- Operating principle

- Underfloor heating example

- Plumbing example

- Roof heating example

- The nuances of installation work

- Video description

- Briefly about the main

- Connection Features

- Heating cable - principle of operation and application

- Laying and connection

- External laying SNK

- Hidden samreg wiring

- Self-regulating heating cables

- More about outdoor installation

- How to choose a self-regulating heating cable, consider the technical specifications

- Specifications

- Choosing the type of heating cable and calculating the power

- Marking

- How is power calculated?

- Advantages and disadvantages

- Cable types

- resistive

- self-regulating

- Self-regulating cable general description

- Cable selection by power and manufacturer

- Supply voltage, volt

Operating principle

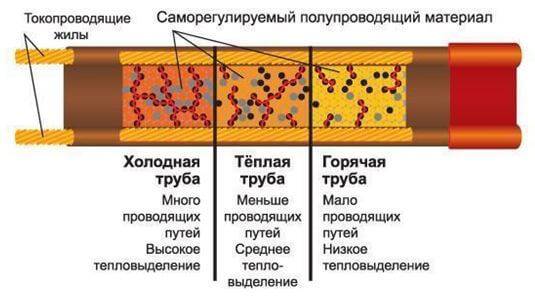

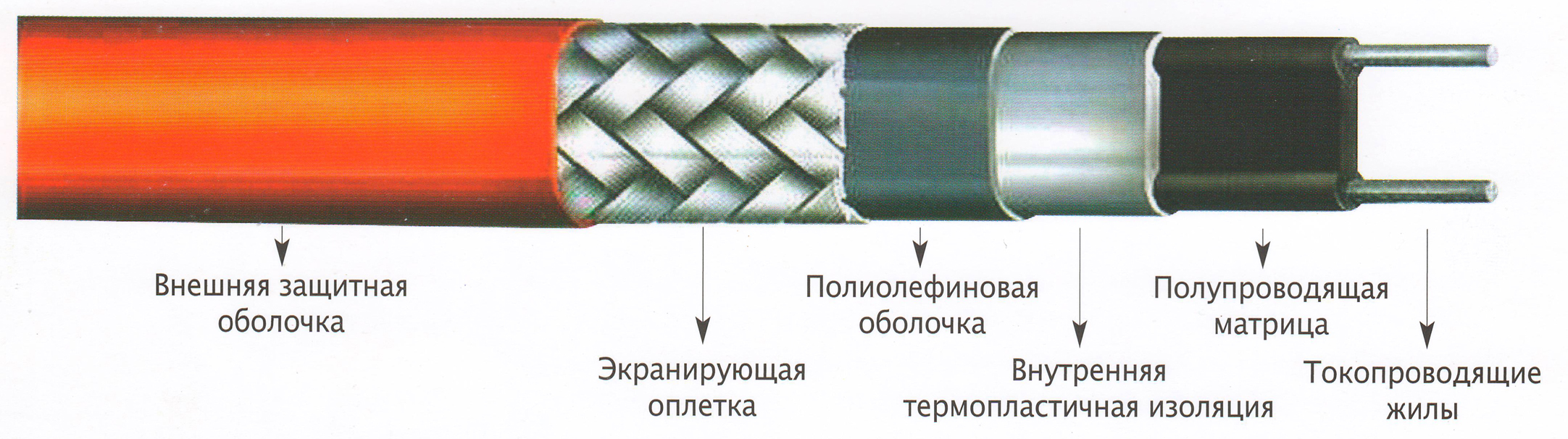

The principle of operation of the device is the use of the property of the matrix of the heating self-regulating cable. Two parallel conductive wires are enclosed in a plate. It is a conductive polymer that changes its electrical resistance in direct proportion to changes in ambient temperature. In some models, the conductors are connected by spiral matrix threads instead of a plate. To understand how self-regulating heating cables work, it is necessary to consider several types of heating.

SNK device

SNK device

Underfloor heating example

The comfortable temperature for heating the floor covering is 36-380C. To select the length and power of the SNK, a special method of thermal calculation is used. As long as the samreg is switched on, a stable comfortable temperature will be set in the room. The only drawback of such warm floors is the inability to adjust the level of heating.

Self-regulating heating cable for underfloor heating

Self-regulating heating cable for underfloor heating

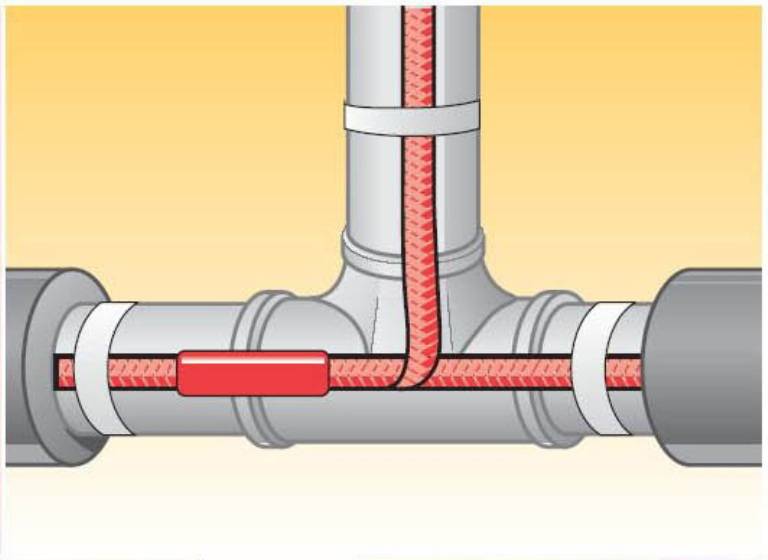

Plumbing example

SNK heats the water pipe at a certain level. When the air temperature begins to drop, the matrix resistance simultaneously drops, which causes an increase in the current flowing in the copper conductors of the samreg. As a result, the degree of heating of the conductors increases. As the temperature rises, the process proceeds in the reverse order.

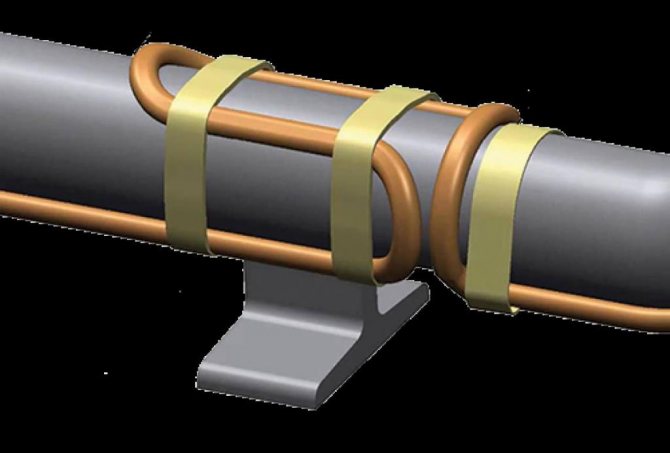

Installation of SNK outside the pipeline

Installation of SNK outside the pipeline

Roof heating example

It is well known what danger accumulated masses of snow on the roofs of houses and hanging icicles pose. Self-regulating heating system roofing is SNK, laid in a special way. The shape of the samreg layout depends on the configuration of the roof.

The level of roof heating is constantly adjusted by a self-regulating cable. This ensures the gradual melting of the snow cover and its runoff in the form of melt water.

Outdoor SNK for gutters and roofing

Outdoor SNK for gutters and roofing

Important! With this method of heating the roof, two goals are achieved. Snow precipitation does not accumulate on the roof and does not create a risk of snow masses falling on people, at the same time, the roof of the house is not subjected to excessive snow load.

The nuances of installation work

When the wire is securely fastened inside or out, it is important to take care to insulate the end of the conductor.Experts recommend using heat shrink tubing

This product will perfectly protect the cores from moisture, which will reduce the risk of short circuits and repair work. We must not forget that it is required to connect the heating part with the "cold" one.

Wire connection

Tips and advice from experienced craftsmen:

- If you use two methods of laying the wire inside and outside the pipe at once, you can increase the rate of water heating by several times, but this will require additional installation costs.

- Heating water pipes with a self-regulating heating cable will allow you to ignore warm sections and direct current to cold places. It is allowed to cut, so there will be no problems in installation even in hard-to-reach places. The length of the cable does not affect heat dissipation.

- Resistive wire is half the price, but its service life is much lower. If a conventional two-core cable was installed, but it is worth preparing for the fact that after 5-6 years it will have to be replaced.

- The braid on the wire serves to ground it. You can skip this stage of work, but it is better to familiarize yourself with the methods of grounding.

Video description

How to make a water pipe grounding is shown in the video:

Most often, a linear cable laying method is chosen for self-assembly.

The level of heat transfer directly depends on which pipes are installed in the room

For plastic pipes, this indicator will not be high, which means that when installing a heating cable for plumbing, it will be necessary to wrap the pipes with aluminum foil.

Before attaching the cable to the outside of the metal pipe, it is important to make sure that there is no rust. If it is, cleaning and treatment with a special antiseptic is required.

If this is neglected, then in the future there is a risk of damage to the insulation.

If fastening is carried out from the outside, then the distance between the insulating bundles should not be more than 30 cm. If you take a wider step, then after a while the fasteners will disperse.

In practice, some craftsmen stretch two wires at once to increase the heating rate. It is important that there is a small distance between the cables.

For fastening to plastic, it is better to use special clamps.

Fastening with clamps and thermal insulation in the section

- If it is decided to twist the wire in a spiral, then initially the pipe is wrapped with metallized tape.

- To fix the insulation, it is better to use special ties. They can be purchased at any hardware store.

- It is necessary to completely isolate the temperature sensor from the electrical cable in order to eliminate the risk of short circuit and fire. This requires not only maintaining the distance between these devices, but also making the insulating gasket a special material.

- Heating pipelines with a heating cable using a thermostat will provide constant temperature support. This device is best mounted next to the electrical panel or directly in it. It will not be superfluous to install an RCD.

wire with thermostat

Briefly about the main

First of all, it is important to choose the right cable for heating pipelines.

There are self-regulating and resistive types of cable that are used for plumbing

When choosing a cable, pay attention to the number of cores, type of section, heat resistance, length, presence of braid and other characteristics.

For plumbing, a two-core or zone wire is usually used.

Of the ways to install the wire, it is better to give preference to the outer one.Fasten the cable inside the pipe only if it is not possible to mount it from the outside. In general, internal and external installation technologies practically do not differ from each other, but the second method minimizes the risk of blockages, and also increases the life of the wiring.

Connection Features

You, like many novice home craftsmen, may be interested in the question of how to connect a self-regulating heating cable. The principle of such work is very simple. The connection is made to the network 220. In this case, conductive wires are used. The second end is insulated to prevent contact between conductive wires. You will also need a braid to ground.

Which connection method you use depends on what tools you have available and how you plan to use the cable. However, the schema remains the same. When connecting, you can use an adhesive sleeve kit and unshielded cables. If the laying is carried out inside the pipe, then the product will differ in the presence of an end cap. The heating cable is powered from the mains. Ground will need to be connected if the cable is shielded

It is important not to forget to seal the end

Heating cable - principle of operation and application

Advantages and disadvantages determine the scope of these types of products:

- Heating of various tanks to avoid hypothermia.

- Underground heating of greenhouses.

- Melting snow and ice that can form on the facades and entrances of various buildings.

- Heating of concrete. Often such cables can serve as fittings.

- Creation of warm floors.A separate broad scope that deserves further consideration.

- Prevention of freezing at pipes.

The principle of operation is described quite simply. When an electric current passes through any conductor, heat is inevitably generated. The amount of this energy is directly proportional to the electrical resistance of the conductor itself.

This rule formed the basis of the work of resistive cables.

In fact, any heating cable is thin metal wires. In their manufacture, materials with maximum resistance are used. At the same time, the veins themselves have a small thickness. The design is built on one core, or on two at once.

The cable cores are surrounded by materials that do not allow electricity to pass through, this is necessary to comply with safety standards. Such a dielectric structure is called insulation. Materials in this case also have resistance to elevated temperatures.

Cables are placed in a metal braid to reduce the negative effect of electromagnetic fields that appear around products. Due to this, mechanical resistance to various damages is also enhanced.

The entire self-heating cable is placed in a single sheath, which ensures integrity and tightness.

Laying and connection

The laying of the heating self-regulating heating cable is carried out in both open and closed ways.

External laying SNK

Insulation of pipelines is carried out by longitudinal installation of a samreg. The laid cable along the pipe is fixed with aluminum tape rings. Aluminum fasteners increase the heat transfer area of the thermal cable.The cable must be fixed at the bottom of the pipeline, because it is there that water begins to freeze.

In some cases, the pipes are wrapped with a cable in the form of a spiral. The wire is wound in increments of 50-70 mm. This is done in places where the risk of freezing is especially high.

Additional Information. To achieve an improved heating effect, the pipe with the cord can be additionally wrapped with mats of mineral wool or other materials.

External laying SNK is used in the installation of heating systems on the roofs of houses and structures. When laying, take into account the complex relief of roofs. For this, there are special methods for designing roofing snow protection. Also, heating cables are pulled under weirs. In winter, melt water does not freeze in them and flows into the funnels of drainpipes.

For any exposed electrical wiring, a sheath made of a material that is resistant to UV radiation is important. External SNCs tolerate fairly low temperatures, but do not withstand repeated bending loads. Therefore, when laying the cable externally, sharp bends in the wiring should be avoided and its secondary use should not be allowed.

Hidden samreg wiring

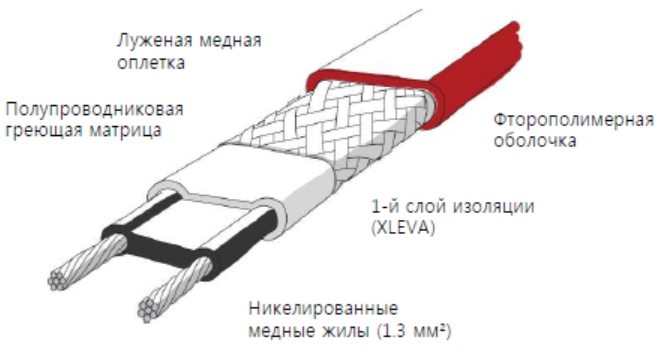

In pipelines of large diameter, samregs are pulled inside them. This applies to both water pipes and sewers. For plumbing use heating wires certified as food cables. This is confirmed by the labeling on the products themselves.

The disadvantages of this method of heating include the fact that during the operation of the system, the cable sometimes becomes overgrown with slag deposits. This causes a decrease in the clearance of pipes, which significantly affects the performance of water supply.

Installation of SNK inside pipes is carried out through tees and valves. Replacing the cable is not difficult. The old wire is pulled out and replaced with a new thermal cord.

Concealed installation of SNK for underfloor heating is carried out in the same way as the installation of a standard heating cable. For this, the base of the floor is specially prepared and SNK is laid on it. Then the heating system is closed with a cement screed or special tile material. After that, the floor covering is installed. It can be ceramic tiles or laminate parquet, linoleum, etc.

For hidden laying of a self-regulating heating cable in the walls, strobes are cut out with a perforator. Channels make a snake vertically or horizontally. After laying the SNK, it is covered with plaster or other facing material. If drywall is installed, then the cable is laid between the cladding and the main wall.

Self-regulating heating cables

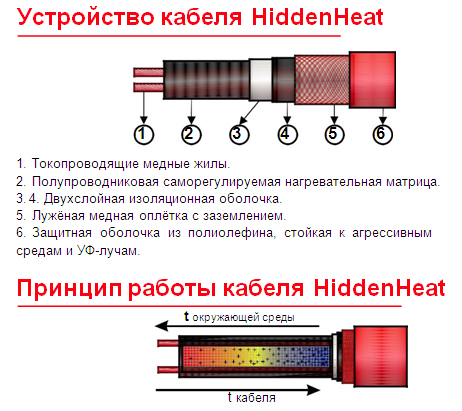

DEVI self-regulating heating cables are used to protect pipelines from freezing, to maintain the temperature of hot water, as well as to melt ice and snow in gutters and drains. The principle of operation of a self-regulating cable

Between two parallel copper conductors of the cable along its entire length there is a temperature-dependent resistance element - a polymer with coal dust. When the conductors are connected to a voltage of 220 V, the current passes through this resistance element and heats it up.

When the polymer is heated, it expands, the distance between the coal dust increases and, accordingly, the resistance increases. This results in less current and less heat/power. This explains the self-regulation effect.

Power control occurs independently along the entire length of the cable in accordance with the ambient temperature of each section of the cable. As the ambient temperature rises, the power output of the cable decreases.

This self-regulating capability prevents overheating of individual sections of the cable, as well as when it is crossed or comes into contact with another cable. By supplying voltage in parallel to the entire heating cable, it can be shortened at any point. This makes it easier to design and install on site.

It is necessary to observe the maximum permissible power for the various temperatures possible when the cable is switched on. Cable bend diameter must be at least 50 mm

The cable can only be bent on the flat side.

To reduce power consumption, we strongly recommend that if the cable length is more than 3 m, turn it on using Devireg thermostats.

ATTENTION!

There are several different types of self-regulating cables. one

Devi-iceguard is used for snow melting systems on roofs and in gutters 2. Devi-pipeguard is used for all types of cold pipes to protect against freezing and solidification of viscous liquids in pipelines.

More about outdoor installation

Heating of water pipes with a heating self-regulating cable with internal installation is not recommended if you plan to use more than one cable. If the pipe has a small diameter, within 50 mm, then one wire will be enough. If we are talking about a large pipe, then usually 2 to 4 pieces are used, which are located in areas with low temperatures.

Installation of a self-regulating heating cable is also carried out for pipes placed in the ground.Here you can use the golden mean: in this case, two cables should run in parallel, along opposite sides. If mounting on aluminum tape, which increases heat transfer and protects the cable, is not enough, you can use a more durable mount - on ties. If, during operation, direct sunlight falls on certain sections of the pipe, black ties, which are resistant to ultraviolet radiation, should be used.

How to choose a self-regulating heating cable, consider the technical specifications

When choosing, first of all, they are determined with its appearance. Resistive devices are prone to burnout, in addition, they are produced in measured lengths, and do not allow shortening / lengthening. Their power is constant regardless of the need for heat at the moment. Usually they are used to heat small diameter pipes, water tanks or drains.

Self-regulating conductors are more common. They painlessly endure power surges in the network, do not burn out and make it possible to save electricity. When using them, the length is not limited. Of course, this option is more acceptable, despite the higher price.

When choosing, you need to pay attention to the design of the product. In an effort to reduce the price, manufacturers sometimes do not install a braided shield. This is the so-called budget option.

This is the so-called budget option.

And the purpose of this structural element is to strengthen the product and the grounding device, which is important

You should also pay attention to the outer braid of the self-regulating cable. For domestic use, a polyolefin sheath (downspouts or roofing) is sufficient.When installing a heating cable on gravity sewer systems, it is better to use devices with a sheath made of fluoroplastic, resistant to aggressive environments

When installing a heating cable on gravity sewer systems, it is better to use devices with a sheath made of fluoroplastic, resistant to aggressive environments.

Not all products are suitable for indoor and outdoor use. The appointment should be clarified with the sales assistant or checked according to the quality certificate.

When choosing a self-regulating cable, the temperature class must also be taken into account. Low-temperature ones heat up to a temperature of 65 degrees, consuming power up to 15 W / meter. They are used to protect against freezing water pipes of small diameter.

Medium temperature - heat up to 120 degrees, using power in the range of 10-33 W / m. They can warm up pipes of medium diameter and drainpipes.

The choice is determined by the size of the heated pipes. As a first approximation, the following parameters can be recommended:

- for pipes 25 - 40 mm - 16 W / m;

- 40 - 60 mm - 24 W / m;

- 60 - 80 mm - 30 W / m;

- More than 80 mm - 40 W / m.

Specifications

Choosing the type of heating cable and calculating the power

In accordance with various consumer properties, there are three main types of temperature-controlled wire in terms of power and purpose of heat consumption.

- Cable with a maximum temperature of up to 70 degrees

- up to 105 degrees

- up to 135 degrees

The increase in power and temperature height is achieved through the use of copper cores of various diameters.

Marking

- D - used for marking the low-temperature version

- Z - medium temperature

- Q - option with maximum temperature (usually additionally marked with red insulation)

- F - anti-corrosion treatment

Refractory polyethylenes and fluoroethylene are used for the insulating coating.

About working with copper wire. Copper is an ideal conductive material, copper wire is ductile and flexible.

Therefore, when working with a cable with a copper core, it is important to prevent kinks and the possibility of physical abrasion.

How is power calculated?

According to the rated power, voltage class and heat transfer class. That is, you can see the table of power and energy consumption for each type of cable.

Sectional view of self-regulating cable devices

Heat dissipation linear type for self-regulating wire from 6 to 100 watts per meter.

If you count offhand, according to average parameters in practical use, heating 1 meter of wire will cost about 30 watts. It is highly desirable to connect through a separate transformer.

Advantages and disadvantages

- Does not require complex calculations during installation. This allows you to significantly save on the project.

- Does not require temperature adjustment. It performs its functions without human intervention.

- In different areas, the temperature increases only when necessary. As a result, electricity consumption is significantly reduced.

- Resistant to temperature changes and chemical influences.

- Never burns out. Absolutely fireproof.

The only downside is its cost.

The cost of self-regulating is much higher than the cost of resistive. But this impression is deceptive.The huge service life and economical power consumption allows you to recoup all initial costs.

Cable types

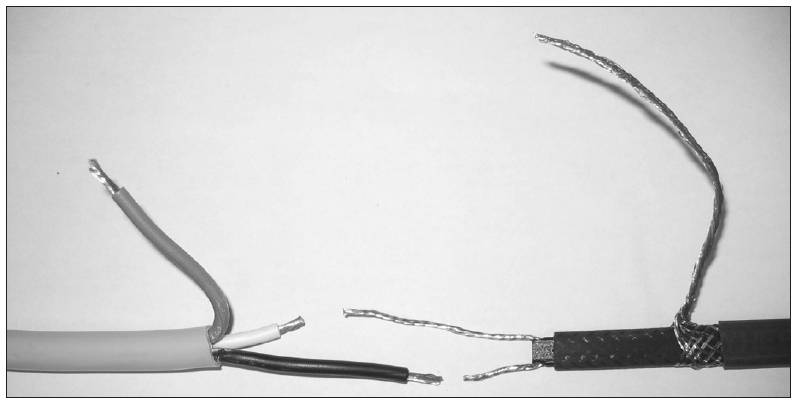

Before installation, it is important to study what heating wires are and how to install them. There are two types of cables: resistive and self-regulating

There are two types of cables: resistive and self-regulating.

The difference between them is that when an electric current passes through the cable, the resistive one heats up evenly along the entire length, and the feature of the self-regulating one is the change in electrical resistance depending on temperature. This means that the higher the temperature of the self-regulating cable section, the lower the current strength will be on it. That is, different parts of such a cable can each be heated to the desired temperature.

In addition, many cables are produced immediately with a temperature sensor and auto control, which significantly saves energy during operation.

Self-regulating cable is more difficult to manufacture and more expensive. Therefore, if there are no special operating conditions, then more often they purchase a resistive heating cable.

resistive

A resistive-type heating cable for a water supply system has a budget cost.

Cable differences

It is divided into several varieties, depending on the design features. Each of them has its own advantages and disadvantages:

| cable type | pros | Minuses |

| single core | The design is simple. It has a heating metal core, a copper shielding braid and internal insulation. From the outside there is protection in the form of an insulator. Maximum heat up to +65°С. | It is inconvenient for heating pipelines: both opposite ends, which are far from each other, must be connected to the current source. |

| Two-core | It has two cores, each of which is isolated separately. An additional third core is bare, but all three are covered by a foil shield. External insulation has a heat-resistant effect. Maximum heat up to +65°C. | Despite the more modern design, it is not much different from a single-core element. The operating and heating characteristics are identical. |

| Zonal | There are independent heating sections. Two cores are isolated separately, and a heating coil is located on top. The connection is made by means of contact windows with current-carrying conductors. This allows you to create heat in parallel. | No cons were found, if you do not take into account the price tag of the product. |

Resistive wires of various types

Most buyers prefer to lay the wire "the old fashioned way" and purchase a wire with one or two cores.

Due to the fact that a cable with only two cores can be used for heating pipes, a single-core version of the resistive wire is not used. If the owner of the house unknowingly installed it, this threatens to close the contacts. The fact is that one core must be looped, which is problematic when working with a heating cable.

If you install the heating cable on the pipe yourself, then experts advise choosing a zonal option for outdoor installation. Despite the peculiarity of the design, its installation will not cause serious difficulties.

Wire design

Another important nuance in single-core and twin-core structures: already cut and insulated products can be found on sale, which eliminates the possibility of adjusting the cable to the optimal length. If the insulation layer is broken, then the wire will be useless, and if damage occurs after installation, it will be necessary to replace the system throughout the area. This disadvantage applies to all types of resistive products. Installation work of such wires is not convenient. It is also not possible to use them for laying inside the pipeline - the tip of the temperature sensor interferes.

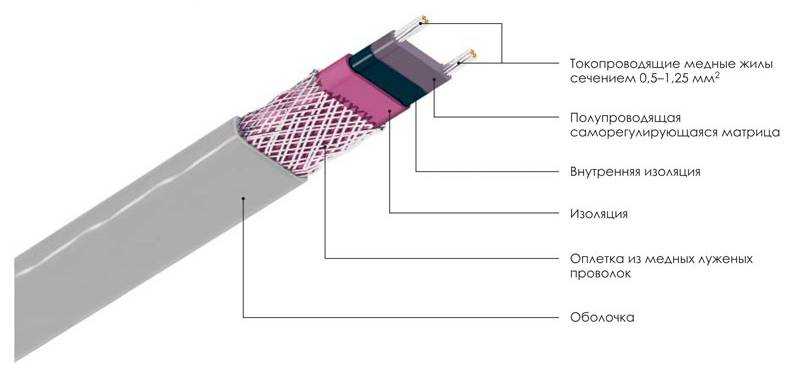

self-regulating

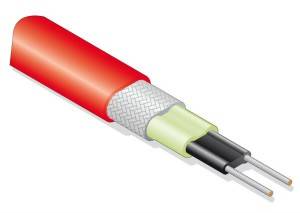

Self-regulating heating cable for water supply with self-adjustment has a more modern design, which affects the duration of operation and ease of installation.

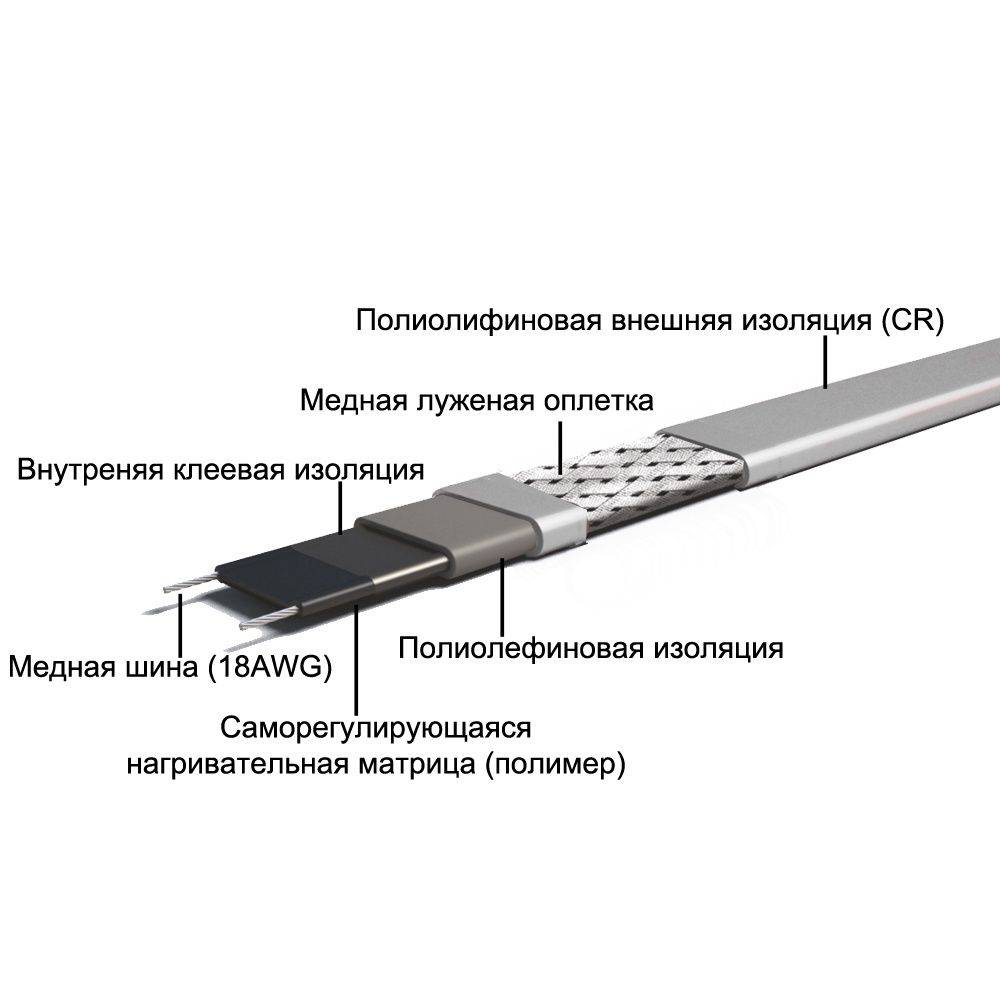

The design provides:

- 2 copper conductors in a thermoplastic matrix;

- 2 layers of internal insulating material;

- copper braid;

- external insulating element.

It is important that this wire works fine without a thermostat. Self-regulating cables have a polymer matrix

When turned on, carbon is activated, and during an increase in temperature, the distance between its graphite components increases.

Self-regulating cable

Self-regulating cable general description

It is easy to get heat from electrical energy - it is released even in ordinary wires, not to mention special ones. Incandescent lamps and electric stoves are familiar to everyone. This principle is also used by floor heating systems with constant resistance cables. Uniform heat transfer along the entire length of the cable is extremely important for them, otherwise it will fail.

This parameter can only be provided indoors, and even then with difficulty. As for roof heating systems, gutters and pipes, their snow cover or icing are completely random, no automatic system is able to keep track of them. And how to control the electric power in each section?

The solution to the problem is to use a self-regulating heating cable. Its resistance varies with the ambient temperature. The lower it is, the higher the current flowing in this area, and, accordingly, the higher the heat transfer. The process proceeds without the participation of any additional control devices.

This adjustment of the heat output is made possible by the carbon-based polymer matrix, which is the first sheath of the self-regulating cable. It contains two stranded copper conductors. Between them is a flat area through which current flows. At the same temperature, the resistance is the same along the entire length of the cable, and the same amount of heat is released at any point. Cooling of any section will cause a drop in resistance on it, the current increases, the temperature of the cable rises, but there is no short circuit: the change in resistance has its limits, due to the manufacturing technology of the conductive matrix. There is no overheating or melting of the cable - all its sheaths are designed for maximum heating, which usually does not exceed 85 degrees.

The conductors and polymer matrix in a self-regulating cable are enclosed in several sheaths:

- Thermoplastic shell that protects the matrix from moisture, abrasion and evens out thermal transitions between areas.

- Metal braid providing shielding and grounding.

- Outer sheath to prevent mechanical damage.

Advantages of self-regulating cables

Supporters of resistive heating cables use the same very strong argument to prove their point - self-regulating cable is significantly more expensive. This is true, but not all. There are also attractive sides in the use of a self-regulating cable:

- the possibility of complete or partial rejection of the automatic thermal control system,

- efficiency - the roof heating system on a self-regulating cable consumes, on average, half the power than any other,

- ease of installation,

- operational safety,

- versatility.

There are several other properties that distinguish self-regulating cables from resistive ones. They can be cut anywhere into pieces of arbitrary length. Do not do this with a resistive cable. Self-regulating cable allows overlaps, which often happens when heating shutoff valves in pipelines. A resistive cable with this installation will quickly fail.

The self-regulating cable is the best choice for heating systems pipelines of gases and liquids at low ambient temperatures, in anti-icing systems, to prevent freezing of fire mains and hydrants, sewer pipes. The increased capital investment is more than offset by operational benefits.Heating systems on self-regulating cables have proven their reliability and efficiency both in domestic conditions and in production, including in cold regions.

Cable selection by power and manufacturer

The internal self-heating cable for heating the water supply is divided according to the type of use according to the power indicators.

At the time of purchasing a heating cable for water supply, you need to ask the seller to provide information on cable consumption per 1 meter of pipeline (provided by the manufacturer for each power).

For use in a short household line, it is better to install a low-power heating kit. For example, for a country house and a cottage, a power of 5 to 25 W / m is used for heating. But then again, everything is individual here.

On an important main line for heating, a cable system with high power is installed. Before installing such a system, you should know that the power in the heating wire is selected in accordance with the diameter and length of the main line

But, the consumption of electricity for heating in this case will be noticeable.

Watch the video

The products of Raychem (Germany) are the most popular among specialists. This trade line is represented by a variety of models that are used not only in industrial enterprises, but also in domestic pipelines.

Any cable kit offered by this manufacturer has a higher price than similar options from other manufacturers. But this is fully compensated by the quality of the products.

Also, professional craftsmen in the line of high quality products include the Russian company Ulmart, which quickly gained popularity among consumers.

Particularly noteworthy is the Underlux pipe heating kit made in Germany. This kit, which is designed for laying inside the network, is most often used in everyday life.

This system has received an expert opinion on hygienic safety, which is evidence that it is allowed to be installed in a network supplying drinking water. The heating temperature of the "Underlux" set is constantly monitored throughout its length.

It is not difficult to install Underlux products. This is done using fittings made by casting. The main advantage of this self-regulating device is the ability to independently change the operating parameters, depending on the ambient temperature.

This advantage ensures long and reliable operation. The kits provided by this manufacturer are distinguished by high work efficiency and the ability to save electricity. They can be placed in the plumbing and drain system, in drains, etc.

The review of various manufacturers can be continued for a long time. The main thing to do when choosing is to carefully study the pros and cons of the proposed options. Also, each model comes with instructions from the manufacturers. It also needs to be carefully studied before work.

Watch the video - warming the water supply from the trench to the house

You can buy a good and high-quality product from many manufacturers, but it is better to contact a trusted company.If there are difficulties in determining the amount of wire to be purchased, then consultants will help to make such a calculation.

They will also help you choose the right product at a reasonable price. By the way, it must be added that the Leroy Merlin construction hypermarket is considered the best place to buy an electric wire for pipes. There is always a large selection of goods of high quality and reasonable cost.

Supply voltage, volt

Some manufacturers simply indicate the supply voltage range, for example: 220 - 275 Volts, without additional comments and a table of coefficients for recalculating the output power depending on the supply voltage. The fact is that the rated power indicated in the documentation and brochures of manufacturers is normalized at a supply voltage of not 220, but 230 or 240 Volts. This voltage must be checked with the manufacturer.

Moment one. Supply voltage deviations must be taken into account to evaluate the power dissipated by a self-regulating cable. Manufacturers offer special tables with coefficients for recalculating the released power depending on the deviation of the supply voltage from 230/240 Volts.

Second moment. For each brand of self-regulating cable, there are restrictions on the magnitude of the supply voltage. For example, for cables designed for a voltage of 230 volts, a supply voltage exceeding 275 volts is unacceptable. An increase in the supply voltage (for example, due to installation errors, sometimes a voltage of 380 volts is applied to the heating section) causes increased heat generation in the matrix and its rapid degradation and complete cessation of heating, i.e. cable failure.