- Types of self-priming pumps: device and principle of operation

- Centrifugal self-priming pump

- vortex self-priming pump

- Pump classification

- Types of self-priming pumps by the presence of an ejector

- Backflow pumps

- Counterflow #1 - Speck

- Counterflow #2 - Glong Electric

- Countercurrent #3 - Pahlen

- vortex suction pump

- Advantages and disadvantages of centrifugal pumps

- The optimal sequence of actions in case of a problem with a part of the pipeline in the apartment

- Watch the video: Overview of the Pedrollo JCRm 2A self-priming pump

- Useful video: Capabilities of a self-priming pump without liquid filling

- The principle of operation of a vortex self-priming pump

- Classification of centrifugal pumps

- According to the location of the nozzles of the pumps

- By number of pump stages

- Shaft seal type

- By type of connection to the electric motor

- By appointment

- Types of self-priming pumps

- Centrifugal pump

- vortex pump

- Self-priming units

- Characteristics of pumping stations

- The best submersible pumps for a well

- Pedrollo NKM 2/2 GE - pump for wells with moderate energy consumption

- Water cannon PROF 55/50 A DF - for pumping contaminated water

- Karcher SP1 Dirt is a silent model with low power consumption

- Grundfos SB 3-35 M - powerful pump with low starting current

- conclusions

Types of self-priming pumps: device and principle of operation

As for the main types of self-priming pumps, they have a different principle of operation, so it is worth considering them separately from each other.

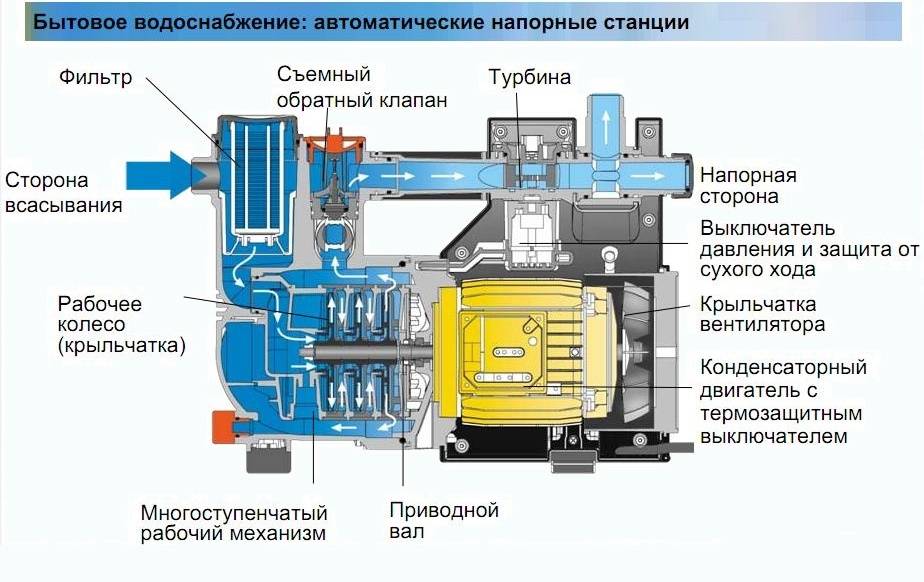

Centrifugal self-priming pump

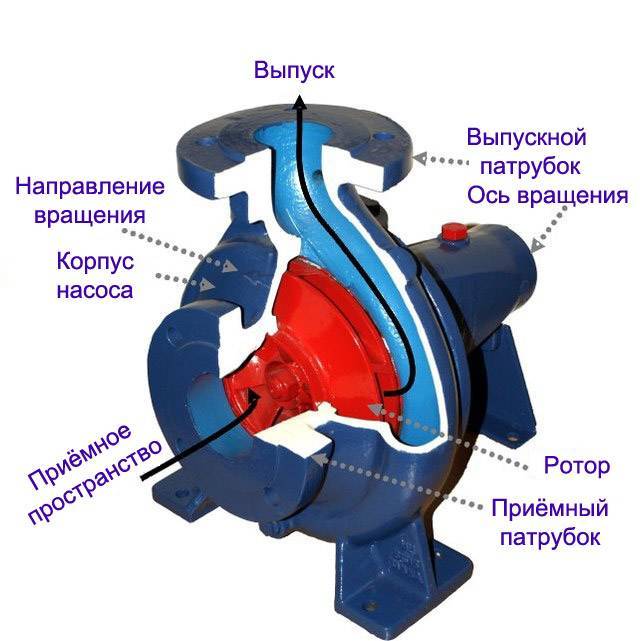

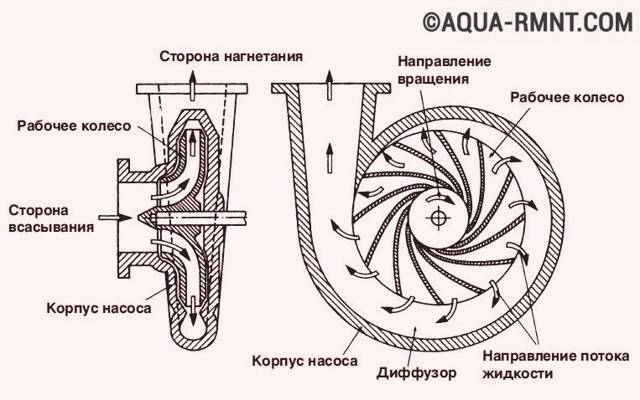

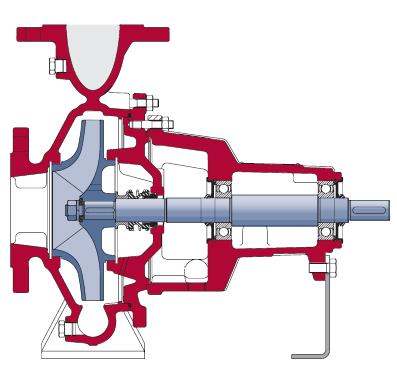

So, a centrifugal self-priming pump is represented by a snail-type design, inside of which there is an engine, on the shaft of which an impeller is fixed. An exhaust hole is made above the impeller in the housing, and an inlet hole is made in the end (directly opposite the shaft).

Consider the principle of operation of this device. When the impeller moves, a vacuum is created in the end part of the housing (this happens due to centrifugal force). As a result, water moves from the central part of the device to the side, where the pressure rises strongly and the water is actually pushed into the pressure pipe.

Centrifugal self-priming pump

In the central part of the device, the pressure is significantly reduced, due to which a new portion of water enters the pump. Curiously, the water supply is virtually uninterrupted, which allows you to use the pump without topping up the liquid.

Centrifugal pumps are most often used for pumping complex liquids:

- viscous;

- with the presence of solid particles;

- abrasive.

It is due to this ability that centrifugal pumps are used mainly in industry. If we are talking about domestic use, then we can safely use centrifugal models for pumping water from a stagnant, not very transparent water source: the device quite successfully pumps water with silt clots, mud, etc.

Attention! The centrifugal pump can only be turned on after its "snail" is completely filled with water, since the impeller is simply not able to carry out the suction action in the absence of water.

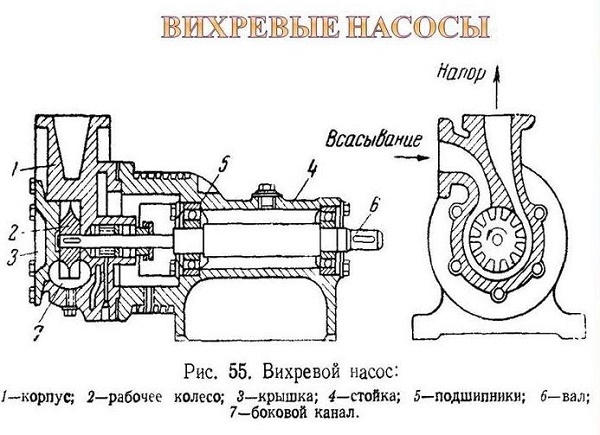

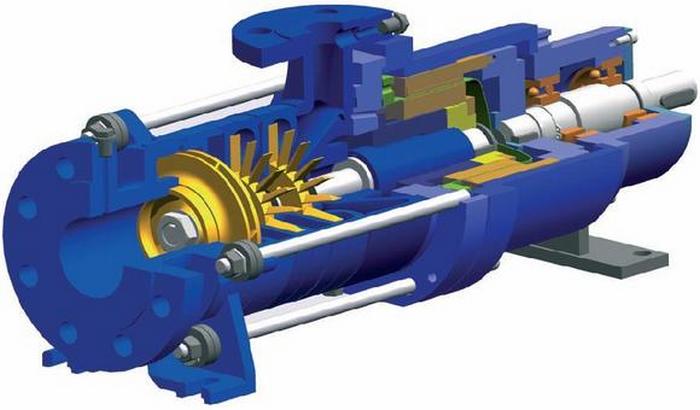

vortex self-priming pump

The design of a vortex pump has one feature that distinguishes it from a centrifugal one: the presence of an impeller instead of an impeller. This element pumps air into the interior of the "snail", where it mixes with water and exits through the outlet pipe.

During the release of air to the outside, the liquid circulates in a closed cycle and during the passage of the gaseous medium through the liquid, a vacuum occurs in the suction pipe, which draws in a new portion of water. The further part of the work of the vortex pump coincides with the centrifugal one.

By the way, unlike a centrifugal pump, a vortex pump can be turned on even if there is no water in the housing, since it works not only with water, but also with a water-gas mixture. And this means that the device will start even on the basis of air.

Pump classification

The organization of water supply from an autonomous source is impossible without the use of a hydraulic mechanism in the water supply system. To direct the flow of water in the right direction, the unit gives the liquid kinetic energy. According to the design features of the working element, the devices are divided into several types:

- centrifugal;

- vibration;

- vortex.

According to the operating conditions, pumps are divided into two groups:

- Surface - located outside the source of water supply, supplying fluid through the supply pipeline. This is the best option when organizing garden watering from a reservoir or reservoir.After the end of the season, the mechanism is easy to dismantle and put away for storage. Surface unit

- Submersible - units operate completely immersed in liquid. They are installed in wells and wells with a depth of 10 m. A huge range of models allows you to choose an option for a well of 80 m. Pumps operating under water are equipped with automatic protection against "dry running". Such models are recommended for houses with year-round use.

By the way, various hand pumps for extracting water from a well can also be attributed to surface pumps. Invented over 150 years ago, they are the forerunners of today's surface pumps. Even now, many water equipment companies continue to produce such varieties. Sometimes a hand pump is the only alternative if a full-fledged well is not possible on the site, and there are constant problems with the power supply. In addition, the price of the issue is much lower in comparison with electrical counterparts.

Submersible pump

Depending on how the water pump is arranged, its working element is the blades or the piston.

- Vane pumps. Hydraulic machines pump liquid with the help of a rotating wheel, with radially curved blades fixed on it. The rotational moment is provided by the shaft of the included electric motor. Centrifugal and vortex models work according to this principle.

- vibration pumps. The device of vibration units is characterized by the absence of rotating mechanisms. The movement of the liquid occurs due to the reciprocating movements of the piston. The device activates an electromagnetic field.

Types of self-priming pumps by the presence of an ejector

The best mobile application for experienced BPlayers has appeared and you can absolutely free download 1xBet on your Android phone with all the latest updates and discover sports betting in a new way.

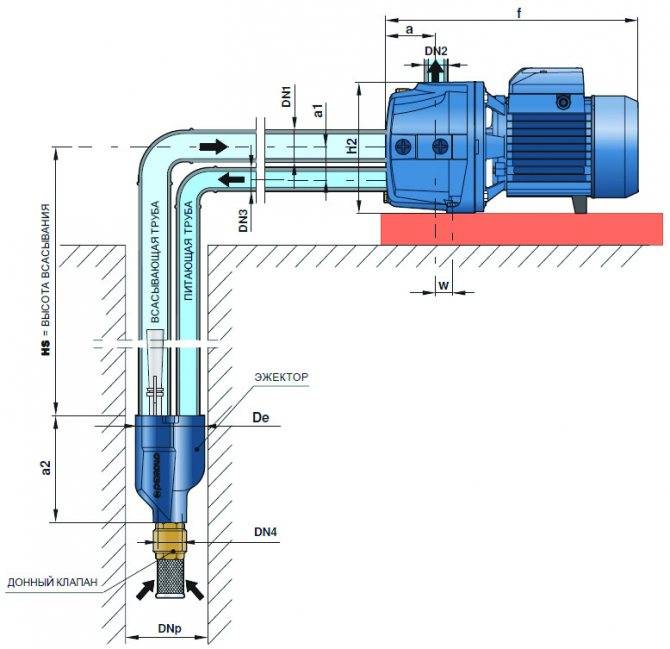

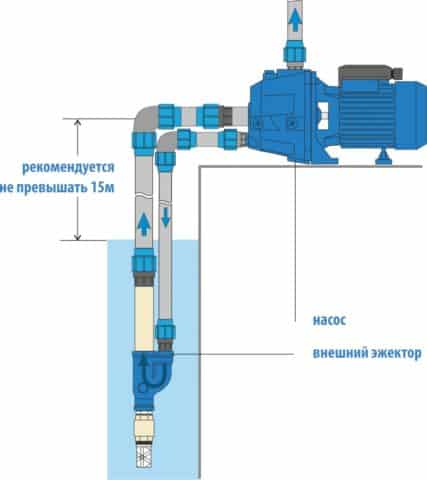

All models of self-priming units are divided into two types:

- Devices with built-in ejector;

- Pump with remote ejector.

In the first case, the mechanism pumps water by discharging the liquid itself. At the same time, the pump unit makes too much noise during operation, which requires a special room for equipment installation. The main advantage of such a unit is the ability to supply water from a depth of up to 10 meters.

Pumps with an external ejector are quieter, but at the same time, the level of immersion of the intake hose is several times lower. The principle of operation of such a mechanism is based on a hydraulic working unit that sucks in water and delivers it upward under high pressure.

Backflow pumps

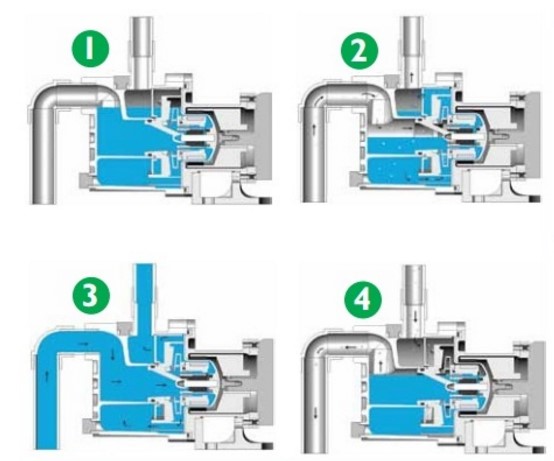

With a special backflow pump, you can also swim in a small, domestic pool. There are two types of counterflow pumps:

- Mounted. Suitable for small seasonal pools. These are units that have everything in one: a pump, nozzles, lighting, handrails, automation and control. The advantage of this design is the ease of installation.

- Embedded. Equipped with a suction mechanism capable of extracting water from above and below its level. They are more expensive and complex in design. They are mainly used in the arrangement of stationary pools.

When installing counterflows, you should pay attention to the water level: the level of the counterflow platform should be 120-140 mm higher than the water level

Counterflow #1 - Speck

The Speck company was founded in 1909 in Germany and specializes in the production of pumping equipment for liquid and gaseous media.

Countercurrent is a swimmer's treadmill that turns a small pool into an endless one.

The model has excellent characteristics and nice design.

Main characteristics:

- power consumption - 2.9 kW;

- productivity - 53 m3.

It is possible to connect special nozzles for hydromassage to the device. Easy to install without damaging the walls of the pool. There is an adjustment of the amount of mixed air.

The built-in counterflow pump is mounted below the water level. Professional model for continuous work

Main characteristics:

- power consumption: 3.3 kW;

- productivity: 58 m3.

Mounted countercurrent have increased power, are connected to a three-phase power supply. It is calculated on the maximum loadings for athletes. It has a built-in LED spotlight.

Counterflow #2 - Glong Electric

Glong Electric is a Chinese manufacturer of electric motors and water pumps. The company produces an extensive line of pumps: from cheap plastic to expensive ones with a bronze body and high performance. The company was founded in the mid 90s.

The counterflow in winter must be removed and stored in a dry, heated room.

The model is easy to install and carry.

Main characteristics:

- power consumption: 2.9 kW;

- productivity: 54 m3.

A single-jet countercurrent can serve as a hydromassage. To turn the device on and off, it is not necessary to leave the pool, there is a special pneumatic button.

Countercurrent #3 - Pahlen

The Swedish company Pahlen was registered over 40 years ago.Specializes in the production of equipment for swimming pools. Carries out deliveries to more than 70 countries of the world.

The minimum size of the pit for built-in counterflow LxWxD 1x0.6x0.6 m

It can be completed with an embedded part in the form of a handrail.

Main characteristics:

- power consumption - 2.2 kW;

- productivity - 54 m3.

Requires connection to a three-phase power supply. Made from bronze and stainless steel.

The delivery set includes a pneumatic start-up unit.

You may also be interested in how to properly organize the ventilation of the pool.

vortex suction pump

This type is only suitable for clean water.

Important! It must not be installed if the liquid may contain solid particles or viscous media. This will lead to an immediate breakdown.

The structure of the vortex model is not much different. Also, work is carried out due to the wheel with blades that rotate around the channel. Water along a helical path enters through a special tube when the wheel rotates. There is pressure and energy that raises the liquid to a certain level. After the removal of air, further movement of water is carried out according to the centrifugal mechanism described above.

The vortex suction pump should be tested for functionality before purchase

The advantages of such models:

- Small size;

- Strong pressure;

- Simple installation and easy assembly.

But these advantages do not make the vortex pump popular because of its significant disadvantages.

Advantages and disadvantages of centrifugal pumps

Advantages of the equipment:

- high performance characteristics of centrifugal pumps;

- stability of the parameters (pressure and volume per unit time) of the fluid flow;

- small dimensions and weight, which allows you to install equipment in tight spaces;

- maintenance does not require special tools and skills;

- the absence of rubbing elements (except for bearings) increases the service life of the product;

- increased equipment efficiency due to the lack of additional mechanisms;

- it is possible to regulate the performance using a throttle valve or a frequency converter that corrects the speed of the electric drive.

At the same time, there are also disadvantages of pumps:

- the device and principle of operation of a centrifugal pump allow you to start working only after pouring a portion of liquid into the housing;

- when air pockets appear, the pump performance drops;

- to achieve increased pressure in the line, it is required to use multi-stage installations;

- cavitation wear of the rotor and the surface of the working chamber;

- when pumping liquids with abrasive inclusions, the wear of working elements increases;

- the design of the pump does not allow pumping liquids with a viscosity of more than 150 cSt;

- the turbine has increased parameters at the design speed, an increase or decrease in frequency leads to a deterioration in the performance of the pump.

The optimal sequence of actions in case of a problem with a part of the pipeline in the apartment

The proposed solutions require a lot of time to service the system. It is much easier to find the main cause and quickly eliminate it, thereby returning normal pressure. Sometimes you can find a problematic place on the water supply by a buzzing sound. At the problem point, where the flow of water slows down, a hum is created when the mixer is opened. If you listen, it is possible to immediately diagnose a malfunction, and not waste time on unnecessary maintenance.

When it was not possible to determine the cause by ear, then you should start servicing the system. First of all, you can clean the aerator at the tip of the mixers. Before that, if you unscrew their flexible piping, you can see the current supplied to the water tap. If it is normal, then changing the faucet boxes and flushing the aerators will solve the problem.

This is what a clogged aerator looks like

When the reason is not in taps and flexible pipes, then you need to look for it at the level of the meter and other fittings. Ideally, immediately contact the management company to remove the seals from it. After dismantling them, you can start a full-fledged service that was not available before, since the seal wire prevents the disassembly of many important components.

Then you can proceed according to the following scheme:

- Dismantle the coarse filter and wash or replace its mesh.

- Check the pressure before and after the counter, it may be jammed and should be replaced.

- In a similar way, evaluate the operation of the check valve and replace if necessary.

- Carry out diagnostics of ball valves, in case of failure, change them.

If all else fails, then the reason is in the pipes, which will have to be changed. To do this, you need a tool, so you have to call a plumber. If you plan to install metal-plastic pipes, then soldering can be done on your own by renting equipment. This service is offered in many major cities.

Ball valve, oblique filter and counter - problem areas accumulating calcium salts

Watch the video: Overview of the Pedrollo JCRm 2A self-priming pump

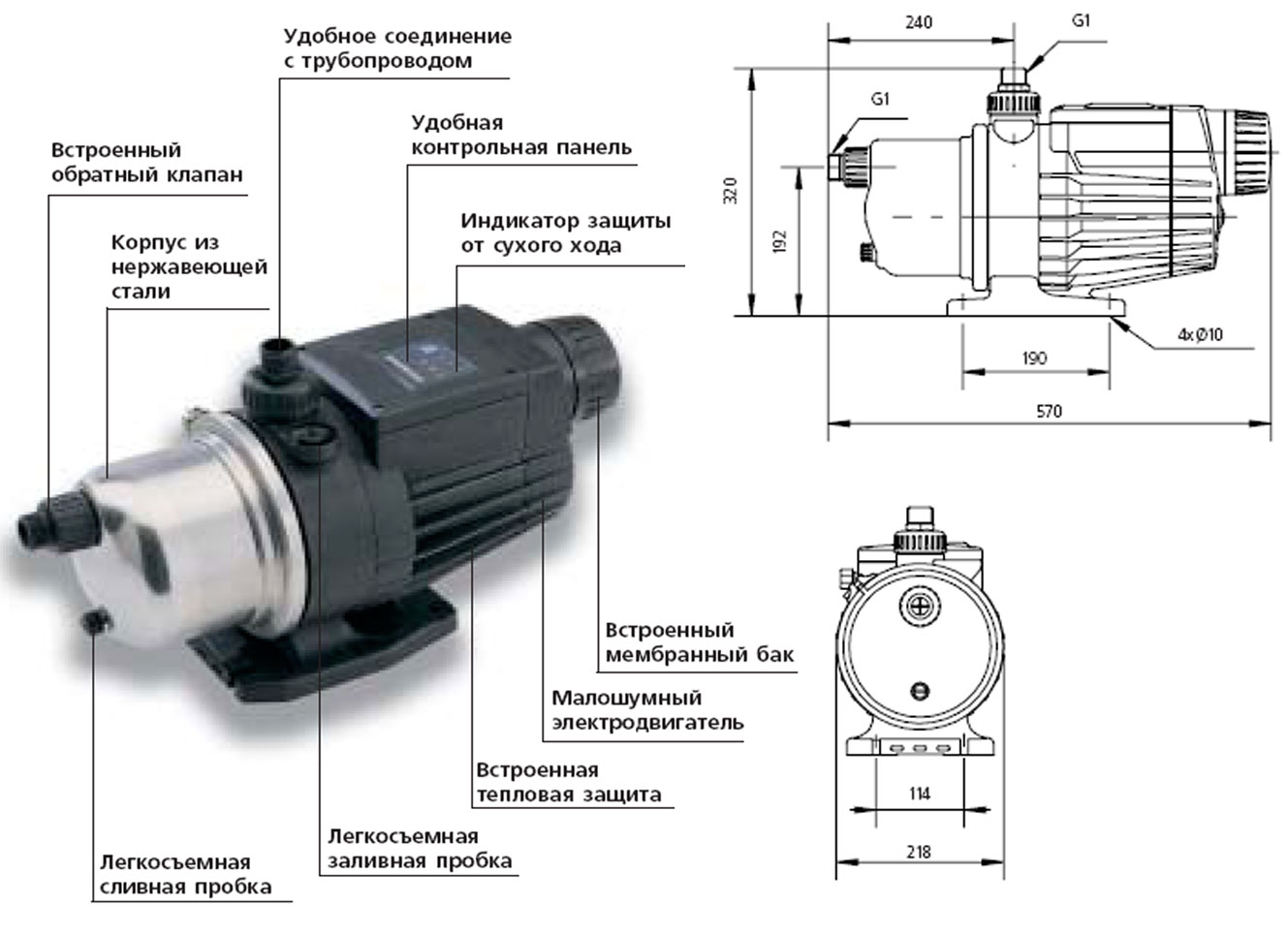

Pumps without ejectors draw liquid by means of a hydraulic device, which is equipped with a multi-stage design. The operation of such an installation is silent, but the suction depth is smaller and inferior to ejector counterparts.

A centrifugal pumping unit in a volute casing has a rigidly fixed impeller consisting of two discs with curved blades placed in the middle. The blades have a curved shape, which is located on the opposite side of the suction, pressure pipes.

The centrifugal self-priming pump fills the housing and the suction pipe with water without pre-filling the liquid during operation, while the wheel sets in motion. When the wheel moves, centrifugal force appears, it displaces water from the central part and overtakes it to the side parts. Pressure builds up, forcing water into the pressure pipe. At this point, the pressure in the center of the moving wheel drops.

Useful video: Capabilities of a self-priming pump without liquid filling

This allows a new portion of liquid to be poured into the body through the suction pipe. At the same time, water is supplied continuously, and it is not necessary to pre-fill the liquid. There may be several impellers in various models of such a pump. The more of them, the more stages the pump has, but this does not affect the operation (water supply) and liquid filling. In any pump, the liquid moves with the help of centrifugal force in the wheels.

The principle of operation of a vortex self-priming pump

The vortex pump supplies water according to this principle: air is sucked into the housing using vacuum. The vacuum is formed during the operation of the impeller (wheel). The air in the wheel is mixed with water. The liquid during the operation of this pump can rise to a height of 8 meters. The bottom valve is not required for operation.

When air with liquid enters the chamber and they are separated, since they differ in density.The air goes into the special supply line, and the water is distributed in the chamber. With the complete displacement of the liquid, water is poured and the centrifugal mechanism is turned on. A non-return valve is located on the inlet suction flange of the self-priming pump. It does not allow air to pass back and leaves the necessary amount of water in the case for work.

In addition to water, these units are capable of pumping various liquid-air mixtures. Centrifugal self-priming pumps are heavy and bulky. Vortex pumps are produced with less weight and dimensions. The centrifugal pump runs quietly and this allows it to be used in private homes. A vortex pump without liquid filling has a lower cost and at the same time exceeds the head capacity of a centrifugal analogue up to seven times.

When choosing a self-priming pump without liquid filling, you must be guided by your needs and pay attention to the principle of operation. Thus, you can make inexpensive water supply in the house

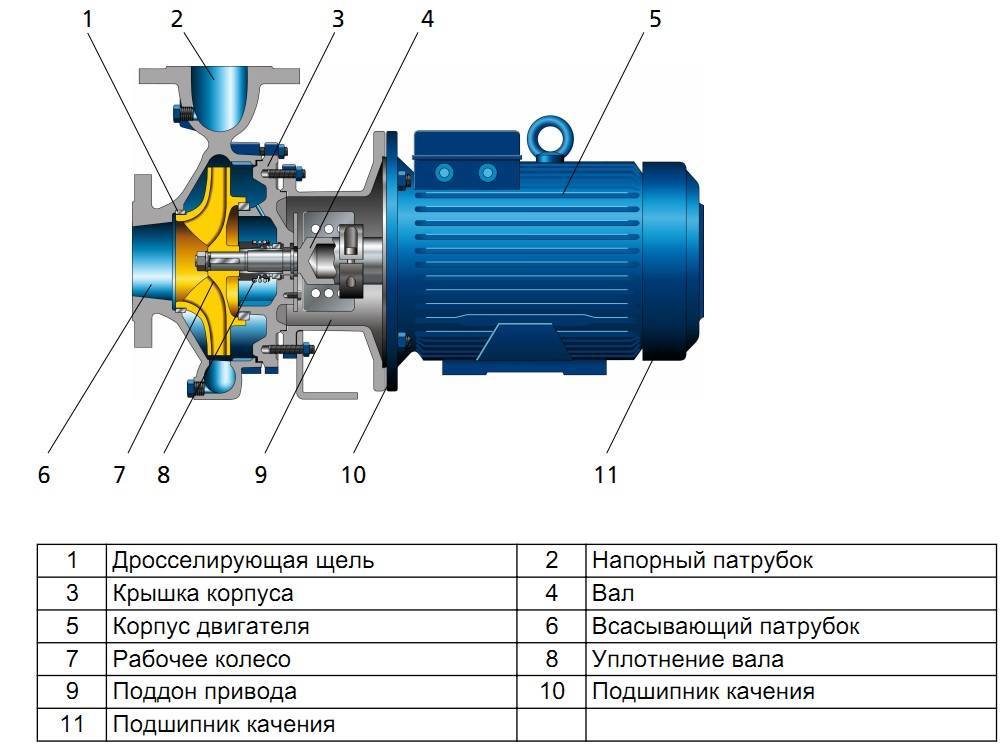

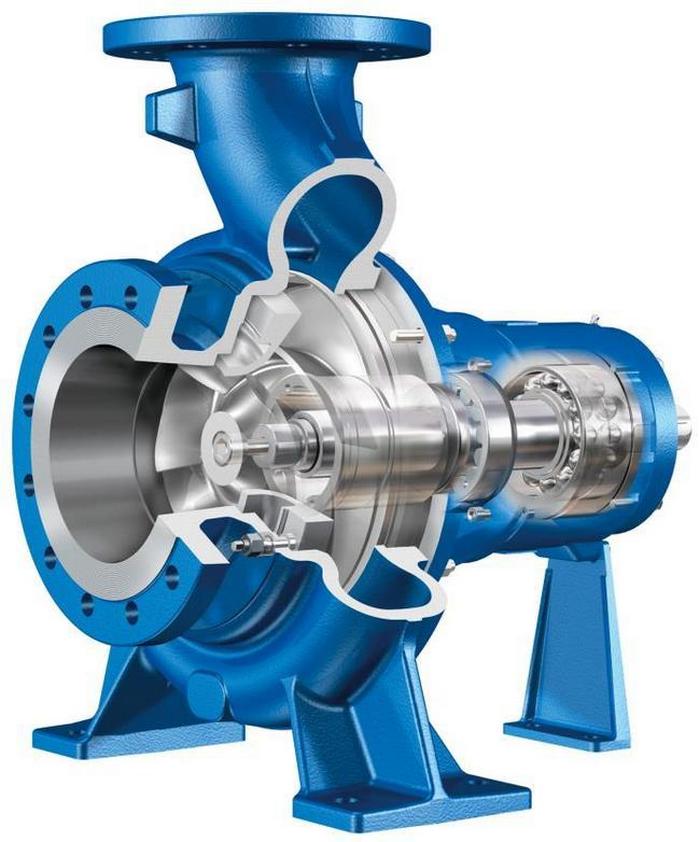

Classification of centrifugal pumps

There are various types of centrifugal pumps; differences in the design of the casing and the number of stages for injecting liquid into the pressure hose are used for classification. The equipment differs in the method of shaft sealing, the method of connecting the working body with the power drive. Additional differences are imposed by the type of liquid that the pump pumps. There are spiral type pumps that divert liquid into a spiral labyrinth, in some devices a fixed wheel with guide vanes is used to flow the liquid.

The equipment is divided according to the installation method; small-sized pumps can be mounted on portable frames or mounted inside household appliances cases. Structures for water supply of a residential building or an industrial facility are placed on a concrete base, in which anchors are located in advance. When installing the unit outdoors, a protective visor is provided to prevent atmospheric precipitation from entering the motor housing.

According to the location of the nozzles of the pumps

Depending on the location of the nozzles, centrifugal pumps are divided into 2 categories:

- Classical or cantilever type, the layout scheme provides for the location of the input line in the center of the rotor axis. The outlet pipe is located on the top of the body, the angle between the channels is 90°. The design uses a power drive with a horizontal shaft.

- In-Line scheme, characterized by the location of the suction and pressure channels on the same horizontal or vertical axis. The equipment is intended for placement on straight sections of the pipeline, the engine is installed vertically.

By number of pump stages

single stage pump

Classic centrifugal pumps are equipped with 1 impeller, the devices are used to supply liquid under low pressure. To provide increased pressure, pumps are used with a series installation of 2 or 3 rotors located on the same axis.

Multistage pump

Each impeller is equipped with an individual chamber, the liquid passes from one compartment to another, sequentially gaining pressure. The outlet pressure is equal to the sum of the pressures provided by the pump stages (taking into account losses during pumping liquid inside the device).

Shaft seal type

Depending on the design of the unit, the installations are divided into the following types:

- stuffing box equipment;

- devices with mechanical sealing rings (single or double type);

- sealed type products with a wet rotor;

- equipment with back pressure shaft seal (dynamic type).

By type of connection to the electric motor

conventional clutch

Standard units are equipped with a pump and a motor with separate shafts, which are equipped with flanges. Elements are fixed on the surface with dowels, flanges are connected by rubber couplings that reduce vibrations

Coupling with an intermediate element

To speed up the maintenance procedure for pumping equipment, a design with an intermediate insert is used. The element allows replacement of pump packings without removing the electric motor from the frame.

Blind coupling centrifugal pump

To reduce the size and eliminate vibrations associated with shaft misalignment, monoblock type pumps are used. The impeller is mounted on an elongated shaft of the electric motor rotor. Monoblock designs include products equipped with a fixed coupling of a deaf type. The installation of such a connecting part requires preliminary alignment of the axes of rotation of the rotors.

By appointment

The purpose of centrifugal pumps allows you to divide the equipment into several categories:

- for water supply from wells and wells (drainage and borehole installations);

- pumps for pumping out waste products (fecal devices and sludge pumps);

- slurry pumps that allow pumping out a mixture of liquids and solid components;

- equipment for food production;

- fire pumps, characterized by increased reliability and performance.

Types of self-priming pumps

Centrifugal pump

The design of such equipment consists of a working unit located in a spiral housing. In this case, the node itself has the shape of a wheel with blades on it. The blades are curved in the opposite direction from the direction of movement of the impeller.

The principle of operation of such equipment is high-speed rotation of the wheel and the creation of centrifugal force. As a result, water enters the pump reservoir through the inlet and leaves it through the outlet valve. In the intervals between the inflows and expulsions of water from the pump in the area of the working unit, the pressure changes from higher to lower and vice versa, depending on the position of the water in it.

vortex pump

There are also models of self-priming pumps with a vortex working unit. Here the suction pump has a working unit in the form of an Archimedes screw. An example of such an element is a standard kitchen meat grinder. The depth of water intake with the help of such equipment is up to 8 meters, but at the same time the unit is able to pump water mixed with sand or clay. Such inclusions do not affect the wear of pumping equipment in any way.

The principle of operation of the vortex water unit is the rapid rotation of the Archimedes screw and the change in pressure in the working chamber under the influence of first air, and then water. As a result of pressure drops, the water that has entered the tank is pushed out into the outlet through a special valve.

Self-priming units

Many, for sure, remember that in order to start the water pump, it is necessary to first fill the system with water, otherwise the device cannot draw in the liquid itself and its current will not start.Also, due to dry running, overload and overheating occur, which can lead to premature equipment failure.

The main difference between a self-priming pump is that it is able to independently remove air from the pipes, so it does not require constant monitoring, although water will also have to be added for the first start.

These devices are used for different purposes:

- Increasing pressure in the water supply system;

- Raising water from a well or well.

Self Priming Centrifugal Pump

All self-priming pumps are divided into the following types according to the principle:

- centrifugal;

- Vortex;

- Axial;

- Inkjet;

- Membrane;

- piston;

- Rotary.

There is also a division according to the installation method:

- Submersible - work directly in the water, sink to the bottom of the well, where they push the water up. The advantage of such equipment is greater productivity - they are able to raise water to a greater height. The disadvantage is the complexity of maintenance.

- Surface - placed in a dry place in a well or in a specially equipped room. They cannot raise water to a height of more than 7-8 meters.

Centrifugal self-priming food pumps with ejector

By power, working life and performance, pumps are divided into domestic and industrial.

Self-priming pumps are not only used for plumbing. They are used in storm systems, for watering land, sewers, drainage systems, and so on.

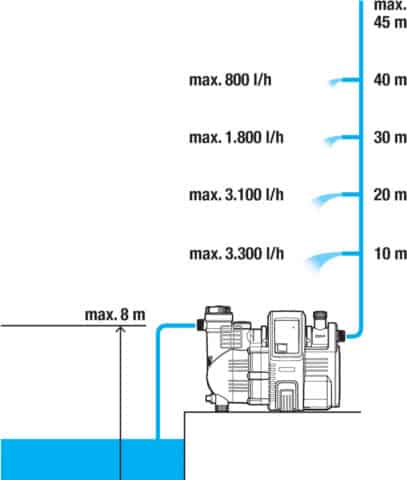

Characteristics of pumping stations

Now let's take a closer look at the main operating parameters of pumping equipment.

First of all, it is worth correlating the depth of water rise with the capabilities of the selected unit. In this case, the horizontal length of the pipeline to the pump must also be taken into account.

As mentioned earlier, for surface pumps, this parameter rarely exceeds 7 meters. Theoretically, it is possible to reach 10, but then such power and its losses will be required that such water will literally become “golden”.

Maximum liquid lifting height for the pump

If the depth of the well is much greater, then you will have to use a submersible or ejector pump. The first one goes down, and the second one is also mounted on the surface, but unlike the simple version, it is equipped with an additional device - an ejector.

The principle of operation of the external ejector

Such a unit is capable of lifting water from a depth of up to 25 meters. The effect is achieved due to the fact that part of the raised water returns back down and is injected under pressure through an additional nozzle into the main stream. Bernoulli's law comes into force, and water from the bowels rushes up due to the speed of the current.

The disadvantage of such units is increased noise and reduced efficiency, since part of the raised liquid is transferred back.

It is also worth paying attention to other parameters:

Maximum temperature of the working environment;

Maximum outlet pressure;

The volume of pumped liquid in liters per hour;

Permissible degree of water pollution - important when choosing a garden pump;

The best submersible pumps for a well

As the name suggests, these pumps are designed to be fully or partially submerged in water. Among them, well and borehole models are distinguished. Depending on the type chosen, the height of the water column varies from 9 to 200 m. Submersible pumps are characterized by high efficiency (compared to surface models) and the presence of a sealed casing.

Usually they are equipped with a filter and automatic protection against dry running.

Experts also recommend paying attention to the presence of a float that will turn off the power to the pump when a critical water level is reached.

Pedrollo NKM 2/2 GE - pump for wells with moderate energy consumption

5.0

★★★★★editorial score

100%

buyers recommend this product

A productive and reliable pump that is able to "digest" water with minor mechanical impurities up to 150 grams / 1 m3 without harm to itself. With an immersion depth of 20 m, the unit provides up to 70 liters of water, raising it by 45 m. Also, this model can work stably in networks with a "drawdown" of voltage.

Advantages:

- Reliability.

- Excellent performance.

- Stable operation in polluted water.

- Low power consumption.

- The presence of a float switch.

Flaws:

High cost - 29 thousand.

A very good model for organizing the water supply of a private house. The main thing when using this pump is to take into account the flow rate of the well.

Water cannon PROF 55/50 A DF - for pumping contaminated water

4.9

★★★★★editorial score

97%

buyers recommend this product

See review

The novelty of this year is a submersible pump with impressive technical characteristics. When submerged to a depth of 30 m, this unit is capable of delivering up to 55 l / min. to a height of up to 50 m. Protection against dry running is provided by a float switch.

The main feature of the device is the floating design of the impeller. This technical solution makes it possible to pump water containing solids up to 2 kg/m3. The cost of the unit is 9500 rubles.

Advantages:

- Good performance and pressure.

- Existence of protection against an overheat.

- Ability to work in water with a high content of mechanical impurities.

- The presence of drainage channels to reduce the load on the engine at start.

Flaws:

Non-return valve included.

A good model for creating an automated water supply system at home. However, its construction requires equipment with additional elements and accessories (hoses, fittings, check valve, etc.) that must be purchased separately.

Karcher SP1 Dirt is a silent model with low power consumption

4.8

★★★★★editorial score

90%

buyers recommend this product

See review

A reliable submersible pump from a well-known German manufacturer is designed for a maximum performance of 5.5 m3 / h at a depth of immersion up to 7 m. The unit is equipped with a carrying handle, a patented quick connection system, has the ability to work in manual and automatic modes with float switch fixation.

The main feature of Karcher SP is the possibility of stable operation in turbid water with mechanical inclusions up to 2 cm in diameter. At the same time, the price of the device is quite low - 3300 rubles.

Advantages:

- High performance.

- No noise during operation.

- Quality build.

- "Digestion" of large mechanical inclusions.

- Extended warranty (5 years) from the manufacturer.

Flaws:

- There is no inlet filter included.

- Large outlet diameter - 1″.

The extremely low pressure of 4.5 m indicates the narrow specialization of the device. It is suitable for watering the site, draining drainage wells and pools.

Grundfos SB 3-35 M - powerful pump with low starting current

4.7

★★★★★editorial score

85%

buyers recommend this product

Structurally, this model differs from analogues in the absence of automation, due to which the manufacturer has significantly reduced its cost.The pump is equipped with a 0.8 kW motor, which provides a solid performance of 3 m3/h with a water column of 30 m.

Alas, the cheapening of the device affected its ability to work with polluted water. The device is able to "digest" no more than 50 g/m3 of mechanical impurities. The price of the unit was a little less than 16 thousand.

Advantages:

- Reliability.

- Simplicity of design.

- Good pressure and performance.

- A small load on the power grid when starting the device.

Flaws:

No dry run protection.

A very good model for a private house with increased water consumption. In case of urgent need, the problem of lack of automation is easily solved by purchasing and installing a float switch.

conclusions

Do you already have a self-priming pump in your garden?

Of course! No, but it will be!

Summing up, it is worth noting the following:

- The most suitable for domestic use are dynamic self-priming pumps of centrifugal and vortex types. They are able to provide both watering and water supply in the house.

- Maximum performance with a self-priming pump can be achieved with careful observance of the requirements for the installation site of the device, its process and operation.

- Choose options that suit your specific tasks and are able to work correctly in the conditions you set.

- Before starting the self-priming pump, check the quality and tightness of the connections, the quality of the incoming liquid, the correct placement of the pipelines to the installation and the level of immersion of the hose in water.

- Pumping station for a summer residence. How to choose? Model overview

- How to choose a fecal pump? Types, characteristics, overview of models

- Surface pumps for wells. Overview and selection criteria

- Pumps for watering the garden. How to choose, rating models