- Cesspool made of other materials

- Cesspool made of bricks

- Cesspool of tires

- Cesspool made of plastic

- How to clean a cesspool

- Stages and features of installation work

- Pit arrangement

- Mounting

- Supply of sewer pipes

- Ventilation system device

- Sealing joints between rings and pipes

- Installation of floors and backfill

- Stages of installation of a well for sewerage

- Location selection

- Calculations and scheme of a septic tank

- Of the three chambers:

- Carrying out calculations

- Preliminary work

- Location selection

- Volume calculation

- Selection of materials

- Construction stages

- Video description

- How to choose the best place for a septic tank

- Pit preparation

- Installation of rings and sewer pipes

- Sealing and waterproofing

- Manhole installation and backfill

- How does the septic tank start up

- What rules must be observed when maintaining a septic tank

- The nuances of the work

- How to create a filtration well

- Do-it-yourself construction stages

- Preparation of materials and tools

- Location selection

- Pit preparation

- Installation of rings, piping

- Sealing

- Waterproofing

- Covering and backfilling the well

- Arrangement of the bottom of the tank

Cesspool made of other materials

In addition to the most common version of a cesspool made of concrete rings, there are many analogues.Some are cheaper but not suitable for permanent residences, some are more expensive but have restrictions on use in certain types of soil.

Cesspool made of bricks

To lay out the walls of the well with bricks, it is not necessary to be a bricklayer. It is enough to have minimal knowledge and acquire basic bricklaying skills. To complete the work you will need:

- shovel ordinary bayonet - for leveling the soil in the right places;

- shovel shovel - for collecting and removing excess earth;

- stairs - in order to go down and get out of the pit;

- tape measure - to measure the required dimensions;

- buckets - for carrying mortar and various materials;

- trowel - to apply the mortar to the masonry;

- level - allows you to control the strict verticality of the walls.

Of the materials you will need - brick, cement, sand and water.

If you are laying a hole with a sealed bottom, then first you need to prepare a concrete base. To do this, it is necessary to make a compacted sand cushion with a thickness of at least 20 cm. After installing the cushion, you can start pouring concrete. The thickness of the concrete bottom should be at least 5-7 cm, it is also possible to reinforce such a base to make it more rigid.

After the concrete has hardened, you can begin the construction of the masonry. At the same time, there are no special requirements for either the quality of the brick or the quality of the masonry itself, the main thing is to maintain the level and the absence of cracks in the masonry. The pit can be either square or round - it all depends on your imagination.

If you are building a sewer without a bottom, then as a brick sole, you need to make a pillow and pour concrete in the form of a ring so that water can escape into the inside.

Cesspool of tires

A cesspool made from waste car tires is distinguished by its low cost and ease of assembly. To install such a pit, you will need old tires of the desired diameter, tires from a passenger car are suitable for a small volume, and for a large one you can take from a truck or even a tractor.

To add usable area, the side parts of the tires must be cut in a circle. You can easily do this with a jigsaw or a grinder. But if they are not available, an ordinary, only very sharp, knife with a rigid blade will do.

The prepared tires are stacked one on top of the other in a pit dug in advance for the diameter of the blanks and fastened together with plastic ties, bolts with nuts, etc. If necessary, the joints between the tires can be sealed with bitumen or other adhesive.

This type of cesspool is often used to collect wastewater in a bathhouse or summer kitchen.

Cesspool made of plastic

The easiest way to make a drain hole is from a ready-made plastic container that you can buy at the store. You just need to dig a pit and install the container itself there.

The indisputable advantages of this method is that you will deprive yourself of an unpleasant smell and be one hundred percent sure that the drains will not fall into the soil and will not mix with groundwater. But as it fills up, you will have to call the sewage equipment for pumping out, which will undoubtedly entail spending money.

Also, restrictions for such containers are imposed by the level of groundwater, since at their high level, the container can be squeezed out of the ground.

How to clean a cesspool

You can pump out the contents of the cesspool by inviting specialists with equipment that should not be less than the volume of your cesspool in volume.The hose of such a sewage machine should be enough to completely lower into the pit, and the entrance to the pit should be convenient.

There are also special products for cleaning cesspools, which are bacteria that are completely safe for nature and process waste products. You can buy such funds at any store for home and garden. Such products remarkably clean even the walls and bottom of the pit, processing solid waste into sludge, gas and water.

Thus, a cesspool in a private house is an economical option for organizing sewage, requiring attention only a few times a year. The indisputable advantage of a cesspool made of concrete rings is its durability, low cost and the possibility of installing such a system with your own hands using minimal equipment.

Stages and features of installation work

The main stages of installation work in the construction of a septic tank from concrete rings:

- arrangement of the pit;

- installation of concrete rings;

- supply of sewer pipes;

- device of the ventilation system;

- joint sealing;

- installation of ceilings and backfilling.

Pit arrangement

Excavation work can be carried out using special equipment or manually. When building a new house, it is better to dig a pit with an excavator. But at the same time, one nuance should be taken into account: when digging a pit with a bucket, a pit is obtained, the shape and dimensions of which are much larger than those required by a septic tank made of concrete rings. It will not be easy to lower products weighing 400 kg or more into such a pit on your own. Therefore, you will have to use the services of a crane. Digging by hand takes much more time, but allows you to make a foundation pit exactly in size.

Concrete rings with a bottom should be installed in the pit first, i.e. - bottom

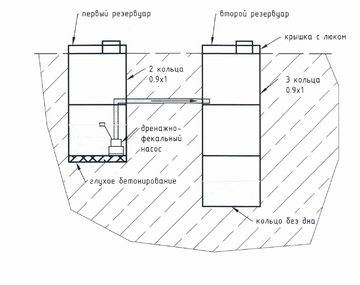

The bottom of the pit must be concreted to prevent the penetration of untreated sewage into the soil. If the septic tank is made of concrete rings and its device involves the use of special products with a bottom, then the bottom of the pit does not need to be concreted.

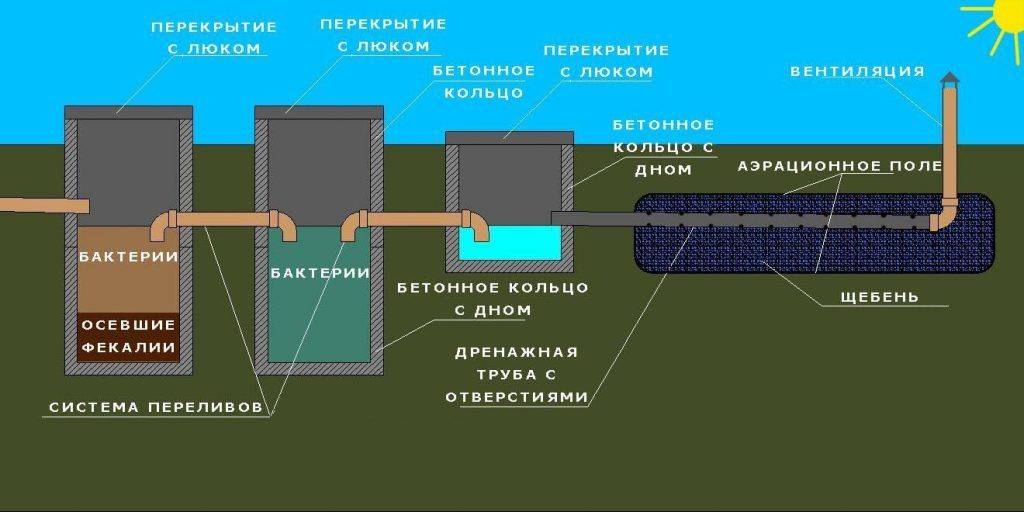

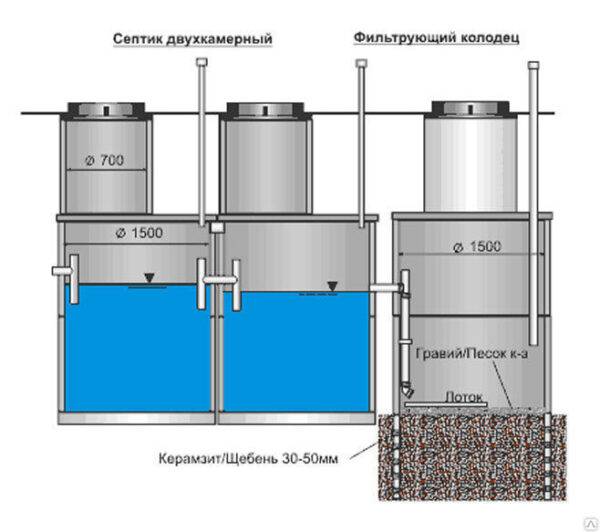

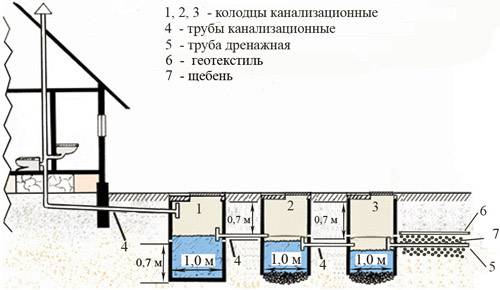

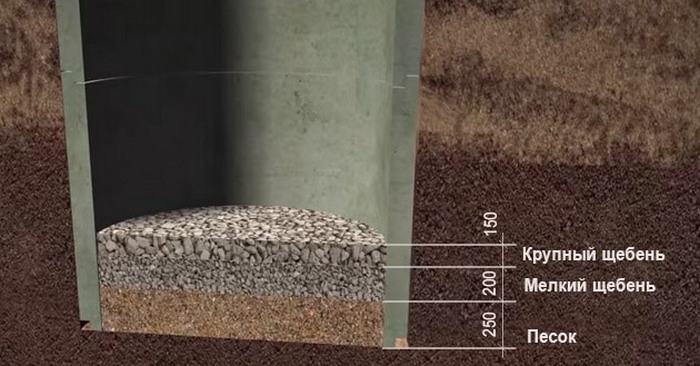

If a three-chamber version is being constructed from concrete rings for a bathhouse or a house, then in the third filter well a pillow of gravel and sand 50 cm thick is made. At the stage of digging a pit, trenches are made for pipes connecting the tanks and leaving the house. A layer of sand 10 cm thick is covered at the bottom of the trenches.

Mounting

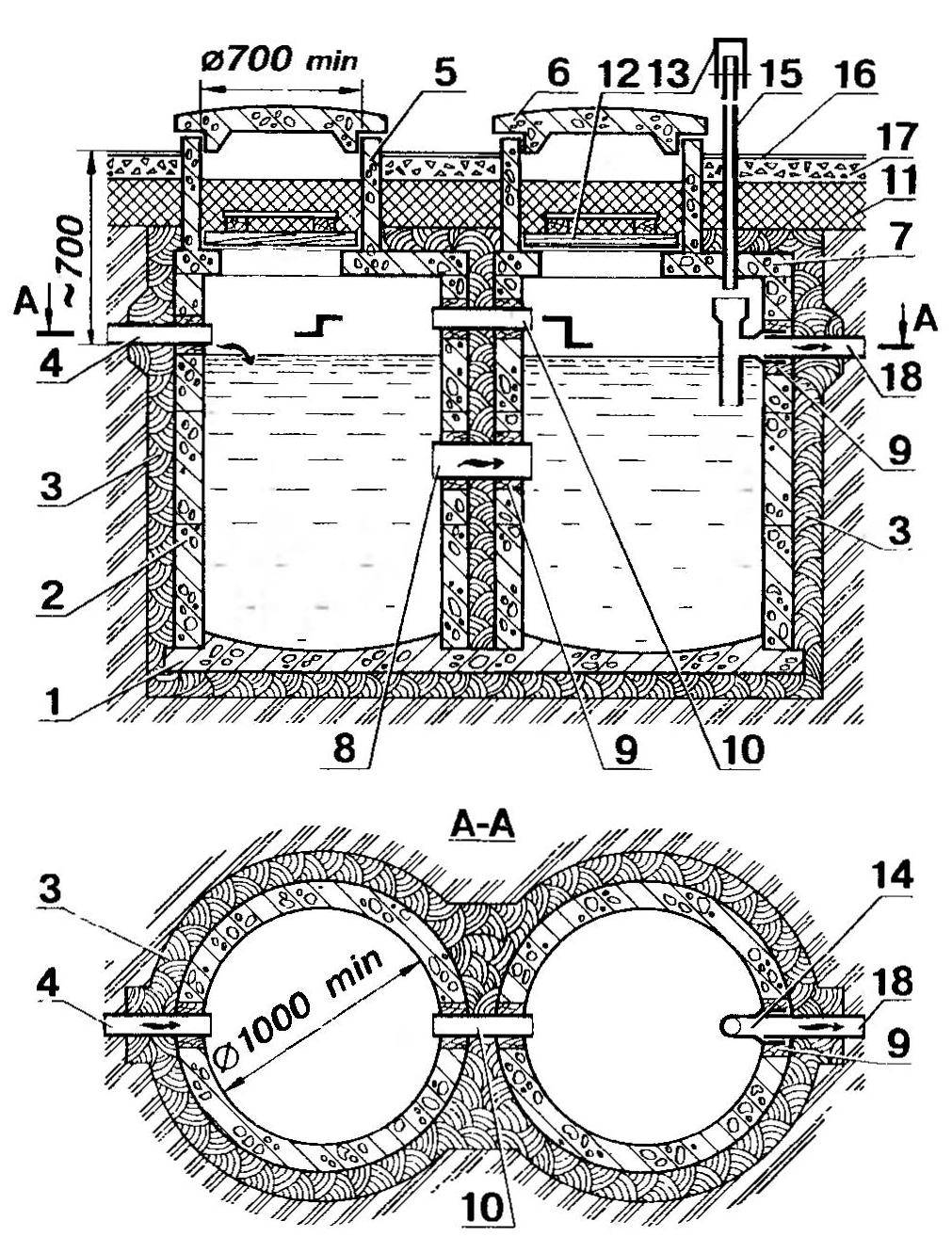

Since the concrete elements are quite heavy, a truck crane or a homemade winch is used to install them in the pit. You can use another method - the sequential installation of rings with digging, but this method is very labor-intensive. In addition, it is rather inconvenient to concrete the bottom of the septic tank, in which the rings are already installed.

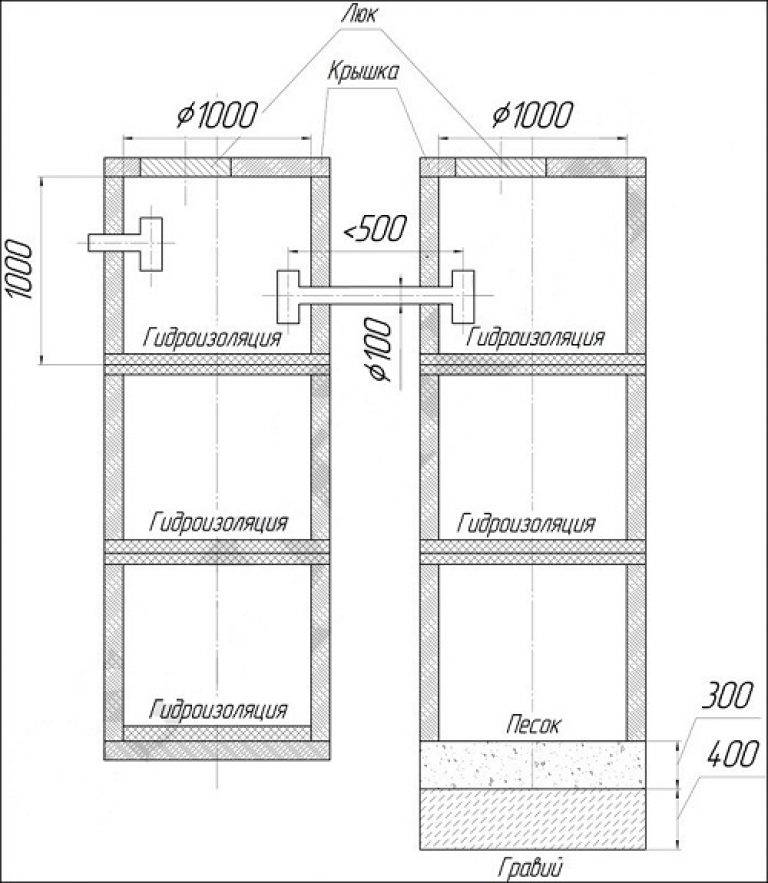

After installation, the rings must be fastened together with a cement-sand mortar. Additionally, they can be fastened with metal brackets.

This precaution will prevent the formation of cracks in the rings during seasonal ground movements.

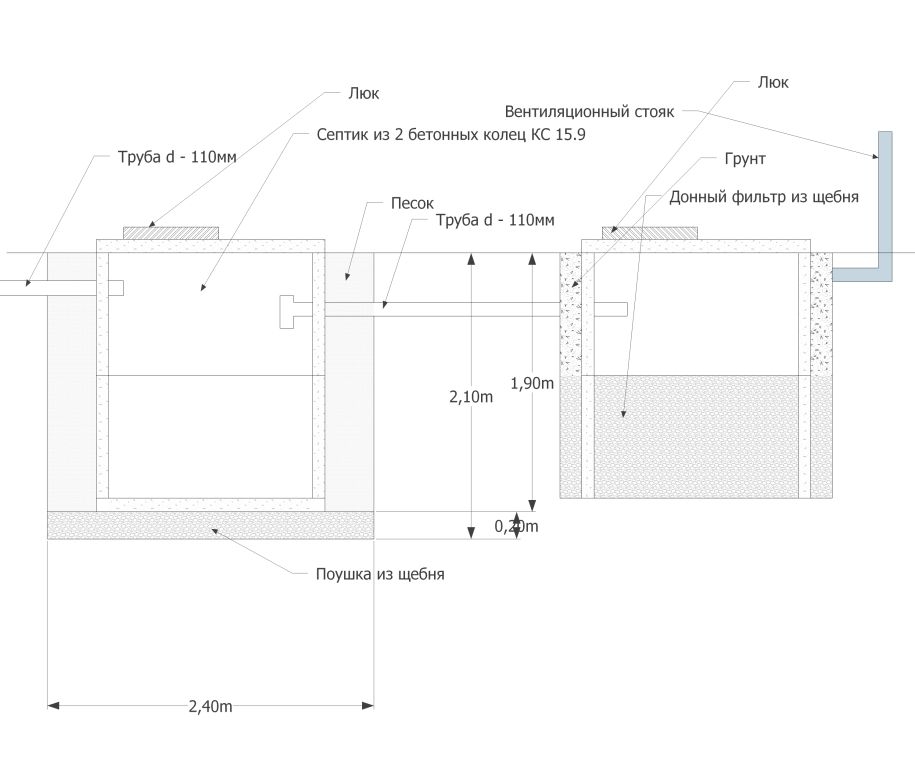

Supply of sewer pipes

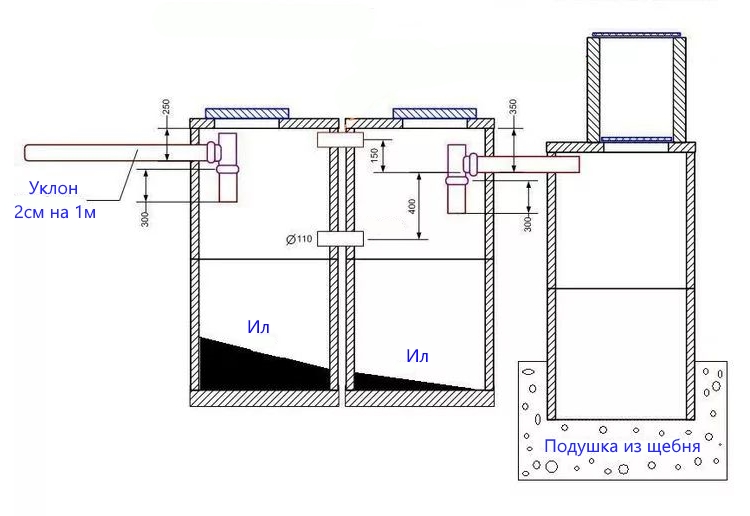

Holes for pipes are punched in the mounted rings. The pipe transporting wastewater to the first well is placed at a slight angle. The pipe that connects the first and second wells should be 20 cm lower than the previous one, and the pipe supplying the treated effluents to the filter well should be installed another 20 cm lower.

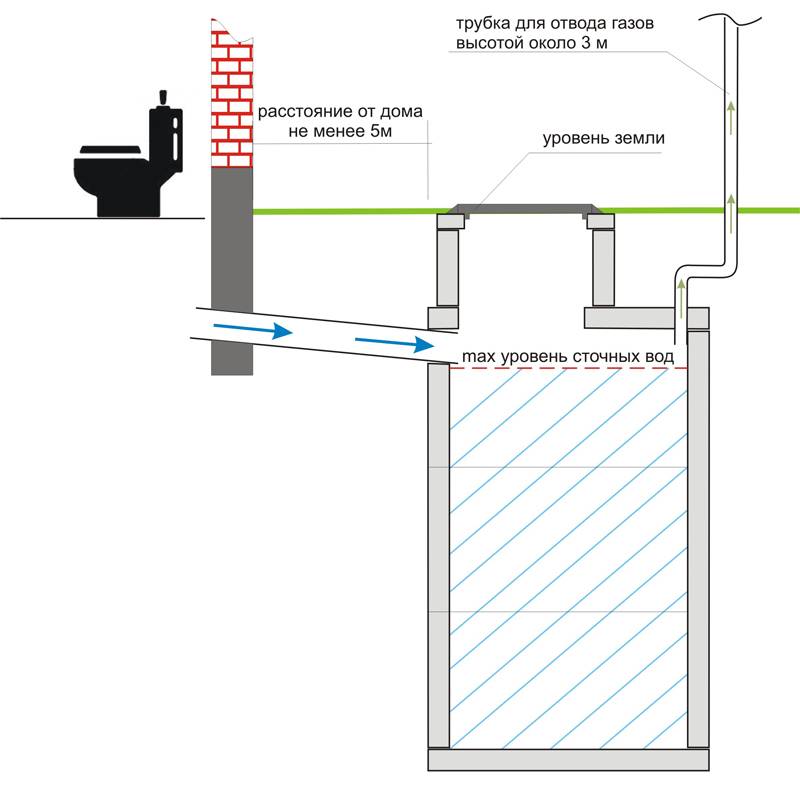

Ventilation system device

To ensure ventilation of the septic tank, it is necessary to connect the sewer pipe to the ventilation riser, which goes to the roof of the building. The riser pipe in diameter must be no less than the pipe transporting domestic wastewater to the septic tank.

If the ventilation pipe is made smaller than the sewer pipe, then the drains will create a “piston” effect, and this leads to the disappearance of the water seal in the siphons of plumbing fixtures. As a result, sewage odors begin to penetrate into the room.

Therefore, it is very important to build a septic tank from concrete rings, the ventilation of which will perform two main tasks as efficiently as possible:

- to exclude rarefaction of air in sewer pipes;

- eliminate unpleasant odors from sewer lines and wells.

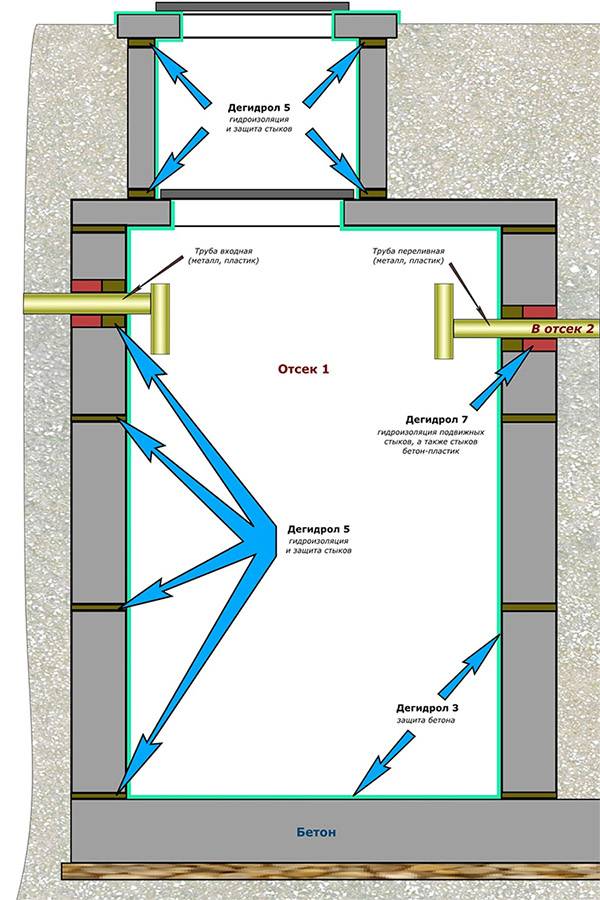

Sealing joints between rings and pipes

Ordinary concrete, contrary to popular belief, does not hold water. A septic tank made of concrete rings is no exception.

The waterproofing of the internal and external surfaces of the septic tank must be carried out very carefully. To do this, use a solution of liquid glass, bituminous mastic or well-proven polymer mastics. The best results when deciding how to properly make a septic tank from concrete rings with the best waterproofing are given by a concrete solution with special additives.

Installation of floors and backfill

Mounted sewer wells are covered with concrete slabs, in which holes are made for the installation of hatches. After installing the plates, the septic tank is backfilled. To do this, use the soil taken out of the pit. Upon completion of backfilling, the septic tank is completely ready for operation.

Stages of installation of a well for sewerage

Consider how to make a sewer in a private house with your own hands from concrete rings.And if a decision is made to entrust the performance of work to a specialized organization, then the information received will help to carry out quality control over the installation progress and facilitate communication with employees.

Location selection

The location of the sewer septic tank is selected taking into account certain norms and requirements. It should be no closer than: 5 m - from the boundaries of the estate; 5-10 m - from a residential building (so as not to wash the foundation); 30 m - from the shore of the nearest reservoir; 20 m (50 m) - from the water intake on clay (sandy) soil; 3 m - from trails, roads, trees, shrubs, vegetable gardens. The bottom of the well should always be above the groundwater level in the area. To the chosen place, an entrance should be provided or later laid for periodic pumping of silty masses by special equipment.

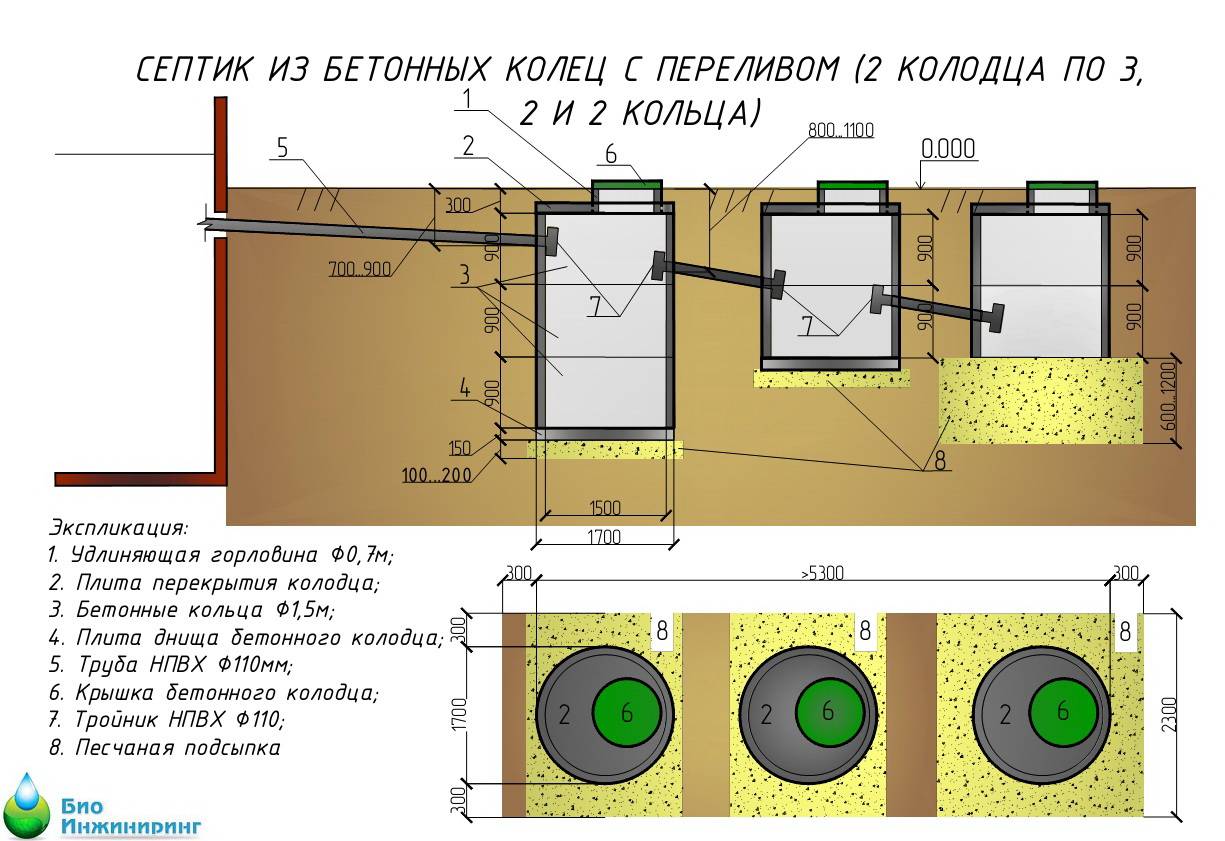

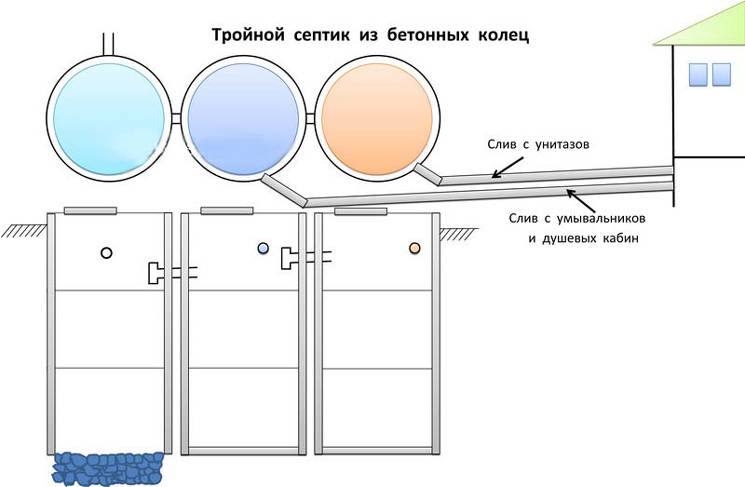

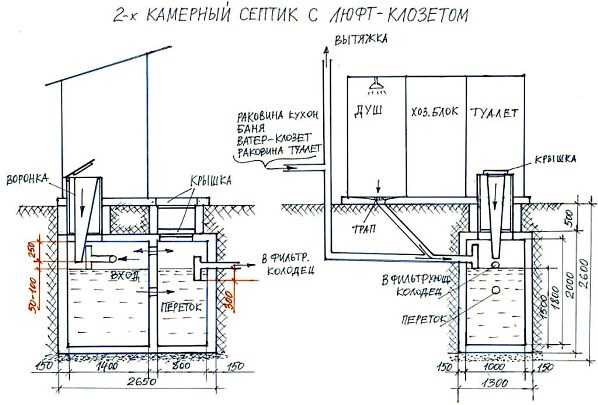

Calculations and scheme of a septic tank

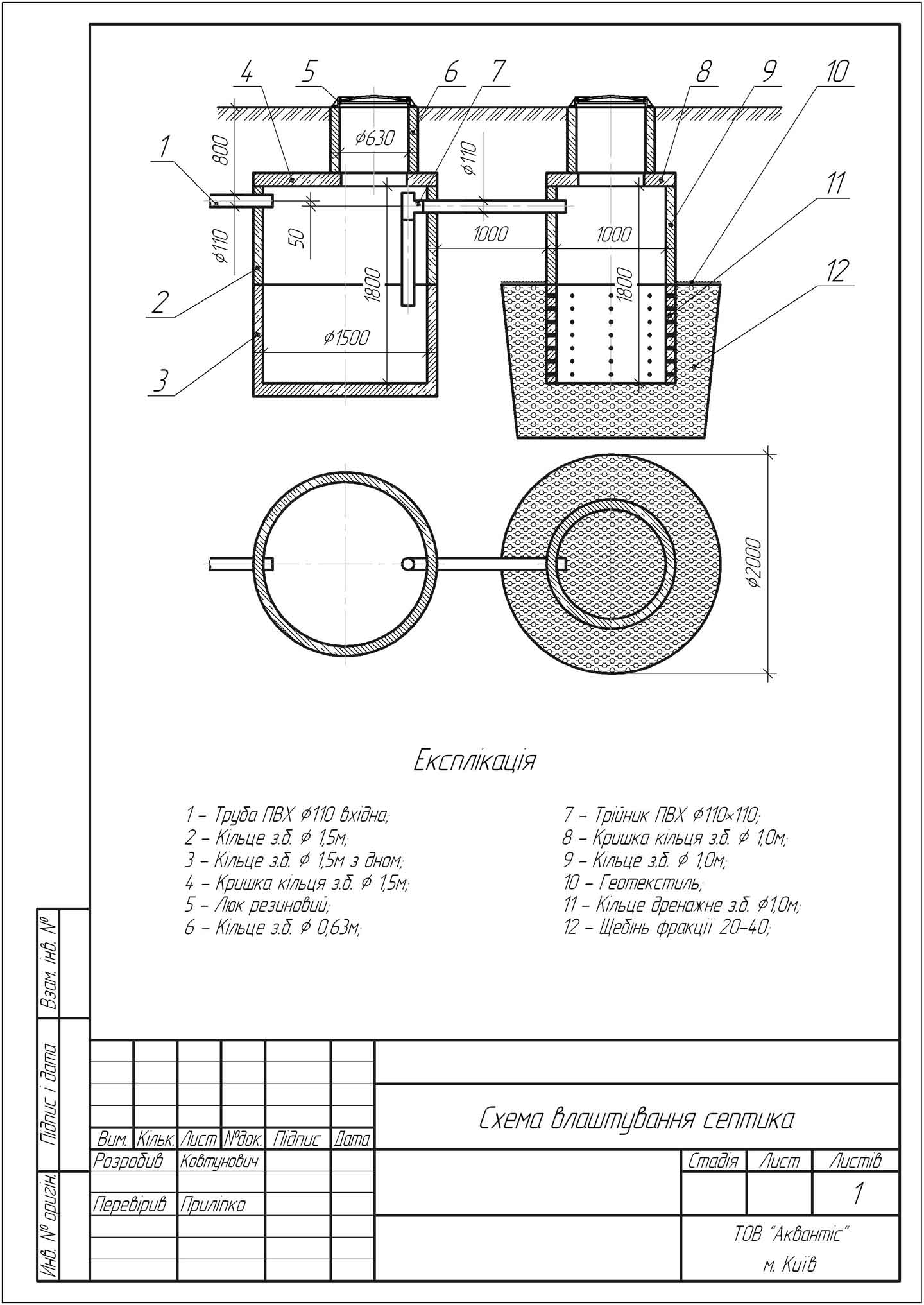

To install a sewerage system in a private house with your own hands from concrete rings, you will need a construction scheme drawn up according to preliminary calculations of the volume of water consumption by all residents. The volume of the septic tank must correspond to the amount of water consumed by residents in three days. The daily rate for one resident is 200 liters. The final figure for the minimum internal volume of the septic tank is obtained by simple multiplication.

The resulting value is very important if you are building a sewer in a private house with your own hands. The scheme of the rings provides for the presence of 1-3 septic tank chambers

The number of wells depends on the composition of the family, the number of devices and mechanisms for sanitary purposes, and the intensity of their use. A three-chamber septic tank can be considered a real biotechnical complex. Its construction and maintenance will cost more, but the productivity and quality of wastewater treatment are significantly increased.

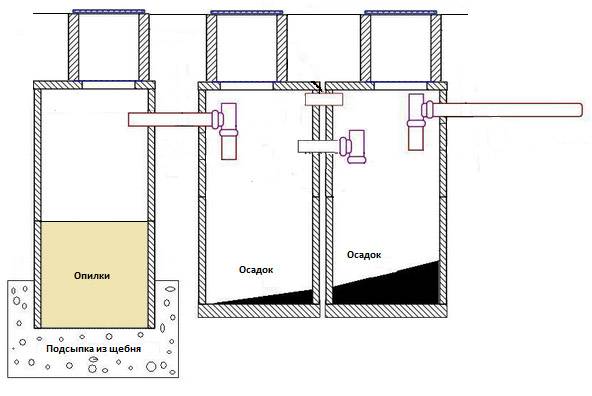

Of the three chambers:

- 1st - settling of accepted effluents;

- 2nd - purification of liquids (already clarified) from contamination;

- 3rd - filtering chamber.

In the treatment chambers, the lower concrete ring should be with a blank bottom to protect against leakage of not yet treated liquid effluents. The third chamber is distinguished by the presence of a lower perforated ring, as well as a drainage layer at the bottom of the well. After passing through the drainage, the purified liquid is absorbed into the soil. In the predetermined walls of the rings, inlets are made to connect the wells with overflow pipes. In the first chamber of the septic tank, a hole is also prepared for the pipe coming from the house. This pipe must be below the freezing level of the soil. All pipes are laid with a slope to ensure gravity flow of wastewater.

For all wells, round concrete slabs with holes for

installation of inspection hatches and ventilation pipes.

Drawing up a preliminary sewerage scheme helps to prevent

possible errors, outline the order of work, make a quality

preparation for a complex of construction

measures, calculate the number of necessary products and materials.

You may also like: Sewerage in the country - choice and device

Carrying out calculations

You can calculate the required volume of tanks using the example of a family of four people. On average, each of them consumes 200 liters of water per day, which is a total volume of 0.8 m³. If friends or relatives are visiting the house, then the total discharge can reach 1.5 m³. When designing, an indicator equal to three daily volumes of effluents is laid down. That is, it is necessary to lay a well with a capacity of 4.5-5.0 m³.

Next, you should decide on the rings.Their conditional capacity is calculated by a simple mathematical formula by multiplying the square of the inner radius by 3.14.

As a result, we obtain the following data for standard pipes 90 cm high with the following cross section:

- 100 cm - 0.7 m³;

- 150 cm - 1.4 m³;

- 100 cm - 2.8 m³.

Thus, the need for rings only to collect liquid will be as follows:

- 100 cm - 7 pcs;

- 150 cm - 4 pcs;

- 100 cm - 2 pcs.

This is only the need for reinforced concrete for the construction of the first tank.

To build a filter well, you need 1 ring more. The lower product will be used for backfilling crushed stone and sand. This is how many of these materials are needed to ensure high-quality wastewater treatment.

Preliminary work

Location selection

The installation of septic tanks from concrete rings begins with the choice of a place for this treatment plant. Of course, many people want to reduce the labor costs for laying trenches from the house to the reservoir, but still, some restrictions due to the need to maintain a sanitary condition should be taken into account without fail.

Diagram showing the main setbacks for the treatment plant

So, we have a septic tank:

- no closer than 5 m from a residential building;

- no closer than 50 m from the water intake point (well, well);

- no closer than 5 m from the road;

- no closer than 3 m from fruit trees and berry bushes.

In addition, when choosing a place, I would advise looking for a small hill (otherwise melt and rainwater will drain into the septic tank from a large area).

Don't do this, it's too close to home

It will also be useful to arrange a convenient entrance: even the most efficient septic tank needs to be pumped out when overflowing, so we leave the path for sewage equipment without fail.

Volume calculation

The next stage is the calculation of the required volume of the chambers of our treatment plant. Understanding how to calculate a septic tank is quite simple:

Two rings, as in the diagram, may not be enough

The volume is calculated by the formula:

V \u003d n x 3 x 0.2, where:

- V is the required capacity of the septic tank in cubic meters;

- n - the number of people living in a house that is connected to a septic tank;

- 3 - the average number of days for which a portion of the waste is completely processed;

- 0.2 - the average daily volume of wastewater (in cubic meters) per person.

As an example, we calculate the volume of a septic tank for 3 people:

V \u003d 3 x 3 x 0.2 \u003d 1.8 m3. This is the minimum from which you can start. It will turn out to do more - do more, less often you have to pump out.

Now let's calculate how many concrete rings of a standard size (1 m high and 1 m in diameter) are needed to equip the cells:

- The volume of one ring is 0.785 m3;

- We can use the upper ring only for 1/3 of the volume, i.e. its capacity will be approximately 0.26 m3;

- Therefore, for one container, we need a minimum of 0.785 + 0.785 + 0.26 = 1.83 m3, i.e. three rings.

Variants with different well shapes, but with the same effective volume

Finally, we decide on the number of cameras. As a rule, a two-chamber design is sufficient for a suburban area - with a sump and a filtration well.If we are building a septic tank for a large house that uses significant volumes of water, then it is advisable to install a third chamber, or to additionally attach a pipe to the septic tank for output to the filtration field.

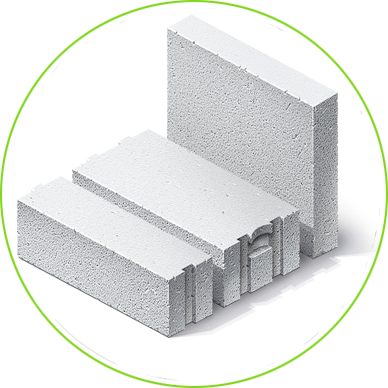

Selection of materials

The septic tank technology does not involve the use of expensive materials, however, taking into account the amount of work, I must note that the price in any case will be very, very significant.

This is the main element of the design

For the construction of a treatment plant, we will need:

- concrete rings for sewer wells (standard size);

- covers for sewer wells;

- sewer manholes with covers (cast iron or polymer);

- gravel for drainage;

- sand for backfilling;

- cement for sealing joints between elements and for making footings of foundations;

- waterproofing materials (roofing material, mastic, liquid glass);

- outdoor sewer pipes.

We make communications from pipes for outdoor work

In addition, for the effective functioning of the septic tank, it is desirable to purchase a special bacterial culture containing a complex of microorganisms for the efficient utilization of organic matter.

Biological product for the decomposition of organic matter

Construction stages

Installation is carried out in the following order:

- A place is selected, an installation scheme is built, and the parameters of the septic tank are calculated.

- A hole is being dug.

- Rings are installed, pipes are connected.

- Sealing and waterproofing works are underway.

- Covers are installed.

- Backfilling is underway.

Video description

The order of work and the installation of a septic tank from concrete rings on the video:

How to choose the best place for a septic tank

The structure is mounted above the groundwater level.The best location is at the maximum distance from the house (at least 7 meters, but not more than 20, so as not to increase the cost of pipeline construction). It is logical to have a septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving the tanker-vacuum truck is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage truck does not need to drive into the yard, and the hoses will not roll on the beds or paths (otherwise, when the hose is rolled up, the waste can get into the garden).

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of rings and their waterproofing. The bottom is covered with rubble and concreted.

Preparing a pit for a septic tank from concrete rings

Installation of rings and sewer pipes

Rings for a septic tank are installed using lifting equipment, which saves a lot of time (when compared with manual installation). Fixation of the seams is provided with cement mortar, metal ties (brackets, plates) are additionally placed.

The crucial moment is the process of installing rings

Sealing and waterproofing

Sealing the seams of the septic tank from concrete rings is carried out on both sides of the structure. For this, cement and coating protective solutions are used. Inside the well, you can install ready-made plastic cylinders. Such additional costs will make the system 100% hermetic.

In the process of waterproofing concrete rings for a septic tank, the joints are treated with liquid glass, mastic based on bitumen or polymer, concrete mix.To prevent freezing (and destruction) of the structure in winter, it is recommended to insulate it with a layer of polystyrene foam.

Sealing joints and waterproofing a septic tank from concrete rings

Manhole installation and backfill

The wells are covered with concrete slabs, with holes for manholes. In the first two wells, ventilation is necessary to remove methane (gas appears as a result of the vital activity of anaerobic bacteria). To backfill the installed floors, use the soil taken out of the pit (backfill).

Backfilling of finished wells

How does the septic tank start up

In order for the system to begin to function effectively, the erected septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- A new septic tank is filled with wastewater and defended for 10-14 days. Then it is loaded with sludge from an operating anaerobic septic tank (2 buckets per cubic meter).

- You can buy ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes that are intended for other treatment systems).

Ready to run septic tank from the rings

What rules must be observed when maintaining a septic tank

There are simple rules that support the quality of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (and preferably in 2-3 years), bottom heavy fats are cleaned. The volume of sludge must not exceed 25% of the volume of the tank. During cleaning, part of the sludge is left to restore the microflora.

- Quality of work.Effluent at the outlet of the system must be cleaned by 70%. Analysis of wastewater in the laboratory will determine the acidity index, which will allow you to know the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after enhanced ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (wet environment).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

The nuances of the work

If the sewerage system is being built independently, then in order to properly organize the work, several factors must be taken into account.

One of the problems is the increase in soil under the influence of external factors (soil heaving). This must be taken into account and, before installation, create a soil belt (sand cushion) with a thickness of at least 30 cm. Expanded clay or similar can serve as a material.

Also, to prevent the consequences of heaving, according to the standard installation scheme to prevent shear, they are interconnected by means of metal plates fixed with brackets or bolts.

A really working legal way to save money. Everyone needs to know this!

It is better to prepare in advance and rent a crane and a truck. It is better to dig all three wells in advance and think over the entrance to the place of work.

During installation, chips and cracks in the concrete should be avoided.

Great attention must be paid to sealing so that sewage does not seep through the first two treatment tanks. Pillows and liquid glass will help to properly protect the soil from leakage.

Stages of assembling a septic tank from concrete rings with your own hands.

After selection, the schemes are determined with the area where the sewer will be located. It is necessary to place containers at a distance of a meter from groundwater. The GWL indicator is a problem that is characteristic of almost all of central Russia. A septic tank with a high level of groundwater is much more difficult to install and use, so when planning a sewer, you need to take into account the state of the soil of the area.

A high GWL is considered to be a parameter less than a meter. The maximum indicator will be the most objective, so measurements are best done in the spring when the snow melts or in the fall during the rainy period. If there is a well on the ground that is fed from groundwater, then the GWL is determined by measuring the distance between the liquid level in it and the ground surface.

If there is a problem with the GWL, then more attention should be paid to sealing. Due to the fact that structures consisting of prefabricated elements (brick or concrete rings) do not provide proper tightness, you should resort to installing an industrial septic tank.

2. Digging a pit.

The diameter of the pit for a concrete septic tank should be wider than the concrete rings, so that after installation there is room for laying a waterproofing layer. The shape of the pit can be square (under a concrete slab) or oval (under a cement stretch).

3. Sealing the pit.

Inside, 0.3 m of sand is poured, and, after pre-treatment with cement mortar, slabs or stretching are laid.

4. Installation of rings.

The rings go down one by one.The pipe passages are insulated to prevent cracks after concrete shrinkage, the joints between the rings are sealed with cement and treated with silicone grease for sealing.

5. Septic tank treatment wells.

Wells are made with a depth of 1 m, pipes are placed in them, inside which crushed stone is poured to protect the walls from organic plaque.

6. Sewer pipes.

It is necessary to ensure the unhindered movement of water between the tanks. To do this, the pipe is brought into the well, the first in a row, at a slight angle, and in each subsequent one it is placed 20 cm lower.

The outer walls of the sewer are treated with clay.

Finally, a plastic hatch is placed on a septic tank made of concrete rings.

Tips for installing a septic tank for giving yourself:

- So that the sewer does not freeze, the rings should be insulated.

- A ventilation hole is desirable on each container of a concrete septic tank.

- The strength of the structure is increased if the rings are connected with metal brackets.

- A manhole cover helps to monitor the condition of the septic tank.

- Rental of special equipment will facilitate the construction of a septic tank.

Professional installation rates

The cost of installing a turnkey septic tank depends on the size of the sewer. On average, the price of one ring is 2000. The cost of work is 2500 rubles.

The cost of elements, rubles

The cost of drainage is 7,500 rubles, installation with the necessary pipes and insulation - 14,000, running pipes into the house - 2,500 with a column foundation and 6,000 with a strip foundation.

Also, once every few years (depending on the intensity of use), the services of cesspool cleaning companies will be required. Prices start from 1000 rubles per 1 m3.

Under the waterproofing of concrete means measures to protect it from moisture.

Cement-based stones (bricks are a separate category) by definition.

One of the important elements of a country house with a layout of more than one floor.

Aerated concrete house projects

Aerated concrete house projects

Choosing a foundation for a house of foam blocks

Choosing a foundation for a house of foam blocks

What is better foam concrete or aerated concrete?

What is better foam concrete or aerated concrete?

Pros and cons of aerated concrete blocks

Pros and cons of aerated concrete blocks

Overview of concrete grades

Overview of concrete grades

The use of DSP in construction

The use of DSP in construction

How to create a filtration well

A filtration well can be made by purchasing ready-made material - plastic, concrete, metal, or you can build it yourself. The installation scheme is similar to a septic tank, but has its own differences. So let's set up the sequence of actions:

- We tear out a ditch;

- We install a ring that has connectors with a diameter of 5 cm around the entire perimeter;

- We fill the ring with gravel, crushed stone and slag with a layer of 1 meter;

- The outer part of the ring should have a distance to the ground - 50 cm;

- We install a pipe for drains;

- We fill the well with soil;

- The building is covered with a ceiling, which can be concrete or wooden, and we leave the entrance for the ventilation system.

Now the whole system is ready.

Do-it-yourself construction stages

Installation for the construction of a septic tank on its site includes several stages. All calculations have been carried out, the schemes have been approved - we are preparing materials.

Preparation of materials and tools

Dimensions of concrete rings for a septic tank.

When preparing a list for the purchase of materials, we write down concrete structures in the first paragraph. Knowing the number and height of the tanks, it is easy to calculate the required number of rings (height 90 cm). Purchasing lower rings with a ready-made bottom will make the job easier. Required tools:

- plastic pipes;

- corners, tees;

- asbestos, ventilation pipes;

- cement;

- waterproofing material;

- crushed stone;

- shovel, perforator, ladder, hacksaw, trowel.

Location selection

The location of the septic tanks is of great importance. The decision is influenced by sanitary-epidemiological and construction requirements:

- correct calculation of the distance from the house, the source of drinking water;

- low location of groundwater;

- availability of free access for transport.

It is worth knowing that the sewerage device at a distance of more than 20 m requires additional costs for the supply pipeline and the arrangement of revision wells.

Pit preparation

Preparation of a pit for a septic tank.

All preparatory work has been carried out - a swarm of pits. To dig a hole, it is worth using special equipment, which will save time, or dig a hole yourself. The advantage of manual digging is that the required dimensions are immediately observed, no adjustment of these dimensions is required. The depth of the pit is at least two meters, dig the width with a margin so that the sides of the moat do not cling to the concrete rings.

It is considered to be a classic version of the pit - a round shape. This claim is easy to refute. A square-shaped pit is excellent, it is easier to dig it, and a square-shaped concrete slab will lie more freely. With a three-chamber septic tank, we dig three holes, with a two-chamber septic tank - two. We place each subsequent hole 20-30 cm lower.

Installation of rings, piping

Plumbing to a septic tank.

It is forbidden to roll the rings on the surface; cracks appear from such transportation. It is worthwhile to involve specialized equipment in the installation, which will ensure that the rings are fed in a vertical position.Before installation, it is worth preparing the base: a sand cushion 30 cm high and a concrete screed 20 cm high. The base prevents runoff from entering the soil. The screed can be replaced with a solid concrete slab or rings with a concrete bottom. Single-chamber septic tanks are not concreted, a drainage cushion is sufficient.

Sealing

Rings are placed on the concreted bottom. Holes for the overflow pipe are punched in the ring, connecting lines are carefully sealed with cement. Coating protective solutions are used for exterior finishes. If there is financial potential, it is worth buying plastic cylinders and putting them inside the well to prevent contaminants from entering the soil. You can start the stage of waterproofing.

Waterproofing

Protecting the structure from water penetration is perhaps the most crucial stage. Despite the belief that concrete does not absorb water, the well is completely waterproofed. Liquid glass. bitumen or polymer mastic, concrete mix with additives - great for responsible work. Ring joints are carefully processed.

Covering and backfilling the well

The final factor of the main work is the installation of overlappings on the rings. The containers are covered with a concrete slab with a hole for the hatch. The well is covered with previously excavated earth mixed with sand. Spread evenly over the entire surface and compact thoroughly.

Arrangement of the bottom of the tank

The bottom plate is designed to seal and prevent toxic waste from entering the ground.

The bottom is made in the following sequence:

- The soil is qualitatively leveled and rammed. If there are plant roots, they are cut off, and their sections are treated with an antiseptic.

- A geotextile is laid on the ground. It will prevent grass germination and erosion of the soil under the container.

- At a height of 15 cm, holes with a diameter of 12-16 mm are drilled in the walls. Measurements are taken, reinforcing pins are cut. They are inserted and fixed in holes, forming a lattice with a mesh of 15-20 cm.

- A mixture of sand and crushed stone 10-12 cm high is poured onto the geotextile. The material is wetted and leveled.

- The concrete is mixed. The proportion of cement, sand and gravel is taken 1:3:3. The solution is poured until it covers the reinforcing cage with a layer of 5 cm. It takes at least 14 days for the concrete to gain strength.

This manufacturing technology of the bottom will ensure its resistance to pressure and tightness.