- Expert assessment of specialists. Independent analysis.

- Scope of application

- Description

- With the help of the Krot cultivator, you can perform the following agrotechnical work on the site:

- The design of the septic tank Mole

- Advantages and disadvantages for comparison

- User manual

- Setting up a motor cultivator before plowing with a cutter:

- Setting up a motor cultivator depending on the tasks:

- Attachment Overview

- Device ↑

- Vertical Models

- Mole 1.8

- Mole 3.6

- Horizontal Models

- Septic Rostock - a unique overflow system

- Design features

- Installation nuances

- Concrete septic tank Aspen

- Features of gas connections

- Warning

- Installation rules

- Why do owners of country houses choose Mole?

- For what types of work is it used

Expert assessment of specialists. Independent analysis.

Even a small sewage treatment plant requires a serious attitude. This is our ecology, and not only our own site, but also neighboring lands. When we put the “Mole” septic tank at our dacha, we must understand that the water comes out of it, purified only partially, and it is impossible to leave it to the mercy of fate. It is necessary to provide additional cleaning on our own in order not to get contamination of the surrounding space.If you cannot immediately spend money on an expensive septic tank, from which almost pure water comes out, almost 100% free from pollution, then you need to find funds for the construction of a filtration well, an aeration zone. If you yourself do not understand how to do this, then invite a specialist. These costs will still pay off with the good work of your septic tank.

Design engineer,

Kirill Matyukhin.

Septic tanks "Mole" - this is the same tit in the hands. This is a good quality septic tank at a real price. If it is installed by specialists who competently build a treatment system, then it will turn out cheap and cheerful.

hydraulic engineer,

Aidar Mammadov.

Scope of application

The Krot-1A cultivator is rightly considered one of the very first Russian agricultural machines of agricultural small-sized agricultural machinery, which is used to carry out shallow processing (milling without layer turnover) - up to 30 centimeters - harrowing, loosening, weeding between rows and leveling. As it is written in the operating instructions, it is effective to use the Krot MK-1A-02 motor cultivator on their own garden, garden, household plots, the cultivated area of which is in the range of 0.04-0.10 hectares. You can read more about this by opening a special brochure "Motor-cultivator MK-1A-02" Krot "operation manual MK-1A-02".

Motor-cultivator "Krot" MK-1A-02 is an indispensable agro-helper for any agronomist and person closely associated with agriculture. The motor cultivator "Krot" MK-1A has a compact size, while this agricultural machine is quite high-performance.It is able to quickly and seamlessly prepare the soil for planting, hill up and weed the beds. Motor cultivator "Krot" "Krot"-1A is also ideal for planting various crops, such as potatoes.

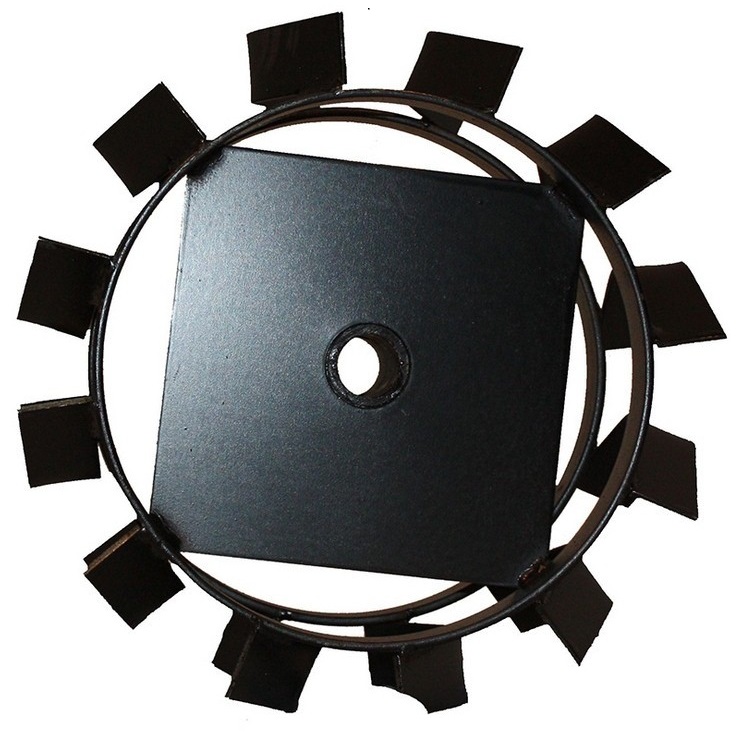

Milling cutters and other additional parts for the agricultural machine

Spare parts for the Krot MK-1A-02 motor cultivator are of great importance. Four phrases are included with the device upon purchase.

They need to be fixed on different sides of the gear shaft. Alternatively, six cutters can be used simultaneously.

To dig or hill potatoes, the cutters are replaced with other spare parts for the Krot MK-1A-02 motor cultivator - wheels. And the coulter is replaced by a plow or hiller.

For watering work, spare parts such as pumping agricultural equipment MNU-2 are used. It is attached in front of the agricultural system, a V-belt drive is additionally attached to it (it can be disconnected from the motor-block gearbox).

Conclusion

We hope that this article has helped you to get the most complete impression of the operation of this type of equipment, to understand all the functional nuances and scope of the described agricultural technology.

Motor cultivator "Krot" MK-1A-02 is produced by the domestic plant JSC "MMP im. V.V. Chernyshev". The first units were produced by the manufacturer in the 80s of the last century. These devices, although they differed (characteristics, device, principle of launch and operation, trailed equipment, etc.) from the modern motorized cultivator "Krot" MK-1A-02, but were appreciated by the owners of vegetable gardens, greenhouses (small farms ).From the very moment of its appearance, “Mole” has become an indicator of reliability, strength, functionality and high manufacturability.

Description

The modern unit marked MK-1A-02 was modernized, as a result of which its power (2.6 l / s) and, accordingly, its productivity increased. A two-stroke engine running on mixed fuels (gasoline + oil) is able to ensure uninterrupted operation of the cultivator for a long time. Relatively light weight (only 48 kg) allows you to easily transport equipment to any place that requires processing with a motor cultivator.

With the help of the Krot cultivator, you can perform the following agrotechnical work on the site:

- plowing of soil of any severity;

- cutting the soil for sowing;

- planting potatoes;

- hilling planted plants;

- weeding from weeds;

- digging potatoes;

- mowing;

- snow removal;

- transportation of goods, etc.

| Parameter | Meaning |

|---|---|

| Manufacturer | JSC "MMP im. V.V. Chernyshev" |

| Producing country | Russia |

| Cutter diameter | 33 cm |

| Power | 2.6 HP |

| Number of speeds | 1 forward/0 backward |

| Reverse | Not |

| Steering column | 1 position |

| Capture width | 35-60 cm. |

| Capture depth | 25 cm. |

| The weight | 48 kg. |

| Dimensions | 1300x810x1060 mm. |

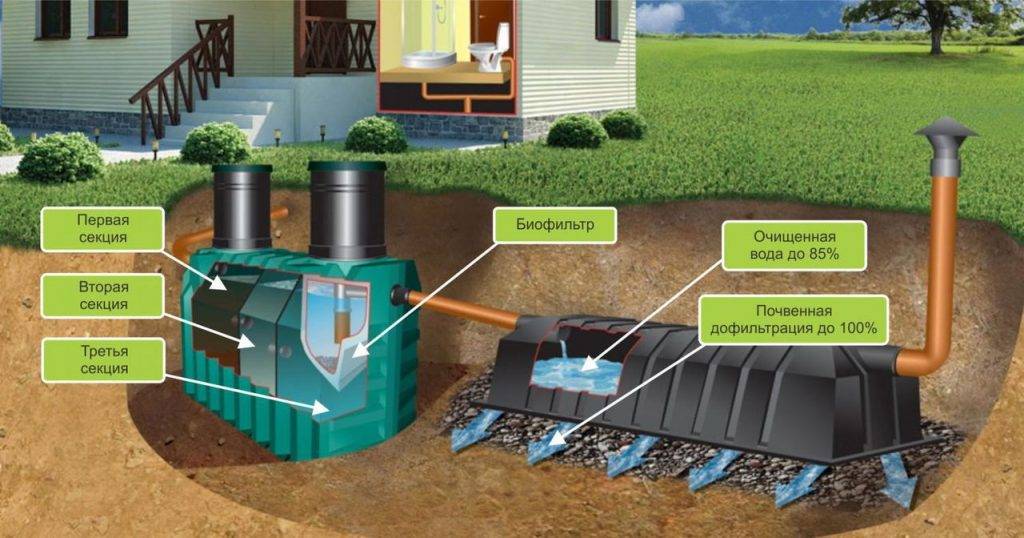

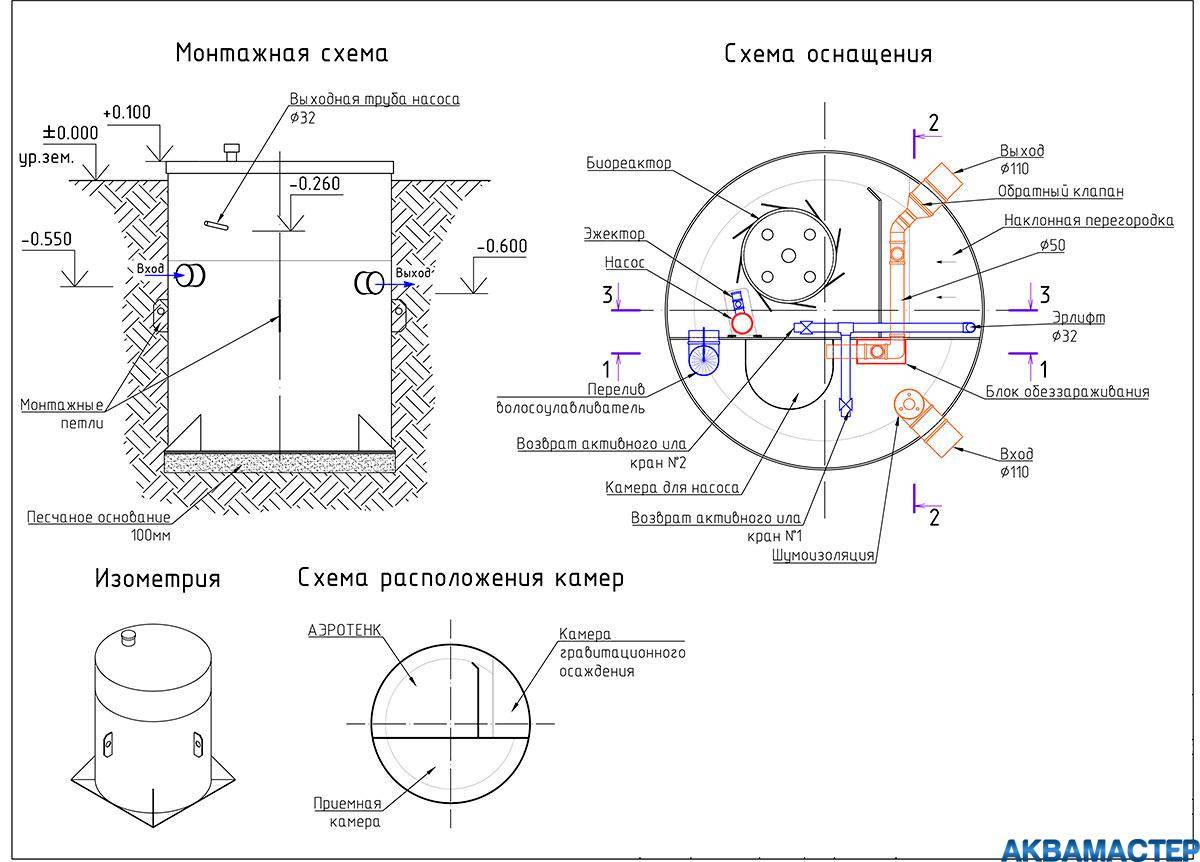

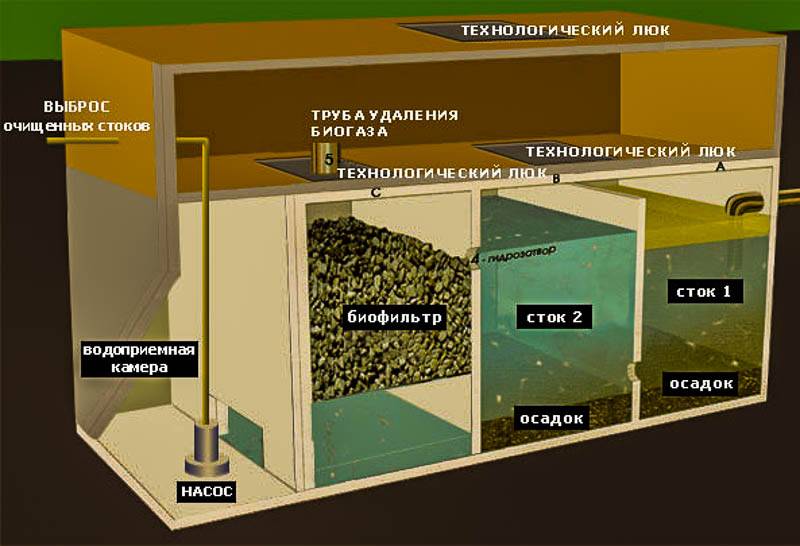

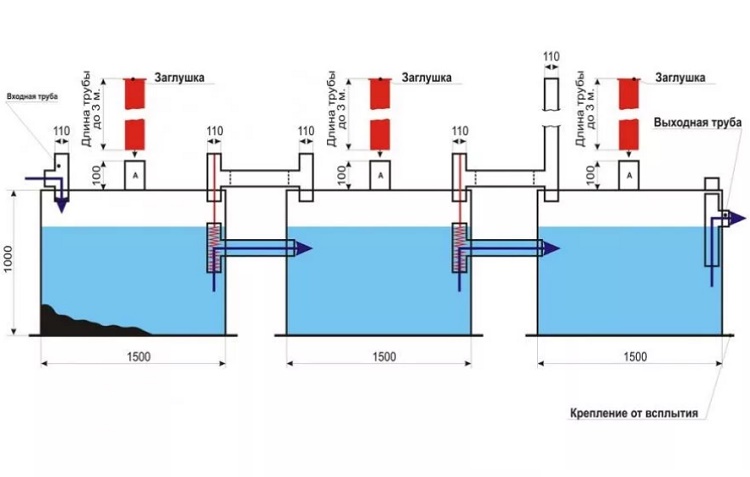

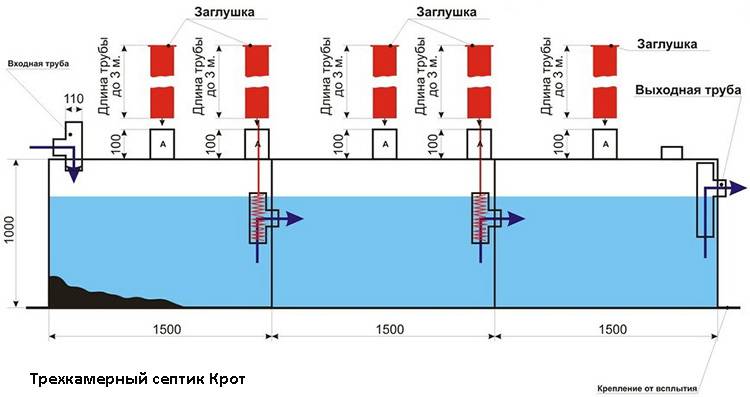

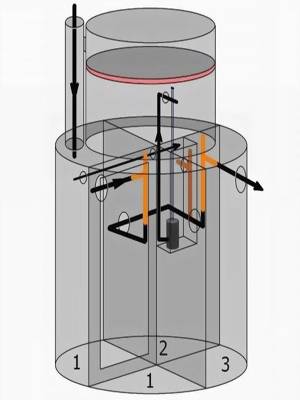

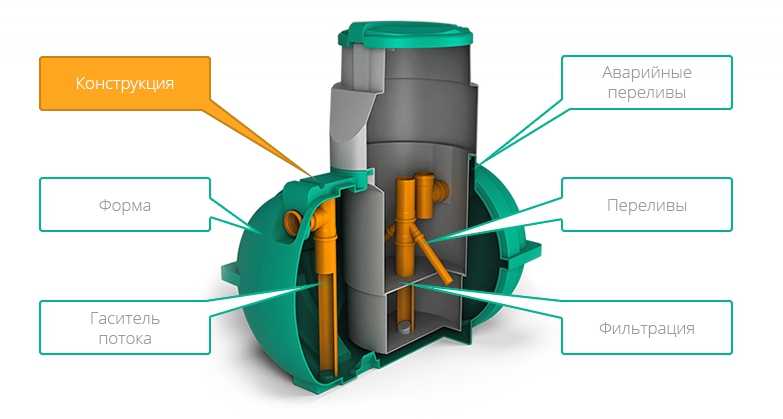

The design of the septic tank Mole

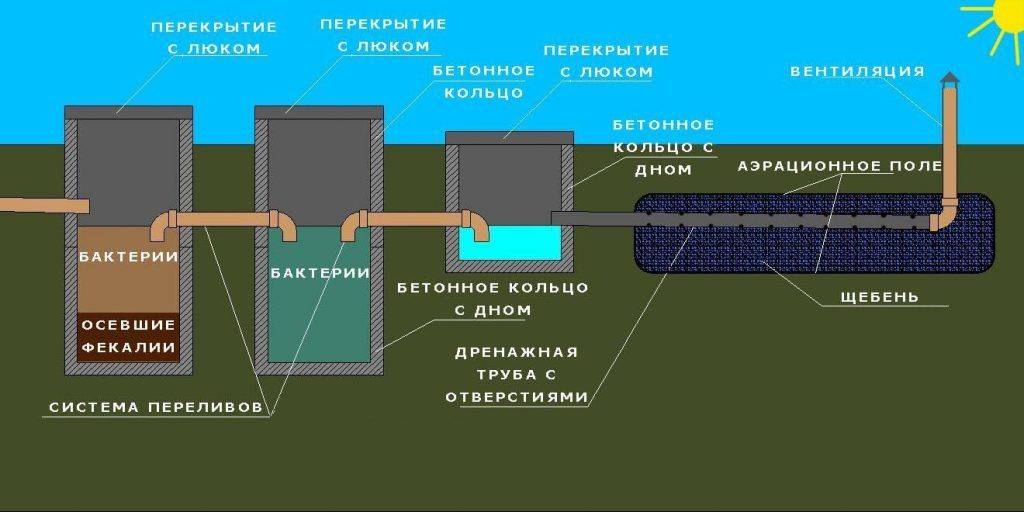

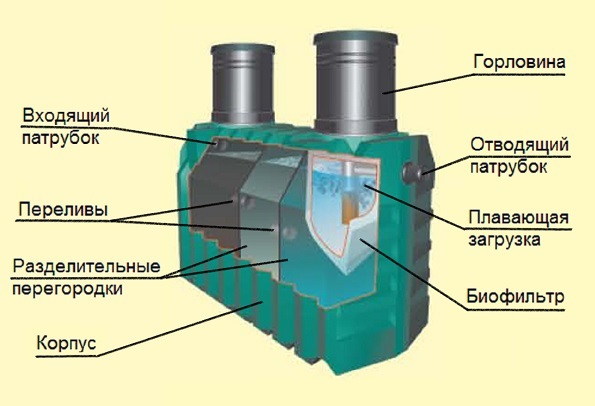

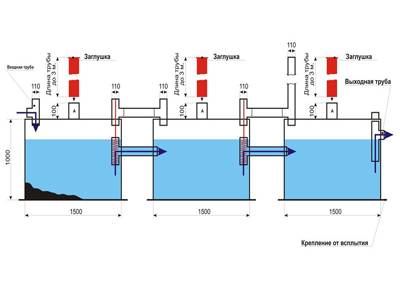

Overflow holes are made in the partitions between the chambers at a certain height. In the model range there is one modification with a horizontal arrangement of these cameras and two with a vertical one.

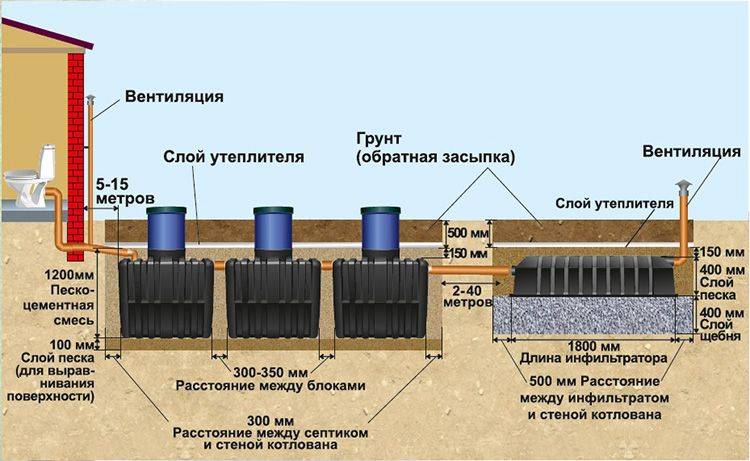

A vertical septic tank takes up less space on the site, but the construction of a pit for it is more laborious due to its considerable depth.

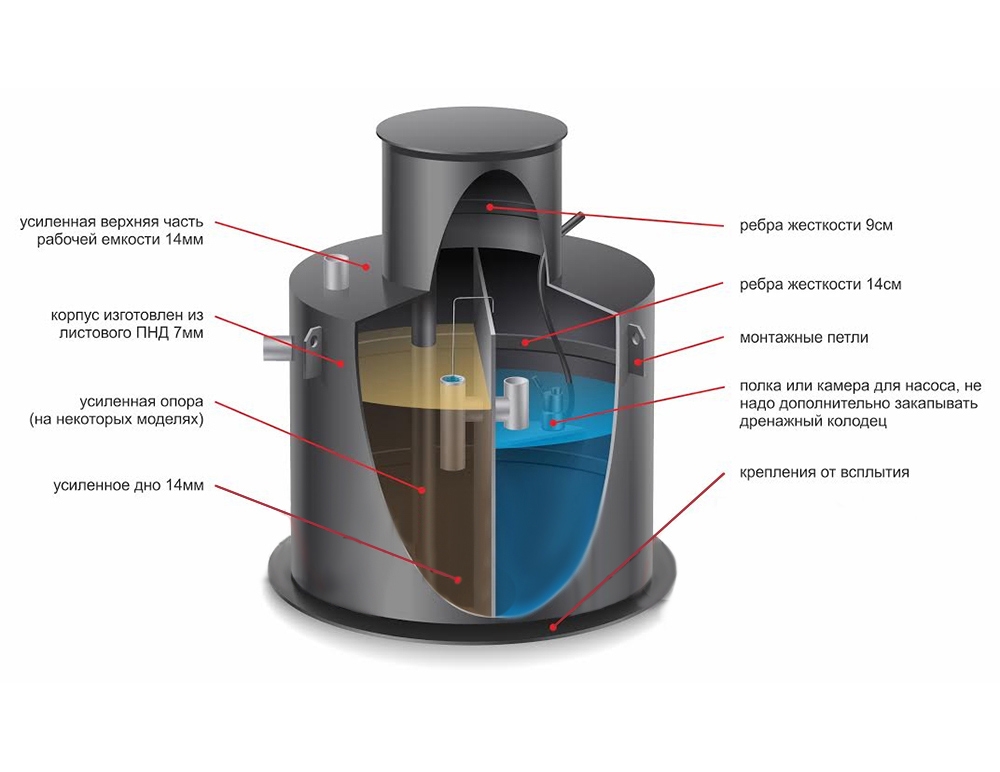

The septic tank is made of HDPE (low pressure polyethylene) with a wall thickness of 7 to 14 mm and is equipped with powerful 15 cm stiffeners. The presence of the latter allows you to place the product in the ground without the construction of a protective shell of concrete.

The first - the largest - chamber has sewer connection holelaid from the house. Another hole - the outlet - is made in the wall of the last chamber and serves to exit the clarified water to the filtration field or well, followed by post-treatment with a sand and gravel filter and distribution into the ground.

It is also possible to connect a sewer pipe to the second chamber, through which the so-called gray sewage water will be discharged from the washing machine and dishwasher into it. In the upper part of the septic tank there are inspection hatches through which the sediment accumulated in the sedimentation tanks is pumped out.

In its simplest form, the scheme of operation of a septic tank provides for wastewater treatment only through multi-stage settling. Pollution settles to the bottom, and purified water through the overflow hole enters the next chamber, where a new stage of purification takes place. To improve the technology, the second chamber of the device can be equipped with a brush-like biofilter.

Three-chamber septic tank Mole

It traps and destroys large inclusions and all kinds of garbage like polyethylene and paper, and the anaerobic bacteria (able to live in an oxygen-free environment) that live on its villi decompose toxic substances into simpler and safer ones.At the request of the customer, the manufacturer of the septic tank, the Aquamaster company, can equip it with a compressor, which will allow the use of cultures of more effective aerobic (oxygen-requiring) microorganisms in the biofilter.

Optionally, the treatment plant can be equipped with:

- Anti-float mounts.

- A non-return valve (mounted on the outlet pipe), which protects the interior of the septic tank and the sewer pipe from ingress of groundwater in the event of a rise in their level.

- Drainage pump for pumping out sewage and sediment, as well as shelves and sections on which it can be fixed.

Advantages and disadvantages for comparison

Speaking about the advantages and disadvantages of Krot septic tanks, first of all, buyers note its exceptionally low price for this type of device.

If we compare the “Mole” with more expensive autonomous treatment facilities, it is worth mentioning one more important fact - this device is non-volatile, i.e. It does not require a septic tank to be connected to electricity. Of course, except for those cases when the kit is supplemented by a compressor.

Almost all septic tanks that use aerobic bacteria and the aeration necessary for their normal functioning, must be permanently connected to power supply. In areas where power outages occur frequently, this circumstance can cause many problems.

If “Mole” is installed on the site, you simply don’t have to worry about it. The manufacturer willingly provides the device with additional options that allow you to adapt the septic tank to specific operating conditions.

The possibility of installing a check valve has already been mentioned, drain pump for forced discharge of treated water, shelves for installing this device, another inlet to the second chamber for gray drains, protection against ascent, etc.

This table allows you to get an idea of the cost of various models of the Krot septic tank and the possibility of completing them with additional options.

If a decision is made to install such a septic tank, it makes sense to think over these points and discuss the option of additional equipment with the supplier. As a result, the price of the product will, of course, increase, but the septic tank continues to compete with analogues in this area very confidently.

The next fact that speaks in favor of the “Mole” is a simple installation. All you need is a pit, no concreting or other “wet” work is needed, and even a concrete slab at the bottom to fix the septic tank is also not required. Although it should be remembered that the foundation pit for the vertical model will need to be quite deep, it is even easier to install a horizontal septic tank.

Durability is another plus. And the material itself, and the welds that connect the structure, and the stiffeners - all this is done at a high quality level. The service life of the tank is estimated at 40-50 years, which is very decent for such an inexpensive device.

Septic tanks "Mole" are often characterized as non-pop-up. What does it mean? The design of the device is thought out in such a way that, after installation, it effectively resists both soil pressure and the effects of groundwater, even with a noticeable increase in their level.

In areas where this figure is consistently high, it is strongly recommended to use a special protective mount against ascent.The word “fastening” in the name of this element evokes associations with the process of attaching the device body to a concrete slab at the bottom of the pit.

In fact, this weighting element is designed to be installed directly on the body of the device. The weight of the body increases, which prevents the septic tank from surfacing. According to reviews, the solution found by the manufacturer turned out to be quite effective, despite the fact that the device is not attached to any static object.

Septic tank maintenance has been simplified as much as possible. The design provides access to the inlet and outlet pipes so that they can be quickly cleaned in case of blockage.

The process of cleaning biofilters has already been described above and is also extremely simple. If the cleaning efficiency has decreased, the biofilters can simply be washed in clean water to correct the situation. Annual removal of silt deposits will not cause big problems.

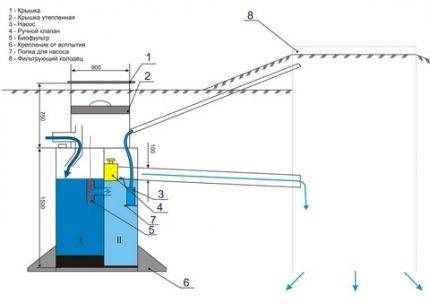

This scheme allows you to get an idea about the features of the installation of the septic tank "Krot" in areas with an increased level of groundwater flow (+)

This scheme allows you to get an idea about the features of the installation of the septic tank "Krot" in areas with an increased level of groundwater flow (+)

At the same time, the buyer does not have to rely on a high degree of wastewater treatment. Even when installing a compressor, the manufacturer does not guarantee any high result. Therefore, the contents of the septic tank after processing cannot be used immediately as fertilizer.

It is recommended to remove it or put it in compost heaps for further processing. The water obtained as a result of settling and processing wastewater will also not become clean enough for irrigation or to meet technical needs on the site.

In addition, the design does not provide for a separate storage tank for purified water, therefore, when installing the Krot septic tank, an absorption well or a filtration field is necessarily created for additional purification and removal of water into the ground.

User manual

The motorized cultivator MK-1A-02, in addition to additional functions, has the main purpose - plowing the soil. For this, cutters are used that are mounted on a shaft coming from the gearbox.

Setting up a motor cultivator before plowing with a cutter:

There is another way of plowing the soil - with the help of a reversible mounted plow, which is attached to the place of the coulter, metal wheels are installed instead of cutters.

In the case when it is necessary to carry out other agrotechnical work with the unit (weeding, planting, etc.), it is necessary to carry out one more re-equipment of the MK-1A-02 motor cultivator.

Setting up a motor cultivator depending on the tasks:

- When weeding plants, knives are removed from the cutters, and weeders are installed in their place (these devices are L-shaped). In the case of weeding potatoes, the coulter installed at the rear of the cultivator will act as a hiller.

- Potato hilling is carried out without milling cutters, instead of which metal wheels equipped with lugs are installed. Instead of an opener, a hiller is placed.

- Potato harvesting is carried out as follows: metal wheels with lugs are installed in front, and attachments - a potato digger - are attached to the back.

- If you want to use the MK-1A-02 cultivator as a lawn mower, buy the mower itself and attach it to the front of the motor unit.To carry out the movement, it is necessary to fix the pneumatic wheels on the shafts of the gearbox, and the transmission of the necessary torque will be provided by belts that must be put on the pulleys of the mower and the cultivator itself.

- You need a pump - buy the appropriate MNU-2 nozzle, fix it on the MK-1A-02 cultivator frame using a belt drive, remembering to disconnect the traction gearbox belt.

- Transportation of goods up to 200 kg is possible with a special trolley (trailer), which is equipped with a special coupling mechanism (swivel). Transportation of goods is carried out with the help of pneumatic wheels.

Attachment Overview

You can get acquainted with the attachments for the Mole motor cultivator in more detail at this.

crow's feet

weeder

Okunchik T

Plow

Mounted mower

Pumping plant

Grousers

Potato digger KRT-1

Cart

Device ↑

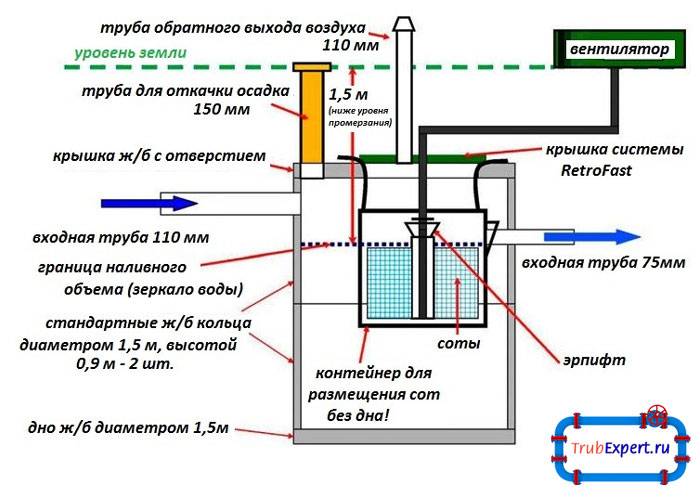

A small production company "Aquamaster" (Kirov) since 2003 has been manufacturing concrete cleaning stations for private houses.

But at the end of 2011, the production of low-pressure polyethylene (HDPE) septic tanks under the Krot trademark was launched.

Currently, two types of models of cleaning devices are produced:

- horizontal;

- vertical.

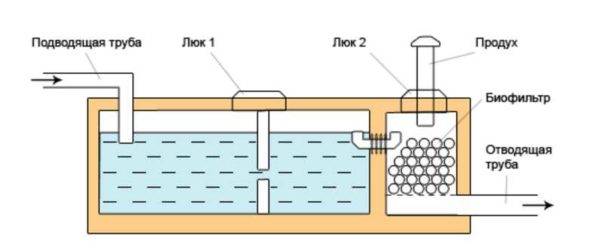

For a complete understanding of the principle of operation of a septic tank, it is best to consider the most popular model of a septic tank - a 3-chamber vertical one.

Drainage water is supplied through the upper vertical pipe. They fill the first chamber of the structure, which is the largest. There is a partial clarification of the waters.

Overflow into the second is carried out using the neck, which is located on the partition. If there is a need to separate the so-called gray and sewer waters, then the design provides for an additional connection of the drain immediately to the second chamber.

Further, the clarified liquid enters the third chamber, from which it is discharged by gravity through the outlet pipe.

It should be noted that for the normal operation of the system, it is desirable to install infiltration wells immediately after the septic tank, which are needed for additional cleaning. And already from them, about once a year, with the help of a sewage machine, a septic tank is pumped out.

They partially contribute to the grinding of large drain fractions and retain household waste - plastic wrap, fabric, etc.

As an option, the company offers a mounting shelf for the pump, which is triggered when such a situation occurs. It automatically turns on and pumps out clarified water.

According to the representatives of the company, the mole non-floating septic tank is a unique design.

Despite the fact that it is made of polymeric materials, the large dimensions of the horizontal stiffeners give the septic tank additional stability after installation.

Vertical Models

Models with a vertical arrangement of the case are the most popular among consumers.

The company offers several options for such septic tanks, which differ in the number of chambers and usable volume.

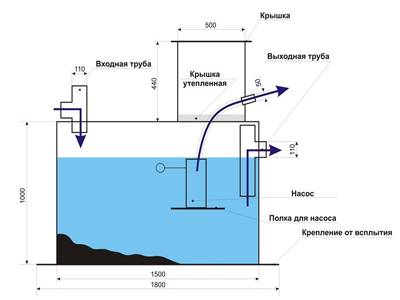

Mole 1.8

Cylindrical design with a maximum filling volume of 1.8 m³. It is intended for processing of small amounts of sewage masses. By installing internal partitions, you can make a 1 or 2-chamber structure.

Specifications:

- base diameter - 1.3 m;

- the height of the receiving chamber (from the bottom of the structure to the neck) - 1.5 m;

- the total height of the septic tank is 2.25 m;

- empty structure weight - 105 kg.

Supplied as standard with an external protective cover and an insulated internal hatch.

Mole 3.6

According to the principle of construction, its device is completely identical to that described above. The differences are only in overall dimensions and usable volume, which is 3.6 m³. In addition, the septic tank has the shape of an ellipse, in which you can make from 2 to 3 chambers.

Specifications:

- base dimensions - 1.45 * 1.8 m;

- the height of the receiving chamber (from the bottom of the structure to the neck) - 1.5 m;

- the total height of the septic tank is 2.25 m;

- empty structure weight - 170 kg.

In these models, an inspection neck with a diameter of 90 cm and a height of 75 cm is installed. It also allows you to quickly remove a blockage in the inlet pipe of the device.

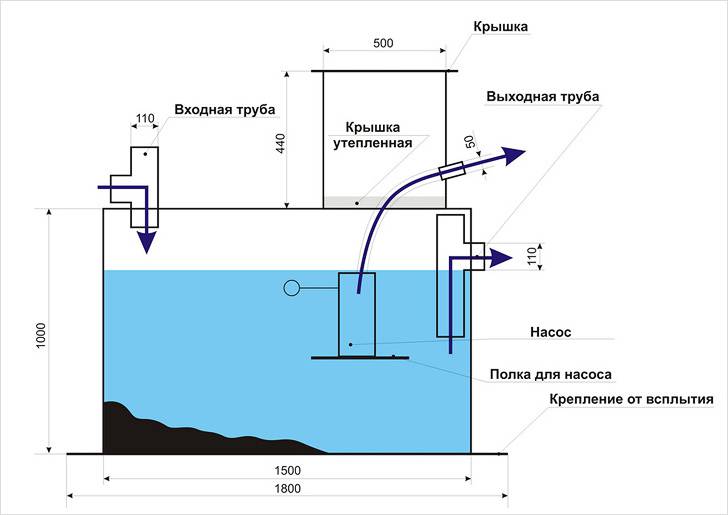

Horizontal Models

The horizontal septic tank Mole is available in only one version - 1.17 m³ of usable volume.

Moreover, its design is only single-chamber. Therefore, it can be used as a storage tank or as an anaerobic overflow treatment device.

Specifications:

- base - 1.8 * 1.5 m;

- the height of the receiving chamber (from the bottom of the structure to the neck) - 1 m;

- the total height of the septic tank is 1.44 m;

- empty structure weight - 84 kg.

A distinctive feature of this small cleaning device is the wall thickness - up to 14 mm. This allows the septic tank to withstand almost any external ground pressure without damaging the structure.

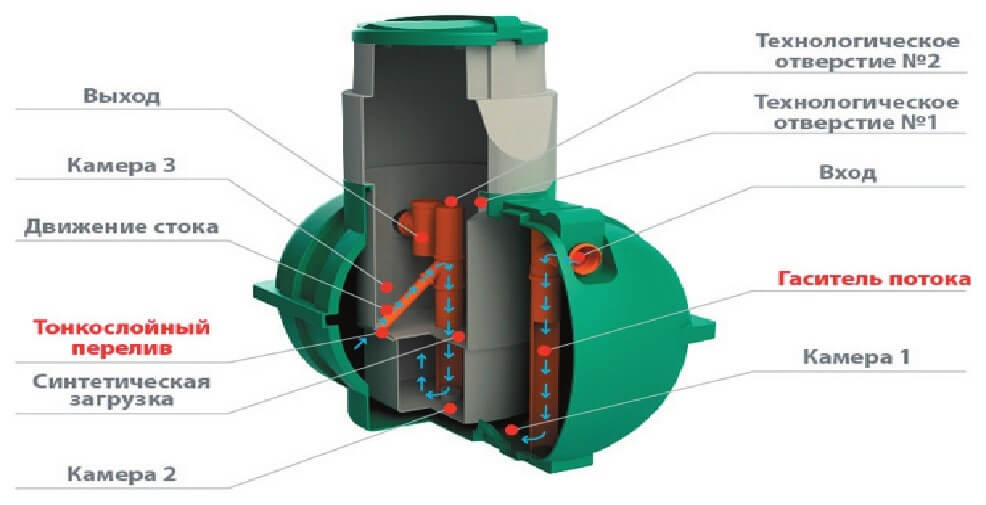

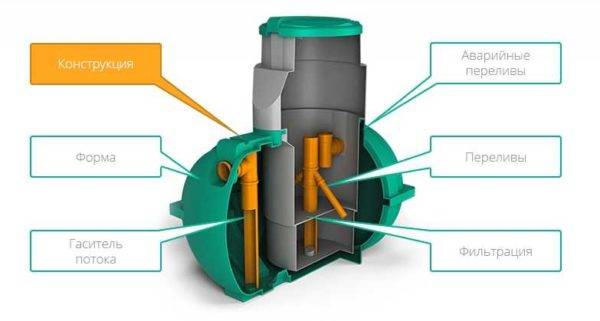

Septic Rostock - a unique overflow system

This instance differs not so much in external structure as in internal. The container is divided into two chambers, but the second one also has a horizontal perforated partition, on which a filter layer is laid. From the upper part of the second chamber, clarified effluents go for further treatment (without this they cannot be dumped onto the ground).

Design features

For final wastewater treatment, the manufacturer has a filter in which expanded clay is used as a filter element. Such a pair, according to the manufacturer, gives a purification of 90-95%.

Septic tank Rostock - internal structure

This design has several unique solutions:

-

- Flow damper installed at the inlet. This is a pipe through which drains come from the entrance. It is not solid, it has a cut out sector directed from the side opposite from the partition. In this way, manufacturers make the path of the drains longer.

- The overflow from the first chamber to the second also has an unusual shape. This is a thin layer module. Its structure is not specified anywhere, but the overflow occurs from the bottom / up, which reduces the amount of suspensions entering the second chamber.

- In the second chamber there is a tee with overflow pipes installed at an angle. Water rises along them from the bottom to the top. Due to the nature of the movement of water, fewer contaminants enter the inclined pipes.

Septic tank Rostock - internal structure

As you can see, this design also has interesting solutions. Operating experience suggests that they work, cleaning at the outlet of the septic tank is quite normal.

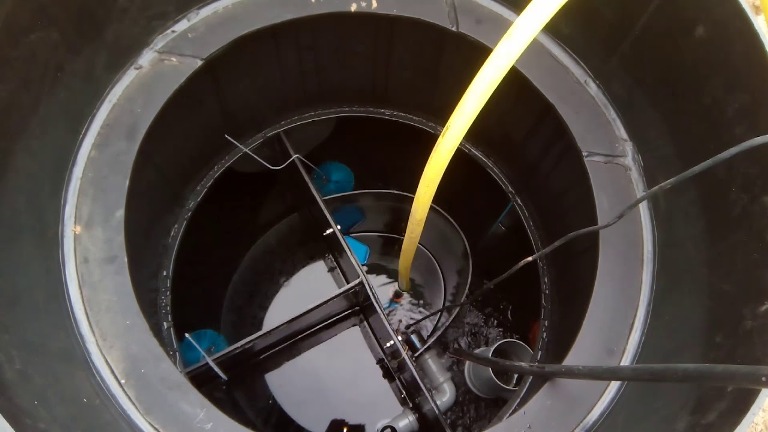

Installation nuances

To protect this structure from ascent, it is necessary to dig niches on the sides of the pit (the dimensions are traditionally 20-30 cm larger than the size of the septic tank) into which anchors are installed. Most often, these are curb stones with ribbon cables tied to them (ordinary ones are not suitable). The ends of these cables are fixed around the body.

Sand filling with spillage

Backfilling is done with sand while filling the container. Water is immediately poured into the filter cup (gray container), then into the main chamber. Sand is poured in layers, spilling it for compaction.

Concrete septic tank Aspen

This type of local sewage differs from all the others in the material of the body - it is made of concrete. With a high GWL, this can be useful - it will not push out, and concrete is stronger.

Manufacturers position this structure as a mechanical and biological installation. A biological component is added to the usual waste processing for a septic tank with the help of anaerobic bacteria and fermentation. Manufacturers recommend adding some bacteria to the sewer every two weeks (down the drain through the toilet or sink). They recommend the French "Biosept", which they themselves also sell, but are not against the use of other drugs.

The structure of a concrete septic tank Aspen

Manufacturers say that the septic tank will have to be pumped out in 3-5 years. In principle, this is possible - bacteria significantly reduce the amount of sediment. But no one bothers to use them in other treatment plants.

Aspen's appearance

In this brand, you can choose from three models - for 6 people (up to 1 m3 / day), for 12 people (up to 2 m3 / day) and for 18 people (up to 3 m3 / day). As you can see, there is no model for small houses.

Installing it will be expensive. Firstly, the cost of transportation, and secondly, the installation, since it can only be installed in the pit with a crane. But the case is certainly reliable, and the system itself is simple and reliable, but nothing special is different.

The choice of this option is justified. This saves money. But before construction, you need to obtain permission from the SES, and during construction, comply with the norms of SNiP.

Features of gas connections

When connecting gas stoves, columns and other types of equipment, flexible connections are also used. Unlike models for water, they are yellow and are not tested for environmental safety. For fixing, end steel or aluminum fittings are used. There are the following types of devices for connecting gas appliances:

- PVC hoses reinforced with polyester thread;

- synthetic rubber with stainless steel braid;

- bellows, made in the form of a corrugated stainless steel tube.

Holding "Santekhkomplekt" offers engineering equipment, fittings, plumbing and fixtures for its connection to communications. The assortment is represented by products and materials of well-known foreign and domestic manufacturers. Discounts apply for bulk purchases, and product quality is confirmed by standard certificates. For information support and assistance, a personal manager is assigned to each client.The ability to arrange delivery within Moscow and other regions of the Russian Federation allows you to quickly receive the purchased goods without any hassle.

Warning

Powdered preparation is ideal to fall asleep and leave for a while. It is better to close the drain with a rag, as an unpleasant odor is emitted during a chemical reaction. After an hour and a half, pour a couple of liters of hot water into the drain, let it stand for another 30 minutes and work with a plunger. After all manipulations, rinse the pipeline with hot water.

The drug is intended not only to eliminate blockages in the pipes, but also to protect the sewer system from blockages.

The main advantages of the product are its ease of use, high-quality cleaning and a loyal price.

Note. Some motorists use the mole tool to clean the cooling system in a car (radiator). As practice has shown, two vials of a liquid preparation are enough. The radiator is dismantled, filled with the drug for a couple of minutes and washed with water. The action is repeated several times.

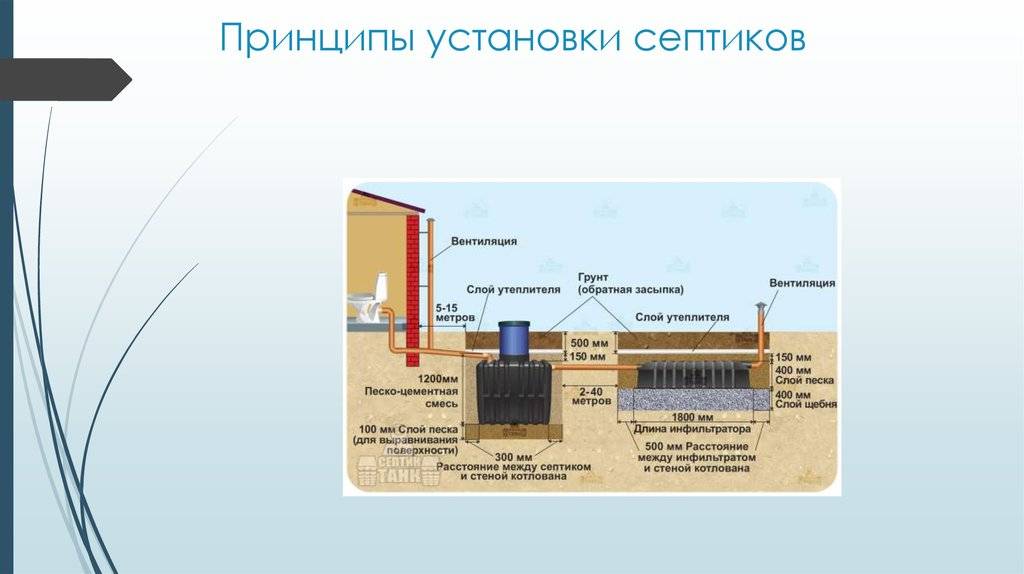

Installation rules

- The septic tank Mole is installed away from the main buildings, trees and shrubs.

- The possibility of laying sewer pipelines from buildings to the tank with the required angle of inclination is provided.

- The underground filtration system should be located below the groundwater intake site, no closer than 20 meters from a well or drinking water well.

- The septic tank is mounted in a specially dug pit with a compacted and leveled sand cushion 300 mm thick.

- Backfilling with sand is carried out, which is compacted along the edges.

- The device is filled with water for the final compaction of the soil.

After that, sewer pipes are brought in and insulated, thermal insulation is laid on the upper part of the unit. The developer of the Krota design provides for a special fastening system, which excludes the possibility of squeezing the container onto the surface during heaving of the soil in winter.

Why do owners of country houses choose Mole?

Septic tanks of this brand have a number of advantages that distinguish them from similar systems from other manufacturers.

All equipment is lightweight, easy to install, equipped with a unique system of fastening in the ground. No additional weights required.

Rigid design eliminates the use of sand-cement backfill around the perimeter to strengthen the hull.

The installed treatment plant is characterized by simplicity and unpretentiousness in maintenance. The design provides free access to all its elements. All that is required of its owner is periodic cleaning or replacement of filters and removal of bottom sediments.

The cost of the Krot system, depending on the brand and configuration, ranges from 25 to 70 thousand rubles. At the same time, the quality of cleaning is not inferior to more expensive septic tanks.

For what types of work is it used

The main task of the "Mole" is plowing the land, but summer residents adapt this unit for many jobs:

- weeding;

- hilling potatoes;

- digging up root crops;

- hay making;

- watering the beds.

Depending on the model, the functionality of the cultivator may vary, as well as the specifics of the work performed by it. Milling cutters are considered the main working body of this device. Virgin lands are crushed exclusively with internal cutters, and for light ones, the entire set can be used.Up to six cutters can be put on cultivators, they can’t pull more, as there is a high risk of engine overheating.

When weeding, L-shaped weeders are required to be installed, and external cutters are changed to discs that will protect the plants. When hilling root crops, wheels and separate lugs are installed instead of soil cutters. In place of the coulter, a potato hiller is attached.

The versatility of the cultivator lies in the possibility of attaching it to the front of the mower. A pulley is placed on the output shaft and, using a V-belt type of gear, the hitch is connected to the engine.

When pumping water, a motor cultivator, using a V-belt drive, is equipped with a pump. If the milling cutters are replaced with rubberized wheels and a trolley is attached to the frame, then with the help of a cultivator it is possible to transport the harvested crop.