- The principle of the applied biological treatment

- Design and main characteristics

- The lineup

- Scheme of operation of the installation

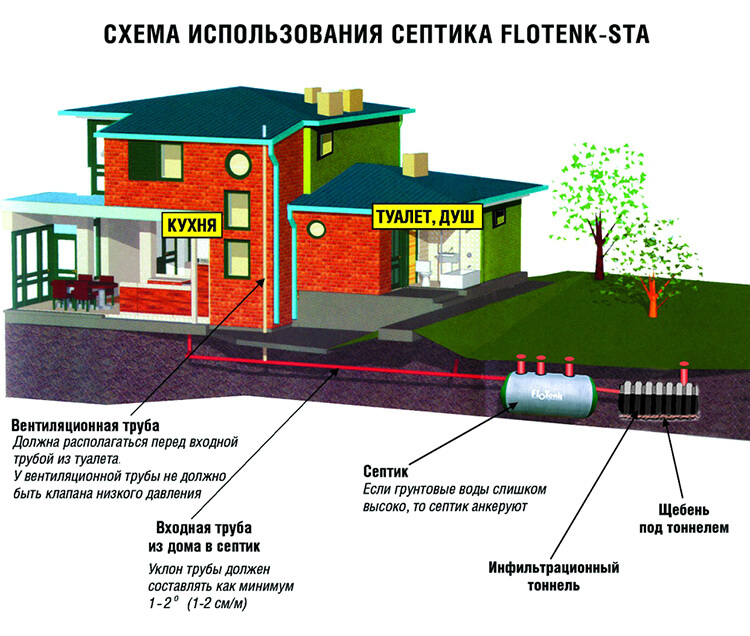

- The principle of operation of the Flotenk septic tank

- How to install a Flotenk septic tank?

- Features of the station Flotenk STA

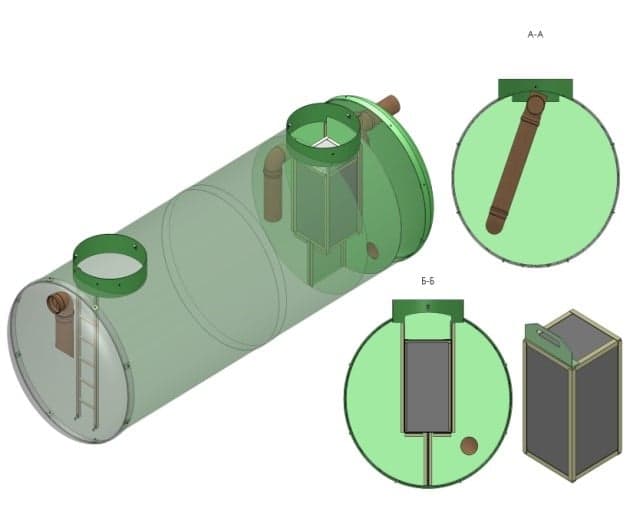

- Features of the station Flotenk BioPurit

- Cost (price) of a septic tank Flotenk

- Model range: technical features

- Flotenk STA 1.5 m³

- Flotenk STA from 2 m³

- Flotenk STA YES

- What models does the manufacturer offer?

- Triton-Mini

- Septic tank Triton-Micro

- Septic tank Triton-N

- Septic tank Triton-T

- Septic tank Triton-ED

- Device and principle of operation

- Overview of the range

- How to install a Flotenk septic tank?

- Features of the station Flotenk STA

- Features of the station Flotenk BioPurit

- Conclusion

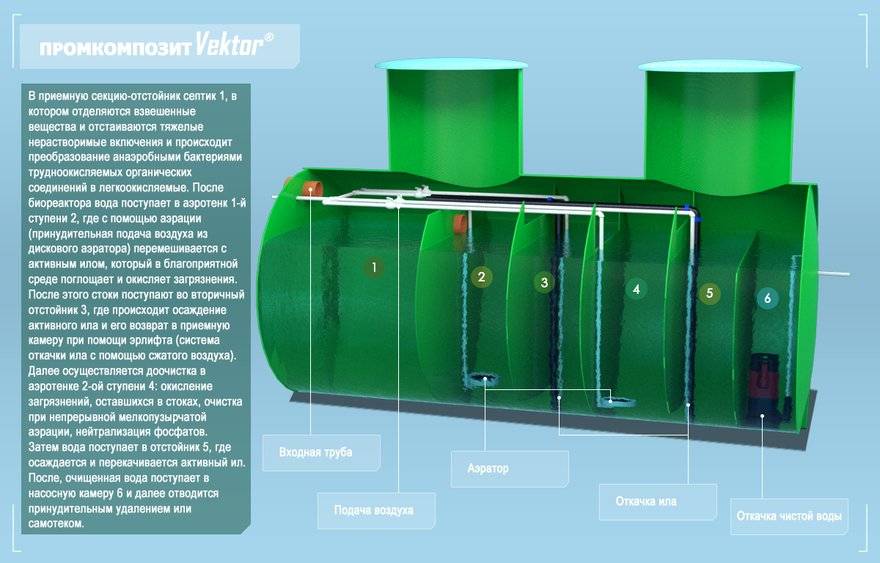

The principle of the applied biological treatment

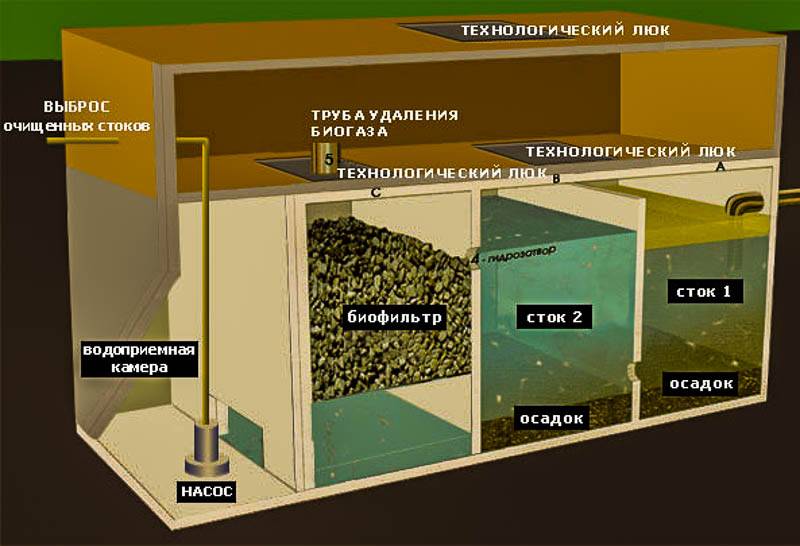

Purification of domestic wastewater occurs gradually, as they sequentially pass through all the departments of the septic tank.

Polluted water flows by gravity through the sewer pipe from the house to the first section of the structure. In order to prevent blockage, the pipe is inserted in such a way that the outlet is below the level of the drains. Most of the contaminants are retained in this compartment: fats and films floating to the surface, heavy particles settling to the bottom.

The cleaning tank is equipped coming to the surface pipes - one from each section. They are necessary for pumping solid sludge

Oxygen deficiency is the cause of the anaerobic process, which can be divided into two stages:

- Acid fermentation. All substances, including fats, decompose until they turn into lower fatty acids (butyric, formic, acetic), alcohols, hydrogen sulfide, carbon dioxide.

- methane fermentation. Alcohols and fatty acids finally decompose, forming hydrogen, carbon dioxide, methane.

Having overcome the blocker, the effluents enter the second section for further settling. Overflows are located above the level of sedimentary masses and below the fatty films floating on the surface. In this compartment, in addition to mechanical processing, anaerobic processing continues.

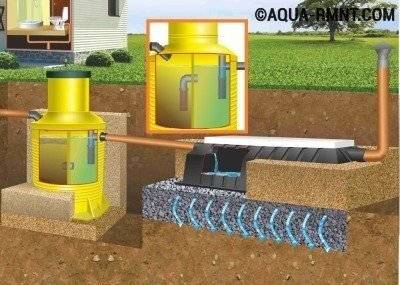

The septic tank is located not far from the house and taking into account the fact that a separate piece of land will be occupied by an equipped filtration field

In the third section, suspended organic particles form a sediment, and almost purified water enters the filtration field through a pipe for final post-treatment.

When installing a filtration tunnel (drainage field), it is necessary to take into account the distance to some objects, for example, groundwater must be at a minimum distance 1m

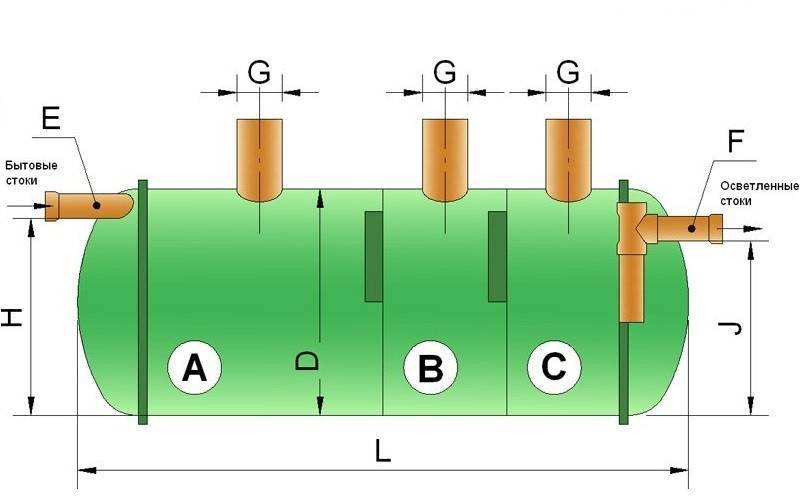

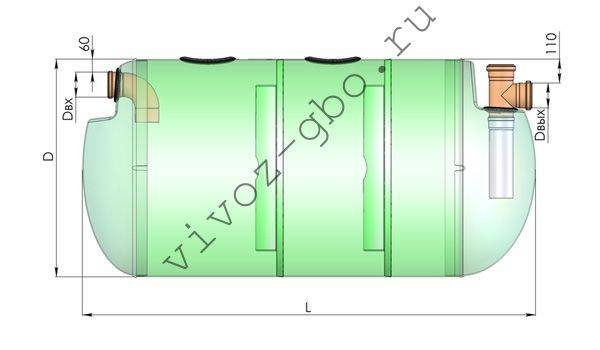

Design and main characteristics

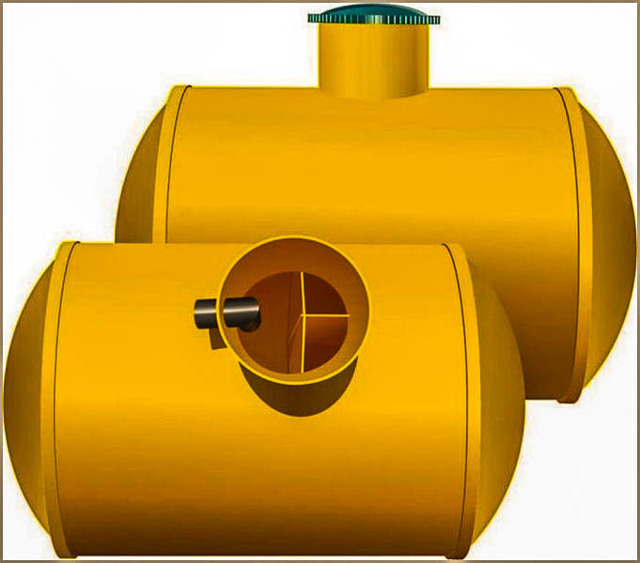

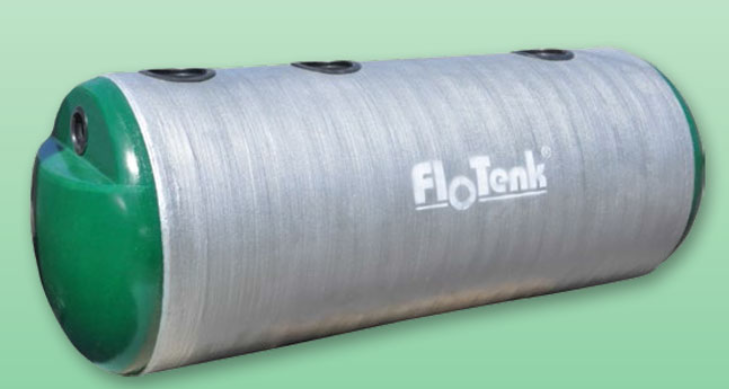

The material for the manufacture of the body of the Flotenk STA septic tank is durable fiberglass. The housings of the units are manufactured under strict quality control, so there is no doubt about their tightness and reliability.

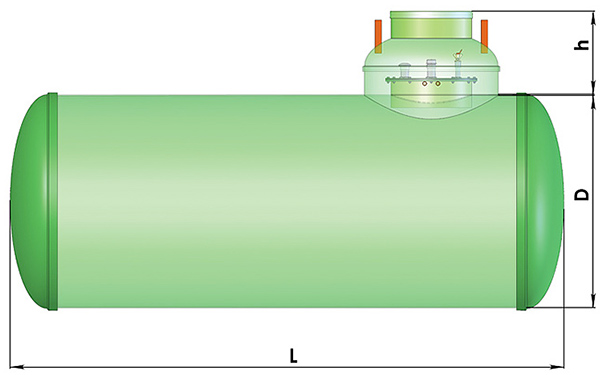

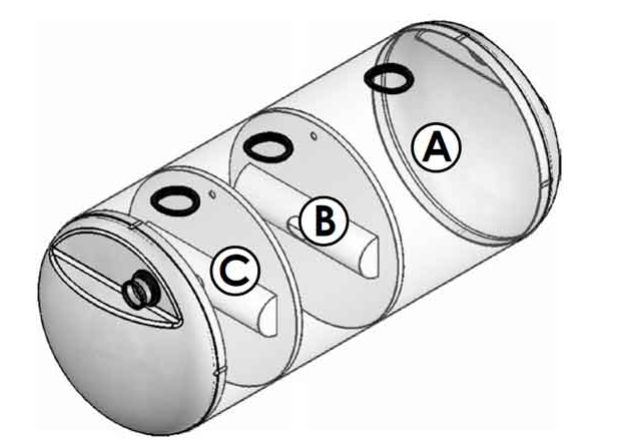

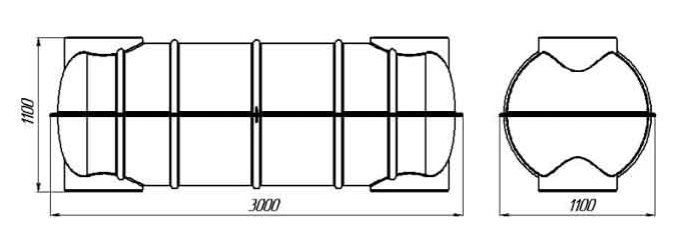

Externally, the body of the Flotenk STA septic tank resembles an ordinary tank, that is, it is a horizontal cylindrical container. Inside container is divided into partitions three sections. Tanks are produced in different volumes and, accordingly, different capacities.

The lineup

Today, 7 variants of the Flotenk STA septic tank are produced.The youngest model in the line is capable of processing 500 liters of contaminated liquid per day, and the total capacity is 1.5 cubic meters. The most productive model in the series can clean 3.3 cubic meters of sewer drains per day, and its total volume is 10,000 liters.

Scheme of operation of the installation

There are three isolated containers inside the Flotenk STA septic tank. When undergoing treatment, wastewater flows sequentially through all three sections of the treatment plant:

- The receiving section of the Flotenk STA unit performs the functions of a sump in which the largest impurities that are not dissolved in water are deposited;

- The sediment at the bottom of the sump undergoes anaerobic (passing without air access) fermentation. Conventionally, this rather complicated process is divided into two stages. At the first stage, the so-called acid fermentation is carried out, in which organic matter decomposes with the formation of fatty acids, alcohols, hydrogen sulfide and carbon dioxide. Next, methane fermentation takes place, during which fatty acids and alcohols decompose to form methane, water and carbon dioxide;

- Having settled, the water through the overflow device enters the second section, where the process is repeated. The effluents are settled again, particles are separated from the water that did not have time to settle in the first section. The sludge is also subjected to anaerobic processing;

- Already clarified water enters the third section, in the process of settling, small particles are released from the effluents, which are in the form of suspensions;

- Then the water is removed from the installation and fed to the filtration sites or filtering wells.

The principle of operation of the Flotenk septic tank

The Flotenk treatment plant is a conventional three-chamber septic tank that purifies wastewater due to the anaerobic decomposition of solid particles (biomass) and gravitational clarification (settling) of the liquid.

Therefore, the working area of Flotenk systems consists of the following zones:

Septic tank for a country house Flotenk

- Primary sedimentation chamber, at the bottom of which the heaviest particles settle.

- Secondary settling chambers, where smaller particles are retained.

- Chamber-clarifier of effluents already practically free of solid particles.

The flow of wastewater between the chambers is implemented by integrating overflow barriers with wide channels into the working area. That is, the drains will enter the second chamber only after the first one is filled. And so on. And from the third chamber, the “clarified” waters flow into the filtration fields, where additional treatment takes place before being discharged into the ground.

Anaerobic decomposition, destroying solid particles in currents, occurs in all three chambers. Moreover, in the first compartment, acidic fermentation occurs, decomposing organic matter into fatty acids, alcohols and hydrogen sulfide. In turn, methane fermentation occurs in the second and third compartments, decomposing fatty acids, alcohols and hydrogen sulfide into hydrogen, carbon dioxide and methane.

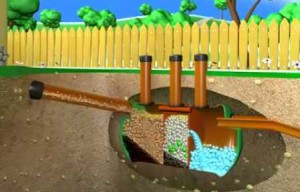

Additional purification in the filtration field occurs due to the passage of wastewater through sand and gravel filters and subsequent contact with bacteria contained in the soil. And with full observance of the construction technology of the treatment plant, almost pure water goes into the ground.

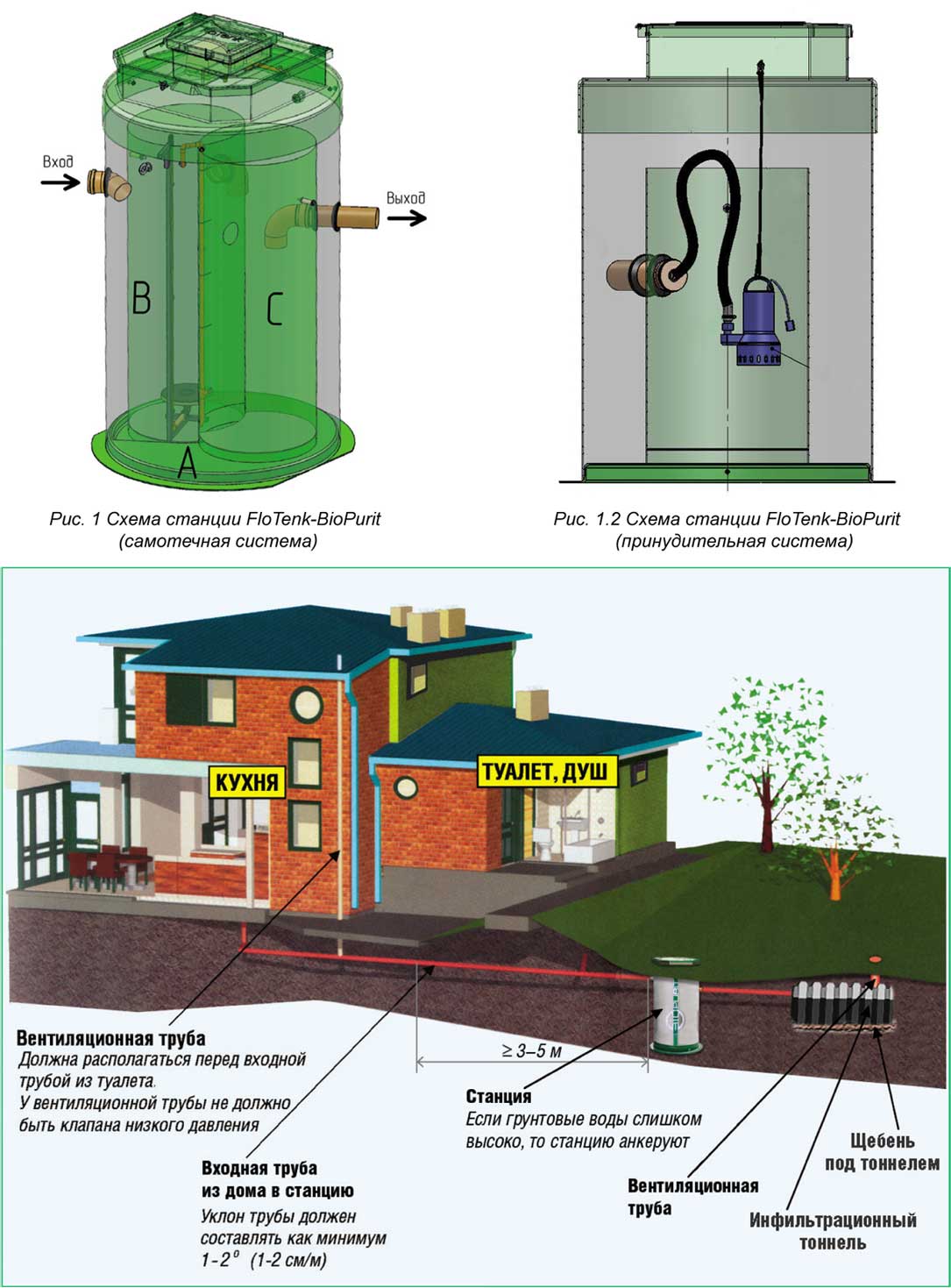

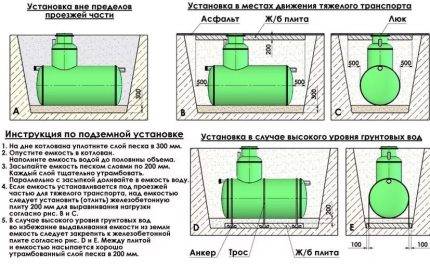

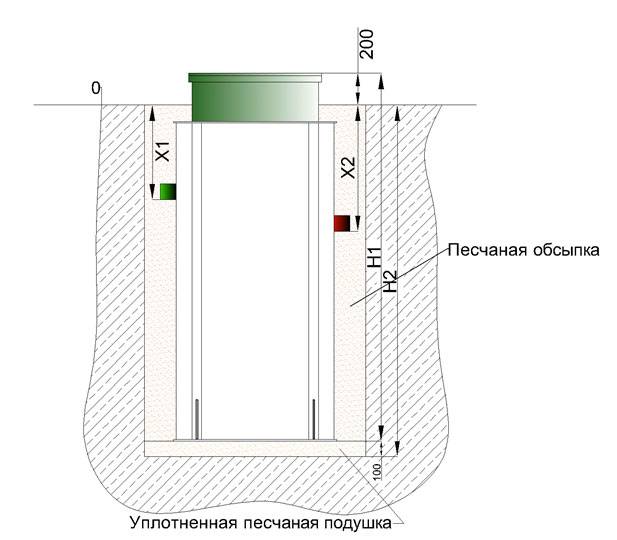

How to install a Flotenk septic tank?

1.Before installing the station, be sure to make sure that you are going to locate it away from the house itself, wells and sources of drinking water.

2. If you have taken into account all the necessary sanitary standards, then the first stage in the installation of the installation will be the preparation of the pit. The excavated hole should correspond to the size of the station. Lay a sand cushion at the bottom of the pit. And also, in order to provide additional strength to the structure, install a concrete tile and fix anchor rings at the base of the slab, which must be threaded into a stainless steel cable. The cable is used to provide additional immobility to the installation.

3. After you have dug a hole, bring all the necessary sewer pipes to it, which must first be cleaned. Be sure to place the pipes at a certain angle so that the wastewater flows off on its own. Pipes should also be insulated. Fix the fan riser.

4. Using diamond drilling, make special holes in the walls of the pit, in which sewage pipes will be laid.

5. Load the station into the pit, install the upper necks. Be sure to fill the system with clean water before laying out the soil again. Install filtration equipment and infiltration tunnel.

There are three types of septic tanks:

- Flotation tank STA;

- Flotation tank BioPurit;

- SeptiX float tank.

Features of the station Flotenk STA

The material from which the unit is made is fiberglass. Since all parts are produced in large quantities in factories, there is no doubt about their quality, tightness and strength. This station has a cylindrical shape, which is divided into a certain number of sections inside. The larger the volume of the installation, the higher its productivity. It is necessary to clean the station up to three times a year.

Model nameVolume, lProductivity, l/dayDiameter, mmLength, mm

| Flotation tank STA 1,5 | 1500 | 500 | 1000 | 2100 |

| Flotation tank STA 2 | 2000 | 700 | 1000 | 2700 |

| Flotation tank STA 3 | 3000 | 1000 | 1200 | 2900 |

| Flotation tank STA 4 | 4000 | 1300 | 1200 | 3800 |

| Flotation tank STA 5 | 5000 | 1700 | 1600 | 2700 |

| Flotation tank STA 6 | 6000 | 2000 | 1600 | 3200 |

| Flotation tank STA 10 | 10000 | 3300 | 1600 | 5200 |

Features of the station Flotenk BioPurit

The station has four sections and needs to be serviced once a year. The model number in the name corresponds to the number of people who can use this device (specific model).

Model nameVolume, lProductivity, l/dayDiameter, mmHeight, mm

| Flotation tank BioPurit 2 | 200 | 0,4 | 1200 | 1750 |

| Flotation tank BioPurit 3 | 330 | 0,7 | 1200 | 2250 |

| Flotation tank BioPurit 5 | 450 | 1,0 | 1200 | 2750 |

| Flotation tank BioPurit 8 | 800 | 1,6 | 1600 | 2750 |

| Flotation tank BioPurit 10 | 900 | 2,0 | 1600 | 2750 |

| BioPurit 12 float tank | 1000 | 2,4 | 1600 | 2250 |

| BioPurit 15 float tank | 1125 | 3 | 1600 | 2250 |

| BioPurit 20 float tank | 1250 | 4 | 2000 | 2250 |

Features of the station Flotenk SeptiX

Service once a year, complete autonomy and efficient filtration.

Model nameVolume, lDiameter, mmLength, mm

| Flotation tank SeptiX 2 | 2000 | 1000 | 2700 |

| Flotation tank SeptiX 3 | 3000 | 1200 | 3900 |

| SeptiX 4 float tank | 4000 | 1200 | 3800 |

| Flotation tank SeptiX 5 | 5000 | 1600 | 2700 |

| Flotation tank SeptiX 6 | 6000 | 1600 | 3200 |

| SeptiX 10 float tank | 10000 | 1600 | 5200 |

| Flotation tank SeptiX 12 | 12000 | 1800 | 5100 |

| Flotation tank SeptiX 15 | 15000 | 1800 | 6200 |

Cost (price) of a septic tank Flotenk

Model namePrice, rub

| Flotation tank STA 1,5 | 27700 |

| Flotation tank STA 2 | 36700 |

| Flotation tank STA 3 | 47700 |

| Flotation tank STA 4 | 76700 |

| Flotation tank STA 5 | 92700 |

| Flotation tank STA 6 | 112700 |

| Flotation tank STA 10 | 137700 |

| Flotation tank BioPurit 2 | 61110 |

| Flotation tank BioPurit 3 | 68310 |

| Flotation tank BioPurit 5 | 84510 |

| Flotation tank BioPurit 8 | 110610 |

| Flotation tank BioPurit 10 | 130410 |

| BioPurit 12 float tank | 138510 |

| BioPurit 15 float tank | 147600 |

| BioPurit 20 float tank | 193610 |

| Flotation tank SeptiX 2 | 40608 |

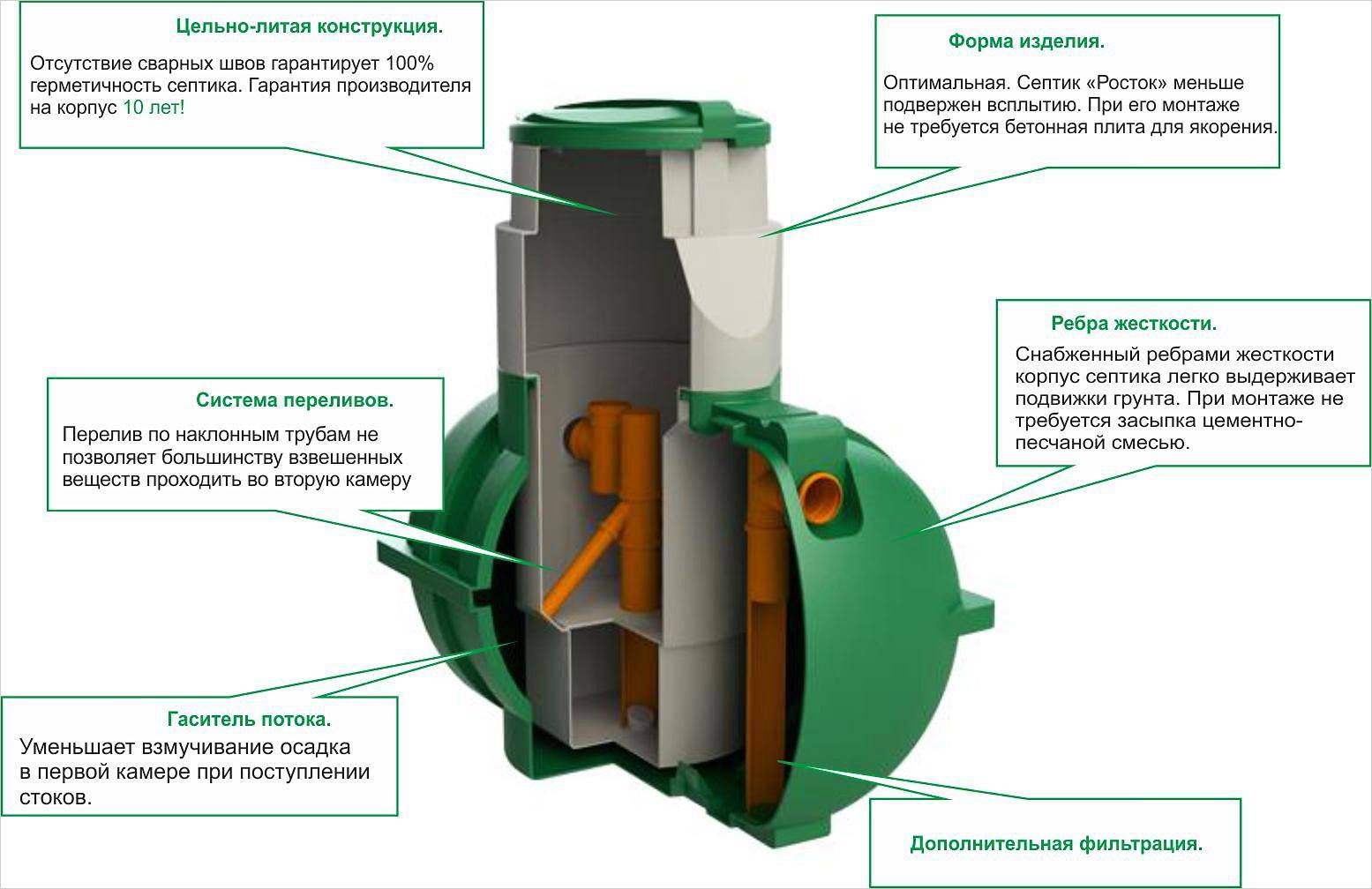

Focusing on the numerous reviews of the owners of the septic tank, a number of advantages of this device can be distinguished.

- Three-stage wastewater treatment process.

- The strength of the material ensures the durability of the use of the station and its reliability.

- Complete energy independence.

- No need to constantly monitor the operation of the septic tank.

- The impossibility of surfacing the device due to the lack of seams on the structure.

- A unique system of water seals, which serves to clean the water drains from the fatty film.

- Pipe connections with rubber sealing cuffs, which provide transportability and convenience in installing the station.

- Minimal risk of device damage.

This septic tank requires minimal maintenance. It is enough to clean the station from silt and waste once or twice a year for its efficient operation.

Model range: technical features

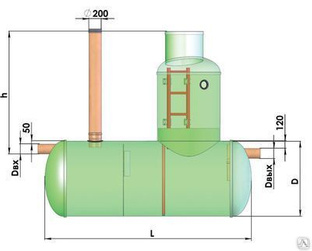

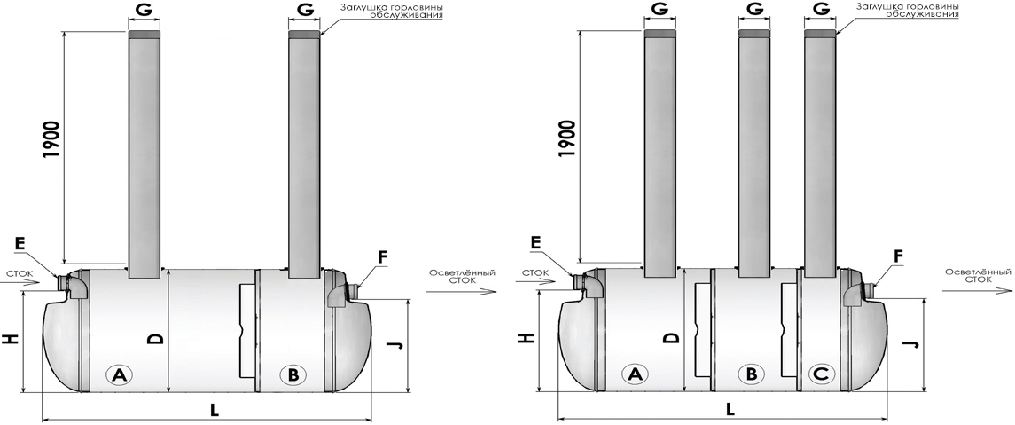

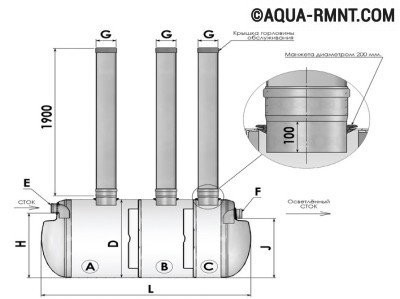

Flotenk septic tanks are two- or three-section (depending on modification) containers with holes in the upper part for the necks and in the end walls for the inlet and outlet pipes.

Enclosures for septic tanks are made of waterproof composite material - polyester fiberglass. It consists of polyester resins and glass-reinforcing components.

Flotenk STA treatment facilities, in addition to the fiberglass tank, are equipped with:

- 160 mm cuffs (for attaching necklines);

- 100 mm cuffs (for mounting nozzles);

- PVC outlet;

- technical passport;

- recommendations on the use of bioenzymes (if the installation technology provides for their use).

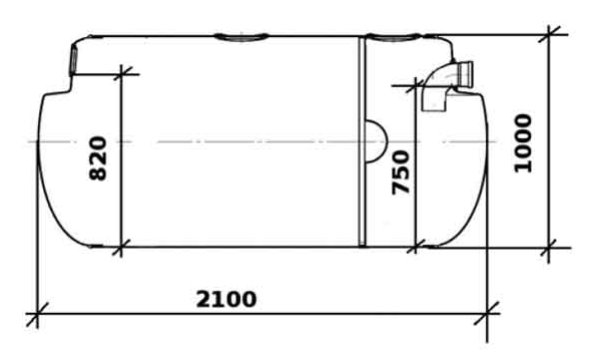

Flotenk STA 1.5 m³

The Flotenk STA - 1.5 septic tank is the smallest unit of the entire model range. It consists of a one-piece two-section body.

In the unit, mechanical and biological wastewater treatment with the participation of anaerobic microorganisms takes place simultaneously. The cleaning process takes place in the following sequence:

Effluent flows by gravity through the inlet pipe into the primary sedimentation tank (section A). At this stage, the liquid settles.Solid components settle to the bottom of the chamber, fatty components collect on the surface in the form of a film (turn into a crust over time), and water remains in the middle part.

Simultaneously with mechanical settling, biological anaerobic processes take place in section A. They are launched as a result of the vital activity of a special type of bacteria, for which the best living conditions are an oxygen-free environment.

As a result of fermentation, biological substances (proteins, carbohydrates, fats) decompose into methane, carbon dioxide and hydrogen.

- From the primary clarifier, the partially purified liquid enters through the blocker holes (located in the middle part of the tank, below the greasy film, but above the solid sediment) to section B. In this chamber, effluent treatment with anaerobic microorganisms and mechanical settling continue.

- From chamber B, effluents are sent through the outlet pipe for post-treatment to the filtration fields.

The manufacturer in the product passport gives a table of the main technical indicators of wastewater quality before and after treatment in Flotenk STA septic tanks.

Table: wastewater characteristics at the outlet of the Flotenk septic tank

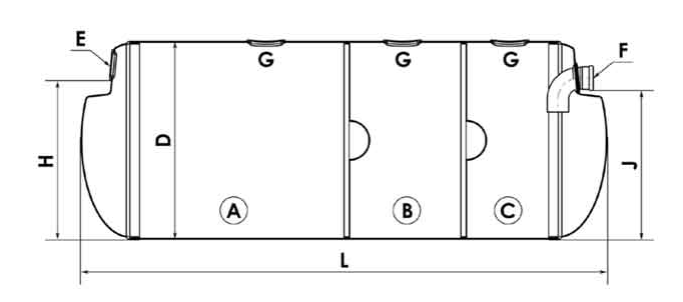

Flotenk STA from 2 m³

Installations with a volume of 2 m³ or more have a fiberglass body, divided into three compartments.

The units are represented by models of various capacities from 2 to 25 m³.

Technical parameters of Flotenk STA septic tanks with a capacity of 2-25

When choosing a device model, the manufacturer recommends being guided by the norms of SNiP 2.04.01-85, which regulate the average water consumption per person.

The cleaning process in the units follows the same principle as in the STA-1.5 model.Chambers A and B serve as primary and secondary clarifiers. However, these septic tanks have a camera C, in which the final clarification of the liquid occurs. Zone B is connected to zone C by a blocker (hydraulic seal). The treated effluents are sent to the infiltration fields through the outlet pipe from zone C.

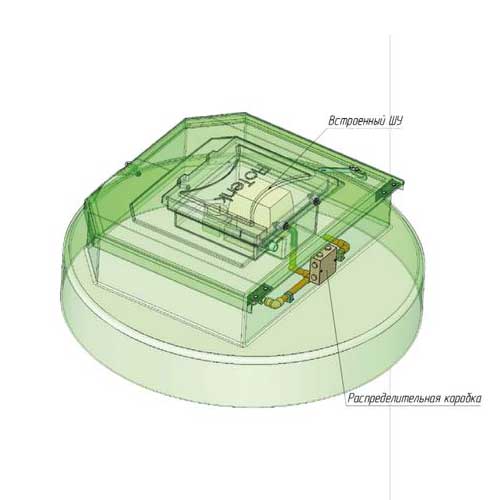

Flotenk STA YES

The new Flotenk STA YES septic tank can be called a modified version of the two-chamber unit described above. The device works on the same principle, also has a fiberglass body. The treatment plant differs only in increased dimensions. According to the manufacturer, a device of this capacity can serve up to 5 people.

What models does the manufacturer offer?

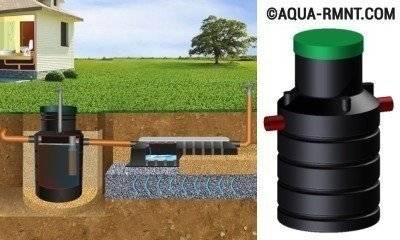

Purification equipment of the Triton line involves biological treatment of wastewater with post-treatment in the ground. Models differ in the amount of wastewater processed, size, installation method.

Triton-Mini

Tank volume - 750 l, wall thickness - 8 mm. A small economical model sump, easy to operate and install, able to withstand severe frosts. Fits to serve the family of 2 people.

Within two days septic tank triton mini able to clean 500 liters of wastewater at maximum load (if 5 people lived in the house). To prevent the container from becoming clogged with solid waste, they must be pumped out once a year.

Triton-Mini is a great option for a septic tank, the installation of which is not so difficult to carry out on your own

Septic tank Triton-Micro

Volume - 450 l, productivity - 150 l / s. The best option for non-permanent residence of an average family (from 1 to 3 people). Small in volume, easy to transport and install. Compact septic tank triton micro can be used autonomously for a guest house or bathhouse.It attracts with an inexpensive cost: a set with an infiltrator, a lid, a neck costs about 12,000 rubles.

Triton-Micro is suitable for installation during the construction of a country house

Septic tank Triton-N

Accumulative capacity from 1000 l to 40000 l. Wall thickness - 14-40 mm. A good choice for owners of a personal plot that has a small area (there is no possibility of equipping a filter site), as well as a high level of groundwater. Wear-resistant and durable septic tank Triton n is sealed, made of polyethylene, able to serve more than 50 years.

Triton-N septic tanks are made to order if the finished model does not fit

Septic tank Triton-T

A three-chamber polyethylene tank, representing a small independent treatment plant. Volume - from 1000 l to 40000 l. Easily serves a large house with 1 to 20 or more people. If the triton septic tank is located below the infiltrator, a drainage pump is installed that pumps out partially purified water from it to the filter field.

Triton-T is a great option for a country house of permanent residence

Septic tank Triton-ED

Volume - 1800-3500 l, productivity - 600-1200 l / s, it can be horizontal and vertical. The design consists of two-section modules in which water is purified from contaminants. Moving from section to section, the water is purified by 65%, then it enters the infiltrator zone, from there into the ground. The dimensions of the absorbent area depend on the volume of the septic tank. The material for the production of the product - extruded polyethylene - is so durable that the Triton ed septic tank is ready to serve for more than 50 years.

When installing a septic tank, do not forget about the access road for the sewage truck

Device and principle of operation

CJSC "Flotenk" supplies to the market of the CIS countries a wide range of systems for the organization of autonomous sewerage with its own treatment plant. The range includes energy-dependent and non-electricity supply equipment for solving various problems of private households.

Externally, the Flotenk septic system is a cylindrical container installed horizontally or vertically. Inside the cavity of the device is divided into two or three sections of different sizes.

To move drains between different sections of the septic tank, special overflow holes are provided in the partitions.

Gallery of images Photo from Wastewater treatment plant for autonomous sewage Housing material Septic tanks FloTenk STA series settling tanks Three-chamber design of settling tanks Ground wastewater treatment system Excavation in clayey soil FloTenk BIO Purit station Manhole of Flotenk sewage station

The first compartment is the largest and acts as a sump. All waste water coming from the house is first collected here.

Effluent is gradually accumulated and settled. The solid component of wastewater, as well as contents that cannot be processed by microorganisms, accumulate at the bottom.

A fatty film is formed on the surface of those wastes that are lighter than water. In the process of accumulation of primary effluents, the volume of the contents of the sump increases, and the liquid level rises. Over time, it reaches the overflow hole, through which the liquid partially purified during settling enters the second compartment of the septic tank.

The diagram shows the device of the Flotenk septic tank, which consists of three chambers of different sizes. In the first one, sewage is settled, and in the other two, they are actively cleaned (+)

Here, microorganisms continue to work on the treatment of wastewater already freed from solid fractions. As the volume of drains in the second section of the septic tank increases, the liquid level rises again and reaches the overflow hole leading to the third section.

Here, the waste water is finally clarified to a degree considered acceptable to transfer the resulting liquid into the surrounding soil. To remove liquid treated effluents from a septic tank, it is necessary to create a special filtration field in the thickness of the soil.

This diagram allows you to get an idea of the principles of operation of the Flotenk brand septic tank. Effluent from domestic premises enters the device, undergoes biological treatment and is discharged to the filtration field (+)

To do this, at a distance from the septic tank, a series of trenches or a pit are made, at the bottom of which a sand and gravel filter is arranged. It includes layers of sand, crushed stone and gravel. First, a layer of filtering gravel-sand backfill is laid in the trenches, on top of which a system of perforated pipes - drains - is placed.

The drainage sewer system is wrapped with geotextile and covered. Each branch of the filtration field is equipped with its own ventilation riser to remove the methane formed during the processing of wastewater.

Post-treatment using such a filter will make the resulting effluents completely safe for the environment. Moreover, the microorganisms contained in the soil aeration zone also continue the process of processing the remains of substances that came along with wastewater.

The field of filtration for soil post-treatment can only be arranged in permeable soils: sand, gavial, pebble, crushed stone deposits - in rocks that can absorb and pass processed effluents. In addition, between the groundwater level at the site construction and bottom drainage system must be at least a meter

From above, each section of the Flotenk septic tank has an operating hole that provides constant access to the device. This provides conditions for the successful vital activity of aerobic bacteria, and also allows you to remove from the tank the gases obtained during the biological processing of wastewater.

Of course, solid waste will gradually accumulate in the sump. A significant part of them will turn into neutral sludge. The more waste, the smaller the capacity of the septic tank, i.e. its performance. The first compartment of the septic tank should be periodically cleaned with a suction pump.

Overview of the range

Septic tanks of the Flotenk series are produced in various modifications. Each owner of suburban real estate can easily choose a device suitable for his conditions. On sale you can find the following models of septic tanks:

- Flotenk STA 1.5 - the device is designed to serve a family of three. The septic tank is capable of processing up to 0.5 cubic meters of wastewater per day. The cost of such a product is about 30 thousand rubles;

- Flotenk STA 2 - the device is designed to serve a family of four. The septic tank is capable of processing up to 0.6 cubic meters of wastewater per day. The cost of such a product is about 38 thousand rubles;

- Flotenk STA 3 - the device is designed to serve a family of six people. The septic tank is capable of processing up to 1.0 cubic meters of wastewater per day. The cost of such a product is about 49 thousand rubles;

- Flotenk STA 4 - the device is designed to serve a house with eight permanent residents. The septic tank is capable of processing up to 1.4 cubic meters of wastewater per day. The cost of such a product is about 76 thousand rubles;

- Flotenk STA 5 - the device is designed to serve a house with ten permanent residents. It is capable of processing up to 1.6 cubic meters of wastewater per day. The cost of such a product is about 90 thousand rubles;

Exactly these models are most popular among country house owners. But besides this, the company also produces more powerful Flotenk septic tanks. So you can buy a Flotenk STA 10 device, such a septic tank is able to process up to 3.2 cubic meters of sewage per day. This device can serve several houses at once.

How to install a Flotenk septic tank?

1.Before installing the station, be sure to make sure that you are going to locate it away from the house itself, wells and sources of drinking water.

2. If you have taken into account all the necessary sanitary standards, then the first stage in the installation of the installation will be the preparation of the pit. The excavated hole should correspond to the size of the station. Lay a sand cushion at the bottom of the pit. And also, in order to provide additional strength to the structure, install a concrete tile and fix anchor rings at the base of the slab, which must be threaded into a stainless steel cable. The cable is used to provide additional immobility to the installation.

3. After you have dug a hole, bring all the necessary sewer pipes to it, which must first be cleaned. Be sure to place the pipes at a certain angle so that the wastewater flows off on its own. Pipes should also be insulated. Fix the fan riser.

4. Using diamond drilling, make special holes in the walls of the pit, in which sewage pipes will be laid.

5. Load the station into the pit, install the upper necks. Be sure to fill the system with clean water before laying out the soil again. Install filtration equipment and infiltration tunnel.

There are three types of septic tanks:

- Flotation tank STA;

- Flotation tank BioPurit;

- SeptiX float tank.

Features of the station Flotenk STA

The material from which the unit is made is fiberglass. Since all parts are produced in large quantities in factories, there is no doubt about their quality, tightness and strength. This station has a cylindrical shape, which is divided into a certain number of sections inside. The larger the volume of the installation, the higher its productivity. It is necessary to clean the station up to three times a year.

| Flotation tank STA 1,5 | 1500 | 500 | 1000 | 2100 |

| Flotation tank STA 2 | 2000 | 700 | 1000 | 2700 |

| Flotation tank STA 3 | 3000 | 1000 | 1200 | 2900 |

| Flotation tank STA 4 | 4000 | 1300 | 1200 | 3800 |

| Flotation tank STA 5 | 5000 | 1700 | 1600 | 2700 |

| Flotation tank STA 6 | 6000 | 2000 | 1600 | 3200 |

| Flotation tank STA 10 | 10000 | 3300 | 1600 | 5200 |

How to make a cesspool with your own hands, read here

Read about how to connect sewer plastic pipes in the article: how to connect sewer plastic pipes

Features of the station Flotenk BioPurit

The station has four sections and needs to be serviced once a year. The model number in the name corresponds to the number of people who can use this device (specific model).

| Flotation tank BioPurit 2 | 200 | 0,4 | 1200 | 1750 |

| Flotation tank BioPurit 3 | 330 | 0,7 | 1200 | 2250 |

| Flotation tank BioPurit 5 | 450 | 1,0 | 1200 | 2750 |

| Flotation tank BioPurit 8 | 800 | 1,6 | 1600 | 2750 |

| Flotation tank BioPurit 10 | 900 | 2,0 | 1600 | 2750 |

| BioPurit 12 float tank | 1000 | 2,4 | 1600 | 2250 |

| BioPurit 15 float tank | 1125 | 3 | 1600 | 2250 |

| BioPurit 20 float tank | 1250 | 4 | 2000 | 2250 |

Conclusion

If you decide to equip your suburban area with an autonomous sewage system, then you cannot do without a septic tank.This device is able to clean drains and make them safe for the environment. On sale you can find many models of septic tanks, one of the most popular are Flotenk products. They do an excellent job of treating wastewater, are relatively inexpensive and easy to install and operate. And thanks to the high-strength material that is used in their manufacture, Flotenok septic tanks will operate smoothly for several decades.