- Twisting or terminal block which is better

- Advantages and disadvantages of connection types

- What is a terminal block

- What is most often considered the disadvantage of Wago

- Terminal blocks of foreign production

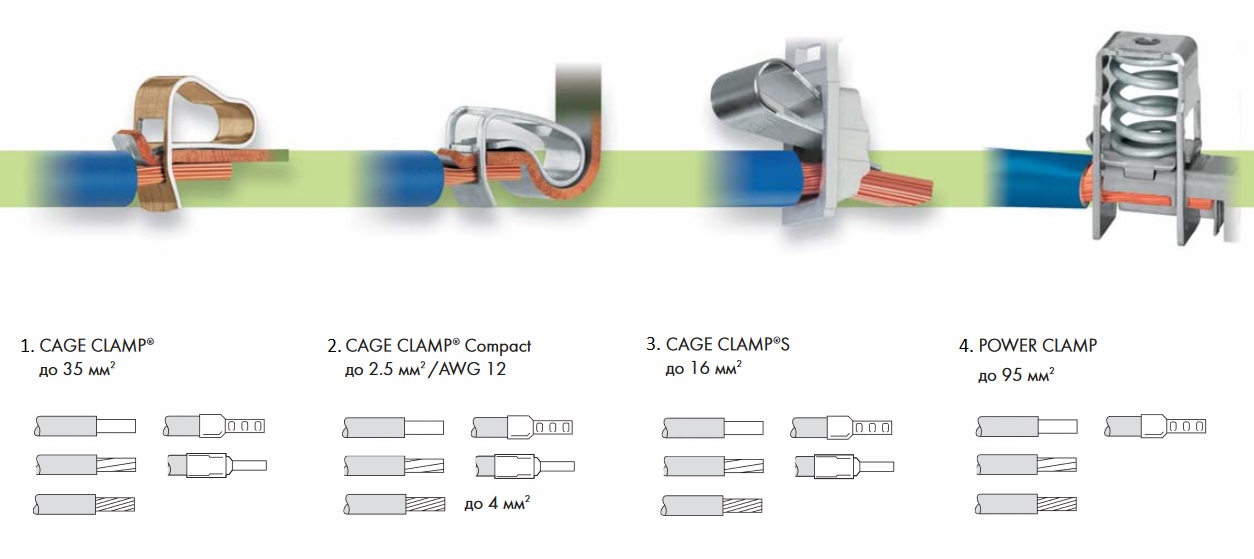

- Clamping Push Wire

- Power spring Power cage clamp

- Type-setting self-clamping Cage clamp

- Self-clamping Cage clamp S

- How terminal blocks work, what is their purpose

- electrical contact

- Wire connection methods

- Twisting

- Soldering

- The main steps in the process of connecting wires using terminals

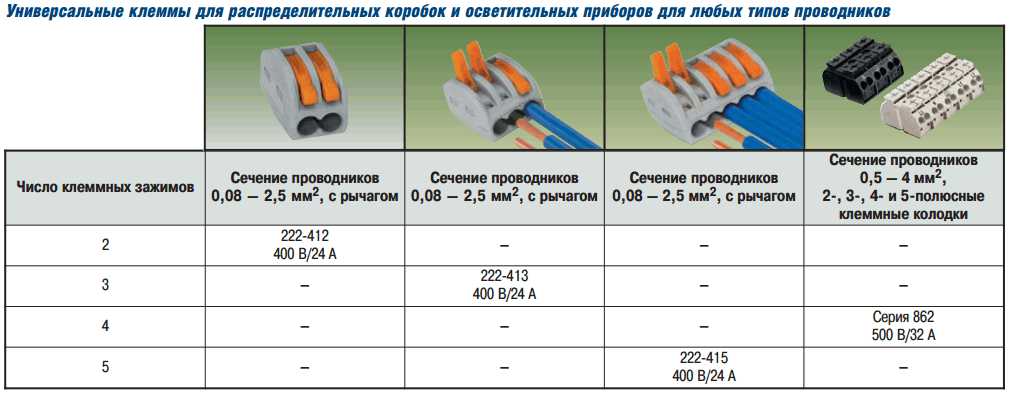

- Other models and series

- TB Series Terminal Blocks

- Welding – high reliability in all conditions

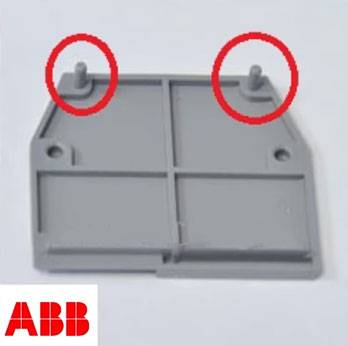

- end insulator

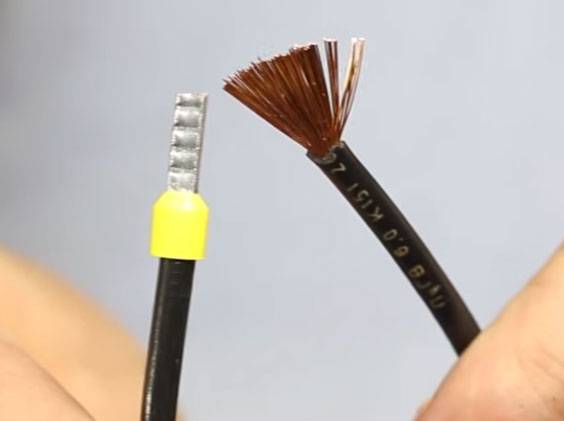

- Why do you need crimping and crimping wires

- How to distinguish an original from a fake

- Terminal connectors: 733 series

- Conclusions and useful video on the topic

Twisting or terminal block which is better

Many experienced electricians will answer this question that twisting is much more reliable than a terminal block and that "good twisting will outlive everyone."

In some ways, they will turn out to be right, but only in part, because many important factors must be taken into account here: the material of the current-carrying conductors of the switched wires, their electrochemical compatibility or incompatibility (for example, copper and aluminum), wire cross-section, twist length, load networks, etc.

d.

However, in the regulatory documents regulating the rules for performing electrical work, in particular - PUE (Electrical Installation Rules), specifically in clause 2.1.21, it is clearly stated about the ban on connecting wires by twisting:

As you can see, the PUE allows only 4 types of wire connections and there is no twisting among them. Therefore, endless disputes and discussions about the advantages or disadvantages of twists lose all meaning, because not a single fire inspector will approve an electrical installation if the switching of its wires is done with twists.

Soldering or welding significantly increases the installation time, this procedure is much longer than using terminal blocks - you need to remove the insulation from the wires, tin each wire, if it is soldering, connect the welder, then insulate all the wires.

If it is necessary to reconnect the wires (for example, add a wire), there are also difficulties - remove the insulation, solder (cook) again. With terminal blocks, everything is much simpler, but the best contact is achieved using welding or soldering.

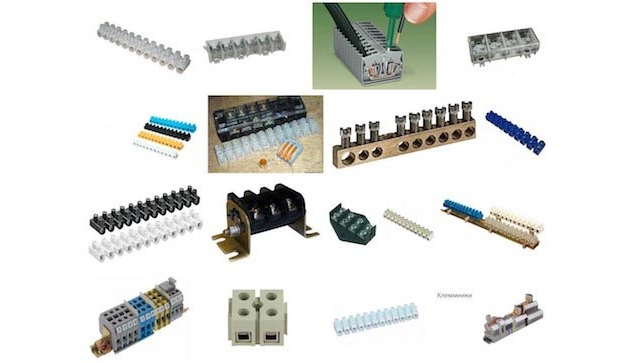

There are different types of terminal blocks in their design, design features, suitable for connecting the wires of the electrical wiring of an apartment or house.

- Here are the main and most common among them:

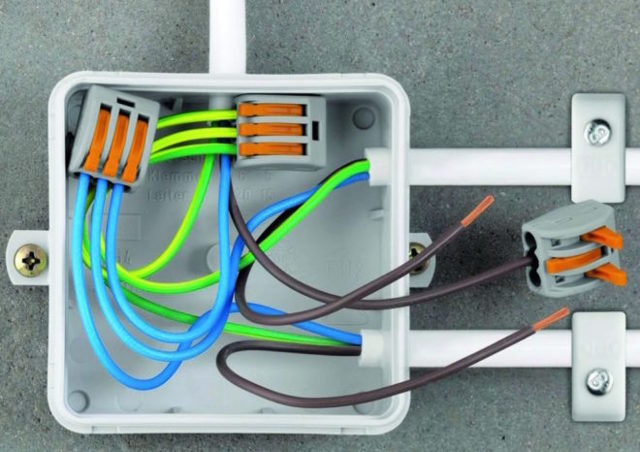

- Self-clamping terminal blocks can have from 2 to 8 places for wires with a minimum cross section of 0.75 mm2 and a maximum of 2.5 mm2. Able to withstand loads up to 4-5 kW (24 A).

- Such clamping terminal blocks are very convenient in installation, greatly reducing its time - there is no need to twist and then insulate the wires. But, they take up more space in junction boxes, in contrast to the twist, which can be given any shape, laid, bent as you like.

- Connecting screw terminals are designed to connect wires to each other. This is the most common type of terminal blocks. Usually used for switching wires in junction boxes.

Material:

Insulating connecting clamps (PPE) are used to connect single-wire conductors of wires with a total maximum cross section of up to 20 mm2 and a minimum one of 2.5 mm2 (depending on the PPE manufacturer).

They have an insulated housing made of polyamide, nylon or fire-resistant PVC, so that the wires do not need further insulation, into which an anodized conical spring is pressed.

When connecting the wires, they remove the insulation (by 10-15 mm), collect them in one bundle and wind PPE on them (clockwise) until it stops. PPE caps are very convenient and easy to install, but they lose a lot to power terminal blocks as a twist, so it is still better to give preference to terminal blocks, for example, barrier ones.

Advantages and disadvantages of connection types

Anyone who believes in Ohm's law understands that the quality of the contact is proportional to the area of contact of the conductors and depends on the reliability of the connection between them. Often, when installing the next object, a dispute arises between young and experienced electricians, which type of wire connections to choose.

Usually, experienced electricians note twisting as the most reliable type of connection and cite objects up to 100 years old as an argument, where twists “stand” reliably. No terminal blocks can yet boast such an impressive service life. They just didn't exist yet.

- Firstly, the PUE clearly speak of the prohibition of connecting wires simply by twisting. When twisting, it is necessary to either weld or solder the wires.

- Secondly, soldering or twisting dramatically increases the installation time compared to terminal blocks. The last circumstance is probably the most weighty argument.

Everyone knows that time is money. But not everyone thinks that civilization has turned to the road of manufacturing disposable products. And the terminal blocks are similar to disposable shaving blades.

What is a terminal block

A conventional terminal block is a special connector for solid and flexible wires or cables. Such devices are used in completely different systems, but their goal is the same - to create a high-quality contact between two wires or to create a fork without the use of additional tools or insulation.

Last options

Last options

Simple but popular twisting today is not even recognized by the PUE and cannot be used by real experts for security purposes. Such connections significantly spoil the contact, contribute to the destruction of conductors and are a very vulnerable place for a fire. This happens due to the heating of the contact. It is not necessary to talk about insecurity in connection with the possibility of electric shock, since this is obvious. To ensure the reliability of the electrical contact and simplify its maintenance, terminal blocks are used.

Varieties of terminal blocks

Varieties of terminal blocks

Power connecting electrical blocks (or simply terminal blocks) are special devices with a special contact line. The wires are attached to it through the use of pairwise connecting locks. Typically, these clamps are made sealed, isolated from external factors and have good protection against mechanical and other irritants.

Note! Terminal blocks have recently been almost universally used in various wiring systems, in which they play one of the main roles. Their task is to quickly install and dismantle a safe wiring connection that has the reliability of electrical fastening required by the PUE.

Classic clamp terminal

Classic clamp terminal

Also, against the background of simple clips, heat-resistant pads and ceramic nozzles stand out. They are not affected by aggressive chemical environments and are not destroyed by moisture. Porcelain and steatite ceramic pads are used to create reliable contacts of conductors subject to the influence of sufficiently high temperatures.

Vag connectors

Vag connectors

If an ordinary block made of polyamide or another type of plastic melts already at 150 ° C, then a ceramic block can easily withstand temperatures up to 350 ° C, and begins to change its properties only at a mark of 500 ° C.

What is most often considered the disadvantage of Wago

The main disadvantage of such terminal blocks, oddly enough, can be called the incompetence of people who call themselves specialists. On the Internet, you can find a huge number of photos with burnt Vagos, on the basis of which inexperienced home craftsmen draw wrong conclusions about the operation of such parts. However, one has only to take a closer look at most of these photo examples, as it becomes clear that the cases were melted from the outside, which is impossible if the terminal block is to blame.

In fact, such terminal blocks are very reliable when used correctly.

It is also worth paying attention to the critical load on the connection.It is not worth exceeding the parameters specified in the technical documentation as limiting

But this applies not only to Wago, but also to any terminal blocks or twists, which means that the disadvantage is not justified from this side either.

Twisting can also fail if contact loosens.

Terminal blocks of foreign production

The best manufacturers have developed user-friendly technologies and innovations that have made it possible to transform classic terminals into unique connection interfaces.

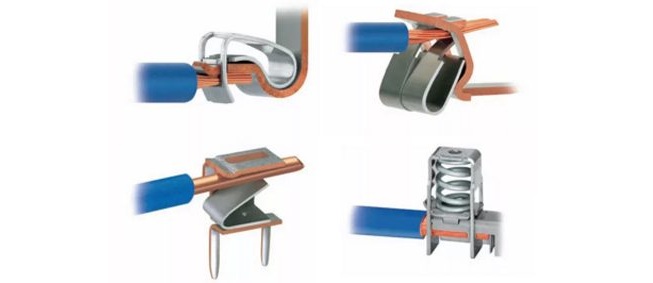

Clamping Push Wire

A one-piece product that uses stiffness properties for secure fastening. Installation is carried out by pushing the stripped end of the wire into the hole. Extraction is carried out by twisting the wire.

Connector types:

- for single wire;

- for wires with reduced stiffness.

Power spring Power cage clamp

Universal terminal block for all types of electrical wires with a cross section up to 95 mm². It consists of a double cage equipped with a spring with a press and a metal bar.

The connection is made using a hexagon for tightening. After installation, the key turns and the lowered press securely presses the conductor.

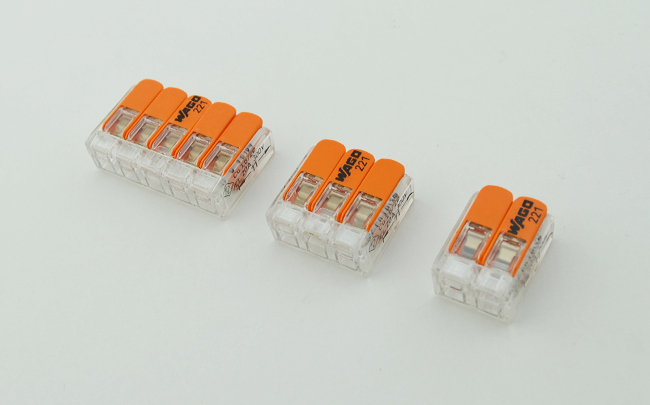

Type-setting self-clamping Cage clamp

Exclusive technology, patented by WAGO, for conductors of any strand up to 35 mm². The connection is made by lifting the spring clip using a special lever. After installing the conductor, the clamp is lowered back.

terminal block WAGO

Self-clamping Cage clamp S

Use does not include the use of electrical tools. The connection is made by installing the bare end of the wire until it stops.

How terminal blocks work, what is their purpose

Devices make it possible to significantly simplify the process of wiring wiring, its connections and significantly increase the safety of the entire circuit. This is especially true when the scope of work is small.

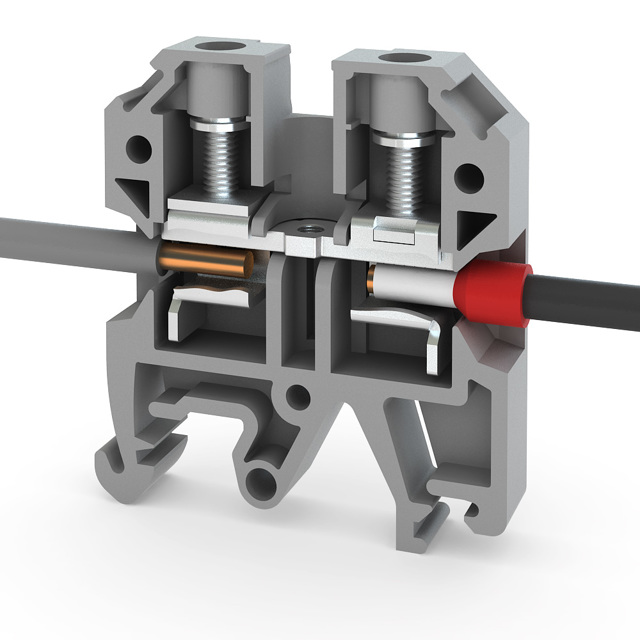

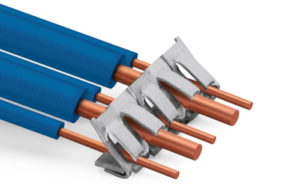

Reliable and safe contacts in the terminal blocks are made with screw or spring clamps. They are able to fix a wire or cable between special clamping plates or tubes made of brass and other metals. Such types are called, respectively, screw and spring (crimp). Different types of terminal blocks use different locking mechanisms:

- in screw processes, the process is carried out due to pressure on the plate or tube of the end part of the screw, which is located perpendicular to it and to the clamped cable. The result will be high-quality contact with a large contact area. On the other side of the plate or tube, another conductor enters (naturally, before the first one is fixed), which creates good contact and the ability for electricity to move without any obstacles;

- in spring clamps, approximately the same thing happens, but the fixing elements are a spring and a lever. After laying the cables stripped of insulation, a simple press on the lever takes place, which securely locks the mechanism and prevents the conductors from falling out. There may also be records or a tube inside.

Clamping element designs

Clamping element designs

Important! And in one, and in another form, the fixing element is perpendicular to the holding mechanisms and the cable itself. Also, most terminal blocks do not need additional insulation, as happens with twisting, soldering or welding.

electrical contact

Electrical contact depends on the quality and reliability of the wire connection.When installing electrical wiring, it is impossible to do without connecting wires.

- At the connection points, electrical contacts must meet the following basic requirements:

- reliable contact, without additional resistance. The resistance of the connecting contact should not be greater than the resistance of a whole piece of wire;

- mechanical strength, in case of stretching. If the wire at the junction is subject to accidental stretching, then the strength of the contacts must be no less than the strength of the conductor itself.

Wire connection methods

The connection of wires in the junction box is done taking into account many factors:

1. Type of material from which the wires are made:

-

aluminum;

-

copper;

-

steel and alloys.

2. From the environment in which the wiring will be located:

-

the outside;

-

room;

-

underground wiring;

-

running a cable under water.

3. Number of wires used.

4. The cross section of the cores matches or not.

Taking into account all these aspects, the installer chooses the way in which he will mount the contact node in the junction box. There are eight ways to connect wires

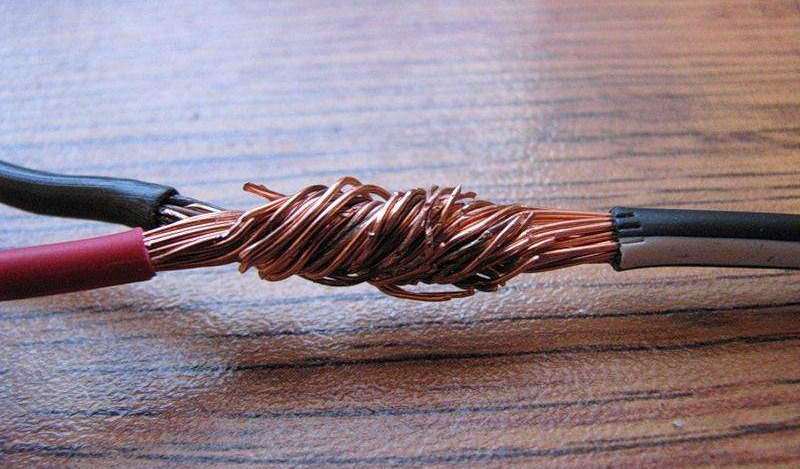

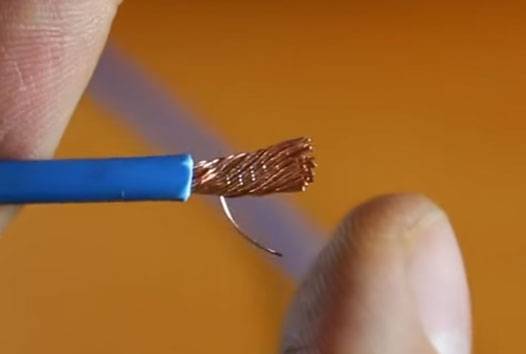

Twisting

One of the easiest and most affordable ways is to twist the wires. It was used by our grandfathers. Despite the fact that this method has been used for a long time, it is not the best and is completely prohibited in the rules for installing electrical appliances. The reason for such a ban is that the twisting of wires made correctly, in those days, was used only for watching TV and listening to the radio, as well as for lighting the room. Thus, it did not bear the load, unlike modern apartment equipment.

Twisting is the easiest way to join wires.

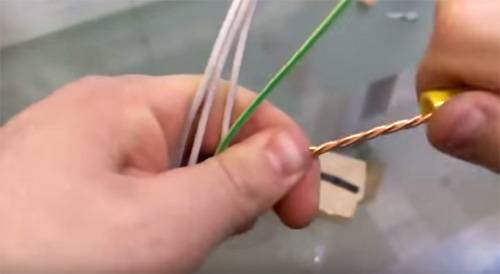

Still, twisting is necessary.It is the basis for other wiring methods such as soldering and welding.

Benefits of twisting:

-

Does not require additional costs to purchase additional accessories.

-

No effort is required to do this job.

-

It is possible to connect several cables together.

Minuses:

-

This method is the most unreliable for use in modern electrical wiring.

-

It cannot join cables whose veins are made of different metals.

-

Twisting cannot be used for modern use, because when changing wiring, the ends cannot be separated several times in a row. On the other hand, twisting cannot be called an all-in-one method, since it unwinds easily.

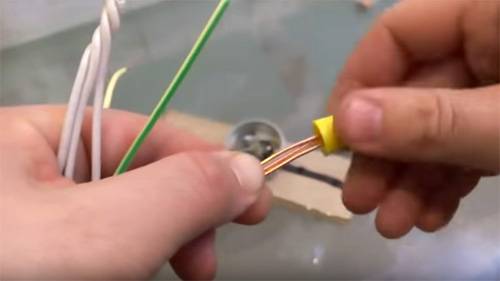

During installation, the twist must be done with high quality, so that later it does not have to be redone. For this, pliers are used, with which the wires are clamped at one end and with the help of the second they make rotational movements. Thus, the wires are twisted evenly.

The twist must be insulated to protect it from the effects of the external environment, due to which it can oxidize and become unusable. To do this, use thermotubes, putting it first on one of the cables, and then on the junction. If everything is done correctly, the wiring will serve for several years.

Twisting as a basis for connecting a cable using soldering. Source viva-el.by

Soldering

The soldering method involves the connection of all the veins of the wiring using molten solder. Most often, wires made of copper are soldered in this way. But today, various fluxes have been invented that can also solder aluminum veins.However, electricians do not approve and refrain from such connections. But sometimes there are situations when there is nothing left but connect copper and aluminum wireusing special fluxes.

Advantages:

-

connecting wires to each other by soldering is much more reliable than twisting;

-

multi-core cables can be soldered together;

-

more reliable in operation and does not require additional checks;

-

refers to one of the cheapest ways to install electrical components.

Flaws:

-

requires a large investment of time and labor, since the material must be properly prepared for work;

-

this method requires a skilled worker who knows how to work with a soldering iron.

-

even considering the complexity of soldering, one cannot but admit that this method is much more efficient than twisting.

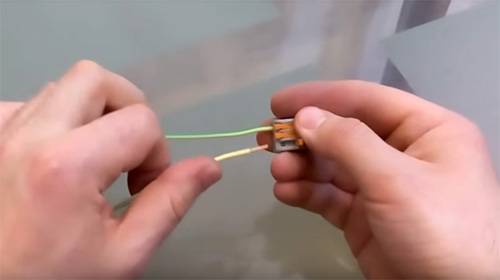

The main steps in the process of connecting wires using terminals

How to connect wires using terminals, you can learn in detail from our table. Consider connection options using examples of different Wago models:

| A photo | Process description |

| To connect the wires using the 22÷73 series terminal block. It is necessary to strip the conductors to a length of 10 mm. |

| We insert the bare parts into the terminal block until it stops. |

| If necessary, remove the terminal block, it must be scrolled in the opposite direction. Both parts must be inside the fixture. This option is used to connect the light. |

| Wago series 222 terminal blocks are recommended for repair work and temporary connections. |

| The connection is made using special levers. The wire is also stripped 10 mm and inserted into the terminal block, then the levers snap into place. |

| 224 series is used to connect all kinds of chandeliers, lamps and sconces. |

| This terminal can be used to connect solid and stranded wire. |

| Single core is inserted into the hole with lubrication. |

| Stranded is inserted into another hole. |

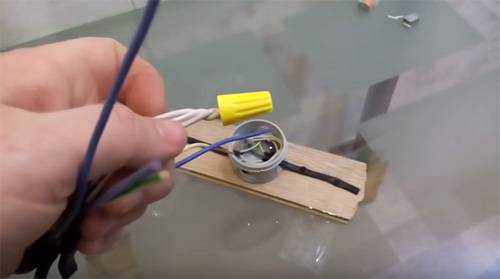

| A special cap is used for PPE conductors. |

| The cap is screwed onto the conductors. |

| To improve the quality of such a connection, the wires need to be stripped by about 6 cm. |

| Then the PPE cap is screwed on. This results in a very reliable connection. |

| The connection is insulated with electrical tape. |

| You can use a household terminal block. The monocore must be stripped and placed inside the terminal block. Then twisting is done with a special screwdriver. |

Other models and series

In addition to the first two, there are other models with their own specific features. For example, using the 273 series terminal block (Fig. 1), three wires with a cross section of 1.5-4 mm2 can be connected. There is a paste inside the device, thanks to which aluminum wires can be connected. The 274 series, which is close to them, is used with lighting fixtures, connecting wires with a cross section of 0.5-2.5 mm2. Available with and without paste.

Series 243 (Fig. 2) is designed for low currents. The operating current of these terminal blocks is only 6 A.

Terminal blocks of the 862 series (Fig. 3) are used to connect exclusively copper conductors. 2-5 wires can be connected to the device, the cross section of which is 0.5-2.5 mm2. The case is fixed with self-tapping screws on any basis.

Some features of the use of Wago connectors should be taken into account. When using these devices in lighting and other places where the current is limited to 10 A, there are no special requirements for them.However, if the load in the network increases to a value of 10-20 A, then the surface of the wire must be clean when connected to the terminal block. A 10, 13, 16 or 20 A circuit breaker is installed in the circuit for protection. In cases where the load exceeds 25 A, it is recommended not to use terminal connectors, but to use welding, soldering or crimping of wires.

Terminal blocks for connecting wires

Terminals for connecting wires - purpose, varieties and features of the application

Connecting wires: how to connect wires together, what terminal blocks are, mounting options with and without soldering

Terminal block: types and applications

Ground terminal: purpose and application

Mounting terminals Wago

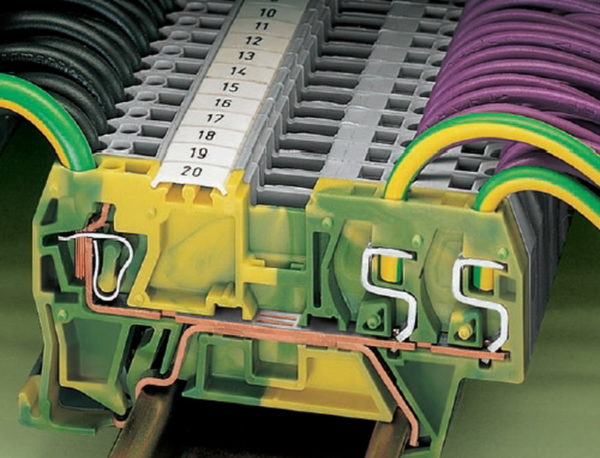

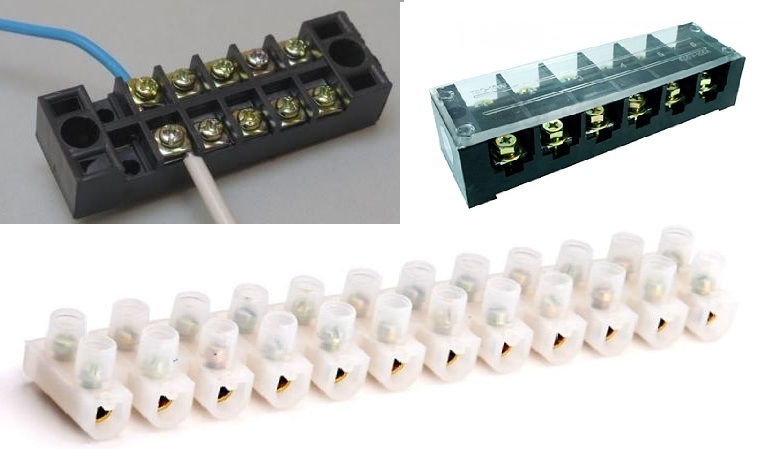

TB Series Terminal Blocks

Hard black plastic pads. Already better.

Removable cover:

And here is the internal structure:

We unscrew, we put the wire, we clamp it.

Pros - it is not a screw that clamps, but a metal plate. We press to the lower steel plate. In addition, the upper part is not flat, but with a characteristic surface, which increases the clamping surface:

As a result, stranded and aluminum wires can be clamped. Aluminum, however, it is advisable to at least occasionally check for weakening of the clamp. I saw the pads themselves for currents of 25A and 40A.

The inconvenience is that it can’t be cut or divided, or buy a bunch of small ones (I haven’t seen less than 6 pieces), or even put one big one on two wires.

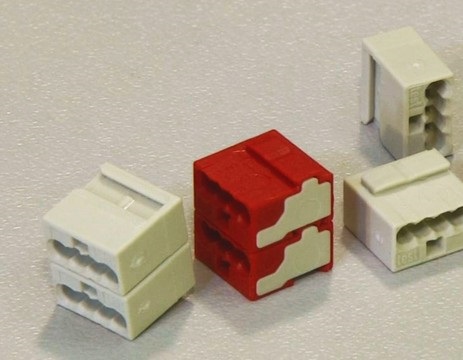

Self-clamping terminals (WAGO or REXANT series 773 and their copies)

Or they are also called express terminals. Like these ones:

Very handy stuff. I stripped the wire, put it inside to the end, you're done:

Inside there is a pressure plate (blue arrow) and a small shank (orange) made of tinned copper:

When wires are shoved into it, this is what happens:

The plate presses the wire against the tire, maintaining pressure all the time. And the design of the pressing part does not allow the wire to fall out. And it's hard to pull it out. In general, they are disposable, but if you really want to, then gently rotating the wire around its axis, you can pull it out.

Since the copper contact is tinned, an aluminum wire can be inserted into such a terminal without fear of problems. At the same time, constant pressure will not allow the aluminum wire to fall out.

White paste (in the next photo you can see a white mass on the contact) is quartz sand with technical petroleum jelly, especially for aluminum wires. Quartz sand is an abrasive that cleans off the oxide film from the surface of aluminum, and petroleum jelly prevents it from re-forming.

The same terminals, but transparent:

They do not differ in anything, except for the dye. Well, in transparent terminals it is more convenient to see the wire - whether it is stuffed to the end or not.

Plastic is non-flammable, melts when the temperature rises, without releasing harmful substances into the air.

Designed for 25 A, which is approximately 4 kW. Attention! Currents are indicated only for original WAGO terminals.

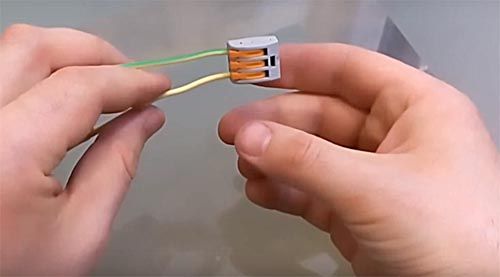

WAGO series 222 terminals with levers. I saw only vagovskie, others do not produce. . For particularly difficult cases, when there are several types of wires, different thicknesses, aluminum, copper, etc.

Raise the lever:

We push the wires, lower the lever:

If necessary, you can raise the lever, pull out the wire, insert another

And so many, many times. A great thing for those circuits whose wiring can change a bunch of times.

For particularly difficult cases, when there are several types of wires, different thicknesses, aluminum, copper, etc.

Raise the lever:

We push the wires, lower the lever:

If necessary, you can raise the lever, pull out the wire, insert another. And so many, many times. A great thing for those circuits whose wiring can change a bunch of times.

They eat everything. Current - up to 32A. Inside - a plate that presses against a common tire is connected to a lever.

Tricky design, in general.

The shank is tinned copper, as usual:

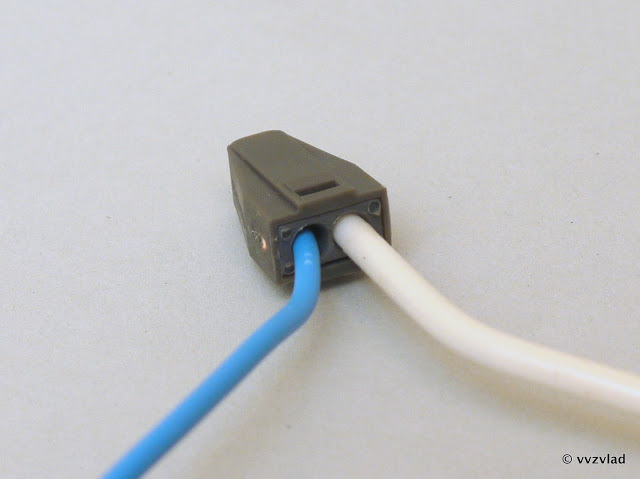

Scotch locks, ScotchLok, electrical connector with mortise contact.

This is for low current (network, telephones, LED lamps, etc.).

The meaning is simple - several wires are pushed into such a thing:

After that, it snaps into place with pliers or any pressing tool. No, there is of course a special tool, but I don’t see the point in it - it is a small pliers with flat jaws.

They are especially loved by SCS and network installers, for their simplicity, cheapness, water resistance, and the lack of the need to strip the insulation.

Inside there is a hydrophobic gel that protects against corrosion, moisture, oxidation, etc. And a plate with a cutting-clamping surface:

Or two plates:

Here you can see what happens to the cable after termination:

Knives cut through the insulation, and firmly pressed against the wire. There is also a version for two cables at once, and the plates are a little thicker - quite suitable for lighting:

Of course, they are disposable and maintenance-free. It is necessary to replace - a piece of cable is bitten off with them, and a new one is put in.

Welding – high reliability in all conditions

When connecting wires by welding, the conductors are twisted, and their end is welded. As a result, a ball of metal is formed, which provides a stable and very reliable connection under any conditions.Moreover, it is reliable not only in terms of electrical characteristics, but also mechanically too - the metal of the connected wires after melting forms a monolith and it is impossible to isolate a separate conductor.

Welding - it is important to heat the metal, but not to melt the insulation

The disadvantage of this type of wire connection is that the connection is 100% one-piece. If you need to change something, you need to cut off the fused piece and redo it all over again. Therefore, for such connections, a certain margin of wires is left - in case of a possible alteration.

Other disadvantages include a welding machine, appropriate electrodes, flux and work skills. In addition, welding takes a lot of time, it is necessary to protect surrounding objects, and it is also inconvenient to work with a welder at a height. Therefore, electricians practice this type of connection in exceptional cases. If you are doing “for yourself” and know how to handle a welding machine well, you can practice on scraps. The trick is not to melt the insulation, but to weld the metal.

After cooling, the welding site is isolated. You can use electrical tape, you can use heat shrink tubing.

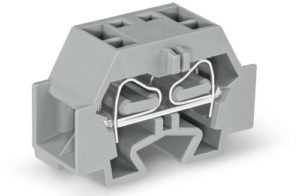

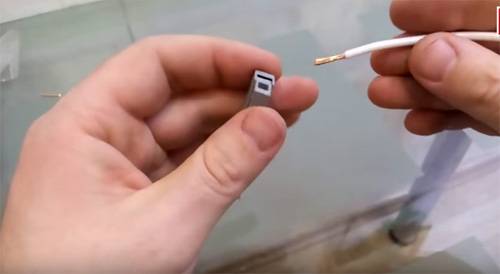

end insulator

Another important point is that the insulated part of the terminal should always be on the left, the non-insulated part on the right.

That is, the bare contact part should be located on the right side. When the terminal block is dialed, most installers stop at this design. Wiring begins.

However, do not forget about one of the bare sides. All manufacturers make their equipment so that it is protected from accidental contact with live parts.

Therefore, along with the purchase of terminals, do not forget about the end insulated covers.

They are rarely sold individually, you have to buy a whole set in a bag. Although often the entire assembly in the shield may require no more than 3 pieces.

Technically competently, such a product is called an end insulator. With a slight movement of the hand, it snaps into place thanks to its protruding parts.

End insulators are also available in various colors. But what if you do not have end insulators, but you need to insulate the last right terminal?

The easiest way out is to put an additional empty terminal next to it. There is no need to connect wires to it. Although she will be naked, but already without tension.

Or forcibly remove all metal insides from it. Another option is to use the ground terminal as the last terminal.

Why do you need crimping and crimping wires

Is it possible to do without sleeves and compression at all? What is wrong with simply attaching wires to machines and other devices?

With a simple clamp, the bundle of wire fluffs up and is crushed to the sides. Some individual conductors may be damaged at all. Such veins, destroyed and separated from the main bundle, no longer take part in the contact and passage of the current load through them.

All this leads to the fact that the remaining cores are not enough and the joints are heated.

In addition, the bare copper from which the wire strands are made remains accessible to moisture and oxygen. And this leads to its darkening and oxidation.

Once crimping the conductor with a tip or sleeve, you will save yourself from all these problems in the future.

How to distinguish an original from a fake

It often happens that a consumer buys cheap clamps, similar to products from well-known manufacturers, after their installation, electrical circuits fail. This suggests that fakes were purchased.

You can distinguish a fake from the original as follows:

- At the end of the product, the Wago marking must be applied. If there is none, then this is a Chinese or another country's fake.

- The original parts have a pronounced coloration. Fakes are usually painted in dark, gray tones.

- On the back of the IC, the firm indicates the length of the wire stripping and a diagram of how to connect the wires. Forgeries do not have such inscriptions.

- On the side of the case of the original product, the nominal values \u200b\u200bof current and voltage are indicated. On the Chinese terminal block, only the voltage value is mentioned.

- When examining the clamping device, the difference between the original and the counterfeit is visible. German parts are made of thicker metal.

- The main factor in determining a fake is its cheapness.

Push-in connectors have made a small revolution in the field of electrical wiring. The ease and simplicity of connecting wire elements using screwless terminal blocks greatly facilitates the work of electrical engineers. With large volumes of work, the use of SC can bring a significant economic effect.

Terminal connectors: 733 series

The manufacturer of terminal blocks Wago has divided products into certain series, in accordance with the types of wires for which they are intended.

The cheapest model is the Wago 733 connector, with which one-time switching of wires is performed. They do not have a traditional lever, and fixation is made by a lock located inside the device.Biting the vein, he does not allow it to move in the opposite direction.

These terminal blocks can operate at voltages up to 400 volts and rated current up to 20 amperes. As a rule, they are used to connect solid wires. Inside some models, a special paste is placed that prevents oxidation and allows you to work with aluminum wires. Their body is painted grey.

Terminal blocks without paste are placed in a transparent case with colored inserts. These devices are more advanced, since they make it possible to control not only the connection of the core, but also the quality of its fixation.

The switch itself is very simple. The core is cleaned of insulation by 1-1.2 cm, and then inserted all the way into the terminal. If necessary, the wire can be pulled back. To do this, you need to scroll it with great effort and pull it towards you. In this case, the deformation of the internal latch occurs and the terminal is unsuitable for further use. Modifications of these clamps allow switching from 2 to 8 wires.

Conclusions and useful video on the topic

The video below demonstrates a comparative analysis of branded terminal blocks with products that are a complete fake and are widely represented on the market.

The moment is considered - how to distinguish a branded self-clamping terminal from a fake:

Self-clamping devices, with the help of which an electrical connection is organized, are convenient and practical. But with all the advantages of such accessories, their use is somewhat limited by technical and operational parameters.

But the development of such devices is actively continuing. It is not surprising if in the near future some kind of universal terminals for working in different conditions will appear.

Tell us about how you repaired or upgraded the electrical network using clamp connectors. Share the technological nuances that beginner electricians should use. Please leave comments in the block below, post photos and ask questions on the topic of the article.