- Device and principle of operation

- Septic tank care Microbe

- Features of the septic tank DKS

- Models of septic tanks DKS and their characteristics:

- Device and principle of operation

- Camera assignment

- Technical characteristics of the installation

- Advantages and disadvantages of buildings brand "Leader"

- Recommendations for installation and maintenance

- The order of installation and operation of the DKS septic tank

- Location selection

- Tank installation

- Pipe installation

- Step-by-step description of cleaning technology

- Settling tanks

- Biofilter

- What is the difference between plastic septic tanks

- Installation order: choosing a place

- Positive traits

- The device and technical characteristics of this septic tank

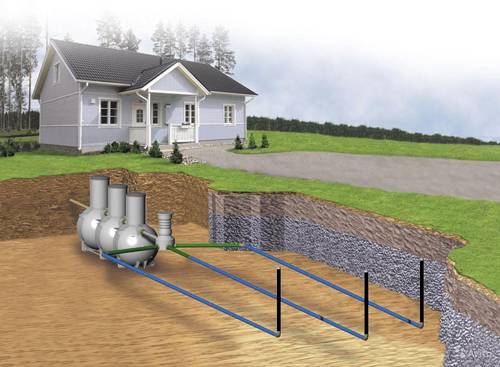

- Arrangement of drainage

- Surface drainage

- Other methods of wastewater

- Conclusions and useful video on the topic

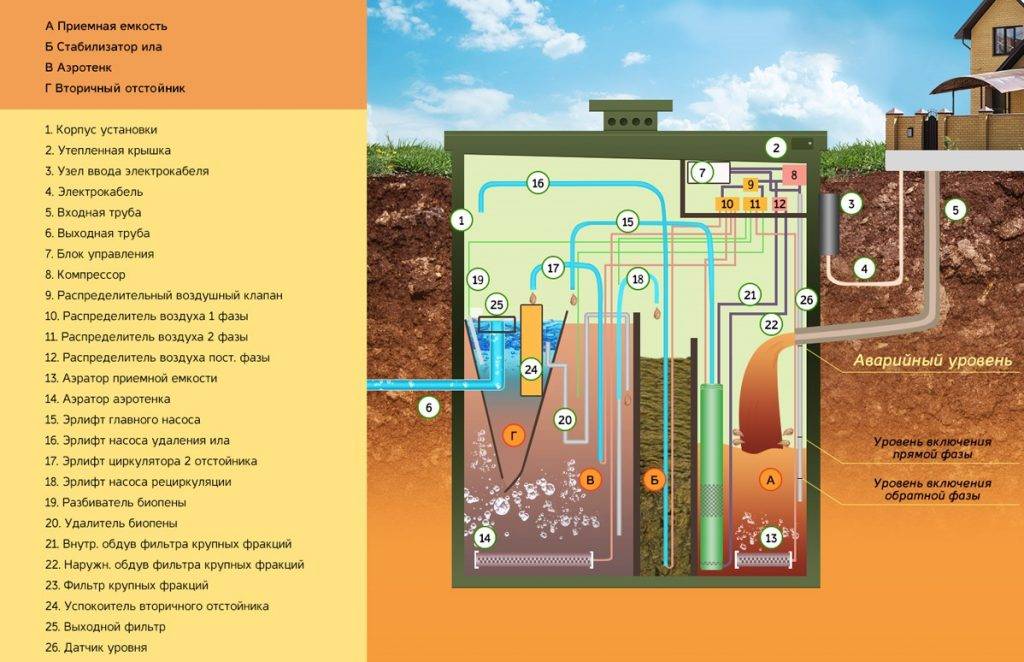

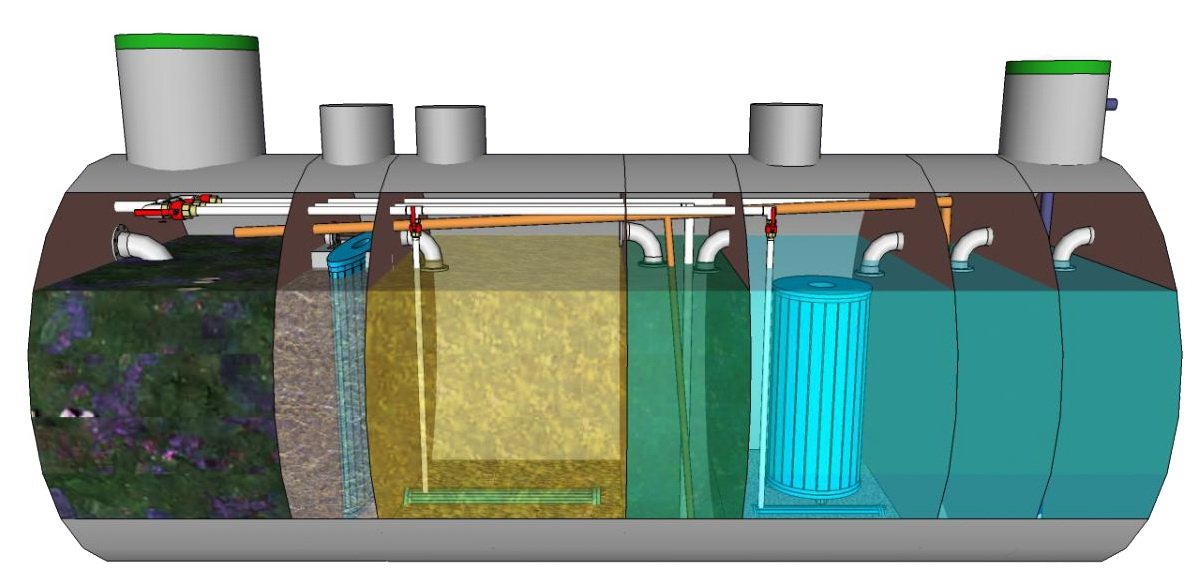

Device and principle of operation

Purification equipment such as, for example, a septic tank Cleansing - storage tanks, tanks or reservoirs that are designed to accumulate and purify sewage wastewater.

Some installations have the simplest structure because they represent only one chamber that accumulates and purifies wastewater by settling with the help of bacteria.

Other models have chambers inside their hollow capacity, which allow you to gradually clean sewage by pouring purified water from one chamber to another with sludge settling in each of them.

Silt and water are decay products under the influence of anaerobic bacteria. The number of chambers depends on the volume of liquid household waste entering the septic tank. Usually septic tanks for a private house are made with division into compartments from 2 to 3 chambers.

Two-chamber types of equipment include a septic tank for cleaning 2500 liters or more (capacities up to 4000-5000 liters). These units do an excellent job with the tasks assigned to them to accumulate and purify household liquid waste, reducing it in size.

Three-chamber models are usually made for a larger displacement. Such equipment can be: a 4000 cleaning septic tank, a 5000 cleaning septic tank or a 6000 liters cleaning septic tank.

The principle of operation inside the Chistok septic tank is quite simple. The chambers are always connected to each other by holes with locks, which are always located in the upper part of the chambers themselves.

So wastewater can freely accumulate and be cleaned in the first chamber, decomposing into sludge and water.

Reaching the first hole, the purified water is poured into the second chamber and there it is also cleaned with the help of bacteria. Secondary purification allows you to more thoroughly free the water from the decomposition included in it.

After all, primary sewage treatment is carried out only by 60 or 70 percent. This is the basic principle of operation of the Chistok septic tanks.

work of septic tanks Chistok

If we consider in more detail its structure and operation, then the following can be noted.The sewage enters the inlet pipe of the first chamber through a special tee, which is designed to slightly slow down the rate of fall of liquids.

In the first chamber, all effluents are exposed to anaerobic (airless) bacteria and fermented, separating into silt, which settles on the bottom of the first chamber, and water, which accumulates, rises up to the hole that goes into the second chamber.

In the second chamber there is a secondary purification of the so-called "gray water" received from the first chamber. Here, water is purified from colloidal particles and the small heavy elements included in it are settled.

After the purified water reaches the second hole leading to the biofilter, it enters there in order to be finally purified.

It should be noted that the opening in the second chamber, which receives the effluents from the first, is located below the inlet from the first chamber.

This is necessary so that the purified water does not return back to the first chamber, and there is no premature overflow of the first chamber.

and septic operation

The biofilter is a special container, at the bottom of which there are holes covered with a synthetic fabric "Algae" attached from the inside of the container, which filters the liquid coming from the second chamber.

However, even when loading the biofilter, synthetic fibrous fabrics "Ruff" are used, on the surface of which a biofilm of microorganisms is formed, which not only purify the water for the last time, but also saturate it with bioflora.

After that, the water seeps through the synthetic fabric "Algae" into the soil or into the drainage system with perforated or conventional sewers - it all depends on the design model of the septic tank.

After aerobic microorganisms finally work on the purified water from the septic tank, such water can be used for technical and agricultural needs, for example, for accumulation in tanks for watering the garden.

Septic tank care Microbe

Maintenance of septic tanks The microbe does not require the involvement of specialists. All work can be done independently. To clean the equipment and preserve it for the winter, you must:

- use fecal sediment;

- use the services of a sewer machine.

After pumping, it is enough to rinse the walls of the septic tank with clean water.

There are situations when the septic tank begins to emit unpleasant odors. In most cases, this happens due to a lack of bacteria that process wastewater. You can replenish a number of bacteria with special means, for example, Unibac.

Anaerobic bacteria suitable for septic tanks Microbe

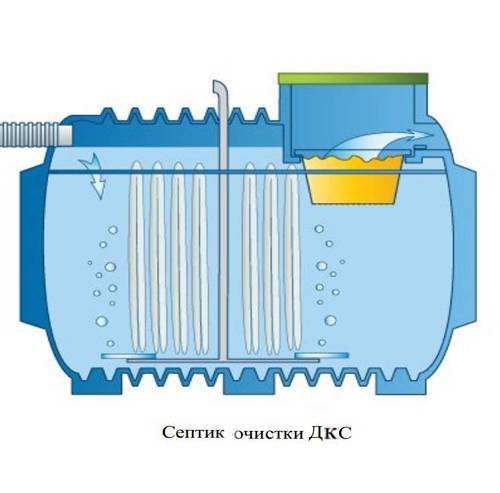

Features of the septic tank DKS

The DKS septic tank is made of polypropylene - thanks to this factor, the systems are light in weight and are sold at a reasonable price. This allows you to create an uncomplicated transportation of the system to its destinations.

The table shows the models of septic tanks DKS.

Models of septic tanks DKS and their characteristics:

| DKS station model | Capacity l/day | Weight, kg | Length, mm | Width, mm | Height, mm | Approximate cost, rub |

|---|---|---|---|---|---|---|

| Optimum | 250 | 27 | 1200 | 1300 | 995 | 20000 |

| 15/15M | 450 | 52 | 1500 | 1100 | 1100 | 35000 |

| 25/25M | 800 | 72 | 1500 | 1300 | 1500 | 47000 |

| MBO 0.75 | 750 | 80 | 880 | 1965 | 68000 | |

| MBO 1.0 | 1000 | 92 | 1070 | 1965 | 73000 | |

| MBO 1.5 | 1500 | 110 | 1210 | 1965 | 90000 | |

| MBO 2.0 | 2000 | 120 | 1360 | 1965 | 115000 |

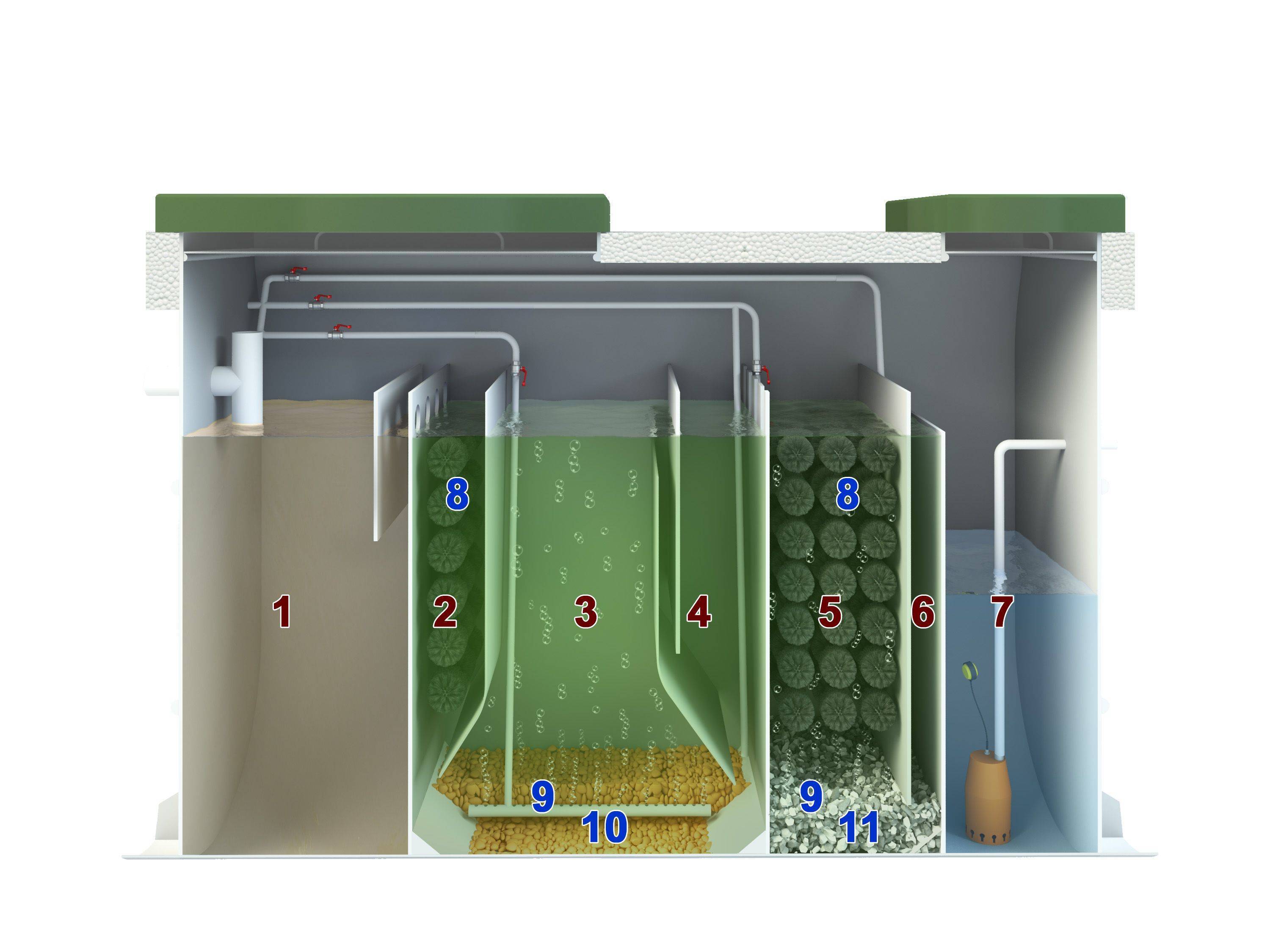

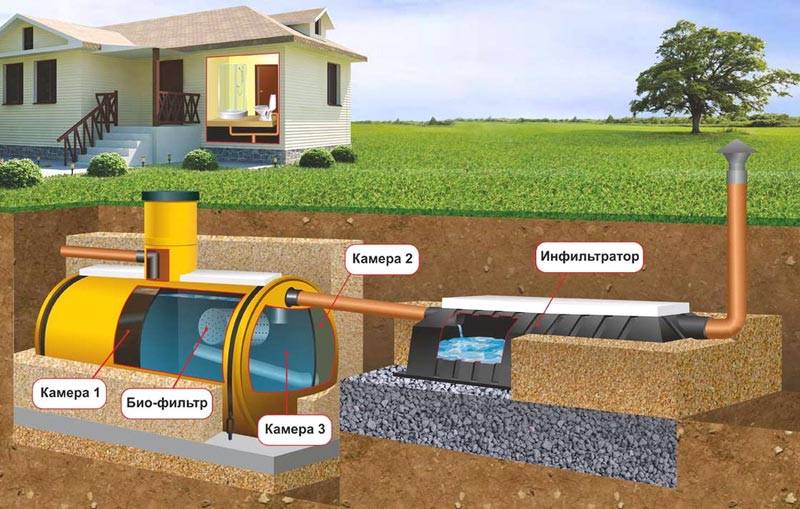

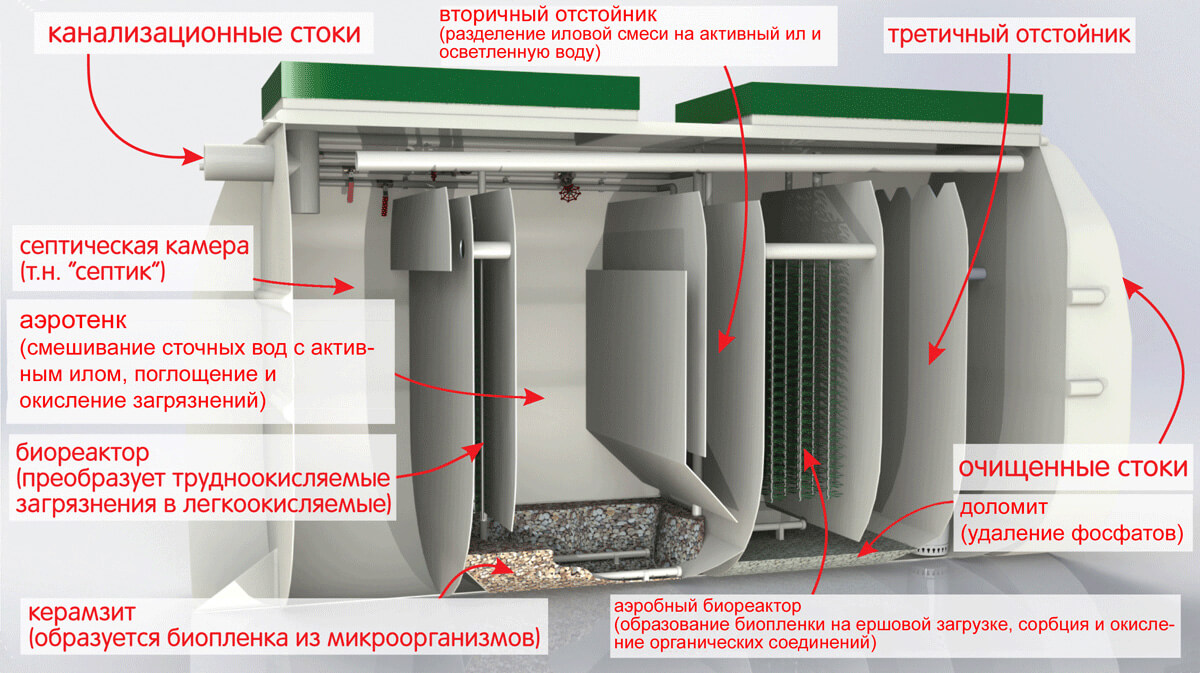

Device and principle of operation

A sealed container made of durable material - polypropylene - plays the role of a sump isolated from the environment. This is an autonomous treatment facility necessary for the accumulation and disinfection of waste in places where there is no centralized sewage system - for example, in a country house.

To install the Kedr Septic tank, a small plot of land near the house is enough, but one should not forget about additional drainage structures - a trench or a filtration field

A septic tank differs from a conventional tank in that it consists of several chambers, each of which has its own functional focus.

Camera assignment

1 - receives wastewater that flows by gravity from the building. All suspensions are divided into two groups: heavy solid particles sink to the bottom, forming a sediment, and light fats rise to the surface of the water and accumulate there in the form of a thick film.

2 - under the influence of anaerobic bacteria, there is a moderate treatment of wastewater, their partial clarification.

3 - a replaceable biofilter, which must be washed from time to time, collects aerobic and anaerobic microflora.

4 - the clarification process ends. If there is a need to raise the level of filtered water, a drainage pump is installed in this chamber.

When ordering a septic tank, you need to remember about its various versions, which differ in the height of the head

Technical characteristics of the installation

-

- height - 3 m;

- diameter - 1.4 m;

- total weight - 150 kg;

branch pipes (DN 110) are provided for connection with inlet and outlet sewer pipes; eyeliner at a distance of 1.2 m from the top, outlet - 1.4 m.

The well-thought-out composition of the drainage will allow you to maximally clean the water coming from the septic tank

Advantages and disadvantages of buildings brand "Leader"

One of the advantages that Leader brand devices have concerns the location of the structure relative to a residential building.Due to the absence of an unpleasant odor and the quiet operation of the equipment, the septic tank can be placed at a minimum allowable distance of 5 m (SNiP).

Other norms should be taken into account, for example, to the nearest well - 25-30 m with non-cohesive sandy (gravel, gravel) soils, 45-50 m with coherent ones, i.e. clayey rocks (loams, sandy loams).

Residents of cottages who have been using septic tanks for more than a year note such advantages as:

- high efficiency of sewage treatment - several processing chambers are able to purify the liquid by 95%;

- the ability to work without biologically active additives, which are recommended to be added to septic tanks by specialists from some companies;

- stable operation even with regular long interruptions in the supply of effluents, which does not require conservation;

- easy tolerance of power outages - in the event of force majeure, the system is able to operate normally for 2 weeks, without changing the properties of treated water;

- the possibility of using one of the drainage schemes with a focus on the type of reservoir or the presence of a facility for discharging treated liquid;

- compactness of the structure, which allows economically distributing the free territory of the site;

- the possibility of installation in clay soil or on a site with high groundwater without a specially provided concrete base (the presence of a stable concrete slab at the bottom of the pit is one of the conditions for installing septic tanks from competitors).

The manufacturer recommends selecting a structure so that the useful volume of the device is approximately 3 times greater than the daily amount of sewage.Many consider this a disadvantage, in fact, this ratio helps to easily withstand salvo discharges and clean the liquid by at least 95%.

The possibility of building necks is also an advantage. It is necessary to deepen the septic tank below the usual level. Such a need arises in the northern regions with deep freezing of the soil.

Another plus can be found by buying the Leader cleaning system directly from the manufacturer. Without extra charges, the cost of equipment that belongs to the middle price segment is much lower.

One of the disadvantages is the poor functioning of the installation at low temperatures and the need for additional insulation, but this problem applies to any VOC.

Some users note a bad smell, but it most likely occurs due to incorrect installation or untimely removal of sediment or sludge. According to the reviews, it can be judged that the advantages of the Leader septic tank prevail over its shortcomings.

Recommendations for installation and maintenance

It is better to dig a pit for installation away from roads in order to protect the septic tank from accidental collision. The case is a single reservoir, so even a small breakdown or leakage can lead to a complete replacement of the device.

Installation must be carried out in the warm season, since the air temperature at the time the device is put into operation must be at least + 12ºС, and the temperature of the water that is poured into the housing before starting work must not be lower than + 15ºС

In addition to the basic rules for installing a septic tank in a pit, you need to know a few more engineering nuances:

- for external sewerage it is necessary to use polymer pipes with Ø 100-110 mm;

- the slope of the supply pipeline is 0.02 m per meter of length;

- the slope of the discharge pipeline is 0.05 m per meter of length (should not be too long);

- the base of the pit is covered with sand or sand-gravel mixture and carefully compacted (concreting or installation of a concrete slab is not needed);

- the liquid inside the housing must reach the level of the weirs;

- insulated maintenance hatches must be kept closed.

A few remarks apply to the installation of the compressor. It must be in the winter in a heated room (basement, utility room), for ease of maintenance - near the sewer outlet. The device requires a power point to operate.

When the sludge excavation procedure takes place, the compressor should be turned off.

During the operation of the septic tank, make sure that the performance matches the nominal value. If it exceeds the declared figures by 20%, you should think about replacing the installation with a more powerful one. When using a biological station, it is necessary to review the range of detergents and cleaners: they should not include petroleum products or chlorine.

The owner of the septic tank "Leader" can perform the main part of the service on his own. Once every three years, lime filling in the 2nd aeration tank will have to be replenished, and the walls of the hull and weirs will have to be cleaned at the same frequency.

The polymer brush loading should be washed annually, and the excess activated sludge should be pumped into the first compartment (receiving chamber) using airlifts. Silt is removed as it accumulates, approximately every 3-6 months. Once a year, to remove the accumulated sediment, the help of sewers will be required.

If seasonal operation of the Leader brand treatment plant is planned, then it will be necessary to conserve for the winter. What it is, you will learn from our recommended article.

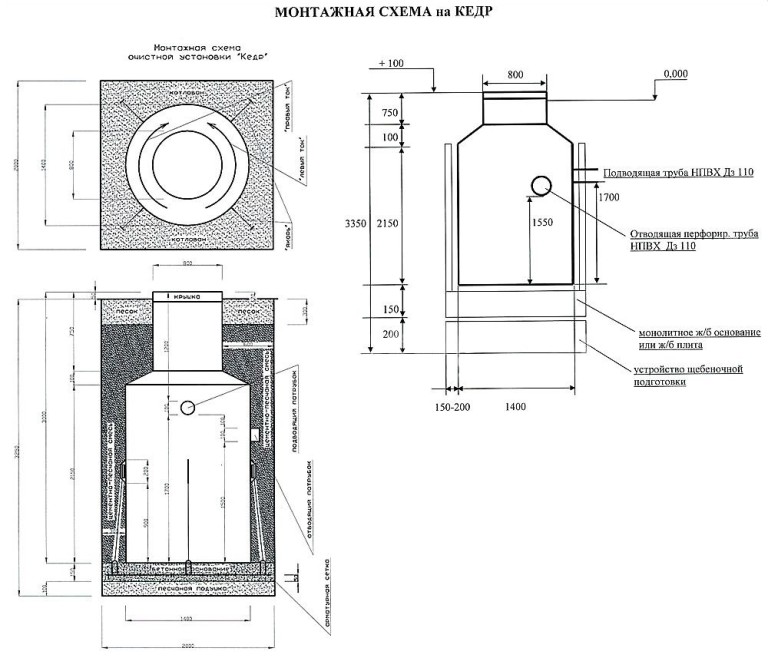

The order of installation and operation of the DKS septic tank

Location selection

a silt pumping machine could drive up.

It is also worth carefully analyzing the soil where it is planned to place the cleaning system for the presence of groundwater. The correct conditions for the location of the DKS septic tank will be its proximity to the corrugated sewer pipe that exits the house.

It is also worth considering that the septic tank is at a certain distance from engineering networks and sources of electricity. Under a tree with a spreading root system, the location of the septic tank will also be unsuccessful.

Tank installation

For the next step you need:

- dig a rectangular hole to install the working tank of the septic tank and next to it - trenches for placing the pipe;

- the bottom of the pit is covered with an even layer of sand 10 cm high;

- a reservoir is installed in the pit and covered with clean sand from all sides, preferably wet. During installation, it is good to add water to the tank to keep it in a strict horizontal position;

- from all sides and from above it will be good to overlay the septic tank with thermal insulation or foam.

Pipe installation

placed at an angle

The distance from the house to the septic tank, which is considered optimal, is from 3 to 6 m. The best option is when the pipes from the drain are located directly to the tank, but if there are turns, it is good to use a rubber pipe at the bend.

The tank is leveled horizontally, during the installation process, the sand around is periodically compacted. Pipes can be covered with soil.

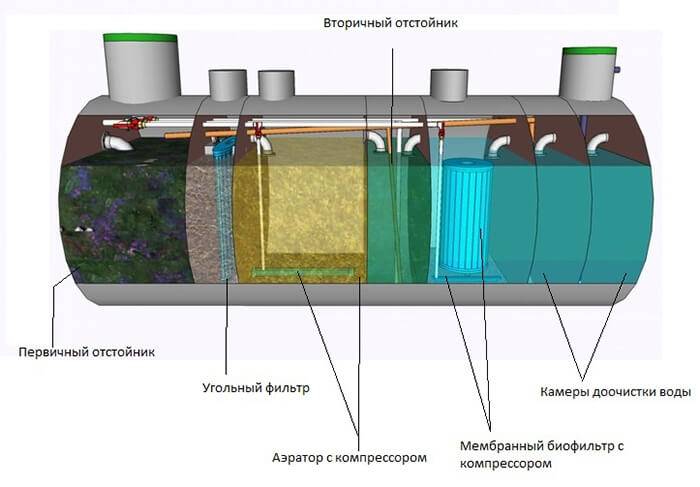

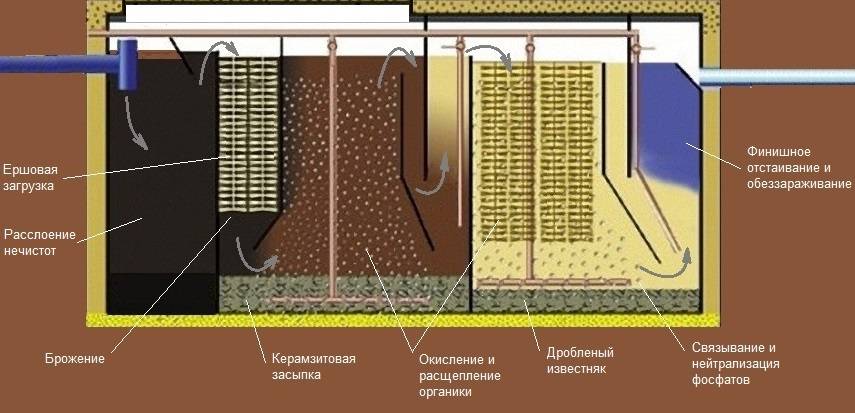

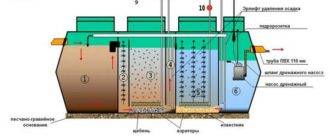

Step-by-step description of cleaning technology

Settling tanks

Effluent through the sewer pipe through pipe 1 enters the primary sump I. Here, heavy fractions sink to the bottom, light fractions float. The liquid fraction flows into section II of the tank. Overflow 3 is located at a level equal to 1/3 of the tank height, so solid fractions do not enter the secondary sump. In the second compartment, the sedimentation process continues and small particles of waste remain at the bottom.

In settling tanks, faeces are processed into sludge under the influence of methanogenic microorganisms. These microbes are present in the human body and enter the sewer with its waste products. The fermentation process occurs without access to air and is called anaerobic. After fermentation, light fractions are released from gas bubbles and sink to the bottom, where they mix with heavy components.

The tanks are connected to the atmosphere through water seals. The valves allow you to equalize the pressure between the cleaning system and the external environment, but do not let oxygen in. Thanks to them, the unpleasant smell on the surface is almost not felt.

Biofilter

Biofilter III consists of a supply pipe, a drip sprinkler and a brush load. In the filter, water is cleaned of small inclusions, and fecal residues are decomposed by microorganisms.

Through a vertical pipe 5, water enters at a low speed to a drip sprinkler 6. This unit is designed to evenly distribute water over the brush load 7. The brush load has a developed surface on which conditions are created for the development of colonies of aerobic microbes. Aeration of the septic tank is carried out by supplying air to the filter through a pipe connected to the atmosphere.

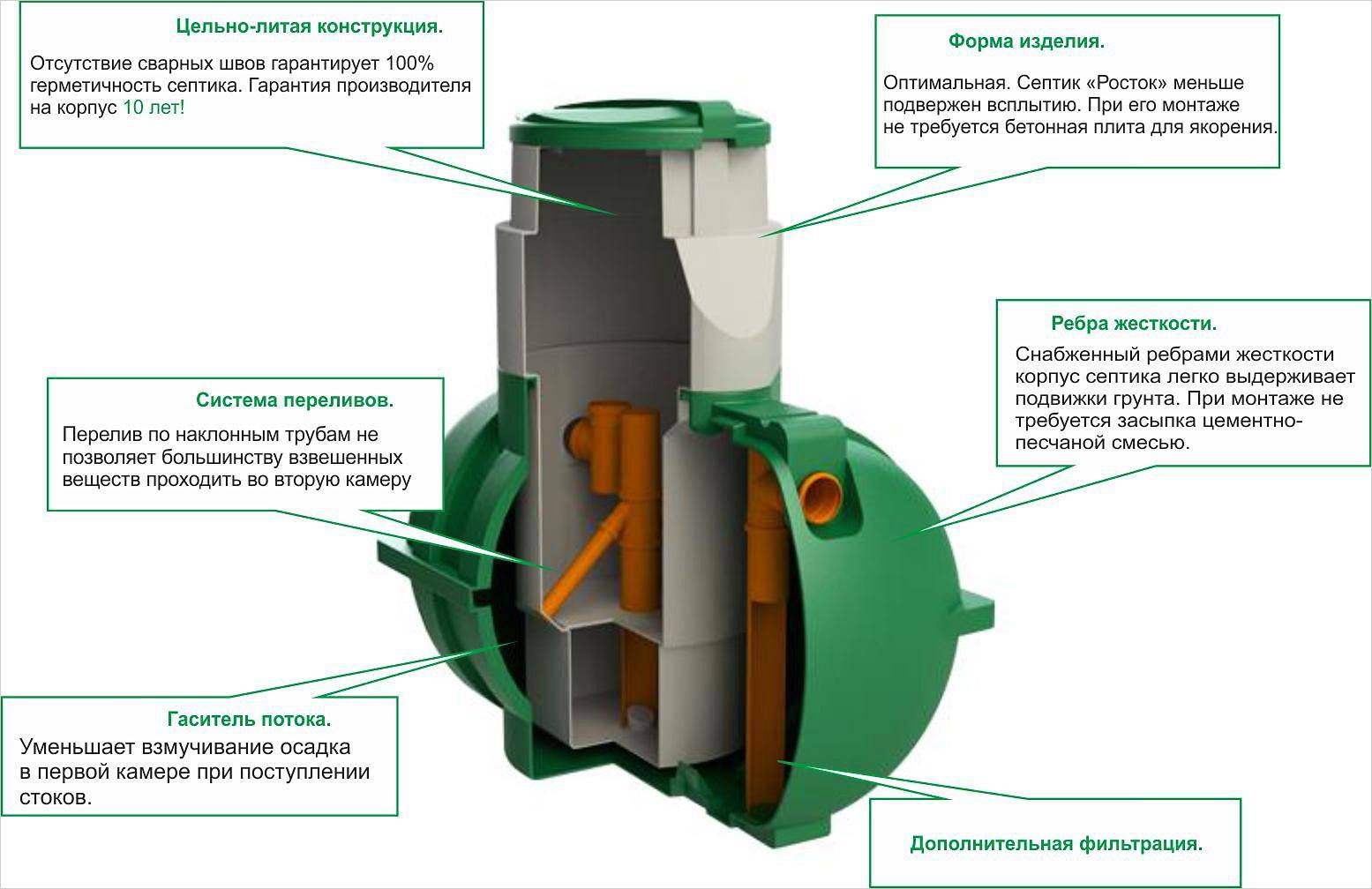

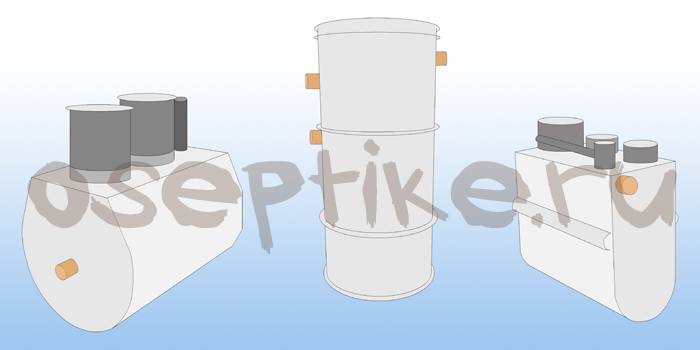

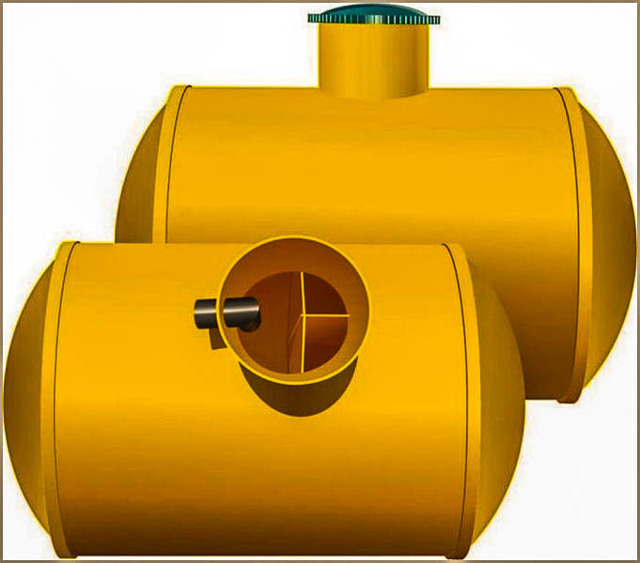

What is the difference between plastic septic tanks

In our market, plastic septic tanks are represented by the trademarks "Tank", "Evrolos", "Dochista", "Termite", "Rostok", "Krot", FloTenk, etc.

There are vertical and horizontal septic tanks. The former take up less space on the site, but for them you have to dig a deep pit, which can be problematic to do with a high groundwater level. The latter take up more space, but provide a more extended route for the movement of wastewater from the inlet to the outlet. This improves the quality of wastewater treatment.

Plastic septic tanks come in different shapes. Rounded (cylindrical) products are better than septic tanks in the form of a cube or parallelepiped, they resist squeezing with soil.

The most economical septic tanks are made of low-density polyethylene. They are produced by rotational forming, which makes them seamless and therefore completely sealed. This is an absolute plus, especially in the case of a site with a high GWL. But with this manufacturing method, it can be difficult to achieve the same thickness of all walls: for some products, it can vary, for example, from 8 to 17 mm. Meanwhile, there is no doubt: the thicker the wall of any plastic septic tank, the more reliable and durable it is (by the way, there are no national standards for the thickness of the walls of plastic septic tanks).

Polyethylene itself does not have high strength and therefore the design of the septic tank requires reinforcement. Otherwise, there is a risk of its deformation during frost heaving of the soil or the extrusion effect of groundwater. Strengthening measures - stiffeners throughout the body and internal partitions: the more of them, the higher the rigidity of the product. Note that such partitions are provided in any plastic septic tanks.

Partitions form chambers, which are interconnected by overflows. Moreover, many manufacturers explain the presence of several cameras as a way to improve wastewater treatment. However, a number of experts argue that this is just a marketing ploy, and partitions are nothing more than structural elements to prevent deformation of the product body. Here we can recall the requirements specified in the main standard for septic tanks - STO NOSTROY 2.17.176-2015 "Autonomous sewage systems with septic tanks and underground wastewater filtration facilities." According to the standard, for septic tanks with a working volume of up to 3 m³, one chamber is enough to ensure effective wastewater treatment

Please note: polyethylene septic tanks usually need to be anchored to prevent them from being squeezed out by groundwater.

Polypropylene septic tanks also belong to the segment of inexpensive products. They are made by extrusion welding of sheet materials. This method makes it possible to make not only stiffeners on the body of the product, but also lugs, loading outlets or other protruding elements that reduce the likelihood of a septic tank surfacing. Anchoring such septic tanks is often not required. The strength of polypropylene septic tanks is quite high, the thickness of their walls, as a rule, is not less than 8-13 mm, depending on the volume.

But fiberglass septic tanks have the highest strength. These are already relatively expensive products, which are distinguished by a very high resistance to soil pressure. They are optimal for installation at great depths (up to 3 m).

In addition to classic septic tanks, there are products on the market that provide for the so-called "biofilter". Do not confuse such septic tanks with aeration plants.The biofilter is a load, for example, a ruff made of synthetic material or in the form of a container with expanded clay backfill. On loading the colony of anaerobic bacteria is formed. According to the manufacturers, the biofilter allows either to improve the quality of cleaning, or to reduce the working volume of the septic tank while maintaining the same quality of cleaning. It should be borne in mind that the biofilter does not eliminate the need for post-treatment of wastewater, while at the same time requiring periodic flushing.

Separate models of septic tanks allow the possibility of subsequent completion with a compressor that saturates wastewater with atmospheric oxygen, starting the process of aerobic treatment. Thus, over time, the septic tank can be turned into a budget aeration unit.

Installation order: choosing a place

To install the described system for wastewater treatment, at the first stage it is necessary to choose a place

It should be near the house, but it is important to ensure that a sewage truck can drive up to pump out sludge. At this stage, you should analyze the soil where the cleaning system will be located.

It will be necessary to find out how deep the groundwater is. The correct location condition is the proximity of the septic tank to the corrugated sewer pipe from the house

When installing DKS septic tanks, it is important to ensure their remoteness from engineering networks and sources of electricity. You should not choose a place near a tree that has a powerful root system.

Positive traits

Series 5 and 5H are not too demanding for maintenance - it is enough to remove sediment once every 2 years using a fecal pump or a sewage truck.Among other advantages it is worth highlighting:

- Operational durability

- Full autonomy (Klen 5)

- Constructive simplicity

- Minimum Maintenance

- Absolute tightness

The unique technology, along with the simple design of the septic tank, allows the equipment to be operated for half a century. It is recommended to trust the installation of a septic tank only to specialists, however, if necessary or desired, you can handle the installation of an autonomous sewage system yourself. Thanks to the sealed design, there is zero harm to the environment.

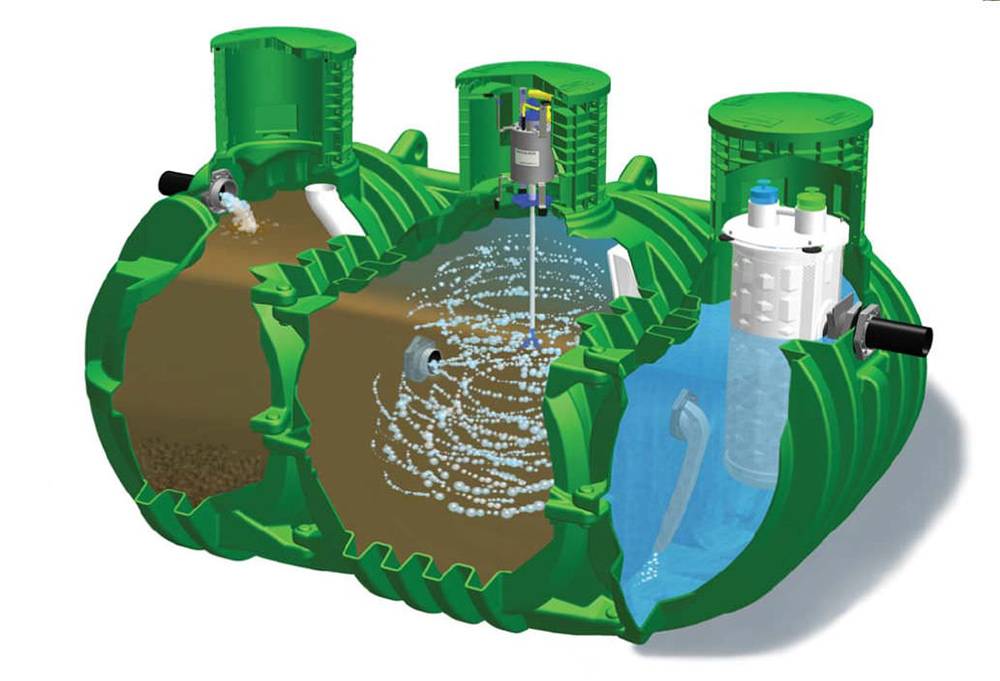

The device and technical characteristics of this septic tank

As a local wastewater treatment plant, Eurobion treats domestic wastewater through biological oxidation. The manufacturer abandoned the anaerobic processes that cause an unpleasant odor and created a rhythmic aerotank capable of decomposing domestic wastewater using activated sludge.

The range of Eurobion septic tanks is quite large, it is designed to serve from 2 to 150 people. For dachas, Eurobion-5 or Eurobion-8 installations are usually used.

The septic tank is a compact installation that is mounted in the ground in convenient proximity to the house. Thanks to a wide range of models, it is possible to choose the most suitable device - the choice depends on the number of people living in the house at the same time, the number of showers and toilets, the availability of household appliances.

The design of the Eurobion septic tank is thought out to the smallest detail, from the control unit located under the lid to the overflow system in the working tanks

Consider the technical characteristics of one of the popular models - Eurobion-5. It has the function of uniform sewage treatment, while the flow rate reaches 170 l / h.The secondary sump has a volume of 590 liters. The unit is designed for a one-time drain of 390 l. If the operating rules are followed, the quality of wastewater treatment reaches 98%.

The compressor has a power of 39 W, electricity consumption is 0.94 kW / h. Compressor diaphragms must be replaced every four years.

The membrane compressor of the Japanese company Hiblow (Hiblow) is designed to pump air into the compartments of the septic tank - only under this condition will aerobic bacteria successfully develop

The advantage of the Yubas septic tank is self-maintenance, which is required every six months and consists in lowering the level of activated sludge, sometimes in removing solid undecomposed waste.

Arrangement of drainage

There are several options for removing treated water from a septic tank, such as a drainage well or surface drainage, with the latter having a huge advantage both financially and technically.

Surface drainage

Since the resorption area of the discharged water during surface drainage is 5 times the area of the drainage well (5 sq/m vs 1 sq/m), a surface drain 10 meters long can be located above the groundwater level. To do this, we will use a flexible corrugated pipe with holes. You can also purchase a ready-made kit (set) for surface drainage. (click on the photo you are interested in)

We dig a trench 0.5-0.6 m deep and 0.4 m wide, the length is 10 meters - it will run in the direction from the septic tank along the ditch or parallel to the fence. If there is a natural slope, you need to use it, otherwise we lay the pipe with a slight slope - 1 cm per meter of trench.

In the dug trench, we first lay a special non-rotting fabric made of polypropylene (geo-textile), the edges of which are fixed with pegs to the ground.

The diagram shows the laying of the pipe. (click on the photo you are interested in)

Other methods of wastewater

In order for you to see the full picture, we have also prepared for you diagrams of other drainage options. (click on the photo you are interested in)

Conclusions and useful video on the topic

With the help of videos shot by TACOM representatives, you can get an idea of the operation of FAST septic tanks.

Video #1 General information about Bio-Microbics products:

Video #2 How the MicroFAST 4.5 model looks and functions:

Video #3 The degree of purification of the liquid taken from the drainage well:

Video #4 Engine noise level:

Video #5 Installing the RetroFAST system in a concrete tank:

If you need high quality wastewater treatment and you are not experiencing financial difficulties, pay attention to VOC “FAST”. You can choose the most suitable model on your own, after consulting with a representative of TACOM, and it is still better to entrust the installation to specialists.

And what treatment plant did you use in organizing an autonomous sewage system for your site? Tell us what are the advantages of the option you have chosen, share why you chose it. Please write comments in the block below, publish photos on the topic of the article, ask questions.