- Scope of self-priming pumps and their types

- Self-priming surface pump

- Self-priming submersible pump

- Types of self-priming pumps

- The device and principle of operation of a centrifugal pump

- Working principle of self-priming peripheral pump

- Water pump device

- What is the difference between vortex and centrifugal designs?

- Purpose and operation of self-priming pumps

- Working principle of self-priming peripheral pump

- Water pump repair technology

- Pump "STsL" 00a

- Peculiarities:

- The device and diagram of a hydraulic pump with a manual drive

- Classification

- Open-vortex and closed-vortex

- Submersible and surface models

- Combined options

- jet pumps

- Compact domestic pumping stations

- Operating modes of universal pumps

- Selection of the pump unit according to the pool type

- Criterias of choice

- Video: submersible pump for pumping water from the pool

- vortex suction pump

- Types and action of high pressure pumps

- Dry rotor units

- Glandless devices

- About water supply and its pressure

Scope of self-priming pumps and their types

If we evaluate the entire range of applications of self-priming pumps for dirty water, then the list is as follows:

- Pumping out waste water with subsequent removal outside the site.

- Drainage of a pit, well, basement after seasonal floods.

- Organization of watering and irrigation of a personal plot, landscaping areas.

- Water intake for irrigation from nearby reservoirs, reservoirs, streams.

- Elimination of consequences of flooding of premises.

In this case, centrifugal mud pumps are most often used, which are unpretentious and resistant to the effects of impurities contained in the pumped liquid. According to the principle of operation, all models are divided into surface and submersible. Each type has its own advantages, which determine the scope.

Self-priming surface pump

There are models of self-priming pumps designed for stationary use and portable, which will turn on when necessary. Scope of application - occasional use. A flexible hose is attached to the suction pipe, which is enough to lower into a container with liquid and start the equipment to start pumping.

It will not be possible to raise water from a great depth, but if you equip the system with an ejector, then for a horizon of 10 meters this will not be a problem. This means that this pump can be mounted on a frame above the well and pump water from the source until it runs out.

Such devices are classified into categories:

- Pressure.

- Circulating.

- Garden universal.

- Pump stations.

There is another category that is designed for cleaning cesspools. These devices are made of materials that are resistant to aggressive environments, which are formed due to the processes of decomposition of organic compounds and the presence of a large number of specific bacteria.

Self-priming submersible pump

This kind of self-priming pump is supposed to be lowered into the liquid. The lower fence allows you to pump water from the bottom. To prevent suspended particles from clogging the pump and putting it out of action, there is a metal grate that serves as a dirty cleaning filter. With this configuration, stones from the bottom cannot damage the mechanism.

It is also assumed that the pumped substance is not feces and household waste. For these purposes, submersible equipment is not used. It is another matter to pump out water from the pool, drain the well, organize the flow of water from the reservoir for irrigation, etc. Distinguish pumps well, fecal, drainage and borehole type. Each of them has its own purpose, and not all are interchangeable.

No water intake sleeves are required. The pump is lowered with a cable along with a hose through which water will rise to the surface. Water is sucked directly into the working chamber of the device through a protective metal mesh that protects the device from stones and debris.

Types of self-priming pumps

Manufacturers produce self-priming pumps with a built-in or remote ejector. In this type of pumping equipment, the suction and rise of the liquid occurs due to its discharge. During operation, ejector installations make too much noise, so a special room is selected for their placement on the site, located at a sufficient distance from the residential building. The main advantage of self-priming pumps with an ejector is their ability to lift water from a great depth, on average about 10 meters.In this case, a supply pipe is lowered into the water intake source, and the pump itself is installed at a certain distance from it. This arrangement allows you to freely control the operation of the equipment, which affects the duration of its use.

The second type of equipment includes self-priming pumps that provide water lifting without ejectors. In models of this type of pumps, liquid suction is provided by a hydraulic device that has a special multi-stage design. Hydraulic pumps operate silently, unlike ejector models, but they are inferior to them in terms of the depth of liquid intake.

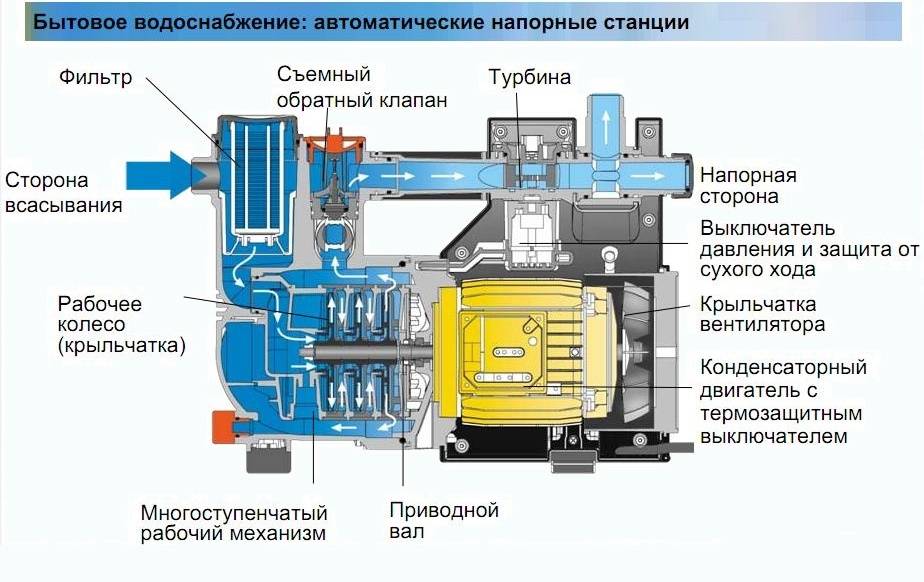

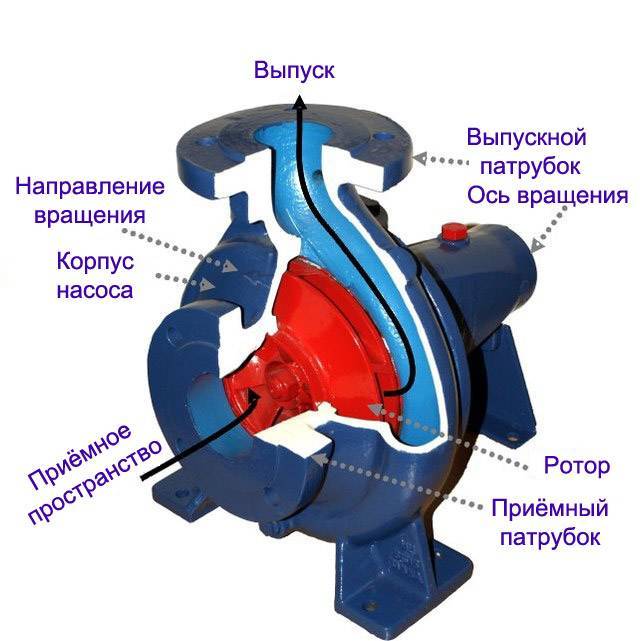

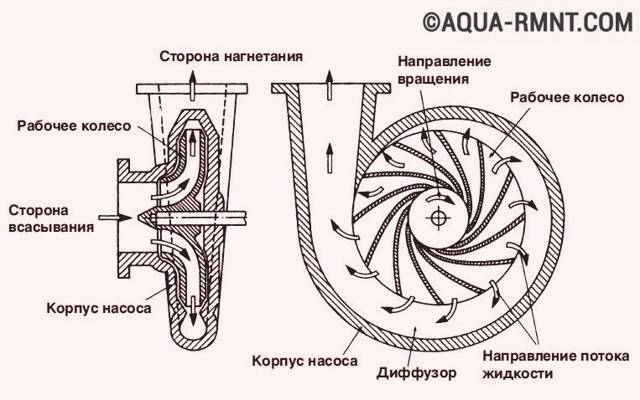

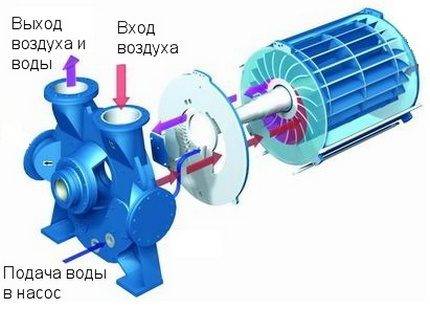

The device and principle of operation of a centrifugal pump

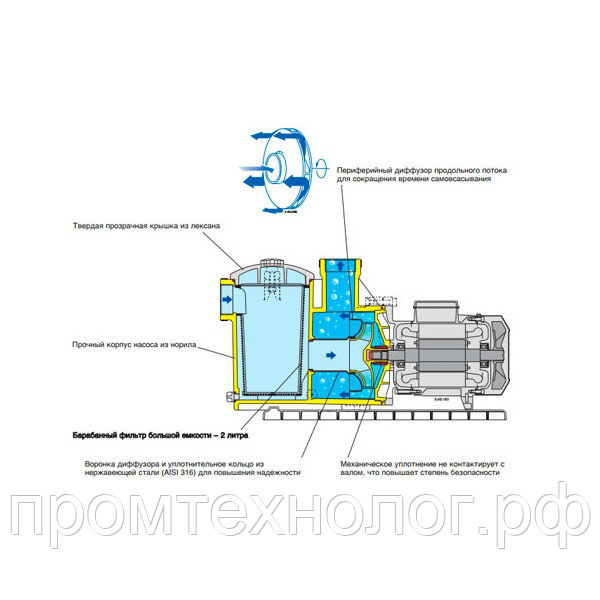

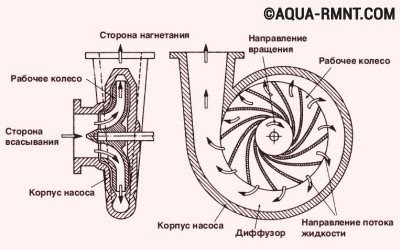

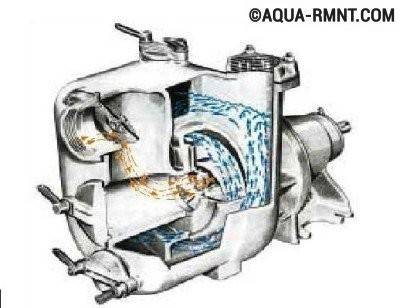

The figure shows the device of a self-priming centrifugal pump. In the body, which has a spiral shape, there is a rigidly fixed wheel, which consists of a pair of disks with blades inserted between them. The blades are bent in the opposite direction from the direction of rotation of the impeller. With the help of nozzles of a certain diameter, the pump is connected to the pressure and suction pipelines.

So schematically, you can imagine the device of a self-priming centrifugal pump for pumping water used in private homes and cottages

The principle of operation of centrifugal self-priming pumps is as follows:

- After the casing and the suction pipe are filled with water, the impeller starts to rotate.

- The centrifugal force that occurs when the wheel rotates displaces water from its center and throws it to the peripheral areas.

- Due to the increased pressure created in this case, the liquid is displaced from the periphery into the pressure pipeline.

- At this time, in the center of the impeller, on the contrary, the pressure decreases, which causes the flow of liquid through the suction pipe into the pump casing.

- According to this algorithm, water is continuously supplied by a self-priming centrifugal pump.

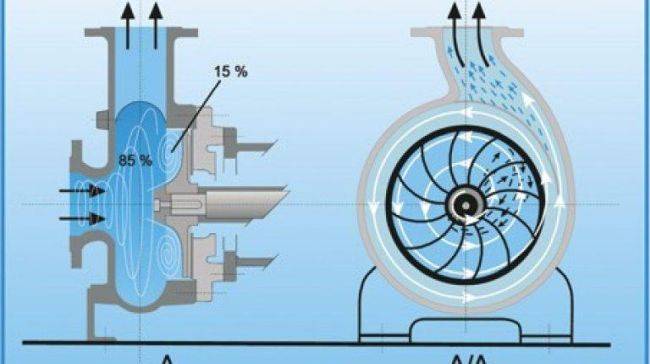

Working principle of self-priming peripheral pump

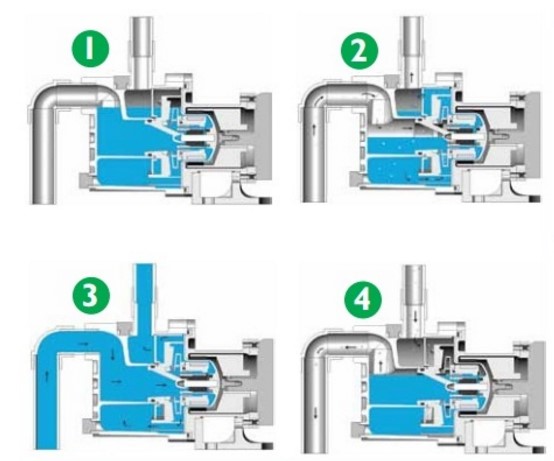

The air, shown in yellow in the figure, is sucked into the pump housing due to the vacuum created by the rotation of the impeller (impeller). Next, the air that has entered the pump is mixed with the working fluid contained in the unit housing. In the figure, this liquid is shown in blue.

This figure shows the device and principle of operation of a vortex self-priming pump for lifting liquid to a height of no more than eight meters.

After the mixture of air and liquid enters the working chamber, these components are separated from each other, based on the difference in their densities. In this case, the separated air is removed through the supply line, and the liquid is recirculated in the working chamber. When all air is removed from the suction line, the pump fills with water and starts working in centrifugal installation mode.

Possible versions of vortex self-priming water pumps manufactured by manufacturers for domestic use by owners of private houses and country cottages

A non-return valve is installed on the suction flange, which is designed to prevent air from returning to the pipeline, as well as to ensure the constant presence of working fluid in the pump chamber.Thanks to this device and the principle of operation, vortex self-priming pumps are capable, with a filled chamber, of lifting liquid from a depth not exceeding eight meters, without installing a bottom valve.

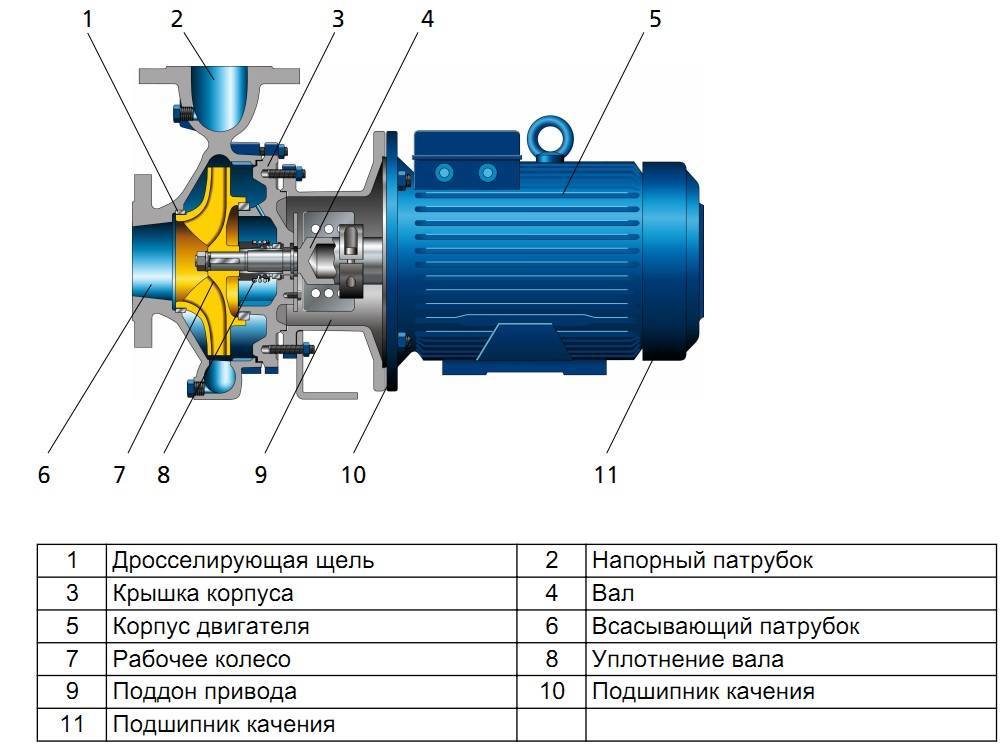

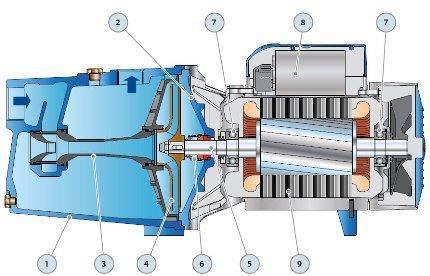

Water pump device

The pump consists of the following main units:

-

-

- Corps;

- electric motor;

- Discharge pipe;

- Suction pipe;

- Impeller (rotor);

- working shaft;

- Salnikov;

- bearings;

- guiding device;

- Casing.

-

The bowl body is made of steel or cast iron, an impeller is located inside it. The design of the housing has an opening located at the bottom for suction of liquids and for the exit, located on the side edge of the housing.

The body can be a separate element to which the branch pipes are connected, or it can be cast, representing a single structure. On the body there are brackets for mounting the pump. A receiving branch pipe is screwed into the hole where liquid is sucked into the working chamber. With it, a pipeline is connected to the pump, which is located in the source of the liquid. The design allows the branch pipe as part of the body and as a separate element, depending on the principle of operation of the pump.

A discharge pipe is connected to the outlet on the side of the body, through which water is transferred from the working chamber to the consumer using a pressure pipeline connected to this pipe. The branch pipe is a part of the cast case.

What is the difference between vortex and centrifugal designs?

The centrifugal unit is more massive in size than the self-priming vortex water pump, which is characterized by compact dimensions

But centrifugal pumps make little noise, which is important when used in everyday life.Vortex models are sold at a lower price, which is also important for the consumer.

At the same time, the water pressure created by vortex pumps can exceed the capabilities of centrifugal models up to seven times.

When choosing a self-priming pump, you should not be guided only by prices, since cheap equipment may not ensure the normal operation of water supply systems. It is desirable to build on the purpose of the pump and its technical characteristics. With the right choice of the pump model and the observance of the manufacturer's recommendations on the method of its operation, you can count on the long-term operation of the purchased equipment.

Purpose and operation of self-priming pumps

A pleasant country life can be accompanied by certain difficulties, which you will have to solve on your own. To do this, self-priming pumps for dirty water can become a convenient and necessary type of home equipment that can help in eliminating a number of problems:

Pumping and disposal of sewage.

- Pumping out dirty water from drainage systems, pits, wells, flooded basements.

- Supplying the site with water for irrigation and watering green spaces.

Watering the garden from a nearby natural reservoir.

Cleaning the premises in case of water leakage in case of an emergency.

Working principle of self-priming peripheral pump

The air, shown in yellow in the figure, is sucked into the pump housing due to the vacuum created by the rotation of the impeller (impeller). Next, the air that has entered the pump is mixed with the working fluid contained in the unit housing. In the figure, this liquid is shown in blue.

After the mixture of air and liquid enters the working chamber, these components are separated from each other, based on the difference in their densities. In this case, the separated air is removed through the supply line, and the liquid is recirculated in the working chamber. When all air is removed from the suction line, the pump fills with water and starts working in centrifugal installation mode.

A non-return valve is installed on the suction flange, which is designed to prevent air from returning to the pipeline, as well as to ensure the constant presence of working fluid in the pump chamber. Thanks to this device and the principle of operation, vortex self-priming pumps are capable, with a filled chamber, of lifting liquid from a depth not exceeding eight meters, without installing a bottom valve.

Water pump repair technology

The most common failure of the water pump is the failure of the stuffing box. To get rid of the malfunction, it is necessary to replace the broken part. We will tell you the principle of getting rid of this problem.

First, we will disassemble the pump. We do everything in this sequence:

- We bend the lock washer;

- Next, we unscrew the cap nut, while holding the shaft from turning;

- Remove the impeller from the stuffing box;

- We remove the sealing and thrust rings;

- We take out the drive pulley and the key is knocked out;

- Remove the dust deflectors of the retaining ring;

- Next, the shaft of the water pump with bearings splashes out;

- And the last we remove all the compaction.

Our device is disassembled and ready to replace the gland, after that we assemble everything in the reverse order.

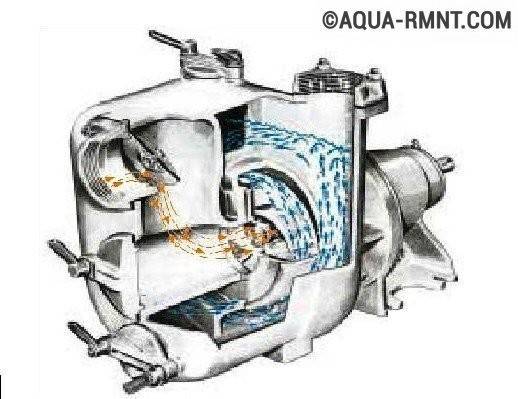

Pump "STsL" 00a

Refers to left-hand rotation devices.Its 2-stage mechanism allows pumping liquid medium and producing pressure. Such a centrifugal-vortex apparatus can be easily aggregated on a fuel truck and water-pressure systems. For installation on agricultural machines, special equipment and irrigation units, it is additionally equipped with a gearbox, the purpose of which is to increase the gear ratio from the power shaft.

Peculiarities:

- cast iron impeller;

- wide range of operating conditions.

Its technical parameters correspond to the above model.

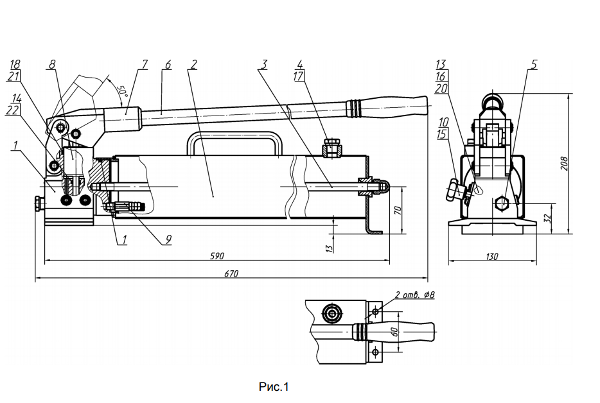

The device and diagram of a hydraulic pump with a manual drive

Scheme of the hydraulic hand pump

The manual hydraulic pump consists of two main parts, the pumping unit (1) and the hydraulic tank (2). They are interconnected with a hairpin (3).

Filling liquid through the hole, having previously unscrewed the plug (4) that closes it.

The handle (6) with the lever (7) drives the plunger (8) of the first and second stages, made as one piece.

The pumping unit has a two-stage structure.

Overload protection is provided by a safety valve (9).

The release of pressure and the extraction of hydraulic fluid from the cavity of the cylinder into the tank occurs with the help of a screw (10).

Classification

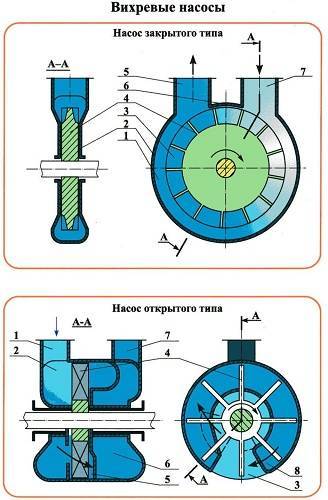

Vortex devices can differ in several ways. Currently, there are the following types of vortex pumps:

- open and closed - vortex;

- submersible and surface;

- combined.

Each of them has a different purpose and structure.

Open-vortex and closed-vortex

An open-vortex pump differs from a closed-vortex one in that it has longer blades, the impeller is smaller in diameter than the outlet channel, and the annular channel itself is connected only to the discharge pipe. In closed models, the blades are shorter and located at different angles, the diameter of the wheel matches the diameter of the inner chamber, and the channel connects the inlet and outlet.

The difference in work is as follows. Water enters through the inlet and enters the working chamber, where it is sent in the form of a vortex to the connecting channel and exits through it under pressure through the outlet pipe. In closed devices, due to the same diameter of the working chamber and the wheel, water immediately enters the connecting channel, a vortex is formed there and the pressure increases.

Submersible and surface models

The difference between these models is clear from the name: submersible ones are located directly in the pumped medium, surface ones are located next to it. The first option is most often used simply for pumping liquids or not too viscous substances, the second is used for water circulation, for example, in irrigation systems or for home water supply.

Combined options

Free-vortex models allow you to work with heavily contaminated substances. They are used as fecal or drainage pumps, used in sewage treatment plants and in the mining industry for pumping water from wells during drilling.

Centrifugal vortex pumps have a higher efficiency in comparison with classic vortex models, they are able to work with liquids with a heating temperature of not more than 105 degrees. The difference lies in the fact that both centrifugal and vortex wheels are installed here at the same time.

Rotary type vacuum pumps are a kind of blowers. With their help, you can ensure the distribution of hot or cold air, as well as achieve a small vacuum. It is often used for drying glass containers and aerating water bodies.

jet pumps

Inkjet models are the simplest of all possible devices. They were created back in the 19th century, then they were used to pump water or air from medical test tubes, later they began to be used in mines. At present, the scope of application is even wider.

The design of the jet pump is very simple, thanks to which they practically do not require any maintenance. It consists of four parts: suction chamber, nozzle, diffuser and mixing tank. The entire operation of the device is based on the transfer of kinetic energy, while no mechanical force is used here. The jet pump has a vacuum chamber into which water is sucked. Then it moves along a special pipe, at the end of which there is a nozzle. By reducing the diameter, the flow rate increases, it enters the diffuser, and from it into the mixing chamber. Here, the water is mixed with the functional fluid, due to which the speed is reduced, but the pressure is maintained.

Jet pumps come in several types: ejector, injector, elevator.

- The ejector only pumps the substance. Works with water.

- The principle of operation of the injection pump is the injection of a substance. Used to pump out steam.

- Elevator is used to lower the temperature of the carrier, which is achieved by mixing with a functional fluid.

This type of pump is common in various industries. They can be used alone or in combination with others.The simplicity of the design allows them to be used in emergency situations with water shutdown, as well as for fire fighting. They are also popular in air conditioning and sewage systems. Many jet-type models are sold with a variety of nozzles.

Pros:

- reliability;

- no need for constant maintenance;

- simple design;

- wide scope.

Minus - low efficiency (no more than 30%).

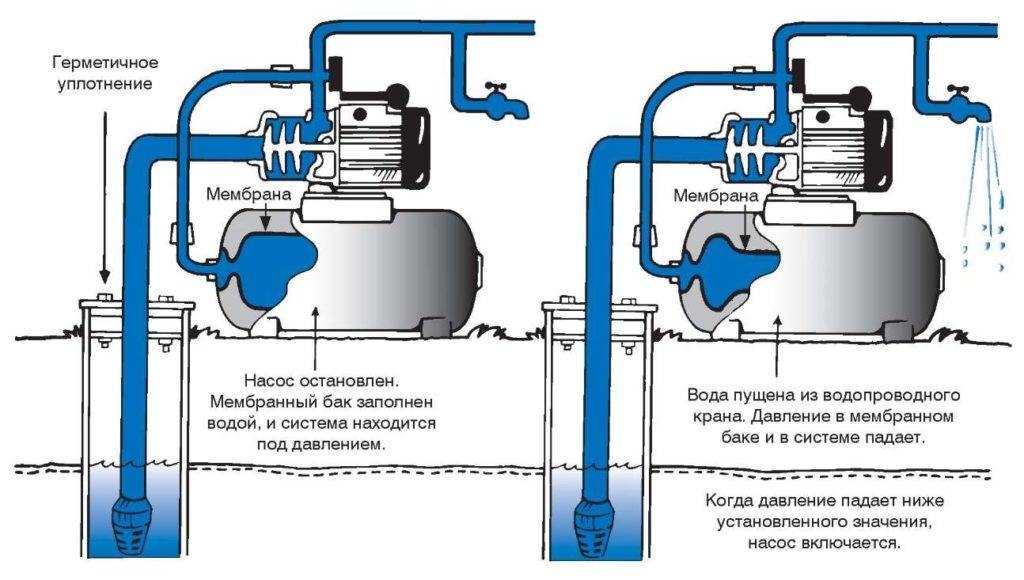

Compact domestic pumping stations

For the uninterrupted and efficient functioning of autonomous water supply systems for cottages and private houses in automatic mode, compact pumping stations have been increasingly used in recent years. The use of such stations, which include several technical devices, allows minimizing human participation in controlling the operation of pumping equipment due to automation elements. The compact dimensions of household pumping stations for pumping water, which, despite their small size, are characterized by high performance and are able to create good pressure in the pipeline system, allow such equipment to be installed in any convenient place, including in the basement of a residential building.

The household pumping station includes the following technical devices:

- submersible centrifugal pump pumping water from an underground source;

- filtering plant, in which water from an underground source is purified from solid inclusions;

- a circulation pump designed to pump water from the filter unit to the station's hydraulic accumulator;

- a hydraulic accumulator, the internal chamber of which, filled with water, is equipped with a special membrane (the task of this device is to maintain a constant pressure of the liquid medium in the autonomous water supply system, and also to provide this system with water at those moments when the station pump does not work due to a breakdown or lack of power).

Automatic pumping station for individual water supply systems and small garden plots

The operation of a household pumping station in automatic mode is provided by a pressure switch that automatically turns off the pumping equipment if the water pressure level in the accumulator rises to a critical level, and also turns it on when such pressure falls below the permissible value.

Mini-pumps are actively used not only in everyday life, but also in industry, in particular in food industry enterprises. For pumping liquid and viscous media used in technological processes at enterprises in this industry, special food pumps are needed, the structural elements of which are made of materials that are highly resistant to oxidation and do not emit harmful substances into the pumped medium.

Operating modes of universal pumps

Choosing a universal pump for arranging a pool, the owner of the pool can set several modes of operation. So, acting in the "circulation" mode, the pump solves the following tasks:

— uniform heating of water;

- its supply to the filter system;

- prevention of flowering;

- Help with cleaning.

The "heating" mode can also be used by the user.It involves work, both for pumping water and for draining it, and also helps in the process of mixing the supplied water layers. As a result, the temperature at different depths will be the same and swimmers in the pool will feel maximum comfort during water fun.

Selection of the pump unit according to the pool type

If a mobile inflatable or frame pool is installed on the site, which the owners mount from season to season, there is no need to spend money on expensive stationary equipment of the pumping group. Water can be scooped out of the bowl with buckets, provided that it has a small volume, and the rest can be drained by gravity using an ordinary garden hose. You can also use portable filtration pumps, which are usually supplied with portable pools.

However, this option is completely unsuitable for capital pools made of monolithic concrete, which are built in a house or in a backyard. For such pools, you need high-quality equipment, correctly selected in terms of power and functionality.

Criterias of choice

In addition to the main criterion - the power of the pump and its format, in the process of buying equipment in a store, the buyer's attention should also be focused on other technical characteristics that determine the scope of use and functionality. Among them:

- throughput;

- throughput;

— dimensions and weight of the body;

— network parameters;

- the presence of a guarantee from the manufacturer;

- ease of use;

— features of the engine;

- appointment;

— complete set of equipment;

- diameter of pipes;

- material of manufacture.

Indirect parameters are also important.Therefore, the list of the following positions deserves careful consideration - the noise level emitted by the pump, the availability of emergency engine shutdown options in it, the possibility of uninterrupted continuous operation, ease of maintenance and operation of the device.

Video: submersible pump for pumping water from the pool

Properly selecting pumping equipment for pumping water from the pool, the developer will be able to avoid many problems. If necessary, he will be able to quickly drain the bowl, preparing the pool for conservation for the winter or cleaning the walls of the pool as part of the scheduled maintenance of the structure.

vortex suction pump

This type is only suitable for clean water.

Important! It must not be installed if the liquid may contain solid particles or viscous media. This will lead to an immediate breakdown.

The structure of the vortex model is not much different. Also, work is carried out due to the wheel with blades that rotate around the channel. Water along a helical path enters through a special tube when the wheel rotates. There is pressure and energy that raises the liquid to a certain level. After the removal of air, further movement of water is carried out according to the centrifugal mechanism described above.

The vortex suction pump should be tested for functionality before purchase

The advantages of such models:

- Small size;

- Strong pressure;

- Simple installation and easy assembly.

But these advantages do not make the vortex pump popular because of its significant disadvantages.

Types and action of high pressure pumps

Before deciding to install a stimulation pumping device, the condition of the pipeline should be assessed. It is possible that the pressure deficit is due to pipes clogged with sediment.If you can get out of a predicament only by installing the device, then you should familiarize yourself with their technical specifics in more detail.

The principle of operation of high-pressure pumps, regardless of the version of the working body and the type of design, is the same. During the operation of the working unit, the device creates a vacuum space inside the cavity, due to which water is absorbed.

By creating a vacuum space, water is “drawn” from the source into the chamber, and then, under the action of high pressure, is pushed through the outlet pipe

On sale are models of a universal type, suitable for water of any temperature, and those that can only be used in a cold or only in a hot environment.

Depending on the method of cooling the running motor, the units are of two types: dry and wet rotor.

Dry rotor units

Dry rotor modifications difficult to confuse with wet counterparts. They have an asymmetric shape with a clear preponderance towards the power part of the device. The fact is that its engine is equipped with an vane cooling device, tk. is not washed in the process of work with water.

Due to the asymmetric shape and the displacement of the axis towards the motor, “dry” models are equipped with console devices for additional fixation on the wall.

Pumping devices equipped with a dry rotor are famous for their high level of performance and are used when it is necessary to supply large areas with water

Due to the fact that the engine in such models is separated from the hydraulic part at the end of the axle by a stuffing box seal, they serve much longer “wet”. True, the seal, like the rolling bearing, tends to wear out and needs to be replaced periodically.

For this reason, units equipped with a dry rotor require more frequent maintenance and regular lubrication of rubbing parts. Another disadvantage is that “dry” appliances are noisy, so the place for their installation should be carefully considered.

Glandless devices

Flow units require cooling due to the pumped water. In this case, the rotor of the device is placed in an aqueous medium and isolated from the stator by a waterproof damper.

Wet rotor units are characterized by a low level of generated noise interference. Glandless circulation pumps are designed for arranging heating systems, but are often used for water supply systems for heating residential premises.

Devices of this type have a modular design, due to which they can be easily disassembled into component units if it is necessary to replace an individual element.

Devices of this type have a modular design, due to which they can be easily disassembled into component units if it is necessary to replace an individual element.

The plain bearings used in the assembly of the structure do not require additional maintenance. However, “wet” pumps serve less and lose to “dry” units in terms of the pressure generated. There are restrictions on the direction of installation - it can only be horizontal.

A significant disadvantage of pumps of this type is the vulnerability when working with dirty water, foreign inclusions of which can disable the device.

About water supply and its pressure

If you are going to choose a liquid pump, you need to look at its parameters. All characteristics are important, but one of the key ones is the rate of water supply. It is necessary to calculate how many cubic meters of water the owner of the house spends per hour to find out which option is suitable.

The next, no less important characteristic is pressure. It indicates the force with which the unit will supply water.This parameter is calculated according to how far the water source is from the house. The pressure is lost under the influence of height and forks in the pipeline, so it is better to provide a small margin when calculating.