- How to tie a boiler

- Forced circulation and three-way valve

- Use of two pumps

- Non-volatile boiler

- Hydraulic connection application

- Recycling equipment

- Do-it-yourself indirect heating boiler

- An example of connecting the BKN to a single-circuit boiler

- Video - Tying a single-circuit boiler and boiler

- Design of an indirect heating boiler

- Tying the "indirect" with the boiler

- Diagrams for connecting the boiler to the boiler

- Piping with boiler water circulation pumps

- Piping with a non-volatile boiler unit

- Piping with 3-way valve

- Scheme with a recirculation line

- Is it possible to connect a boiler to a double-circuit boiler

- Types and features of indirect heating boilers

- Preparing to connect the heater

- The device - what's inside it?

- Systems with two boilers

- Step-by-step piping in gravity systems

- Distinctive features of an indirect heating boiler

- General principles

How to tie a boiler

There are several strapping schemes, which we will give below. Choose the most convenient for you.

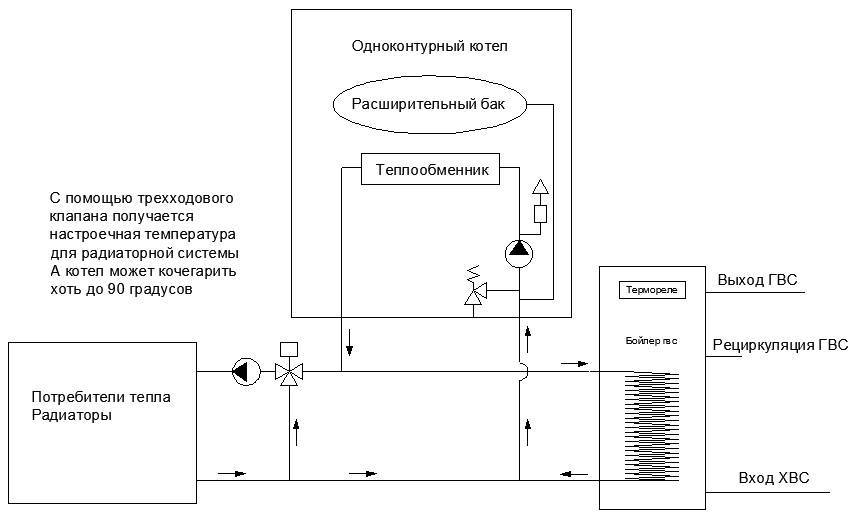

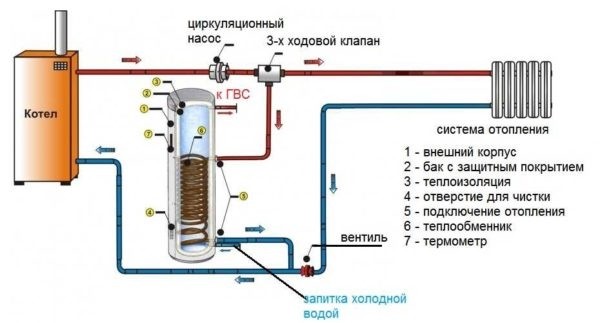

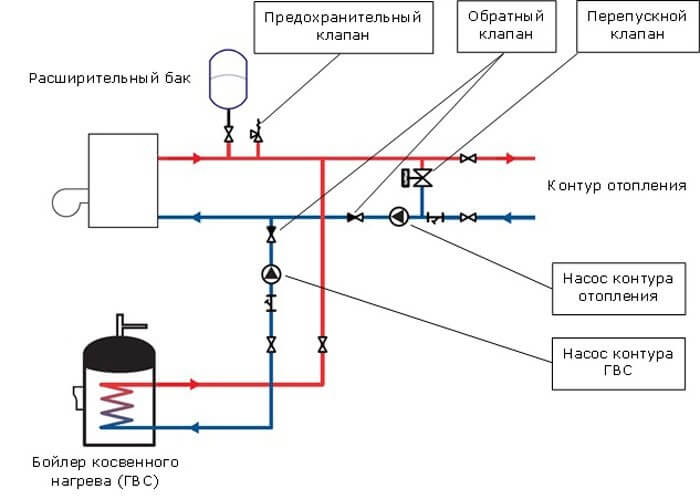

Forced circulation and three-way valve

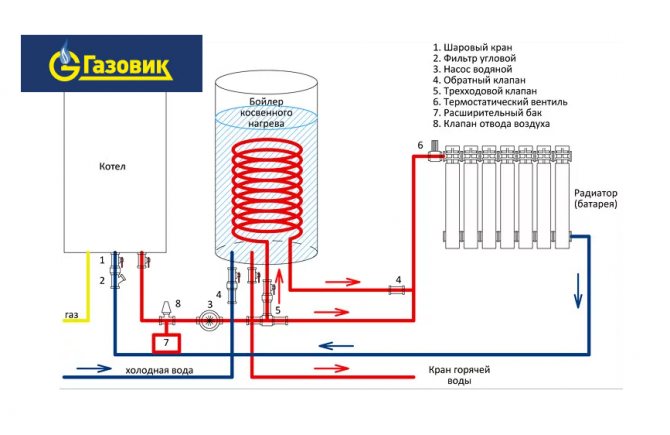

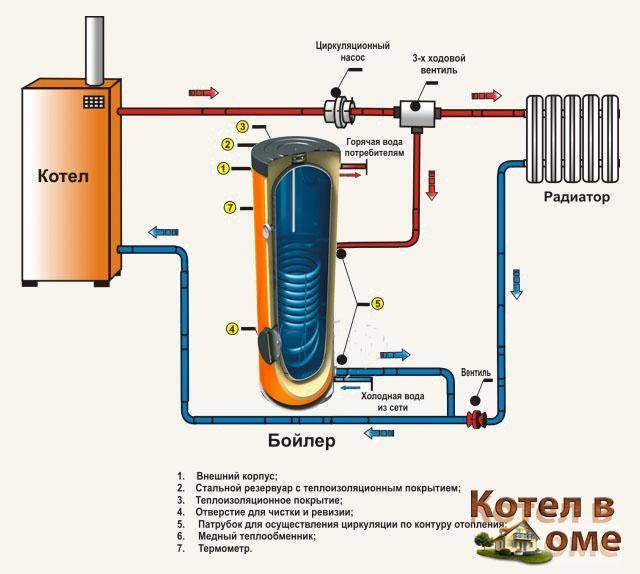

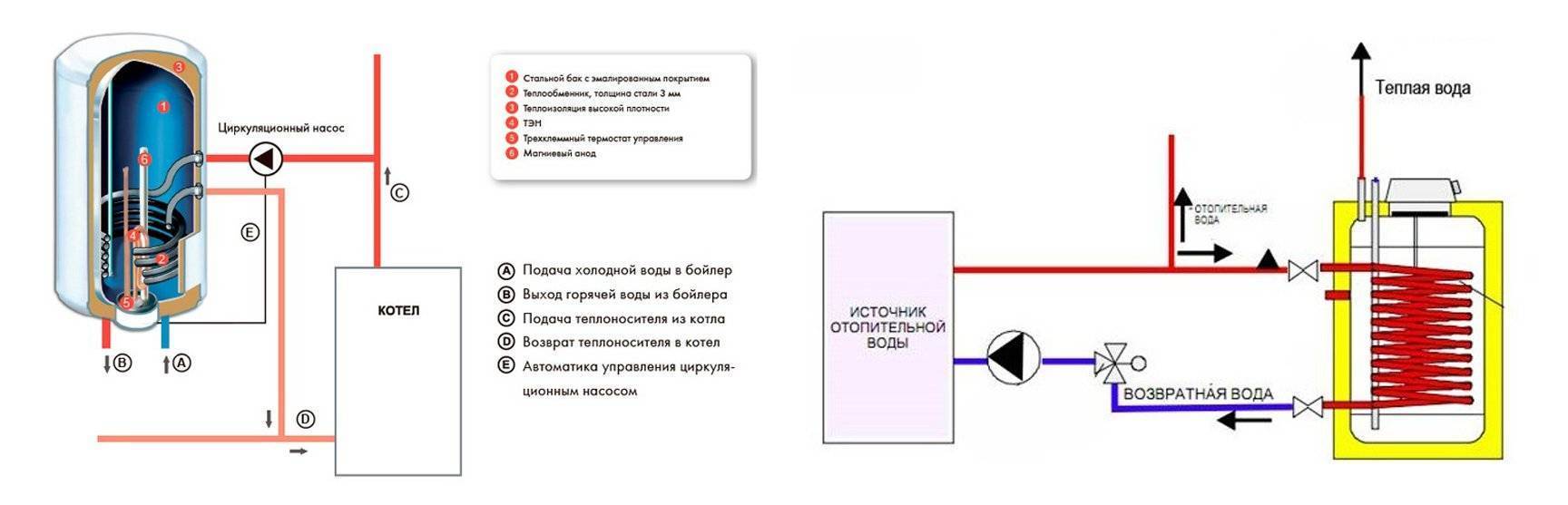

The scheme is suitable for strapping single-circuit or double-circuit boiler with a boiler. If a gas boiler is already installed at the moment, place the BKN nearby. A circulation pump is mounted on the supply.After that, a three-way valve is connected, which is controlled by a temperature sensor.

A tee cuts into the inlet pipe in front of the body, to which a hose is connected to drain fluid from the heat exchanger. How it works:

- As soon as the temperature sensor informs the control board that the temperature has been reduced, the valve turns on the water heater's coolant. The heating system starts up.

- The content of the coolant passes through the heat exchanger, heats up in the tank.

- As soon as the heating reaches the set temperature, the valve switches to heating operation.

Convenient scheme for regular use of the water heater.

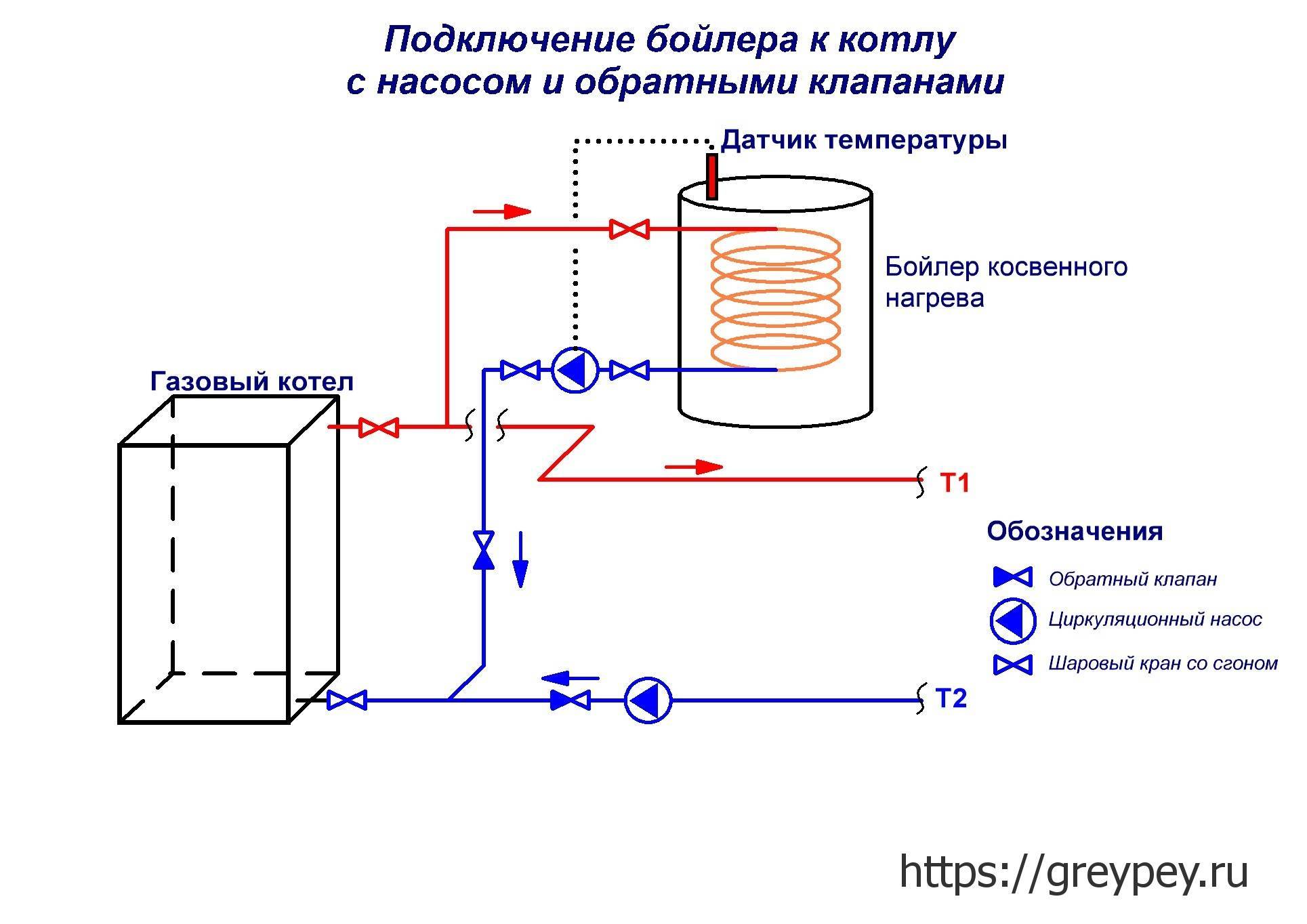

Use of two pumps

If the BKN is installed at a great distance from the boiler or you rarely use it, it is better to include a circulation pump in the system.

Connection diagram for an automatic boiler:

One the pump is mounted on the inlet pipe, and the other - on the heating body. The piping is done with tees, without a three-way valve. The thermostat controls the start and stop of the pumps.

Non-volatile boiler

For this scheme, it is better to use wall-mounted models, since the boiler should be located above the rest of the appliances.

Priority is provided by a large circuit that is connected to the water heater. It should be one step larger than the one that is supplied to the heating system.

Temperature and flow switching is provided by a thermostatic head with a sensor. It sets the desired parameters. If the sensor indicates that there is cold water in the tank, the heating switches to the boiler - and vice versa.

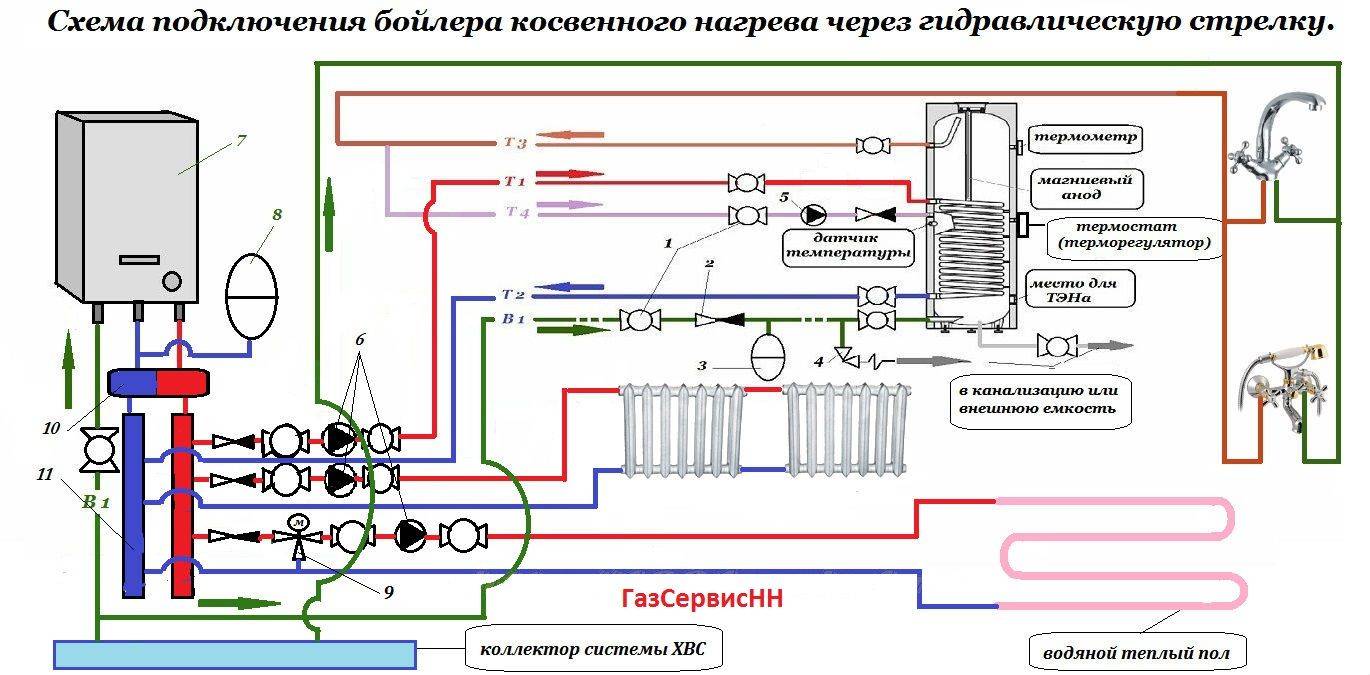

Hydraulic connection application

Suitable for installations with multiple circuits and large tank volumes.Similar schemes are used in apartment buildings, when, in addition to heating, it is necessary to provide, for example, floor heating.

The hydraulic distributor (hydraulic arrow) helps disperse the pressure so as to avoid thermal shock. It is risky to carry out independent installation, it is better to contact a specialist.

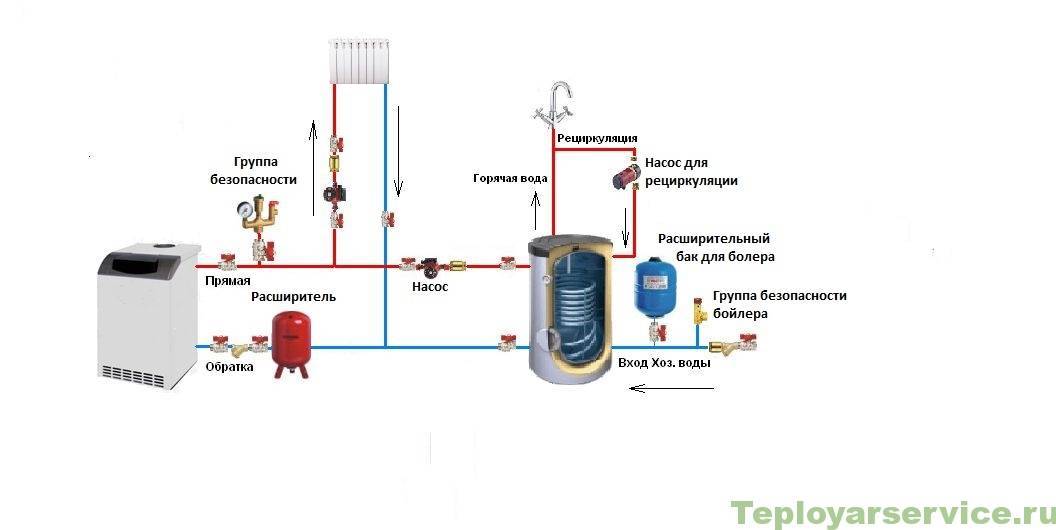

Recycling equipment

If you want to turn on an additional heating device, a towel dryer, you need to organize the connection so that water constantly circulates in the pipes. You can immediately buy a device with a recirculation function or turn it on using tees. However, such a connection has negative aspects:

- Large consumption of electricity, fuel. Passing through the pipes of the dryer, the water cools down, so the device needs to be turned on more often.

- Blending layers. During normal operation, hot liquid rises. The flow that comes out of the pipes mixes the layers, and at the exit you get a lower temperature liquid.

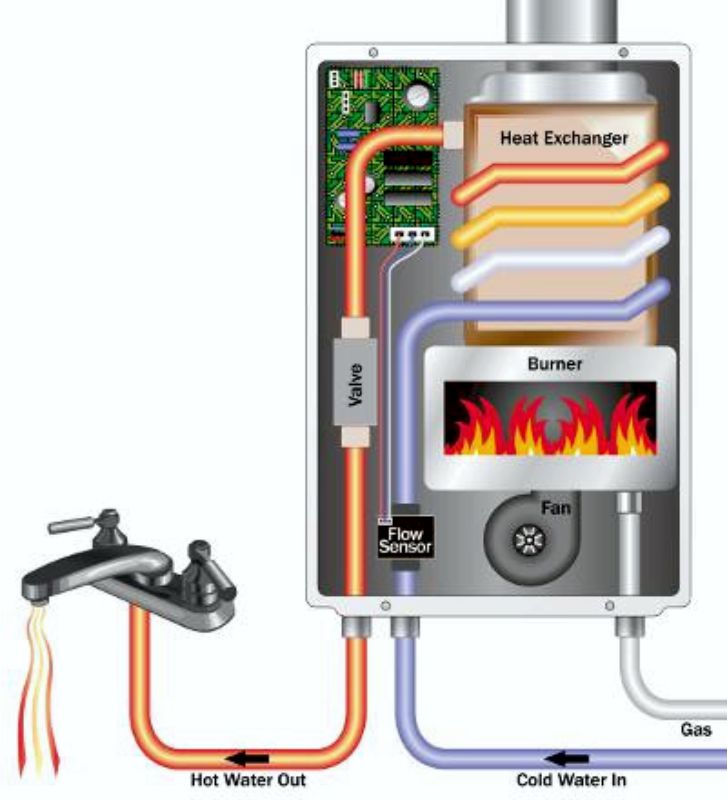

Do-it-yourself indirect heating boiler

Indirect heating boiler - this is a budget analogue of an electric one that does not depend on electricity or a gas main. The heating of water in the boiler occurs due to a spiral pipe located inside the tank. Hot water flows from the heating circuit through the coil, which, through the surface of the tube of the heating element, gives off heat to the water in the water heater. The outlet pipe for delivering hot water is usually located at the top of the storage tank. Both tubes are equipped with ball valves, which make it easy to connect the structure to the water supply and heating system. To minimize heat loss, the container is securely wrapped with a layer of thermal insulation.

The main advantages of a self-made boiler include:

- installation next to the boiler of the heating system;

- low cost of installation work;

- lack of energy consumption for heating water;

- constant maintenance of water temperature in the heater;

- Possibility of connection to the central heating line.

This option also has disadvantages:

- enough free space is required for the installation of the boiler;

- heating a large volume of cold water will take a long time;

- during the heating of the tank, the efficiency of the heating circuit is somewhat reduced;

- plaque quickly forms on the coil inside the tank, which requires regular (once or twice a year) cleaning.

Building a boiler with your own hands is much easier than a full-fledged water heater. It is the simplicity of the design that makes it so popular.

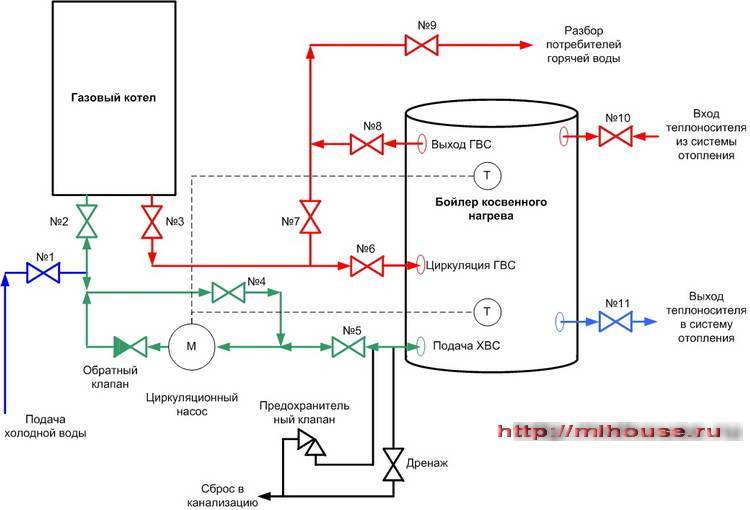

An example of connecting the BKN to a single-circuit boiler

Step 1. First of all, you need to mount the entire heating system and connect it to the distribution manifold system and the heating boiler.

First, the entire heating system is mounted

Step 2. Next, you need to install and securely fix the boiler itself in its place in the room. It uses a floor version, which is installed on a small platform near the heating boiler.

The next step is to install the boiler

Step 3. A thermal relay must be installed on the BKN body, which will help to set the desired water temperature.

Thermostat for temperature setting

Step 4 Behind the boiler itself, you need to connect all communications. These are pipes for supply and output of water. To the uppermost outlet, you need to connect the hot water outlet for consumption through a shut-off valve.

Hot water outlet connected via shut-off valve

Step 5The intake of heated water in this boiler model can be carried out from above boiler or behind topmost output. Here it is necessary to install a Mayevsky air vent valve in the upper outlet.

Mayevsky air bleed valve

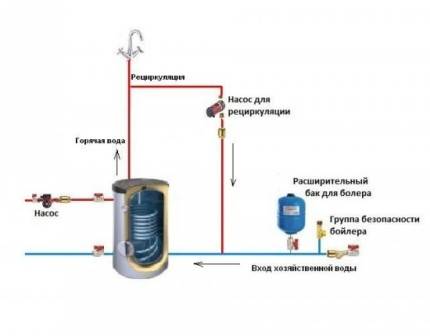

Step 6. The next way out is to connect the hot water recirculation

Here it is important to mount a check valve, directly the recirculation pump itself and a ball valve. A system equipped in this way, in the presence of a ball valve, will, if suddenly necessary, turn off the water flow and repair or replace the pump

The equipment turns off when the liquid has warmed up to the temperature desired by the user. When water cools the pump will turn on again. In general, recirculation is required so that hot water is always immediately supplied from the boiler, without a small amount of cooled water dripping. It also allows you to connect heated towel rails.

Hot water recirculation connection

Step 7. Below the recirculation equipment, it is required to connect the water supply directly from the heating pipes to the coil circuit inside the boiler. A pump, a check valve and a shut-off valve are also mounted.

Pump and stopcock

Step 8 At the bottom, you need to connect the return pipes, which will bring the water coming from the heating system back out of the boiler chamber.

Return pipes connected

Step 9. Chilled water enters the boiler chamber through the lowest pipe. Here you need to mount a tap, then a safety valve, and also a special expansion tank. The last element you need to buy is the one that is suitable for water supply, and not for heating.

How to connect the downpipe Expansion tank

Step 10. After the connection point of the expansion tank, it is also necessary to install a check valve in this part of the communications.

Another check valve

Step 11. A stopcock should also be installed on the tank drain and the drain should be drained into the sewer.

Shut-off valve for draining the tank

Video - Tying a single-circuit boiler and boiler

Connecting a KN boiler is not as easy as it seems. Moreover, the main difficulty lies precisely in pairing all the indicators of the purchased equipment. And the rest, where and how to connect the supply and return pipes and the rest, is not so difficult to figure out. But in the absence of proper experience, it is better not to install the boiler yourself, but to invite specialists.

Design of an indirect heating boiler

Design of an indirect heating boiler Electric storage water heaters are gradually becoming more and more common sources of domestic hot water, using a conventional household power supply for power. Then there are special thermostatic valves for domestic hot water.

In order for hot water supply to work efficiently and without interruptions, you need to think in advance of its design features and nuances that may arise in the process of work

How to use coolant recirculation Recirculation is useful when there is a circuit that needs a constant supply of hot water - for example, a heated towel rail.

On the one hand, they say that the efficiency of the boiler becomes higher if the temperature of the coolant is degrees.

It is important to choose a good manufacturer and at the same time not to overpay.

How to use coolant recirculation Recirculation is useful when there is a circuit that needs a constant supply of hot water - for example, a heated towel rail. In such a boiler, the reception of more power increases due to the preservation of the coolant in the boiler, which has an inertial nature of temperature preservation.

How the pump will affect the heating system is not exactly known, but in practice, as a rule, it actually short-circuits more than half of the coolant jet to the boiler, in the worst case, it overturns the jets in other parallel branches, which is sometimes not acceptable.

Disadvantage of getting hot water? Therefore, not all boilers are equipped with a special inlet for organizing such an additional circuit.

How to connect an indirect heating boiler

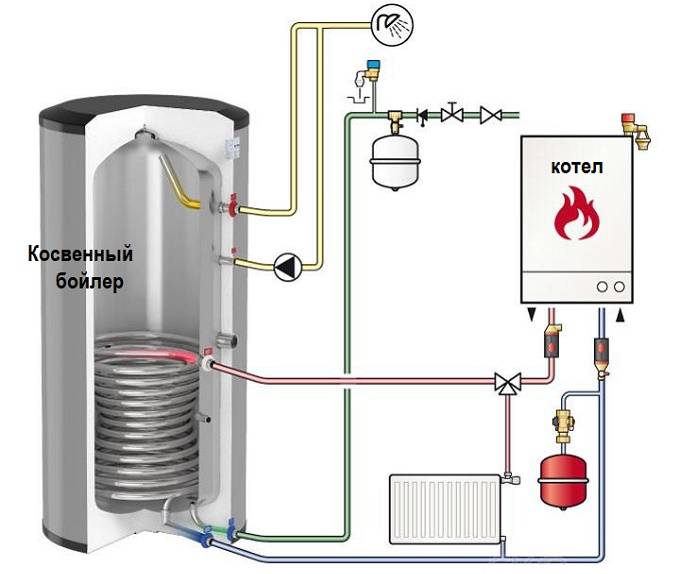

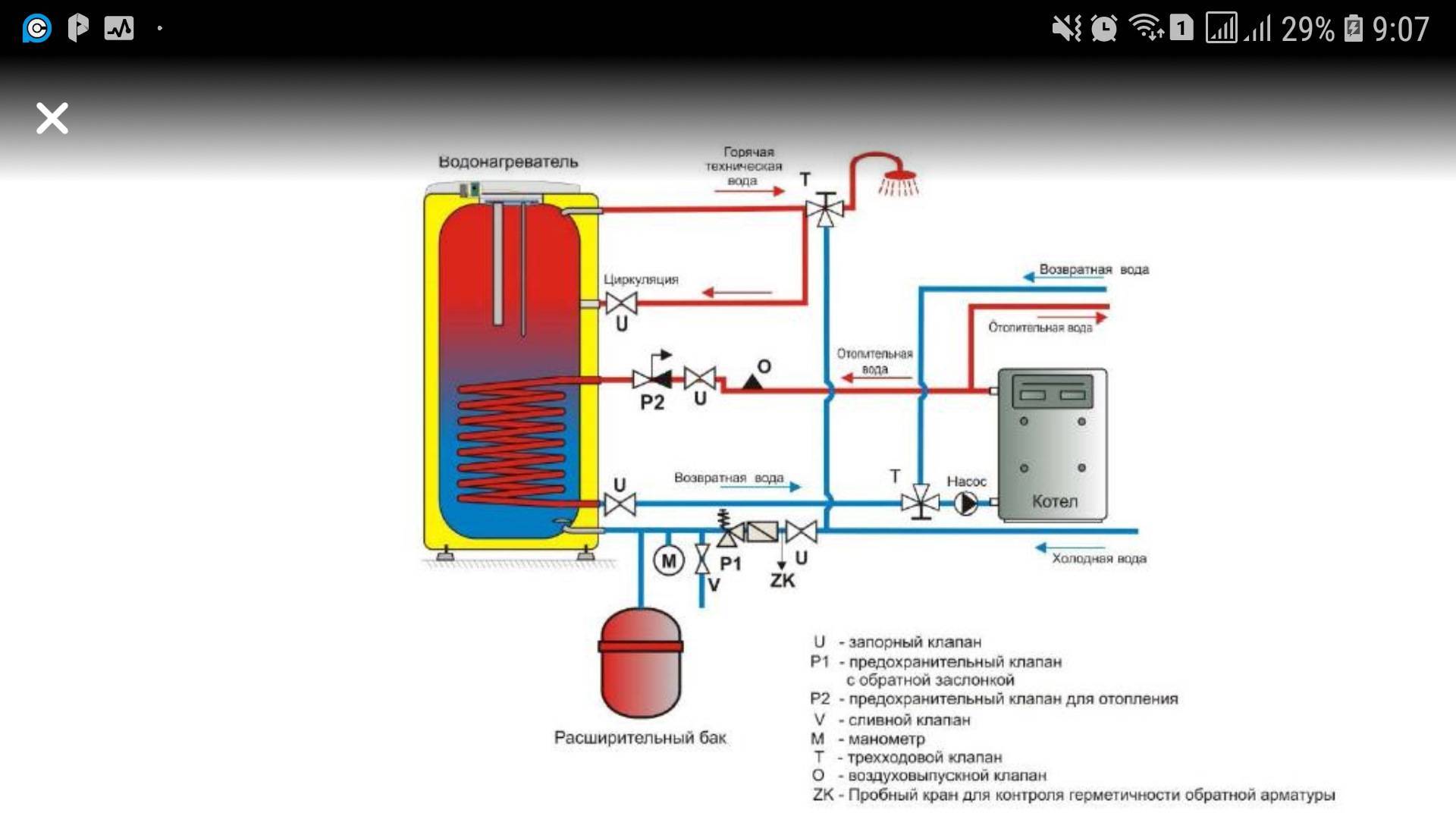

Tying the "indirect" with the boiler

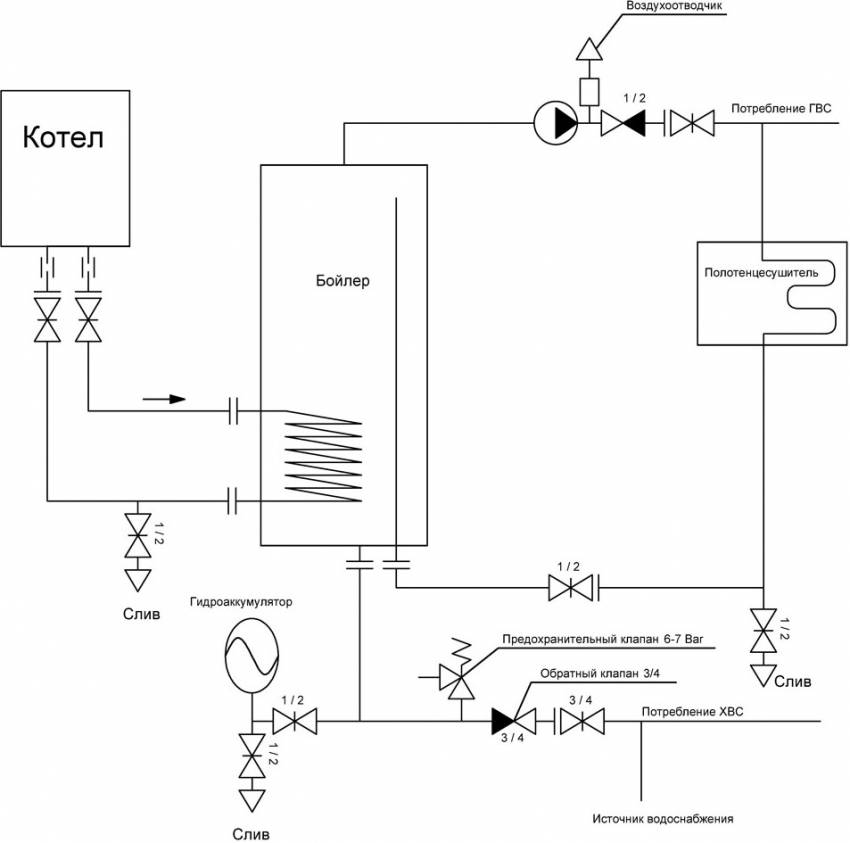

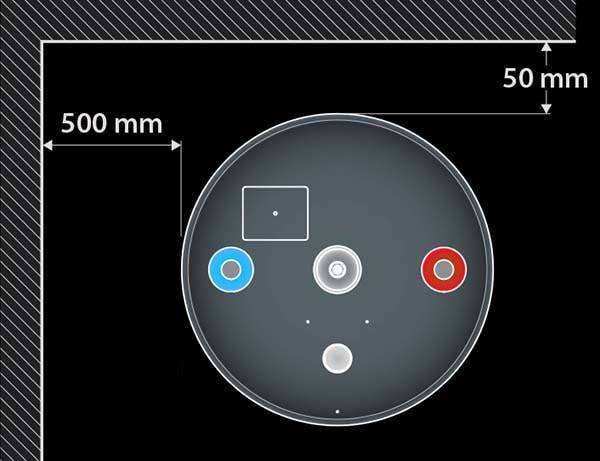

First of all, the unit must be installed on the floor or securely attached to a main wall made of brick or concrete. If the partition is built of porous materials (foam block, aerated concrete), it is better to refrain from wall mounting. When installing on the floor, keep a distance of 50 cm from the nearest structure - clearance is necessary for servicing the boiler.

Recommended technological indents from floor standing boiler to nearest walls

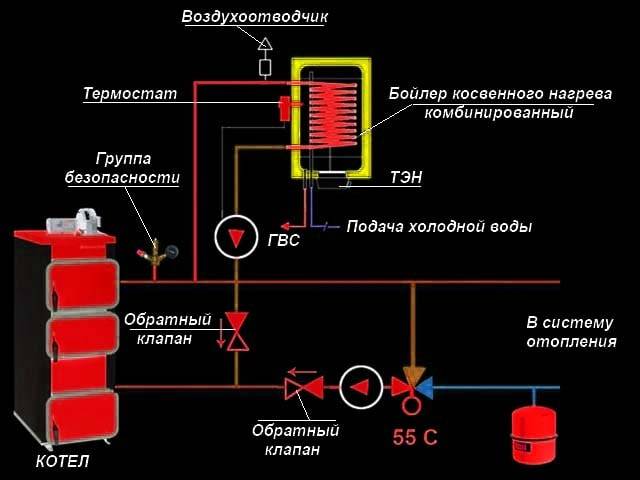

Boiler connection to solid fuel or gas boiler, not equipped with an electronic control unit, is carried out according to the diagram below.

We list the main elements of the boiler circuit and indicate their functions:

- an automatic air vent is placed at the top of the supply line and discharges air bubbles that accumulate in the pipeline;

- the circulation pump provides the coolant flow through the loading circuit and the coil;

- a thermostat with an immersion sensor stops the pump when the set temperature inside the tank is reached;

- check valve eliminates the occurrence of parasitic flow from the main line to the boiler heat exchanger;

- the diagram conventionally does not show shut-off valves with American women, designed to turn off and service the apparatus.

When starting the boiler “cold”, it is better to stop the circulation pump of the boiler until the heat generator warms up

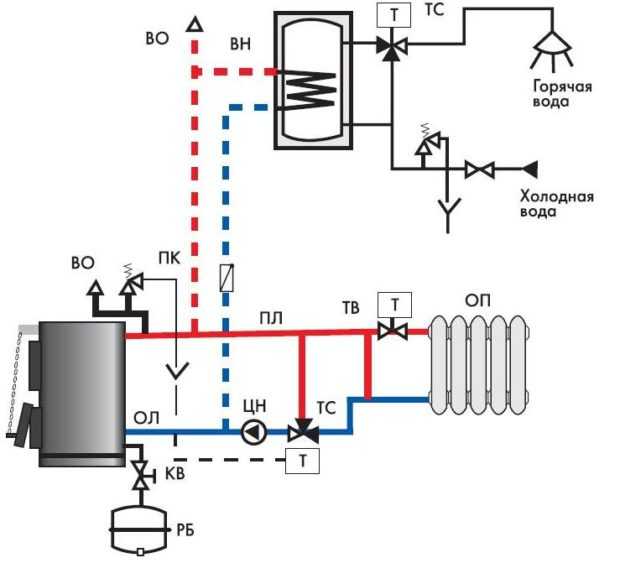

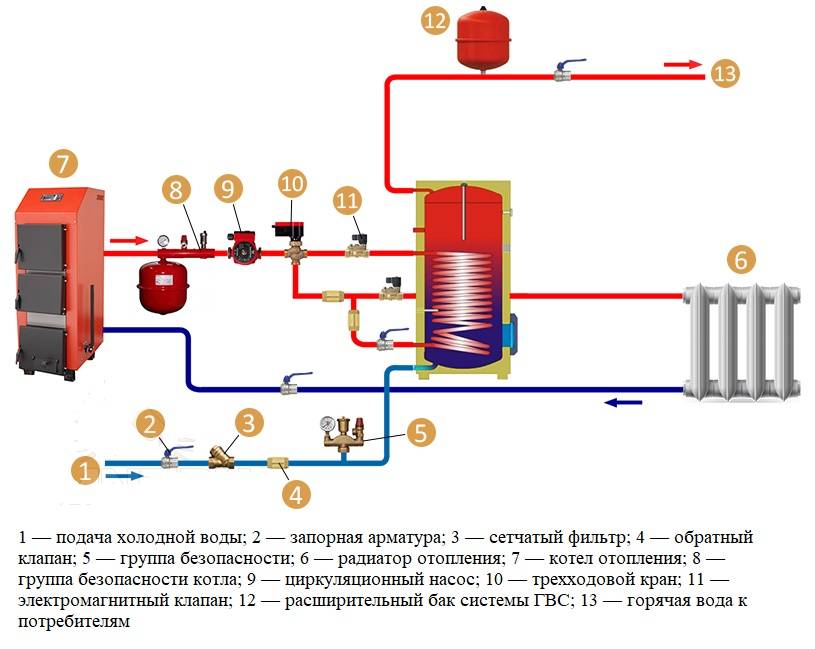

Similarly, the heater is connected to more complex systems with several boilers and heating circuits. The only condition: the boiler must receive the hottest coolant, therefore it crashes into the main line first, and it is connected directly to the hydraulic arrow distribution manifold, without a three-way valve. An example is shown in the primary/secondary ring tying diagram.

The general diagram conventionally does not show the non-return valve and boiler thermostat

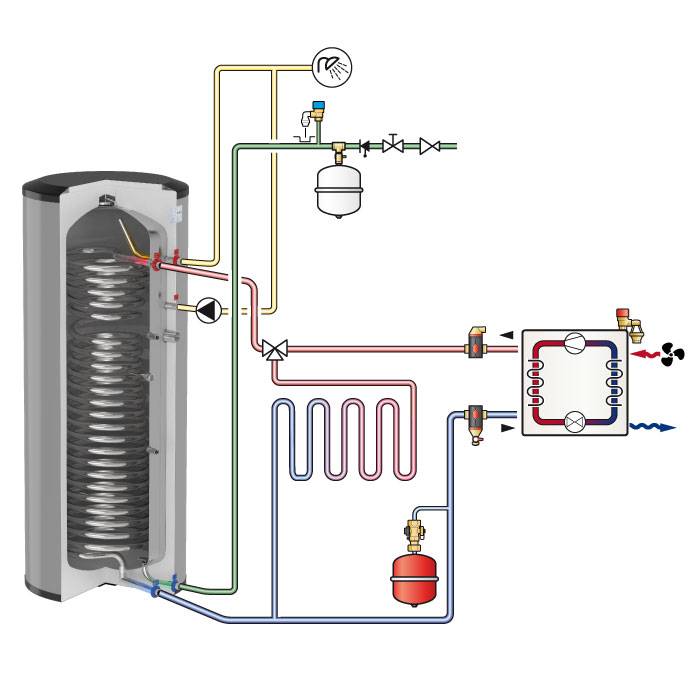

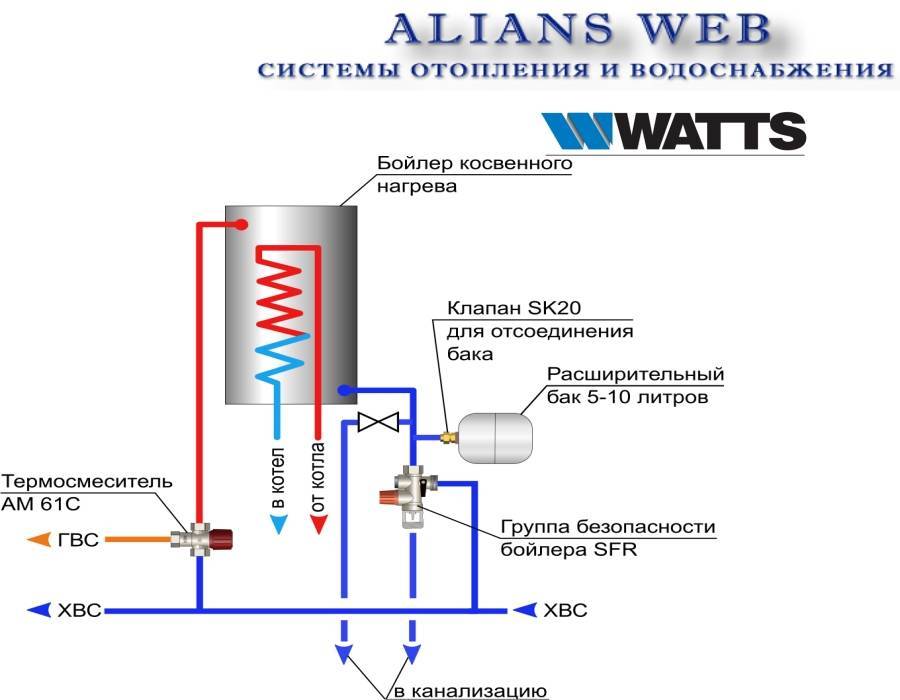

When it is required to connect a tank-in-tank boiler, the manufacturer recommends using an expansion tank and a safety group connected to the coolant outlet. Rationale: when the internal DHW tank expands, the volume of the water jacket decreases, there is nowhere for the liquid to go. Applied equipment and fittings are shown in the figure.

When connecting tank-in-tank water heaters, the manufacturer recommends installing an expansion tank on the side of the heating system

The easiest way is to connect an indirect heating boiler to wall-mounted boilers, which have a special fitting.The remaining heat generators, equipped with electronics, are connected to the water heater via a motorized three-way diverter valve controlled by the boiler controller. The algorithm is this:

- When the temperature in the tank drops, the thermostat signals the boiler control unit.

- The controller gives a command to the three-way valve, which transfers the entire coolant to the loading of the DHW tank. The circulation through the coil is provided by the built-in boiler pump.

- Upon reaching the set temperature, the electronics receives a signal from the boiler temperature sensor and switches the three-way valve to its original position. The coolant goes back to the heating network.

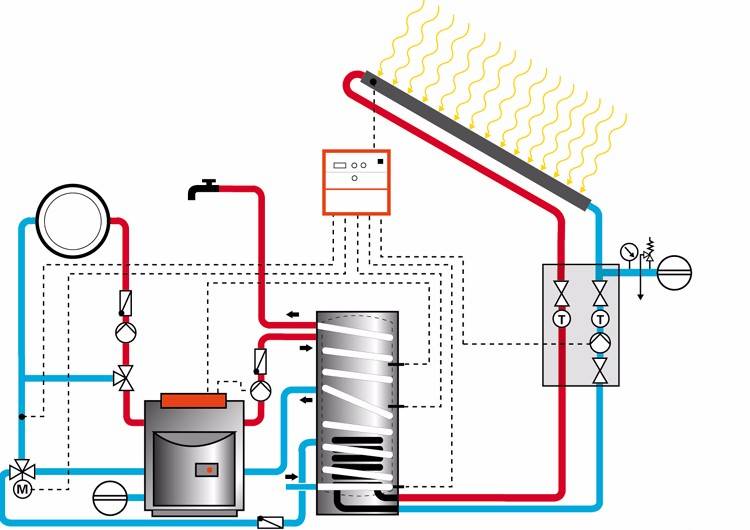

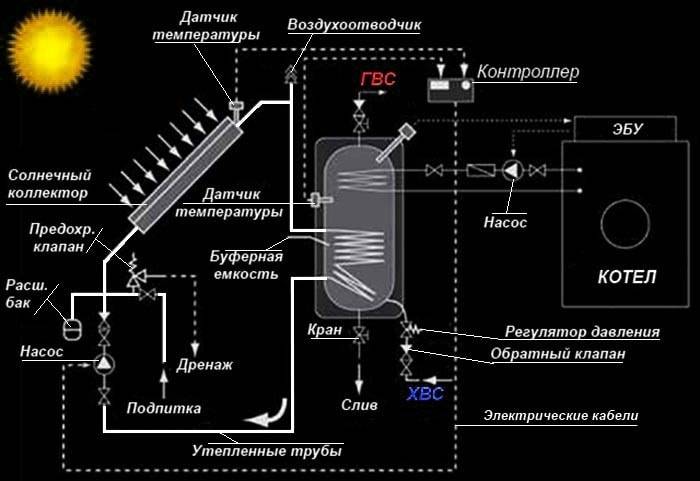

The connection of the solar collector to the second boiler coil is shown in the following diagram. The solar system is a full-fledged closed circuit with its own expansion tank, pump and safety group. Here you can not do without a separate unit that controls the operation of the collector according to the signals of two temperature sensors.

Heating water from the solar collector must be controlled by a separate electronic unit

Diagrams for connecting the boiler to the boiler

Before connecting an indirect heating boiler, an executive connection diagram and installation parameters of the BKN are developed. They depend on the modification of the device, the scheme of the boiler unit and the heating system in the household.

The BKN boiler connection kit is most often used for double-circuit units and with three-way valves.

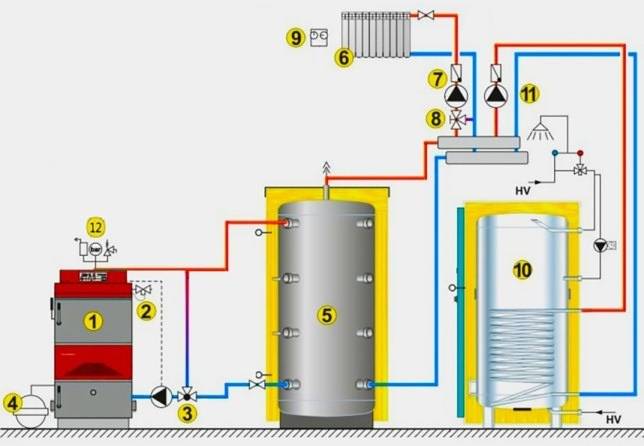

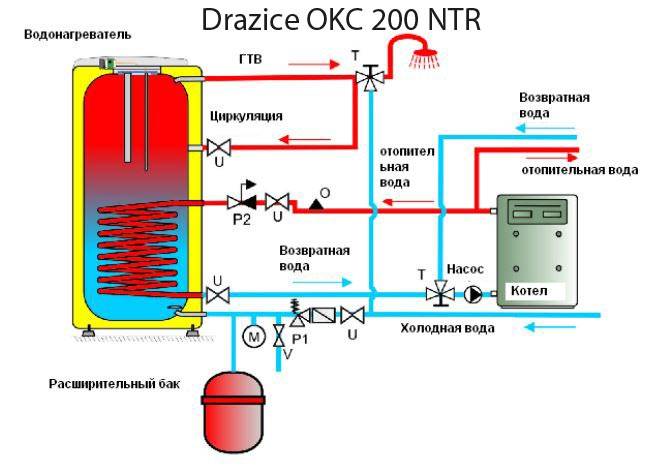

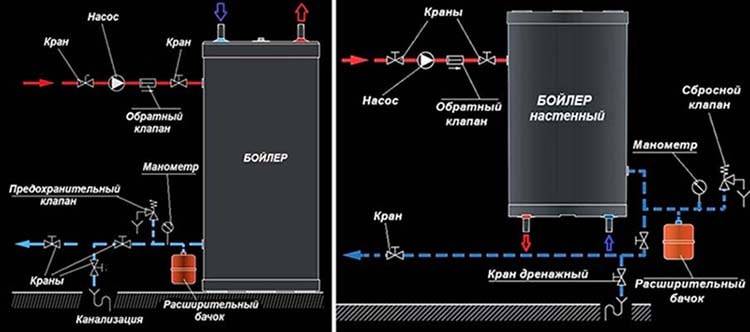

Piping with boiler water circulation pumps

The scheme with 2 circulation electric pumps is used for temporary heating of domestic hot water, for example, during seasonal operation of the BKN and when used on weekends.In addition, this option is applicable when the DHW temperature is set lower than the T of the heat carrier at the outlet of the boiler.

It is carried out with two pumping units, the first is placed on the supply pipe in front of the BKN, the second - on the heating circuit. The circulation line is controlled by an electric pump through a temperature sensor.

According to its electrical signal, the DHW pump will be switched on only when the temperature drops below the set value. There is no three-way valve in this version, the piping is carried out using conventional mounting tees.

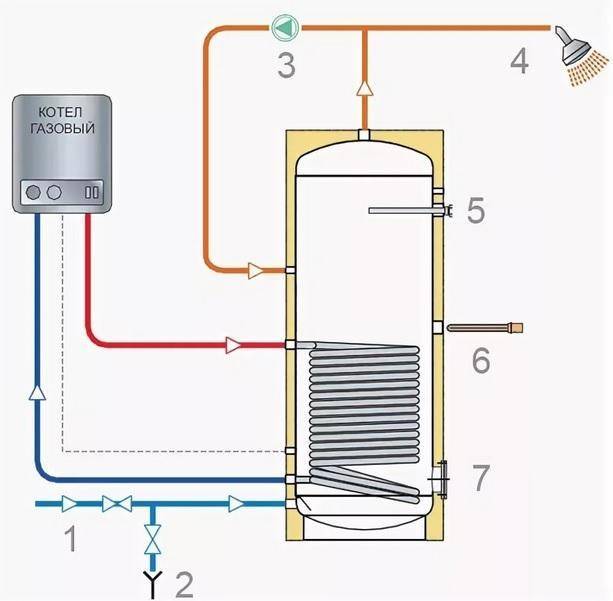

Piping with a non-volatile boiler unit

This scheme is used for a non-volatile boiler unit operating with natural circulation of the coolant, therefore, in order to ensure the required hydraulic regime and the coolant could circulate through the boiler unit and radiators in the rooms. This scheme is for wall modifications that allow installation at a level of 1 m from the “O” mark in the furnace.

Floor models in such a scheme will have low circulation and heating rates. It may happen that the required level of heating cannot be achieved.

This scheme is used only for emergency modes, when there is no electricity. In normal energy-dependent modes, circulating electric pumps are installed in the circuit to ensure the required speed of the coolant.

Piping with 3-way valve

This is the most common piping option, as it allows the parallel operation of both heating and hot water. The scheme has a fairly simple execution.

BKN is installed next to the boiler unit, a circulation electric pump and a three-way valve are mounted on the supply line. Instead of one source, a group of boilers of the same type can be used.

The three-way valve acts as a mode switch and is controlled by a thermal relay. When the temperature in the tank drops, the temperature sensor is activated, which sends an electrical signal to the three-way valve, after which it switches the direction of movement heating water from heating on the hot water supply.

In fact, this is a BKN operation scheme with priority, which provides fast heating of the DHW with the radiators completely turned off during this period. After reaching the temperature, the three-way valve switches and the boiler water enters the heating system.

Scheme with a recirculation line

Coolant recirculation is used when there is a circuit in which hot water must circulate all the time, for example, in a heated towel rail. This scheme has great advantages, because it does not allow water to stagnate in the pipes. The user of DHW services will not need to drain significant volumes of water into the sewer in order for hot water to appear in the mixer. Consequently, recycling saves the cost of water supply and hot water services.

Modern large BKN units are supplied to the market with an already built-in recirculation system, in other words, they are equipped with ready-made pipes for connecting a heated towel rail. Many for these purposes acquire an additional small tank connected to the main BKN through tees.

Is it possible to connect a boiler to a double-circuit boiler

This option is performed using the scheme connecting an indirect boiler heating with a hydraulic arrow for structures with a working volume exceeding 220 liters and multi-circuit heating schemes, for example, in a multi-storey building with a "warm floor" system.

A hydraulic arrow is an innovative unit of a modern in-house heat supply system that simplifies the operation and repair of a water heater, since it is not necessary to install recirculation electric pumps on each heating line.

It increases the security system, as it prevents the occurrence of water hammer, since it maintains equal pressure of the medium in the circuits of the double-circuit boiler unit.

Types and features of indirect heating boilers

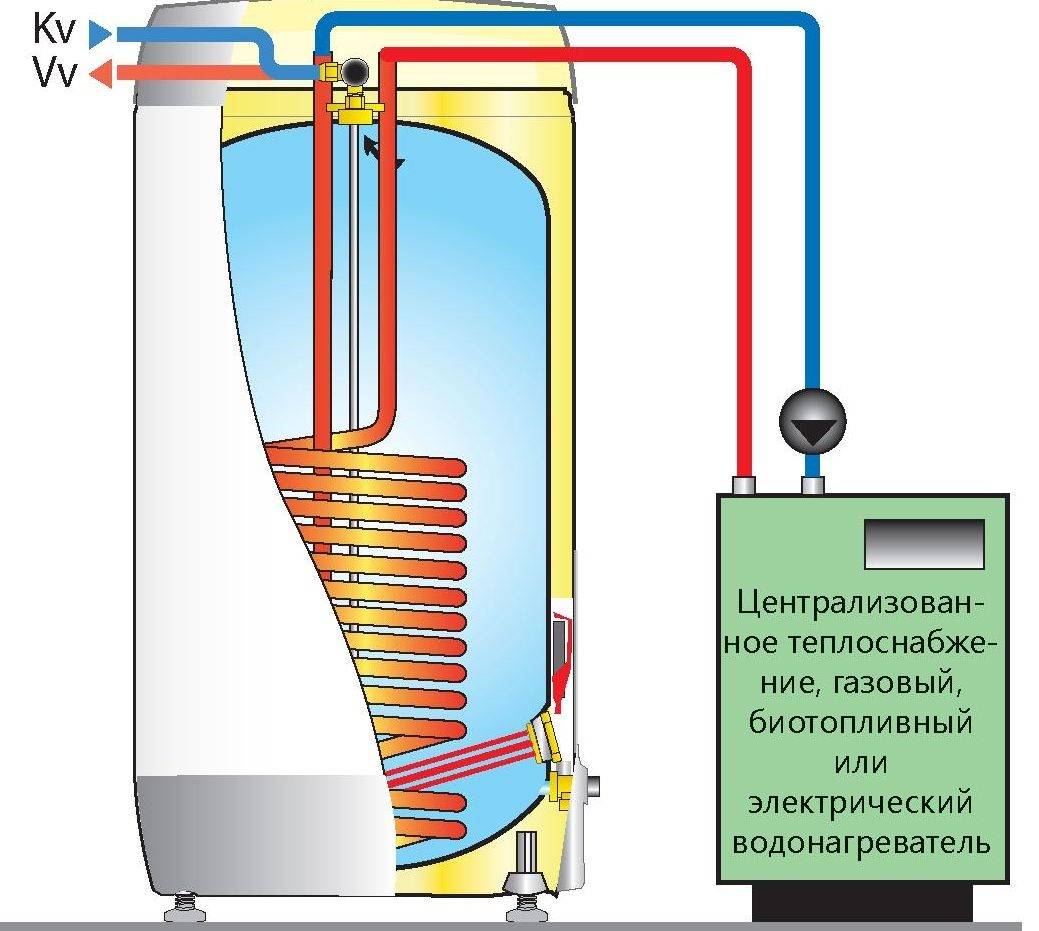

Water heaters with an indirect principle of operation transfer heat by consuming it from an already heated liquid circulating inside the device. The structural element responsible for heat exchange is called a heat exchanger and can be made in the form of a coil or a tank (“tank in tank” system).

The main consumer features of the boiler are:

Size The most popular and convenient fixtures with a capacity of 100 - 120 liters. But there are tanks that can hold 300 liters or more. They can be used as a heat accumulator to provide the premises with heat during periods when the boiler stops working.

Shape The shape of the equipment can have the following configurations:

- cylindrical;

- cubic;

- rectangular.

This option does not so much satisfy the aesthetic needs of the buyer, but rather helps to integrate devices into the spaces allocated for the placement of the device.

Recirculation This type of device is the most expensive, but also the most versatile.It has the ability to supply heated liquid to the tap in the shortest possible time, which is very convenient.

Preparing to connect the heater

Boiler volume selection

Choose a place to place the unit. It is better that you have free access to all the connecting elements of the system - it will be more convenient carry out equipment maintenance and carry out repairs when necessary.

An example of installing a boiler in a bathroom

If a storage heater model is chosen, make sure the wall can support its weight with water. Thin interior walls and drywall partitions will definitely not cope with this task.

An example of installing a boiler on a solid bathroom wall

Install the water heater in close proximity to the water supply pipes - this way you will save yourself from the need to lay additional infrastructure. Therefore, the ideal place to install the boiler is the bathroom.

Boiler in the bathroomWater heater power selection scheme

Once you have chosen a location for the heater, start preparing your tools and accessories.

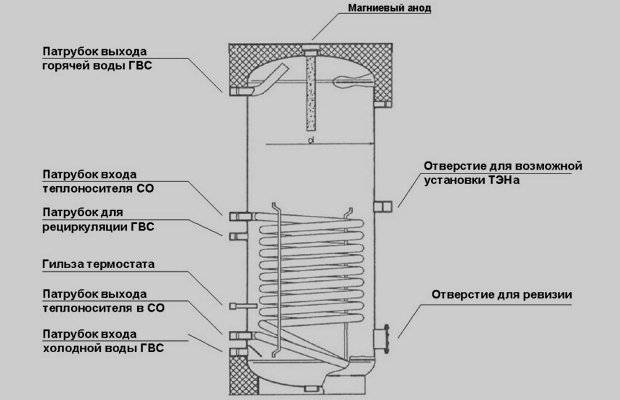

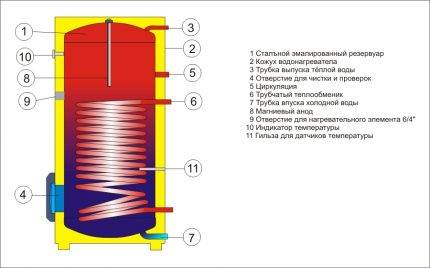

The device - what's inside it?

The unit mainly consists of a tank of a given volume. This reservoir can be designed both for several tens of liters and for holding hundreds of liters of water. Inside is a heat exchanger coil. It is usually made of steel or brass. The complex shape of this element allows the coolant to heat up better. Basically, the coils of the heat exchanger are located at the bottom, because it is here that the coolest water settles. True, in some designs they are evenly distributed throughout the volume.There are also special units with two heat exchangers. In this case, one element is intended for the liquid coming from the heating system, and the second for the coolant from other alternative sources, such as a heat pump, solar collector, etc.

Heating unit device

There are also models in which, instead of heat exchange tubes, another container is installed inside the tank. The interior must be made of stainless steel. Fluid circulates in the space between these two reservoirs. The tank also contains a magnesium anode, which provides reliable protection against galvanic corrosion. Due to the fact that the electrical potential of this element is lower than that of the base metal, corrosion affects the first one. Therefore, it periodically needs to be replaced.

It is also very important to minimize heat loss; for this, the water heater is protected with a special material (mineral wool, polyurethane foam, etc.)

This coating will additionally protect the unit from mechanical damage. Do not underestimate the work of the thermostat. This element establishes control over the temperature of the liquid and plays an important role in ensuring the safety of the device.

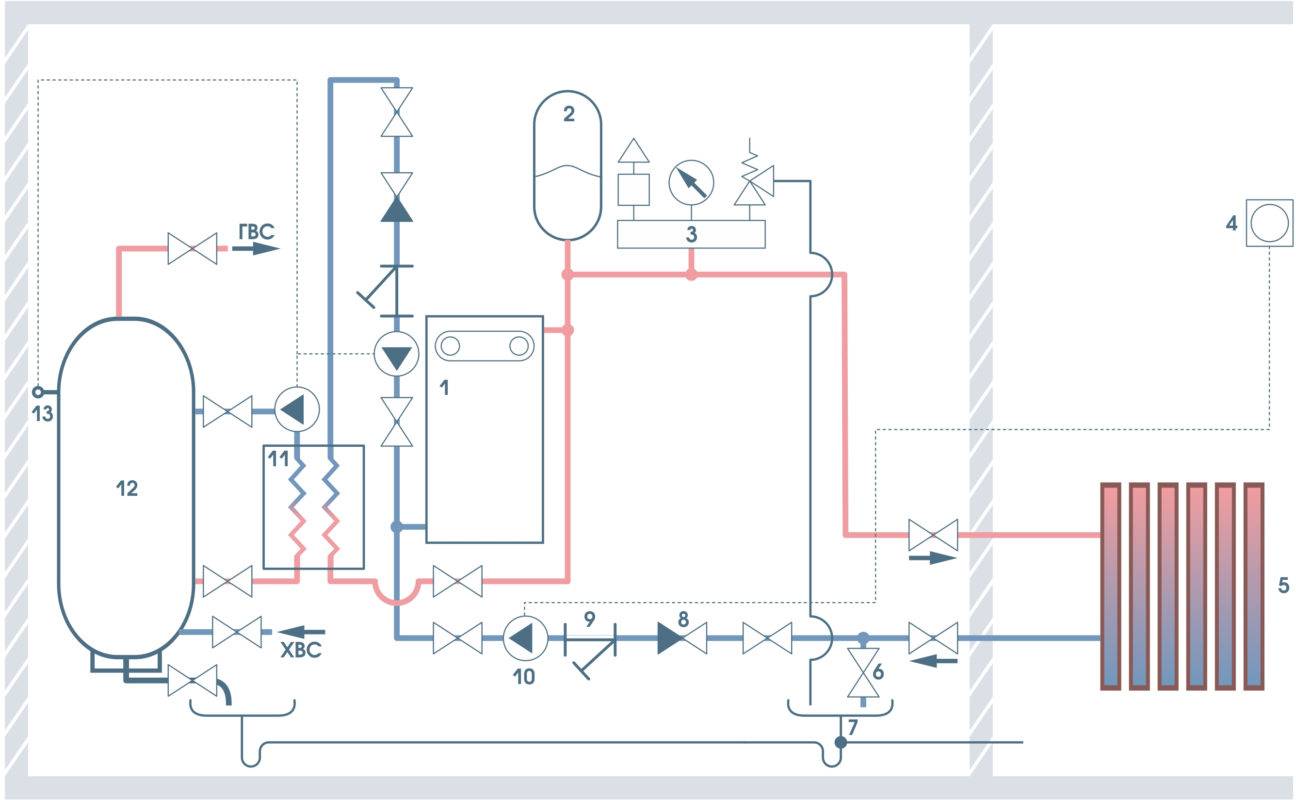

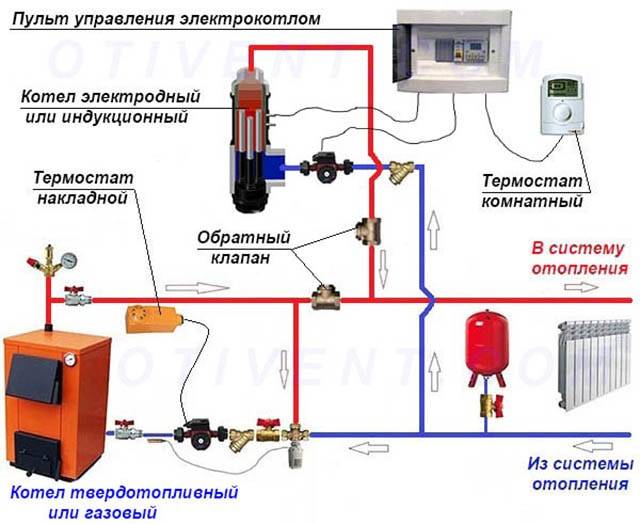

Systems with two boilers

If it is necessary to organize the heating of the coolant in a closed circuit from two heat generators, use the principle of parallel connection. Let us explain the algorithm for the joint operation of two boilers - electric and solid fuel (the piping is shown in the figure):

- The main source of heat is a TT-boiler, connected in a standard way through a three-way valve.To prevent flows from ringing in the other direction, a check valve is installed on each branch.

- When the firewood burns out, the air in the house begins to cool. The drop in temperature is fixed by the room thermostat and starts the electric boiler with a pump.

- A decrease in the temperature in the flow line of the TT boiler to 50-55 ° C causes the overhead thermostat to cut off the circulation pump of the solid fuel circuit.

- After the next loading of firewood, the supply pipe heats up, the temperature sensor starts the pump and the heating priority returns to the solid fuel unit. The room thermostat no longer turns on the electric boiler because the air temperature does not drop.

At the outlet of the electric boiler, it is also necessary to put a safety group, it is conditionally not shown in the figure

An important point. The above piping option can be used for any pair of boilers. When installing a wall-mounted heater, a second pump is not installed.

Two heat generators, for example, gas and electric, are easily tied up through a heat accumulator. Both boilers can be switched on and off in various ways - by the temperature of the water in the tank, by time through a timer. Check valves are not needed here.

If it is necessary to dock 2-3 units of heat power equipment with several heating circuits, it is better to assemble a scheme of primary / secondary rings. The principle is as follows: all heat sources and consumers with their pumps are connected to a common ring from a pipe of increased diameter Ø26 ... 40 mm (depending on the number of branches). The circulation inside the ring is provided by a separate pump.

The sequence of installation of equipment matters: the hottest coolant receives a water heater, followed by batteries, at the end - TP (along the flow of water)

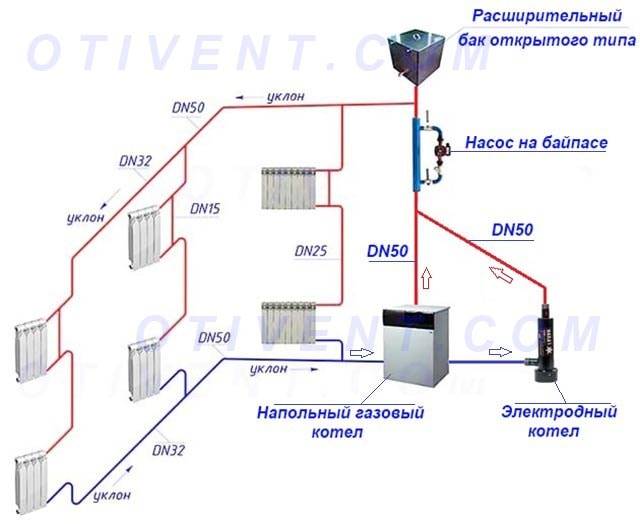

In a system with natural movement of the coolant, two boilers are also combined in parallel

Here it is important to withstand pipe slopes of Ø40…50 mm, as well as to avoid sharp turns by using elbows at an angle of 45° or elbows with a large bending radius.

Water diverges in two parallel branches with boilers. But the unit that is turned on at the moment will make it move by gravity, the pump starts at the request of the owner

Step-by-step piping in gravity systems

Installation of a water heater in networks of this type is carried out in such a way that it is located above the radiators. Therefore, for gravity systems, usually not floor-mounted, but wall-mounted suspended boilers are purchased.

Includes the correct installation of water heaters in networks with natural circulation of the coolant, the following steps:

- supply from the boiler is connected to the boiler coil using a pipe of a larger diameter than in the heating system;

- further, the supply of the heating system is cut into this segment between the boiler and the water heater;

- between the boiler and the resulting branch, a thermostatic head with an overhead sensor, powered by batteries, is mounted;

- the boiler is connected to the boiler with a return pipe;

- a line for removing the cooled coolant from the radiators is cut into the return pipe;

- an expansion tank is installed closer to the boiler on the return line.

Water is heated when using such a scheme due to the difference in the cross section of the supply pipes boiler and heating systems. The water heater in this case is a priority.As soon as the water in the boiler is heated to a certain temperature, the sensor is activated and the pipeline is blocked. As a result, water begins to flow into the heating system.

Distinctive features of an indirect heating boiler

A boiler is a large barrel, the main function of which is storage. It can be of various sizes and shapes, but its purpose does not change from this. Without a boiler, a problem may arise when using, for example, two showers at once or a shower and a kitchen faucet.

If a household 2-circuit boiler with a capacity of 24-28 kW gives out only 12-13 l / min to the flow, and 15-17 l / min is required for one shower, then when any additional tap is turned on, there will be a shortage of water supply. The boiler simply does not have enough working capacity to provide several points with hot water.

If a large storage tank is installed in the house, even with several water points turned on at the same time, everyone will be provided with hot water

If a large storage tank is installed in the house, even with several water points turned on at the same time, everyone will be provided with hot water

All storage boilers can be divided into 2 large categories:

- direct heating, creating a supply of hot water using a heating element - for example, an electric heating element;

- indirect heating, heating the water with an already hot coolant.

There are other types of boilers - for example, conventional storage water heaters. But only volumetric storage devices can indirectly receive energy and heat water.

BKN, unlike volatile equipment operating on electric, gas or solid fuel, uses the heat generated by the boiler. Simply put, it does not require additional energy to function.

BKN design.Inside the tank there is a coil - a steel, brass or copper tubular heat exchanger that acts as a heating element. The heat inside the tank is stored according to the principle of a thermos

BKN design.Inside the tank there is a coil - a steel, brass or copper tubular heat exchanger that acts as a heating element. The heat inside the tank is stored according to the principle of a thermos

The storage tank easily fits into the DHW system, and does not cause problems during operation.

Users see many advantages in using BKN:

- the unit does not require electrical power and benefits from the economic side;

- hot water is always “ready”, no need to skip cold water and wait for it to heat up;

- several points of water distribution can freely operate;

- stable water temperature that does not fall during consumption.

There are also disadvantages: the high cost of the unit and additional space in the boiler room.

The volume of the storage tank is chosen, focusing on the number of people permanently residing in the house. The smallest boilers are designed for 2 consumers, so when choosing, you can start from a volume of 50 liters

The volume of the storage tank is chosen, focusing on the number of people permanently residing in the house. The smallest boilers are designed for 2 consumers, so when choosing, you can start from a volume of 50 liters

According to all characteristics, BKN is suitable for use in tandem with a gas boiler. Moreover, it is one of the best solutions for equipping a hot water preparation system for a private house with a large number of residents.

But boilers are different, so we will consider both acceptable options and those where problems may arise.

General principles

The boiler piping procedure means its connection to the heating system and the water supply line. From the quality of the work directly depends on the efficiency of the water heating system.

That is why the installation of the boiler should not be carried out according to an arbitrary technology, but in compliance with the following mandatory principles:

- Water supply - through a pipe in the lower zone of the boiler.

- Hot water must be drawn from the connection at the top of the equipment.

- The recirculation point must be in the center of the boiler.

- The coolant enters the boiler tank from top to bottom - through a pipe in the upper zone. And to exit, that is, to return to the system, through the lower zone.

Boiler device

If all four principles are observed, the water at the outlet in the upper zone of the boiler will always be hot, which will maximize the efficiency of the equipment.

Consider the specifics of different strapping methods.