- Where to drill

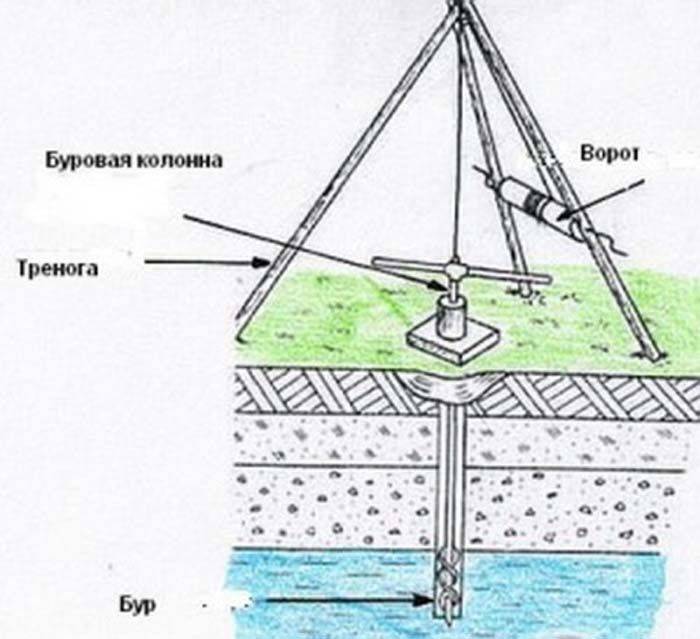

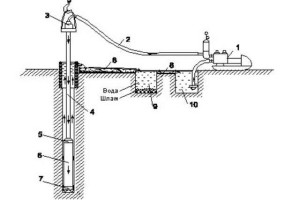

- The buildup of a homemade well

- Manual drilling methods

- impact method

- Rope percussion lesson

- Manual auger drilling

- How to drill an artesian well

- Filters

- Advantages of self-drilling

- Types and methods of drilling wells

- Afterword

- Scope of core drilling

- Horizons and types of wells: accessible and not very

- Horizons have boundaries

- The whole range of wells

- Abyssinian well

- Well on the sand

- Artesian well

- Methods for self-drilling

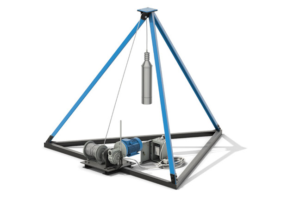

- Shock rope

- Auger

- Rotary

- Puncture

- Necessary tools for a drilling rig

- Manual drilling techniques

- Screw

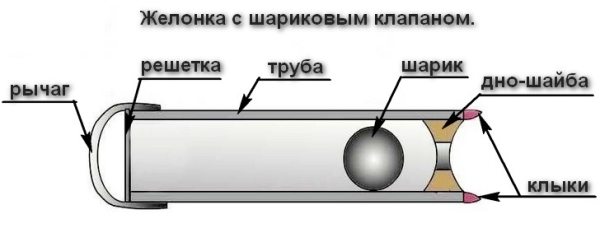

- Kolinsky

- Shock-rope

- Conclusions and useful video on the topic

Where to drill

To minimize the cost of drilling, you need to determine the place where the well should be. There are several rules for drinking springs:

- The nearest building is at least 30 meters away.

- From potential sources of pollution (road, cesspool, production workshop, etc.) at least 100 m.

But this is not all that needs to be considered when it is required to drill a well for water. The cost and time costs directly depend on the depth of groundwater. Therefore, before drilling, you need to find out where the water comes as close to the surface as possible.This can be done in several ways:

- Analysis of vegetation on the site. Determine which crops grow in mass. There are catalogs on the Internet that indicate the length of the rhizome. This is the depth of the nearest layer of water.

- Frames and pendulums. This method is not particularly accurate, although the watchmen claim that earlier the place for the well was determined in this way. There is no magic here. The dowser monitors the deviations of the frame or pendulum, and draws conclusions.

- Geological exploration of the site. The most accurate method. The disadvantage is the need to spend money on test drilling. It is necessary to hire specialists who will study the cut and determine where the water approaches the surface of the earth at a minimum distance.

But there is an equally effective way - to talk to the neighbors. They will tell you whether water rises during floods, whether it floods basements. And if there is a well or well in the adjacent area, you can focus on their depth. Differences will be, but insignificant.

The buildup of a homemade well

A drilled well is not everything. It will not give water of the required quality in the right quantity. To do this, it is necessary to open the aquifer or "shake" the well. If you open the reservoir (directly or reversely - no difference), water can be obtained within a day, but complex expensive equipment will be required. And the buildup of the well will last several days, but for it it is enough to have the most ordinary household submersible pump (only centrifugal, because vibration will not work).

To swing a drilled well, silt is first removed from it with a bailer, and then they begin to pump water - completely, as soon as the volume covering the involved pump is reached.

You can build up with the help of a manner, but then you will have to draw water for a long time - 2 weeks, no less.

Important: The buildup of the well can be considered complete when the transparency of the water reaches 70 cm. You can check this in an opaque vessel (for example, in a clean barrel), using a white enameled or faience disk, the diameter of which is about 15 cm (take, say, a saucer or saucepan lid)

You should look at the immersed disk strictly vertically, and as soon as the liquid begins to spread along its edges, blurring the contours - this is already opacity, you need to stop. As soon as transparency is achieved, a water sample must be taken and submitted to the laboratory for analysis. If the regulatory authority confirms the quality of production, the annulus of the well is concreted or sealed with clay, and then a filter is installed.

Manual drilling methods

The choice of option depends on the level of groundwater in the area. If this knowledge is there, then it is realistic to prepare and implement the plan. However, many "pioneers" note that the work requires huge physical costs, time and a strong nervous system. Therefore, it is better to think about everything well in advance.

impact method

It is used for arranging an elementary country well-needle - an Abyssinian well. A simple "drilling rig" consists of a shaft formed by pipe sections and a sharp tip that cuts through the soil layers. A heavy woman (but not a wife) acts as a hammer, she is lowered and raised with ropes. She falls on a podbok - a collar under her. After one segment enters the ground, it is built up with another, changing the “dislocation” of the headstock and collar. The operation is continued until the tip enters the water carrier by two thirds of the formation.

The first advantage is the ease of operation, which allows you to get a well anywhere, even in the basement. The absence of additional expenses is also quite attractive, since other methods entail high costs.

Rope percussion lesson

This is the second hit method, often used in country “amateur activities”. The installation consists of:

- a high tripod placed over the drilling site;

- rods, driving glass;

- bailers, if the soil is loose;

- cable winch.

A driving cup is a piece of steel pipe with a sharp cutting edge at the bottom. The base of the "dishes" is the anvil, which the bar strikes. Raise and lower the projectile with a cable winch. The soil gets inside the glass, but is held there due to the force of friction. The full container is lifted out and rid of the rock. Then the operation is repeated.

Bailer - replacing the glass if the soil in it is not able to hold. At the end of it is a special valve that closes when the structure is raised to the surface. When lowered into the well, the valve opens.

Manual auger drilling

This method, described earlier, is also often used in practice. It does not make sense to describe it additionally, but you can dwell on the advantages. The pros are:

- profitability;

- ease of maintenance and repair of equipment;

- no need for "engagement" of technology;

- practicality, as easy access to any site is provided;

- efficiency coupled with low time costs.

The auger drill is not without its drawbacks. This is a small maximum depth that requires water purification, the inability to cope with hard rocks.

The first drilling of wells for water by hand may seem like a daunting task to many dacha and country masters, so the watched video will help to “chew” everything and put it on the shelves. For example, this educational video:

How to drill an artesian well

- a drill, the components of which are a core barrel, a drill rod, a core for drilling, an active part;

- metal screw;

- tripod;

- winch;

- several pipes with different diameters;

- valve;

- caisson;

- filters;

- pump.

It is not necessary to buy all these tools, because they can cost a fortune. It is advisable to rent them. The work proceeds according to the following algorithm:

- Dig a 1.5 m x 1.5 m hole. Line it with plywood and boards so that it does not crumble.

- Install a sturdy derrick, preferably made of metal or wood, directly over the recess. Then fix the winch at the junction of the supports. This device is used for lifting and lowering equipment.

- Choose the right pump that will fit easily into the pipe.

- Lower the filter column, which consists of a pipe, a sump and a filter. But it is worth doing this when the required depth has already been reached. In order to strengthen the pipe, the space near it is covered with sand. In parallel with this, pump water into the pipe, the upper end of which is airtight.

Next, simply lower the pump, and then a hose or water pipe is needed to bring water out of the depths. Connect them too. To do this, remove the pipe and weld it to the head of the caisson. Next, install a valve that will regulate the level of water inflow - and your well is ready.

Filters

The quality of water from any well is largely determined by the presence of a special well filter. And this part, more than others included in the well structure, is subject to wear. So, her choice should be approached responsibly.

For limestone wells, for example, a simple screen filter will suffice - that is, perforation on the lower casing elbow. It can also become the basis of the well filter "on sand" (in combination with gravel backfill). In this case, the requirements for perforation are as follows:

hole diameter from 15 to 30 mm, depending on the soil;

duty cycle (the ratio of the total area of the holes to the area they occupy) 0.25-0.30;

the arrangement of the holes is transverse, in a checkerboard pattern;

the area (total) of the holes must not be less than the cross-sectional area of the casing pipe (its clearance).

When the pump is placed in a well equipped with an internal filter, its (filter) upper edge is considered to be the bottom of this well. Because of this, the single volume of water intake is significantly reduced. In addition, the filter strongly silts up the well structure, because water seeps into the gap between it and the casing. The service life of the filter itself and the pump are reduced, since sand inevitably gets into the latter. Therefore, the pump is often placed in a separate pipe, which is mounted on the filter outlet. But for this you need to make a well of a larger diameter.

If the drillers have an expensive and structurally complex centrifugal pump at their disposal, everything is simple - it is connected to the filter outlet, and as a result, both silting and sanding stop. But when there is no such equipment, something has to be invented.

Note! Many masters make parts for filters on their own, using PVC pipes, a polymer mesh and springs made of stainless materials. But such designs rarely serve for a long time, and they do not filter water very well.

It is better to spend money, but choose and buy a truly reliable, well-functioning filter. Moreover, there are plenty to choose from:

Advantages of self-drilling

Manual drilling with self-made fixtures has the following advantages over automatic penetration methods using special drilling equipment by individuals and organizations:

Cheapness. Making a drill with your own hands from improvised materials and drilling a well without the involvement of third-party assistants, specialists, organizations is the most profitable option from a financial point of view, if other ways of employment in your free time do not bring cash income.

Versatility. Independent drilling by hand is universal due to the following features:

- Manual drilling in many situations is the only possible option for carrying out work if it is impossible to enter the site of special equipment or the well is located in a built room.

- Narrow borehole channels are laid manually without the use of casing strings of standard diameter, which significantly reduces the cost of organizing and arranging water supply at an individual site.

- Manual drilling is carried out to a depth of 5 to 35 m, which corresponds to the characteristics of the Abyssinian and sand wells.

- The made drill can be used for other economic purposes, if it is necessary to make holes in the ground - when constructing fences, planting garden plants, installing pile foundations and other household work. As unnecessary, the structure can always be disassembled and used on the farm at your discretion.

Flexibility of application. Depending on the depth of the water reservoir, the quality of the soil and the dimensional parameters of the borehole channel, various drilling technologies, designs of drilling devices, or combinations thereof are used. With individual production, it is always possible, through experiments, to independently make a drill for a well, the most convenient and effective for specific conditions.

Of course, for the cheapness of the manual method, you will have to pay for the speed of work and intensive physical labor, the latter are to some extent useful in terms of improving health.

Types and methods of drilling wells

We will not consider the types of drilling using special mechanisms and industrial equipment, the article focuses only on those that can be done independently using ordinary tools and fixtures. Table

Domestic Well Drilling Techniques

Table. Domestic Well Drilling Techniques

| Drilling method | Brief description of the technology, advantages and disadvantages |

|---|---|

Hydro drilling Hydro drilling | When drilling a well, water is used, it greatly facilitates the process. Water can be supplied under relatively low pressure, only to soften the earth and bring it to the surface.This method is very often used in summer cottages, where only a submersible pump is required for drilling. There is also hydro-drilling with water under high pressure. Water independently makes a well in the ground for water pipes. This method is used quite rarely, it is necessary to have a high-pressure water pump and an open reservoir for its intake. Some summer residents somehow negotiate with firefighters and wash the earth out of the well with the help of a fire truck. Hydrodrilling allows you to get a large diameter well, a casing pipe is lowered into it. The presence of such a pipe makes it possible to use deep-well pumps, they are connected in series to a hydraulic accumulator - the quality of water supply is no different from a centralized urban one. The pump is switched on/off automatically. |

mechanical drilling mechanical drilling | In summer cottages, two methods of mechanical drilling can be used: percussion and screw. In the first case, the pipe is driven into the ground with a load. It rises up and falls on the end of the pipe. Potential energy is converted into kinetic energy, as a result of a strong blow, the pipe is driven into the ground. In terms of labor intensity, they are approximately the same, a competitive choice must be made after analyzing the physical characteristics of soils. If they are sandy or sandy loamy, then it is recommended to make a well with an impact method. The sand is not very hard, smaller weights can be used, and the deepening process proceeds relatively quickly and easily. On heavy clay soils, it is better to drill with a screw method. This technology involves periodically raising the tool to clear it from the ground.If the drill is taken out in sandy soils, then there are high risks of their shedding, the work must be repeated, but the clay perfectly holds the walls of the well. The disadvantage is that if the depth of the well exceeds ten meters, then great efforts must be made to get the tool, various devices have to be made: tripods with cranks, chain hoists, etc. |

Well types

Well types

The decision on the choice of drilling method should be made by each owner of a suburban area separately, while always taking into account the approximate depth of the aquifer, the physical properties of the soil, the approximate water flow, the required pressure and your technical capabilities.

The choice of drilling method depends on many factors.

The choice of drilling method depends on many factors.

For each method, it is necessary to prepare devices for excavation, drill tips, helical blades, casing pipes, clamps, etc. There are a huge number of different options, each master selects the best one for himself, taking into account the availability of materials and professional skills.

Drilling a well requires special tools and fixtures.

Drilling a well requires special tools and fixtures.

Afterword

The drilling masters who once mastered Tyumen and Urengoy are still alive. There were no geophysical equipment that builds a 3D picture of what is in the earth on a computer display, and there were no fully robotic drilling rigs then, but they already saw through the earth with their intuition, experience and were on “you” with all the spirits of the bowels. And the then ministers and members of the Politburo, who had more arrogance than the old Testament boyars and specific princes, addressed these aces as “you” by name and patronymic and respectfully shook hands with them.

So, any of the old bison drillers have unsuccessful wells on their account, which they are not shy about - such is the work. What then to say to beginners acting independently? Don't be discouraged by failure, if the first hole is empty, or collapses, or the drill gets stuck. Not without that in the drilling business. But annoyance and disappointment will instantly subside under a powerful pressure, as they say now, positive, as soon as your well gives water.

***

2012-2020 Question-Remont.ru

Display all materials with a tag:

Go to section:

Scope of core drilling

Core drilling is a method that allows you to determine with the greatest accuracy the depth of the roof and the bottom of the soil layers, as well as the depth mark of the groundwater table.

Core drilling technology is widely used in the following industries:

- Water supply in industrial and private sphere. Drilling wells for private water supply, organization of water intake of entire villages or city blocks is effectively performed by core drilling due to the fact that the drill easily penetrates to great depths. The core shell is capable of lifting almost any destroyed rock, except for water-saturated and loose non-cohesive soils (sands, gravel, pebbles);

- Geological exploration in the mining industry. When the rock passes, a point effect on the soil occurs along the radius of rotation. In other words, a projectile, structurally resembling a pipe, drills a solid array of rocks without disturbing their structure and condition.

- Construction. Carrying out engineering and geological research to study the physical and mechanical properties of soils, the state of rocks.The column technology provides an opportunity to identify groundwater levels with high accuracy and take water samples to study their aggressiveness in relation to concrete.

During core drilling, a core is extracted - a column of soil or adjacent soil layers. The core is characterized by an integral natural structure, which provides a comprehensive analysis of the studied rock. Drilling with a core pipe allows you to determine the depth of the rock with the highest accuracy for the purpose of studying.

Core drilling ensures the integrity of the extracted core, which contributes to the qualitative study of the rock. At the same time, the most high-quality cleaning of the face from the destroyed rock is carried out.

The use of a core drill in construction greatly facilitates and speeds up the process. A pile is easily hammered into the hole prepared by a core drill or a finished reinforced concrete structure is mounted. Core drilling allows you to create cylindrical holes in brick and concrete structures.

Horizons and types of wells: accessible and not very

Before you start preparing for such a large-scale work, you need to find out where to drill, but without conducting geological exploration, you will not be able to find the exact answer.

Horizons have boundaries

Water is located on different horizons, these sources do not communicate with each other. This is provided by layers of impermeable rocks - clay, limestone, dense loam.

- The shallowest source is perched water, which is provided by precipitation and reservoirs. It can start at a depth of 0.4 m and end at 20 m from the surface. This is the dirtiest type of water, it always has a lot of harmful impurities.

- Having drilled a well up to 30 m deep, you can “stumble” on cleaner groundwater, which is also fed by precipitation. The upper boundary of this horizon can be located at a distance of 5 to 8 m from the surface. This liquid is also recommended to be filtered.

- The underground water source, located in the sandy layer, is already filtered with high quality, therefore it is optimal for water supply. It is this horizon that must be reached by those who want to drill their own well.

- Depth from 80 to 100 m is an unattainable ideal with crystal clear water. Artisanal drilling methods do not allow you to get so deep.

Since the occurrence of horizons is influenced by relief and other factors, the boundaries of perched water and groundwater are conditional.

The whole range of wells

Drilling water wells manually depends on the type of future well. The types of structures cannot be called numerous, because there are only three of them:

- Abyssinian;

- on the sand;

- artesian.

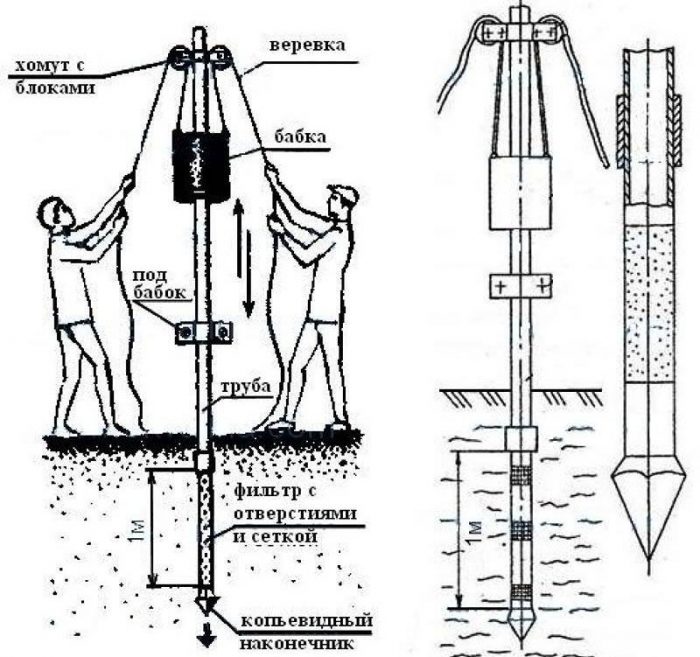

Abyssinian well

This option is optimal when the water in the area is 10-15 m away from the surface. It does not require a lot of free space. Another advantage is the relative simplicity of work, which allows even a beginner who is just learning the science of drilling to cope with the task. This is a well-needle, which is a column constructed from thick-walled pipes. A special filter is arranged at the bottom of it, drilling holes at the end of the pipe. The Abyssinian well does not require drilling as such, since the chisel is simply hammered into the ground. But the most common way to make such a well is still called impact drilling.

Well on the sand

If the aquifer lies at a depth of 30 to 40 m, then it is possible to build a sand well, with the help of which water is extracted from sands saturated with water. Even a 50-meter distance from the surface does not guarantee the purity of drinking water, so it must be given for laboratory analysis. Since in this case there will be no insurmountable obstacles on the way - hard rocks (semi-rocky, rocky), manual drilling of water wells does not imply any special difficulties.

Artesian well

This aquifer can be located at a depth of 40 to 200 m, and water has to be extracted from cracks in rocks and semi-rocks, so it is inaccessible to mere mortals. Without knowledge and serious equipment for drilling, the task of building a well for limestone is an impossible mission. However, it can serve several sites at once, so drilling services ordered together promise significant savings.

Methods for self-drilling

To drill a well for water in a country house, a personal plot, a rural courtyard, it must be taken into account that there are three ranges of depths at which aquifers occur:

- Abyssinian well. Before the water will have to drill from one and a half to 10 meters.

- On the sand. To make a well of this type, you need to pierce the soil to a mark in the range from 12 to 50 m.

- Artesian source. 100-350 meters. The deepest well, but with the purest drinking water.

In this case, each time a separate type of drilling rig is used. The determining factor is the chosen method of drilling operations.

Shock rope

With such drilling of wells for water, the technology of the process involves raising the pipe with three cutters to a height. After that, being weighted with a load, it descends, and crushes the rock under its own weight. Another device necessary for extracting crushed soil is a bailer. All of the above can be bought or made with your own hands.

But before you drill a well with your own hands, you will have to use a garden or fishing drill to make the primary recess. You will also need a metal profile tripod, a cable and a system of blocks. The drummer can be lifted with a manual or automated winch. The use of an electric motor will speed up the process.

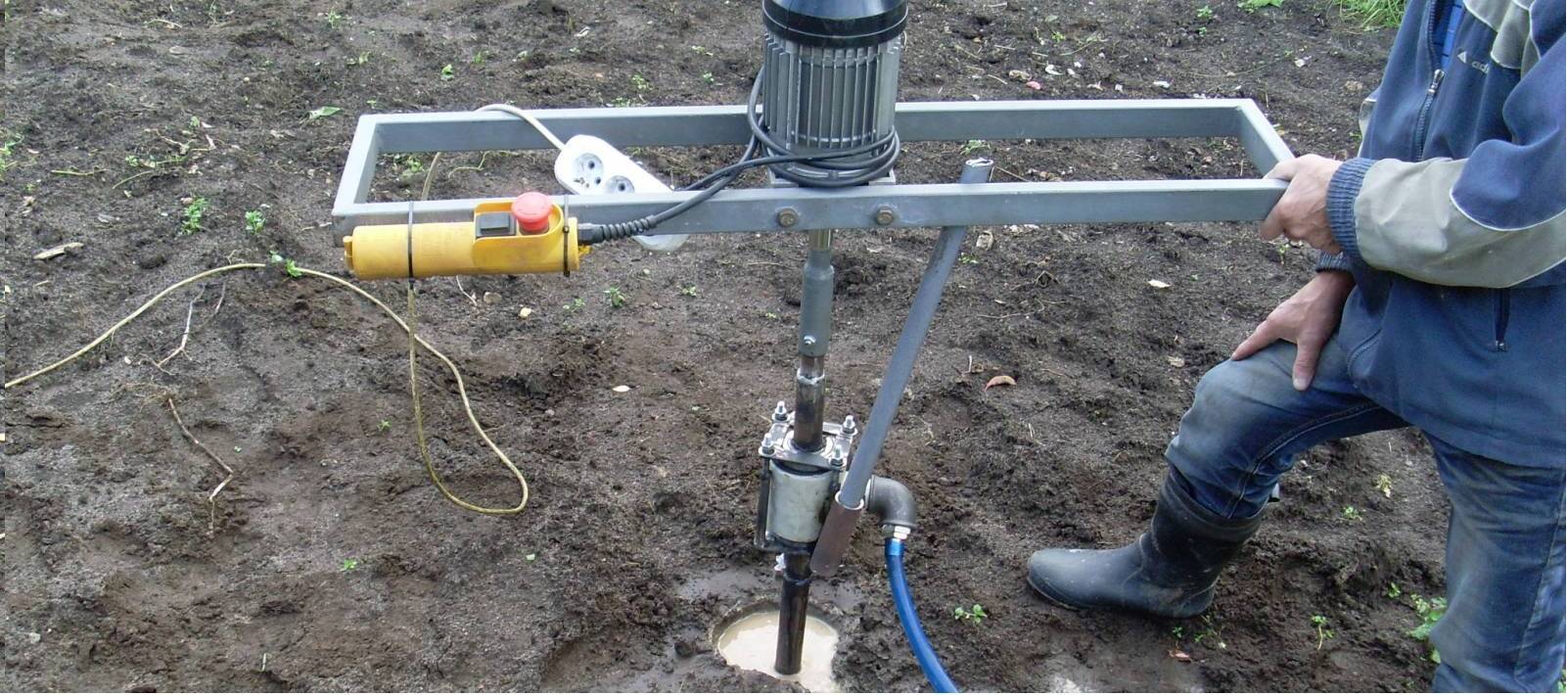

Auger

This technology of drilling wells under water involves the use of a drill, which is a rod with a helical blade. A pipe with a diameter of 10 cm is used as the first element. A blade is welded onto it, the outer edges of which form a diameter of 20 cm. To make one turn, a sheet metal circle is used.

A cut is made from the center along the radius, and a hole equal to the diameter of the pipe is cut along the axis. The design is “divorced” so that a screw is formed that needs to be welded. To drill a well in the country with your own hands using an auger, you need a device that will serve as a drive.

It could be a metal handle. The main thing is that it can be disconnected. As the drill deepens into the ground, it is increased by adding another section. The fastening is welded, reliable, so that the elements do not come apart during the work. After the procedure is completed, the entire structure is removed, and casing pipes are lowered into the shaft.

Rotary

Such drilling of a well in the country is not the cheapest option, but the most effective. The essence of the method is the combination of two technologies (shock and screw). The main element that receives the load is the crown, which is fixed on the pipe. As it sinks into the ground, sections are added.

Before you make a well, you need to take care of the water supply inside the drill. This will soften the ground, which will extend the life of the crown. This method will speed up the drilling process. You will also need a special installation that will rotate, raise and lower the drill with a crown.

Puncture

This is a separate technology that allows you to penetrate the ground horizontally. This is necessary for laying pipelines, cables and other communication systems under roads, buildings, in places where it is impossible to dig a trench. At its core, this is an auger method, but it is used for drilling horizontally.

The pit is dug, the installation is installed, the drilling process begins with periodic sampling of rock from the pit. If water in the country can be obtained from a well separated by an obstacle, a puncture is made, a horizontal casing pipe is laid, and a pipeline is pulled. Everything can be done with your own hands.

Necessary tools for a drilling rig

- low requirements for the qualification of the driller and ease of installation of equipment;

- no restrictions on the place of drilling. You can manually drill almost anywhere in the area;

- maintaining most of the usable land area in its original state. That is, heavy special equipment will not damage the plantings in your territory.

For work you will need:

- container with water;

- drill with reinforced edge.Recommendation: you can strengthen the drill by welding drilling cutters onto the screw, their role can be played by elements of a metal shank or a file. In addition, the incisors can be sharpened using a grinder;

- shovel;

- a pump with a hose like a "baby";

- land cart.

For the drilling rig will also come in handy:

- metal wire for the filter;

- gravel or gravel for a pillow;

- wire for the filter device at the bottom;

- pipes.

Manual drilling techniques

Screw

Manual drilling usually means the performance of all work using small-sized equipment.

Most often, a screw mechanism is used to equip shallow wells:

- The deepening of the drill is carried out by rotational movements.

- In this case, the auger blades cut through the soil and extract it to the surface.

- If a small-sized installation is used, then flushing liquid is supplied to the auger.

- When working with a hand drill, most often the work is carried out “dry”, however, there are techniques that make it easier to pass through dense layers of soil by wetting from a hose.

Using an auger with flushing

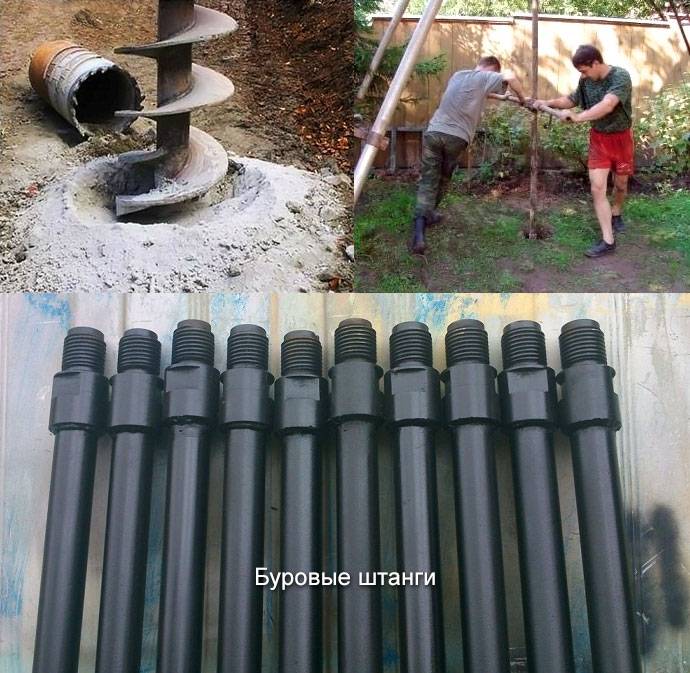

Kolinsky

Unlike auger, core drilling is carried out using a special tool:

- The device is a solid steel pipe, at the end of which a core bit with cutting elements is fixed.

- When rotating, the chisel destroys the soil mass that enters the pipe.

- Sinking is carried out gradually, with periodic extraction of the drilling part and removal of soil.

- For immersion to a considerable depth, the pipe is equipped with extension rods.

Photo rods and head for core drilling

Shock-rope

This technique can also be implemented on a small area.The main thing is that there is somewhere to raise the shock part:

Bailer device

- A massive drilling tool (bailer) is lifted and dropped onto the ground.

- Deepening under the action of gravity, the edges of the tool cut through the rock, which enters the cavity.

- Well drilling is carried out gradually, with periodic cleaning of the internal cavity from the substrate.

- It is also possible to combine impact and rotational action - for this special manual gates are used.

- To facilitate the work, experts recommend building a tripod up to 2 meters high, however, shallow (up to 10 m) wells can be made without it.

Organization of impact penetration with flushing

Conclusions and useful video on the topic

Video #1 Demonstration of the principle of classical core drilling with core extraction by water pressure:

Video #2 Features of drilling a well with an auger:

Video #3 Core drilling of a well with bottomhole flushing and installation of a double casing, the outer part of which is made of steel pipes, the inner part of polymer:

Drilling an aquifer is a labor intensive process. Not only the speed of the device of an autonomous water source, but also financial costs depend on the correctness of the chosen drilling method.

The first thing you should pay attention to when choosing a drilling method is the type of soil and the depth of the aquifer. Based on these parameters, you can choose the best option that will allow you to drill a well quickly and inexpensively.

Do you want to share the history of drilling a well in your own area or useful information on the topic of the article? Please leave comments in the block below. Here you can also ask a question or point out controversial points in the text.