- Types of underfloor heating and their scope

- water floor

- Electric floor heating

- Drawing up an installation diagram

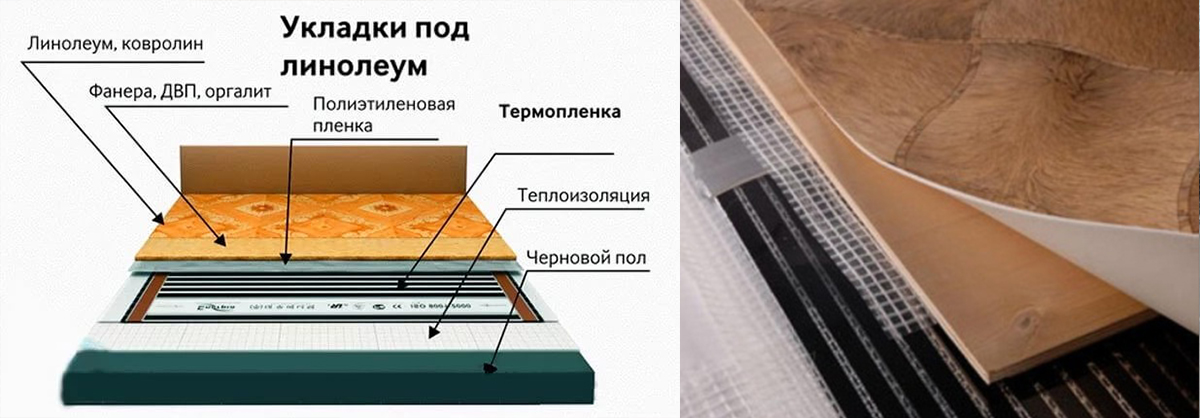

- Laying underfloor heating under linoleum

- Stages of installation of a warm floor under linoleum

- The principle of operation of the infrared floor

- Is it possible to put linoleum on a warm floor

- Compatibility features of linoleum and underfloor heating

- Electric floor heating device

- Choosing linoleum for underfloor heating?

- How to lay linoleum on a warm floor?

- Recommendations and possible errors

- Floor preparation, calculation of materials and components

- How to lay a film electric floor

- Benefits of an innovative electric underfloor heating system

- Recommendations and possible errors

- Conclusions and useful video on the topic

- Outcome

Types of underfloor heating and their scope

According to many people, a warm floor is of one type, but this is not true. Today there are a lot of them and each of them is adapted to certain conditions. But that's not all, as warm floors differ in the way they are laid. Warm floors are water and electric.

water floor

The water floor is heated with a heat carrier, it can be water or a special liquid. You can heat this coolant using your home heating system.

Water heated floor

By and large, a water-heated floor is a pipe system laid under the floor covering. It is best to use a metal-plastic pipe for these purposes, always one-piece, since any connection will sooner or later turn into a leak, and when it is under the floor it will cause a lot of problems, so it is better that the pipe is solid, and not from pieces.

Such a system will cost less than an electric system, since by and large you only need a pipe. In terms of installation complexity, such a system is not inferior to the electric one. Very often, this type of underfloor heating can replace the heating system and the house will be warm, although when I heard it for the first time, it seemed to me to be nonsense, but it turns out that it is not.

If we consider laying a warm floor under linoleum, I would refuse such an undertaking, this is my opinion, and I do not impose it on anyone, but below I will describe how installation can be done.

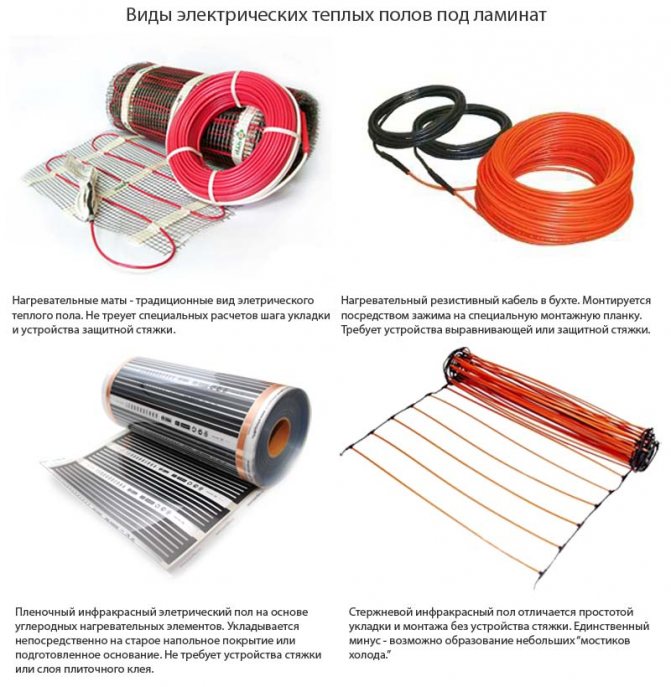

Electric floor heating

Electric underfloor heating has several varieties. Most often, this type is used for a concrete base, but there are types for a wooden coating. Actually, the system itself does not matter where it is laid, but not every surface can be laid with any kind.

Electric floor heating

The first type is the heating cable. The heating cable, in turn, is also divided into 2 types: simple and self-regulating. The difference between them is that for a simple one, the heating is controlled by a special thermostat. Actually, this type is more suitable for a warm floor.

But the self-regulating wire is more interesting, although not difficult.There are two conductive wires in it and they are separated from each other by a special heating matrix, which is able to change resistance with temperature. So it turns out that the colder the surface it comes into contact with, the more it heats up.

In the air, such a cable will not heat up. Most often used to protect water pipes from freezing. There is a kind of underfloor heating, where a simple heating wire is laid on a fiberglass mesh. When laying such a mat, it is rolled out and poured with a screed. Well, okay, let's go directly to the type that interests us.

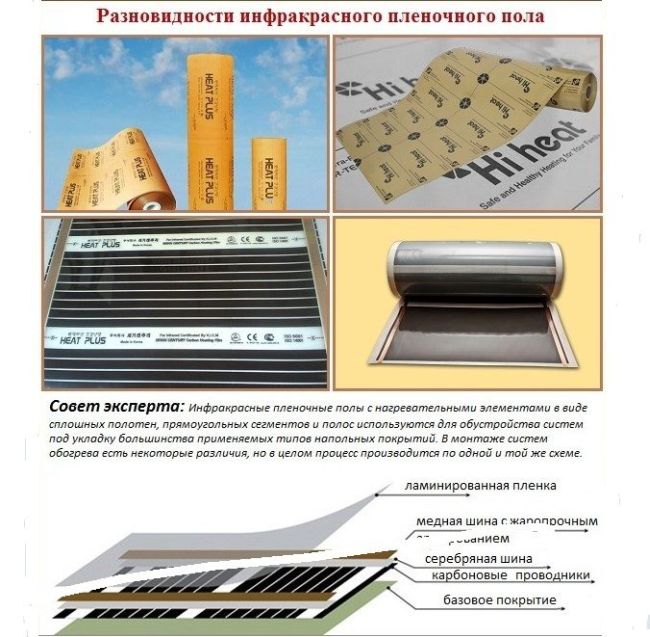

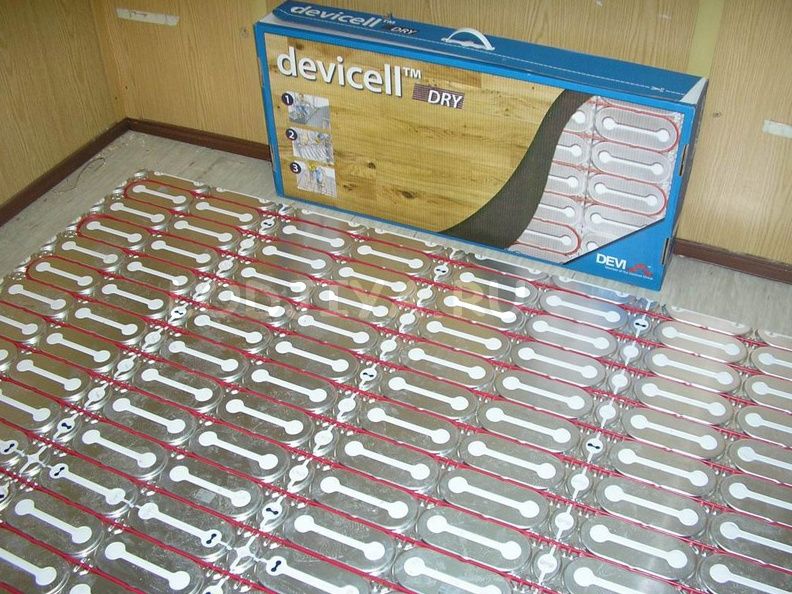

The most suitable underfloor heating under linoleum on a wooden floor is an infrared heating system. It consists in the fact that such a system emits infrared rays that heat objects, and not air, thereby reducing heat loss, because heat is not wasted.

infrared film

This system consists of carbon plates interconnected by a copper bus and laminated with a special film. They look like a roll about 50 centimeters wide, very thin like 2-3 sheets of paper. This type of heating is ideal for linoleum. It is sold both by the footage and in whole pieces, designed for a certain area.

You can cut the infrared floor along special cut lines applied by the manufacturer, these lines go every 20-30 centimeters. The kit includes special terminals for connecting to electricity, as well as bitumen-based insulating material. I will tell you about the laying technology a little lower.

Drawing up an installation diagram

The film underfloor heating under linoleum is not laid over the entire area of the room, but only in its open areas.It is impossible to put a heating film under furniture and household appliances. It can be damaged and torn there. Plus, in such areas, local overheating of the coating and elements of the infrared system itself will occur. To don't make mistakes, it is necessary to draw up a plan of the premises in advance, indicating on it all such places.

IR thermal film for floor heating is placed:

- exclusively in the middle of the room where people will walk;

- indented from the walls 5–10 cm;

- at a distance of 30–50 cm from radiators, fireplaces and stoves with an oven;

- stripes not overlapping and with a cut only across in the places indicated on the film.

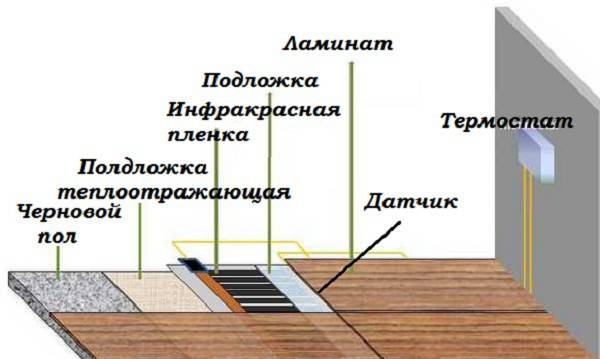

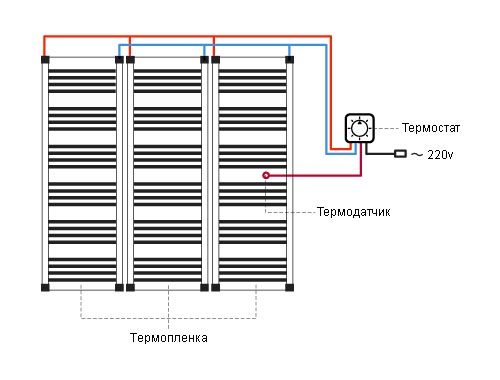

All these nuances of installation must be foreseen when drawing up a plan. Also on it, you should immediately determine the installation location of the thermostat (thermostat) and the temperature sensor for the infrared floor heating. Without these two elements, it is not recommended to lay the floor heating system in question.

Varieties of IR sex

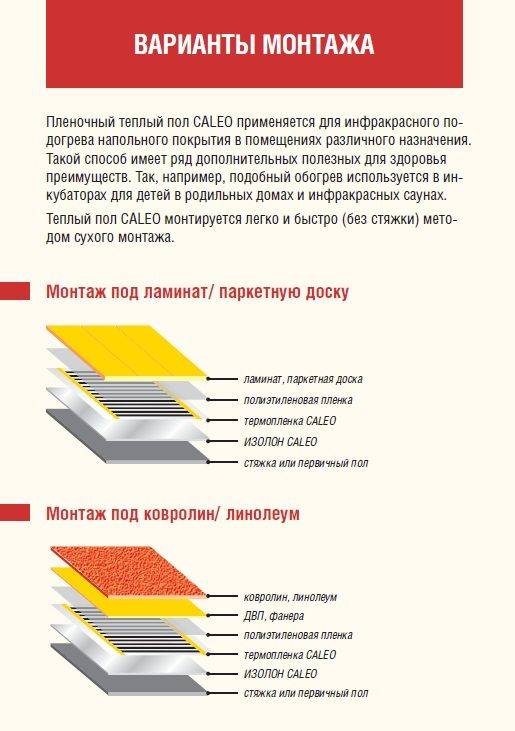

Laying underfloor heating under linoleum

Underfloor heating under linoleum: installation diagram

Regardless of the source of heating - water or electric, there are general rules for laying a warm floor under linoleum. Heating elements are laid on an area free from plumbing and bulky items. The heating system is mounted with thermostats to prevent the floor heating temperature from exceeding 28 degrees. Underfloor heating electric under linoleum can be performed in two ways: with a screed device under linoleum and laying hard slabs under linoleum, that is, without a “wet” process. Under an electric heater, a heat-insulating material must be laid that reflects heat and directs it upwards.It is desirable to use the material rolled with a coating of metallized lavsan film or polypropylene

Attention! Do not use material that has a reflective aluminum foil coating. Under linoleum, experts recommend using a lining with a soft layer, for example, isolon 3-5 mm thick

Stages of installation of a warm floor under linoleum

- Surface preparation - remove all unnecessary and level out irregularities.

- Thermal insulation - so that the floor directs heat only upwards, rolled thermal insulation with a reflective coating should be spread under the heating element

- Laying an electric heating film - mark the film, cut it along lines where there is no graphite layer, lay it out with a 10 cm indent from the wall, avoid stripes overlapping

- Connection of heating elements - connection of a warm floor is carried out through a thermostat, the maximum area of connection to a thermostat is 15 m2

- Installation of protective material - according to its characteristics, linoleum belongs to the type of soft materials and under external influences it bends, can damage the infrared film, therefore, rigid sheets of glass magnesite or gypsum fiber sheets are laid on top of the heating and vapor barrier film

- Laying linoleum - PVC canvases cut and laid out around the room should be in a free position for a day, then the canvases are fastened with double-sided tape, and if gaps form between the canvases, then they should be filled with special glue

Heated electric floors under linoleum

The principle of operation of the infrared floor

The combination of combustible polymer linoleum and electric floor heating seems unacceptable at first glance.However, the risk of a short circuit and fire in an infrared film heating system has been reduced by manufacturers to almost zero. It is only necessary to follow the instructions when assembling it, doing everything according to the rules. At the same time, the linoleum coating itself can be found today with fireproof characteristics "G1" + "B1".

The work of the infrared floor is based on the emission of infrared waves by carbon heating elements. These rays first heat the surfaces of various objects in the room. And already from the furniture and walls, heat spreads around the room, creating comfortable conditions in it.

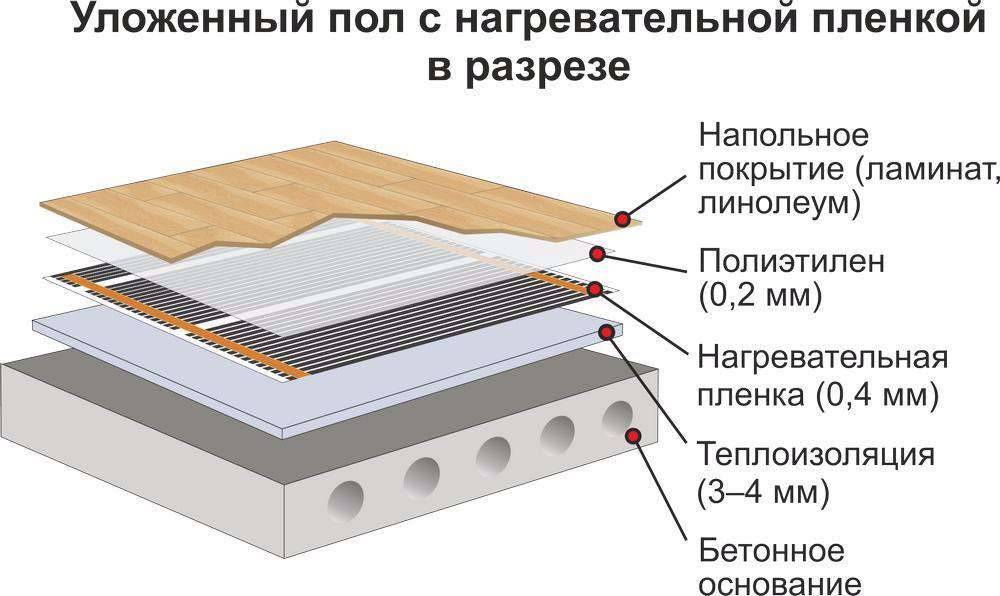

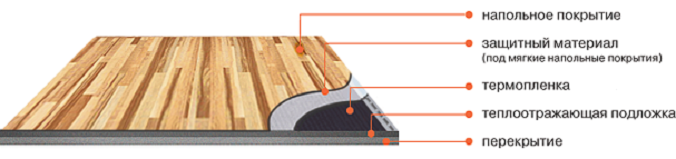

Necessary layers for laying underfloor heating

Among the advantages of film underfloor heating are:

- instantaneous heat dissipation after switching on;

- installation according to dry technology without pouring concrete screed;

- service life of 50 years;

- silent operation;

- ease of installation work;

- safety of IR radiation for humans.

Electricity is converted into infrared rays by a thermal film with an efficiency of 90-100%. And unlike a water-heated floor, a film analogue cannot cause a flood, because there is no water in it.

On top of it, it is allowed to lay both linoleum and laminate, tile or carpet. Moreover, it takes only a couple of hours to lay such floor heating in a room up to 20 m2 on a prepared base.

The disadvantages of this heating system are as follows:

- high price of IR film;

- high electricity bills;

- dependence of heating on the presence of voltage in the mains.

With a small active area of the heating floor powered by electricity, the power it consumes is within 1-3 kW. For work, it will be enough for him to have a regular outlet.But with higher consumption for thermal film, you will have to lay an additional cable from the electrical panel and install the appropriate RCD there, which costs money.

Underfloor heating design

And whether the required kilowatts are available is a big question. Apartments and private houses are designed for a very specific energy consumption, which cannot be exceeded. Before purchasing infrared floors for linoleum, you must first clarify the moment about the very possibility of their connection to the existing network. If there is no capacity, then you will have to look for another option for arranging heating.

Is it possible to put linoleum on a warm floor

However, not all types of underfloor heating can be laid under linoleum. A water floor is exactly the type for which another material should be used as a topcoat.

In recent years, linoleum has been increasingly used together with an infrared film floor, since the rolled synthetic material is compatible with the electric option, and only with a film one.

But electric heating is also not used of all types. To lay linoleum on a warm floor, infrared film is ideal. With this design, a screed is not needed, which facilitates installation and reduces the heat consumption spent on heating the screed itself.

This is interesting: How to fill the floor in the garage with concrete - we convey all the nuances

Compatibility features of linoleum and underfloor heating

Under linoleum, due to its physical properties, not every material that generates heat can be placed. It is more similar in properties to rubber, which easily changes properties with increasing temperature. Factors that negatively affect the laying of a heat-generating layer under linoleum are:

- The presence of an additional insulating pad on some types of linoleum, which makes it pointless to use it as a covering for a warm floor.

- Linoleum without an insulating layer, but reacting to an increase in temperature by deformation, at which it becomes unusable.

- The use of low-quality linoleum, which, when heated, begins to emit toxic fumes.

Conditions conducive to the use of linoleum as a coating for underfloor heating:

- The use of linoleum, made of pure and natural material that does not emit harmful substances, and does not have insulation.

- The use of a layer that separates linoleum from direct contact with a hot surface. For this, in some cases, fiberboard is used.

- Use as a heating element only the kind that will be effective.

It is not possible to use a warm floor with linoleum as a heating system, since the maximum temperature of its heating will not exceed 26 ° C.

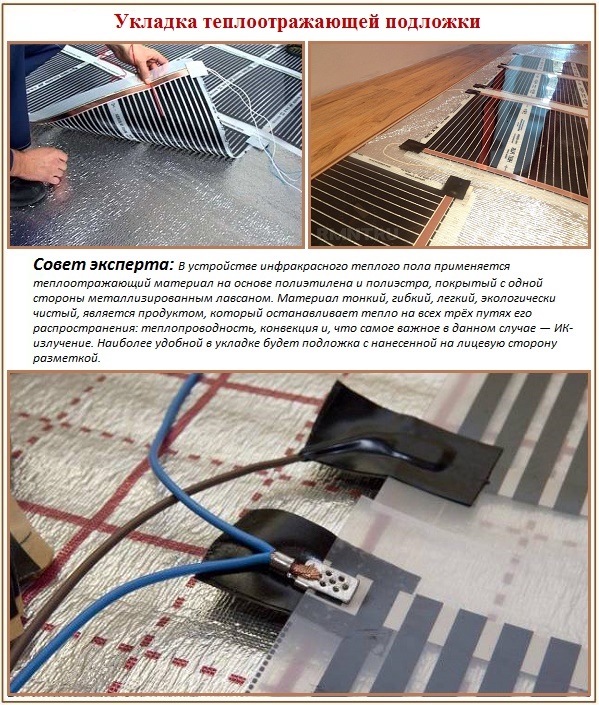

Electric floor heating device

When laying film electric heating on a concrete subfloor, it is necessary to carefully prepare the base. The screed should be completely cleaned of debris and dust and made as even as possible.

After that, a special film with heat-reflecting properties is laid. This thermal insulation is attached to the base with adhesive tape.

Next, the pre-prepared heating elements themselves are laid on top of it.

In this case, it should be ensured that the contacts of the individual strips do not come into contact with each other.

To prevent further displacement of the heating strips, they should be attached to the draft base and this can be done with adhesive tape or a stapler.

At the final stage of laying, it is necessary to carefully check the reliability of fastening of all supply wires and insulation.

After the installation of the infrared film is completed, it is necessary to install a special control relay and check the floor in operation.

Next, a polyethylene film is laid over the electric strips of the warm floor, which should completely cover the surface of the base.

Electric underfloor heating should never be filled with concrete screed.

On top of the film, it is recommended to lay sheets of plywood or chipboard, pre-treated with special protective compounds. Only after this is the laying of linoleum.

As in the case of a water floor, in order for the material substrate to take the correct shape, it is necessary to turn on the heating for two days.

Only after the linoleum substrate takes the form of a base, the material is finally fixed in place.

You can learn more about how to install an electric heated floor with your own hands by watching the video below.

Video:

Underfloor heating makes it possible to create the most optimal temperature conditions in the house. It is allowed to lay linoleum on top of it, however, for this it is necessary to take into account the specifics of this material.

In any case, subject to certain rules and technology for installing a warm floor, all the work can be done by hand in the shortest possible time.

Choosing linoleum for underfloor heating?

What do you need to know and how to choose heat resistant linoleum? First of all, you need to know that for the installation of an electric floor, you need to consider the following types of coverage:

- alkyd;

- rubber;

- PVC, etc.

Important: linoleum with a heat and sound insulating base significantly reduces heat transfer

One of the best and budget options for underfloor heating is polyvinyl chloride multilayer linoleum (PVC), which is not only rich in a variety of color shades, but is also suitable for active use in apartments and residential premises.

If your choice fell on PVC linoleum, then pay attention to the maximum surface heating temperature and the power of the installed electric floor. Professionals do not advise creating heating conditions of more than 26 degrees, with a heating power of 65 W / m2 and above.

Disadvantages of PVC:

- at high temperature, large shrinkage and deformation of the coating may occur;

- At the beginning of operation, there is an unpleasant smell of the material, which disappears over time.

Important: for a healthy and comfortable thermoregulation of a person in a room, doctors advise not to heat the floor above 24 degrees!

If you plan to make the most of the electric underfloor heating, you can pay attention to vinyl-coated linoleum. It is able to withstand a higher degree of heat.

Important: in Europe, they are skeptical about vinyl coatings, this is due to studies of the level of fire safety of the material and the possible development of allergic diseases in people who are constantly indoors

The choice is yours.

Important: in Europe, they are skeptical about vinyl coatings, this is due to studies of the level of fire safety of the material and the possible development of allergic diseases in people who are constantly indoors. The choice is yours.

A worthy option for floor insulation is another material - marmoleum. Unlike synthetic linoleum, this coating is made from natural ingredients. Marmoleum contains cork, wood flour, jute and chalk, natural dyes and oils, the technology is constantly being improved. Some characteristics make you look at it in more detail:

- high wear resistance;

- environmental friendliness;

- antibacterial properties of the material do not allow microorganisms to multiply on the coating;

- during installation, heat and noise insulation is not required;

- resistance to high temperatures and physical influences.

How to lay linoleum on a warm floor?

Laying linoleum is not a difficult task. Since the flooring comes in rolls, it must first be leveled. To do this, linoleum is spread on the surface without fixing and left for several days to level it. In the case of underfloor heating, it is recommended to turn on the heating.

The floor covering will become warm and the leveling process will go faster. It is recommended to use plywood or fiberboard as a base for linoleum. When fixing the base, make sure that the fastener does not damage the IR film located below.When using a cable floor, the risk of such damage is much less.

To fix the linoleum, which is laid over the warm floor, it is better to use a special mastic, this will make the heating of the coating more uniform.

After that, the linoleum must be laid on the base and secured using a special double-sided tape or glue. It is better to lay a laminate on a warm floor with glue. Then the coating will fit tighter, which contributes to uniform heating. After that, it remains to install the skirting boards, under which the underfloor heating wires will be hidden, and test the system again to set the appropriate temperature.

Work on the installation of underfloor heating and laying linoleum is not particularly difficult

It is important to make a good plan, take into account all the requirements of the technology and perform the work as best as possible. Following these simple rules will allow you to get a comfortable and reliable underfloor heating.

Number of blocks: 17 | Total characters: 28246

Number of donors used: 4

Information for each donor:

Recommendations and possible errors

The cake from the infrared floor and linoleum should have five layers from the rough base:

- Isolon (heat-reflecting substrate).

- Infrared thermal film.

- Polyethylene film (waterproofing).

- Flooring made of wood or gypsum-fiber boards 3–5 mm thick.

- Linoleum finish.

Without a heat-reflecting substrate, the high energy efficiency of an IR underfloor heating system will be in serious question. And without polyethylene and protective flooring, sooner or later it will fail. The plywood layer takes on part of the thermal radiation, but it is impossible without it.

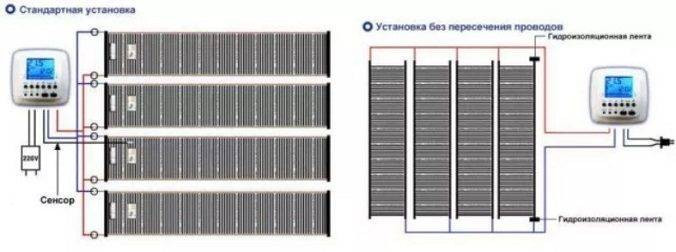

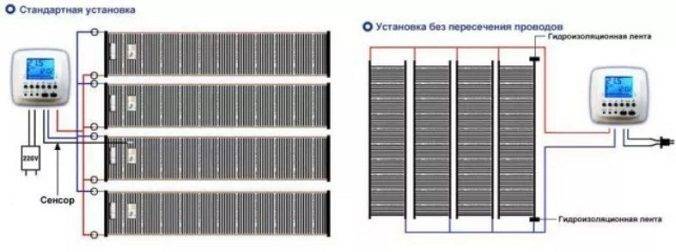

Wiring diagrams

Linoleum on top of the infrared floor heating should be placed in the form of natural marmoleum or vinyl PVC. In this case, its marking should have a special icon. And it should go without a warming underlayer from below. Choosing an air conditioner will require even more thought. Everything is easier with the finish here. The main thing is not to take the colloxylin or rubber version, which, when heated, will begin to release harmful substances.

Floor preparation, calculation of materials and components

To install a warm film floor, you will need the following materials

and tools. In addition to the linoleum itself, you will need an infrared film, electrical

contacts for it, copper wire, thermostat with temperature sensor, wide

polyethylene film 2 mm thick, wide strong adhesive tape, heat reflective

underlay, thin plywood.

From the equipment: a sharp knife or large scissors, pliers,

construction stapler, Phillips screwdriver. It may be necessary and

some other accessories and equipment.

Measure the room in length and width. Count how many times the width of a roll of infrared film is laid. Multiply the length of the room by the number of stripes. Now it is worth considering each floor element, its area and configuration.

Under cabinets, sofas and other massive and constantly

objects located in one place, heating devices are not placed.

This is harmful to furniture and useless in terms of heating rooms. The best thing

draw a diagram on a piece of paper. Just in case, increase the desired length

by about 5-10%.

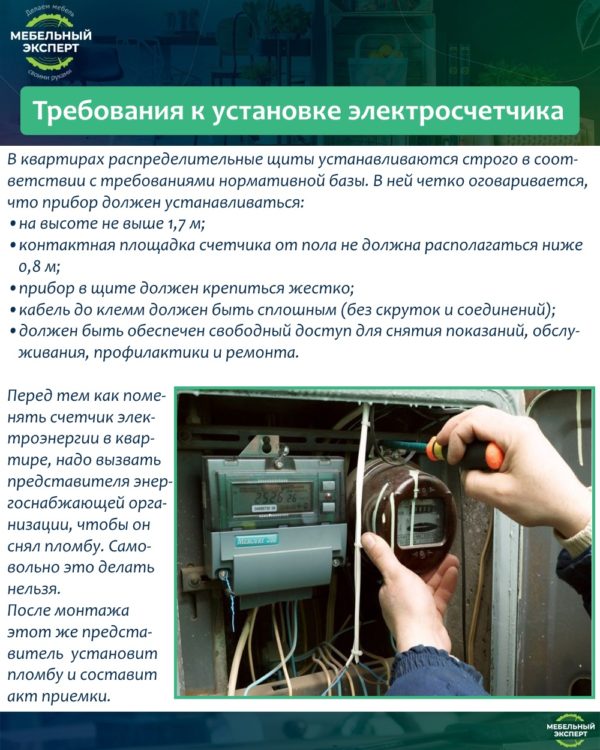

You also need to consider the place where the thermostat will be located. It is placed next to the outlet. Please note that the infrared floor consumes about 200 W per 1 m2.This means that a room of 16 m2 may require up to 3.2 kW. If the consumption is more than 3 kW, be sure to stretch a separate power line.

But, even if the consumption is less, it is necessary to check the wiring. It is advisable to replace the thin aluminum wire with a high-quality copper one. It may be necessary to change all the wiring in the apartment and it will be necessary to obtain consent to increase the power consumption from the mains.

It is best to connect a film underfloor heating with

installation of separate fuses on the shield. This is done before

work on the floor will begin. If the power grid refuses to increase capacity, then

you will have to abandon the film infrared floor.

In the same way, the need for underlying plywood, underlayment and film is calculated. But count on the fact that the film must be laid with an overlap - this will increase the amount by 10-15%. Elements are laid throughout the space of the room.

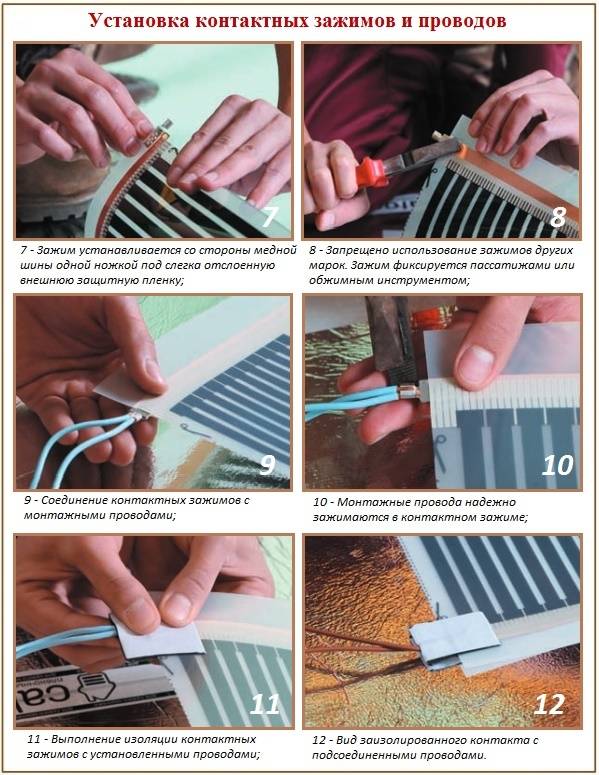

How to lay a film electric floor

Description of technology, how to properly lay a warm floor:

Drafting

This is especially important in cases where rooms of a large area are made out. It is recommended to lay only open areas with a heating film - it is not needed under furniture

In addition, the weight of heavy objects can cause system failure. The distribution of strips is recommended to be carried out in the longitudinal direction, which will reduce the number of butt sections. If there is electrical wiring at the base of the floor, it must be indented by 5 cm. Other sources of heating (oven, fireplace, radiator, etc.) must be removed from the film at a distance of at least 20 cm.

Foundation preparation. All dirt must be removed from the rough surface, drops and defects must be eliminated. This is best done with a leveling compound. Further installation work may be continued only after the complete drying of the filling. To improve the heating efficiency, it is desirable to arrange the base with a layer of thermal insulation, gluing the joints with special adhesive tape.

Film laying. The main task is to correctly distribute it over the entire floor area. Almost always, this requires cutting the film into separate fragments: this operation can only be carried out along special lines applied to the surface of the material. If you cut the film in any other place, it will cause serious damage to it.

Fixation. Having laid the strips of material according to a previously drawn up drawing, how to lay an electric floor heating, they must be well fixed. This can be done with adhesive tape, staples or regular furniture nails. There are special transparent areas for fasteners along the edges of the film: it is forbidden to do this in other places due to the risk of damage to the heating circuit.

Network connection. Having fixed the heating strips, they must be connected to electricity. For this, special contact clamps are included in the product kit. They are connected to the system in a special way: each element is inserted into the gap between the layers of the film and is connected to a copper wire. Strong fixation of each clamp is carried out with the help of an eyelet, which must be riveted with a special tool.

In its absence, a conventional hammer can be used for these purposes: you need to act very carefully to avoid damage to the graphite inserts. Further, the contact clamps are switched by pliers with a copper wire in a protective sheath.

Performing the installation yourself, it is recommended to arm yourself with some useful tips on how to properly lay a warm floor:

The individual parts of the film must be separated by some space. The presence of overlaps is unacceptable due to overheating of the material. This usually ends with a quick system failure and damage to the finish.

The temperature regulator during the operation of the film floor is not recommended to be set above +30 degrees. If linoleum is laid on top of the film, then the optimum temperature in this case will be +25 degrees.

Mounting temperature sensors is allowed only after a complete power outage in the house. Voltage supply is allowed after the installation and connection of the device is completed.

When starting to test the IR film, it is recommended to conduct a thorough inspection of all areas of switching contacts

It is very important that the protective insulation is not damaged.

When decorating a large area with a heating film, it is important to take into account the total power of the circuit. If this parameter exceeds 3.5 kW, it is better to equip it with a separate power cable in order to avoid network overloads.

Due to the minimum film thickness, the patch areas usually rise slightly above the surface

So that this does not lead to a deterioration in the general condition of the floor covering, the insulation in these areas needs to be cut a little, leveling the height.

The optimal place for installing the temperature sensor is those areas under the film where there are no heating elements. To fix this device, tape is usually used.

The system may only be tested after it has been connected to the thermostat. After turning on the underfloor heating, it is necessary to check the wiring connections. If defects are found, they must be corrected. A sign of high-quality work of a heat-insulated floor is uniform distribution of heat on its surface.

After the warm floor under the linoleum is correctly laid, a vapor barrier material is laid on top of the film: it is also fixed with adhesive tape. Then you can proceed to the final design of the floor.

Benefits of an innovative electric underfloor heating system

The installation system of underfloor heating in a residential area has long been associated with the creation of comfort and coziness. It is difficult to imagine a modern renovation without the use of thermal insulation materials and additional electrical innovations.

Advantages of installing a warm floor under linoleum:

- preservation, control of the normal level of humidity in the room,

- uniform distribution of heat over the surface of the floor covering,

- the speed of installation of the electric floor heating system,

- minimal electricity costs

- absence of dangerous electromagnetic radiation for humans,

- increase in free and safe space from heating equipment.

Recommendations and possible errors

The cake from the infrared floor and linoleum should have five layers from the rough base:

- Isolon (heat-reflecting substrate).

- Infrared thermal film.

- Polyethylene film (waterproofing).

- Flooring made of wood or gypsum-fiber boards 3–5 mm thick.

- Linoleum finish.

Without a heat-reflecting substrate, the high energy efficiency of an IR underfloor heating system will be in serious question. And without polyethylene and protective flooring, sooner or later it will fail. The plywood layer takes on part of the thermal radiation, but it is impossible without it.

Wiring diagrams

Linoleum on top of the infrared floor heating should be placed in the form of natural marmoleum or vinyl PVC. In this case, its marking should have a special icon. And it should go without a warming underlayer from below. Choosing an air conditioner will require even more thought. Everything is easier with the finish here. The main thing is not to take the colloxylin or rubber version, which, when heated, will begin to release harmful substances.

Conclusions and useful video on the topic

This video demonstrates in detail and clearly the process of laying the infrared floor:

Film underfloor heating is an excellent choice for laying under linoleum. Installation of such systems does not seem too complicated, but this is deceptive simplicity.

When laying infrared film, it is necessary to strictly adhere to the technology of work and strictly follow the manufacturer's recommendations. This will avoid mistakes and lay the system correctly to ensure a long service life.

Do you want to talk about how you arranged the floor heating system with your own hands? Would you like to share information that will be useful to site visitors? Please write in the block below, publish photos on the topic of the article, ask questions.

Outcome

The possibility of laying linoleum on a warm floor is considered - three simple ways. Each has undeniable advantages, certain disadvantages, secrets of installation. Anyone ready to be the perfect solution in certain situations

It is important to remember: with any warm field, linoleum can be heated up to a maximum of 30 degrees

Do not be alarmed if within 10-14 days after the installation of a warm floor, PVC linoleum becomes a source of an unpleasant odor even without heating. To make the “aroma” disappear faster, regularly ventilate the room, do not stay in it for more than five minutes. If after a month the smell has not gone away, most likely, the linoleum was not chosen correctly and you will have to look for another floor covering.

To avoid such unpleasant situations, entrust the installation of a warm floor to professionals.

average rating

ratings over 0

Share link