- Features of Eurobion septic tanks

- The difference between the Bioxi septic tank and other models

- A short overview of popular models

- BioDeca -3 S-600

- BioDeca -5 P-1300

- BioDeca -8 P-1800

- Septic tank maintenance

- Varieties according to the principle of work

- storage tanks

- Settling tanks

- Deep biorefining

- Advantages and disadvantages of the treatment system

- How can a country septic tank survive the winter

- Features of the cleaning devices

- Septic tank

- Uponor bio septic tank

- The principle of operation of the treatment plant

- Advantages

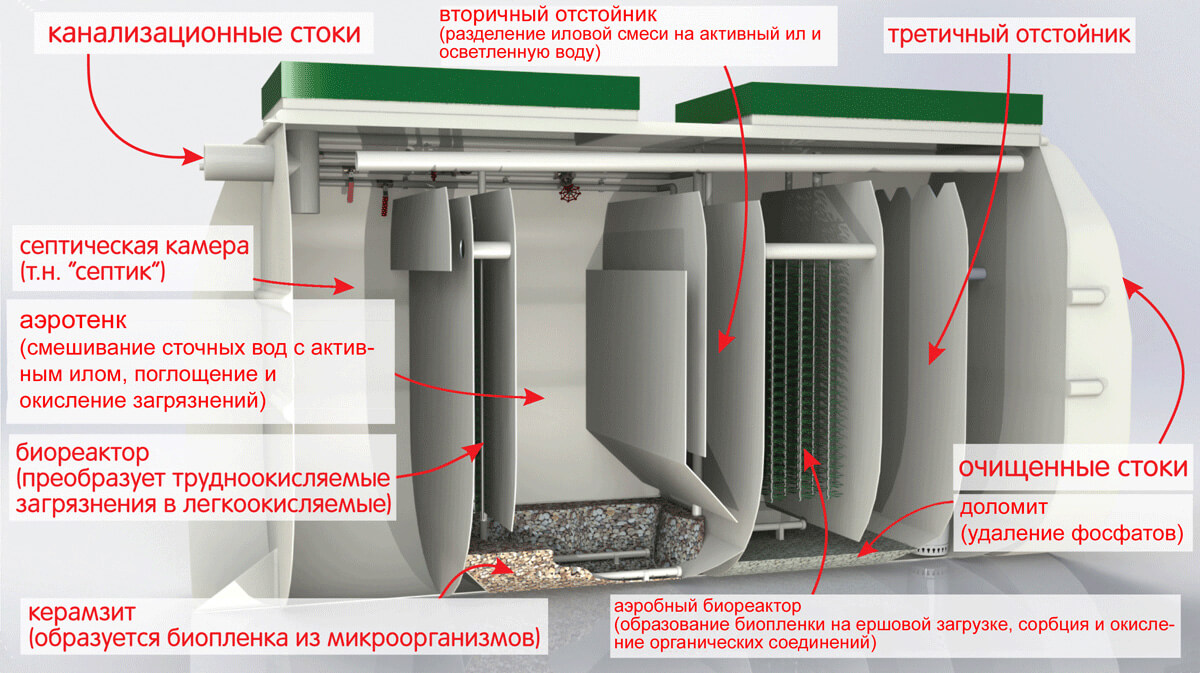

- The device of the bio-cleaning station.

- First manufacturer:

- Second manufacturer:

- Third manufacturer:

- Fourth manufacturer:

- Models of septic tanks "Bioxi" and average prices for them

Features of Eurobion septic tanks

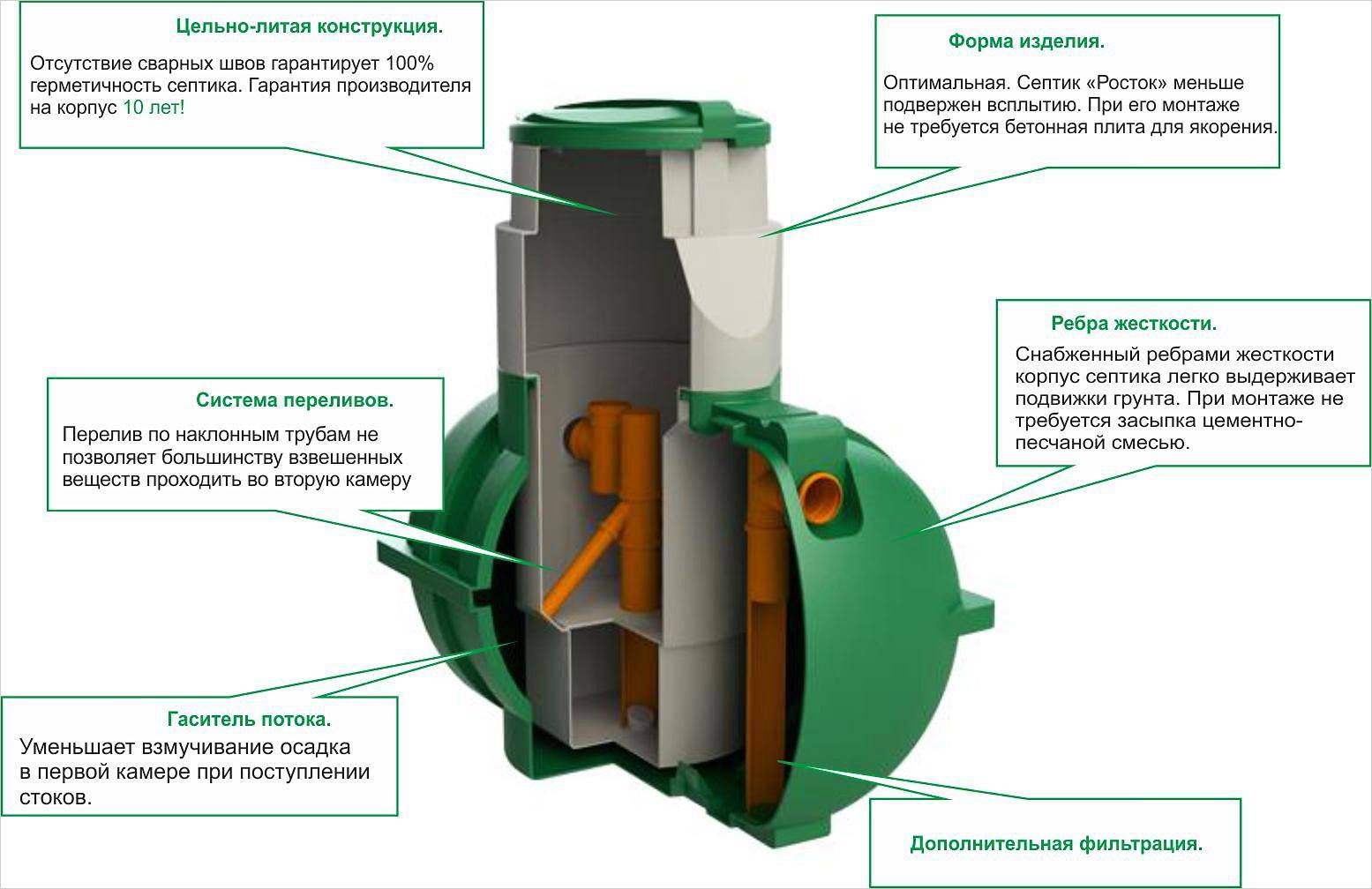

The septic tank itself is a plastic vertical tank, the size of which depends on what goals the customer himself pursues. For example, if he plans to equip a summer house, then a model with a working capacity of 0.8 m3 per day is suitable, but for a large country house this will not be enough and it is better to take care of buying a model that will withstand 1.6 m3 of drains. One of the features of a septic tank is that all modifications are designed for a certain volume of one-time wastewater intake. For example, the last of the above models can handle 630 liters of liquid at a time.

As for the composition of the septic tank itself, it consists of three separate chambers connected and interacting with each other through pipe systems and overflow holes. The chambers are in such a position that the appearance of sediment is almost completely eliminated, since it is in constant motion, moving through the chambers, which reduces its amount in the system to a minimum. At the same time, in its work, Eurobion uses both a mechanical cleaning method, both auxiliary and biological, which consists in cleaning waste using aerobic bacteria.

The difference between the Bioxi septic tank and other models

Comparing Bioxi to cesspool systems is inherently unethical. The second type of waste communications goes into the distant past, and can no longer compete with septic tanks. However, along with modern wastewater filtration systems such as Unilos Astra septic tanks with directional treatment fields, Bioxi has a clear superiority potential. Using the principle of bio-purification in its mechanisms, it allows not only to accumulate waste material, but also to actively clean it from various levels of pollution using biological processes. Therefore, it surpasses most domestic manufacturers.

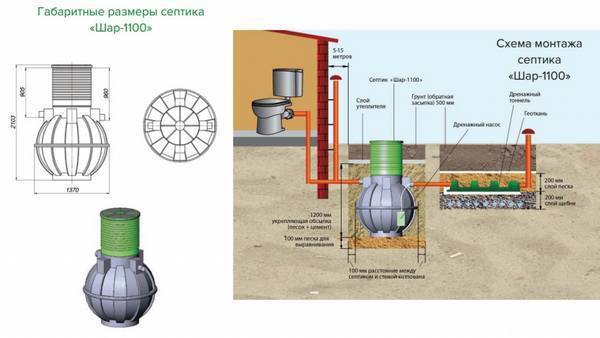

Bioxi septic tank, how to install

Bioxi septic tank, how to install

The mechanism of such filtration is based on the stages of activation of natural bacteria. At the same time, most people consider this process difficult and difficult to achieve. However, this is not the case and its schematic representation is easy to understand:

- At the first stages, the sorption mechanism of purification operates. Its essence lies in the fact that all heavy sedimentary materials accumulate on the bottom surface of the tank. Moreover, this process does not take more than 30 minutes.

- Then the decarbonization of materials comes into play. This is the active reproduction of the beneficial bacterial sphere of purification under the influence of oxidative biological processes. The process time is up to 60 minutes.

- The penultimate stage involves the direct absorption of the elements of pollution by a mass of necessary bacteria. This period takes about a day.

- At the final levels of filtration, natural oxidation mechanisms operate. They are needed to eliminate most of the resulting sludge masses. The last stage is the longest and takes approximately 3 days.

In total, we get a complete cleaning cycle, which fits into four days, after which a completely clarified liquid is formed, ready for removal.

A short overview of popular models

By purpose and principle of operation all septic tanks are the same, they differ in performance, dimensions and depth of sewage inlet.

BioDeca -3 S-600

This minimum capacity system assumes the presence of up to 3 people in the house. The indicators of household waste and sewerage (bathroom) are taken into account. The system will work effectively with the simultaneous use of sewerage by all three family members.

The dimensions of the installation are small - up to 2 meters high, which allows you to freely dig it into the ground. The entrance of sewer pipes to the structure is at a depth of 0.6 meters, therefore, in order to install the system in regions where cold weather prevails, additional insulation of the sewer pipe in the ground is necessary.

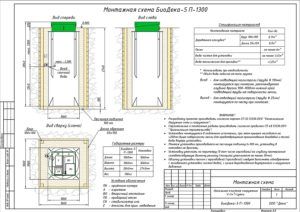

BioDeca -5 P-1300

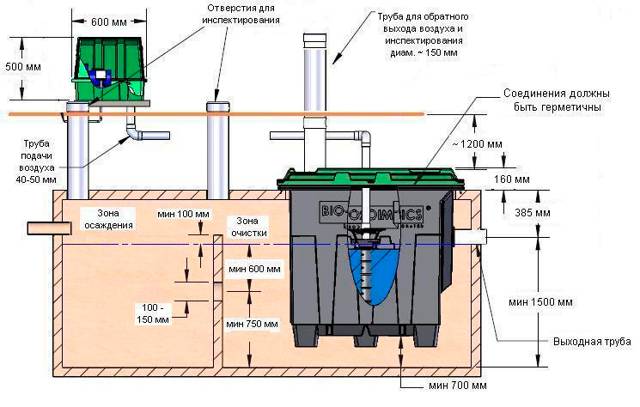

Mounting diagram BioDeca-5 P-1300

Mounting diagram BioDeca-5 P-1300

The system is designed for residential buildings with 5 people. The size of the station in height significantly exceeds the size of the previous instance.The plant has excellent performance. The depth to which the sewer pipe must be laid is 1.2 meters. The biological treatment system is suitable for most regions where the depth of soil freezing is small. Communications do not require additional insulation.

The letter C or P indicates the presence of gravity or the possibility of connecting a forced sewage disposal during the installation of the station. Models with forced drainage are placed in places with a close location of groundwater. The price of the system will be an order of magnitude higher than the sample for 3 people.

BioDeca -8 P-1800

Mounting diagram BioDeca -8 P-1800

The cleaning system has a high productivity, designed for the simultaneous use of sewerage by 8 residents. The installation proved to be excellent when working on two residential buildings at once. The biological treatment system has large dimensions with a sewer pipe entry depth of 1.8 meters, which makes it difficult to carry out earthworks. Widely used in northern regions with cold climates. The system is expensive.

There are units designed to serve up to 20 people. They are suitable for sewerage and household drains of public buildings, cafeterias, gas stations, private hotels.

Septic tank maintenance

Maintenance work of the station requires the following activities:

-

Aeration fields are transferred after 5 years of operation.

-

Taking into account the frequency of use of sewerage, the maximum duration of the aeration field is 15 years.

-

Silt sediment is removed from the bottom once a year. With additional biologics devices, the service life can be extended by several years and the presence of odor can be reduced.

-

When choosing one of the Uponor models, it is worth considering that a two-chamber installation can accommodate no more than 0.5 cubic meters. m of liquid per day. The Uponor Sako septic tank is designed for a daily volume of more than 1.5 cubic meters. l.

Varieties according to the principle of work

For private households, the following types of septic tanks can be used:

- storage tanks;

- settling tanks with soil filtration;

- installations with forced aeration, providing deep biological treatment.

Consider the features of each option

storage tanks

This is the simplest type of equipment, it is a volumetric sealed tank used to collect and store wastewater. It works on the same principle as a cesspool, the difference is the environmental safety of the drive. After all, the drive, unlike cesspools, excludes the ingress of contaminated liquid into the ground.

As the storage tank fills up, it will need to be cleaned. This work is carried out using sewage machines. The contents of the container are pumped out by the pump into the tank installed on the vehicle and transported for disposal in the prescribed manner.

This option for organizing the disposal of wastewater can be recommended for summer cottages, provided that the volume of wastewater is small. Otherwise, you will need to clean the drive frequently, which will incur additional costs.

Settling tanks

This option is universal, it is recommended for a small summer cottage or for a spacious country cottage. The difference in this case will be only in the volume of sedimentation tanks and the area of devices for post-treatment.The greater the daily volume of effluents, the more capacious the sedimentation tanks should be. To ensure the best quality of cleaning, multi-stage settling is organized.

The treatment plant works like this:

the first section of the installation, as a rule, is made the most voluminous. Here there is an accumulation of effluents and their primary settling;

- water enters the second section, which has already been freed from most of the large inclusions, here the liquid settles additionally, already smaller undissolved particles settle to the bottom, which did not have time to precipitate in the first section;

- then water enters the compartment with a biofilter, if it is available in the design of the treatment plant, and then it is fed to the soil filtration plant, where it is finally cleaned;

sediment at the bottom of the settling tanks is gradually compacted. The bacteria contained in the effluents initiate methane fermentation processes, due to which the sludge partially decomposes and decreases in volume. Due to this, it is not necessary to pump out the sediment frequently, it is enough to perform this operation annually.

Pros of this option:

- simplicity of the device, reliability;

- sufficiently high efficiency;

- inexpensive and easy maintenance.

Minuses:

- Substantial volume of containers. In order for the water to settle well, it is necessary that the water has been in the sump for at least 72 hours. Therefore, with a large flow of water, it is necessary to use large-capacity tanks.

- The need to build devices for soil filtration. This increases construction costs. It is especially difficult to have if there is clay or a high GWL on the site.

Deep biorefining

A modern septic tank is no longer just a sump, but a station that provides complete cleaning in the shortest possible time. Due to this, the plants are compact in size, and there is no need to build devices for soil aftertreatment. Principle of operation:

- the first stage of processing is to settling the liquid;

- but in the second section, additional equipment is installed - an aerator. Through the openings of this device, air is supplied to the medium to be cleaned, which ensures the creation of conditions for the flow of biological aerobic processes;

- then the liquid settles again and is sent to the outlet.

Pros of the option:

- high quality wastewater treatment;

- compactness, choosing a place to install a biotreatment station on a site near a country house is much easier than allocating space for installing sedimentation tanks and fields for filtration;

- the complete absence of odors, so residents and guests of the country house will not feel discomfort.

Minuses:

- high installation cost;

- the need to connect electricity.

Advantages and disadvantages of the treatment system

At there are septic tanks in Tver advantages and disadvantages, like any technical device. However, the number of pluses significantly outweighs, due to which these treatment facilities are widely and successfully used.

Design advantages:

- Complete water purification takes place in one tank - no additional additional filtration devices are required.

- A septic tank with a properly selected capacity cleans up 98% of wastewater - such water can be discharged onto the terrain, into a reservoir, and used for household needs.

- The body of the septic tank is made of high-strength polymer material that is not subject to corrosion and erosion, which ensures a long service life of the device.

- There is no need to constantly use bioactivators - the bacteria in the septic tank are restored on their own and actively multiply.

- Purification of toxic phosphates and nitrogen compounds is provided.

- Solid sludge is pumped out once a year or less.

- The Tver septic tank can be used even with intermittent operation - thanks to the combined cleaning method, the intermittent cycle does not create a large load on activated sludge and, in the absence of power supply, the septic tank goes into sleep mode.

- In a septic tank, liquid does not move through pipes or hoses, so there is no danger of clogging the system.

- The design calmly withstands salvo discharges of wastewater without loss of treatment quality.

- Large inspection hatches make it easy to carry out routine inspections of the system, maintenance and pumping of solid sludge.

- The compressor is located indoors - it is convenient for maintenance and significantly extends the life of the unit.

- Compact overall dimensions and light weight allow you to install the Tver septic tank on your own, without the involvement of special equipment.

Flaws:

- Energy dependence of the system;

- The high price of the complex.

However, the rather high cost of a septic tank pays off already during installation - there is no need to build absorption wells or spend money on arranging a filtration field.

Installation of the Tver treatment station is often performed on its own. This allows significant savings. The cost of such a design does not exceed the amount that would have to be spent on the purchase and installation of a treatment system based on a simple septic tank.

How can a country septic tank survive the winter

Many future buyers of the Astra septic tank are worried that during frosts the station will freeze and stop working.This will not happen if the sewer is used regularly. Moreover, the number of drains must correspond to the nominal number of residents for which the septic tank is designed.

Therefore, it is important to clearly determine before buying how many people will permanently live in the country house / country house. If you buy a model with a margin, then nothing good will come of this venture.

But the specialists of the company selling the equipment will definitely consult about this and warn about the consequences.

Be sure to clean the septic tank before preparing the seasonal dacha for winter, following the manufacturer's recommendations

Be sure to clean the septic tank before preparing the seasonal dacha for winter, following the manufacturer's recommendations

In order for Unilos Astra to safely survive the winter, you need:

- preserve the septic tank;

- insulate by constructing a box over the protruding part.

Conservation is carried out only in the case when the cottage is used only during the season, and with the onset of cold weather, no one will live there.

If the sewer is used in winter, then nothing needs to be preserved and insulated - the station warms itself by receiving regular drains and doing its job

For conservation, it is necessary to perform a full-fledged service of the equipment, cleaning all components and pumping out part of the activated sludge. Then immerse 5-liter eggplants half-filled with sand into each of the compartments. This is necessary so that when freezing, the water in the container does not crush the walls.

The box above the lid of the septic tank will help him safely survive the winter. After all, it will not be used - bacteria will not need oxygen

At the station disconnected from the electricity, it is necessary to remove the compressor and place it in the room. The part of the septic tank protruding above the soil level is insulated from above. To do this, a box is constructed from foam or other insulation on top of the container.

A plastic film can be covered over the box to prevent the destruction of the material under the influence of negative environmental factors.

With proper installation and compliance with the maintenance standards of the septic tank in winter, there will be no problems with its operation in frost.

Features of the cleaning devices

uponor septic tanks consist of 3 round containers made of durable polyethylene. They are interconnected by overflow pipes made of the same material. In addition to them, a special well is installed at the outlet of the last chamber, which distributes water to the drainage system.

These devices are divided into two types:

- Septic uponor Sako.

- Uponor Bio.

Septic tank

Product called Sako

A product called Sako conducts only mechanical treatment of wastewater due to its slow passage through series-connected chambers. In this case, the sediment remains at the bottom, the water is gradually clarified, and the main cleaning takes place in the soil using an extensive drainage system.

This type of device is the simplest and most non-volatile. During installation, the unit should be positioned in such a way that free access for sewage equipment is provided for pumping out sludge.

Despite its simplicity, the uponor Sako septic tank is distinguished by its high quality of work and wastewater treatment. It is safe and reliable. The main application of this product is the removal and treatment of domestic water and waste.

Uponor bio septic tank

The next type of installation is uponor bio septic tank. It differs from the previous product in the cleaning method - it combines biological and chemical methods. In appearance, it is also different, since it has two working chambers.

The sequence of wastewater treatment in it is as follows:

- Wastewater flows through the sewer pipe from the house to the first tank, where large fractions of waste settle to the bottom.

- Then the effluents pass into the second tank at a minimum speed - so that as much sediment as possible in the form of sludge is deposited in the settling tanks. Here bacteria break down substances of organic origin into simple elements - silt and water. To create conditions for the rapid reproduction of microorganisms, air (aeration) is supplied to the tank, and they are carefully transferred along with the sludge by airlifts.

- In the last container, in order to eliminate the unpleasant odor as much as possible, chemicals are automatically supplied. They are able to remove phosphorus, which is the basis of unpleasant odors.

- Then the purified water is sent to the distribution tank, and from it through pipes to the drainage system. From here, clean water flows into the soil.

Uponor septic tank range is represented by two cleaning systems

The septic tank with biological and chemical treatment is fully automated. Its operation is controlled by a computer using various sensors. A small, low-power compressor supplies air. This product is optimally suited for permanent residences and cottages. Among the operating modes, a waiting cycle is provided, which is convenient in buildings for temporary residence of people.

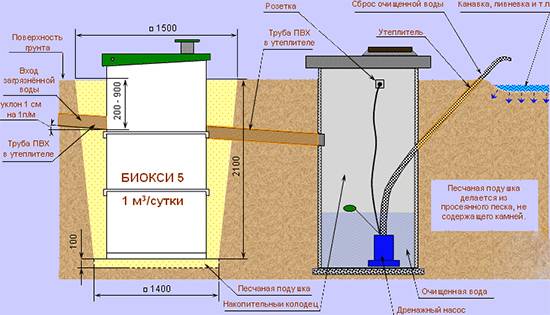

When installing a biological device, it is necessary to provide a place, since its dimensions increase in proportion to the increase in the volume of effluents:

| model type | Qty drains per day (liters) | Dimensions height*length (meters) |

| Uponor Bio 5 | 850 | 2 * 2,4 |

| Uponor Bio 10 | 1500 | 1,65 * 7,1 |

| Uponor Bio 15 | 2200 | 1,65 * 9 |

The figure indicating the model of the septic tank shows how many people living in the house it is designed for. It can be seen that the length of the device increases significantly with an increase in the volume of wastewater.

Maintenance of this product is simple - once a year it is necessary to pump out the waste sludge and waste.

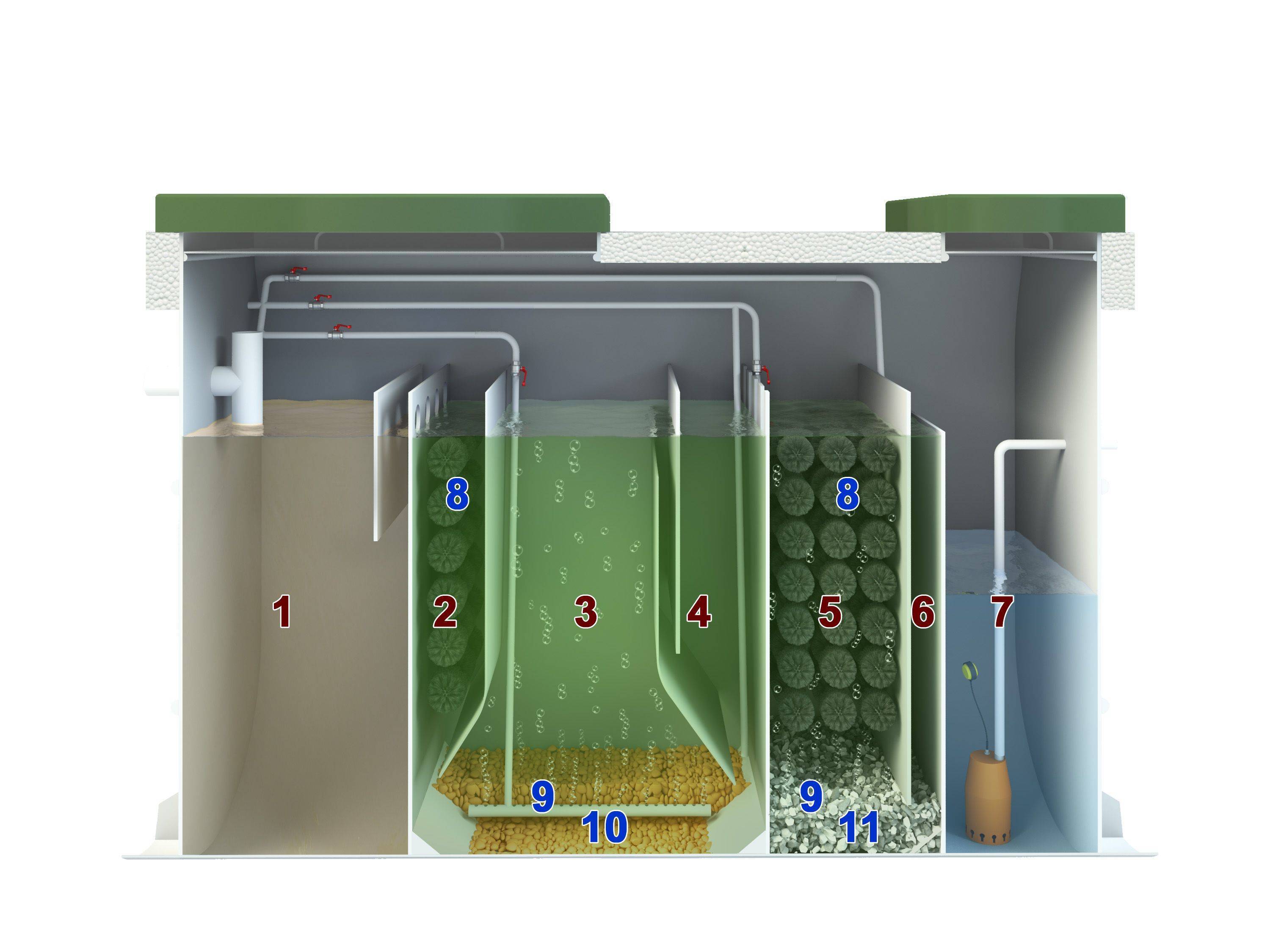

The principle of operation of the treatment plant

The first chamber acts as a receiving compartment. All the dirty sewage coming from the house flows into it through PVC pipes.

All solid fractions settle to the bottom of the section and accumulate there in the form of sediment, while light fat molecules float up and form a fatty film on the surface. Drains that have undergone partial cleaning pass into the second compartment through a small vertical opening 10 cm wide.

When arranging the treatment system, the pipes are laid with a slight slope towards the treatment plant, and from it towards the soil post-treatment system. Such an installation provides a continuous supply of water to the tank from the house sewer.

In the second section, only the primary treatment of sewage flows takes place. In this compartment, anaerobic bacteria living in an airless space come into play, which, in the course of their vital activity, partially clarify the incoming wastewater.

To activate the process of aerobic purification, special biological preparations with microorganisms are added to the third chamber. After clarification, water enters the third compartment through special 10 mm slotted partitions located at a distance of 80 cm from the bottom of the chamber.

The four chambers of the septic tank are completely autonomous and operate independently of each other, the liquid, flowing from one edema to another, is subjected to a higher level of purification

In the third chamber there is a removable biological filter, which is a plastic collector of a lattice design with a filter load. The grate ensures that only purified water enters the filter, retaining the remaining particles of activated sludge formed as a result of the work of aerobes.

With the help of a special filler of microorganisms, the water undergoes deep biological treatment and, completely purified, rushes to the next compartment.

The filtration process is completed in the fourth chamber, where the water is completely clarified and sent to the filter well, filtration field or trench. Purified water moves by gravity. If the filter system is located at a higher level, and water cannot enter there naturally, the level of discharge can be raised by equipping the compartment with any drain pump with a float.

Advantages

The Bioxi septic tank, of any modification, has a fairly large number of advantages that distinguish it from other similar installations. Of the main advantages can be identified:

- High degree of purification - up to 98%;

- Lack of smell;

- No need to turn to vacuum trucks, the station pumps out its own pumps;

- Full tightness;

- Compactness;

- Strength;

- The case and internal knots are not subject to corrosion;

- Environmental Safety;

- Service life of 50 years or more;

- Easy installation;

- No need to insulate;

- Low noise level during operation.

You may be interested to know about other septic tanks:

Topas 5 Triton Tank 3

Unilos Bionic Eurolos

Despite the large number of advantages of the Bioksi septic tank, as well as positive reviews, treat the choice of model carefully and scrupulously. When choosing, consider the volume of stocks, the number of users, etc.

Video: BIOXY Service

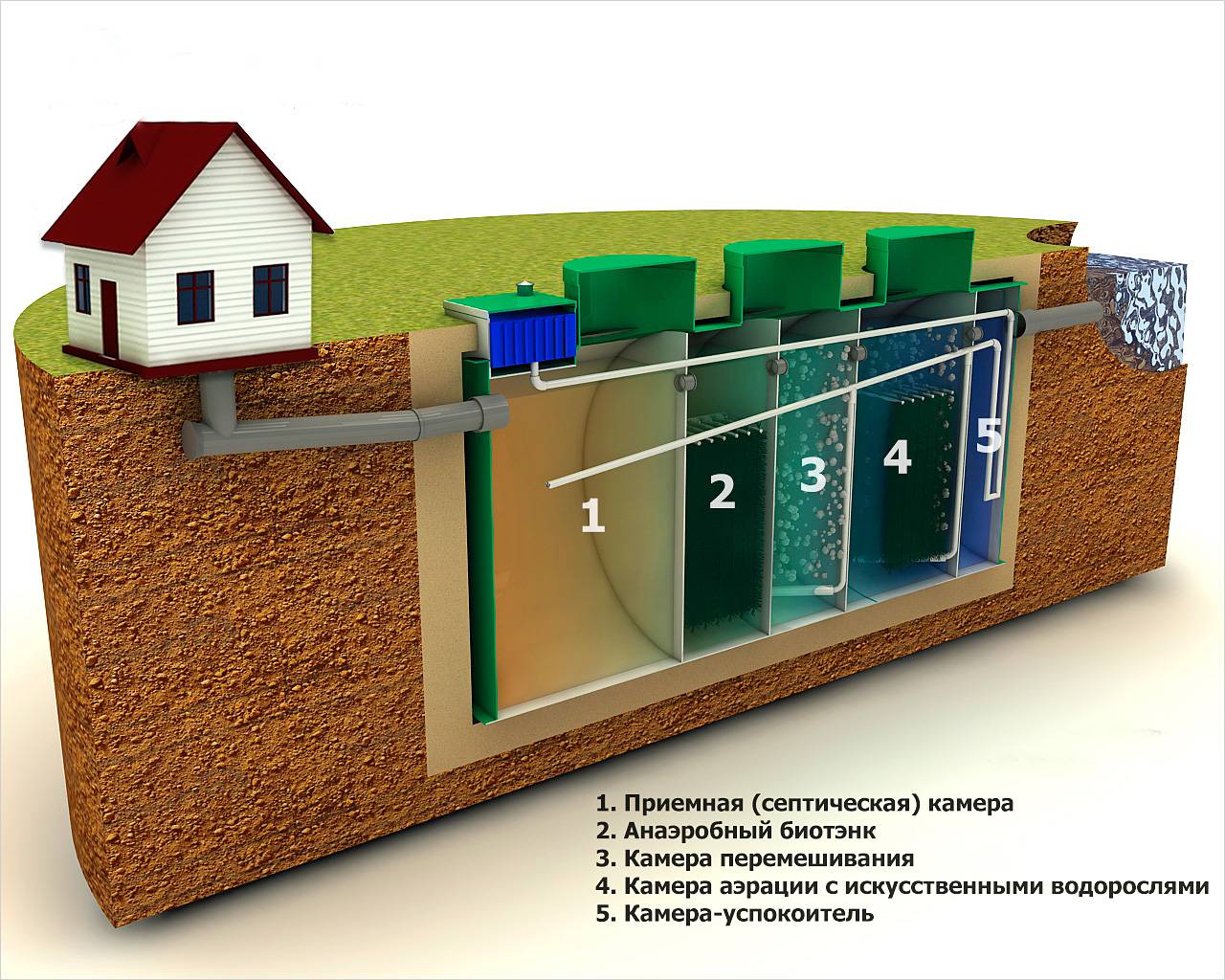

The device of the bio-cleaning station.

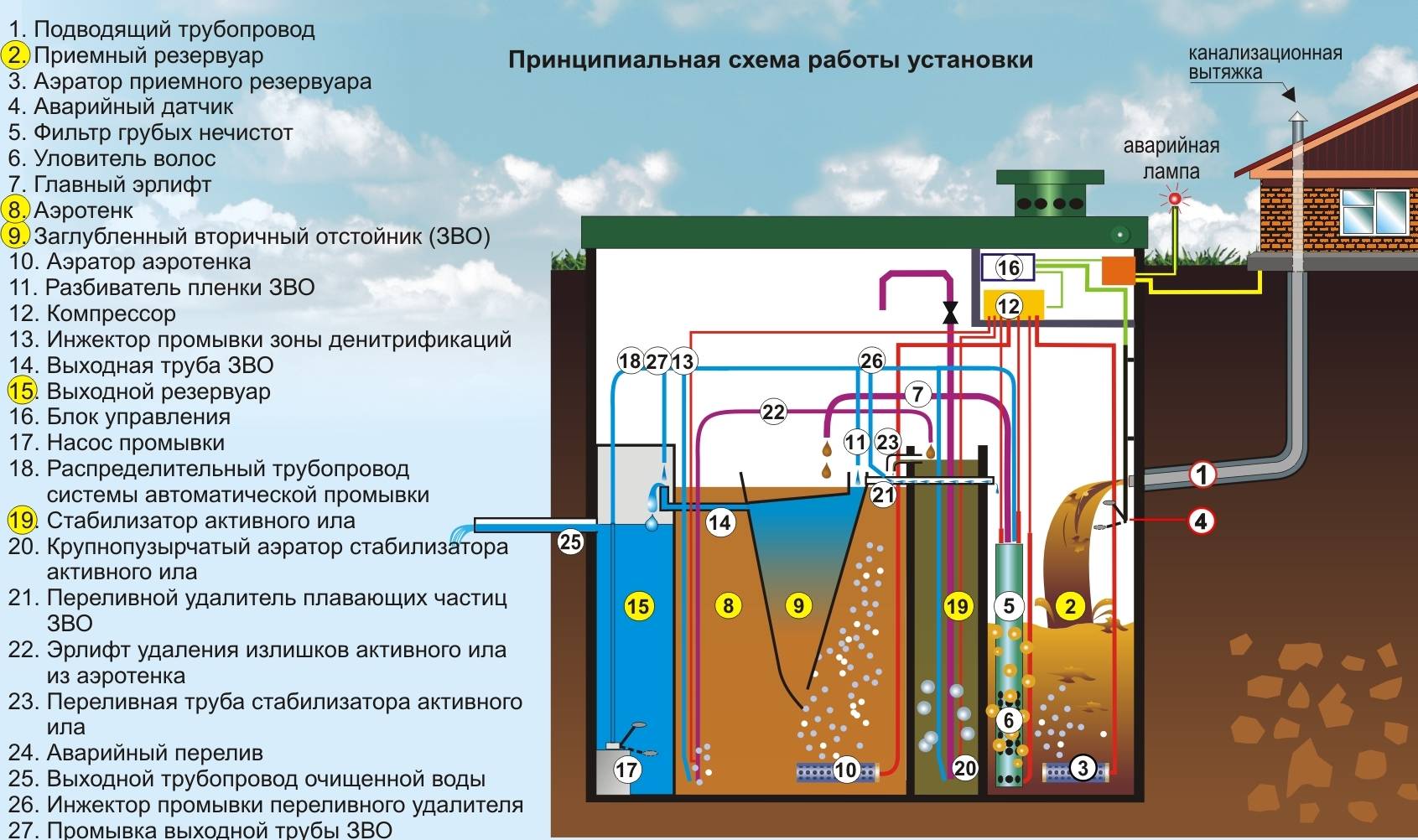

Wastewater treatment in a biological treatment plant occurs due to aerobic bacteria that feed on human biological waste. The station has four chambers in which a circular overflow of sewage flows takes place with the help of special airlifts. That is, drains are pumped from one chamber to another not with the help of a pump, but they are pushed through the hoses by air bubbles that are pumped there by a compressor. This creates a favorable environment for aerobic, biologically active bacteria, since they cannot live without air.

As a result their vital functions toxic sewage are processed into ecological harmless odorless sludge. Wastewater treatment takes place at 97 - 98%, as a result of which the purified water is transparent and does not have an unpleasant odor, it can be discharged into a ditch, a filtration well, a filtration field and even a reservoir.

Wastewater enters the PC chamber, where it is crushed, saturated with air by aerator 1, and the recycling process begins. With the help of airlift 3, wastewater is pumped into chamber A, where aeration by aerator 4 continues, additional purification and settling of sludge in chamber VO is performed.Purified by 97 - 98% water from the VO chamber is discharged from the station, and the processed sludge, using an airlift 5, is pumped into the SI chamber, from where, every 3 - 6 months, dead sludge is pumped out during station maintenance.

PC - receiving camera.

SI - sludge stabilizer.

A - Aerotank.

VO - secondary sump.

2 - coarse filter.

one ; four ; 7 - aerators.

3; 5 ; 8 - airlifts.

6 - biofilm remover.

Below is information about the distinguishing features of the device of different biological treatment plants from four manufacturers:

First manufacturer:

The company "TOPOL-ECO" was the first in this market to start producing biological treatment stations "Topas" in 2001.

This is perhaps the most expensive station of all we have presented, because. the manufacturer does not save on equipment and on the materials from which the station is made. Two compressors are installed in it, each of them is responsible for its own phase of operation: the first when effluents come from the house to the station, the second when there is no effluent and the station operates in a closed mode. Due to this load distribution, the service life of the compressors is increased.

Second manufacturer:

The company "SBM-BALTIKA" organized the production of biological treatment plants "Unilos-Astra" in 2005.

The device of the station differs from the previous one in that instead of two compressors, one is installed there, which switches solenoid valve for first or second phase of work. The downside is that this valve often fails (burns out) due to voltage drops in the network and a voltage stabilizer is required for the full operation of the station. This is a mandatory condition of the manufacturer during the operation of the station, otherwise you will be removed from the warranty.Since there is only one compressor, its service life is shorter and it must be replaced more often.

Learn more about the Unilos-Astra station.

Third manufacturer:

The Deka company has been producing Eurobion biological treatment plants since 2010.

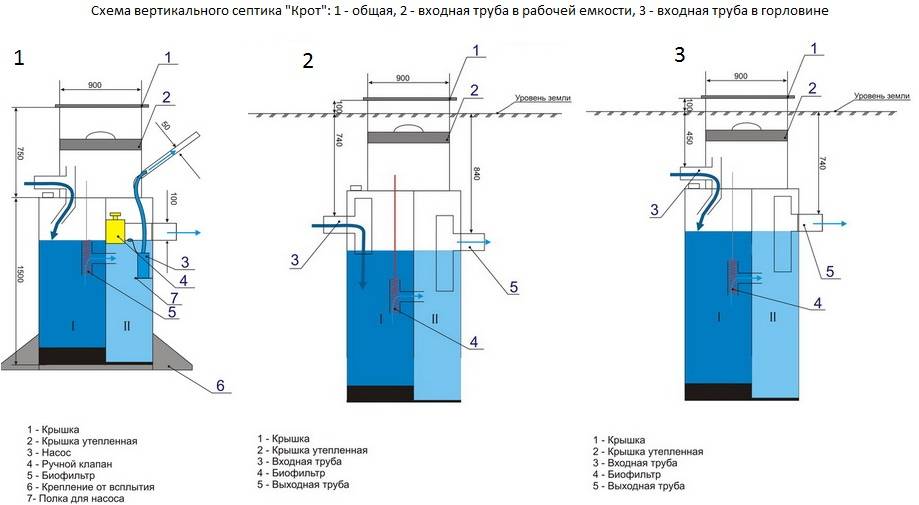

This is a new solution in the operation of a biological treatment plant. The device of the station differs from the two previous ones in that the manufacturer has simplified it as much as possible. Instead of horizontally arranged four chambers, as was done in the two previous stations, there are three chambers in Eurobion: two are located horizontally, and one is vertically below them, the spent dead sludge enters it and collects there. Thanks to the simplified design of the station, salvo discharge increases and this station is less prone to breakdowns.

Click to learn more about Eurobion.

Fourth manufacturer:

The FLOTENK company has been producing Biopurit stations since 2010.

Station Biopurit is a know-how in the operation of the sewer system. In fact, this is an inverted, vertically located septic tank with three horizontal chambers placed in series. In the middle (second) chamber, aeration tubes and plastic honeycombs are placed, in which aerobic bacteria live and, due to oxygen saturation in this chamber, purify wastewater by 97%. When the electricity is turned off (the air supply by the compressor stops), the Biopurit station turns into an ordinary septic tank and cleans the drains by 60-70%.

Click to learn more about Biopurit stations.

We have models of the station in our office: Topas, Astra, Eurobion, Biopurit. You can drive up to us at Grazhdansky 41/2, see how they are arranged and choose the model that suits you!

Got questions? Do not exhaust yourself by searching for material on the Internet. Our experts will answer your questions

Ask the master

More about installing sewerage in the country

Models of septic tanks "Bioxi" and average prices for them

These treatment facilities have a large range of models. They change depending on how many people will use the bathroom connected to the septic tank, respectively, the volume of the entire device changes. There are also three types of models:

- When the supply pipe lies at least 90 cm, such models do not have additional designations;

- Long - the pipe is laid at a depth of 90 to 140 cm;

- Super Long - designed for deeper laying of the supply pipe.

Bioxi models cost 1 from 80,000 to 140,000 rubles, depending on the more specific modification.

Septic tanks 1.6 cost from 100,000 to 150,000 rubles. "Bioxi" 2 have an average cost of 130,000 to 175,000 rubles.

The following models of septic tanks of this company already assume a constant number of users of more than 10 people, therefore, the volume of the device and its price increase significantly. Such cleaning devices are often used in small holiday homes, remote hotels and various work areas where there is no possibility of connecting to a central sewer.

Bioksi septic tanks are becoming more and more in demand, despite their significant cost. They have a large number of advantages, among which are long service life and minimal interference with the autonomous operation of the device, and also contribute to maintaining environmental cleanliness.

We purchased and installed a bioxi 1 septic tank for permanent use in a private house. It works only a month, but when you open the lid, you feel a little unpleasant smell and the water is cloudy.Experts explained this by the fact that the device has not yet accumulated enough waste and does not work at full capacity until there is a need for this. We hope that the purifier will work normally, as long as you are generally satisfied. The septic tank receives water from the washing machine, to wash dishes and a bathroom, sometimes I wash two cars a day, while everything is fine.

We can recommend bioxi cleaning devices, we have been using them for several years, no problems. The essential cost of the device is compensated by minimal interventions in its operation. The main thing is that the water is really clean! Do not use harsh cleaning agents such as bleach, and with standard soap, detergent, dish detergent, there will be no malfunction. We use the 0.6 model, since we live in a small house so far only the two of us, sometimes the noise of work is heard, but it is very quiet in itself, so we don’t pay attention.