- How to make a hole in a concrete base

- Choosing pipes for domestic sewage

- Slab foundation and laying of communications

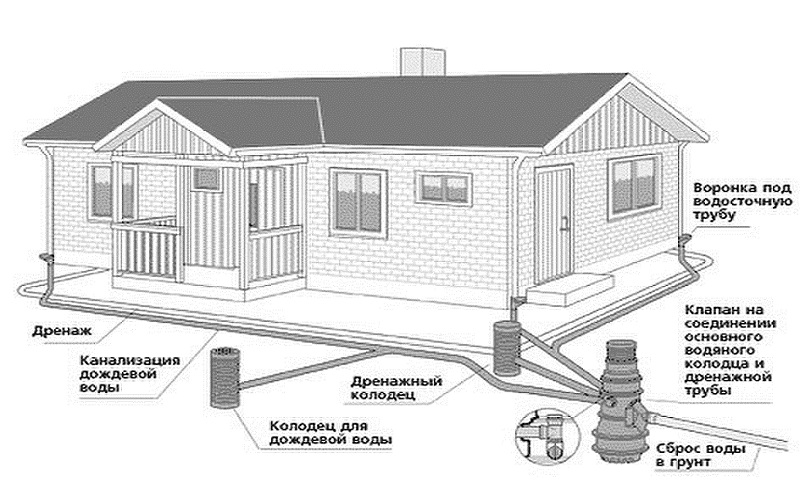

- How to arrange external sewer networks?

- Sewerage scheme for a private house

- Factors that influence the choice of treatment facilities

- Options for the device of the filtering part of the sewer in a private house

- Implementation of pipe installation

- Sewerage scheme

- The procedure for drawing up a plan

- Laying of external sewerage process overview

- Determine the slope of the sewer pipe

- We carry out earthworks

- Laying sewer pipes in a trench

- Commissioning

- Conditions for conducting according to regulatory documents

- What problems can arise during installation?

- Pipe laying

- Excavation work

- Pipe laying and assembly

- Backfilling

- Do I need to insulate the pipeline?

How to make a hole in a concrete base

Any base, and especially slabs, is made of rigid materials. During drilling, cracks may occur. Professionals often argue among themselves about how it is more correct to lay sewer holes in the foundation and have not come to a consensus.

For example, in the base there were no technological places for a drain pipe. How to do it yourself?

During the punching process, various hard and rigid objects may be encountered on the path.Stones are easily destroyed with a jackhammer, rebar is easily drilled with a perforator. If there is no puncher, then punching should be done with a punch. Dust must be removed.

Choosing pipes for domestic sewage

To equip the indoor drainage system, pipes made of cast iron or polymers are used: polyethylene, polypropylene and polyvinyl chloride.

Cast iron products are strong, durable (service life - up to 100 years), resistant to temperature extremes, chemical and mechanical stress and absorb sounds well, but they are expensive, and without special tools and installation skills, it is difficult to install a cast-iron pipeline with your own hands, here you cannot do without the help of specialists .

Independently, the drainage system is often mounted from polymer pipes: polyethylene, polypropylene or polyvinyl chloride. Polymer pipes are easy to install and much cheaper than cast iron pipes, but they have two significant drawbacks: the lack of sound absorption and a shorter service life - up to 50 years.

Each type of plastic has its own characteristics and operating temperature:

| Material | Operating temperature | Peculiarities |

|---|---|---|

| polyethylene | up to 50 degrees | UV resistant |

| polypropylene | up to 80 degrees | easily deformed under mechanical stress |

| polyvinyl chloride | up to 40 degrees, with short-term exposure - up to 80 degrees | stretch with prolonged contact with a hot working environment |

An important factor in the choice of pipes is the throughput. This parameter depends on the diameter of the pipe and the functional purpose of the pipeline section.

| Connected devices | Pipe diameter |

|---|---|

| sink, washing machine, bidet | from 32 mm |

| shower, bathtub, kitchen sink | from 50 mm |

| two or more devices at the same time | 0t 75 mm |

| toilet, stand | from 110 mm |

Slab foundation and laying of communications

This type of foundation requires very precise calculations, even at the very beginning of the project.

After pouring such a foundation with errors, it will be impossible to lay the necessary communications. Therefore, the trench is dug first. All communications and sewer pipes, dressed in special protective sleeves, fit into it.

In a slab foundation, the sleeve plays a very important role. It protects the monolithic slab from high pressure, and also facilitates the process of replacing a damaged pipe section. If the sleeve is missing, it is simply impossible to replace the pipe in such a foundation. The pipe can also be damaged at the time of pouring the foundation.

How to arrange external sewer networks?

Many people in the modern world are concerned about this issue. After all, the installation of external sewerage networks is a very important point that will ensure a comfortable supply of water supply to your home in the future. Modern companies provide such services:

- Laying of wireless sewer pipelines;

- Dismantling and installation of all valves;

- Equipment and maintenance of sewer networks;

- Installation of drain wells and sewers;

- Sewer pipeline testing;

- Cleaning of all cavities.

In the event that you do not trust the experts, you can do the installation yourself. In a private or country house, there is no way to connect to the city's centralized sewerage system. If you periodically live in your house, then in this case you can do it according to a more simplified scheme.

It is necessary to install a drain pipe, which must be laid at a slope and dig a cesspool - these actions will be quite enough. But, if the house is intended for permanent residence, then it would be advisable to arrange a septic tank for settling water in complexes with filtering wells.

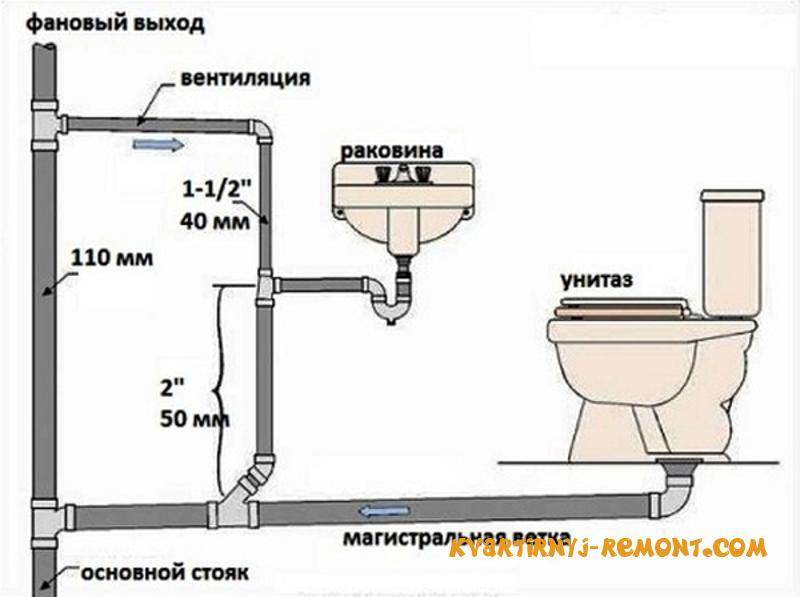

Sewerage scheme for a private house

The riser is a vertical channel made of plastic or cast iron. Its design does not depend on the type of building and its parameters. She is always the same. On the sides make inputs for plumbing fixtures. From below, through the basement, the vertical pipeline is connected to the treatment plant installed on the site. Their composition depends on many factors.

Factors that influence the choice of treatment facilities

- Waste water volume.

- The nature of the pollution.

- Mode of residence (permanent or temporary).

- Soil type.

- Features of the terrain.

- The level of occurrence of groundwater (GWL).

- Depth of ground freezing.

- local government requirements.

To determine the composition of prefabricated elements, you need to think about their design, reliability, features of operation and costs.

At the beginning, mechanical filtration from suspended particles is carried out. For this, gratings, sieves, grease traps are used, followed by pits, septic tanks and settling tanks. Then the sewage, free from suspensions, is subjected to biological treatment. It allows you to get rid of organic contaminants due to their decomposition with the help of natural microorganisms. They "eat" about a quarter of the organic matter and decompose almost the entire remaining part with the formation of water, gases and solid sediment.The released gases (carbon dioxide, nitrogen, hydrogen sulfide, ammonia, methane, hydrogen) not only give rise to odors known to everyone, but are also explosive. Therefore, devices and structures must be provided with reliable ventilation and located as far as possible from residential buildings.

Instagram @kopaemkolodec_dmd

Instagram @vis_stroi_service

There are several ways to organize a horizontal filtering part located underground.

Options for the device of the filtering part of the sewer in a private house

- The central system - the sewer pipe of the site is brought to a common channel. All houses in the district or village are connected to it.

- Accumulative - they dig a pit on the territory and equip a cesspool. If the GWL is less than 2 m or the cesspool is located near the house, the pit must be waterproofed. The walls and bottom are made of reinforced concrete rings, bricks, plastic and metal. Waste is removed by a sewage machine.

- Draining septic tank - instead of the bottom, a drainage pillow is poured. Purified water seeps through it and goes into the ground.

- Filters - use from one to four containers.

Consider the organization and installation of a vertical pipeline and underground sedimentation tanks in more detail. Let's start with the vertical part.

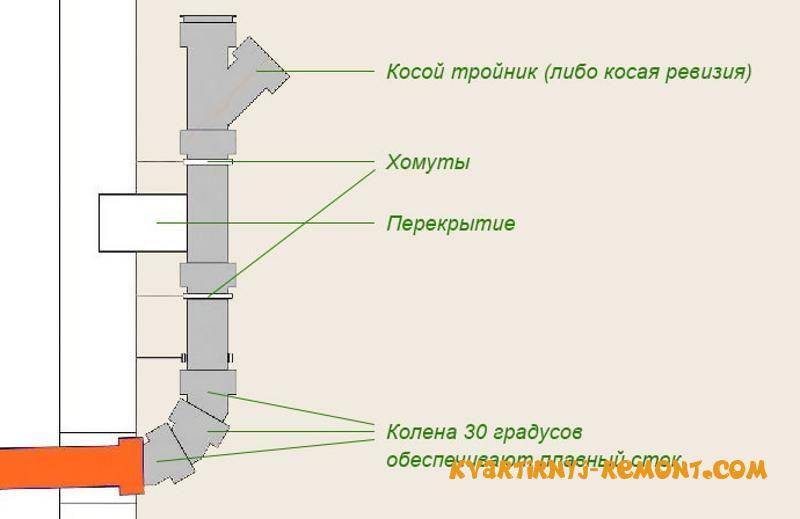

Implementation of pipe installation

How to sewer properly? Do-it-yourself sewerage in an apartment must be carried out in accordance with the rules. In order for the wiring of plumbing in the bathrooms to be correct and of high quality, you should remember the recommendations:

- during the installation of sewerage networks, the most difficult and responsible process is the installation of a toilet bowl.This product is connected to the sewerage using pipes made of plastic material, the parameters of which are 110 mm in diameter;

- then you can make a smooth transition to pipe elements with a diameter size of 50 mm;

- do not immediately install an adapter on such a diameter size. A suitable option would be to use a small bridge with a diameter of 100 mm, and only then you can switch to a diameter size of 50 mm;

- drain and slope are mounted on the same level. Joints are firmly fixed;

- it is undesirable to use adapters with a right angle. A suitable option would be to use 2 angles of 45 degrees;

- usually wiring in bathrooms and connecting the bathroom to the sewer does not require pipe welding;

- after that, the sewage in the bathroom is completely assembled - the pipes are inserted one into the other through the gaskets, which ensures a high level of tightness;

- for good fixation of hot and cold water supply networks, silicone sealant can be used. Thanks to this tool, a strong fixation of all parts of the sewer is ensured. In addition, it will not burst during launch and will be produced in normal mode;

- at the end, a tie-in is made into the sewer and a connection to the sewer.

Sewerage scheme

Before starting work, draw a diagram of the laying of pipes and their connections inside the house. It will be easier if the necessary premises are nearby. Since the scheme for each system is individual, work out all the nuances of the markup. Although in the end you can do as your heart desires. The main thing is that it works, there is enough money and they have not deviated from the norms.

When developing a sewer project, do not forget about the collector pipe. Knowing its location, you can design the wiring of the remaining parts of the sewer system.

The procedure for drawing up a plan

Drawing up a plan for conducting sewer pipes in a private house is a very important stage. As the plan is drawn up, so will the entire purification system serve you. Step by step:

After the plan-scheme for conducting the internal sewerage system is made, you can proceed directly to the pipes. However, there are features that should not be neglected:

- Waste water from the toilet room, namely, from the toilet bowl, must exit through a pipe with a diameter of 10-11 centimeters. Moreover, it is desirable that their length be at least a meter.

- The remaining pipes come from the bathroom and kitchen with a diameter of 50 millimeters. They are prepared, like a PVC or PP pipe for a riser. In my opinion, there is no difference in materials, since they lose their properties when heated above 100 degrees Celsius, and such temperatures are not observed in sewer systems.

- Blockages usually form at 90 degree turns. So consider purchasing some 45 degree plastic elbows to avoid sewer clogs.

- Until now, some people use cast iron, steel, and God still knows what impractical Soviet pipes. But in vain. PVC and polypropylene pipes are much more reliable, durable, and, most importantly, are inexpensive. Moreover, the implementation of a sewerage system with such pipes is much simplified both in a private house and in an apartment building.

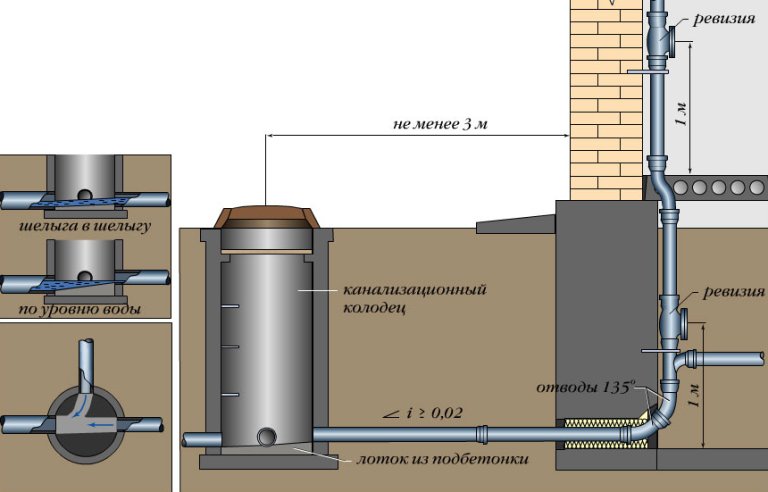

Laying of external sewerage process overview

The very procedure for laying a sewer network of any type involves the consistent implementation of the following work plan:

Choosing sewer pipes for laying in the ground

Plastic sewer pipes

At this stage, you need to choose the diameter and length of the pipe.Everything is simple with the length - it is equal to the distance from the fan outlet to the input to the collector or septic tank. The diameter of the pipe is selected based on the estimated volume of effluents. However, in reality, you will have to choose between 110 millimeters and 150 (160) millimeters. These are typical sizes of household sewer pipes. If you plan to build an industrial highway, then the diameter will start from 400 millimeters.

In addition, you need to select the type of "pipe" material. Usually it is polyvinyl chloride (smooth pipes) or polypropylene (corrugated pipes). PVC products are less durable, but will cost less than PP pipes.

Determine the slope of the sewer pipe

Such a slope guarantees the flow of liquid through the pipeline under the influence of gravitational forces. That is, the system will divert effluents in a non-pressure mode.

We carry out earthworks

The depth of the trench for the sewer should correspond to the level of soil freezing. Otherwise, the system will freeze in the winter.

Laying sewer pipes in the ground

Therefore, the input to the sewer main (outlet from the fan pipe) is immersed in the ground by 1.2-1.5 meters. The withdrawal depth is determined based on a 2-centimeter slope (per linear meter of the pipeline).

As a result, at this stage, a trench is being dug, the bottom of which goes to the catchment point under a slope. Moreover, the width of the trench is 50-100 millimeters. And its walls, after deepening to the mark of one meter, are reinforced with shields and struts. The selected soil is stored in a special area, it will come in handy for filling the trench after the installation of the pipeline.

sewer well

Long sections of the sewer line are equipped with wells, the walls of which are reinforced with concrete rings. The bottom of the well coincides with the depth of the trench or falls below this mark (the missing part of the soil can be poured).

At the same stage, a pit is dug for a septic tank or a waste storage bin. The selected soil is removed from the site and disposed of. It will not be used for bedding. After all, the selected volume will fill the design of a septic tank or bunker.

In addition, at the same stage, you can start laying trenches for the drainage system of an autonomous sewer.

Laying sewer pipes in a trench

Laying sewer pipes

The installation of the pipeline is carried out in measured segments (4, 6 or 12 meters each), which are connected into a socket. Moreover, it is better to lay a layer of sand at the bottom of the trench, 10-15 centimeters thick, it will save the line from possible ground vibrations provoked by heaving deformation.

Laying is carried out with bells upwards, that is, the bell should be the first on the flow path, and the smooth end should be located under a slope. Therefore, the assembly is carried out from the outlet of the fan pipe towards the septic tank.

After completing the assembly, the pipe is covered with coarse sand, after which the trench is filled with selected soil, leaving a tubercle on the surface, which will “sag” next spring, after the soil “settles down”. The rest of the soil is disposed of.

Commissioning

Before backfilling the trench, it would be a good idea to check the tightness of the joints and the throughput of the pipeline. To do this, you can wrap the socket sections with newspaper and drain several buckets of water into the toilet.

If there are no wet spots on the newspapers, the system functions without compromising the tightness of the pipeline.Well, the throughput can be estimated by comparing the volumes of "introduced" and "discharged" fluid. If the same bucket of water “reached” the exit, then there are no stagnations in the sewer, and you will not have problems with system maintenance.

Conditions for conducting according to regulatory documents

The laying of any pipeline, whether it be polypropylene or steel, is determined by the standards. It is SNiP that regulate many technical issues that allow you to perform all work efficiently, ensuring safety. For laying polypropylene pipes, the following requirements must be met:

Scheme of the advantages of polypropylene pipes over other materials

- Be sure to take into account the freezing point of the soil. Usually it is at a level of 1.4 meters, so if the pipeline is at a lower level, then in winter the water in it will simply freeze, and it will not be possible to use the pipe. Therefore, during installation, it is necessary to accurately calculate such moments, in the future it will only benefit.

- The laying of pipes largely depends on what buildings are located on the site, whether there are roads and highways nearby, laid communication and other engineering networks. If you are not sure where exactly you can lay the pipeline, it is better to contact specialized construction companies.

- When laying underground, we also take into account the features of the relief, soil, in some cases it is necessary to protect the pipe with the help of special casings.

The polypropylene pipeline is laid subject to the following steps:

- First you have to prepare a trench for laying, which should be larger than the diameter of the pipe. So, for 110 mm pipes, you will need a trench with a width of 600 mm.The minimum distance between the pipe wall and the trench should be 20 cm. The depth should be 50 cm more.

- The bottom is sprinkled with sand with a cushion thickness of approximately 50-100 mm, after which the sand is compacted.

- The laying starts from the building; when installing sewer pipes, the socket should look at the end of the pipe that goes out;

- To connect the individual elements, a special lubricant is used.

- When laying sewers, it must be remembered that a slope of 2 cm must be observed for each m of the route.

- After laying the pipeline is covered with sand, it is compacted only from the sides. If necessary, before this, the pipe is wrapped with a heat-insulating layer;

- At the very end, polypropylene pipes are connected to a common highway, a treatment plant, and so on. This should be done using polypropylene solder.

What problems can arise during installation?

When laying polypropylene pipes underground, some problems may arise:

- the structure of the soil does not allow digging at the required depth;

- in winter, the soil freezes heavily, which can cause damage to pipes;

- there is a building on the site that cannot be bypassed.

In this case, there are several ways to solve these problems:

- If the soil is too loose or hard, it is recommended to make a puncture, in which a steel pipe is first laid, and a polypropylene pipeline is already inserted into its cavity.

- When the soil freezes, it is recommended to lay a heating cable throughout the entire route. This requires significant costs, the costs during the winter period may be higher than planned, but in any case, this option is cheaper than the constant repair of burst pipes.

- When there is a building or object on the route that cannot be damaged, it is recommended to perform trenchless laying methods, that is, a puncture. In this case, it is possible not only to lay the pipeline, but also to protect it with a steel casing. When laying such networks, it is necessary to carefully look at the layout of communications on the site so as not to damage the existing ones.

Pipe laying

Removal of the sewer pipe from the house

The pipe laying process can be divided into three stages:

- Excavation.

- Pipeline assembly.

- Backfilling.

Excavation work

Before laying sewer pipes, it is necessary to properly prepare the trenches. Rules for excavation:

- Trenches can be dug by hand or with earthmoving equipment.

- The width of the trench should allow the installer to work with the pipe from the bottom.

Advice! If the pipes have a diameter of 110 mm, then the width of the trench should be 60 cm.

Outdoor pipes laid in trenches

- It is more difficult to determine what is the optimal depth for laying sewer pipes. According to the regulations, it should exceed the depth of soil freezing in the area by half a meter. However, this condition is not always met in practice. If the pipes are laid at a shallower depth, then care should be taken to insulate them.

- Trenches need to be dug with a certain slope. As a rule, a slope of 2 cm per meter of pipeline is laid in the project.

- When digging trenches, they are made deeper than the designed pipe laying depth by 10 cm. This depth will be used to create a shock-absorbing cushion.

- The bottom of the dug trench should be well rammed, if there are large boulders or frozen clods of earth on it, then they will need to be removed, the resulting holes should be covered with earth and tamped there.

- Sand or fine gravel is poured at the bottom of the trenches. Sealing the pad along the entire length of the trench is not required. But in the places of the planned installation of revision wells, the poured sand will need to be compacted at a distance of two meters in each direction from the installation site of the well.

- In those places where the sockets of the pipes will be located, pits are arranged.

Pipe laying and assembly

Laying external sewer pipes in trenches

Consider the basic rules for laying sewer pipes:

- Installation of the pipeline begins from the place where the pipe exits the foundation of the house.

- Pipes should be laid along the trench, while the pipe sockets should be directed in the direction opposite to the flow of drains.

- We carry out pipe connections. To do this, you need to clean the bell well and make sure that the rubber o-ring is installed in it. The smooth end of the pipe, which will be inserted into the socket, is also cleaned no less thoroughly. A preliminary measurement is made of the entry of the pipe into the socket until it stops, putting a mark on the smooth pipe. To facilitate the introduction of the pipe into the socket, silicone grease is applied to the smooth end. If there is no lubrication, then you can use liquid soap or dishwashing liquid. The pipe is inserted into the socket, and in order to compensate for the linear deformations of the pipeline, the pipe is not inserted all the way, but a centimeter gap is left (when inserting the pipe, they are guided by the mark set earlier).

- If it is necessary to turn the pipeline, bends with an angle of 15 or 30 must be used.90 degree elbows are not allowed.

- In addition, the technology for laying sewer pipes provides for the installation of revision wells. These devices are necessary to control the operation of the pipeline and carry out cleaning in the event of a blockage.

- If it is provided for by the project, then the pipes are insulated. For this purpose, it is recommended to use a heater based on foamed polyethylene.

Backfilling

Preparing to backfill pipes in trenches

- After the pipeline has been assembled and the slope of the pipes has been checked again, it will be possible to proceed with backfilling.

- The first 10-15 cm of the backfill height is recommended to be filled with sand. In this case, it is necessary to carefully compact the sand along the edges of the pipe, but it is strictly forbidden to ram the backfill on the pipe itself.

- Further, the pipeline can be covered with ordinary soil, which was taken out when digging trenches. You just need to make sure that there are no large stones in the ground.

The process of laying pipes in trenches is a simple job, but it requires accuracy and patience.

It is very important to follow the rules for preparing trenches and installing the pipeline, only in this case, the work carried out will be effective.

Do I need to insulate the pipeline?

The outer part of the sewer line in most cases is laid by a hidden method and is underground.

In warm climates, natural shelter is used. The pipeline is located below the freezing level of the soil, the entire system is simply covered with earth, which serves as a natural insulation.

But in the main part of the Russian territories, this method of insulation is not suitable.For trouble-free operation of drain communications in winter, when laying main sewer lines at a depth of more than 70 cm, care must be taken to insulate the outer part of the sewer.