- Design and preparations

- Preparatory work

- Features of the structure of the grease trap

- Main components of a grease trap

- Technological features of grease traps

- Installation of a septic tank Flotenk

- Device and principle of operation

- Camera assignment

- Technical characteristics of the installation

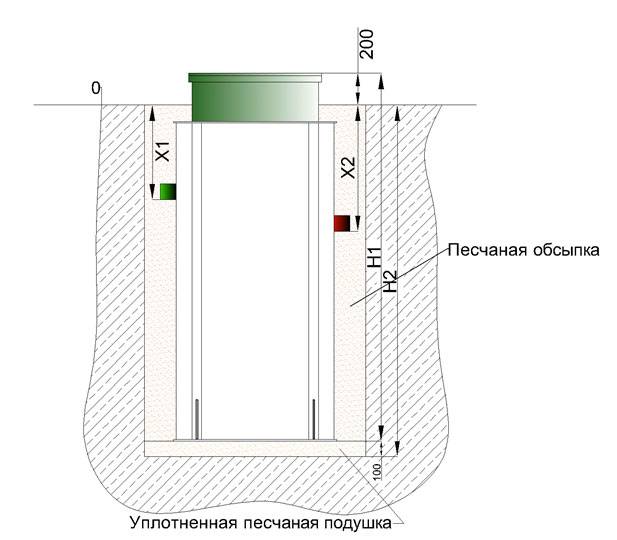

- How to install a Flotenk septic tank?

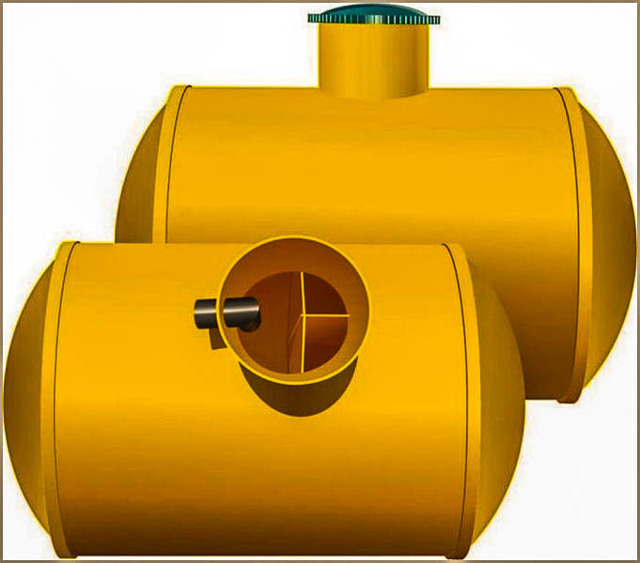

- Features of the station Flotenk STA

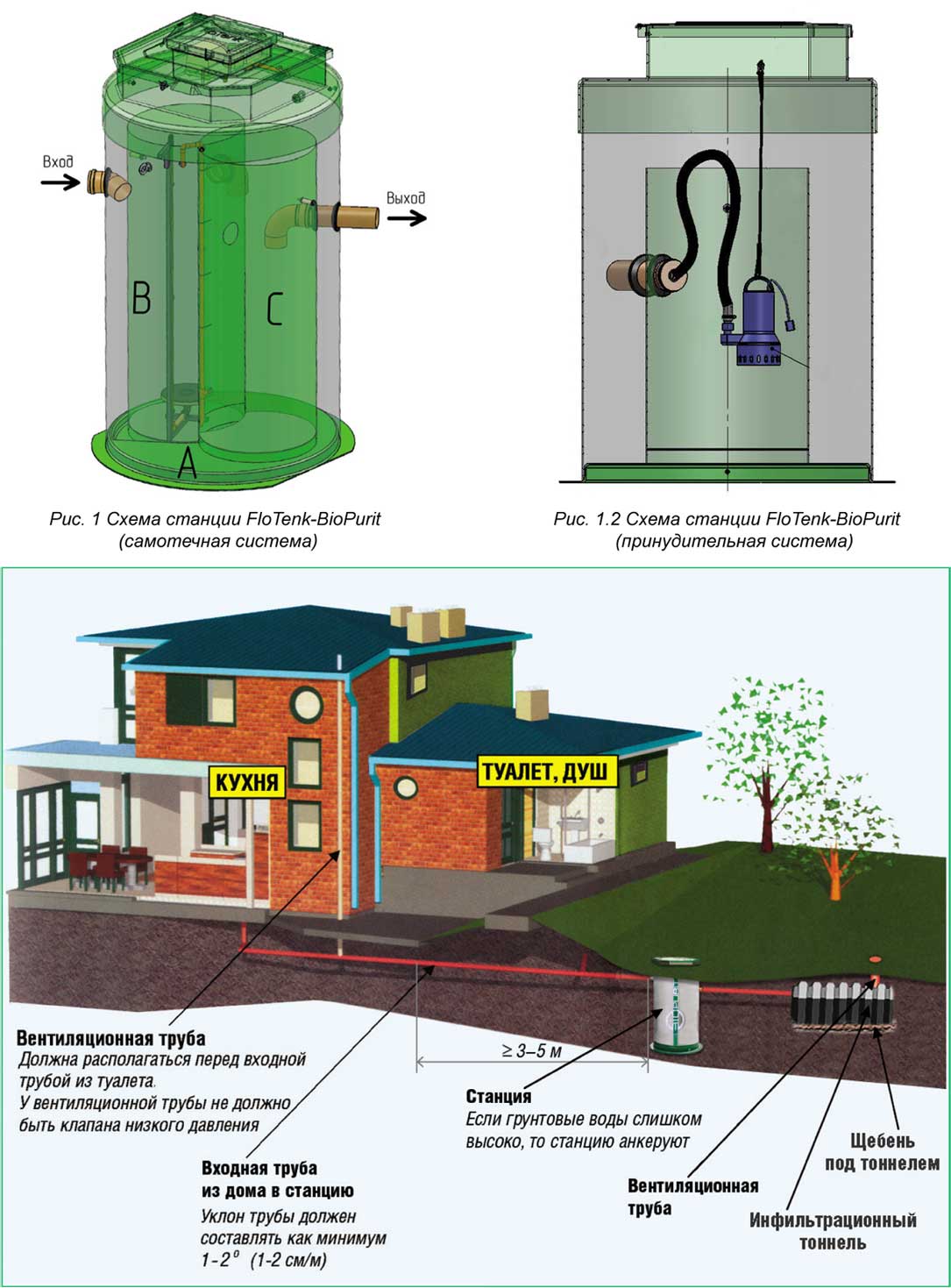

- Features of the station Flotenk BioPurit

- Cost (price) of a septic tank Flotenk

- Model range: technical features

- Flotenk STA 1.5 m³

- Flotenk STA from 2 m³

- Flotenk STA YES

- Strengths and weaknesses of VOC septic tanks

- What models does the manufacturer offer?

- Triton-Mini

- Septic tank Triton-Micro

- Septic tank Triton-N

- Septic tank Triton-T

- Septic tank Triton-ED

- Advantages and disadvantages of septic tanks

- Design and main characteristics

- The lineup

- Scheme of operation of the installation

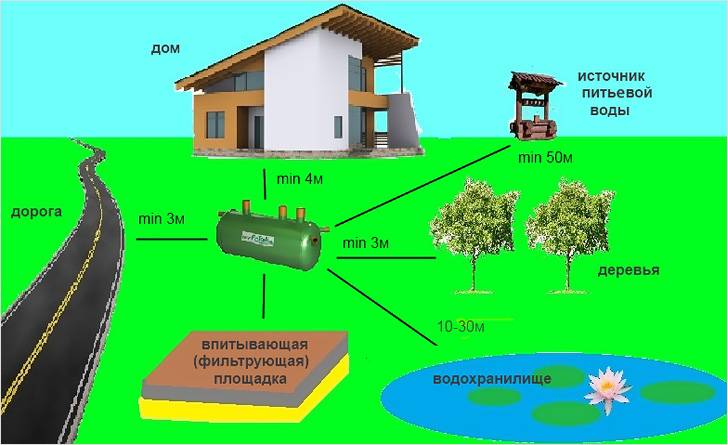

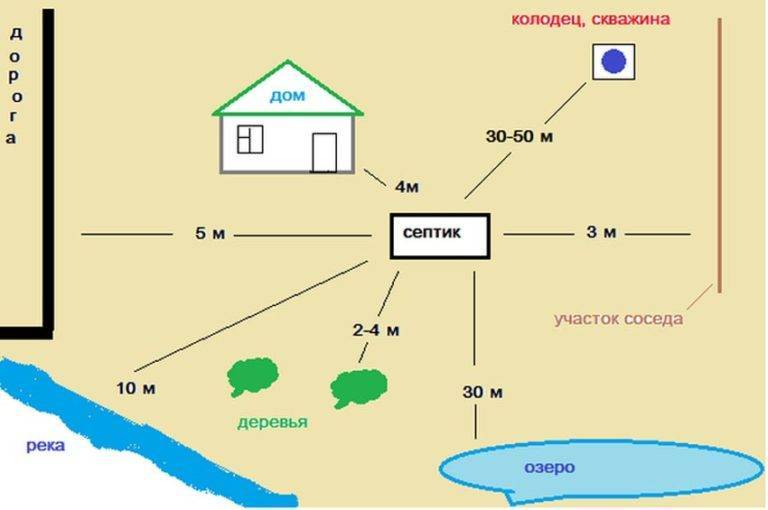

Design and preparations

The main requests for the installation of septic tanks are indicated in SNiP (building codes and rules). Before starting the installation of a treatment plant, it is necessary to coordinate the project in the sanitary and epidemiological station (SES), otherwise the costs may be in vain.

The rules governing the placement of a septic tank on the site

When developing a project for a septic tank, first of all, you need to take into account the requirements of SNiP and SES, while they inform about the following:

- The smallest distance to the building is 5 m.

- The distance to the nearest water intake (well, well) is 50 m.

- Distance to the flowing origin of water (river, stream) - 10 m.

- The interval to the source with stagnant water is 30 m.

For a competent drafting of a project for a septic tank, you need to provide for yourself the prices for installation work, and also know the approximate prices for materials. In addition to this cost, it is necessary to take into account the cost of land works, which are inevitable for such a treatment plant.

Preparatory work

Before proceeding with the installation of a septic tank, you need to prepare. It involves earthworks and the calculation of parameters that affect the correct choice of location and the efficiency of the treatment plant.

Preparatory work includes:

- Analysis of the soil structure and relief of the planned site for a septic tank.

- Checking the depth of groundwater. The depth of the installation, as well as the filtering method, depend on this parameter.

With high groundwater, the design of a volatile septic tank with a drainage pump is most often used.

- Preparation of the site for the future septic tank. (Cleaning the territory from foreign objects).

- Markup.

- Digging a hole for a structure and trenches for sewer pipes.

After the pit has been dug with dimensions for installation, installation can begin.

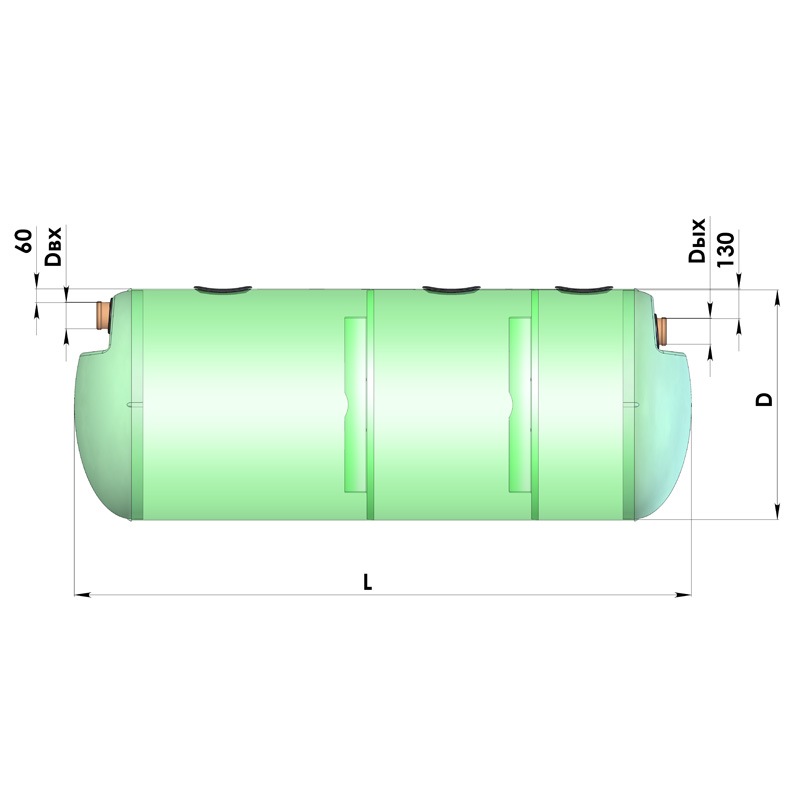

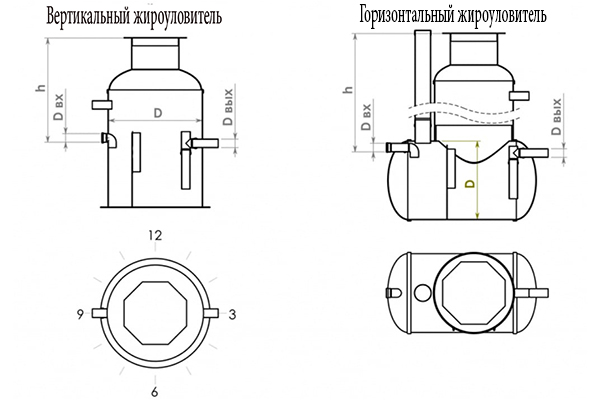

Features of the structure of the grease trap

The industrial version of the equipment has a sump type, where schemes are provided for the release of fats from water already at the first stage of cleaning. In terms of design, the Flotenk OJ grease trap has the shape of a cylinder, where there is an inlet pipe for receiving wastewater and an outlet pipe for removing liquid from the tank.The manufacturer produces products in two versions - for horizontal installation; for vertical installation. The total capacity, depending on the model range, ranges from 0.5 to 15.2 m3.

The principle of operation of the Flotenk grease trap depends on the design of the device, which is made using the technology of reinforced winding of fiberglass materials based on polyester resins. This method prevents the occurrence of corrosion, provides full mechanical strength of the structural solution for the body of the grease trap.

The main purpose of the equipment is to separate fat from water at the very beginning of the flow of sewage, that is, only liquid will flow into the sewer pipe, and the fat remains inside the device body. This method allows you to prevent in advance the accumulation of fat on the walls of sewer pipes, as well as inside septic tanks. This type of technological equipment extends the life of septic tanks and creates comfortable conditions for the operation of utilities in the house.

The products have the appropriate certificates and permits for operation in Russia, in particular, the regulation of the standard TU 2296-001-79777832-2009 is provided, and the certificate of conformity N ROSS RU.AB57.H00680 dated 24.09.09. Sanitary supervisory authorities issued an order that allows the installation of a grease trap not only for industrial purposes, but also for preschool and educational institutions, medical institutions, as well as in private households. Mandatory sanitary certification complies with the requirements of the conclusion N 50.RA.02.229.P.0000043.01.10 dated 01.20.10.

Main components of a grease trap

The body is divided into two independent parts. The first compartment is a sand separator, where solid wastes enter, which, in turn, settle to the bottom of the housing. As it accumulates, an effective release of the container from accumulated dirt will be required. According to the manufacturer's instructions, it is necessary to clean this compartment at least once a year, or as waste accumulates, as a rule, up to half of the compartment. The cleaned components, in turn, slowly flow into the second compartment of the case. In the second compartment, the separation of fat and liquid takes place, due to the natural difference in the specific gravity of each material. Then there is a kind of contact of fat with air, the fat slowly rises to the top, settles in the form of an oily film on the surface. After that, fat is deposited at the rate of 50 milliliters per 1 gram of liquid. After that, water flows by gravity into the outlet pipe.

Technological features of grease traps

The manufacturer offers several options for fat traps, which have a different volume and, of course, different schemes for processing fat and water.

| Grease trap Flotenk OJ-1 | 1 |

| Grease trap Flotenk OJ-2 | 2 |

| Grease trap Flotenk OJ-3 | 3 |

| Grease trap Flotenk OJ-4 | 4 |

| Grease trap Flotenk OJ-5 | 5 |

| Grease trap Flotenk OJ-7 | 7 |

| Grease trap Flotenk OJ-10 | 10 |

| Grease trap Flotenk OJ-15 | 15 |

| Grease trap Flotenk OJ-20 | 20 |

| Grease trap Flotenk OJ-25 | 25 |

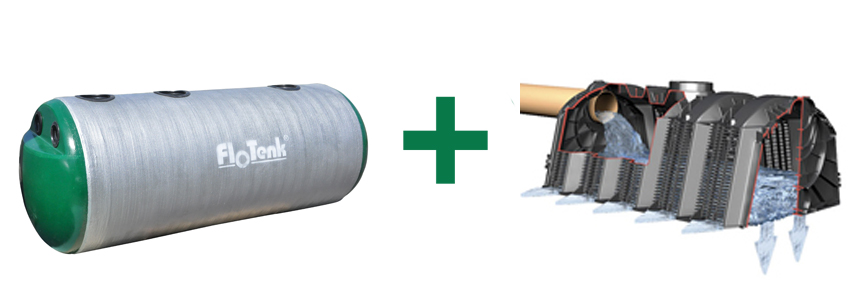

Installation of a septic tank Flotenk

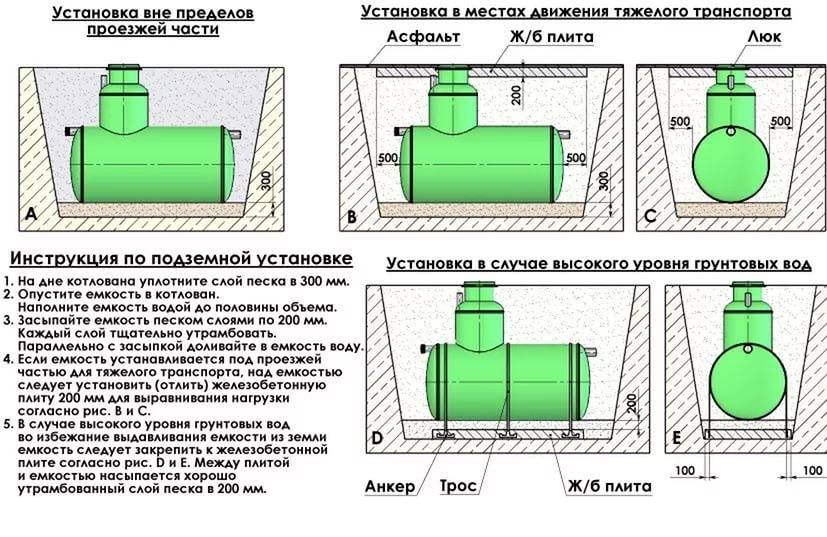

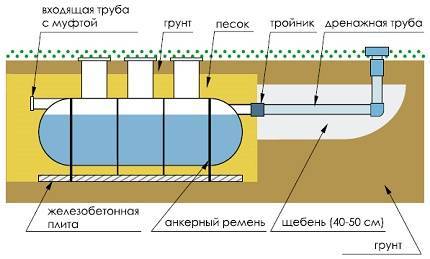

The installation of this septic tank is carried out on the basis of the same rules as the installation of other treatment plants. First you need to prepare a pit where the tank is located. Trenches are brought to it from two opposite sides. Trenches are needed for the subsequent laying of pipes. When installing a sewer pipe, it must be taken into account that for the unhindered passage of domestic wastewater, it will be necessary to observe the angle of inclination.On average, it is 5 cm per 1 linear meter of pipe. If the soil freezes strongly, then the pipes are insulated. This process will be required to avoid problems with sewage in the winter.

What is important to consider when installing a septic tank

The laying of the sewer pipeline can be carried out in the drilled holes. The soil in the pit for the treatment tank is removed, and a sand cushion is arranged at the bottom. The sand base is reinforced with reinforcement. To do this, the grate is welded from separate sections, and the finished crate is poured with concrete mortar.

A solid plate is formed at the bottom, which is able to withstand heavy loads. It will help the septic tank to be motionless and not move under the influence of soil displacement. The septic tank is installed on a concrete slab. To prevent the structure from moving, it is necessary to strengthen the septic tank with a stainless steel cable. Fastening is carried out using anchor rings. After the fastening is completed, the septic tank is covered with soil that was taken out of the pit. Before starting operation, water is poured into the treatment plant.

The supply pipes must be insulated, a fan riser and upper extension necks must be installed. When installing a septic tank, an infiltration tunnel is installed, which is connected to the pipe. The infiltration tunnel under the pedestrian zone is deepened by 30 cm. Under the parking zone or the roadway by 50 cm. Now you should install the filtration system from several modules. Installation can be done in series or in parallel.

If you study the reviews about Flotenk septic tanks, then you will notice that in most cases they are positive.

Owners of septic tanks note the following advantages:

- non-volatile, which allows you to use the septic tank when the electricity is turned off;

- high reliability of fiberglass, which guarantees many years of operation without changes in tightness;

- easy installation.

Of course, the Flotenk septic tank is not ideal and has a drawback. It lies in the fact that to remove the solid residue, you need to turn to the sewers. The frequency of cleaning depends on the activity of using the septic tank. On average, cleaning should be done every 2-3 years.

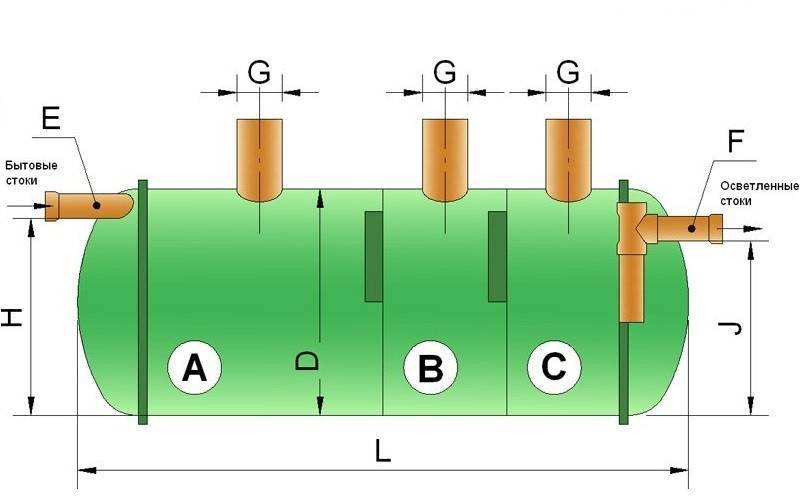

Device and principle of operation

A sealed container made of durable material - polypropylene - plays the role of a sump isolated from the environment. This is an autonomous treatment facility necessary for the accumulation and disinfection of waste in places where there is no centralized sewage system - for example, in a country house.

To install the Kedr Septic tank, a small plot of land near the house is enough, but one should not forget about additional drainage structures - a trench or a filtration field

A septic tank differs from a conventional tank in that it consists of several chambers, each of which has its own functional focus.

Camera assignment

1 - receives wastewater that flows by gravity from the building. All suspensions are divided into two groups: heavy solid particles sink to the bottom, forming a sediment, and light fats rise to the surface of the water and accumulate there in the form of a thick film.

2 - under the influence of anaerobic bacteria, there is a moderate treatment of wastewater, their partial clarification.

3 - a replaceable biofilter, which must be washed from time to time, collects aerobic and anaerobic microflora.

4 - the clarification process ends.If there is a need to raise the level of filtered water, a drainage pump is installed in this chamber.

When ordering a septic tank, you need to remember about its various versions, which differ in the height of the head

Technical characteristics of the installation

-

- height - 3 m;

- diameter - 1.4 m;

- total weight - 150 kg;

branch pipes (DN 110) are provided for connection with inlet and outlet sewer pipes; eyeliner at a distance of 1.2 m from the top, outlet - 1.4 m.

The well-thought-out composition of the drainage will allow you to maximally clean the water coming from the septic tank

How to install a Flotenk septic tank?

1.Before installing the station, be sure to make sure that you are going to locate it away from the house itself, wells and sources of drinking water.

2. If you have taken into account all the necessary sanitary standards, then the first stage in the installation of the installation will be the preparation of the pit. The excavated hole should correspond to the size of the station. Lay a sand cushion at the bottom of the pit. And also, in order to provide additional strength to the structure, install a concrete tile and fix anchor rings at the base of the slab, which must be threaded into a stainless steel cable. The cable is used to provide additional immobility to the installation.

3. After you have dug a hole, bring all the necessary sewer pipes to it, which must first be cleaned. Be sure to place the pipes at a certain angle so that the wastewater flows off on its own. Pipes should also be insulated. Fix the fan riser.

4. Using diamond drilling, make special holes in the walls of the pit, in which sewage pipes will be laid.

5. Load the station into the pit, install the upper necks.Be sure to fill the system with clean water before laying out the soil again. Install filtration equipment and infiltration tunnel.

There are three types of septic tanks:

- Flotation tank STA;

- Flotation tank BioPurit;

- SeptiX float tank.

Features of the station Flotenk STA

The material from which the unit is made is fiberglass. Since all parts are produced in large quantities in factories, there is no doubt about their quality, tightness and strength. This station has a cylindrical shape, which is divided into a certain number of sections inside. The larger the volume of the installation, the higher its productivity. It is necessary to clean the station up to three times a year.

Model nameVolume, lProductivity, l/dayDiameter, mmLength, mm

| Flotation tank STA 1,5 | 1500 | 500 | 1000 | 2100 |

| Flotation tank STA 2 | 2000 | 700 | 1000 | 2700 |

| Flotation tank STA 3 | 3000 | 1000 | 1200 | 2900 |

| Flotation tank STA 4 | 4000 | 1300 | 1200 | 3800 |

| Flotation tank STA 5 | 5000 | 1700 | 1600 | 2700 |

| Flotation tank STA 6 | 6000 | 2000 | 1600 | 3200 |

| Flotation tank STA 10 | 10000 | 3300 | 1600 | 5200 |

Features of the station Flotenk BioPurit

The station has four sections and needs to be serviced once a year. The model number in the name corresponds to the number of people who can use this device (specific model).

Model nameVolume, lProductivity, l/dayDiameter, mmHeight, mm

| Flotation tank BioPurit 2 | 200 | 0,4 | 1200 | 1750 |

| Flotation tank BioPurit 3 | 330 | 0,7 | 1200 | 2250 |

| Flotation tank BioPurit 5 | 450 | 1,0 | 1200 | 2750 |

| Flotation tank BioPurit 8 | 800 | 1,6 | 1600 | 2750 |

| Flotation tank BioPurit 10 | 900 | 2,0 | 1600 | 2750 |

| BioPurit 12 float tank | 1000 | 2,4 | 1600 | 2250 |

| BioPurit 15 float tank | 1125 | 3 | 1600 | 2250 |

| BioPurit 20 float tank | 1250 | 4 | 2000 | 2250 |

Features of the station Flotenk SeptiX

Service once a year, complete autonomy and efficient filtration.

Model nameVolume, lDiameter, mmLength, mm

| Flotation tank SeptiX 2 | 2000 | 1000 | 2700 |

| Flotation tank SeptiX 3 | 3000 | 1200 | 3900 |

| SeptiX 4 float tank | 4000 | 1200 | 3800 |

| Flotation tank SeptiX 5 | 5000 | 1600 | 2700 |

| Flotation tank SeptiX 6 | 6000 | 1600 | 3200 |

| SeptiX 10 float tank | 10000 | 1600 | 5200 |

| Flotation tank SeptiX 12 | 12000 | 1800 | 5100 |

| Flotation tank SeptiX 15 | 15000 | 1800 | 6200 |

Cost (price) of a septic tank Flotenk

Model namePrice, rub

| Flotation tank STA 1,5 | 27700 |

| Flotation tank STA 2 | 36700 |

| Flotation tank STA 3 | 47700 |

| Flotation tank STA 4 | 76700 |

| Flotation tank STA 5 | 92700 |

| Flotation tank STA 6 | 112700 |

| Flotation tank STA 10 | 137700 |

| Flotation tank BioPurit 2 | 61110 |

| Flotation tank BioPurit 3 | 68310 |

| Flotation tank BioPurit 5 | 84510 |

| Flotation tank BioPurit 8 | 110610 |

| Flotation tank BioPurit 10 | 130410 |

| BioPurit 12 float tank | 138510 |

| BioPurit 15 float tank | 147600 |

| BioPurit 20 float tank | 193610 |

| Flotation tank SeptiX 2 | 40608 |

Focusing on the numerous reviews of the owners of the septic tank, a number of advantages of this device can be distinguished.

- Three-stage wastewater treatment process.

- The strength of the material ensures the durability of the use of the station and its reliability.

- Complete energy independence.

- No need to constantly monitor the operation of the septic tank.

- The impossibility of surfacing the device due to the lack of seams on the structure.

- A unique system of water seals, which serves to clean the water drains from the fatty film.

- Pipe connections with rubber sealing cuffs, which provide transportability and convenience in installing the station.

- Minimal risk of device damage.

This septic tank requires minimal maintenance. It is enough to clean the station from silt and waste once or twice a year for its efficient operation.

Model range: technical features

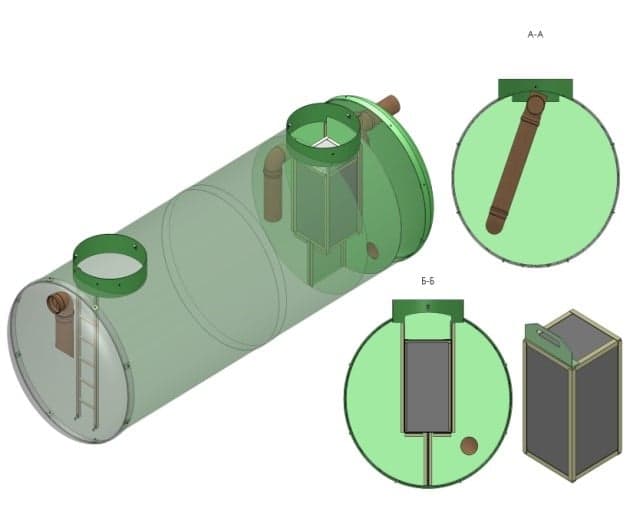

Flotenk septic tanks are two- or three-section (depending on modification) containers with holes in the upper part for the necks and in the end walls for the inlet and outlet pipes.

Enclosures for septic tanks are made of waterproof composite material - polyester fiberglass. It consists of polyester resins and glass-reinforcing components.

Flotenk STA treatment facilities, in addition to the fiberglass tank, are equipped with:

- 160 mm cuffs (for attaching necklines);

- 100 mm cuffs (for mounting nozzles);

- PVC outlet;

- technical passport;

- recommendations on the use of bioenzymes (if the installation technology provides for their use).

Flotenk STA 1.5 m³

Septic tank Flotenk STA - 1.5 - this is the most low-power installation of the entire model range. It consists of a one-piece two-section body.

In the unit, mechanical and biological wastewater treatment with the participation of anaerobic microorganisms takes place simultaneously. The cleaning process takes place in the following sequence:

Effluent flows by gravity through the inlet pipe into the primary sedimentation tank (section A). At this stage, the liquid settles. Solid components settle to the bottom of the chamber, fatty components collect on the surface in the form of a film (turn into a crust over time), and water remains in the middle part.

Simultaneously with mechanical settling, biological anaerobic processes take place in section A. They are launched as a result of the vital activity of a special type of bacteria, for which the best living conditions are an oxygen-free environment.

As a result of fermentation, biological substances (proteins, carbohydrates, fats) decompose into methane, carbon dioxide and hydrogen.

- From the primary clarifier, the partially purified liquid enters through the blocker holes (located in the middle part of the tank, below the greasy film, but above the solid sediment) to section B. In this chamber, effluent treatment with anaerobic microorganisms and mechanical settling continue.

- From chamber B, effluents are sent through the outlet pipe for post-treatment to the filtration fields.

The manufacturer in the product passport gives a table of the main technical indicators of wastewater quality before and after treatment in Flotenk STA septic tanks.

Table: wastewater characteristics at the outlet of the Flotenk septic tank

Characteristics of wastewater with decoding of parameters according to the official website

Flotenk STA from 2 m³

Installations with a volume of 2 m³ or more have a fiberglass body, divided into three compartments.

The units are represented by models of various capacities from 2 to 25 m³.

Technical parameters of Flotenk STA septic tanks with a capacity of 2-25 m³ according to the official website

When choosing a device model, the manufacturer recommends being guided by the norms of SNiP 2.04.01-85, which regulate the average water consumption per person.

The cleaning process in the units follows the same principle as in the STA-1.5 model. Chambers A and B serve as primary and secondary clarifiers. However, these septic tanks have chamber C, in which the final clarification of the liquid occurs. Zone B is connected to zone C by a blocker (hydraulic seal). The treated effluents are sent to the infiltration fields through the outlet pipe from zone C.

Flotenk STA YES

The new Flotenk STA YES septic tank can be called a modified version of the two-chamber unit described above. The device works on the same principle, also has a fiberglass body. The treatment plant differs only in increased dimensions. According to the manufacturer, a device of this capacity can serve up to 5 people.

Strengths and weaknesses of VOC septic tanks

The advantages of the devices of this model range are as follows:

- relatively low cost (more on that later);

- high cleaning efficiency;

- reliability and durability of the body due to the use of high-quality materials in its manufacture;

- at the same time, the design of septic tanks is extremely simple.

The disadvantages include:

- volatility - if you turn off the device from the power supply, then the quality of cleaning from this will significantly decrease;

- also on the Internet there are many negative reviews about the pumps that the stations are equipped with.

At the same time, wastewater that has gone through the entire cycle meets modern standards and requirements for discharge into the soil or for use for economic purposes.

Model range of VOC septic tanks

What models does the manufacturer offer?

Purification equipment of the Triton line involves biological treatment of wastewater with post-treatment in the ground. Models differ in the amount of wastewater processed, size, installation method.

Triton-Mini

Tank volume - 750 l, wall thickness - 8 mm. A small economical model sump, easy to operate and install, able to withstand severe frosts. Suitable for serving a family of 2.

Within two days, the triton mini septic tank is able to clean 500 liters of wastewater at maximum load (if 5 people lived in the house). To prevent the container from becoming clogged with solid waste, they must be pumped out once a year.

Triton-Mini is a great option for a septic tank, the installation of which is not so difficult to carry out on your own

Septic tank Triton-Micro

Volume - 450 l, productivity - 150 l / s. The best option for non-permanent residence of an average family (from 1 to 3 people). Small in volume, easy to transport and install. The compact Triton micro septic tank can be used autonomously for a guest house or a bathhouse. It attracts with an inexpensive cost: a set with an infiltrator, a lid, a neck costs about 12,000 rubles.

Triton-Micro is suitable for installation during the construction of a country house

Septic tank Triton-N

Accumulative capacity from 1000 l to 40000 l. Wall thickness - 14-40 mm.A good choice for owners of a personal plot that has a small area (there is no possibility of equipping a filter site), as well as a high level of groundwater. Wear-resistant and durable septic tank Triton n is sealed, made of polyethylene, able to serve more than 50 years.

Triton-N septic tanks are made to order if the finished model does not fit

Septic tank Triton-T

A three-chamber polyethylene tank, representing a small independent treatment plant. Volume - from 1000 l to 40000 l. Easily serves a large house with 1 to 20 or more people. If the triton septic tank is located below the infiltrator, a drainage pump is installed that pumps out partially purified water from it to the filter field.

Triton-T is a great option for a country house of permanent residence

Septic tank Triton-ED

Volume - 1800-3500 l, productivity - 600-1200 l / s, it can be horizontal and vertical. The design consists of two-section modules in which water is purified from contaminants. Moving from section to section, the water is purified by 65%, then it enters the infiltrator zone, from there into the ground. The dimensions of the absorbent area depend on the volume of the septic tank. The material for the production of the product - extruded polyethylene - is so durable that the Triton ed septic tank is ready to serve for more than 50 years.

When installing a septic tank, do not forget about the access road for the sewage truck

Advantages and disadvantages of septic tanks

Depending on how the septic tank is arranged, the living conditions of the family are dramatically improved, and this will be the main advantage of such a treatment plant. In addition, it has many other advantages. Let's consider them in more detail:

- Long service life.

- There are no unpleasant odors in the local area.

- It is not required to frequently order a sewage truck.

- Significantly reduces the risk of soil contamination.

- Ease and reliability of installation. When they are installed, ready-made septic tanks "Termite storage" or "Tank" are also used - stations for the complete decomposition of waste.

The disadvantages of settling tanks include a large amount of excavation during installation and the high cost of polymer septic tanks.

Design and main characteristics

The material for the manufacture of the body of the Flotenk STA septic tank is durable fiberglass. The housings of the units are manufactured under strict quality control, so there is no doubt about their tightness and reliability.

Externally, the body of the Flotenk STA septic tank resembles an ordinary tank, that is, it is a horizontal cylindrical container. Inside the container is divided by partitions into three sections. Tanks are produced in different volumes and, accordingly, different capacities.

The lineup

Today, 7 variants of the Flotenk STA septic tank are produced. The youngest model in the line is capable of processing 500 liters of contaminated liquid per day, and the total capacity is 1.5 cubic meters. The most productive model in the series can clean 3.3 cubic meters of sewer drains per day, and its total volume is 10,000 liters.

Scheme of operation of the installation

There are three isolated containers inside the Flotenk STA septic tank. When undergoing treatment, wastewater flows sequentially through all three sections of the treatment plant:

- The receiving section of the Flotenk STA unit performs the functions of a sump in which the largest impurities that are not dissolved in water are deposited;

- The sediment at the bottom of the sump undergoes anaerobic (passing without air access) fermentation.Conventionally, this rather complicated process is divided into two stages. At the first stage, the so-called acid fermentation is carried out, in which organic matter decomposes with the formation of fatty acids, alcohols, hydrogen sulfide and carbon dioxide. Next, methane fermentation takes place, during which fatty acids and alcohols decompose to form methane, water and carbon dioxide;

- Having settled, the water through the overflow device enters the second section, where the process is repeated. The effluents are settled again, particles are separated from the water that did not have time to settle in the first section. The sludge is also subjected to anaerobic processing;

- Already clarified water enters the third section, in the process of settling, small particles are released from the effluents, which are in the form of suspensions;

- Then the water is removed from the installation and fed to the filtration sites or filtering wells.