- Appearance, testing and performance check

- Garage heaters: gas, infrared, diesel, energy-saving, mikathermic

- Instrument Requirements

- Potbelly stove from a used cylinder

- Vertical design

- Model with a horizontal body

- Homemade device from a gas burner

- Building a garage heater

- How to make garage heating with your own hands cheap and fast: choosing the right place

- Garage heating methods

- Varieties of diesel heat guns

- General recommendations for creating devices

- No. 2. Gas heating

- Autonomous heating systems

- Gas

- Electricity

- Firewood and coal

- Working off

Appearance, testing and performance check

The final stage in the manufacture of the heater is to check it for performance and safety. First of all, you need to connect the heater to an ohmmeter, and then to a power source.

To increase the strength of the heater, you can cover it inside with epoxy glue. If the size of the heater is 0.5x0.5 meters, then you will need about 150 g of glue, which must be applied along the snake.

Then the structure is closed with the second half of the textolite, and in order for it to grab well, it is necessary to install a load of approximately 40 kg on it.

It will be possible to use a homemade heater after 24 hours. Its surface can be decorated with some kind of finishing material (plain fabric, vinyl film, etc.).

It is also possible to rivet textolite sheets and install fasteners for wall mounting on their surface. When leaving the garage, it is necessary to turn off the heater, especially homemade one.

The creation of such a heater is quite simple and it does not require a lot of money. You will not only acquire the knowledge that will allow you to make a good heater in just a couple of days, but also enjoy the process of creation itself.

Garage heaters: gas, infrared, diesel, energy-saving, mikathermic

Car enthusiasts use various sources of heat to heat the garage: electric heaters, gas burners or heat guns, solid or diesel fuel boilers, waste oil stoves. These useful garage gadgets can be made independently, each of them has pros and cons. The advantages of electric heaters are ease of use and efficiency of heating, and the disadvantage is the high cost of electricity. Gas burners emit large amounts of carbon monoxide and can be unsafe. Solid fuel boilers (factory-made or home-made) need a constant supply of fuel and, with their efficiency, have a “non-independence” of work. Diesel fuel is not cheap. The used oil heater heats well, but a lot of soot is released, and besides, it is unsafe.

Instrument Requirements

Whatever heater is used, a homemade garage heater must meet several requirements:

- ease of manufacture and operation;

- safety;

- the speed of heating the room;

- economy.

When making a heater, you need to be extremely careful

</p>

An important requirement for heating systems is safety, therefore it is imperative to equip a ventilation system in the garage, regardless of the heating method. The presence of exhaust gases and combustion products, a decrease in the amount of oxygen is fraught with a serious outcome and carries a risk to life

Table of contents

Potbelly stove from a used cylinder

Potbelly stoves, popular a hundred years ago, still do not give up their positions today, acting as the main source of heat in garages and utility rooms. And their main advantage is that they can work not only on wood, but on everything that burns.

Potbelly stoves are made from gas cylinders containing propane before emptying, with a volume of 40-50 liters, pieces of steel pipes and thick-walled barrels with a small volume

The minimum wall thickness of such structures should be 2-3 mm, but still the best option is 5 cm, so that any type of fuel can be used. If we compare the models of horizontal and vertical execution, then the former win in terms of ease of loading logs.

Vertical design

The simplest option for manufacturing a potbelly stove involves the use of a gas cylinder: the body of the heating structure is already ready, it remains only to equip the compartments for laying fuel and an ash pan.The height of the cylinder is about 850 mm, the diameter in the girth is 300 mm, and the sufficient wall thickness allows the use of any type of fuel.

To build a vertically mounted structure, the balloon is divided into two parts unequal in volume:

- upper - occupies 2/3 of the structure acts as a receiving chamber for laying firewood;

- lower - occupies 1/3 of the structure and serves to collect ash.

For the manufacture of a potbelly stove in the wall of the cylinder, holes are cut out for the arrangement of doors to the size of each of the two sections. The doors themselves can be built from a cut piece of the balloon wall or cut from sheet metal.

On the border between the upper and lower compartments, grates are mounted. But since it is difficult to find a ready-made cast-iron grate of a suitable size, thick rods are used for its manufacture.

The basis for the manufacture of grates is steel reinforcement with a thickness of 12-16 mm, the cut rods of which are placed at a distance of 2 cm from each other

The basis for the manufacture of grates is steel reinforcement with a thickness of 12-16 mm, the cut rods of which are placed at a distance of 2 cm from each other

A hole for a chimney with a diameter of at least 150 mm is cut out in the upper part of the cylinder. This element can be welded from a cut of sheet metal. The main thing is that the diameter of the resulting pipe matches the size of the chimney in order to simplify the docking process.

The doors are equipped with locks and attached to the body by welding. If desired, the loops can be made from several links of a thick steel chain.

Since the potbelly stove was not originally one of the hermetic heating structures, there is no need to use seals

To close the gap formed along the perimeter of the door, it is better to weld a small side on the outside along the perimeter of the blanks - a strip of metal 1.5-2 cm wide.The finished structure can only be connected to the chimney and tested.

Model with a horizontal body

With a horizontal arrangement of the body, the ash collection compartment is welded from the bottom of the structure. The main compartment is designed for laying fuel and unloading burnt coals. It is equipped with a chimney pipe with a diameter of 10 cm.

It is fashionable to build an ash collection compartment from a suitable channel size or weld it according to the given dimensions from a cut of sheet steel

A hole is made in the side wall of the housing for the installation of a furnace door. Its size should not exceed the diameter of the chimney pipe. The door itself is equipped with a latch and mounted on hinges.

Holes are made in the wall of the housing, which will be directed downwards. They will perform the function of a grate.

To improve the heat transfer of a red-hot furnace, the chimney can be made in the form of an elongated broken structure. The main thing when arranging a stove chimney is to avoid horizontal sections. Some craftsmen build casings made of sheet metal around the cylinders to improve the heating of the room.

But do not forget that the potbelly stove carries a potential danger. Therefore, the room where it will be installed should be periodically ventilated.

On our site there are several articles on making potbelly stoves with your own hands. We advise you to read:

- Do-it-yourself potbelly stove from a gas cylinder: diagrams, drawings + step-by-step guide

- Do-it-yourself potbelly stove: a diagram of a home-made potbelly stove for a summer residence and a garage

- How to make a potbelly stove with used oil with your own hands: options and examples of making a stove

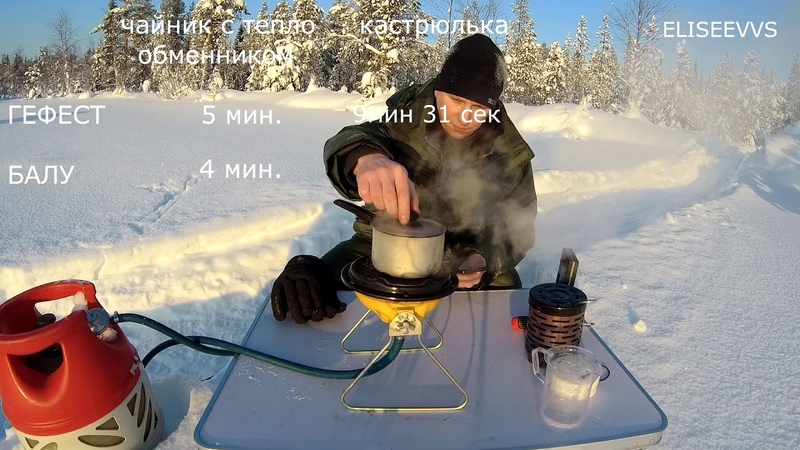

Homemade device from a gas burner

Using the method we have proposed, you can assemble a not too powerful, but convenient, compact, portable gas heater. Such a device is suitable for heating small rooms, a garage, a small greenhouse, a basement or a tent.

To assemble the structure, a gas burner-primus is used. It is used for cooking. This scheme is also applicable when using collet valve cylinders.

Gas burners and stoves are connected to steel or composite gas cylinders. They work from any mixture of liquefied gases

In addition to the burner, you will need the following material at hand:

- tin sheet of small area;

- round metal sieve;

- rivets.

You will also need some tools: an electric drill with a small drill bit, a riveting device and metal shears.

The operation of homemade gas devices requires increased attention to detail from the user. The safety of the user directly depends on whether the safety precautions are observed or not.

The assembly of the device is carried out as follows. First you need to take a pre-prepared tin sheet and attach a sieve to it. The sieve must be circled with a marker or construction pencil around the circumference.

After that, a sieve is laid down and with a pencil with a ruler on the tin over the circle, rectangular ears or the so-called sweep are carefully drawn. One ear should be slightly longer than the remaining three.

Then you need to take scissors and carefully cut out the lined workpiece.

It is important to cut the parts so that there are no irregularities on their surface.

After the circle is cut out of the sheet, it must be attached to the burner with bolts. To do this, you need a drill, with which you carefully drill even holes. Then you need to trim the drilled holes and erase the remnants of the metal with a file or cut (grind) with a grinder.

As a result, it is possible to assemble a heater with a vertically or horizontally located gas cartridge. It depends on the type of burner and on the desire of the collector.

At the resulting design, you need to bend the rectangular ears on top and attach a metal sieve. The main task of the sieve during the operation of the heater will be heat dissipation. This design can be improved by additional use of a grid.

First of all, another circle with ears is additionally cut out of the tin sheet. Its dimensions must match the dimensions of the first part. Then, using a drill, it is necessary to drill holes in the cut out circle, which should be located at a small distance from the edge of the workpiece. After that, you need to cut a small strip from the grid.

The cut out narrow strip is attached above the sieve to the first and to the second tin circle by the ears with the help of rivets. The ears should be bent at an angle of 90 degrees. As a result, the design will resemble a metal cylinder.

After manufacturing do-it-yourself such a gas heater using a gas burner, the design must be checked. You need to make sure that it is safe to use. The gas cartridge is connected to the burner, the gas supply is turned on, the burner lights up, and the device starts heating the room.

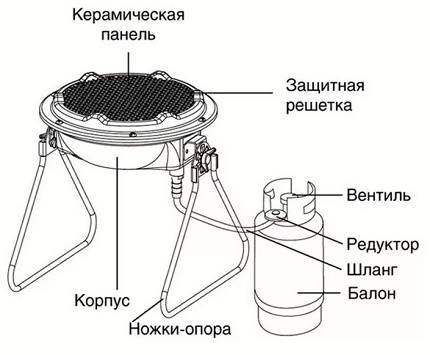

Using an adapter hose, you can connect such a burner to a large gas cylinder.Then you do not have to spend extra time on replacing and refueling the gas tank. A gas reducer must be installed on the cylinder, which protects the structure from the reverse movement of gas and allows you to adjust the pressure.

It is convenient to pour gas from one container to another with similar home-made or factory-made hoses, as well as connect the heater to a gas source

It is worth remembering that manufacturers of gas cartridges do not recommend reusing their products and refilling cartridges.

Using a similar approach, you can design a larger homemade gas heater. Such devices will already resemble gas stoves and can be powered directly from a gas pipe or a large cylinder. Naturally, the power of such a furnace is enough to heat a larger room.

However, such structures are not so easy to move from one place to another, they take up a lot of space and often require additional construction of a chimney and ventilation system.

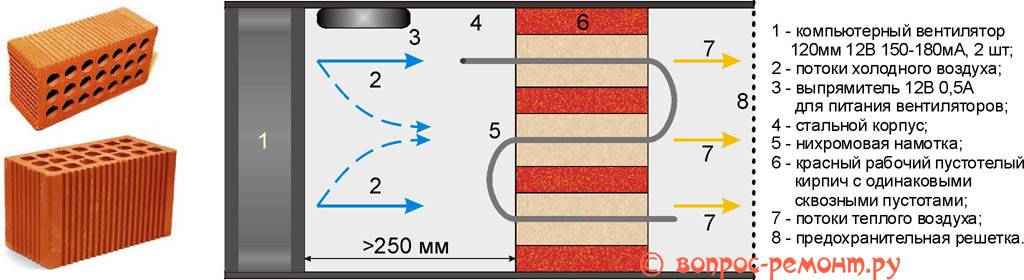

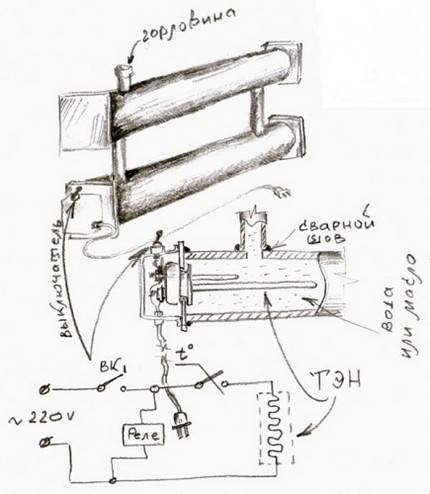

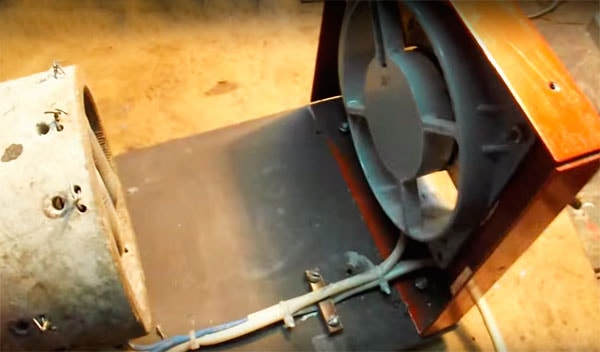

Building a garage heater

To maintain a comfortable temperature in the garage, it is not difficult to make a waste oil heater yourself. At the same time, the problem of its disposal will be solved, which is also a topical issue for car owners. To assemble it, almost all the elements and spare parts can be found in your own garage.

When making a heater you will need:

- metal pipes;

- TEN (heating element);

- waste oil;

- plug wire.

Structurally, the body can be made in any form, convenient for placement in the garage. The photo shows one of the possible schemes of the device.

Scheme of a homemade oil heater

Metal pipes are used in any diameter. It must be borne in mind that the thinner they are, the more they will be needed. The temperature of the room will depend on the area that gives off heat. The length of the pipes is also arbitrary, it is desirable that it be maximum, but at the same time it is in perfect harmony with the dimensions of the wall on which it will be installed. The metal from which the pipes are made does not matter. The wall thickness of the pipe can be any.

The heating element is selected by power and voltage. Practice shows that 1.5-5 kW of the heater is enough for heating. Here it is necessary to take into account that the comfortable temperature of the garage and the apartment differ significantly. And such a wide difference in power is given based on the size of the heater. The voltage for connecting the heating element is taken as standard - 220 V. (other parameters are not considered here).

Used oil. Most motorists almost 2 times a year change the oil in the engines of their cars on their own. Therefore, working off, as a rule, is available for everyone. It remains to collect the required amount and proceed to the manufacture of the heater.

How to make garage heating with your own hands cheap and fast: choosing the right place

The place for installation of equipment is selected taking into account fire safety. Gas-fired heaters can be used in rooms with excellent ventilation

In addition, it is important to consider the chimney device. The selected device should be attached to the main wall

It is important to correctly calculate the performance of the hood. It is important to provide free access to heating equipment.

Fireplace stoves are not only high-quality heating, but also an aesthetic appearance

Using an economical heating method will allow you to fully use the garage at any time of the year.

Garage heating methods

There are several options for the heating system for the garage, and they differ in the type of fuel:

- Liquid;

- solid fuel;

- Gas;

- Electricity.

The main criterion for choosing the type of heating system is the location of the garage. Proximity to a residential building will allow you to choose a water radiator connected to the house system. If the garage is far from home, use the boiler on the type of fuel that suits you. The presence of a nearby gas main will allow you to connect gas heating equipment. If there is no gas pipe nearby, your choice is a solid fuel boiler with a metal or brick stove. There are options for installations that allow the use of two or more types of fuel, but they are less reliable.

There are two ways to heat the garage: air and water, each of which has its own advantages and disadvantages.

Don't need permanent garage heating? For temporary heating of the room, the best option would be non-freezing liquid, antifreeze. Electric heating will allow you to quickly heat the garage to the desired temperature.

Varieties of diesel heat guns

Guns of this type are also called liquid fuel: they can be used as fuel for both diesel and kerosene or diesel fuel. It is strictly forbidden to use gasoline, alcohol and other flammable liquids to refuel such devices.

Diesel heat guns can be not only mobile, but also stationary.Similar designs have an outlet pipe connected to a chimney through which combustion waste is removed.

The choice of fuel must be approached very carefully, since the use of poor quality or contaminated fuel can clog the nozzle and / or filter, which will require the intervention of repairmen.

Diesel guns are characterized by high power, high efficiency, as well as compact size, so that such units are quite mobile.

All units operating on economical diesel fuel can be divided into two groups of heat guns: with direct and indirect heating.

Devices with direct heating. The operation is based on an elementary principle: a burner is arranged inside the body, through the flame of which air blown by a fan passes. As a result, it heats up, and then breaks out, giving off heat to the environment.

A diesel heat gun with open heating cannot be used for heating residential premises, since its design does not provide for exhaust pipes. As a result, exhaust substances, including carbon monoxide, enter the room, which can lead to poisoning of people in it.

A diesel heat gun with open heating cannot be used for heating residential premises, since its design does not provide for exhaust pipes. As a result, exhaust substances, including carbon monoxide, enter the room, which can lead to poisoning of people in it.

Such devices are distinguished by high power of 200-250 kW and almost 100 percent efficiency. They are inexpensive, easy to install, but they have an important drawback: not only warmed air flows into the outer space, but also combustion products: soot, smoke, fumes.

Even good ventilation will not be able to completely rid the air of unpleasant odors and the smallest particles, and if it is completely absent, living beings in the room can get severe poisoning.

A device with indirect heating is much more complicated.In such models, the air is heated indirectly, through a special chamber - a heat exchanger, where heat is transferred to the air flow.

Diesel heat guns with indirect heating have a higher cost and lower efficiency compared to similar products with a direct heat source. However, they are widely used due to the best indicators of environmental friendliness and safety.

In such units, the heated exhaust gases, together with the heat, enter the heat exchanger, from where they are discharged into the smoke channel, to which a special pipe is connected. With its help, the products of combustion are removed from the closed space to the outside, providing fresh air in the heated room.

Heat guns with indirect heating are often used to heat the garage.

Models of diesel heat guns with high power may have large parameters. They are used for heating large premises: warehouses, factory floors

Models of diesel heat guns with high power may have large parameters. They are used for heating large premises: warehouses, factory floors

The advantages of such models include:

- Mobility. Although the dimensions and weight of such devices are somewhat larger than those with open heating, they are still quite compact in size, which allows them to be transported around the room within the length of the connecting element and the chimney.

- Great power. Although this figure is higher for devices with direct heating, the power of indirect diesel guns is enough to heat a large area in a short time.

- Reliability. Such devices have a well-thought-out design, which minimizes the risk of fire, and also increases the durability of the guns.

- The presence of a protection system.In many factory models, a protective complex is provided that automatically turns off the gun immediately after the room temperature reaches a predetermined value.

- Reduced risk of burns. Factory-made products are equipped with thermal insulation pads to prevent heat build-up in the case, reducing the risk of injury to the user.

- Duration of work. On some models, tanks of large volumes are provided, which allows them to be used for a long time without thinking about fuel.

The disadvantage of such structures can be considered a high noise level, especially for high-power units.

General recommendations for creating devices

In an effort to save an expense item, many owners, choosing among heater options, are in no hurry to purchase ready-made factory models.

After all, having a desire and having the appropriate skills, a heating device can always be designed on its own.

Image gallery

Photo from

A self-built heater will provide a comfortable temperature in the garage for the period of repair work

An ordinary radiator connected to a mini-system with hot water circulation will perfectly cope with heating tasks.

Home craftsmen who own the skills of a welder and have a device are quite capable of making a buleryan furnace

Those who wish to quickly build a device with minimal effort and labor will need a register left after the dismantling of the old heating system

The register welded from pipes, as well as the device remaining after dismantling, is filled with either just water or technical oil.As a heating element, a conventional boiler or heating element from unnecessary household appliances is used.

A self-made heater only works in the presence of the owners of the garage. Energy consumption due to short stay is usually low

The IR film system works efficiently and most economically compared to other electrical appliances

If it is not rational to spend electricity for temporary heating of a room, it is better to build a mini-stove that runs on solid fuel

Homemade heat gun

Ingenious solution with a heatsink

Stove buleryan for arranging a garage

Using the old register

Homemade electric type

Garage Electric Heater Option

Infrared film on garage wall

Solid fuel stove-potbelly stove from a pipe

When choosing a garage heater option that you can do yourself, many are guided by two parameters:

- The heating device should be easily activated, quickly warming up the room.

- The device should have a simple design, devoid of complex parts and elements.

- The operation of the device should be carried out at minimal financial cost.

All these requirements are met by three options for the home-made heaters described below, which operate from different energy sources: gas, solid fuel and electricity.

An original and at the same time safe heater can be constructed even from improvised means used on the farm

The safety of the device is also important. Therefore, regardless of the method of heating in the garage, it is necessary to equip a heating system

After all, a decrease in the amount of oxygen and the accumulation of combustion products carries a risk to human life.

No. 2. Gas heating

Gas is a much more economical fuel than electricity. It can be used for burning in a heating boiler, but this will require the presence of a main gas pipeline and the execution of a number of documents, you will also have to pay the cost of the tie-in, and this is not counting the expensive installation of the heating system itself. As mentioned above, this is an option only for spacious garages that need to be heated almost constantly.

When there is no access to the main gas pipeline, liquefied bottled gas can be used. According to safety rules, cylinders are installed in metal boxes at least 20 cm above the floor level and away from flammable objects. You can have a supply of cylinders, but for this you need to allocate space. Most get by with one cylinder, which is periodically taken to the gas station.

The following types of equipment can be connected to the gas cylinder:

- heat gun equipped with a burner for burning gas. The heated air is distributed throughout the room by means of a built-in fan. In this way, you can warm up the garage very quickly, but the air will also cool very quickly;

- a ceramic gas heater does not heat the air, but objects that subsequently heat the air in the room;

- a gas convector heats the air by changing its properties as the temperature rises. Cold air passes through the heat exchanger, heats up and exits the room. Warm air is lighter than cold air, so it immediately rises, giving way to unheated air, which is sucked in by the convector.To circulate air faster, the convector is often equipped with a fan. The body of the device and the heat exchanger are made of durable heat-resistant materials, because the gas will constantly burn inside. The lower the convector is installed, the better. The room will warm up quickly, but just as quickly and cool down.

The disadvantage of such heating is the formation of combustion products that do not go anywhere and remain in the garage. Reliable ventilation or regular ventilation is indispensable.

Autonomous heating systems

Let us dwell in more detail on the advantages and disadvantages of different methods of autonomous garage heating, which have their own characteristics and nuances that can cause a lot of problems if they are not taken into account at the design stage.

Gas

The main advantage of a gas heating system is the economic benefit. In terms of cost, gas is the cheapest fuel, outperforming both electricity and diesel. In addition, the gas generator has a fairly high efficiency - 90%.

However, it must be remembered that gas is a dangerous explosive. Install a gas heating system DIY garage by no means is it possible. It is necessary to invite a qualified specialist who will be able to independently install and start the system, guaranteeing its complete safety during further operation.

Scheme of gas heating in the garage

In addition, dubious home-made parts are prohibited - only high-quality industrial equipment should be used. There is no need to be afraid to play it safe once again - after all, it is not only about the safety of your property, but also about your life.

Despite all the above advantages, it will be impossible to organize a gas system in the garage if there is no main gas supply nearby.

Electricity

Electricity is the most accessible source of energy for conversion into heat. The ways of its use for heating the garage are varied - these are heaters, and a heat gun, and an electric boiler. If you wish, you can assemble your own design with your own hands or buy a ready-made one.

The availability of electricity and a large selection of appliances powered by it are the main advantages of this option, which is why this type of heating is so popular.

Scheme of electric heating

However, there are also disadvantages.

- Electricity costs will be higher than, for example, gas or coal;

- Cheap electrical appliances are not very reliable and often fail.

- Wiring must be made of thick cable.

Firewood and coal

If independence from centralized sources of gas and electricity is critical for you (for example, there are interruptions in one or the other), old proven tools can come to the rescue - solid fuels such as wood or coal.

This option is very economical - it is quite possible to assemble a simple stove with your own hands. But in operation, such a stove requires special attention and care, it must be cleaned regularly, monitor its operation and remember that there should not be explosive substances in the garage. In addition, the garage must be equipped with a good ventilation system.

Working off

Waste engine oil can serve as fuel for heating your garage - it only needs to be cleaned and recycled in a special heat plant.This option is suitable if you have a desire to assemble such an apparatus with your own hands - it is simple and allows you to use waste materials cost-effectively.

Important! Due to the fact that the used oil is not homogeneous, it can be expected that such a device will wear out soon and break down quite often.

Summarizing the above, we can summarize: the choice of an autonomous heating system is the choice of a balance between the cost of fuel, the cost of equipment and the complexity of operation. Electric heating for a garage is quite expensive, but perhaps the easiest to organize, gas is cheap, but installation of equipment will require significant material costs.

However, home-made heating devices using solid fuels (wood, coal) cannot be discounted in any way - sometimes, in the absence of other sources of energy, they may be the only way out.