- Differences between a crane and a valve

- Helpful Hints

- Why are there taps on radiators?

- Scope of application

- Coupling

- Flanged

- Welded

- Combined

- Classification of water ball valves

- Locking device

- Ball

- valve

- Obtaining approval for the replacement of the gas pipeline

- and its varieties

- Cons of operating ball valves

- Ball device

- PTFE sealing elements

- Principle of operation

- Angle ball valves

- Differences of ball valves for water and gas

- For water

- For gas

- Mounting

- Conclusion

Differences between a crane and a valve

The main difference between a valve and a valve is the principle of their operation. The gate valve can have a gate of various shapes - a wedge, a disk or a sheet - but it always makes perpendicular movements relative to the axis of the fluid flow in the pipeline on which it is installed. To block the flow, it is required to turn the spindle on which the locking part is fixed.

The valve gate always has an opening for the passage of the working substance. Accordingly, to start the flow of the medium, it is only necessary to change the position of the gate element so that the opening in it coincides with the axis of the pipeline. Spindle rotation is not necessary.

Helpful Hints

There are several aspects, the observance of which will help facilitate the installation procedure, as well as guarantee the successful operation of the ball valve. The first one concerns product selection. Before purchasing, you need to consider the following points:

diameter of the pipe on which you plan to install. It is necessary to select a ball valve with an appropriate indicator, thread type. Again, it all depends on where you will be installing.

Pay attention to what threads are on both sections of the pipe, and select the product so that it matches the existing parameters. The following types of ball valves are distinguished by the location of the thread on both sides: both external, both internal, one external, the other internal, one internal, the other "American"

If for some reason the ball valve does not match the pipe according to these indicators, then you can use an adapter, but this will significantly reduce the strength and reliability of the pipeline, since each additional connection increases the possibility of leakage, the presence of free space. The ball valve can be either with a short or with a long handle. The choice depends on how much free space there is where you will place this product. You should be able to turn the handle without bumping into obstacles. So, if the space around the connection is not spacious, it is better to purchase a model with a short handle.

The choice of location for the installation of the crane is also important. It is necessary, firstly, that there be free access to the connection points. That is, this section of the pipeline should be located in an open way.If, for the sake of aesthetics of the room, you mask the pipeline in the wall or in a special decorative box, then provide for the presence of a door in those places where you will need to look in order to check and maintain the joints.

During the installation process, knowledge of some of the nuances may also be useful:

when dismantling the old faucet, even if the riser is turned off, the remaining water will drain from the pipes. In order not to make a flood on the floor, prepare several large rags in advance, and place a basin or other suitable container under the place where the valve is installed. Thus, you will make the process of work more comfortable, do not forget about sealing the joints. To do this, you can use either FUM tape or linen tow in combination with a special paste. Both materials do an excellent job of their function, but they must be used correctly. Winding on the thread is carried out in the same direction in which the element will be wound

When installing a ball valve, pay attention to how freely it is screwed on: you must make efforts for this, but not excessive, because in this case you can seriously damage the element

If you are installing the pipeline on the street, then do it taking into account the climate. The use of ball valves is unacceptable at air temperatures below zero. Otherwise, the faucet will simply burst, freezing.

When using such a product in a central heating system or in the case of high pressure in the pipeline, it is necessary to choose especially high-quality equipment. Firstly, there must be an oil seal on such a crane.In the absence of it, when a leak occurs, you will not be able to fix the problem yourself, you will have to call the emergency service.

Secondly, pay attention to the popularity and reputation of the manufacturer. Ball valves are classified as equipment of increased responsibility

After all, it directly depends on them whether, in the event of, for example, a mixer failure, you can quickly turn off the water in the system, thereby minimizing trouble both for your home and for your neighbors' apartment.

Therefore, it is better not to skimp, but to give preference to products of well-known and well-established manufacturers, even if the cost of such products is several times higher than the price of the cheapest ones. But in return, you will receive a guarantee that, if necessary, the crane will work as it should.

As you can see, friends, the procedure for installing a ball valve does not raise any special questions or difficulties. If you follow all the installation rules, then the result will surely please you. To also get a visual picture of what you have to do, watch the video, the link to which is just above. I'm sure you'll do great. Good luck!

Why are there taps on radiators?

Each heater is a separate element of the system that needs adjustment and periodic maintenance. If, however, the flow of coolant through the batteries is controlled depending on the need for heat, then good results can be achieved in terms of energy savings. That is, radiator valves and taps for heating are designed to solve such problems:

- Complete isolation of the heating device from the system.

- Restriction of the coolant flow through the battery.

- Change in coolant flow depending on external conditions.

- Bleeding air from the radiator and piping network.

There are many situations in which it is difficult to do without disconnecting the battery. For example, a properly functioning central heating in the middle of spring, when it is already warm outside, and the apartment is just hot. Another case is the need to remove the heater in order to replace, flush or repair. In the absence of shut-off valves, it becomes problematic to carry out any action with the radiator.

Valves put on batteries in retro style

Restriction of the flowing coolant is carried out in order to balance individual heating in a private house or apartment

No matter what type of heating system you have, without balancing with valves, the first batteries will always receive more water than the last ones. To limit the coolant flow at the beginning of the network and thereby equalize all the devices with each other is the task of the control radiator fittings. Automatic control of the flow of the incoming coolant is a way to save energy used to heat the house

If every tap on the heating battery will maintain the set air temperature in the room, controlling the flow of water through the radiator, then in general the system will consume only the required amount of heat, no more. And that's a big savings.

Automatic control of the flow of the incoming coolant is a way to save energy used to heat the house. If each faucet on the heating battery maintains the set air temperature in the room, controlling the flow of water through the radiator, then in general the system will consume only the required amount of heat, no more. And that's a big savings.

Well, the problem of air release when filling the system or during operation is also solved by special air valves installed on all modern radiators. Below is a list of varieties of shut-off and control valves, listed in the same order as the tasks it solves:

- Semi-turn ball valves in straight and angle versions. They are made of brass, bronze or polypropylene with a metal insert.

- Balancing valves for radiators - straight and angled.

- Adjusting valves with thermal heads (thermostatic valves).

- Drain valves - automatic and manual.

For reference. Some home craftsmen use three-way mixing valves to connect heaters. But such a solution is unreasonably expensive and rarely used in practice.

Now we should consider in detail which taps are best placed on radiators in various conditions and circumstances. Some options are clearly shown in the video:

Scope of application

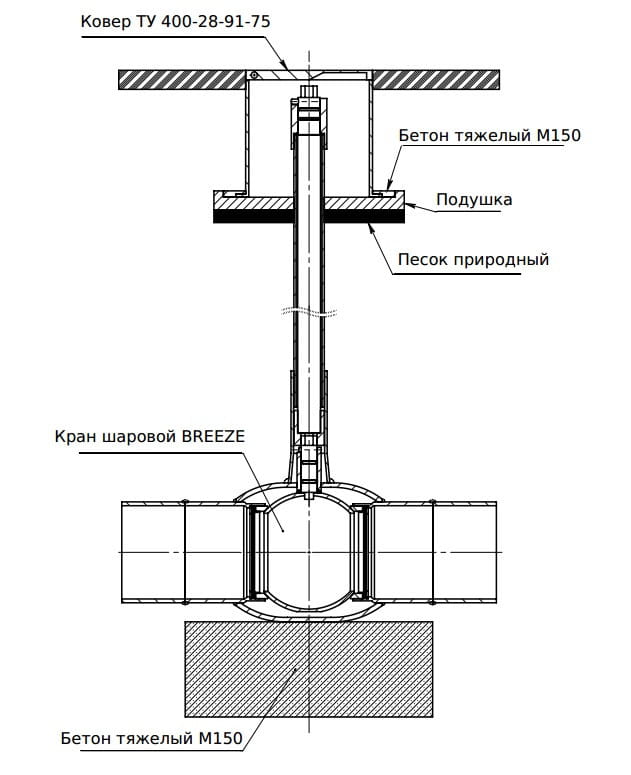

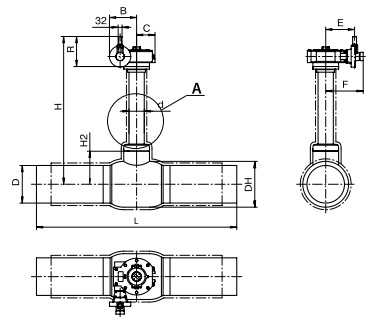

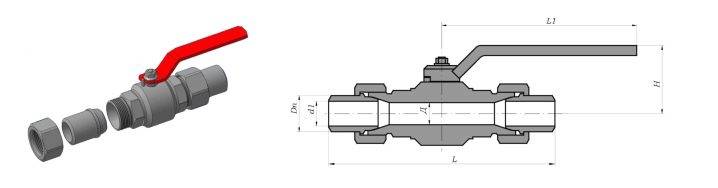

Coupling

They are used to equip gas, water and heating systems of residential buildings and public buildings. Most often used for standard radiators, even under the carpet. Union valves are convenient and easy to use, practical, compact, easy and quick to install without special equipment. Suitable for pipes with a diametrical section of not more than 40 millimeters. If the pipe is larger, it is better to opt for a flanged valve.

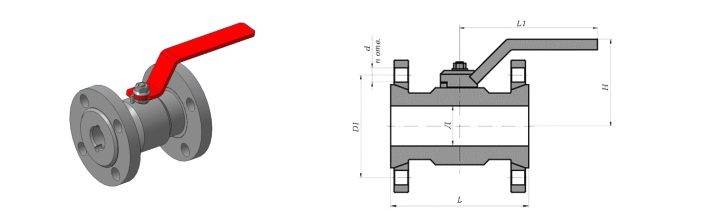

Flanged

Mounted on pipes with a diameter of more than 5 centimeters.To achieve maximum tightness, special seals are used during their installation. This type of spherical structures is characterized by increased strength indicators. They are collapsible non-collapsible. In the first case, the design consists of two elements (to ensure easy and quick disassembly). This is necessary in order to easily replace a faulty structural part. Non-separable flange options have an integral body, and in case of damage to any part, the valve must be completely replaced.

Welded

Most often, such ball valves are mounted in closed places and cannot be dismantled. For example, they are often used in the construction of buildings. This is the main difference between the welded type and all the others. The structure is created by welding.

Combined

They include several options for attaching to pipes. The number of branch pipes for combined cranes is different, in connection with this they are: through passage, angle, multi-way. The latter option is simply indispensable in situations where there is a need to mix several different media at the same time.

There is another, much less common type of ball valves - choke. It is used in various industries: chemical, food, etc. The main feature of such structures is the possibility of multiple dismantling. They are simple to implement and convenient to use.

Classification of water ball valves

Speaking of ball valves, it is worth separating the concepts of “faucet” and “faucet”. Both varieties are united by a common structural element for them - a locking or regulating part in the form of a body of rotation of a rounded configuration.

Actions for locking the pipeline or adjusting the flow are performed by turning this element around its conditional central axis.

Cranes can be installed between the elements of the plumbing system, or they can be the end point of the pipeline.

In the first case, the devices are called shut-off devices, and in the second they play the role of water folding devices and most often are well-known mixers.

A huge range of faucets for water supply allows you to choose a device for any water supply system with optimal parameters and external design

A huge range of faucets for water supply allows you to choose a device for any water supply system with optimal parameters and external design

A mixer is a mechanism for mixing water and regulating its temperature, while a faucet can only regulate the amount of pressure.

Shut-off ball valves are divided into passage valves, i.e. installed in a straight section of the pipeline, angular, i.e. located on the site with a change in the direction of flow by 90º, and on a three-way, i.e. supplying the flow to two receiving nozzles.

Due to the simplicity of the design, the ball valve rarely breaks, it is extremely easy to repair and install

Due to the simplicity of the design, the ball valve rarely breaks, it is extremely easy to repair and install

Valves with ball valves are used in water supply and heating circuits.

According to the throughput parameters, the taps used in thermal systems are divided into:

- Full bore. Ball devices, in which the diameter of the outlet of the ball plug, it is also a shutter, is equal to the diameter of the pipeline on which the valve is installed.

- Reduced. Plumbing fixtures in which the diameter of the outlet of the ball plug is less than the same size of the pipeline in most cases by one standard size.

Cranes of the reduced type allow you to shut off the heat main quickly, but without the threat of the formation of a water hammer.

By type of connection to the water supply system:

- Threaded. Fittings with internal or external conical or cylindrical threads. Mounted by screwing on couplings or screwing in spigot fittings. The most common type in public utilities is easy to install, makes it easy to carry out repairs.

- Combined. Devices equipped with internal and external threads. On the one hand, they are connected by means of a coupling with an internal thread, on the other hand, by a nipple fitting.

- Welded. Mounted by welding. With impeccable performance, the connections provide perfect tightness, do not require periodic adjustment of the position of the couplings, like the previous version. However, they are inconvenient to repair, because. together with them it is necessary to dismantle part of the pipeline.

- Flanged. Are established by means of flanges on responsible pipeline highways. They can be repeatedly dismantled and re-installed. Periodically require control of the bolted tightening of the flanges.

In autonomous water supply systems, conventional threaded devices are most often used, which allow the assembly of a pipeline of any complexity from all known types of pipes or a combination of them.

Ball valves are produced with external and internal threads, allowing them to be connected to the pipeline by means of couplings or fittings.

Ball valves are produced with external and internal threads, allowing them to be connected to the pipeline by means of couplings or fittings.

By hull type:

- all-welded, the body of which is a single structure;

- collapsible, when the body elements are bolted together and can be easily disassembled.

The first type of product is considered the most reliable, but in the event of a malfunction, such a device cannot be repaired. Collapsible cranes often fail, but are easy to repair.

Information on how to repair a ball mixer is discussed in our other article.

By type of liquid passed:

- for cold water up to +35 ºС;

- for hot water up to +90 ºС.

Devices are controlled using a lever or butterfly valve. The choice of a valve with a particular control method depends on the location of the valve and the preferences of the owner. Cranes with a lever are often installed on the central sections of the pipeline, with a "butterfly" - on the branches of the system.

Ball valve mixers are installed in kitchens, bathrooms and are the end points of the water supply system.

There are a lot of options for distributing the water supply system inside the house, but in all cases, ball valves are installed on the plots as shutoff valves

Locking device

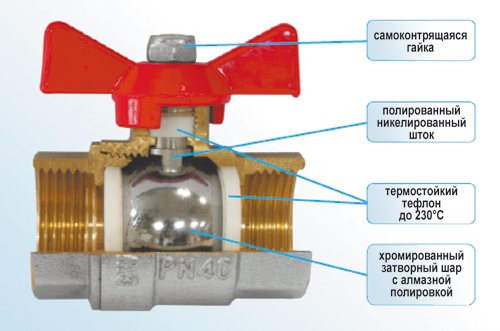

Ball

Ball valves are the most commonly used angle fittings today. The constipation of this device is made in the form of a ball with a through hole. When the ball is turned with holes perpendicular to the body, the flow passage is closed.

The tightness of this mechanism is achieved with the help of elastic rings that fit snugly against the ball.

The advantages of this design include:

- Long service life due to the simplicity of the mechanism.

- Low price.

- Tightness in the closed state, due to which this valve can be used for gas pipelines.

- Ability to withstand high pressure.

- To fully open or close the passage, you need to turn the lever only 90 degrees, which is very convenient.

Diagram of the Bugatti ball valve

As for the shortcomings, they include the following points:

- Instructions for the use of ball valves suggest its use only for the complete opening or blocking of the passage, i.e. it cannot be used to regulate the flow, otherwise the mechanism will quickly deteriorate and the valve will begin to pass water.

- The device is not repairable, so if it fails, it must be replaced.

Since in most cases the task of the shut-off valves under consideration is to completely shut off the flow, it is ball valves that are used for plumbing fixtures, heating appliances and gas pipelines.

In the photo - a valve valve

valve

Not so long ago, only valve taps were used everywhere. The principle of operation of their constipation is based on the use of a worm mechanism that presses a stem with an elastic gasket against a seat with a hole. As a result, the gasket blocks the passage.

When the handwheel is rotated, the worm gear raises the stem and thereby opens the passage.

Among the advantages of such a product are:

- The ability not only to block the passage, but also to regulate the flow pressure.

- Ability to withstand high pressure;

- The ability to repair the locking mechanism with your own hands.

Along with the advantages of this device, there are quite a few disadvantages:

- Due to the fact that the moving gasket is constantly in contact with water and a metal surface, it wears out quickly.This leads to depressurization of the constipation, and the device begins to leak water. True, you can replace the gasket yourself. As a rule, the kit includes an assembly drawing of a valve-type angle valve, which shows how to disassemble the product and replace parts.

- To fully open the valve, it is necessary to make several turns of the flywheel.

- Since the mechanism is more complex, it fails faster than ball valves.

For these reasons, valve valves have recently been used only where it is necessary to regulate the flow. (See also the article Water pipes: features.)

brass valve

Obtaining approval for the replacement of the gas pipeline

Whether or not a transfer is possible can only be decided by the authorized bodies, that is, the gas service of your city (district). Only a qualified specialist has the right to engage in any dismantling and installation work. Of course, without agreement, the transfer of pipes cannot be carried out.

Even such a simple step as cutting the pipe by 10 cm must be agreed, since all work related to the gas pipeline is included in the risk category

Permission is issued in the following order:

- You find out the contact details of the gas service at the place of registration, contact the specialists, explain the situation, consult.

- Compose an application (according to the standard form), which will “launch” the approval process.

- Based on the application, a representative of the gas service arrives at your home. The time is specified in advance.

- The specialist examines, listens to wishes, answers questions.Often at this stage it is necessary to change plans, since the desired transfer does not meet safety requirements (a preliminary study of the gas pipeline installation standards will save you from this unpleasant moment).

- Approval of the final transfer scheme, budgeting. All documents are drawn up by the organization providing services. No work will be done without the consent of the landlord.

- If the transfer conditions are satisfied, you pay for the service according to the receipt and agree on the start time of work.

The approval procedure usually takes several days; it can stretch for a long period for only one reason: if the property owners and representatives of the gas service have not found a compromise solution.

Any factors that violate the norms for installing gas stoves (boilers, meters, columns) can cause a refusal to transfer pipes.

and its varieties

Depending on the engineering features, valves are classified into several varieties. According to the form of construction, cranes are divided into:

- straight-through;

- corner;

- mixing;

- walk-throughs.

Depending on the functional features, the valves are divided into:

- locking;

- with the possibility of locking adjustment;

- special valves.

Another feature for dividing mechanisms into subspecies is the functional bandwidth. Here the cranes are divided into:

- standard;

- full bore;

- incomplete bore.

To determine the bandwidth, the cross-sectional area of the hole in the ball valve is calculated to the cross-sectional area in the cylinder.

The purpose of the ball valve is also determined by the material of its manufacture: titanium, steel, polyethylene, cast iron, bronze.

Depending on the direction of work, there are three types:

- Valves for opening and closing the flow in the pipe. The main requirement that they should comply with is to ensure tightness in the closed state and a minimum level of resistance in the open position.

- Adjustable ball valves are used to change the flow rate in the pipeline.

- Special purpose valves - to ensure high-quality work with aggressive media.

Cons of operating ball valves

- Difficulties with flow control. Opening or closing occurs with a rough, short-stroke turn. Such taps are inappropriate for work in systems where smooth pressure control is required (shower, washbasin).

- Ball valves do not tolerate downtime. With a long absence of any manipulations with the valve, corrosion forms on the surface of the ball, which, if necessary, open or close the flow, will prevent the rotation of the sliding mechanism. Jamming of the locking mechanism or damage to the fluoroplastic rings leads to breakage or leakage of the device.

- Capriciousness to impurities in water. Particles of sand or rust damage the polished surface of the ball, leave scuff marks on it, which subsequently become the cause of a leak. Saves from this additional installation of filtering devices.

Despite the existing flaws, the ball valve is a worthy invention of the present. By most parameters, and most importantly by reliability, it surpasses analogues. A minimum of components once again confirms the statement: - "The simpler, the more reliable."

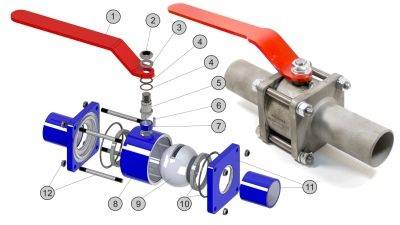

Ball device

In the saddle there is the main element - a cork in the form of a ball with a different number of cavities. The ball rotates freely inside the seat.The internal devices of cranes are divided into full passage and reduced (standard passage).

Fully through passage valves in their device have a ball with an opening equal to the diameter of the pipe. During the passage of liquid in ball valves in the fully open state, hydraulic losses are minimized. This quality ensured the use of fittings of this type as the main locking device.

Reduced valves are used in pipelines where pressure does not play a special role. The ball is connected to the levers by means of a rod. The lever controls the water directly. Lever valves are used in the central sections, and butterfly valves are used in the branch parts of the system.

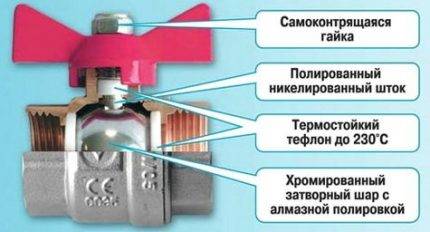

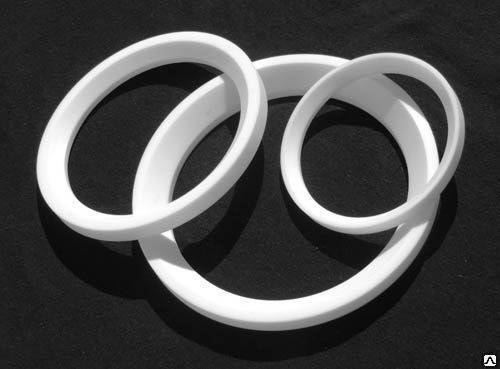

PTFE sealing elements

In the early use of ball valves for water, a complete shutoff of the flow was not ensured. The lack of providing the elements of the crane with metal parts did not allow this to be achieved. The beginning of the use of new materials led to the widespread use of ball valves. Seal rings and sanitary gaskets are now made from a variety of materials.

For these purposes, metal alloys, rubber, plastic of all kinds, graphite or teflon can be used. Even as materials for the manufacture of these important mechanisms, synthetic rubbers began to be used. At the same time, PTFE sealing elements are widely used. They provide tight closing and reduce the effort used when working with a crane.

This new generation material is resistant to aggressive liquid and gaseous media.In domestic use, it is recommended to use it when installing heated towel rails and laying a gas pipeline.

The main positive quality of PTFE is the ability to twist. Simply put, when using a fluoroplast product, a sufficiently strong twist can be used without undesirable consequences.

In such taps, the connection is sealed due to the creation of contact by means of an o-ring. Therefore, the material for the manufacture of rings plays a crucial role in the further use of the crane.

Fluoroplastic completely seals, gives ease and smoothness to the rotation of the ball plug. To close or open fully, a right angle turn is performed. The lever turns the ball valve of the valve, completely or partially blocking the flow.

Principle of operation

The principle of operation of a ball valve for water is to align the holes in the plug and the valve body. The holes are aligned when the ball is turned with a lever. This ensures that the holes match and allows flow to flow through the aligned cavities. By turning the ball, the passage is blocked by the side that does not have an opening. In this case, the flow of the medium rests against the wall and stops.

Using this principle, you can not only completely stop, but also regulate the flow. When turning at an angle of less than 90 degrees, the flow is only partially blocked.

Angle ball valves

The design of the product provides convenient installation when installing plumbing and heating systems. Our range includes various standard sizes of angle taps equipped with an American.The available variety of products allows you to buy a corner crane with an American to quickly complete the planned installation operations. The brass body of the valves is resistant to water, steam and all kinds of non-aggressive liquids.

The compact American corner faucet is equipped with a removable butterfly-shaped adjustment knob, which allows you to mount stop valves in a limited space. All products in our range are certified and tested by the quality control service. A high-quality American angle crane is capable of trouble-free service for several decades. Accurate execution of a threaded connection has a positive effect on the speed of installation and the tightness of operated systems. The wear-resistant American angle ball valve has a long service life, based on the impeccable technical performance of the components. The perfect fit of the metal ball ensures easy movement when shutting off valves and guaranteed tightness of the pressurized system. When installing heating systems, a 1/2 angle tap with an American pipe provides the possibility of periodic dismantling of the radiator for service.

The use of corner devices helps to optimize the design of pipeline systems for various functional purposes. A small-sized American angle ball valve is in demand when installing systems with a complex configuration. A non-standard device can be installed without difficulty in a narrow opening or niche. Reliable American angular ball valve is designed for repeated use without deterioration of primary characteristics.The use of filter elements helps to increase the stability of the operating system by minimizing sedimentation processes. Reducing the amount of impurities in the coolant or tap water helps to reduce the load on the surface of the ball that blocks the flow of the working fluid.

Compared to standard valves, an American angle ball valve helps simplify installation by using a more convenient type of connection. Our product range includes products that differ in nominal diameter, installation dimensions and functional characteristics. It is possible to buy an angle crane with an American from us for quick installation of systems of standard and non-standard configuration. Brass products are resistant to corrosion, temperature extremes and high humidity. Durable shut-off valves are a reliable component of water supply networks and heating systems for residential buildings and public facilities.

Differences of ball valves for water and gas

For water

Water ball valves adjust the water supply, and also shut off the pipeline if necessary. They are installed on the wiring and lines leading to the washing machine, dishwasher, other household appliances, to the sink, shower. They can be mixers for cold and hot water. The cross section of such taps varies from 1/2 inch to 200 mm.

For gas

To shut off the gas flow, special ball valves are used. They are distinguished from water taps not only by their appearance, but also by their design features in the form of an elongated connecting section, a stronger body and a sealing ring. They are installed on gas pipelines. The diameter of welded gas cocks is from 10 to 70 mm.

Mounting

Proper installation of a ball valve can be easily done by hand. Consider several options for mounting the device.

Photo - winding on a radiator

Pipe mounting:

First you need to drain the water from the entire system. To do this, turn off the water supply and open the valves;

Before you start, you need to select a device. You can buy ball valves with double-sided external or internal threads, models with an American connection on one side and a thread on the other, etc. In addition, note that the size of the valve opening must necessarily match the diameter of the communication;

At the installation site of the future water tee, the pipe must be cut and prepared. Depending on the type, a thread is cut on it or the outlet is simply cleaned of dirt and dust (when dismantling old fittings);

Screwing is carried out using an adjustable wrench

In this case, it is important to monitor the direction of the thread and the pressure force. You can not strongly pinch the device, otherwise it may bend and the sealing of the system will be broken;

A sealing tape is necessarily wound on the tap thread or a special paste is applied

This must be done to protect the threaded connection and ensure the tightest fit of the taps;

Fum-tape (seal) is wound in at least 5 turns;

The product is screwed onto a riser, heating outlet or any other communication only by 5 full turns of the thread. With a smaller amount, there will not be the desired connection, and with a larger amount, a joint may form, on which various rubbish from the plumbing system will be collected.

When the winding is over, you need to additionally check the junction and turn on the water supply.If water has flowed from the lower section of the faucet, then you need to remove it and check the stuffing box (some unscrupulous manufacturers sell devices without them at all). In some cases, you have to install it yourself or additionally seal it with a flax rope or special fillers.

Conclusion

The gas pipeline must be equipped with reliable cranes in case it is necessary to isolate its individual sections. In particular, this applies to places of connection to gas devices, and emergency areas. The best option is ball valves due to its high reliability, many and ease of operation of other advantages (see also the article “Why install a Mayevsky crane in heating systems”).

The video in this article will provide you with additional data that is clearly related to the materials presented. Choose only the best components for arranging a gas pipeline.