- What parameters are important when choosing a ball valve?

- Characteristics

- What are Flanged Water Ball Valves?

- Advantages and disadvantages

- Purpose

- General principle of operation and design

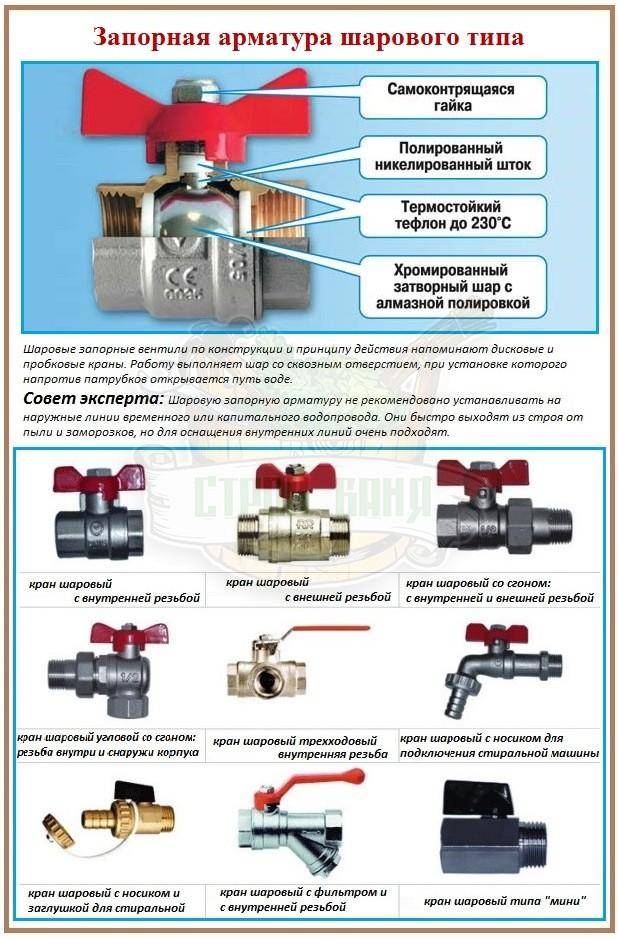

- Types and classification of water valves

- Materials for the manufacture of ball valves

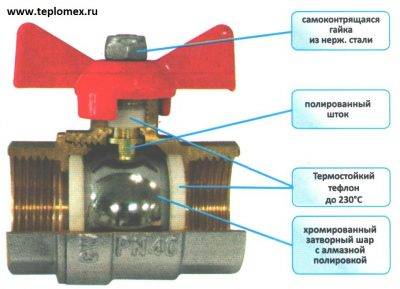

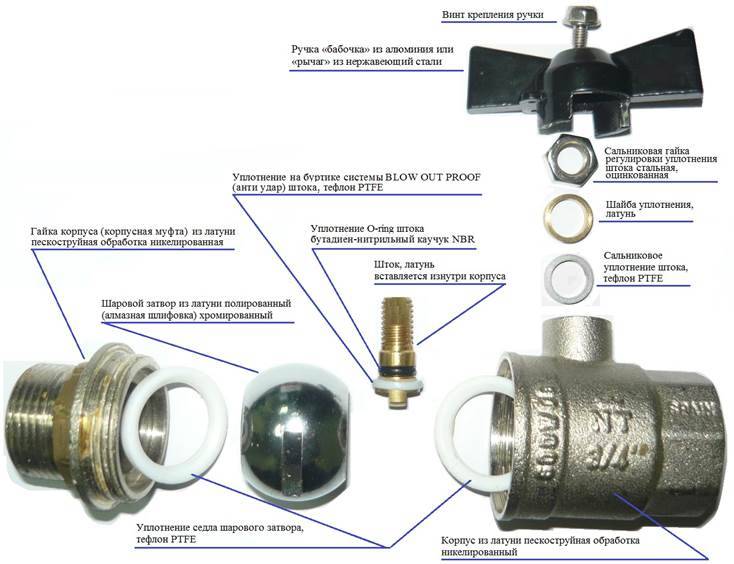

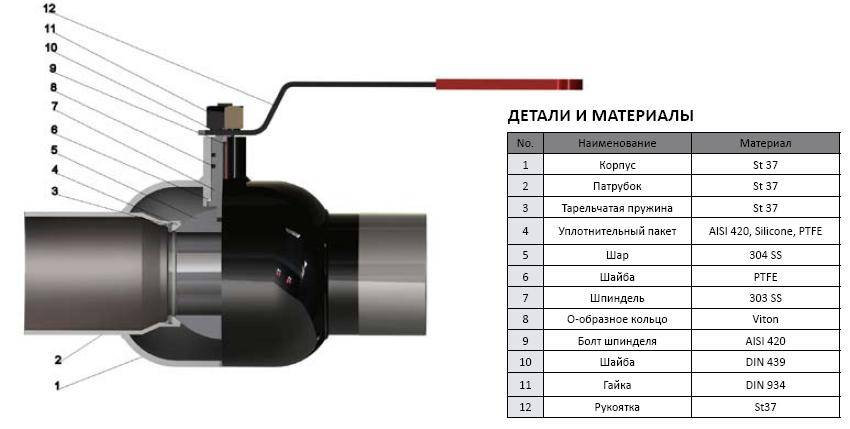

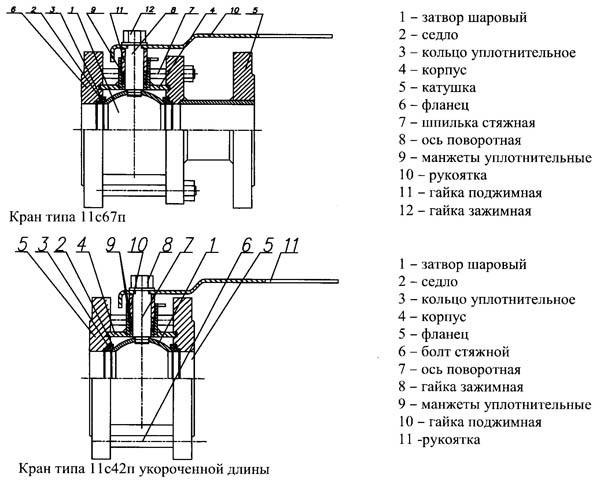

- Device and principle of operation

- The device and principle of operation of the ball valve

- The device and principle of operation of the valve valve

- Characteristics of an angled radiator faucet

- How is it different from a valve?

- Varieties of corner cranes

- Ways to increase the heat transfer of batteries

- Tips

- Device

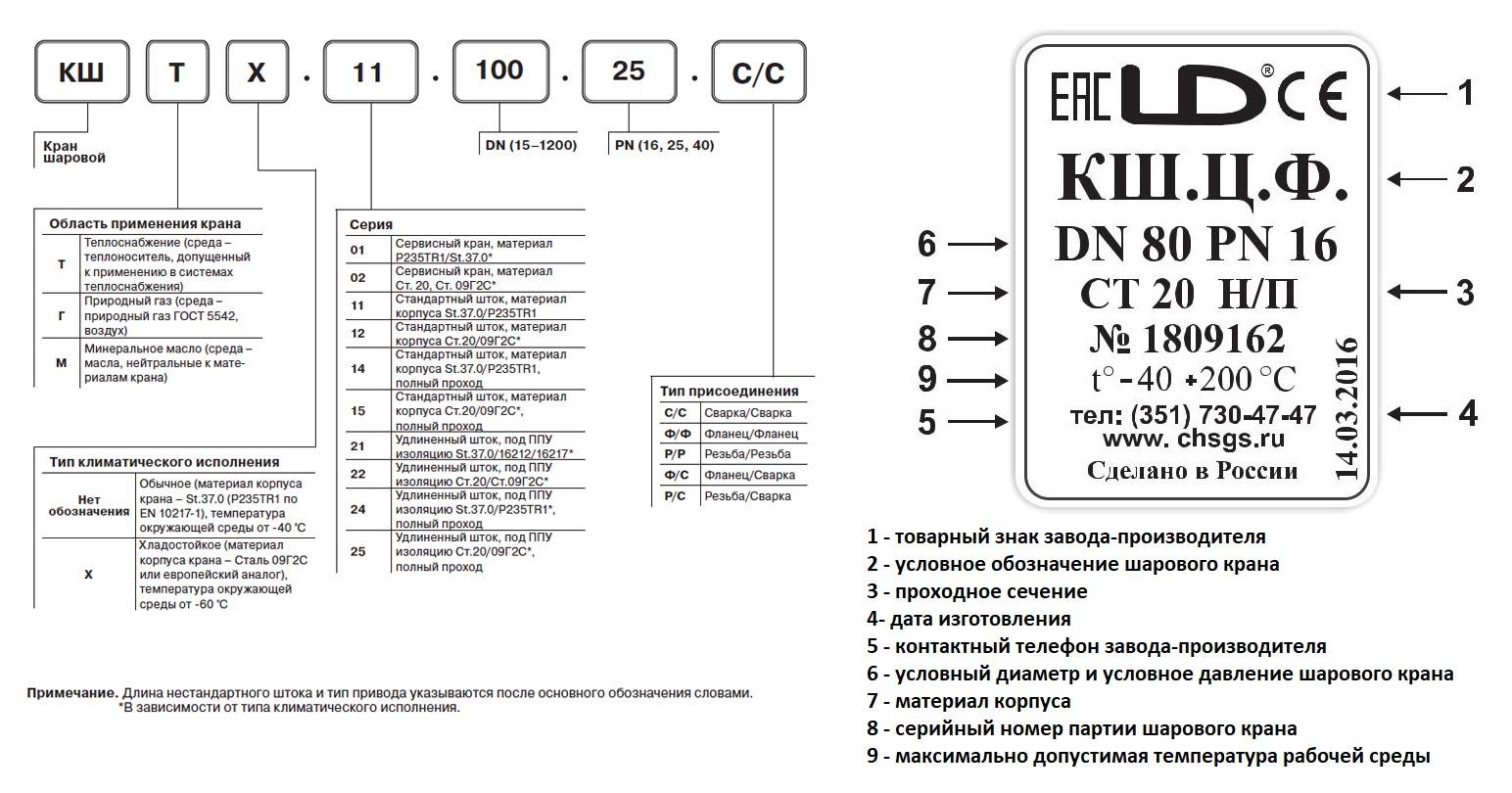

- Ball valve marking

- Advantages and disadvantages of ball valves

- Manufacturers

- The use of brass and alloy steels

- The device and principle of operation of the ball valve

- Angle ball valves

What parameters are important when choosing a ball valve?

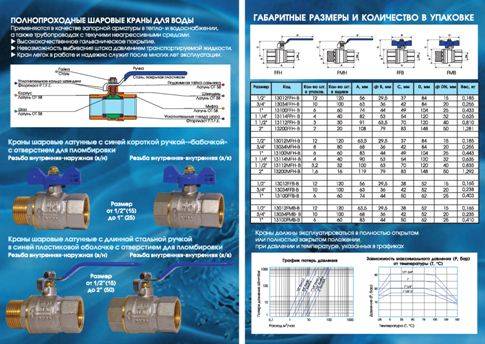

Many of our customers are faced with the need to install a ball valve at the facility, but they do not have a brand. In this case, you can select the valve you need. Consider what parameters are important when choosing a check valve. — valve diameter, DN - usually it coincides with the diameter of the pipeline.Standard range of diameters in millimeters and inches: 6, 8, 10 (3/8"), 15 (½"), 20 (¾"), 25 (1"), 32 (1 ¼"), 40 (1 ½") ), 50 (2”), 65 (2 ½”), 80 (3”), 100 (4”), 125, 150, 200, 250, 300, 350, 400, 450, 500, 600, 700, 800mm . - conditional pressure of the valve, Ru — Standard range of pressures: 10, 16, 25, 40, 63, 100, 160 kgf/cm2. When choosing a conditional pressure, it is worth considering the fact that for stable and long-term operation of the valve, it is necessary that the working pressure be 2 times less than the nominal one. For example, you have a pressure of 12 kgf / cm2 in your pipe. It is necessary to install a crane at 25kgf / cm2. If you install a crane at 16 kgf / cm2, then within a few months the crane may fail. - case material - features of the material of the body of various cranes are described in this article in paragraph 3. - connection type - features of the material of the body of various cranes are described in this article in paragraph 4. - valve design - design features of ball valves are described in this article in paragraph 8. - seal in the gate - the features of the seals of various taps are described in this article in paragraph 7. - equipment manufacturer - this is a very important parameter, because there are a lot of low-quality Chinese handicraft cranes on the market now, which seem to fit in all respects, but during operation they cause so much headache that the savings go sideways. The second extreme is that many European and American brands are trying to sell their equipment 3-5 times more expensive than a normal quality product.How to be an ordinary buyer? In this case, it is advisable to get advice from people you trust - plumbers, installers, reputable sellers.

Characteristics

GOSTs 19681-94 and 25809-96 standardize the classification of water fittings in accordance with the technical characteristics of products:

- throughput to:

- Standard, passing 70-80% of the media;

- Full bore, passing 90-100% of the media;

- Partial bore, passing 40-50% of the media.

- according to the allowable pressure of the working circuit and the tightness class:

- 1 class - up to 1 MPa;

- Class 2 - up to 0.63 MPa.

- noise level:

- Group 1 - 20 decibels or less;

- group 2 - 30-20 decibels;

- Group 3 - more than 30 decibels.

- according to the temperature regime for cold and hot water (up to 75⁰C).

Product characteristics are applied to the packaging in the form of markings and are indicated in the accompanying technical documentation.

What are Flanged Water Ball Valves?

The flanged water faucet also has a spherical shut-off element, the rotation of which vertically opens the opening for the movement of water.

Ball valves of this type are used for pipelines through which steam, oil, water, air are transported. Typically, flanged designs are used in applications where the use of socket valves is limited due to operating conditions (temperature above 100 °C or operating pressure above 16 bar).

It is important to ensure that the valve is turned all the way. Otherwise, contamination will appear on the locking element, which will lead to a leak.

There will be a need to repair or even replace the entire structure.

There are several types of classifications of flanged ball valves for water:

Structurally, such cranes are divided into:

-

Direct-flow;

-

Mixing;

-

Checkpoints;

-

Corner.

By throughput they are:

-

Standard (70-80%);

-

Full bore (90-100%);

-

Incomplete bore (40−50%).

Cranes of this type are made from various materials:

-

Brass;

-

Steel;

-

Bronze;

-

Cast iron.

Ball valves are also available with or without a built-in water filter.

When choosing a flanged valve, pay great attention to the quality of the components, as this ensures a long service life and reliability in operation. Ball valve price should not be too low

When choosing a similar element, specify the working environment and the allowable temperature range. In this case, plumbing repairs will not bring additional trouble.

Advantages of a flanged ball valve for water:

-

Long service life;

-

Reliable tightness when flow is blocked;

-

Small hydraulic resistance;

-

Compactness;

-

Small size;

-

Simple construction;

-

Mounted in any position;

-

No need for maintenance;

-

Ease of use;

-

Cranes with a collapsible body can be repaired;

-

If necessary, quickly blocked by hand.

Cons of such cranes:

-

Expensive;

-

heavy;

-

Long lever for manual operation.

Read related material:

Supplier of engineering plumbing: criteria for the right choice

Advantages and disadvantages

For clarity, the advantages and disadvantages of varieties of water taps are summarized in the table.

| Mixer name | Advantages | Flaws |

| Double valve, single valve | Simple and affordable, reliable, easy to repair, compatible with domestic water supply systems | Rapid wear of the crane bushing gasket, with a ceramic faucet box, it is desirable to have a filter (preventing mechanical particles from entering the cartridge holes). |

| Single lever | Reliable, durable, repairable | They are demanding on the quality of the liquid, they need to install a filter, if the ball mechanism fails, it needs to be replaced, since it cannot be repaired. |

| with thermostat | Economical, the presence of a maximum temperature blocker helps prevent burns | Relatively high cost |

| Touch | Economical, can significantly reduce consumption, hygienic, since direct contact with the device is not required | Requires a stationary power supply or replacement of batteries, less reliable compared to mechanical devices. |

Do you have a question? We published the answer to this question in the next article.

Decided to redecorate your bathroom? Useful information for you how to install and for the bathroom.

A faucet is leaking in the kitchen or bathroom: find out how to fix the device yourself.

Purpose

A water tap is a small shut-off mechanism that performs extremely important functions. The standard sample performs a rather trivial, but at the same time absolutely necessary task for the functioning of the pipeline - it controls the movement of the carrier inside the pipes.

There are situations when the pipeline must be partially or completely blocked, cut off one or more branches from the water supply. There are many reasons for this, ranging from the banal breakdown of plumbing fixtures, and ending with major destruction in the system.

In any case, a breakdown threatens to flood the house or apartment, so it is better to immediately turn off the water supply in order to protect yourself.

You can also turn off the water at the entrance to the main, but then you completely cut yourself off from the water supply for the duration of the repair (which, to be realistic, can be delayed).

That is why any more or less decent length pipeline is divided into logically understandable sectors or branches, isolating each segment with the help of these same cranes. This approach is better and safer than the standard assembly, although a bit more expensive.

One single turn of the faucet handle completely shuts off the water supply in a particular area. If desired, a water tap can be installed not only on individual branches, but in general at the entrances to any plumbing unit.

Pipeline faucet with american connection

In this case, a breakdown, for example, in a water folding mechanism or at the inlet to a water heater is easily and simply eliminated. It is enough to turn the tap and the device is ready for further repair.

Note that different types of water taps are used not only to isolate the branches of water supply systems. There are other appointments as well. For example, the modernization of the heating system, when taps are placed at the entrances to radiators or to the underfloor heating system in order to be able to quickly remove or replace the device in the future.

An equally popular option is a tee or distributor, which acts as a turnout valve, that is, redirects the flow of water from branch to branch.

Don't forget about the faucet. The best way to get an idea of how a faucet works is by looking at your bathroom sink.In any bathroom there is a tap or faucet, and only thanks to it you can comfortably enjoy the benefits of civilization.

General principle of operation and design

There are different types of taps for plumbing, but they all have common design elements. In any case, the crane consists of:

- body or general body;

- locking element;

- pens;

- seals.

It does not matter whether we are considering valves, a tee with a tap, a tap or any other of its varieties. In any case, they will not do without the four elements described above, although most likely, these elements will differ from each other.

The body of the crane depends on what specific task it is engaged in. A conventional coupling sample is, in fact, built into the body of the coupling itself. The angle valve has an angle body, because its task is to form corner connections, for example, at the entrances to heating radiators.

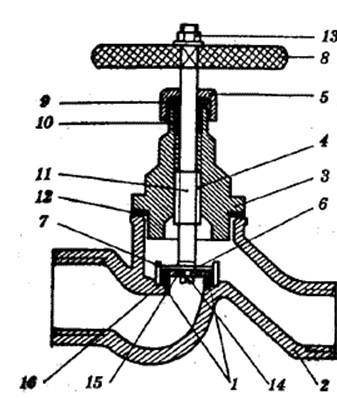

Components of a valve with a locking element in the form of a valve

The tee has a different body. The tee consists of a branched coupling, which is obvious. Water folding solutions can be built-in or special. Their body differences are much more significant.

The handle at the crane is ordinary and necessary for control. If a ball valve is considered, then the handle in it can be in only two positions: closed, open. In gate valves, instead of a handle, a valve is mounted, and the mechanism is controlled by its spiral rotation.

As for the seals, not a single working mechanism in plumbing can do without them. Rubber gaskets are used as seals. In taps, the transitions between the locking element and the body are sealed.

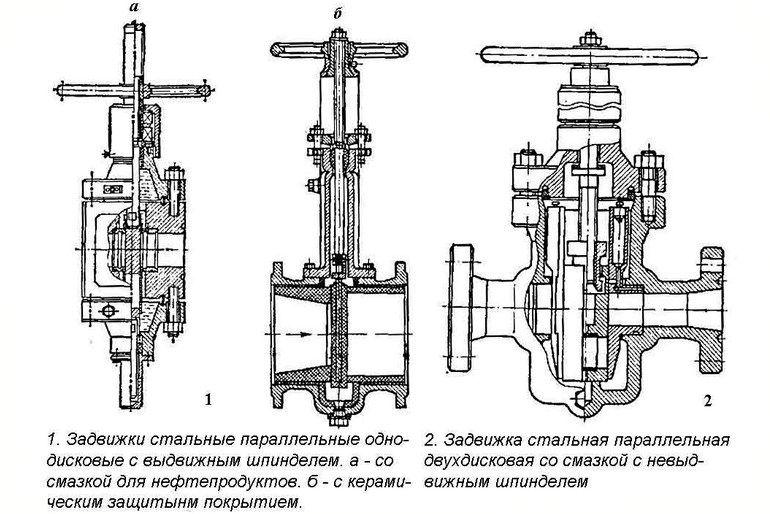

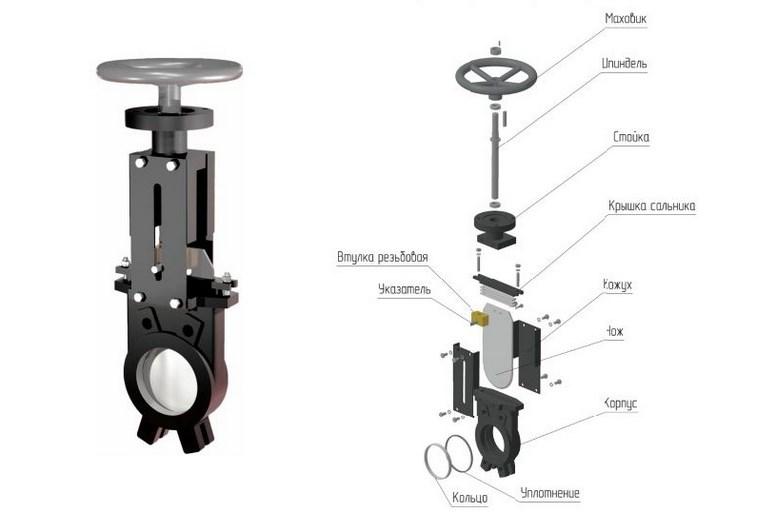

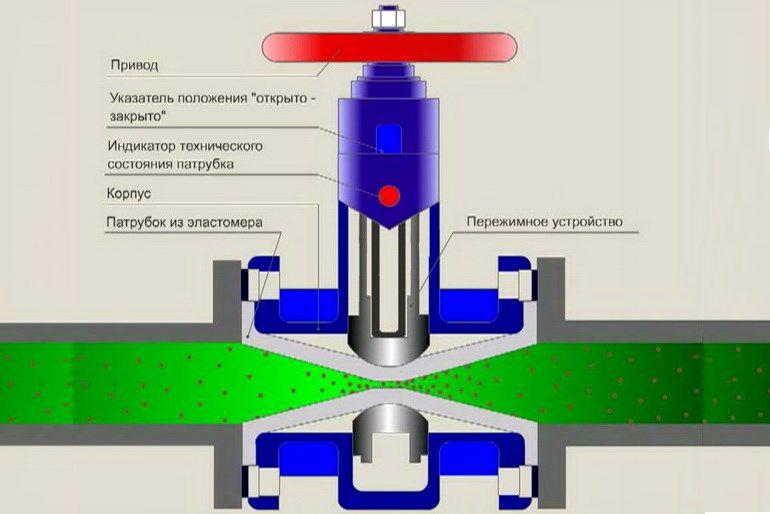

Types and classification of water valves

According to the design of the shut-off body, valves for plumbing systems are divided into:

wedge;

parallel;

gate;

hose.

Wedge gate valves are equipped with a cone-shaped gate, which, in the “closed” position, fits tightly into the space between the saddles. The wedge can be of different types:

- rigid, having the form of a solid plate narrowed to the bottom. It smoothly descends into the lower part of the device and blocks the through holes of the saddles in the perpendicular direction, thus interrupting the movement of the working medium. A stiff wedge securely seals the bore, but is more prone to rusting and more difficult to fit to saddles. Therefore, in such devices there is a danger of jamming and difficulties arise in raising the wedge during sudden temperature changes;

- double-disk - consisting of two disks, which are movably fastened together at an angle to each other. When the valve is actuated to close, both elements rotate relative to each other and close the passage holes in the saddles, firmly pressing against their sealing surfaces. When opened, they move away from the saddles, freeing the passage for the working substance. This design of the locking element provides a good level of tightness, reduces the risk of jamming and increases the working life of the entire device;

- elastic, two disks of which are interconnected by an elastic rubber part. It is able to bend under the influence of water pressure, thus providing a tighter pressing against the sealing materials of the saddles. Gate valves with a rubberized wedge require less effort to operate, have smooth passage surfaces that reduce friction and wear of the shut-off body elements.

Parallel valves include devices in which the sealing surfaces of the shut-off or regulating body are located in parallel planes to each other.

For furnace chimneys, gate valves are used, the design of which includes a frame and a metal plate with a handle. When the valve is opened, the plate moves out of the frame, when it is closed, it returns to its original position.

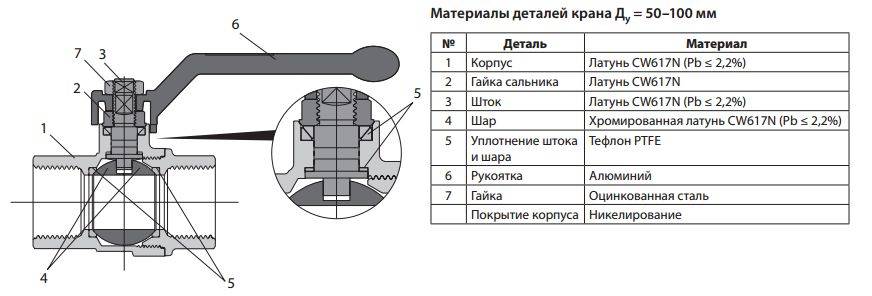

Materials for the manufacture of ball valves

There are brass and steel ball valves on sale. Brass products are installed on pipes of small diameter. If a leak appears, it is enough to tighten the nut to press the Teflon gland. Working resource - 20 thousand openings and closings.

Performance characteristics and advantages of brass devices:

- reliability and durability;

- the crane does not require maintenance and lubrication;

- high tightness ensures no leakage;

- can be mounted in any position;

- handle safety;

- maximum operating temperature up to +150 degrees;

- working pressure - not higher than 1.6 MPa.

Steel fittings do not have bolted connections, therefore they are completely protected from leaks. Technical characteristics and advantages of steel products:

- fluid flow is quickly blocked;

- simple operation and installation;

- no need to carry out maintenance and replace parts;

- withstand high temperatures of the working fluid;

- economy.

Device and principle of operation

The device of the crane-valve, as well as the principle of its operation, depend on the type.

The device and principle of operation of the ball valve

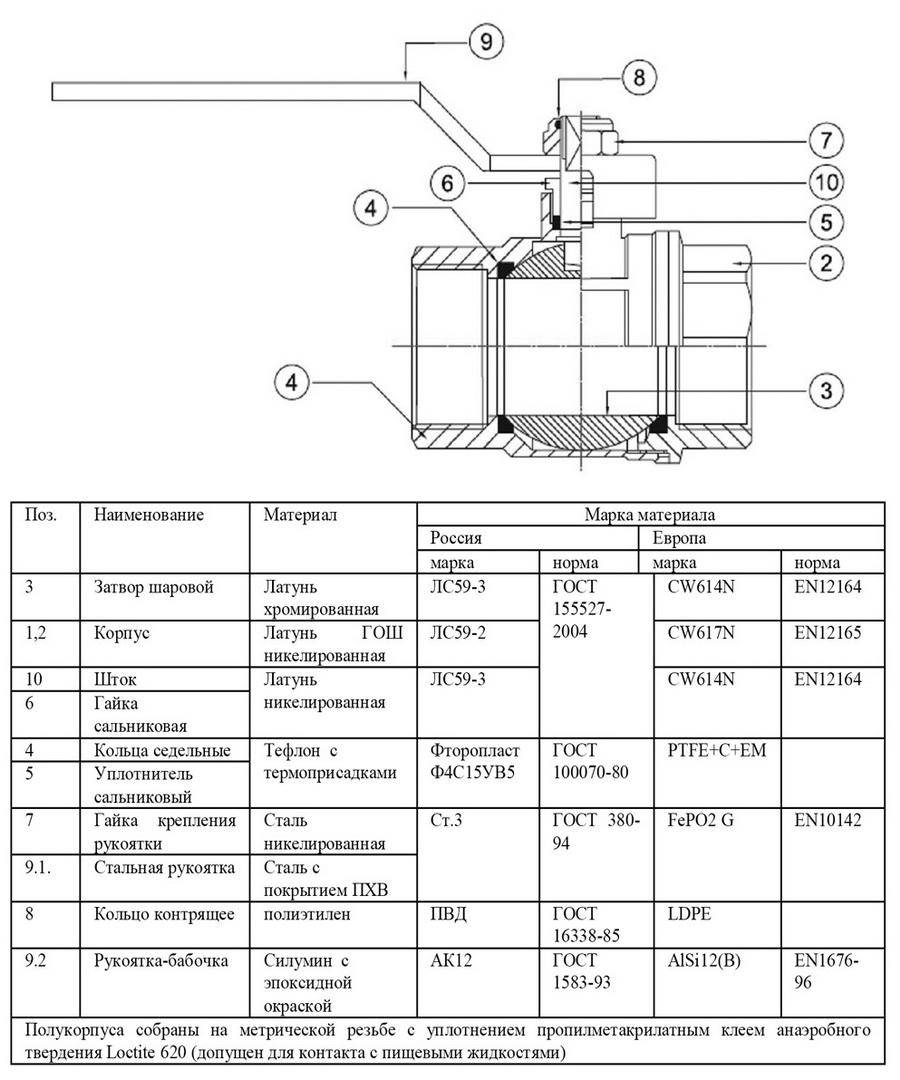

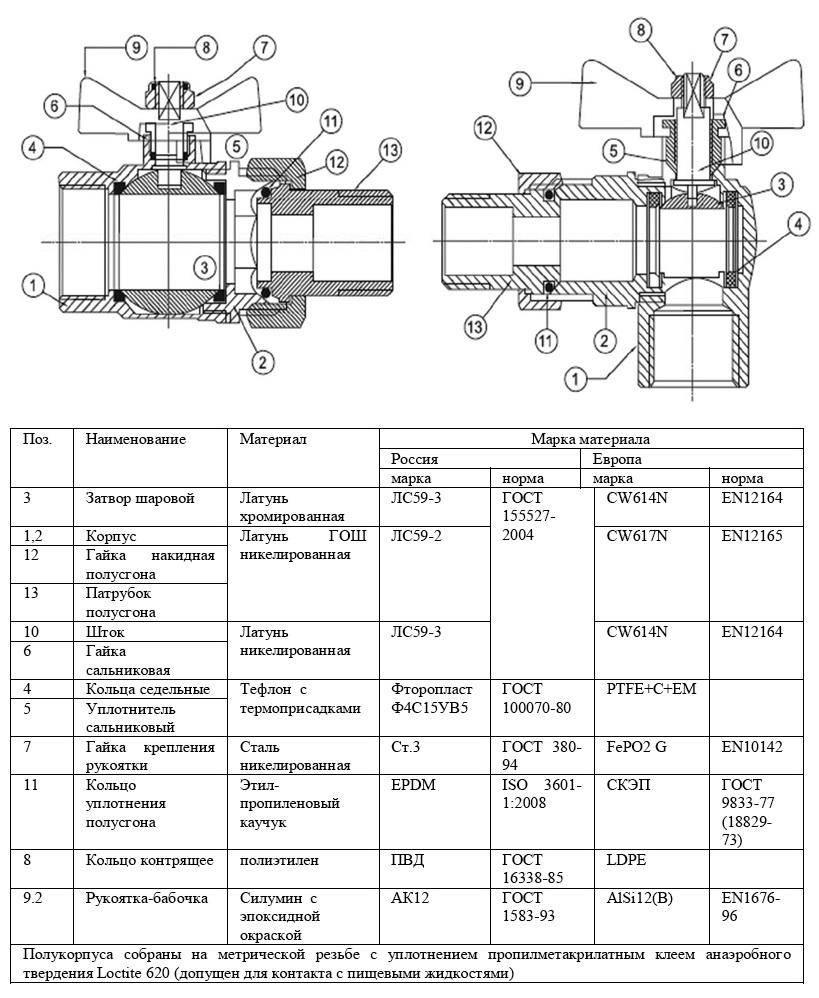

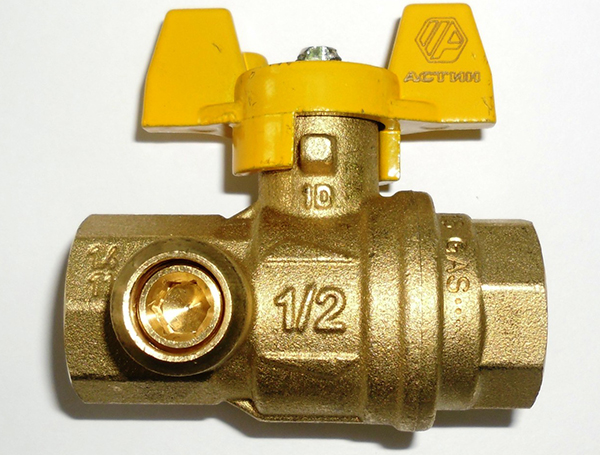

How does a ball valve work? The main elements of the device are:

- valve body (1).The body can be made of materials such as brass, bronze, stainless or structural steel, silumin. The body can be integral, that is, manufactured by welding, or collapsible. The collapsible body has some advantage - if necessary, the valve can be repaired. If a ball valve with a one-piece body is installed, then if there are malfunctions, the device must be replaced;

Main elements of a ball valve

- locking element - ball (2). In most cases, the ball is made of brass, as this material is considered stronger and more durable. The ball has a through hole for liquid (gas);

- sealing rings (3) are installed between the locking element and the body, ensuring the tightness of the device. Gaskets can be made of Teflon, PTFE or rubber. Teflon seals are considered the most durable, which are practically not affected by temperature and chemical environment;

- the valve can be connected to the pipeline using nuts (couplings), flanges or welding (4).

In domestic pipelines, a coupling connection is most often used, and in industrial pipelines, a flange connection. Welded valves are rarely used today, as they require special equipment and certain skills during installation.

Flanged valve

- the locking ball is driven by a rod (5), which is connected to the control handle (6). Sealing elements are also installed between the stem and the handle;

- the handle is attached to the body with a nut (7).

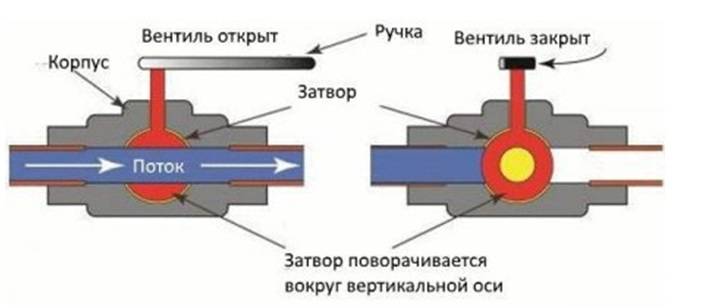

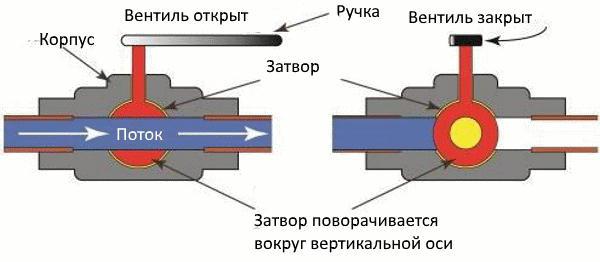

The principle of operation of a ball valve is as follows. When the handle fixed on the body is turned, the locking element of the device - the ball - rotates.If the orifice of the ball is turned in the direction of the flow of the passing substance, then the valve will be opened. If the orifice is turned perpendicular to the flow, the valve will be in the closed position.

The principle of operation of the ball valve

The device of the ball valve, as well as the points that you need to pay attention to when buying a product, are discussed in detail in the video.

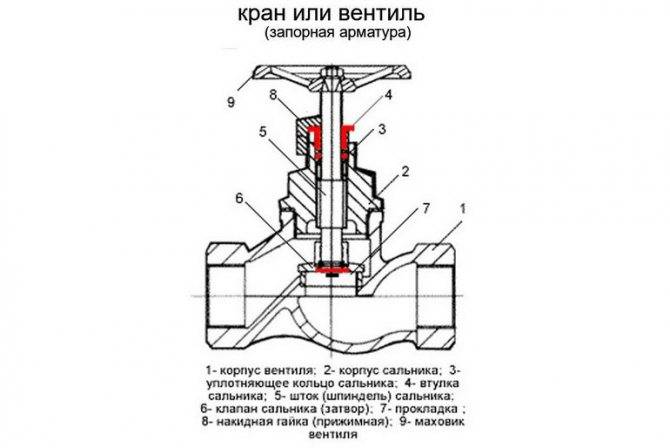

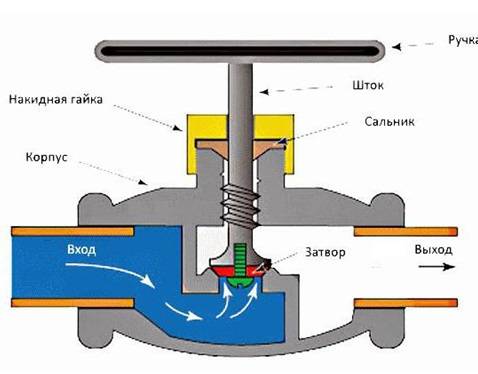

The device and principle of operation of the valve valve

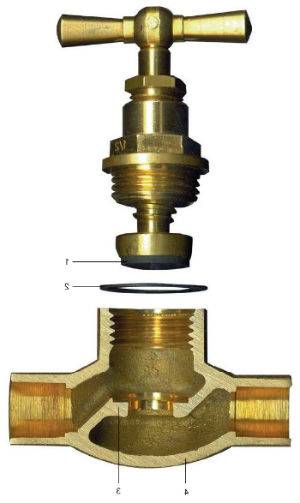

Now let's figure out how a valve equipped with a valve works. The device consists of the following elements:

- the valve body (2), made of various materials, is equipped with a cover (3). A gasket (12) is installed between the body and the cover for tightness. As a rule, the gasket is made of durable rubber, but can be made of other materials;

The main operating elements of the valve with a valve locking element

- the body is equipped with a seat (1) for the valve (6), which is the locking mechanism of the device. For complete blocking of the flow and sealing, the seat is supplemented with a sealing gasket (16);

- a seal (15) is also located on the lower part of the valve;

- the sleeve (7) and the spindle (11) are attached to the shut-off valve with the help of a nut (14);

- on the spindle body there is a thread (4), which serves to control the locking cone;

- the spindle is combined with a handwheel (8) that drives the valve. The flywheel is fixed on the body of the device with a nut (13);

- for hermetic connection of the flywheel and the valve body, an oil seal (10) is installed, fixed with a separate nut (5), supplemented with a sealing ring (9).

The device of the valve determines the principle of its operation. When the handwheel is rotated, the spindle moves up or down in translational movements, which lowers or raises the valve.

The principle of operation of the valve

The valve valve can be a through passage (in the figures above) and an angle valve. An angle valve is recommended to be installed on the bend of the pipeline. The device and principle of operation of the angle valve practically do not differ from the passage device. The main difference is in the shape of the body and the location of the saddle.

Valve Type Angle Valve Device

Ball and valve valves have a different design and differ in the principle of operation. However, both types of products can be installed on domestic pipelines for various purposes.

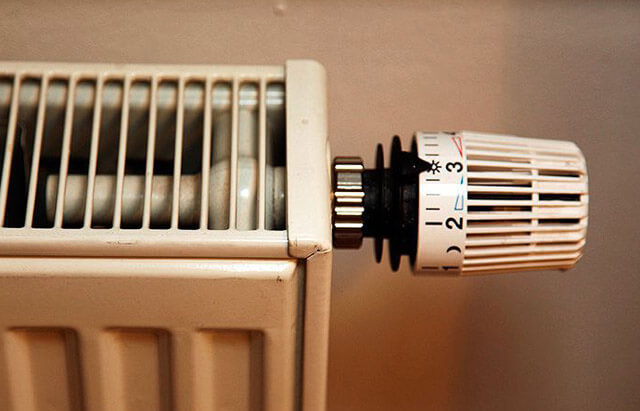

Characteristics of an angled radiator faucet

As a locking element, the corner radiator valve has a ball with a through diametrical hole, the alignment of the axis of which with the axis of the pipe opens the valve and turning perpendicular to the axis closes it. Therefore, such a device is usually called a "radiator angle ball valve".

Straight and angled radiator taps

The ball valve for the angle radiator should only be used as a shut-off valve. Experts do not recommend using ball valves to regulate the flow of water.

Typically, the faucet material is brass with a low lead content. But if water is supplied to the radiator through propylene pipes, then the corner radiator valve is also made of polypropylene. In this case, its characteristics are underestimated, but not by much:

- the temperature of the flowing water is 90-120 ° C versus 150 ° C for a brass tap;

- working pressure - 10-16 atm. against 16-25 atm. at the brass faucet.

An article on our website "Which corner faucet is better" contains an overview of the popularity of brands of manufacturers of these sanitary wares

Read more about Valtec cranes here:

But, for example, Valtec produces corner valves for radiators made of propylene grade PP-R 100 (PP-R 80 is usually used), and the operating pressure of Valtec valves reaches 25 atm. like the brass ones.

How is it different from a valve?

Valves and gate valves are 2 mechanisms that are most often found on industrial pipes.

Without them, it is impossible to imagine the work of any possible supply chain, no matter what size it is. The main purpose of this type of device is extremely simple - to make it possible to control the movement and a certain state of the fluid that is transported inside the pipeline

A valve is a locking mechanism for adjustment. This is a rather large element, with a slightly thickened body and with an overall adjustment ring, it is called a valve. It is necessary in order to 100% shut off or regulate the flow of the liquid used inside the pipe.

This is the main difference between a modern valve and a conventional valve. The valve part, which is fixed, can be mounted in several positions without any problems.

If you turn the valve a number of turns, the flow will be blocked only partially. The constipation element will artificially reduce the diameter of the passage inside, which will limit the amount of transported media. Full closure of the mechanism will block the entire system, the valve does about the same. But the main advantage of the valve is that it can be used to select the desired position for the locking element inside the device itself.

Quite often, in pipes for industrial use, there is a need not to completely block the carrier flow, but only to make it smaller to a specific value. This can be done by mounting the valves in the most suitable places for this.

List of obvious differences.

- The valve can easily adjust the flow force in any system, while the valve can be seen only in two states: it can be open and closed.

- The valve quickly becomes unusable. The valve serves more thanks to excellent characteristics.

- In the valves, the carrier flow will be blocked by a special valve that is pressed against the seat in horizontal planes parallel to the flow of gas or water. For this, a double bend of the carrier flow is carried out at an angle of 90 degrees. The valve will block perpendicular to the carrier flow.

For information on how to repair and replace screw valves, see the following video.

Varieties of corner cranes

All corner valves are divided into three types depending on the mechanism of the locking device:

Ball valves are a type of construction for shutting off or starting the flow of a working medium, but not capable of regulating it.

- The throttle is a manual heat transfer controller.

- Thermostatic valve - a device for automatically setting the required temperature in heating appliances, and maintaining the desired level of heating in automatic mode.

We recommend that you read: Advantages and application of pipes made of unplasticized polyvinyl chloride (UPVC)

All corner taps are also distinguished by the material of manufacture:

- all-metal structures, most often brass with a chromium-nickel coating,

- polypropylene devices with a socket connection for welding, which are used for installation without additional fittings, as well as quick-connect connections of the American type.

Brass products are most often used in the installation of systems made of steel, metal-plastic pipes.

Ways to increase the heat transfer of batteries

The presence / absence of the possibility to increase heat transfer depends on the calculation of the radiator power reserve. If the device is not able to produce more thermal energy, then no fittings will help.

You can try to change the situation in one of the following ways:

- First of all, you should check if the filters and pipes are clogged. Blockages are formed both in old buildings and in new buildings, as various construction waste enters the system. When cleaning does not give results, drastic measures must be taken.

- Increasing the temperature of the coolant. This can be done in the presence of autonomous heat supply, but with centralized heating is unlikely.

- Change connection type. Not all battery connection methods are equally effective. For example, the reverse side connection leads to a decrease in power by about a quarter. Also, the place of installation of the device affects the heat transfer.

- Increasing the number of sections. If the location and method of connecting the radiators are chosen correctly, and the room is also cold, this means that the thermal power of the devices is not enough. Then you need to increase the number of sections.

If the heating system is equipped with temperature-controlled batteries, then they require a certain power reserve and this is their main drawback.As a result, the cost of arranging heating increases, since each section costs money.

Comfort cannot be achieved if the room is cold or too hot, so adjusting the heat in radiators is a universal solution to this problem.

Tips

Sometimes you can hear the term "ball valve under the valve." This means that the construction lengths of the crane itself and the valve match. You need to know the explanation in order to choose the right product when buying. So, the length of valves KSh F DN 50, 80 and 100 corresponds to the lengths of gate valves made of steel 30s41nzh ZKL-2, 31s31nzh ZKL-Z, 31s38nzh, 30s41p, ZKS, ZVK and the lengths of gate valves made of cast iron 30ch6br, 31ch6br, 31ch7bk, 31ch17br, 31ch16brn, zh , 31ch11nzh and ZKVSH, characterized by the same diameters. Usually the length is according to the European DIN standard.

During operation, interflange seals are used. In addition, before installation, it is indispensable to check the axial alignment

It is important that the bolts are screwed evenly around the entire perimeter. With regard to the operation of the product, it is necessary to systematically carry out technical inspection

It does not matter which crane is purchased. If you ignore this aspect, you can allow leakage.

Several factors influence the frequency of inspection. One of the most significant is the working medium itself (liquid or gas inside the pipeline). However, regardless of this, the check is carried out at least once every six months of operation of the ball valve. In addition, you need to take into account an important nuance: the crane should not be constantly in one position. Periodic repositioning will prevent the formation of deposits on the surface and will help to increase the service life of the product. The frequency of such works is approximately 2-4 times a year.

The last factor that determines the quality of the crane is a purchase in a trusted store, while it is important to ask the seller for a certificate confirming that the goods comply with the declared GOST standards

See the video review of the ball flanged valve below.

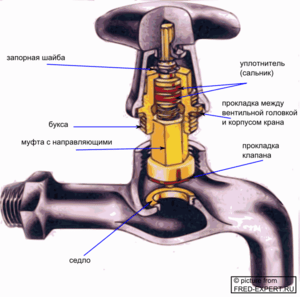

Device

The device of a simple water-pressure mixer is most often the same for all models. The basic composition of the functional elements and its principle of operation remain the same, despite possible external differences.

This faucet includes:

- Mounting screw;

- Spindle;

- Valve handle;

- Gland sleeve;

- Lid;

- Pad;

- Gland packing;

- Nuts on the faucet body;

- Nose and seat.

The handwheel or valve is connected to a vertical spindle so that its lower part 20 mm long has the ability to move inside the nut. In turn, the lower part of the nut is screwed into the housing. The spool is located at the end of the spindle, consisting of a disc with a gasket, which is installed with a nut or button. That is, when we turn the faucet handle, the spindle is screwed in, and this leads to water shut-off. The gasket is tightly pressed against the metal seat of the valve and creates an impenetrable obstacle for the passage of the coolant.

Ball valve marking

Each manufacturer has its own range of manufactured valves, but all Russian-made products, as well as imported devices sold in the Russian Federation, comply with GOST 52760. This standard regulates the marking of shut-off and control equipment, which includes ball valves.

The label must include:

- nominal passage (nominal diameter), denoted by the abbreviation DN;

- nominal pressure indicator - PN;

- the value of the calculated (working) pressure;

- an arrow indicating the direction of water movement;

- maximum operating temperature;

- release date.

In accordance with GOST 4666, devices made of cast iron are black in color, those made of stainless steel are blue (blue). Hot water faucets are marked in red.

Today, more than four thousand sizes of taps are produced for various needs; devices of small diameter are used in household water supply systems

Advantages and disadvantages of ball valves

Ball valves are very popular in various sectors of the economy. They are considered reliable locking devices, are part of the water supply system of a city apartment and a private house.

In addition to reliability and simplicity of design, products of this type have many other advantages:

- large working resource, long service life;

- rarely break, easily repaired;

- high degree of tightness, with proper installation, there are no leaks;

- convenient use, to block the water flow, it is enough to turn or press the lever;

- a huge range of sizes and types;

- ease of installation, you can install it yourself without involving a plumber.

A faucet with a ball mechanism will save its owners the time-consuming and frequent replacement of gaskets, as well as problems with water leakage, which are so common with obsolete faucets.

Ball mixers very rarely fail, the main cause of failure is hard water, so manufacturers recommend installing water filters in the water supply system

Manufacturers

In the modern market for such products, a lot of ball flanged valves are offered to the attention of buyers. According to the consumer's assessment, the shut-off valves of the following companies can be called worthy of attention:

- Broen;

- LD;

- DZT;

- Naval;

- Danfoss Jeep F.

These valve options are able to completely shut off the substance that enters through the pipeline. For example, Naval brand products have an all-welded hull. The product is lightweight and easy to use. Due to the high density, he is not afraid of pressure drops. Thanks to the removable handle, it is possible to change its position by 180 degrees.

The connection of other options can be flanged, welded or threaded. These products are chosen due to the fact that they significantly reduce hydraulic losses. Devices withstand temperatures up to 250 degrees. Their installation is carried out taking into account counter flanges with certain parameters of diameters, fasteners and gaskets. Connecting dimensions are subject to GOST 12815.

The use of brass and alloy steels

As previously noted, brass or alloy steel can be used in the manufacture of the body. The use of such materials causes the following design features:

- The surface of the crane is not exposed to corrosion. Even with prolonged exposure to high humidity, corrosion does not form on the surface. That is why the service life is increased several times.

- The materials under consideration are light in weight.

- Sufficiently high strength and sufficient ductility. Please note that brass and alloy steel do not withstand strong mechanical stress.Therefore, the locking mechanism must be protected from impacts and other mechanical impacts.

The brass version costs more than alloy steel valves, which is worth considering.

In conclusion, we note that the owners of private houses should insist on replacing the locking mechanism. Such work is in the interests of the owner of the house, since replacing a standard faucet can significantly increase the safety of living. Given the low cost of the mechanism itself, the main costs relate only to installation work.

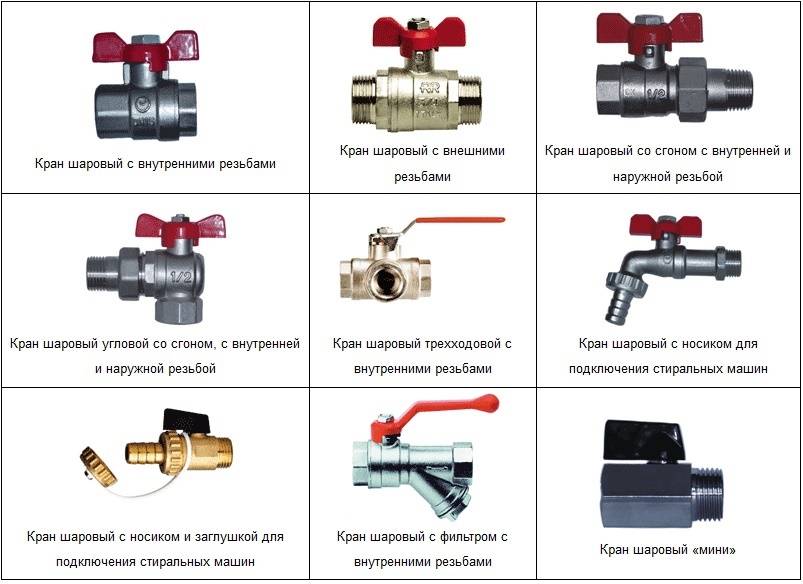

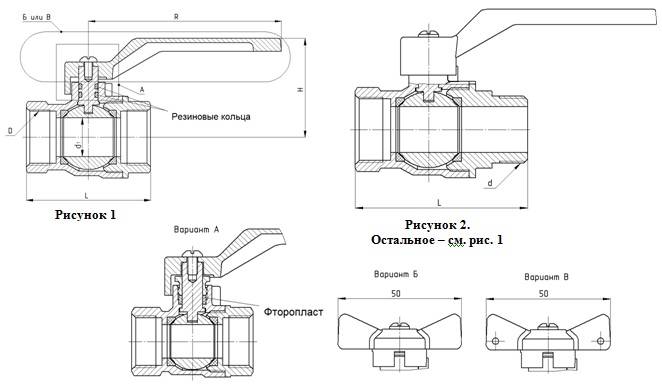

The device and principle of operation of the ball valve

The main working body of the valve is a ball with a through hole. When the handle is positioned along the pipe, the valve is open. If it is turned perpendicular to the pipe, it will close. The hole in the ball can be round, square, in the form of a trapezoid or an oval. In valves of small diameter, the valve is made floating, and for large-sized devices it is made on special supports. High tightness of the shutter is provided by an elastic seal. This allows you to install this type of models on gas pipelines.

The water ball valve operates in two extreme positions when rotated 90 degrees, when it is fully open or closed. Attempting to control flow will result in rapid seal wear.

They have wider possibilities for connecting pipes when installing water supply systems:

- walk-throughs;

- corner;

- with three or more outlets in order to redirect transported flows.

Connections with pipes are made by fitting, flanged and welded. The latter option allows you to permanently install a water valve in the system.

Angle ball valves

The design of the product provides convenient installation when installing plumbing and heating systems. Our range includes various standard sizes of angle taps equipped with an American. The available variety of products allows you to buy a corner crane with an American to quickly complete the planned installation operations. The brass body of the valves is resistant to water, steam and all kinds of non-aggressive liquids.

The compact American corner faucet is equipped with a removable butterfly-shaped adjustment knob, which allows you to mount stop valves in a limited space. All products in our range are certified and tested by the quality control service. A high-quality American angle crane is capable of trouble-free service for several decades. Accurate execution of a threaded connection has a positive effect on the speed of installation and the tightness of operated systems. The wear-resistant American angle ball valve has a long service life, based on the impeccable technical performance of the components. The perfect fit of the metal ball ensures easy movement when shutting off valves and guaranteed tightness of the pressurized system. When installing heating systems, a 1/2 angle tap with an American pipe provides the possibility of periodic dismantling of the radiator for service.

The use of corner devices helps to optimize the design of pipeline systems for various functional purposes. A small-sized American angle ball valve is in demand when installing systems with a complex configuration. A non-standard device can be installed without difficulty in a narrow opening or niche.Reliable American angular ball valve is designed for repeated use without deterioration of primary characteristics. The use of filter elements helps to increase the stability of the operating system by minimizing sedimentation processes. Reducing the amount of impurities in the coolant or tap water helps to reduce the load on the surface of the ball that blocks the flow of the working fluid.

Compared to standard valves, an American angle ball valve helps simplify installation by using a more convenient type of connection. Our product range includes products that differ in nominal diameter, installation dimensions and functional characteristics. It is possible to buy an angle crane with an American from us for quick installation of systems of standard and non-standard configuration. Brass products are resistant to corrosion, temperature extremes and high humidity. Durable shut-off valves are a reliable component of water supply networks and heating systems for residential buildings and public facilities.