- Board repair

- Capacitors

- Resistors

- Thyristor block

- Trigger Diagnostics

- Typical breakdowns of household units

- Calling the master: repair price and ordering

- Overview of error codes

- Vertical machines

- Water problems

- Water is not coming

- Gaining very slowly

- Doesn't drain

- small leak

- strong leak

- The device and operation of washing machines

- The principle of operation of the washing machine

- Causes of breakdowns and ways to eliminate them

- No water coming in

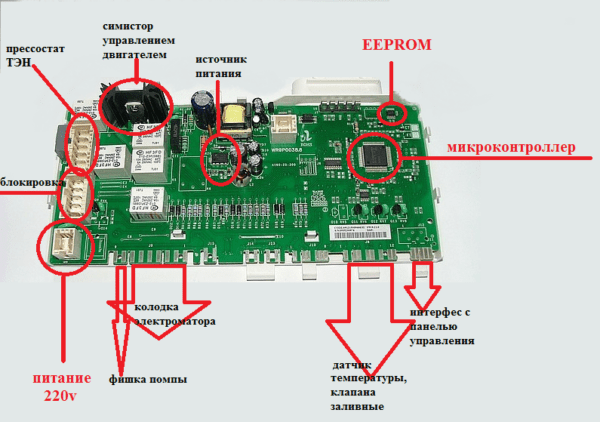

Board repair

It is very difficult to visually determine the cause of the problem, especially if the elements have not been burned out. During operation, the washing machine constantly vibrates, which affects the local electronics.

The soldering of diodes, resistors and other small elements could be broken. For diagnostics and subsequent repair, you will need a multimeter, a soldering iron, tin, rosin, solder and, in fact, the ability to solder. We will analyze a number of components that can be replaced independently.

Control unit CMA Indesit

Capacitors

These elements are responsible for voltage stabilization. The obvious signal of a failed capacitor is swelling. In other cases, the part is called using a multimeter (1 - open / 0 - short circuit). When replacing an element, it must be taken into account that it has polarity.

Resistors

Details must be checked in two stages, taking into account the order. Resistors with a resistance of 8 ohms and up to 2 A are first-order elements. Parts for 10 ohms and up to 5 amperes are the second group. If the values of the resistors do not correspond to these data, then they must be replaced.

Thyristor block

The main reason for the failure of the thyristor block is voltage surges. This element needs to be checked only after diagnostics of capacitors. We set the negative resistance and ring the diodes of the first order. The voltage should not be higher than 20 volts.

The burn-in of elements can be determined both visually and with the help of a multimeter by setting it to ringing mode. The maximum allowable voltage on the filter is no more than 12 volts

Be sure to pay attention to the polarity and try not to damage the ports of the thyristors

Burnt out washing machine control module

Trigger Diagnostics

This element most often fails due to problems with capacitors. Poor soldering and too much vibration can also cause assembly problems. It is enough to solder the output contacts and the problem will be solved. The trigger voltage should be around 12 volts, and the resistance should be about 20 ohms.

Typical breakdowns of household units

To understand the malfunction that has arisen, you need to consider the most common of them and the reasons for their occurrence.

Here is a list of common problems:

- Water is not poured into the tank of the machine - this means that the heating element, or the inlet valve, or the drain pump may be faulty, or the pressure switch may not work;

- The machine does not turn on - the hatch is not closed very tightly, the locking system or the “Start” button does not work, a break in the power cord, poor contact.It can also be more serious problems, such as a breakdown of the heater or engine;

- The drum does not rotate when the motor is running - the drive belt is broken, the bearings or motor brushes are worn out. It is possible that a foreign object has got into the gap between the drum and the tank;

- Water does not drain - this problem means a blockage in the drain hose, either in the filter of the washing machine, or in the sewer system;

- The hatch of the car does not open - a malfunction of the locking system, or the handle is damaged;

- Water leakage - occurs when the seams or parts of the machine are depressurized, as well as the drain hose or pump leaks;

- Self-draining of water - if water is drained before it has had time to accumulate, then this is either a problem with the connection or a malfunction of the control system;

- Problems with spinning - the “Spin off” button does not work, problems with draining or with the electric motor of the washing machine;

- Unusual washing sounds - worn bearings and oil seal. They will have to be changed, and it may also be necessary to replace the drum;

- Large vibration may be caused by a large load of laundry or incorrect installation of the appliance;

- Problems with the control system - the terminals on the buttons are oxidized or the contacts close due to water ingress.

Next will be considered ways to fix them with your own hands, because it is not always possible to call the master. And for this you need to have a set of necessary tools.

A list of the most common problems that occur in the operation of a Samsung washing machine is in the manual attached by the manufacturer to the product. You can often find a solution there as well.

Before starting repairs, you need to make sure that all the tools from this list are available:

- flat and Phillips screwdrivers or a screwdriver;

- set of wrenches;

- pliers, pliers, wire cutters;

- tweezers - elongated and curved;

- powerful flashlight;

- mirror on a long handle;

- soldering iron;

- gas-burner;

- small hammer;

- knife.

In addition to these tools, you may need a magnet to pull out small metal objects that are inside the machine, a long metal ruler to level the drum, a multimeter or a voltage indicator.

A set of the most necessary repair tools will be needed to carry out repair operations available to a home craftsman. Most of the tools can be found in the household, the rest can be borrowed from friends.

But that's not all, in addition to the necessary set of devices, you will need to purchase the following consumables for repairs:

- sealant;

- Super glue;

- insulating resin;

- materials for soldering - rosin, flux, etc .;

- wires;

- clamps;

- current fuses;

- rust remover;

- tape and tape.

Sometimes a multimeter is not needed, it is enough to turn on the machine and select the high water temperature mode. From the operation of an apartment electric meter, it can be easy to understand whether power is supplied to the heating element.

Calling the master: repair price and ordering

If it is impossible to carry out do-it-yourself shock absorber replacement, it is better to call a master from a company that provides repair of washing household appliances. When leaving an application, it is necessary to inform the dispatcher of the automatic machine model, this information is in the passport for the product. If the dampers have already been purchased, then this should also be mentioned.

The cost of the work of a specialist depends on the price list of the company (you can familiarize yourself with it in advance). On average in the capital, the replacement of one shock absorber in washing machine Samsung will cost in the capital from 1,300 rubles (excluding the price of the part).

The duration of the wizard’s work on average is up to 1.5 hours, if along the way there were no problems that also require the attention of a specialist. Upon completion of the work, a test run of the machine is made and a guarantee is issued for the repair.

It is not advisable to call masters on random ads, as there is a risk of falling for scammers. At the same time, high-quality repairs can not be obtained at all. It is better to contact a trustworthy company that has been in the market for the provision of services for several days.

Overview of error codes

In conclusion, we present a short list of error codes most often issued by the unit.

E1 - system error when filling with water. It means that the required water level during filling is not reached within 20 minutes. Eliminated by turning off and then turning on the machine.

E2 - error when draining. Most often occurs when the drain filter is clogged.

E3 - too much water. You do not need to do anything, within 2 minutes the water is automatically drained.

E4 - too many things. Their weight does not correspond to the parameters of the machine. We need to extract the excess.

E5 - water heating does not work.

E6 - heating element malfunction.

E7 - malfunction water level sensor in the tank.

E8 - water heating does not match the selected washing program. Most often due to problems with the heating element.

E9 - water leakage or drain, recorded more than 4 times.

DE, DOOR - bad blocking. Most often - a badly closed hatch door.

Vertical machines

It would seem the simplest version of washing machines, so there is nothing to break. But no! The principle of operation of such brands is no different from the main consumer options. Therefore, similar problems may arise, only access to the repair of the problem area is slightly modified.

For example, repairing a vertical washing machine with a breakdown in the control panel will need to unscrew not one back side of the case, but two sides.

At the same time, unscrewing these parts opens up access to almost all working segments of the device. Whether this is a plus or a minus of this model is up to the consumer to decide. And we continue a detailed acquaintance with other options for the problems of a home assistant.

Water problems

Water is not coming

| Cause | What to do |

| Water supply valves closed | Open the valves, making sure they are closed beforehand. |

| Inlet hose deformed | Look at the hose and if it is flattened, flush the part and bend it if necessary. |

| Inlet filter clogged | After closing the inlet cock, disconnect the inlet hose. Using pliers, remove the filter, then rinse the part under running water. Replace the filter and then the inlet valve, and then connect the inlet hose. |

| Inlet valve damaged | If the filter is unable to trap the dirt, it gets on the valve and causes it to malfunction. In this case, the valve will need to be replaced. After disconnecting the inlet pipes, find the valve and replace it. |

| The switch that closes the inlet valve has broken after the machine has filled the water to the desired level (the tube could be damaged or clogged) | Check the tubing that is on the switch - if it has a hardened end, cut it off and put the tubing back on the switch. Blow into the tube to see if the switch works - you should hear a click. Next, you need to loosen the clamp on the hose, which fixes the pressure chamber on the drum. Inspect the chamber, rinse it thoroughly until the inlet as well as the outlet are completely clean. Check if it is damaged. Verify that the switch is good using a multimeter. In case of breakage, replace the part with a new one. |

| Broken electric motor | Depending on the breakdown, you can repair it or replace it with a new one. |

Related article: Errors and malfunctions of the Siemens washing machine

If water is not poured into the washing machine, watch the video of the "Washing +" channel.

Gaining very slowly

| Cause | What to do |

| Inlet hose kinked | Check the hose and straighten the deformed area. |

| Inlet hose dirty | Flush the hose until the blockage is removed. |

| Water pressure is insufficient | Check if the water supply valve is fully open. Perhaps the cause is low pressure in the line. If such a situation is observed in a private house, the equipment of a pressure tank in the attic can help. |

Doesn't drain

| Cause | What to do |

| Wrong program selected | Make sure that you have not paused the machine, and also have not turned on the delayed wash. |

| Water level switch not working | After checking its operation, install a new switch if necessary. |

| Clogged or kinked exhaust hose | Assess the condition of the hose, then flush it and make sure that there are no foreign objects inside. |

| Clogged exhaust filter | Depending on the degree of clogging, the filter can be washed or replaced. |

| Clogged pump | Putting a rag under the machine, disconnect the clamps from the hoses that are fixed to the pump and make sure that there is no blockage in them. Using a pencil, evaluate the rotation of the impeller - if tight rotation is found, open the pump using suitable tools. Make an audit of the impeller chamber, flush it, and then assemble the pump and install it in place. |

| The pump broke | Replace it with a good part. |

| Electrical problems | After disconnecting the machine from the network, revise the contacts. If necessary, tighten them up and clean them. |

| The timer is broken | Replace this part with a good one. |

If during washing the washing machine stops and does not drain the water, watch the video of the “Wash +” channel.

small leak

| Cause | What to do |

| Hose clamp slightly loose | Carefully inspect the clamp, evaluating whether there are traces of water around it. First, loosen the clamp and move it slightly, then tighten it. |

| There is a crack in the hose | If cracks are found in any hose, it should be replaced with a new one. |

| The door seal has slipped | Replace the door seal with a new part. |

| Tank seal leaking | Completely disassemble the machine and replace the bearing. |

For information on how to replace a bearing in a washing machine, see the video by Vladimir Khatuntsev.

strong leak

| Cause | What to do |

| Exhaust hose slipped out of drain riser | Inspect the outlet hose and replace it. |

| Clogged sewer | Check the condition of the sewer, clean it and make sure that the drain is performed correctly. |

| Exhaust hose disconnected | Check the hose and reinstall it. |

Related article: Paint-enamel PF 115 and its consumption per 1 m2

For information on how to fix a leak in a washing machine, see V. Khatuntsev's video.

If the washing machine constantly drains water and does not collect it, watch the video of Vladimir Khatuntsev.

The device and operation of washing machines

Unfortunately, not all housewives follow an important rule - before loading the machine, carefully check and empty the contents of pockets. As a result, coins, paper clips, buttons and other objects get into the filter compartment. As a result, coins, paper clips, buttons and other objects get into the filter compartment.

As a result, coins, paper clips, buttons and other objects get into the filter compartment.

The filter is traditionally placed under the front panel, on the right side.

On some models, to get to it, you need to remove the entire bottom panel. This is easy to do by prying it with a screwdriver from the side.

But more often, the filter is hidden behind a small hatch, which can also be removed with a screwdriver or a coin.

But even after that, some of it will remain in the system.

Before opening the filter, it is advisable to tilt the machine back a little and put a rag or container under it.

Excess is removed from the compartment, the filter itself must be thoroughly rinsed.

Then we inspect the impeller, which is located deep in the compartment. Sometimes, threads, rags or loose pile from clothes are wound around it. All this must be carefully removed.

The filter is installed in place and you can check the drain. Sometimes this is enough, but what if it doesn't work?

Check if the pump itself is working. To do this, unscrew the fixing screws, remove the back cover.The motor, after the electronics and all relays, is supplied with 220 volts AC.

If the impeller does not spin, the problem is found. Remove the pump for a sample and go to the hardware store for a new one. What if the pump is working, but there is still no drain? Disconnect the hoses and fittings and check if there are any foreign objects in them.

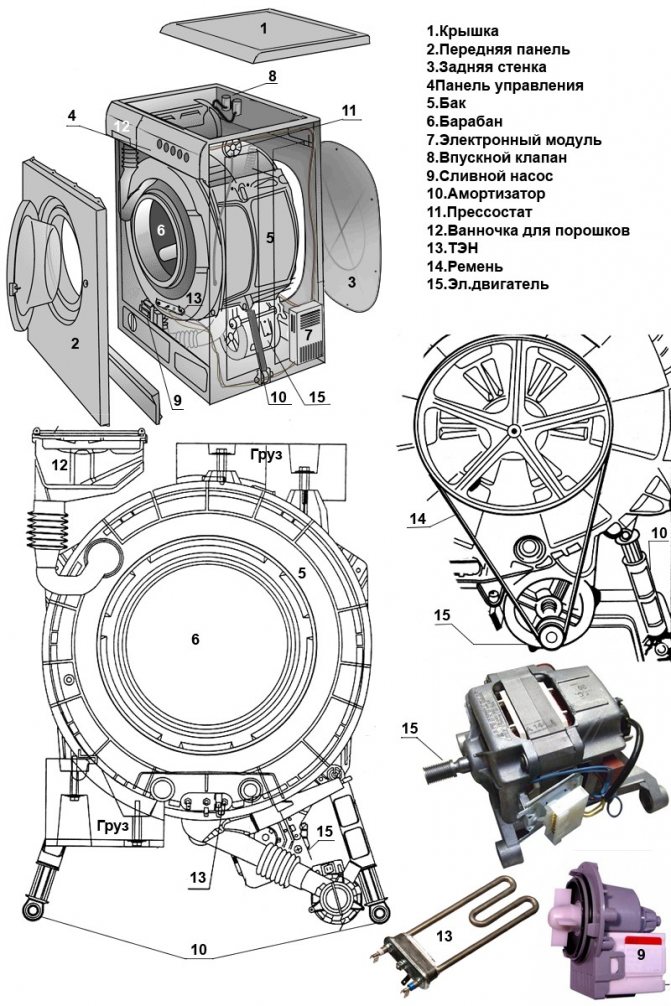

Front-loading and top-loading automatic washing machines have a similar structure. Regardless of the brand (LG, Zanussi, Candy, Ariston), the unit has a metal case, consisting of a top, rear, front wall and, almost always, a base. The internal structure of the machine consists of 20 main elements:

- Control Panel.

- Electronic module.

- Water hose.

- Water tank (fixed).

- Powder dispenser.

- Drum for clothes (rotating).

- Drum rotation sensor.

- Tank springs (spirals).

- Water level sensor.

- Motor (conventional or inverter).

- Drive belt (for a conventional engine).

- Tubular electric heater (TEN).

- Drain pump.

- Collector.

- Drain hose.

- Connections (for example, the connection connecting the detergent drawer to the tank).

- Support legs.

- Hatch door.

- Rubber door seal.

- Latch-lock.

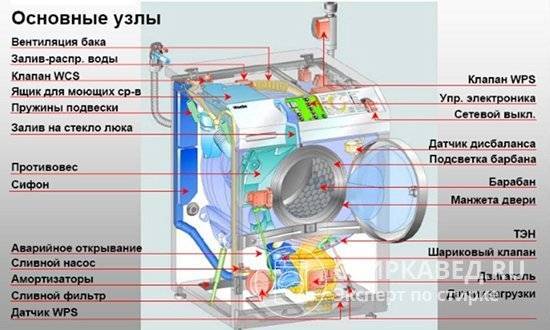

The principle of operation of all washing machines is almost the same. After turning on the unit, the inlet valve opens, through which water passes through the hose to the powder compartment and from there into the tank. The liquid level is controlled by a water level sensor. As soon as the required volume is reached, the control module sends an appropriate signal to the valve and it closes.

Next, the machine heats the water using a heating element, while the temperature is controlled by a timer and a special sensor.Simultaneously with the heating of the water, the engine starts, which rotates the drum in both directions at short intervals in time. After the completion of the main stages of washing, the used water is drained and clean water is taken in for rinsing.

After getting acquainted with the structure and principle of operation of the mechanisms, repairing an automatic washing machine no longer seems an impossible task. Before starting work, do not forget to prepare a minimum set of tools: screwdrivers, keys, pliers, wire cutters and other accessories.

Despite the variety of washing machines, each of them consists of 20 nodes:

- Water valve.

- Inlet valve.

- Program selection knob.

- Inlet hose.

- Buck is stationary.

- Detergent dispenser.

- The drum is rotating.

- Water level regulator.

- Suspension springs.

- Tan.

- Engine.

- Drive belt.

- Pump.

- Collector.

- Drain stand.

- Drain hose.

- Legs.

- Door seal.

- Door.

- Door latch.

- The inlet valve opens and through it water enters the drum of the machine.

- After the water level regulator operates, the valve closes.

- Water heating starts. In machines without a temperature sensor, a timer is activated that turns off the heating element.

- Simultaneously with the heating of water, the engine starts to work. But his work is not at full speed. He begins to scroll the drum in different directions for short periods of time.

- After that, the dirty water is drained and the clean water tank is filled for rinsing.

- At the end of the rinse, the engine turns off and the water is drained.

- The last stage is the spinning of linen at high speeds. At each stage of the wash, the pump remains on.

The principle of operation of the washing machine

All household washing units not only have a similar device, but work on the same principle.

- After turning on the machine, loading the laundry and selecting a program, the door lock mechanism is activated and the machine starts to work.

- Through the inlet valve, water enters the drum of the washing machine, the level of which is regulated by a special sensor.

- After the right amount of liquid has entered the drum, the valve closes.

- Now the water is heated to the desired temperature, the heating element is turned on. Heating is also controlled by a special sensor, and if it is not there, then a timer is triggered.

- Simultaneously with the thermal electric heater, the engine is turned on and the drum begins to slowly turn in different directions with an unequal time interval. This is necessary so that the laundry is evenly wet.

- When the water has heated up to the desired temperature, the heating element turns off and the washing process begins. The drum rotates alternately in different directions with the same time interval. This mode is needed so that the laundry does not stray into a lump.

- At the end of the process, dirty water is pumped out with a pump and new water is collected - for rinsing.

- The drum starts rotating at low speed again, the laundry is rinsed. Depending on the selected mode, the rinsing process may be repeated several times.

- With the end of the last rinse, the pump starts again. It pumps out water, after which the drum starts to rotate again, but already at high speeds.

- This is the pressing process. The pump remains on all the time until the end of the wash.

That's all. As you can see, there is nothing complicated about this.To understand why the washing machine broke down, you first need to know exactly when it happened, that is, to correctly determine the node that is currently working. Since the principle of operation of all units is the same, the main malfunctions of washing machines of any brand are also very similar. In this article we will try to analyze them all, well, maybe, with the exception of some very small ones.

Causes of breakdowns and ways to eliminate them

- the washing machine does not turn on;

- water is not collected;

- water is drawn very slowly;

- water remains cold throughout the wash;

- the washing machine turns off during the wash cycle;

- the drum does not rotate;

- water does not drain;

- the machine is very noisy;

- water flows from the machine;

- the washing machine vibrates very strongly;

- the door does not open.

- Wrong program selected.

- The door is not locked.

- No power supply. (Check the electricity in the apartment, directly the socket, whether the plug is inserted into the socket).

- Check if water is getting into the machine.

- Breakage of electrical wiring in the machine. It is necessary to de-energize the machine, remove the back cover and check the terminals, if they are oxidized, you need to clean them. Check wires for breaks.

- Sometimes the timer can be the cause. To check whether this is so, you need to select different programs, if the washing machine works on one of them, then the timer needs to be replaced.

No water coming in

- Check that there is water in the water supply and that the taps are not closed.

- Check the integrity of the inlet hose and whether it is clogged.

- Check the intake filter for cleanliness. To do this, turn off the water supply, unscrew the inlet hose and unscrew the filter with pliers. Rinse thoroughly under running water and put everything back in place.

- Intake valve blockage. Dirt that has passed through the filter can damage the valve. In this case, you need to find the inlet pipes and replace the valve.

- The water regulator is broken.

When the required amount of water has accumulated, gas is compressed in the compartment with the pressure regulator. The switch is activated, the water supply stops and its heating begins. In fact, this is a tube, if it clogs or breaks, then the machine will not work.

Repair:

- First you need to check how the tube is mounted on the switch. If the end has hardened, then you need to cut it off a little and put it on again.

- To check the switch itself, you should blow into the tube, if a click is heard, then the switch is working.

- There is a hose between the pressure chamber and the tank, you need to check the clamp on it, loosen it a little if necessary.

- Wash the camera and check it for damage.

- The water level regulator is broken. If it is faulty, then the machine does not understand that the water has already accumulated in the right amount and does not turn on the heater. The regulator should be checked and replaced if broken.

- Scale on the heating element. Due to hard water, the heater becomes covered with plaque over time, you need to periodically descale the machine. If this is not done, then you will have to completely unwind the machine and clean the heating element directly.

- Breakage of wires leading to the heater. The wires are checked for breaks and the terminals are cleaned.

- Thermostat failure. If it's faulty. It is possible that the heater is turned off too early.

There can be many reasons: power outage, water supply, blockage in the drain or inlet hose, the pump, thermal relay, heating element, timer, engine broke down.

In this case, you need to check the supply of electricity and water, if this is not the case, then the machine is disconnected from the water supply and electricity. The water is drained manually and all other nodes are checked.

- Drive belt loose or broken. You need to spin the car and check the integrity of the belt. A normally tensioned belt should move 12 mm when pressed. If the machine is equipped with a belt tension regulator, then the engine moves down a little and the bolt is tightened. If there is no such function, then you will have to change the belt.

- If the door latch is broken, the drum will also not rotate.

- Broken engine.

- Check if delayed wash or pause is selected.

- Check drain hose for blockages or kinks.

- Check exhaust filter. If clogged - clean, if broken - replace.

- Check pump. You need to remove it and check for the presence of foreign objects. Before removing it, you need to put a rag for water, release the clamps that attach the hoses to the pump. Check how the impeller rotates, if it is very tight, then loosen it a little. Check if the threads are wound on the rotating shaft. If there are no blockages, then it needs to be replaced.

- Check fluid regulator, timer.

In case of leaks, you need to check the integrity and fastening of the hoses, the door seal.

The reasons:

- Overload.

- Uneven distribution of things.

- The machine is on uneven ground and not level.

- The ballast has loosened.

- Suspension springs broken or weakened.

- Check tank for small items. The most common reason is forgotten coins in pockets.

- Check door latch.

- If a squeal is heard during operation, then the belt is slipping. It needs to be tightened or replaced.

- Crack. Most likely the bearings are broken.

Instructional video