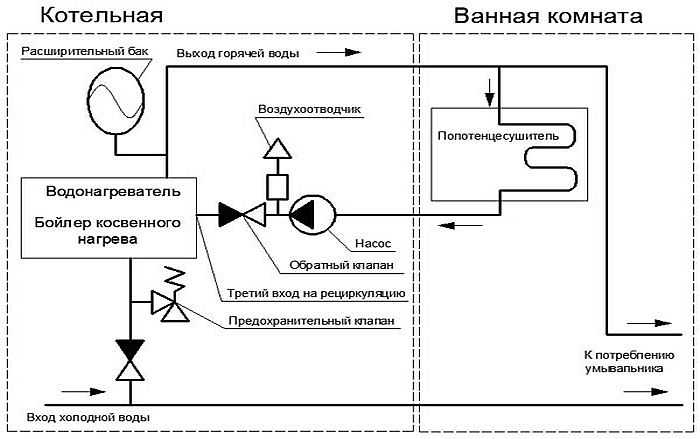

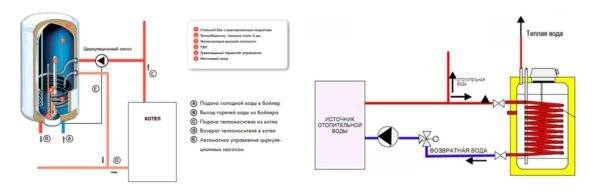

Connection diagrams for the heating system

When choosing a connection scheme for an indirect boiler for heating water, the location of the device in the house, as well as the features of the heating system wiring, are taken into account.

A simple and commonly used scheme is based on connecting an indirect device through a three-way valve. As a result, two heating circuits are formed: heating and hot water. After the boiler, a circulation pump crashes in front of the valve.

If the need for hot water is small, a system diagram with two pumps is suitable.The indirect water heater and the boiler form two parallel heating circuits. Each line has its own pump. The scheme is suitable for country houses where hot water is rarely used.

The connection diagram is more complicated if the house has a “warm floor” system installed along with radiators. To distribute pressure across all lines, and together with an indirect boiler they will get three, a hydraulic distributor is installed. The node normalizes the circulation of water through the "warm floor", water heater and radiators. Without a distributor, pumping equipment will fail.

In indirect water heaters with recirculation, three nozzles come out of the body. Traditionally, two outputs are used to connect to the heating system. A looped circuit is led from the third branch pipe.

If the indirect water heating device does not have a third branch pipe, and recirculation must be done, then the return line circuit is connected to the cold water pipe and the recirculation pump is additionally inserted.

Recirculation allows you to get hot water at the outlet of the tap even before the liquid in the storage tank of the boiler is completely heated.

Indirect heating boiler pros and cons

The advantages of using an indirect heating boiler in the hot water system of a private house include:

- Comfort in use. DHW as in an apartment;

- Rapid heating of water (due to the fact that all 10-24 or even more kW of boiler energy are used);

- No scale in the system. Because heating is carried out through a heat exchanger, and its temperature does not exceed the boiling point of water. Of course, the problem is not completely solved, but its education is significantly reduced.Also, storage water heaters can be equipped with anodes made of various materials (aluminum, magnesium, titanium). Which also contributes to the resistance to corrosion of the tank itself and prevents the formation of scale.

- Possibility to organize a water recycling system. Hang towel warmers. No need to wait and drain a large amount of water until hot water flows. You can't do that on a double boiler.

- The ability to get a large amount of hot water, which is enough for all needs at the same time. With a double-circuit boiler, the flow of hot water is limited by the capacity of the boiler - its power. You can't wash dishes and use the shower at the same time. There will also be clear temperature fluctuations.

As always, there are cons:

- Naturally, the cost in relation to a double-circuit boiler is greater;

- Takes up a decent amount of space;

- Additional troubles for connecting and configuring the system;

- With a recirculation system, additional costs (faster cooling of the system, pump operation, etc.), which will lead to an increase in the DC in payment for energy carriers (gas, electricity);

- The system needs to be serviced regularly.

Connecting the boiler to the water supply from different materials

The boiler is tied in the heat supply system using both traditional steel pipes and more modern polypropylene and metal-plastic pipes. A cheaper option is polypropylene.

The choice will depend on the price of the project and the operating temperature of the heating fluid at the outlet of the boiler. For example, in a solid fuel boiler, the temperature of the coolant is difficult to adjust, there may be cases when it will rise spontaneously up to 100 C, so in this case it is better to install steel pipes.

Although they are less durable, they are designed for high temperature operation of solid fuel devices.

Polypropylene pipelines

Polypropylene pipes are easily mounted using a specialized soldering iron and scissors for cutting pipelines. After choosing the place of inclusion in the pipeline, a section is cut out in width equal to the tee, minus 20 mm: 10 mm for each.

Soldering iron, heat the pipe and fitting to the required technical condition and connect them. At the same time, it is forbidden to scroll them, since this can violate the tightness of the connection.

Further, connecting parts of pipes of various lengths and corners, an inlet to the branch pipes of the BKN is performed. A threaded coupling is soldered to the end of the pipe section, and then the entire line is firmly connected.

Insertion into a metal pipeline

Today, it is possible to connect the BKN to engineering water supply networks without the use of welding; for this, there is a modern “vampire” adapter device, which has a technological hole and a clamp in the body. Installation of this design is very simple. Choose a tie-in point, clean the area.

A clamp with a heat-resistant gasket is installed on top of the prepared area and tightened with bolts for fixation. Next, the water supply is shut off and drained from the desired section of the pipeline by opening the DHW tap on the mixer.

Next, a pipe section is drilled through the hole in the clamp with an electric drill and then the valve is screwed on and the BKN piping is continued according to the scheme.

metal-plastic

This is the most reliable and simplest option for tying the BKN boiler to a double-circuit boiler. The metal-plastic is simply bent at the desired outlet angle, and the connections of the nodes are made with various compression fittings.

Before tying the BKN, cut the pipe of the desired length and size. Next, choose the tie-in point, taking into account the size of the tee and the part of the pipe that will be occupied by the connection.

To prepare a hole in a small area, special scissors are used. The nuts are removed from the tee, and together with the fixation rings they are put on different ends of the pipe. The ends of the metal-plastic are flared using a special calibrator or a screwdriver.

The tee is inserted all the way, after which the rings are shifted and the nuts are clamped with a wrench. You can also use fittings for metal-plastic pipes, which require pressure testing and additional specialized tools and fixtures.