- Useful little things

- Which gas boiler to choose

- Types of heating boilers

- Electrical

- Gas

- Oil boilers

- Solid fuel

- Automation

- The device and principle of operation of pyrolysis boilers

- Solid fuel boilers

- Pros and cons

- Long burning boilers

- The best inexpensive boilers

- Lemax Premium-30

- Mora-Top Meteor Plus PK18ST

- What can replace

- The principle of operation of the long-burning boiler

- Pellet boilers

- Materials and tools

- Conclusions and useful video on the topic

Useful little things

The manufacturing process is complex. If there are no skills in working with welding, it is better not to try to assemble the boiler yourself, but to purchase the unit in a specialized store. When choosing a homemade option, you should consider the following nuances:

- A self-assembled heater must not be installed without permission to connect to the gas line.

- The equipment must be inspected by a specialist.

- Unauthorized installation may result in fuel leakage resulting in poisoning or fire.

- During work, do not forget about personal safety and use protective equipment.

- All items purchased in the store must have certificates and passports.

- Works are carried out only according to drawings.

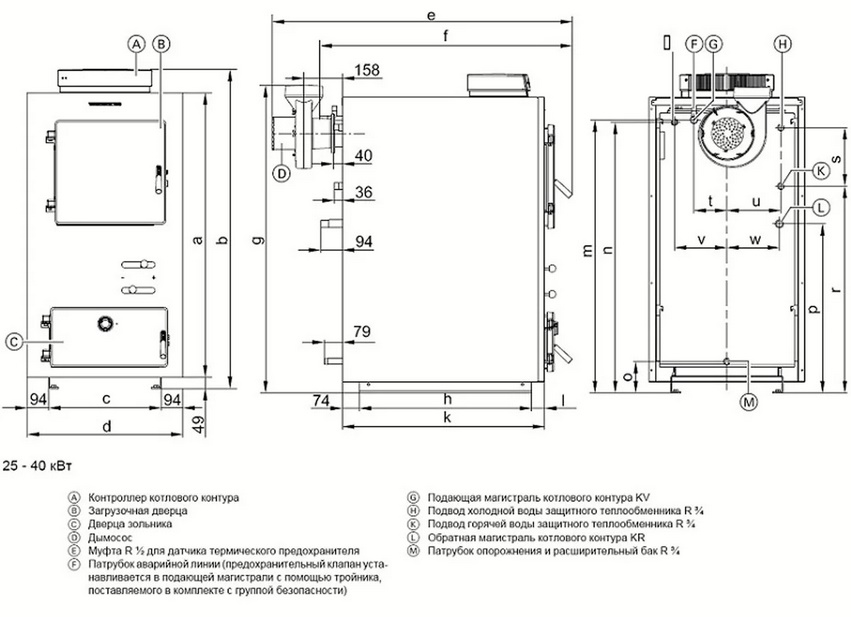

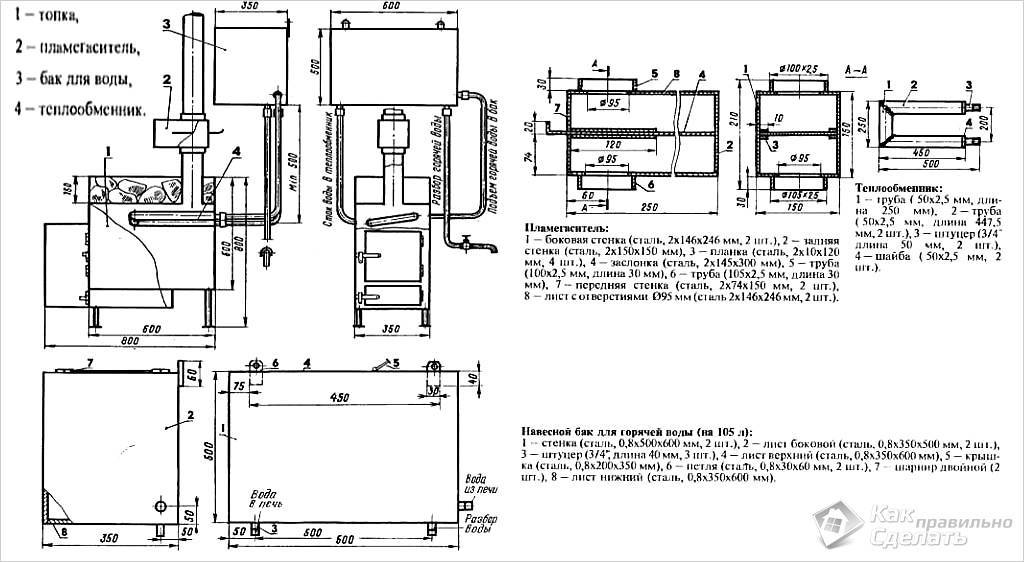

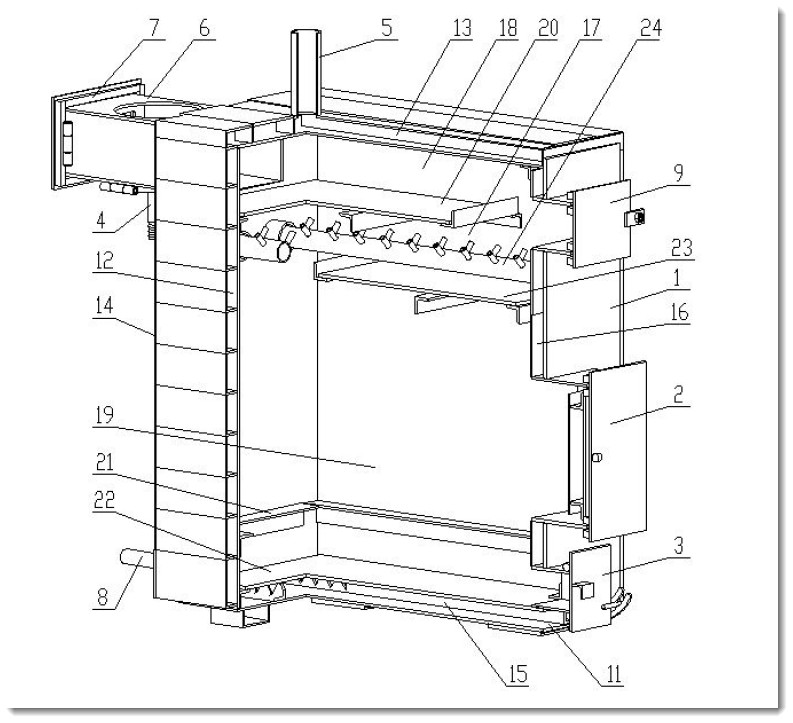

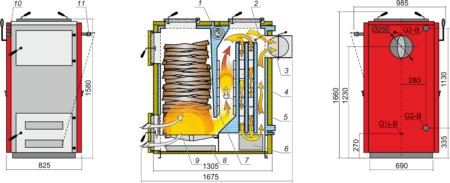

Drawing

Drawing Drawing and working principle

Drawing and working principle

Which gas boiler to choose

Domestic gas boilers are most often used in private houses and apartments, although the latter usually have centralized heating - perhaps not the most efficient. Installation also takes place in cottages, dachas, bathhouses and similar objects.

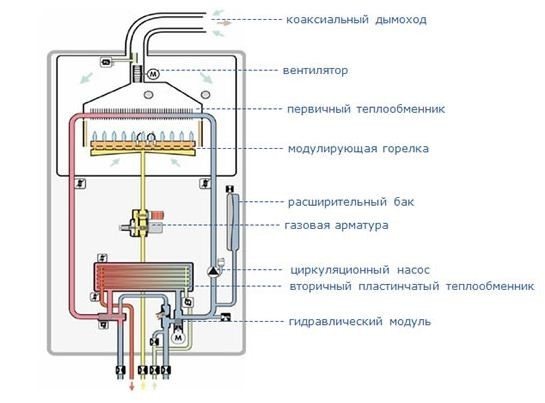

1. The following type of boiler is suitable for apartments: 2 circuits, closed combustion chamber, coaxial chimney, convection type of heating, electronic control, wall mounting, power ranging from 10 to 30 kW

2. The following type of boilers is suitable for the house: 1 circuit + indirect heating boiler, open firebox, vertical chimney, specially equipped room, condensing heating, electronic control, floor installation, power from 20 to 50 kW.

Types of heating boilers

First of all, you need to decide which boiler is needed for your home. This will depend on the fuel that will be used for kindling. Hence the classification:

- gas;

- electrical;

- solid fuel;

- liquid fuel.

Electrical

Any of these boilers can be made by hand. The simplest of them is electric. In fact, this is a tank in which the heating element is mounted. From the tank there are still two branch pipes connected to the supply and return circuits. There is no chimney, no combustion chamber, everything is simple.

all are good, but they have two drawbacks. First, electricity is the most expensive fuel. Second: when the voltage drops in the network (and this happens with enviable constancy), the boiler stops working correctly. Its power decreases, the coolant temperature drops.

Gas

The rest of the designs are more complex. And they are almost identical to each other with some differences.As for the gas boiler, you will need permission from the gas service to install it.

Representatives of this organization may not accept such a heating unit for installation. First of all, they will require it to be pressure tested in their laboratory.

Oil boilers

The operation of this option is associated with great difficulties. First, you will have to build a separate warehouse near the house where the fuel will be stored. Everything in it must comply with fire safety requirements.

Secondly, a pipeline will have to be pulled from the warehouse to the boiler room. It must be insulated. Thirdly, a special burner is installed in this type of boiler, which must be adjusted. This is not so easy to do in terms of setup.

Solid fuel

It is this type of boilers that today is most often made by home craftsmen with their own hands. For small cottages and cottages, this is the best option. Moreover, firewood is by far the cheapest type of fuel.

We will talk about how to make a solid fuel boiler for heating a house below.

Automation

- compliance with the temperature regime in the system;

- control of pumps in the main and auxiliary (mixing circuit) circuits;

- maintenance of the set temperature of hot water supply;

- control of coolant flows using a three-way valve.

In the presence of an automation unit, a person only needs to set the required temperature and load the fuel, then the combustion process is automatically controlled according to the specified settings by controlling the supply of oxygen to the furnace. If the heating is carried out using a pellet unit, then the fuel is loaded automatically.

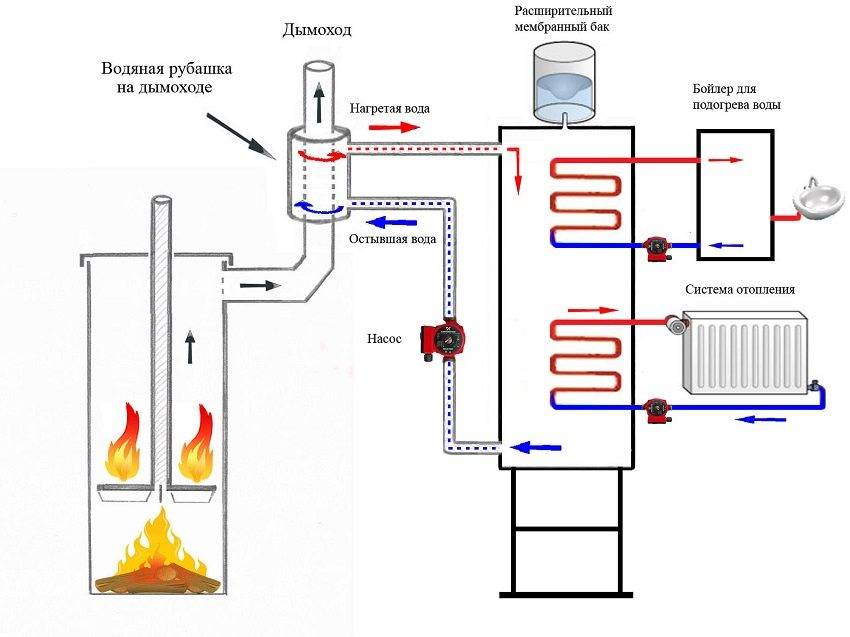

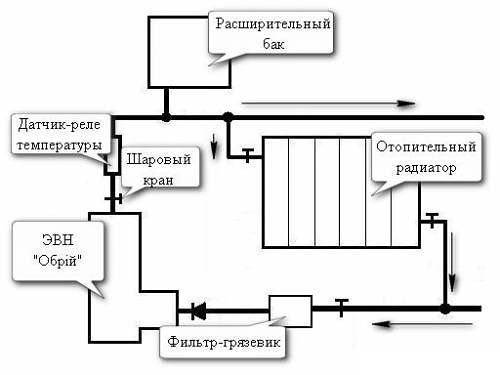

The principle of operation of the three-way valve

In the presence of a three-way valve, the system works on the principle of mixing hot water from the boiler into the main flow when the temperature drops below the set temperature. This principle allows you to heat only the required amount of water. It can be supplied either directly from the boiler or from a buffer tank. At the same time, it can also be heated by alternative sources, such as a solar collector.

The device and principle of operation of pyrolysis boilers

Pyrolysis boiler of industrial productionThe operation of gas-fired boilers is based on the principle of pyrolysis, which consists in the fact that under the influence of high temperature with limited access to oxygen, the fuel decomposes into pyrolysis gas and solid fuel residue. In the main chamber, solid fuel smolders at temperatures reaching 800 degrees. As a result of this, the heat necessary for heating the coolant is released. However, if in devices with a traditional design, the gas released as a result of combustion is immediately removed through the chimney, in these devices it is mixed with oxygen, which is forced in and burns out in the second chamber. Here, additional heating of water takes place, which most often plays the role of the main heat carrier.

Compared to traditional boilers, gas-fired boilers have a number of advantages, among which are the following:

- High efficiency, and in some devices of this type this figure exceeds 80%, while in other devices it is usually 60-70% or even less.

- The minimum amount of hazardous waste, which is facilitated by the interaction of pyrolysis gas and active carbon, which reduces the emission of harmful carbon dioxide into the atmosphere by a third.

- The versatility of pyrolysis boilers, which lies in the possibility of using various types of solid fuels, including wood, wood pellets and even sawdust.

- Easy maintenance, which consists in the fact that fuel loading into many gas-generating boilers occurs no more than 1 time per day.

- Affordable price - given the fact that the efficiency of pyrolysis-based boilers is much higher than even traditional gas boilers, and the cost of waste from woodworking enterprises is completely insignificant, it can be noted that the use of pyrolysis boilers can bring tangible economic benefits.

- The minimum amount of solid combustion waste - ash and soot, which facilitates the maintenance of boilers.

Despite this, it should be noted that during the operation of pyrolysis boilers, it should be borne in mind that not all fuels are suitable for their operation. In particular, wood is most often used to operate pyrolysis-type boilers used to heat a house. However, not all wood will be equally suitable. The essence of the pyrolysis process is to release as many combustible volatile substances as possible, and this is possible only if the wood moisture content is small - no more than 20%. Otherwise, the effect of pyrolysis will not be achieved and the efficiency of such a boiler will be much lower.In addition, industrially manufactured pyrolysis boilers are directly dependent on the electricity needed to organize the air supply. In cases where the latter is turned off, they can, at best, work only to maintain the temperature, without heating the room at all.

Solid fuel boilers

Despite all the shortcomings, solid fuel boilers for heating a private house are used in most cases. Probably, this is largely due to habit and traditions, but the fact remains that there are more solid fuel boilers in our country than all others.

Solid fuel boilers work mainly on wood and coal

Basically, two types of solid fuels are used for heating - wood and coal. What is easier to get and cheaper to buy, so they basically drown. And boilers - for coal and firewood, you need to use different ones: in wood-burning solid fuel boilers, the loading chamber is made larger - so that more firewood can be laid. In TT coal boilers, the furnace is made smaller in size, but with thicker walls: the combustion temperature is very high.

Pros and cons

The advantages of these units include:

- Inexpensive (relatively) heating.

- Simple and reliable design of boilers.

- There are non-volatile models that work without electricity.

Serious disadvantages:

- Cyclic operation. The house is either hot or cold. To level this shortcoming, a heat accumulator is installed in the system - a large container with water. It stores heat during the active combustion phase, and then, when the fuel load burns out, the stored heat is spent to maintain a normal temperature.

- The need for regular maintenance.Firewood and coal must be laid, kindled, then the intensity of combustion must be regulated. After burning out, the firebox must be cleaned and the process restarted. Very troublesome.

The principle of operation of a conventional solid fuel boiler - Inability to leave the house for a long time. Due to the cyclical operation, the presence of a person is necessary: fuel must be thrown up, otherwise the system may freeze during prolonged downtime.

- The process of loading fuel and cleaning the boiler is a rather dirty task. When choosing an installation site, this should be taken into account: the boiler should be placed as close as possible to the front door so as not to carry dirt through the entire room.

Generally speaking, the use of a solid fuel boiler for heating a private house is an inconvenient solution. Although the purchase of fuel, as a rule, is relatively inexpensive, but if you calculate the time spent, it is not so cheap.

Long burning boilers

Long-burning boilers were developed to increase the interval between fuel fillings. They use two technologies:

- Pyrolysis. Pyrolysis solid fuel boilers have two or three combustion chambers. The fuel filling in them burns with a lack of oxygen. In this mode, a large amount of flue gases are formed, most of which are combustible. Moreover, when burning, they emit much more heat than firewood or the same coal. These gases enter the second chamber, where air is supplied through special openings. Mixing with it, combustible gases ignite, releasing an additional portion of heat.

The principle of operation of the pyrolysis boiler - Top burning mode. In traditional solid fuel boilers, fire spreads from bottom to top. Because of this, most of the bookmark burns, the fuel burns out quickly.During active combustion, the system and the house often overheat, which is very uncomfortable. When using top burning, the fire is kindled only in the upper part of the bookmark. At the same time, only a small part of the firewood burns, which evens out the thermal regime and increases the burning time of the bookmark.

Top burning boiler

How effective are these technologies? Pretty effective. Depending on the design, one bookmark of firewood can burn from 6-8 to 24 hours, and coal - from 10-12 hours to several days. But to obtain such a result, it is necessary to use high quality fuel. Both firewood and coal must be dry. This is the main requirement. When using wet fuel, the boiler may not even enter the smoldering mode, that is, it will not start heating. If you have a woodcutter with a two to three year supply of firewood or a large shed that stores coal, a long-burning boiler for heating a private house is a good choice. Better than normal.

The best inexpensive boilers

Low price does not always mean low quality. If the manufacturer saves on minor details that do not affect the operation of the boiler, such a purchase will be justified.

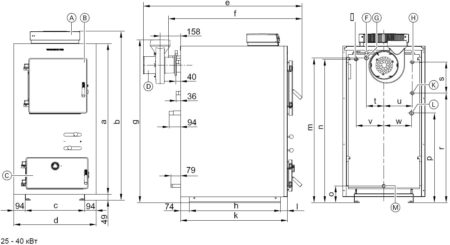

Lemax Premium-30

4.9

★★★★★

editorial score

89%

buyers recommend this product

See review

A 30 kW unit is suitable for economical homeowners for heating an area of \u200b\u200bno more than 250 m2. The set of functions here is minimal, but all the necessary security features are there. The manufacturer abandoned the complex electronic filling, so the boiler is completely non-volatile - just connect it to the gas supply, and everything will work.

The floor model itself is made soundly, the heat exchanger inside is steel. And with an efficiency of 90%, Lemax consumes the minimum amount of blue fuel - no more than 1.75 m3 / h.

Advantages:

- Good build quality;

- Gas control;

- There is protection against overheating;

- Very economical;

- Heat carrier heating up to +90 °С.

Flaws:

Manual control.

To maintain the required temperature in the system connected to Lemax, constant monitoring will be required. Otherwise, there will be no problems with it, and a non-volatile boiler will save a lot of money.

Mora-Top Meteor Plus PK18ST

4.8

★★★★★

editorial score

88%

buyers recommend this product

See review

The Czech company Mora is known for its high-quality gas stoves. But the heating boilers of this brand are no worse. Here, for example, is a Meteor Plus wall-mounted single-circuit unit with a thermal output of up to 19 kW, a built-in expander and a circulation pump. It works flawlessly, consumes no more than 2.16 m3 / h of gas, has the entire minimum set of protective functions and at the same time costs much less than branded counterparts.

Advantages:

- Burner with automatic modulation;

- Low fuel consumption;

- Possibility of external control;

- Quiet operation;

- There is protection against overheating and freezing;

- Calmly transfers pressure drops of gas.

Flaws:

Not the highest efficiency (90%).

To install Mora, you will need a little more space than for compact Italian or German models, and this boiler loses to them in design. But Meteor fulfills its cost completely and is extremely simple to maintain.

What can replace

Today there are many options for heating homes and obtaining warm water, even without the use of a boiler.In particular, these are devices that allow you to effectively and efficiently heat a house. Basically, they work on the energy generated when the fuel burns, turning into heat. Thanks to this, the room is qualitatively filled with heat.

Most often the boiler is replaced:

- steam system powered by mains heating;

- gas or electric system of autonomous type;

- stove heating, for which any fuel is used;

- fireplace;

- autonomous heating system powered by sun or wind;

- air conditioner.

You can choose the heating yourself and combine it, starting with radiators and pipes, ending with a fireplace and a portable heater.

Consider each presented type of heating system used to replace the boiler.

- Stove or fireplace. Both devices heat the room and water by burning wood or coal. To organize such a heating system, you will have to make a stove or buy ready-made communications and install it correctly. As a result, you can get economical and environmentally friendly equipment for heating, cooking and heating water. In this case, the stove can be made of brick or metal and immediately heat adjacent rooms.

- Air conditioner. Not many people realize that the air conditioner heats the air well in the cold season. At the same time, its installation will require a minimum amount of time, unlike the boiler. However, the minus of such equipment is the high cost of maintenance, as well as the heating of a small number of square meters of the room.

- Autonomous heating system with pipe and radiator systems connected to it. It can be obtained from the sun using devices called solar collectors.They are able to convert solar energy into heat for the home. It can also be obtained from the strength of the wind using a wind apparatus, consisting of a turntable with a generator and a battery device, or a wind station.

Important! These devices are suitable for efficient heating of a residential area, which is located away from the gas line. You can get warm even without using the central heating system, pipes with boilers and radiators. This can be achieved by maximum insulation of housing, a change in the usual wardrobe for the home and psychological heating.

This can be achieved by maximum insulation of housing, a change in the usual wardrobe for the home and psychological heating.

You can get warm even without using the central heating system, pipes with boilers and radiators. This can be achieved by maximum insulation of housing, a change in the usual wardrobe for the home and psychological heating.

Maximum home insulation includes wall insulation, adding warm floors to rooms, massive curtains on window openings, etc. Even when the boiler is operating, such nuances retain heat better and allow you to use the system economically.

Changing your wardrobe for the home includes starting to wear knitted sweaters, using blankets while relaxing, using warming capes with heating pads and warm drinks.

Psychological heating includes changing the design of rooms, changing the overall color scheme of rooms to warm shades, adding knitted decor and wood accessories to the room, using aroma candles and photos of warm places. So, you can deceive yourself and make the body psychologically receive heat.

In any case, you can find an option and a way to heat your home without a boiler.Such heating can warm even at sub-zero temperatures outside the window. Using the presented methods, you can heat your home even in the most difficult situation.

The principle of operation of the long-burning boiler

In conventional solid fuel units, one bookmark is enough for 6-7 hours of burning. Accordingly, if the next portion of resources is not added to the furnace, the temperature in the room will immediately begin to decrease. This is due to the fact that the main heat in the room circulates according to the principle of free movement of gas. When heated by the flame, the air rises and exits.

The thermal resource of a long-burning boiler is enough for about 1-2 days from one laying of firewood. Some models can keep warm up to 7 days.

How is this cost-effectiveness and efficiency achieved?

Boiler operation scheme

From a conventional boiler, a TT long-burning boiler is distinguished by the presence of two combustion chambers at once. In the first, the fuel itself burns as standard, and in the second, the gases released during this process.

An important role in this process is played by the timely supply of oxygen, which is provided by the fan.

This principle has been implemented relatively recently. In 2000, the Lithuanian company Stropuva presented this technology for the first time, which immediately gained respect and popularity.

Homemade long-burning boiler

Today, this is the cheapest and most practical way to heat a country house, where gasification is not provided and there are power outages.

Such units operate on the principle of burning top fuel.As a standard, in all furnaces, the firebox is located at the bottom, which allows you to take cold air from the floor, heat it up and lift it up.

The principle of operation of this boiler is somewhat similar to pyrolysis. The main heat here is released not from the combustion of solid fuel, but from the gases released as a result of this process.

The combustion process itself takes place in a closed space. Through a telescopic tube, the released gas enters the second chamber, where it is completely burned and mixed with cold air, which is pumped up by the fan.

TT long-burning boiler (diagram)

This is a continuous process that occurs until the fuel burns out completely. The temperature during such combustion is reached very high - about 1200 degrees.

As mentioned above, this boiler has two chambers: the main one is large and small. The fuel itself is placed in a large chamber. Its volume can reach 500 cubic meters.

Any solid fuel can act as a resource for combustion: sawdust, coal, firewood, pallets.

A constant air supply is carried out by a built-in fan. The advantage of this method is that solid fuel is consumed extremely slowly.

This significantly increases the efficiency of such a heater. Why does firewood burn out so slowly compared to a standard stove?

The bottom line is that only the top layer burns out, since air is blown by a fan from above. Moreover, the fan adds air only after the top layer has completely burned out.

There are many models on the market today that work on the same principle, but, depending on the dimensions, material of execution, additional options, have different efficiency and economy.

Universal TT boilers operate on absolutely any fuel, which will greatly simplify their operation for the owners. A more budget option is a wood-fired TT long-burning boiler. It works exclusively on wood and cannot be used with any other fuel option.

Pellet boilers

Boilers working on pellets are difficult to attribute to any class, because they are usually discussed separately. The fuel for this type of boilers is small pellets made from compressed sawdust. A bunker is made for storing pellets near the boiler. Its size determines the battery life of the equipment. With enough space, the bunker can be made for several tons of fuel. The minimum size is for a couple of buckets, which is enough for a day of work.

Pellet boiler

The pellet heating boiler is equipped with a special burner. Pellets from the bunker are automatically fed into the combustion zone, where they burn almost without residue. Granules of normal quality give only 3-5% of ash. Therefore, cleaning is rarely required - once a week or even once every few weeks. The equipment is fully automated, with a sufficient supply of fuel, you can not visit for weeks.

But even here it was not without drawbacks. The first is the high price of equipment. The second is the exactingness to the quality of the pellets. They should have a low ash content, good calorific value, should not break and crumble. Otherwise, a pellet boiler for heating a private house is a good choice.Its plus is that waste from the woodworking industry is used.

Materials and tools

The following tools and devices are required for work:

- Perforator.

- Pliers.

- Building level.

- Corner.

- Measuring instruments.

- Metal pipe.

- Sheets of steel.

- Pipe for gas supply.

- Doors for the formation of the firebox.

- Refractory brick.

- Fittings.

- Clay.

- Tin for galvanizing.

- Temperature sensor.

- Automation system.

- Ventilation system.

Important components are: deflector, control system and thermostat.

There are two main types of thermostats - wired and wireless. Wired devices are cheaper. It is best to choose models with programmable indicators. This will help maintain a constant temperature.

Automation includes a flame control module, an emergency shutdown system and a traction controller. All of these devices are purchased separately. For the device to function, you will have to install them all.

Conclusions and useful video on the topic

The principle of operation of universal heating equipment in the video:

Rules for choosing a combined boiler in the video:

An example of the operation of a pellet combined heating boiler:

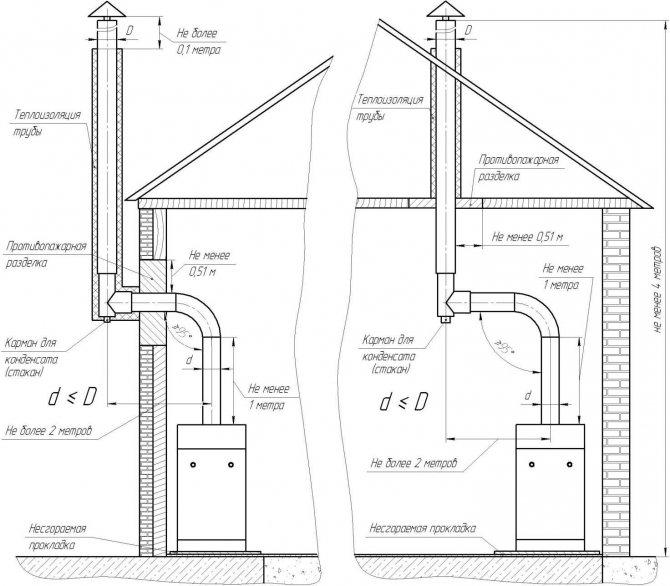

Regardless of the type of equipment chosen, before purchasing it, it is necessary to design a future heat supply system. This includes: pipelines, chimney duct and safety measures during the operation of the heater.

This will ensure the full functioning of the heating system with minimal energy costs.

Looking for an efficient combi boiler for your home? Or do you have experience with these settings? Please leave comments on the article, participate in discussions and share your impressions about the use of heating units.