- Manufacturing of component parts

- Lightweight, small size devices

- Complete hatches

- Making an inspection hatch from improvised materials

- Manufacture of an inspection hatch from ready-made components

- Production material

- Cast iron

- Polymer

- Structures from other materials

- Features of choice

- Overview of the design of the sewer manhole

- Main details

- With lock or without lock

- Appointment of inspection hatches in bathrooms

- Types of inspection hatches

- Swing

- sliding

- Luke - "invisible" push action

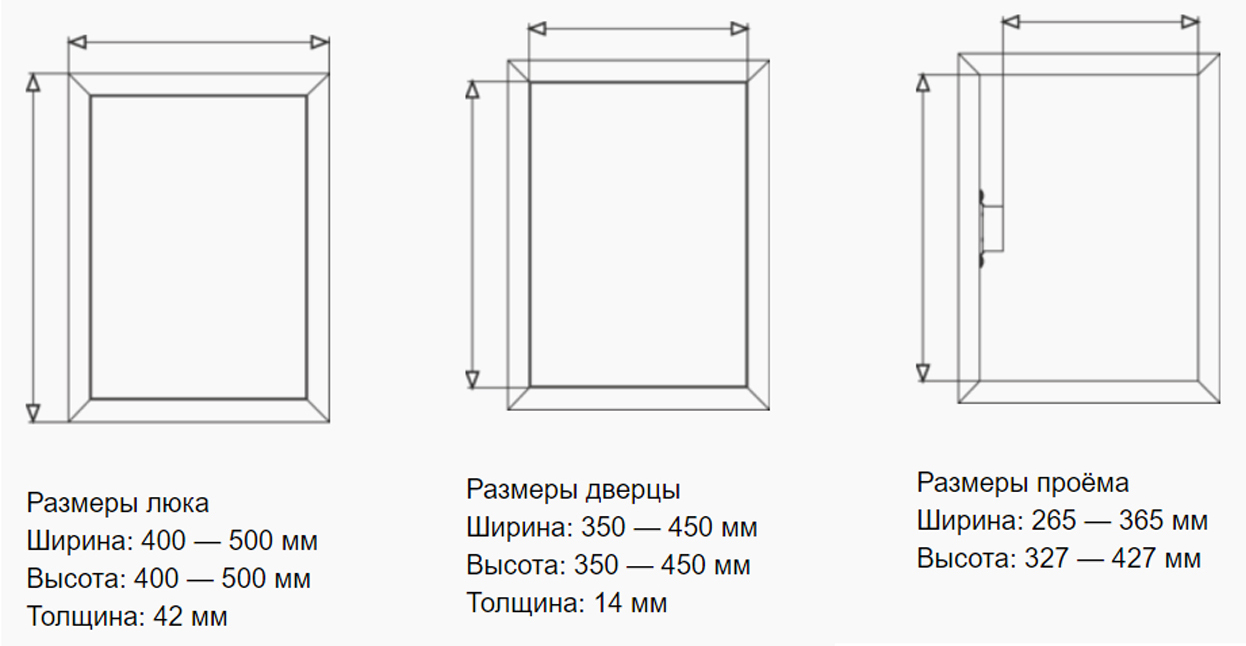

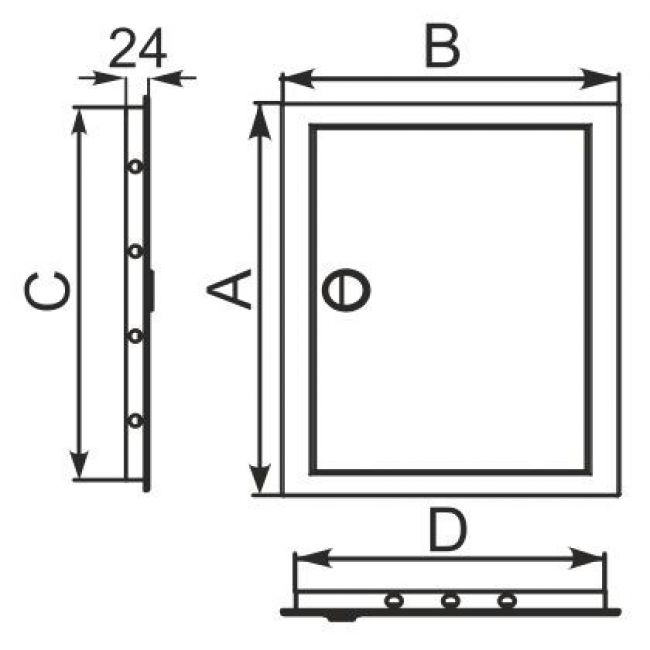

- Design and dimensions of sanitary hatches

- Design approach and form

- Features of choice

- Properties and specifications

- Sanitary revision hatches for ceramic tiling.

- Description of the design of inspection hatches for tiles

- How to do it yourself?

- Decoration options

- What needs to be accessed

Manufacturing of component parts

The material for the manufacture of the hatch - "invisible" depends on the size of the viewing device and the capabilities of the performer. When the dimensions of the revision window do not exceed the size of one or two tiles, the design of such a product can be simplified. If the dimensions of the hatch, and, consequently, its weight after tiling are significant, it is unreasonable to save on materials.

Consider two options for manufacturing a viewing device:

- lightweight fixtures for small openings;

- full hatches.

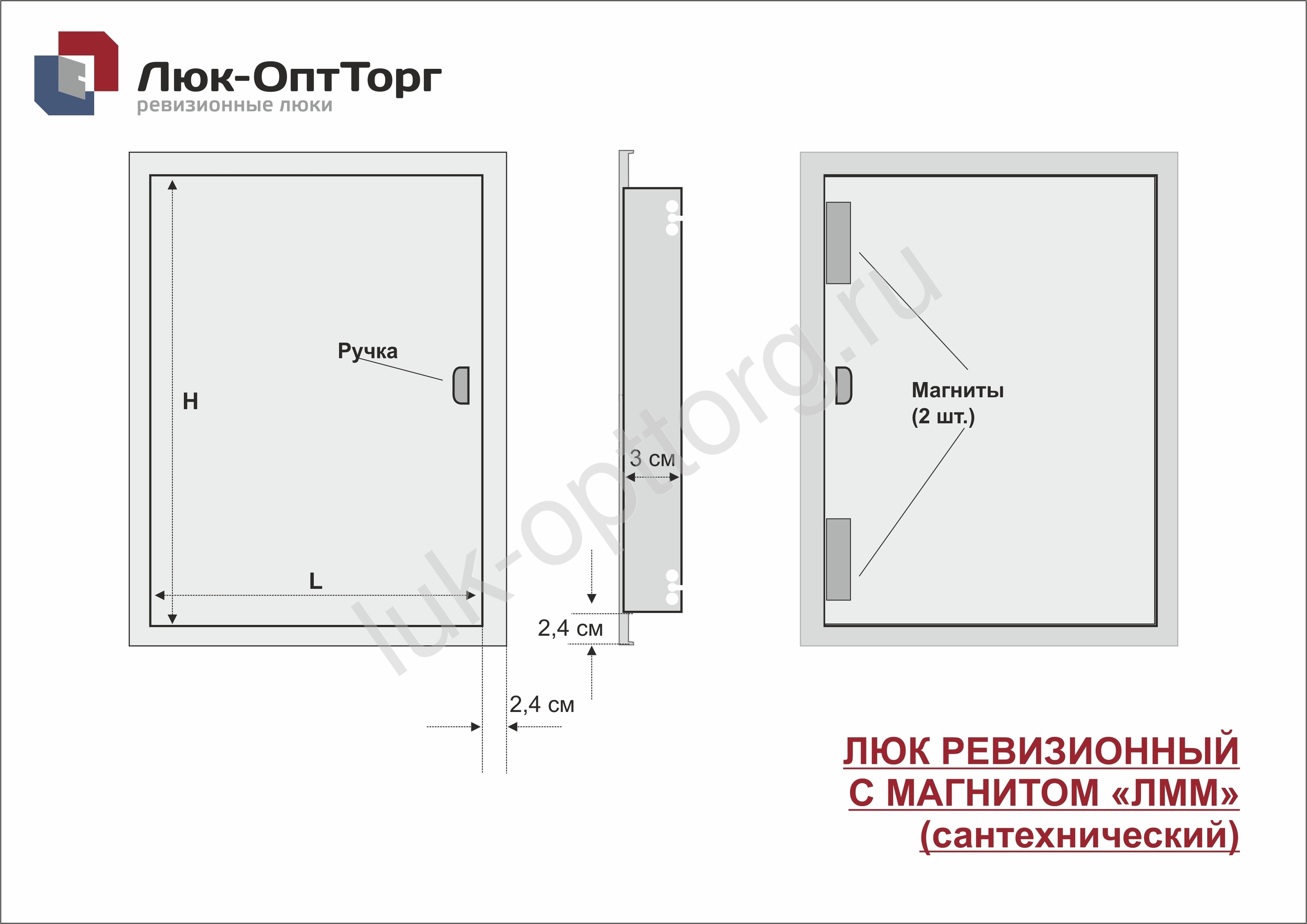

Lightweight, small size devices

An inspection hatch for arranging a small opening can be made without hinges. In this case, the role of the sash will be played by ceramic tiles, on the back of which around the perimeter, depending on the size, you need to stick 4-6 fixing magnets. If the hiding partition in the bathroom is made of drywall, then a steel frame of such dimensions is attached to the opening in it from the inside with self-tapping screws so that its edges protrude from the landing niche and serve as a counter part of the magnetic fastening.

Proper installation of the inspection hatch will solve the problem of access to hidden drainage systems

The dimensions of the fixing magnets are selected (grinded) in such a way that the front surface of the tile - plugs is on the same level with the wall cladding. The opening of such a hatch is carried out using a removable suction cup handle. It is possible to use such a device on the bathroom floor only in places without load on the “sash”, for example, in the floor of a built-in wardrobe.

If the partition is made of brick, then to fix the tile - the door with magnets along the perimeter of the end of the opening, cut-to-size pieces of a steel corner are fixed with self-tapping screws.

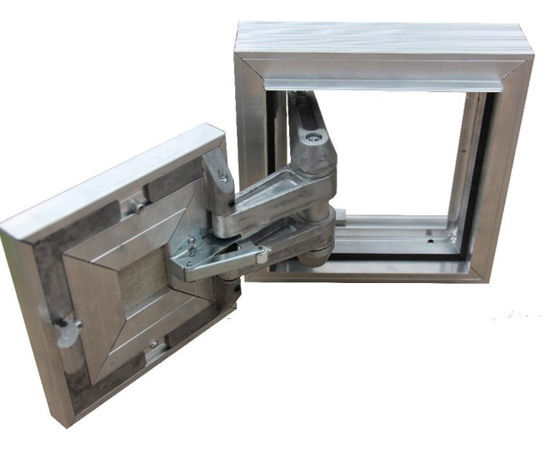

Complete hatches

The inspection hatch of the standard configuration can be made in two ways: from improvised materials, or using special components, copying the technology of manufacturers. The choice of manufacturing method depends on the dimensions and degree of responsibility of the device, which are determined by the characteristics of the operation of each particular hatch - "invisible". Let's take a look at both of these technologies.

Making an inspection hatch from improvised materials

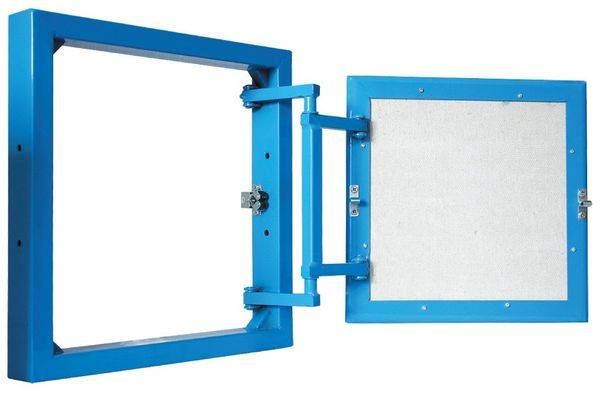

The box-frame is made of a steel corner or a rectangular profile 60x40 or 50x30 mm in size, which are connected by electric welding, followed by grinding the welds with a grinder. Then, from the specified profile, it is necessary to make the frame of the hatch sash, which should fit in the box with a gap of 2 mm on the sides.

Inspection hatches are supplied with a hinged door with a locking mechanism

A square-section steel bar is welded along the inner perimeter of the box so that the door in the closed position lies flush with the front plane of the box on it. Then the sash is fixed in a box on furniture hinges using metal screws, having previously cut round nests under them in the door frame. The number of loops depends on their quality and the weight of the sash.

Instead of furniture hinges, you can use a more advanced door opening mechanism without handles (Push to open), or a push system. The price of a set of these accessories is much higher, but it is justified by the design advantages.

An OSB sheet (oriented strand board) is attached to the frame of the sash using self-tapping screws, the dimensions of which should cover the hatch box.

To fix the closed door in the box, a system of furniture magnets or a ready-made lock of one of the types offered by manufacturers is used.

Manufacture of an inspection hatch from ready-made components

Unlike devices made using improvised means, only special fittings are used in the assembly of these hatches. As a rule, in the independent manufacture of such a device, drawings or a working sample of the product are used.

The box and frame of the hatch sash are made according to the technology described above. Then, an aluminum sheet 3-4 mm thick is attached to the sash frame using self-tapping screws or broaching rivets, the size of which should overlap the box.

Based on the characteristics of operation and the location of the hatch, choose the type of hinges and locking device. The assembly of the product and the adjustment of the components are carried out according to the instructions for the fittings, after which the steel structural elements are covered with two layers of anti-corrosion paint.

Production material

Today, cast-iron hatches are most common, since for a long time there was almost no alternative to the material. Occasionally, concrete and steel products were used. Not so long ago, plastic lids appeared, but they are expensive. Polymer is cheaper, and the quality is superior to plastic.

Cast iron

When the hatch is subjected to increased mechanical and weight loads, cast iron is the optimal solution. The service life of a product made of it is more than a century, it does not deform from frost or heat. Significant disadvantages of cast-iron hatches are a large mass and high price.

At the enterprises, a lid and a neck are cast, which can be with a cast-iron rim and a concrete base. Some modern models are equipped with rubber gaskets. The body metal is less durable, the lid is stronger. The design can withstand heavy loads.

In the home sewer, manholes are located where they are not subjected to heavy loads. Therefore, it is more rational to use models from lighter and cheaper materials. The weight of cast iron products is large, so it is difficult to open them.

Cast iron manhole.

Polymer

In parks, on garden paths, dachas, polymer and plastic covers are more common.Plastic is an expensive material and inferior in strength and durability to polymers. Large plastic covers are rare, mostly small inspection hatches are made.

Distribution received polymer-sand products. This is a synthetic material, for the manufacture of which a special technology is used: 30% polymers, 69% fine sand and 1% iron oxide are mixed. The production uses secondary raw materials from plastic bottles, etc., so the products are cheap. After adding sand and heat treatment, the mass is pressed and cooled. Strength is increased by including reinforcement in rings and caps.

Manufacturers pay much attention to the decorative design of the covers. They are dyed with pigments.

The color masks the product or, conversely, attracts attention, signaling danger. Covers are often made in relief, with patterns and ornaments.

Polymer hatches are easy to use: they open and close easily, do not freeze to the neck in winter.

They are much lighter than cast iron lids, but are far inferior in load bearing capacity. Therefore, polymer and plastic products are not installed on roads with heavy traffic.

polymer hatch.

Structures from other materials

Concrete hatches are most often used in the construction or renovation process. They are a reinforced concrete slab with protruding brackets, with which it is moved.

If the product is of non-standard size or shape, it is closed with a reinforced concrete lid. In home sewerage, these hatches are used to ensure the tightness of a well made of concrete rings or a rectangular monolith. These items are made to order.

Steel hatches are almost never used, because they are heavy, inconvenient, and rarely provide tightness. These products are mainly used as a second inner cover in electric and telephone cable ducts. They are supplied with locks.

Features of choice

First you need to decide on the material. Steel hatch is best placed in places with low humidity. Plastic or aluminum (their dimensions are the same) can be installed in any room, they will withstand different temperatures and aggressiveness of the environment.

When choosing, you should pay attention to:

- Strength.

- Material.

- Moisture resistance.

- Possibility to veneer with other materials.

- The location of the doors (how they open).

- The size.

- Wear resistance and impact resistance.

The main requirements for stability are imposed on ceiling and floor structures. Floor hatches must be resistant to external influences, have a durable mechanism and have additional security, soundproofing. The doors of ceiling models should be light, with a provided closing method (so that they do not accidentally open). Such hatches are more often used in commercial premises, garages.

Overview of the design of the sewer manhole

The design of the hatch is simple, functional and has not changed for decades. Recent innovations relate to the development and installation of locks of various types.

Main details

Covers are mainly made:

- round: even incorrectly installed ones will not fall into the inspection shaft;

- with a ribbed surface: improves grip on pedestrian shoes, car wheels;

- flat or convex so that water does not collect.

Many modern lids are provided with a hole through which they can be hooked to facilitate opening. Holes are made only in covers for sewer, water supply, drainage, storm wells - water gets inside through them.

With lock or without lock

Locks are needed on cast iron hatches for several reasons:

- To protect against third-party penetration into wells that provide access to valuable equipment.

- If the cover has a lock, it cannot be installed incorrectly. Skews with a loose fit can cause an accident on the road.

- Protect against theft for the purpose of scrapping.

Cast iron manhole with a lock.

Locking devices come in several options:

- Flag connection installed between the cover and the rim. Castle with a secret.

- Threaded. The cover is screwed into the body and can get stuck, so this option is unreliable.

- A bolt with a secret that connects both parts.

- The spacer mechanism on a cover blocking a product at closing.

- Crab with 2-6 rays on the hatch to block the entrance.

Access to the manhole with communication and electricity communications is blocked by 2 covers: protective and locking. The latter is located in the shaft, made of steel, equipped with a lock so that outsiders do not penetrate the cables.

Heavy products are equipped with simple locks in the form of protrusions included in the grooves of the neck. They open with special hooks. Flag, bolt or spacer locks are expensive, they are installed on the wells of communication and power supply networks that require increased protection.

Sewer manhole with locking device.

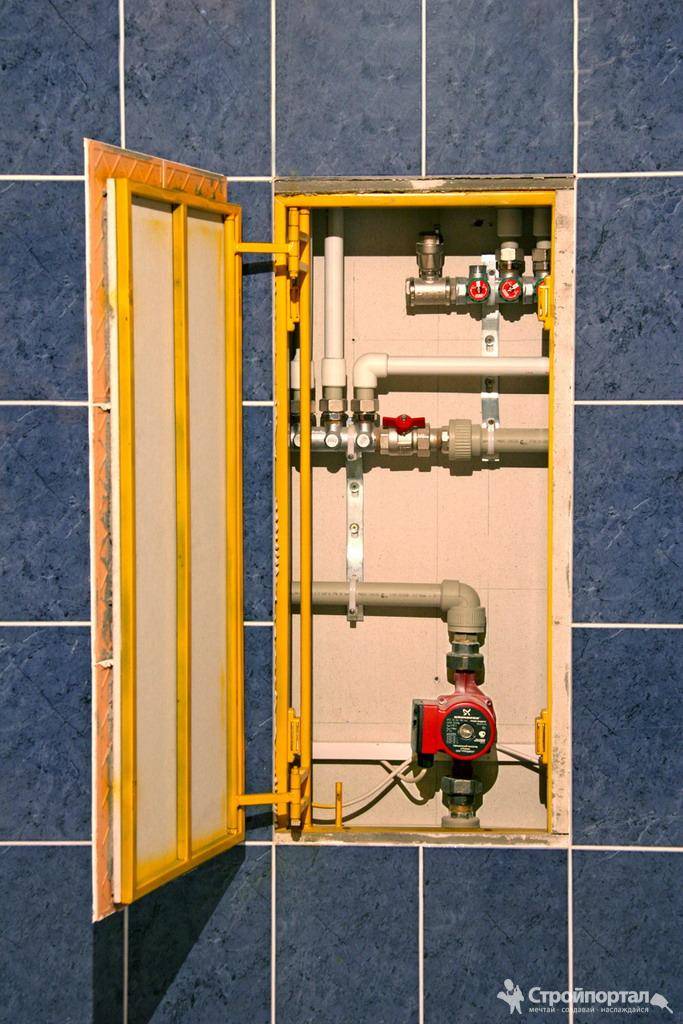

Appointment of inspection hatches in bathrooms

A distinctive feature of modern bathrooms and toilets is a thoughtful design, as a result of which the aesthetic side of the finish comes to the fore. Technical devices that ensure comfortable adoption of water procedures or ease of using the toilet are hidden behind thin structures made of plastic or drywall. Constant maintenance of pipes is not required, but periodically there is a need to use stop valves. For example, to cut off the water supply to the kitchen in connection with the replacement of the mixer, you need to turn off a certain tap.

Devices resembling doors or hatches are necessary for servicing metering devices that are disguised behind partitions. By moving the damper or opening the door, you can quickly take readings from hot and cold water meters

If the bathroom is completely lined with plastic or tiles, more hatches will be required. Suppose one of the nodes to which constant access is needed is the installation site of the water seal for the bath. If the protective screen is made deaf, then it will have to be dismantled every time a blockage occurs in the pipe or a leak occurs at the junction of the siphon parts.

It can be concluded that any components and devices that require regular checks should be freely available. And with full cladding of the premises with tiles or plastic, this can only be ensured with the help of technical hatches.

All of them perfectly cover unaesthetic nodes, but the need for access to communications remains. For this, revision niches are used.

In order to easily inspect and repair plumbing fixtures, pipelines, replace counters, revision niches are left. They are closed with special hatches.

Some models of hatches for revision niches were originally designed so that they could be pasted over with the same coatings that the walls are finished with: wallpaper, tiles or panels.

Such structures do not stand out against the background of the walls, so they are called invisible.

There is plenty of space under the bathroom. It is usually covered with a screen, and a technical niche with a hatch. These designs can perform not only camouflage functions. If shelves are attached to the screen, and large bottles with cleaning and detergents are placed in the revision niche, you can free up space in the wall cabinet and save usable space

Sometimes niches in the walls serve to store a supply of hygiene products, washcloths, towels and other necessary supplies. They serve as cabinets, but do not take up space in the bathroom.

Such storage niches are also closed inspection hatches under tiles, and they do not attract too much attention.

Technical niches closed with hatches not only mask the equipment, but also protect against accidental mechanical damage, moisture ingress, sudden temperature changes

Types of inspection hatches

Swing

The sash of a device of this design, when opened, is fed by the entire area in the direction from the wall, and then swings open on hinges. In most cases, in such designs, suction cups or magnets are used to fix the door, but there are also products with a magnetic pressure, rotary or spring mechanism. Swing hatches are mounted in vertical bases, behind which there is enough space for a hinge system. Installing devices of this type is easier than installing other types of hatches, so it is possible to do it yourself.In addition, the acquisition of a product of this design does not require significant costs.

Hinged inspection hatch

sliding

A design feature is the use of three-phase hinges, which ensure the movement of the sash first flat towards the user, and then to the side - parallel to the wall, resembling the trajectory of a closet door. Sliding hatches usually use suction cups to secure the sash, but roller or magnetic locks can also be used. The use of hinges with a compact leaf movement path allows these hatches to be placed in the walls behind furniture or household appliances. The cost of this design is higher, but in terms of popularity, it is not inferior to swing-type products.

Sliding access hatch

Luke - "invisible" push action

The opening and closing of the sash of such devices is carried out by a spring-type mechanism, which is triggered by pressing the door. The spring type lock provides the tightest fixation of the sash after closing.

Push hatch

Hidden pressure hatches are the most popular, because, unlike sashes with suction cups, they work equally well on smooth surfaces and on bases lined with mosaics or corrugated tiles. Push-action inspection hatches can be equipped with any measuring devices and auxiliary mechanisms, the open location of which harms the aesthetics of the room decoration.

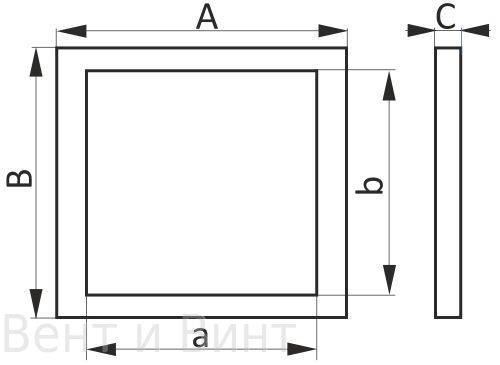

Design and dimensions of sanitary hatches

The standard inspection hatch has a square or rectangular shape, but if necessary, you can find or order a model of any configuration. There are round products resembling portholes, oval, trapezoidal.

Some craftsmen make hatches on their own, and sometimes they differ in non-banal design. The dimensions of sanitary hatches for the bathroom and toilet can be very different - from miniature designs with parameters of 100x100 mm to 800x500 mm.

Small differences in design are usually due to the dimensions of the structures. The installation methods for different models are also approximately the same: the hatch is mounted in the opening using self-tapping screws or special adhesives.

Flush-mounted hatches can vary markedly in cost. One of the most convenient, but also the most expensive options is a tile model with a sliding hinge.

Flush-mounted hatches can vary markedly in cost. One of the most convenient, but also the most expensive options is a tile model with a sliding hinge.

When choosing the size of the plumbing hatch for the bathroom and toilet, you need to focus on the size of the niche. If there is already a niche, you need to measure the opening and look for a model of the required parameters.

If it is only planned, it makes sense to immediately design it in standard sizes so that there are no problems with choosing a hatch. When searching for a hidden model, in addition to the dimensions of the niche, you need to know in advance the size of the tile.

It is desirable that an integer number of tiles fit on the door so that you do not have to cut it. Otherwise, the hatch will be visible on the wall due to mismatched tiles. The tile should protrude 0.5 cm outside the door, and no more than 5 cm from the side of the hinges.

How to choose the right stealth hatches, taking into account all the parameters, the expert says:

Design approach and form

As a rule, the shape of the hatch is a square or rectangle. But this is not a mandatory rule, you can choose the shape you need, for example, a circle, an oval or a trapezoid.

At the same time, they often carry out the installation of a bathroom hatch with their own hands at home. In this case, the design is usually original.

Also, the size of plumbing hatches can be different. So, the hatch can be miniature, while its dimensions are calculated in millimeters.

The dimensions of the structure often determine the design of hatches. However, in order to install the hatch in a place specially designed for it, they use a similar procedure, using either self-tapping screws or specific adhesives.

Features of choice

First you need to decide on the material. Steel hatch is best placed in places with low humidity. Plastic or aluminum (their dimensions are the same) can be installed in any room, they will withstand different temperatures and aggressiveness of the environment.

When choosing, you should pay attention to:

- Strength.

- Material.

- Moisture resistance.

- Possibility to veneer with other materials.

- The location of the doors (how they open).

- The size.

- Wear resistance and impact resistance.

The main requirements for stability are imposed on ceiling and floor structures. Floor hatches must be resistant to external influences, have a durable mechanism and have additional security, soundproofing. The doors of ceiling models should be light, with a provided closing method (so that they do not accidentally open). Such hatches are more often used in commercial premises, garages.

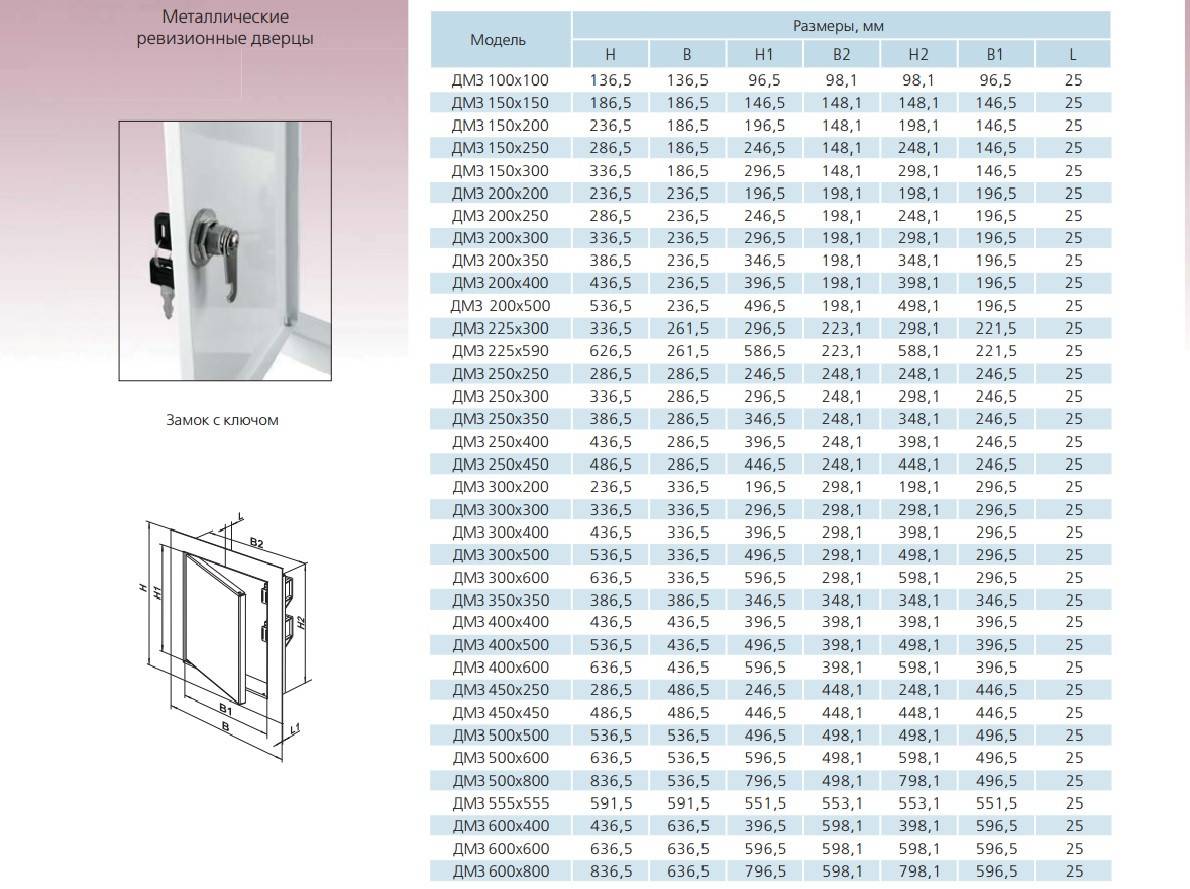

Properties and specifications

Let's look at the technical indicators of plumbing hatches Hammer, Pilot, Lukoff, Modern and other manufacturers.

Hammer models are available for tiles, for painting on the ceiling, for painting on walls, floor, hatches-doors.Tile models are models designed for surface mounting.

For example, a tile hatch from Hammer "Steel":

| Model | Hatch overall size (W*H*D), mm | Door size (W*H), mm | Door load, kg | Weight, kg |

|---|---|---|---|---|

| Steel 20x30 | 200x300x45 | 175x275 | 7 | 2,1 |

| Steel 20x40 | 200x400x45 | 175x375 | 10 | 2,8 |

| Steel 20x50 | 200x500x45 | 175x475 | 13 | 3,5 |

| Steel 20x60 | 200x600x45 | 145x545 | 16 | 4,1 |

| Steel 30x30 | 300x300x45 | 275x275 | 6 | 3,1 |

| Steel 30x40 | 300x400x45 | 275x375 | 8 | 4,2 |

| Steel 30x50 | 300x500x45 | 275x475 | 12 | 5,2 |

| Steel 30x60 | 300*600x45 | 245x545 | 15 | 6,1 |

| Steel 40x30 | 400x300x45 | 375x275 | 4 | 4,2 |

| Steel 40x40 | 400x400x45 | 375x375 | 8 | 5,6 |

| Steel 40x50 | 400x500x45 | 375x475 | 11 | 7,1 |

| Steel 40x60 | 400x600x45 | 345x545 | 14 | 8,5 |

| Steel 40x70 | 400x700x45 | 345x645 | 17 | 9,8 |

| Steel 50x30 | 500x300x45 | 475x275 | 12 | 5,4 |

| Steel 50x40 | 500x400x45 | 475x375 | 14 | 7,1 |

| Steel 50x50 | 500x500x45 | 475x475 | 17 | 8,8 |

| Steel 50x60 | 500x600x45 | 445x545 | 18 | 10,1 |

| Steel 50x70 | 500x700x45 | 445x645 | 22 | 12,1 |

| Steel 50x80 | 500x800x45 | 445x745 | 24 | 14,1 |

| Steel 60x40 | 600x400x45 | 545x345 | 12 | 8,5 |

| Steel 60x50 | 600x500x45 | 545x445 | 14 | 10,1 |

| Steel 60x60 | 600x600x45 | 545x545 | 16 | 12,6 |

| Steel 60x80 | 600x800x45 | 545x745 | 22 | 16,8 |

| Steel 60x90 | 600x900x45 | 545x845 | 24 | 18,9 |

| Steel 60x100 | 600x1000x45 | 545x945 | 29 | 20,2 |

| Pilot | |

|---|---|

| Type of | pressure |

| View | Wall mounted under tiles |

| Material | Steel |

| Guarantee | 60 months |

| Country of Origin | Russia |

| Lucoff ST | |

|---|---|

| Type of | pressure |

| View | Wall mounted under tiles |

| Material | Steel |

| Guarantee | 60 months |

| Country of Origin | Belarus |

| Modern | |

|---|---|

| Type of | pressure |

| View | Wall mounted under tiles |

| Material | Aluminum |

| Guarantee | 60 months |

| Country of Origin | Russia |

| Floor hatch Premium Light | |

|---|---|

| Type of | Lifting |

| View | Floor (for tiles and other materials) |

| Material | Aluminum |

| Guarantee | 60 months |

| Country of Origin | Russia |

Sanitary revision hatches for ceramic tiling.

The design of the hatch is simple, reliable and meets the highest requirements.The location of the hatch will be known only to you, since the seam between the hatch door and the common lined surface remains almost invisible, which allows you to save the overall surface pattern.

The hatches offered by us can be deservedly classified as invisible hatches!

Inspection hatches from the manufacturer:

Hatches are designed for indoor use in order to provide access and maintenance of hidden plumbing, electrical and other communications (including plumbing fittings installed in the niches of toilet rooms, behind decorative bath screens, etc.) in residential and office premises, industrial buildings and structures and can be installed in openings, wall niches and partitions made of various building materials (brick, concrete, foam concrete, drywall, gypsum fiber, asbestos cement, magnesite)

The hatch door is easily finished with any facing materials: tiles, natural and artificial stone, panels of various types, etc., as well as any materials and methods used for finishing (wallpaper, painting, putty).

Hatches are made both in standard sizes and according to the individual dimensions of the customer, which makes it possible to select hatches for almost any tile. Hatches can be made up to 1200 mm wide and up to 1600 mm high. With a hatch width of more than 700 mm, the hatch is made double-leaf.

The production time for custom-made products is from 3 to 10 days (depending on complexity).

Our products are completely ready for installation and further operation. Here you can get qualified advice on the installation and operation of products.The products are conveniently packaged and ready for shipping.

All products come with a 12 month manufacturer's warranty.

Our hatches are necessary in every apartment!

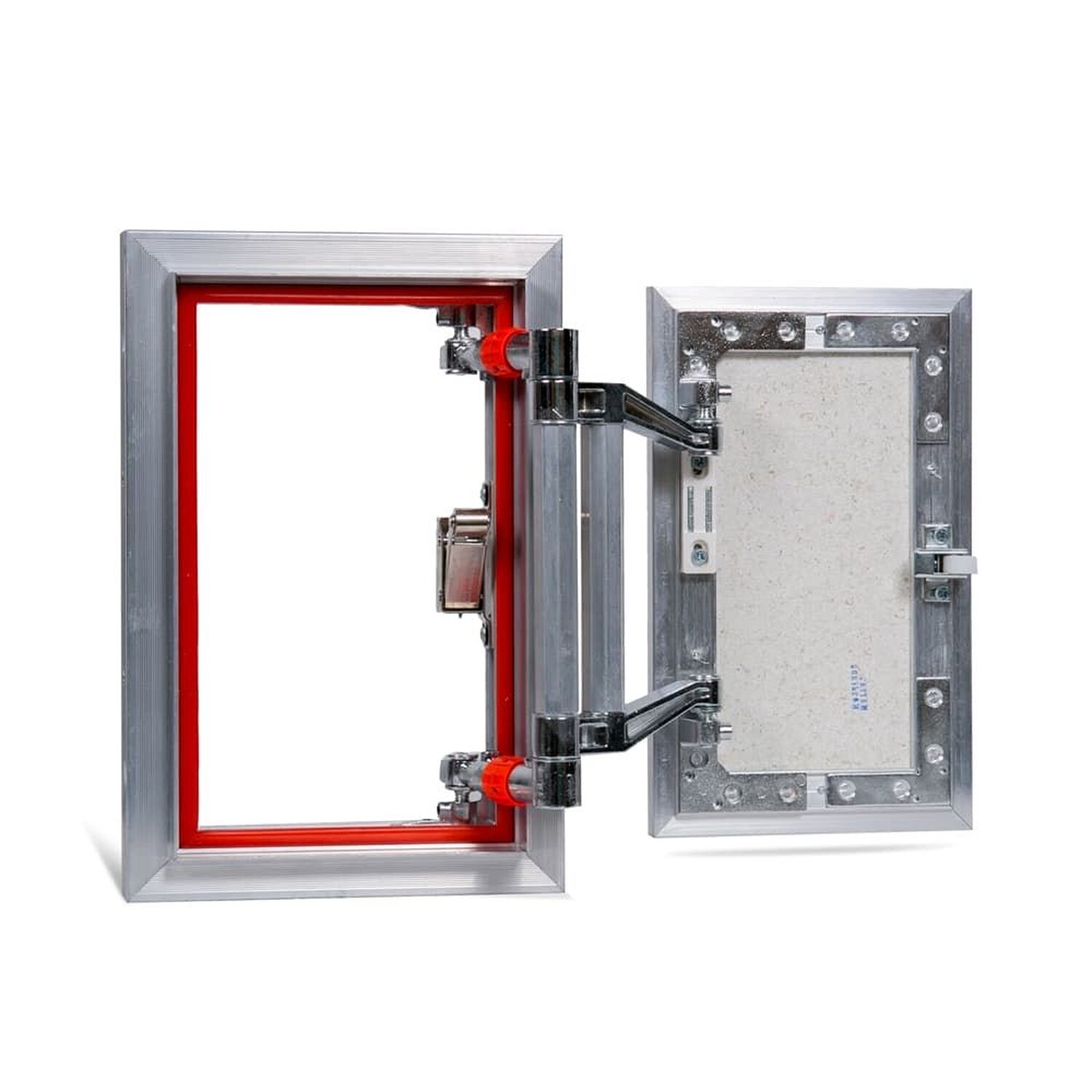

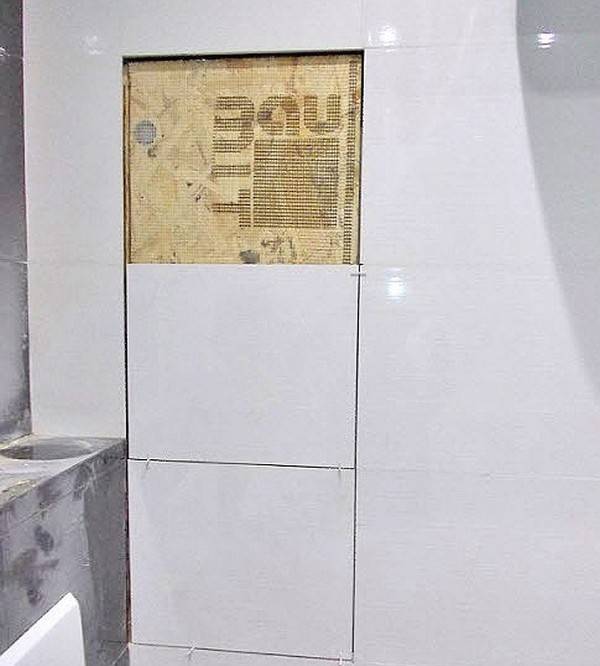

Description of the design of inspection hatches for tiles

The hatches are a closed two-circuit mechanism with a hinge that provides opening of the door with frontal extension at the initial exit from the opening.

Both contours are made of a metal profile. The outer profile is 40 x 20, the inner contour is 15 x 15. The thickness of the hatch (together with the GVLV plate) is 50 mm.

Hatches are produced in 18 standard sizes, as well as according to individual customer sizes, which makes it possible to select hatches for almost any tile.

The design of the hatch provides shock-free closing, and the alignment of the contours along the front surface eliminates the breaking of tiles (porcelain stoneware and other finishing materials). Roller-clamp locks secure the door securely in the closed position.

How to do it yourself?

Not always ready-made inspection hatches satisfy requests. In this case, you can spend a little time and effort and make the desired part yourself.

If you need a small window, then magnetic options are well suited. To do this, install magnets at the corners of the door, and double magnets along the edges of the frame (a total of 8 magnets will go). It is better to equip the lid with a neat handle, it will be more practical. As a handle, use ordinary furniture fittings.

In the manufacture of large doors, furniture parts are also useful: it is convenient to mount ready-made push systems and ordinary hinged hinges.

- Take measurements, mark the future place and check its level to avoid distortions.

- Prepare the base and frame.You can use a regular aluminum profile for the frame, make the frame from planks or from the same profile. Set frame.

- We make a cover: the base must be dense, use wood boards. The coating depends on the thickness of the layer and the planned work. It is better to use drywall: finishing work on it is going better than on a prepared tree. Carefully connect the cover parts with self-tapping screws.

- Prepare the grooves for the hinge mechanism: step back 10 mm on both sides and drill. Having connected the hinges with the cover, attach it to the frame, make markings for the holes for the mechanism.

- Install the hinges in the frame. Now you can hang the hatch in place. The cover should be flush with the raw wall and not rise above it. The hatch should have a gap so that it can be easily opened by pressing (consider future lining).

Redoing plumbing doors is not an easy task. A simple element of the interior requires careful attention. Many only after purchase and installation understand how it would be better to carry out this procedure. It can be useful to ask neighbors from above or below how they solved this issue and whether they were satisfied.

Pay attention to such points:

- When buying a finished plumbing hatch, check if the orientation is the same as desired (vertical or horizontal). Often the size of 20 * 30 confuses both sellers and buyers.

- Use a level when installing.

- Small windows are installed immediately with a lid, and large ones are disassembled into parts.

- Wall cladding is best done immediately under the door of the stealth system, leaving the bottom above-floor row in the end.In this way, the dimensions of the tiles are adjusted and accidental distortions are avoided.

- Unsuccessful operations with sealant cutting can be corrected: apply silicone around the edge and close the hatch. Remove the protruding mass and leave to dry again.

- If the wall is being prepared for painting, then the seam must be cut after puttying, before the mixture dries.

With little experience, you can quickly install ready-made inspection hatches, and if you wish, you can create it yourself. The work of the master is afraid!

13599

0

Openly located communications and instrumentation in the bathroom reduce the aesthetics of the room, so they try to hide them in boxes or closed niches, finished with the same tiles as the room. At the same time, access to hidden mechanisms is provided by installing secret hatches in the partitions.

The first samples of such devices were made of plastic and did not provide for ceramic finishing, so the hatches, hiding the highways, themselves stood out on the tiled surface. After improvement, viewing devices began to be made from reinforced plastic or metal, which increased their rigidity and made it possible to finish hatches with tiles.

Aluminum hatch AluKlik Revizor

Modern plumbing hatches - "invisible" offered by manufacturers - are high-quality products of various designs and sizes, which use special secret hinges and locks of several types, for example, aluminum hatches for AluKlik Revizor tiles or Sharkon steel viewing devices. Accordingly, the price of such devices, depending on the dimensions and technical solutions used, varies from two to several tens of thousands of rubles, and the installation cost can be even higher.

It is difficult to make a hatch on your own, which is not inferior in quality to commercially available finished products. However, if it is necessary to install an irregularly shaped viewing device or optimize the traditional design, having the skills to perform fitter and installation work and knowing the technology, it is still possible to make a hatch for tiles with your own hands.

To make an inspection hatch for the bathroom yourself, consider the following details and technologies:

- viewing device requirements;

- hatch designs;

- manufacturing of component parts;

- hatch assembly - "invisible".

Decoration options

After all the repairs are done, you can think about the decor. Decorations will give the room a more well-groomed and aesthetic look. As mentioned earlier, plastic panels do not need to be decorated, since a variety of materials allows you to choose panels to match the color of your bathroom. But in any case, they can be painted with moisture-resistant paint, having prepared the surface in advance.

Drywall can be decorated in different ways. The most common way is to lay the same tiles as in the entire room. Then all structures will become invisible. And also drywall can be painted.

If the pipes run horizontally near the floor, in order to properly use and save space, you can make a shelf on top and put items needed in the toilet on it. Additional hatches, ventilation are better to choose from plastic, because they are lighter and easier to care for.

Holes for counters and taps also need to be masked so that the structures look beautiful. For this, several materials are used.

Door. It is inserted into the frame, it can be made of drywall, plastic, metal.There are ready-made doors that do not need to be decorated. But, if you still need it, tiling is perfect.

As for materials, it is better not to choose fabric blinds, as they will be difficult to care for. This way of decoration does not take up much space compared to the doors, because when opened they are rolled up.

If you do not want to make sewer pipe sheathing with additional structures, then you can always show your imagination and paint the pipes as you wish. Such pipes become part of the interior, which can be presented in such styles as:

- loft - pipes can be painted gray or black, copper color is also suitable for this style;

- ecostyle - a vertical riser can be disguised as a tree or decorated with artificial flowers;

- marine - pipes can be pasted over with glass pebbles, shells or wrapped around with twine;

- you can use the decoupage technique, a mosaic of a variety of materials.

You can give free rein to your imagination and create a truly unique toilet design solution. Be mindful of how you will take care of your pipes as some materials are not suitable for a bathroom.

As you can see, closing the sewer pipes in the toilet can be done in several ways. It all depends on the conditions of the bathroom, desire and creativity. High-quality designs will last a long time and become part of your interior.

See below for how to quickly build a pipe box.

What needs to be accessed

For easier repair work, the pipeline that supplies water to an apartment or house is divided into sections convenient for maintenance.Each individual section, if necessary, is cut off by a valve or a ball valve installed on the pipe. If possible, most of the valves are mounted in one place.

Collector wiring is a convenient way to divide the system into separate circuits. Advantage - autonomous use of individual lines in case of failure of neighboring ones, disadvantage - more expensive installation

When all significant locking, regulating and water folding devices are disguised behind a false wall, but concentrated in one place, it is much easier to build a hatch to access them. The door will be large, but this will not harm either the appearance of the partition or the functionality of the hatch.

Modern apartments are equipped with so-called blocks or input nodes. The standard assembly, in addition to ball valves, has a water purification filter, a pair of metering devices, and a pressure reducer.

The filter is often installed on a bypass in order to be able to flush with a reverse flow of water. All devices are equipped with ball valves for quick removal for repair or replacement.

The entrance unit with filters and other appliances is hidden behind a partition that protects the equipment and helps to keep the interior of the bathroom in the same style.

In the combined bathroom or toilet there is a sewer riser. Parallel to it are pipes of centralized cold water and hot water systems.

If the corner with vertically placed lines is closed with a decorative and protective box, then a hatch is also installed on it - opposite the stopcocks. As you can see, there are several options for placing an inspection hatch in the bathroom, as well as in the toilet.