- Step #1: Preparing the Sand

- Do-it-yourself chlorination of water in the pool

- What are pool filters?

- The main types of "pool" filters

- Unit #1 - sand filter

- Unit #2 - diatomaceous earth plant

- Unit #3 - cartridge filter system

- Filter cleaning

- Page 2

- Step 3: Mounting the filter

- Nuances of operation

- Filler replacement

- Step by step manufacturing instructions

- Step 1. We select the body

- Step 2. We mount fittings and internal elements

- Step 3. Prepare the sand filler

- Step 4. Install devices that ensure correct operation

- Step 5. We tie and connect the filter system to the pool

- Ratings of the best models

- Crystal Clear Intex 26644

- Bestway 58495

- Aquaviva FSF350

- Hayward Powerline Top

- Sand replacement

Step #1: Preparing the Sand

The effectiveness of the future filter will directly depend on the quality of the sand used, so the first important step is to choose the right filler. Quartz sand is considered the best option in terms of the ratio of durability and availability. Its angular grains with a polished surface are not prone to sticking, therefore guaranteeing thorough filtration. The working diameter of quartz grains is 0.5-1.5 mm. Before use, the quartz filler must go through several stages of processing:

- Screening.It is necessary to remove grains that do not fit in size from the total mass of sand. This applies mainly to small filters - it is not recommended to use a filler with a diameter of more than 1 mm in them.

- Cleaning. It is necessary to rinse the filler several times with warm water until the liquid with sand is clear.

- Elimination of bacterial contamination. Boil the sand for an hour to kill all bacteria. You can also use special chemicals, but in this case, after completing the processing, the filler will have to be washed several more times.

Do-it-yourself chlorination of water in the pool

Which product with chlorine in the composition to choose, and in what quantity to use it, depends on the degree of water pollution. It also affects the temperature of water and air. In a smaller volume, chlorine dissolves in water at 40 ° C, that is, in this case only 4.6 g of the substance is required. More powder containing chlorine (6.5 g) must be diluted in an aquatic environment with a temperature of 25°C. So, in order to chlorinate a liter of water, the physical value of which is 0 ° C, you need 14.8 g of a disinfectant.

Before chlorination, the water in the pool must be prepared. Chlorine should be dissolved in the aquatic environment only if the pH level fluctuates between 7.0–7.5. The pH determines how the chlorine molecules will perform the task. If the pH is more than 7.6, then more chlorine will have to be used, as it is converted into a volatile substance and evaporates. As a result, an unpleasant odor can come from the pool.

Chlorine-containing substance for purifying water in the pool is available in the form of tablets

Generally, when shocking pool water, a lot of instant agent is used. It is better to start chlorination before the bathing season. A re-disinfection of water in the pool is advised to be carried out after 30 days. Shock treatment will eliminate all micro-organisms that cannot be eliminated by dissolving a small amount of bleach and stop the growth of algae.

After disinfecting the water with chlorine, you should clean the filter and check the indicators of the aquatic environment using a tester. Water is considered clean and harmless if the pH is between 7 and 7.5 and the amount of chlorine is 0.3 mg/g - 0.5 mg/g. These values are recommended to be checked periodically and changed if necessary.

There is nothing impossible in self-creation of the filter. It is only necessary to prepare the necessary materials and tools. Having started the manufacture of a mechanism for cleaning the pool, you need to clearly follow all the recommendations.

What are pool filters?

Today, there are many different devices that are ready to diligently take care of the cleanliness of your pool.

- Chemical: the cartridges of such filters contain an active substance that has disinfecting properties. It mercilessly cracks down on bacteria and microbes that wished to keep you company without an invitation. Devices of this type are impressive in size, but this is not their main drawback. The fact is that the swimmer himself is to some extent affected by the filter filler, which, alas, does not add health. Therefore, splashing in the pool for a long time will not work, in addition, after swimming, you will definitely need to take a shower.

- Mechanical: water is pumped through a layer of a substance that plays the role of a very fine sieve. The filter does not have a bactericidal effect on microorganisms, but the largest of them still linger. At the same time, the cost of mechanical filters, as well as their dimensions, is much less than that of chemical ones. Unfortunately, the performance of these devices is just as low, so it is advisable to use them for cleaning only small pools.

With regard to chemical filters, the principle “the more expensive the better” is especially pronounced. Those who had to use both cheap and expensive devices noted a significant difference in the degree of effect on the skin. So the conclusion is obvious: when buying a filter of this type, attempts to save money will be very inappropriate.

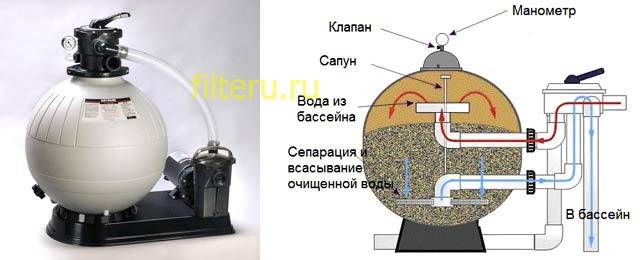

Sand filter after installation

By type of filler mechanical filters are divided into the following types:

The disadvantages of diatomaceous filters are the high cost and the need to involve a specialist to replace the filler, which is due to its high toxicity.

The main types of "pool" filters

Three types of filter units can be used to purify water in the pool:

- sandy;

- diatoms;

- cartridge.

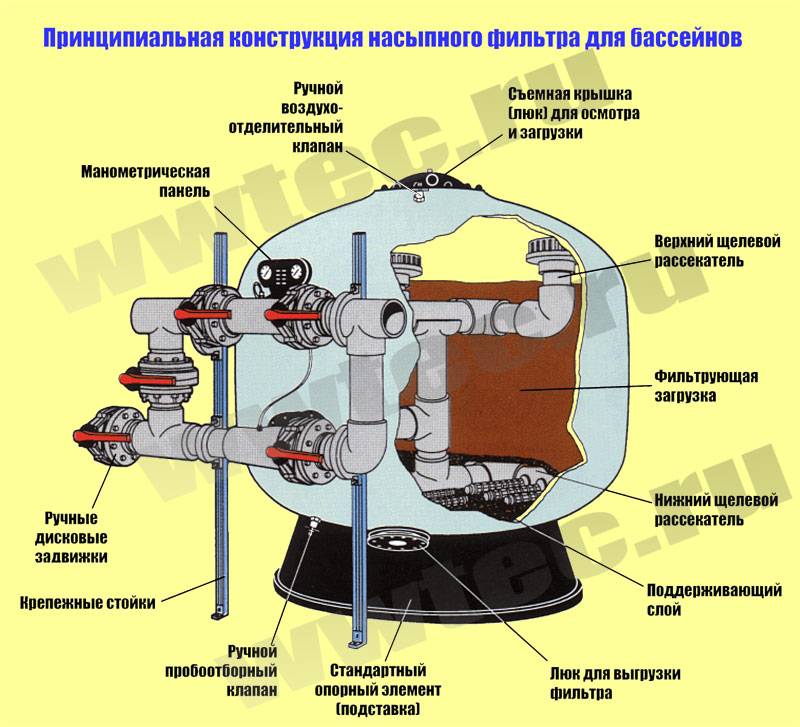

Unit #1 - sand filter

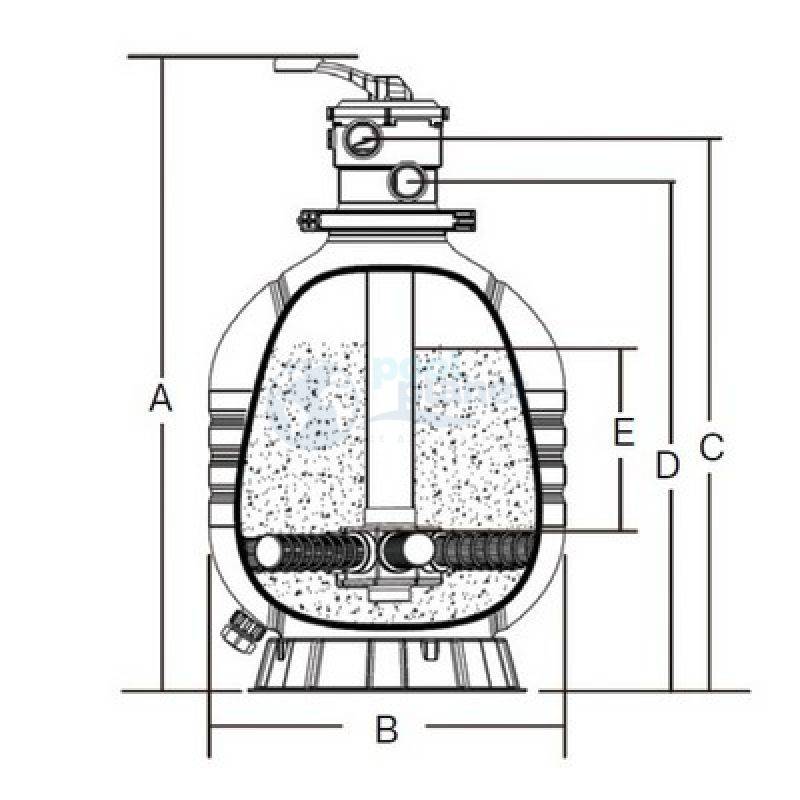

Sand filter systems are the cheapest and easiest way to keep your small private pool clean and tidy. The sand filter consists of a reservoir, a pressure gauge and a six-position valve. The filter medium is quartz sand of several fractions, which is capable of retaining particles with a diameter of about 20 microns. This is enough to keep the water relatively clean.

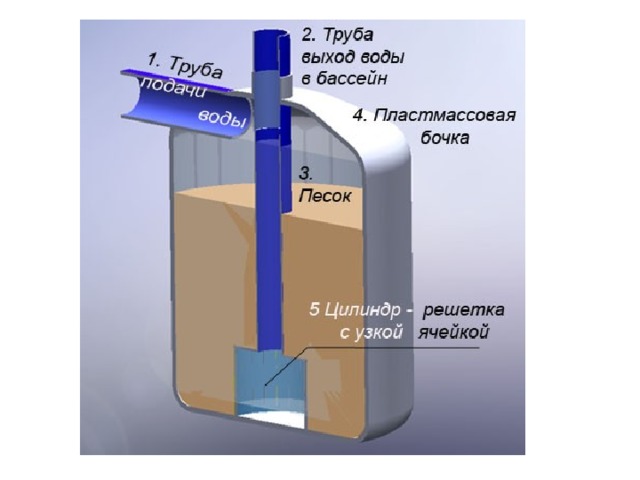

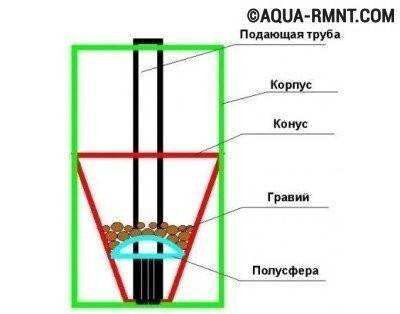

The hemisphere in the diagram is a coarse water filter.It is needed so that sand does not get into the pool from a barrel of water. Its role can be played by a container wrapped with nylon fabric

Through a skimmer or overflow tank, water enters the filter unit through a pipe. Under pressure, it passes through quartz sand, which traps various dirt particles, after which it returns to the pool through the nozzles. The filter mass can consist only of sand, of several layers of "sand-gravel" or "sand-gravel-carbon-anthracite". The last two fillers purify water much better. If glass sand is used instead of quartz sand, then a complete replacement of the filter material will be needed not after three years, but after five to six years.

Naturally, after some time the filter becomes clogged, and the pressure gauge shows an excess of working pressure. The filter is cleaned by backwashing about once every seven to ten days, after which the unit can continue normal operation. If the site has its own source of water, then such frequent cleaning does not affect the budget. But if we are talking about a pool in the city, then the meter will wind up a few additional cubic meters per month.

The construction of a sand filter for a pool is so simple that many craftsmen prefer to assemble them themselves, adjusting them according to their own needs.

Unit #2 - diatomaceous earth plant

A filter based on diatomaceous earth is considered the most reliable and most expensive. It allows you to remove suspended particles with a diameter of up to 1 micron from water.This soil contains silicon dioxide, which gives some healing properties to the water, which is usually called silicon.

The diatom filter is the most expensive of all three, but it is he who allows not only to purify the water, but also gives it some healing properties. So you can both temper and heal

Diatomaceous earth itself is a sedimentary rock formed by the fossilization of diatom shells. It is yellow-brown or grey. If necessary, the filter layer is cleaned by backwashing. If a complete replacement of diatomaceous earth is required, remember that it belongs to the Hazardous Waste category and requires special disposal.

Unit #3 - cartridge filter system

The third type of filtration systems for swimming pools are cartridge filters. The cleaning element - cartridge - consists of several layers of special paper and polyester, on which particles up to 5-10 microns in size settle.

It is recommended to periodically clean the cartridge with special septic tanks that will kill all pathogenic bacteria. To simply remove dirt deposits from the filter element, you can rinse it under running water.

Depending on the brand and model, there are from one to four cylindrical cartridges in the container. If they are clogged, manufacturers recommend replacing them. However, customer experience shows that it is possible to extend the life of the cartridge for some time if it is washed with water from a hose under low pressure or with a cleaning solution of a suitable brand.

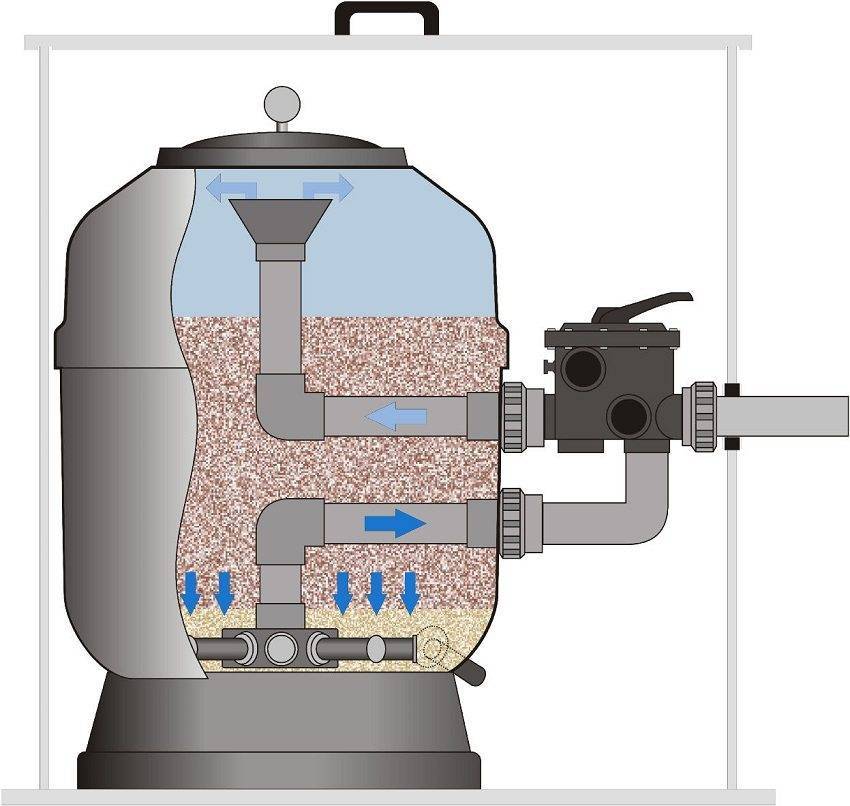

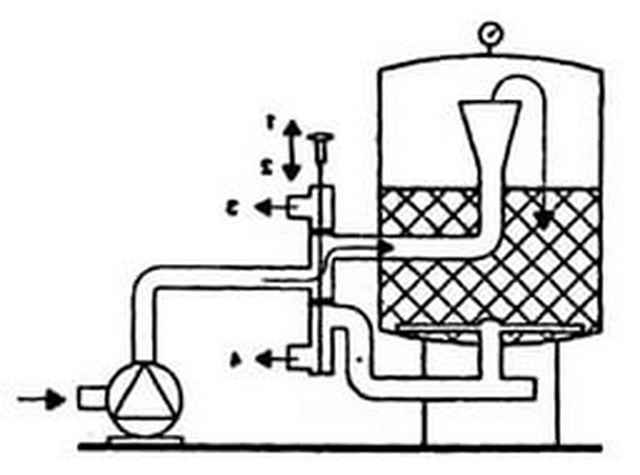

Filter cleaning

For cleaning, the pump must be switched off and flushed.To do this, the hoses are connected a little differently: The pipeline to the pump is connected from below, and the drain is connected from above.

This arrangement is called "reverse flow" where the water flows through the filter in the opposite direction and can wash the dirt off the sand until it is completely clean. After sanding, the filtration mode must be well compacted and then switched on again.

The quartz sand in the filter must be replaced regularly. It is necessary for this purpose:

- to turn off the pump;

- When the filter is installed in the pool, drain the water;

- Disconnect the filter from the system;

- to remove old contaminated sand;

- to clean the nozzles;

- to fall asleep in new sand under water pressure;

- to close the lid;

- Connect the filter to the system.

As you can see, building a sand filter with your own hands is not that difficult, since you have the necessary tools, materials, and installation instructions at hand. The most important thing is not to forget to clean it regularly and change the sand in time.

Watch the video tutorial on how to make a sand filter with your own hands:

Page 2

During the construction of the pool, special attention is paid to the water with which it is filled. I often use tap water for this purpose.

The downside is that this water is not of the highest quality.

It contains many trace elements and other additives. Therefore, it is necessary to seriously look at the equipment of the cleaning system. For this purpose filters for country pools are often used. With their help, you can purify water from various additives and significantly improve its quality.

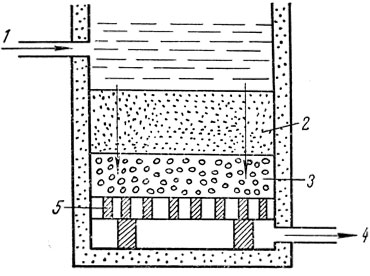

The principle of operation is based on the fact that dirty water flows through a tank with a filter element.

The cleaning process removes microorganisms, particles and other contaminants.

After filling the pool with water, you can use it several times with a filter.

This allows the water to go through multiple cleaning cycles. This reduces tank maintenance costs as water changes are made less frequently than usual.

Each of these materials has its own advantages and disadvantages. To choose the right one, you must carefully consider each type of pool filter. So they happen:

- Sandy. .

Many experts consider such installations ineffective. However, this is offset by the low cost of the filter. The pool sand filter is a barrier tank filled with sand.

During cleaning, all foreign cleaning agents are removed from the water and settle at the bottom of the tank. The disadvantage of this system is its inefficiency.

This is due to the fact that not all foreign bodies are removed from the water during cleaning. This significantly reduces the quality of the outlet water.

The main disadvantage is the costly maintenance of the systems. For example, the sand in the filter must be regularly cleaned of dirt. Rinsing is carried out by water flow in the opposite direction. This requires a lot of water.

diatoms.

A Silica mixture is used as a filter element. It is composed of fossil planktonic particles.

The filter consists of several diatom-coated cartridges. The installation is very expensive due to its efficiency.

Thus, even 3 micron particles can be removed from the water.The maintenance of such filters must be carried out by a specialist. This is because this mixture is hazardous waste and you need to know how to properly dispose of it.

Cartridge.

Such investments are considered golden averages. For reasons of cost, they are intermediate between sand and diatom filters. They are very easy to operate and highly efficient.

With their help, you can clean the pool from particles of 5 microns or more. To clean the cartridges, they must be removed from the housing and rinsed under running water.

As you can see, the mounted filters are easy to maintain. Of course, they should be cleaned regularly with special cleaning agents.

Each of the devices listed above has its own advantages and disadvantages. This information should be used when looking for a suitable option.

When choosing a filter, it is necessary to pay attention not only to its maintenance and operation, but also to its technical properties. This applies, in particular, to the capacity of the installation, which determines the efficiency of its use.

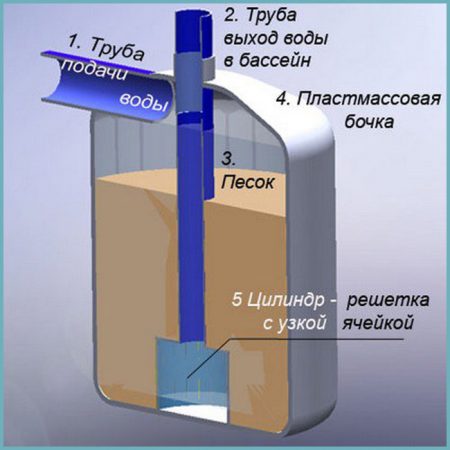

Step 3: Mounting the filter

Before installing the filter device, it must be filled with sand. Backfilling is carried out with a parallel water supply. Either activated carbon or graphite can be added to clean sand - this will significantly improve the quality of water after cleaning. But don't use two components at once.

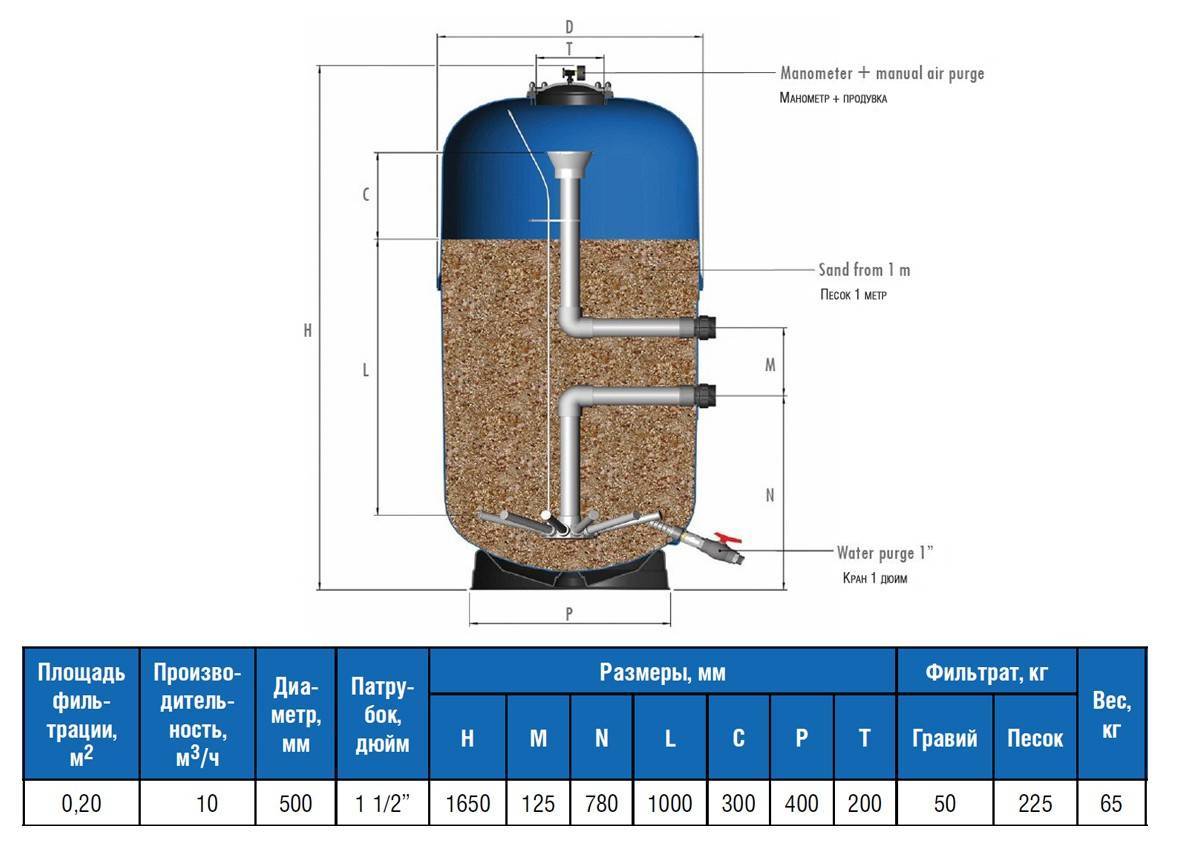

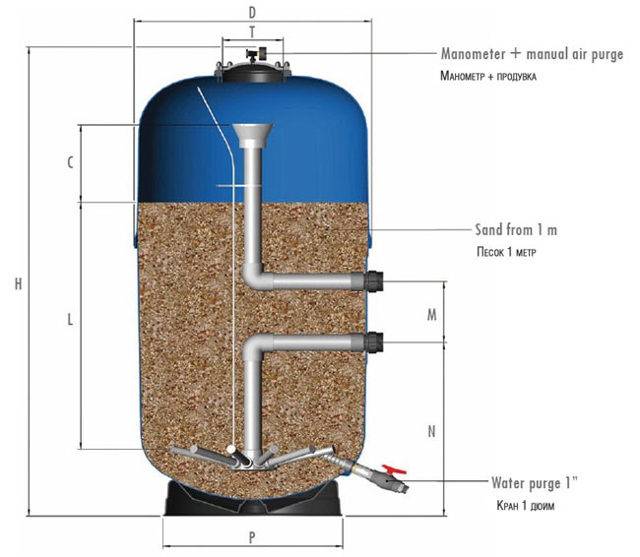

Filter device

Filter device

After you can start installation. The filter must be located in close proximity to the pump. The outlet hose can be located at any depth and in any area of the pool.Make sure that free access to the filter is maintained for its further maintenance.

To complete the simplest installation procedures, perform a trial run of the system.

Now you know how to make a full-fledged sand filter for the pool with your own hands. This is an absolutely doable undertaking, if you follow the step-by-step instructions and do not neglect useful tips. And remember that only after doing everything according to the verified rules, you will receive a functional device that can guarantee high-quality water purification in your reservoir.

Nuances of operation

When purifying water with a self-made sand filter, it is necessary to comply with safety requirements and understand all the intricacies of its work. Periodically, you need to do the following:

- control the readings of the pressure gauge, which informs about the change in pressure inside the tank. With an increase in normal pressure from 0.8 to 1.3 bar, the device needs to be backwashed;

- open the filter when the pump is off. This will avoid getting small particles and dirty water on the mucous membrane;

- connect the device, keeping a distance of one meter from the walls of the pool. To maintain the filter, it is necessary to provide free space;

- remove lime deposits inside the filter after six months of operation. Use a special composition for cleaning from lime;

-

replace the filler once every two years. During operation, the sand gradually hardens, becomes saturated with dirt and compacts, which makes it difficult to filter;

- ensure maximum removal of the suction and supply lines. This will improve water circulation.

Filler replacement

Perform filler replacement activities according to the following algorithm:

- Turn off the filter device.

- Open the filter cover.

- Remove the sand mass using a technical vacuum cleaner.

- Rinse the pipes and the inside of the filter.

- Fill the filter housing with fresh sand. Pour a large fraction to the bottom, and add fine sand on top.

Step by step manufacturing instructions

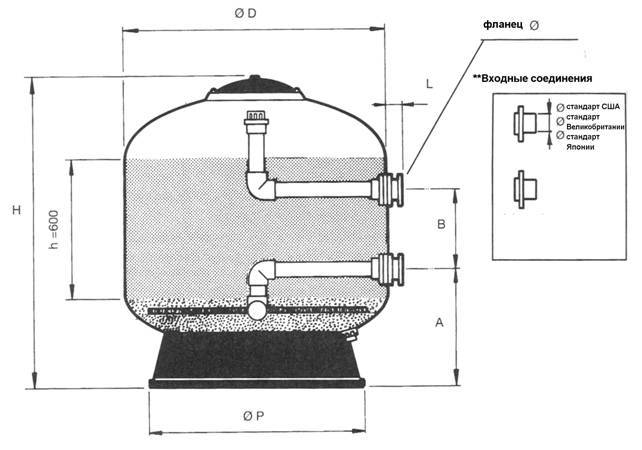

To perform the work, it is necessary to select a housing, insert fittings into it, install internal elements, prepare a filter element and devices that ensure the operation of the structure. Then you should tie the system and connect it to the pool.

Polypropylene barrel

Step 1. We select the body

The choice of the filter chamber is determined by the conditions of its operation - it must be a hermetic container resistant to aggressive influences that can withstand the pressure developed by pumping equipment.

Sixty liter polypropylene barrels or other plastic containers often available in country houses are suitable. Reliable in operation durable expansion tank with a membrane. It should be removed and an analogue of industrial equipment will be obtained.

Step 2. We mount fittings and internal elements

Coarse filter

Coarse filter

To ensure the pumping of the purified liquid and the entry of contaminated liquid into the filter, fittings are cut into its body or cover. Joints are carefully coated with waterproof compounds.

A filtering device is attached to the inlet fitting, which traps large fractions of contaminants, for example, a cone-shaped cut of a plastic bottle covered with nylon tights.

In addition to catching large debris, such a coarse filter prevents the formation of a directed jet that digs funnels in the thickness of the sand.

Expert opinion

Kulikov Vladimir Sergeevich

The drainage chamber connected to the outlet pipe is made from a plastic pipe cut to the desired size with holes made in it. Outside, it is covered with a mesh with small cells that do not allow sand filler granules to pass through. You can also use a prefabricated cylindrical cartridge used to filter drinking water.

Step 3. Prepare the sand filler

Commercially available special quartz sand does not require preparation for use in the filter. It does not contain pathogenic microflora, the filler particles are crushed to the optimal size. Unprepared quartz sand is sifted through a sieve that retains fractions larger than one and a half millimeters in diameter.

The sorted filler is then washed. Ordinary sand is not recommended. Too small is prone to clumping, too large will not purify the water properly.

Installing a pressure gauge allows you to control the pressure and avoid unnecessary breakdowns

Step 4. Install devices that ensure correct operation

When installing pressure pumping equipment, a pressure gauge must be used to control the developed pressure. Installing a safety valve through which excess fluid is bled when the pressure in the system rises critically will help to avoid damage to the housing.

It should also be possible to remove the air released from the water through a separate branch pipe with a stopcock.

Step 5. We tie and connect the filter system to the pool

The pump must be powerful and reliable

The pump must be powerful and reliable

The manufactured sand filter is tied with piping with locking elements and fittings located in appropriate places. The piping should provide the possibility of fluid circulation through the sand thickness both from top to bottom in the filtration mode, and in the opposite direction to flush the filler.

The performance of pumping equipment is selected based on the total pumping through the filter of the entire volume of water in the pool in 6 hours. Reducing this time will lead to the need for frequent replacement of the filler. The filter system is connected to the pool by connecting hoses to the inlet and outlet pipes that supply contaminated water from the pool and drain the purified liquid into the tank.

In conclusion, we note that a well-made sand filter, subject to the rules of operation and timely maintenance, will work without loss of technical characteristics for a long time. The cost of a self-made device is much lower than an industrial copy.

- Surface pumps for wells. Overview and selection criteria

- Pumping station for a summer residence. How to choose? Model overview

- Wood splitter with their own hands. Types of devices and instructions

- Automatic lawn watering system. Do-it-yourself installation and device

Ratings of the best models

To obtain a high degree of water purification in the pool, when choosing a filtering installation, it is recommended to pay attention to the products of companies that occupy a leading position in the market. Among the models that make up the top list of pool filters, there are models of different volume and design

But to evaluate the quality and performance, we chose models that have been on the top of consumer preference lists for several seasons.

Crystal Clear Intex 26644

Popular brand model manufacturer of domestic frame pools. The advantage of this model is high performance with small dimensions. The declared capacity of 4.5 m3 is enough for cleaning pools up to 25 m3. Connection to a standard pool is carried out using branded 38 mm hoses. The model has the ability to work in one of 6 modes. For convenience of use in model the timer and the manometer is provided. Crystal Clear Intex 26644 can be filled with both quartz and glass sand with a fraction of 0.4-0.8 mm. For a standard load, you need 12 kg of ordinary sand, for glass - 8 kg.

The manufacturer's instructions say that one refueling is enough for 3-5 years of operation.

The design is made on the platform. The case is made of impact-resistant polyethylene. Installation differs in the compact sizes by convenient connection to regular connectors of pools of Intex. The instruction, in addition to the description, also has a disk with a film - instructions for connecting and maintaining the installation.

Bestway 58495

The most compact pool filter model. Productivity is 3.4 m3 of water per hour. A 6-position valve is built into the polypropylene tank. The timer provides automatic switching on and off of the unit. The built-in pressure gauge allows you to control the pressure inside the tank.

A feature of the model is the presence of a built-in ChemConnect dispenser. The device allows you to automatically add disinfecting chemicals to the filtered water.The design provides an additional filter to trap undissolved particles. This function provides long-term protection of the pump against damage.

Branch pipes for connecting 3.8 cm hoses make the filter universal for connecting to most popular models of frame pools. The volume of sand to fill in the filter housing is 9 kg.

Aquaviva FSF350

One of the largest filters for home pools. To load, you will need 20 kg of quartz sand with a grain size of 0.5-1 mm. The tank of the filter unit is made of fiberglass. The case material is not afraid of ultraviolet radiation, it can be installed outdoors.

The system has standard connection types with 50 mm hoses. Productivity is 4.3 m3 of water per hour. The housing withstands pressure up to 2.5 bar.

In comparison with other models, Aquaviva FSF350 operates at a water temperature of +43 degrees.

The system has a modular design. The filter housing and pump are mounted on a common platform. The manufacturer recommends using the unit for pools with a volume of 15-18 m3.

Hayward Powerline Top

This is the most famous and high-quality filter for home pools. This model provides water filtration with a capacity of 5 to 14 m3 per hour. Such a variation in indicators is due to the fact that the pump is selected for this filter depending on the volume of the pool. The recommended bowl volume for the Hayward powerline Top is 25 m3. The design is equipped with a standard 6 position valve and pressure gauge. The body is made of shock-resistant polypropylene and is able to withstand a pressure of 2 bar.

For the filter to work, 25 kg of quartz sand with a fraction of 0.4-0.8 kg will be required.All Hayward powerline Top models are connected using 38 mm hoses.

Sand replacement

Ordinary quartz sand must be replaced every three years. Some commercial installations (for example, sand filters for Intex pools) use sand, which needs to be replaced less often - about once every 5 years. The operation is not difficult:

- Turn off the pump supplying water to the filter.

- If you are using a factory made filter system, close the nozzles and shut off the skimmer valves.

- If the filter is installed inside the pool, the bath water must be drained.

- Disconnect the filter from the system.

- After opening the hatch, remove all the sand from the body, remembering to clean the nozzles.

- Under the pressure of water, lay the new sand. As mentioned above, the bottom layer should be formed by the largest sand, then the medium fraction material is laid, and the finest sand is placed on top.

- It remains to close the filter cover on the latch and connect it to the system.

After each sand filter maintenance operation, be it changing the sand or flushing, check that the pressure gauge port is not clogged with dirt or sand.