- Methods for self-drilling

- Shock rope

- Auger

- Rotary

- Puncture

- Drilling methods

- Casing installation

- How to drill an artesian well

- Casing pipes for percussion and auger drilling

- Horizons and types of wells: accessible and not very

- Horizons have boundaries

- The whole range of wells

- Abyssinian well

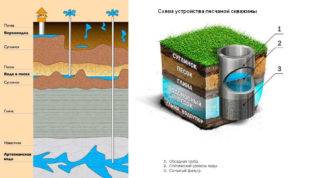

- Well on the sand

- Artesian well

- Percussion drilling of a well for water

- The nuances of installing casing pipes

- How to equip a punched well

- Methods for self-drilling

- Shock rope

- Auger

- Rotary

- Puncture

- When is it more profitable to carry out drilling seasonal features

- Types of wells

- Well on the sand

- artesian well

- Conclusions and useful video on the topic

Methods for self-drilling

To drill a well for water in a country house, a personal plot, a rural courtyard, it must be taken into account that there are three ranges of depths at which aquifers occur:

- Abyssinian well. Before the water will have to drill from one and a half to 10 meters.

- On the sand. To make a well of this type, you need to pierce the soil to a mark in the range from 12 to 50 m.

- Artesian source. 100-350 meters. The deepest well, but with the purest drinking water.

In this case, each time a separate type of drilling rig is used.The determining factor is the chosen method of drilling operations.

Shock rope

With such drilling of wells for water, the technology of the process involves raising the pipe with three cutters to a height. After that, being weighted with a load, it descends, and crushes the rock under its own weight. Another device necessary for extracting crushed soil is a bailer. All of the above can be bought or made with your own hands.

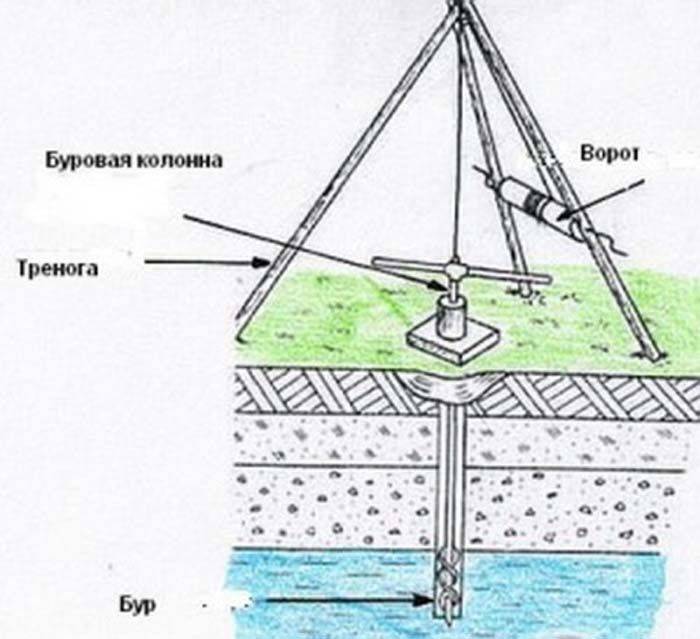

But before you drill a well with your own hands, you will have to use a garden or fishing drill to make the primary recess. You will also need a metal profile tripod, a cable and a system of blocks. The drummer can be lifted with a manual or automated winch. The use of an electric motor will speed up the process.

Auger

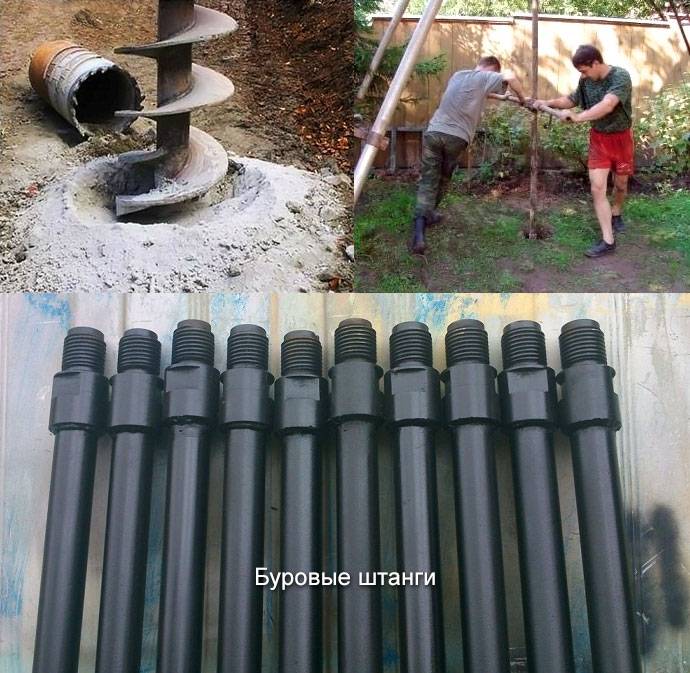

This technology of drilling wells under water involves the use of a drill, which is a rod with a helical blade. A pipe with a diameter of 10 cm is used as the first element. A blade is welded onto it, the outer edges of which form a diameter of 20 cm. To make one turn, a sheet metal circle is used.

A cut is made from the center along the radius, and a hole equal to the diameter of the pipe is cut along the axis. The design is “divorced” so that a screw is formed that needs to be welded. To drill a well in the country with your own hands using an auger, you need a device that will serve as a drive.

It could be a metal handle. The main thing is that it can be disconnected. As the drill deepens into the ground, it is increased by adding another section. The fastening is welded, reliable, so that the elements do not come apart during the work.After the procedure is completed, the entire structure is removed, and casing pipes are lowered into the shaft.

Rotary

Such drilling of a well in the country is not the cheapest option, but the most effective. The essence of the method is the combination of two technologies (shock and screw). The main element that receives the load is the crown, which is fixed on the pipe. As it sinks into the ground, sections are added.

Before you make a well, you need to take care of the water supply inside the drill. This will soften the ground, which will extend the life of the crown. This method will speed up the drilling process. You will also need a special installation that will rotate, raise and lower the drill with a crown.

Puncture

This is a separate technology that allows you to penetrate the ground horizontally. This is necessary for laying pipelines, cables and other communication systems under roads, buildings, in places where it is impossible to dig a trench. At its core, this is an auger method, but it is used for drilling horizontally.

The pit is dug, the installation is installed, the drilling process begins with periodic sampling of rock from the pit. If water in the country can be obtained from a well separated by an obstacle, a puncture is made, a horizontal casing pipe is laid, and a pipeline is pulled. Everything can be done with your own hands.

Drilling methods

You can drill wells on your own in the following ways:

- Rotary, or rotary - the drilling tool rotates, biting into the rock;

- Percussion - they hit the drill rod, deepening the drill projectile into the rock, so needle wells are drilled;

- Percussion-rotational - the rod with the drilling projectile is lifted several times and lowered with force, loosening the rock, and then rotated, taking it into the cavity of the projectile, see below;

- Rope-percussion - a special drilling projectile is raised and lowered on a rope, taking the rock with it.

All these methods refer to dry drilling. During hydraulic drilling, the working process takes place in a layer of water or a special drilling fluid that increases the compliance of the rock. Hydrodrilling is not environmentally friendly, requires expensive special equipment and high water consumption. In amateur conditions, it is used in exceptional cases, in an extremely simplified and limited form, see below.

Dry drilling, except for impact drilling without casing, is only intermittent, i.e. the drill has to be lowered into the trunk, then removed from it in order to select the rock from the drill. In professional hydro-drilling, the crushed rock is carried out by the used drilling fluid, but the amateur needs to know for sure: it is impossible to go through the trunk to a depth greater than the length of the working part of the tool in 1 drilling cycle. Even if you drill with an auger (see below), you need to lift it and shake out the rock from the coils after a maximum of 1-1.5 m of penetration, otherwise the expensive tool will have to be given to the ground.

Casing installation

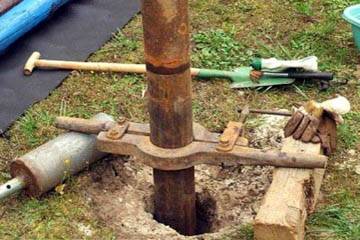

Holding the casing pipe from spontaneous upsetting

An attentive reader may already have a question: how do they put a casing in the barrel? Or, how do they raise / lower the drill, which, in theory, should be wider than it? In professional drilling - in different ways. The oldest is illustrated in Fig. on the right: the axis of rotation of the tool is shifted relative to its longitudinal axis (circled in red), and the cutting part is made asymmetrical. The neck of the drill is made conical.All this, of course, is carefully calculated. Then, in the work, the drill describes a circle that extends beyond the casing, and when lifting, its neck slides along its edge and the drill slips into the pipe. This requires a powerful, precise drive of the drill string and its reliable centering in the casing. As the depth increases, the casing is increased from above. Complex special equipment is not available to amateurs, so they can install casing pipes in the following ways:

- A “bare”, without casing, hole is drilled to the full depth with a drill larger than the casing diameter, and then the casing pipes are lowered into it. So that the whole column does not fall down, they use 2 drilling gates: one is holding the pipe that has already gone into the well, see fig. on the right, and the second is installed on a new one before removing the first. Only then is the column thrown into the trunk, if it itself is no longer moving. This method is often used by amateurs on fairly dense, adhesive (sticky) and cohesive (not loose) soils to a depth of 10 m, but there are no statistics on how many wells collapsed, how many drills and casing were lost.

- The drill is taken with a smaller diameter, and the lower casing pipe is made with divergent sharpened teeth (crown) or equipped with a cutting skirt. Having drilled for 1 cycle, the drill is lifted, and the pipe is forcibly upset; crown or skirt cut off excess soil. This method slows down drilling, because before starting a new cycle, you need to use a bailer (see below) to select the crumbled soil, but more reliably, it facilitates gravel backfilling of the annulus and allows you to use an external sand filter, see below.

How to drill an artesian well

- a drill, the components of which are a core barrel, a drill rod, a core for drilling, an active part;

- metal screw;

- tripod;

- winch;

- several pipes with different diameters;

- valve;

- caisson;

- filters;

- pump.

It is not necessary to buy all these tools, because they can cost a fortune. It is advisable to rent them. The work proceeds according to the following algorithm:

- Dig a 1.5 m x 1.5 m hole. Line it with plywood and boards so that it does not crumble.

- Install a sturdy derrick, preferably made of metal or wood, directly over the recess. Then fix the winch at the junction of the supports. This device is used for lifting and lowering equipment.

- Choose the right pump that will fit easily into the pipe.

- Lower the filter column, which consists of a pipe, a sump and a filter. But it is worth doing this when the required depth has already been reached. In order to strengthen the pipe, the space near it is covered with sand. In parallel with this, pump water into the pipe, the upper end of which is airtight.

Next, simply lower the pump, and then a hose or water pipe is needed to bring water out of the depths. Connect them too. To do this, remove the pipe and weld it to the head of the caisson. Next, install a valve that will regulate the level of water inflow - and your well is ready.

Casing pipes for percussion and auger drilling

As the drilled well deepens and starting from the first three meters, a composite casing pipe is immersed in it, i.e. several pipe segments should be purchased before drilling begins.The diameter of the casing pipe should be 10-15 mm larger than the diameter of the drilling tool (for example, a glass).

In the lower part of the composite casing pipes (the length of the casing segment is 2-4 m), a cutting shoe is installed, which cuts off excess soil on the walls when lowering the casing. At the top there is a branch pipe that protects the thread of the upper segment of the pipe from jamming, which is a segment of the same pipe 150-200 mm long with a thread at one end. If the casing segments are connected by welding, then a spigot is not required.

Until the completion of drilling operations, the casing pipe should sag freely in the wellbore, being held on the surface with a steel or wooden clamp with protruding support handles.

Fixing a mine shaft with a casing pipe is mandatory for several reasons:

- plastic rocks. Such layers of soil (especially clay) after drilling with a drill swell under the influence of water, or swell under the pressure of the upper soil layers, narrowing the borehole and preventing the descent of the drilling tool;

- unstable breeds. When driving sand, gravel, pebble, etc. layers of soil, they fill up the wellbore or, with a moisture content, swim around it;

- hard rocks. Their drilling out is accompanied by powerful blows of the drill rod with a bit, shaking and shedding the walls of the well in the absence of casing. Given that hard rock is drilled slowly and for a long time (sometimes less than half a meter per day), strengthening the walls of the drill shaft is especially necessary.

The casing material for a homemade water well can be steel or plastic. If the wellbore is deeper than 10 m, then steel pipes are better suited for its casing, as they are more durable.

The casing pipe is built up as the well deepens. If the casing channel deviates from the vertical, which is noticeable by the characteristic sounds of the cup or bailer hitting the pipe walls, it is necessary to level the channel. To do this, wooden wedges are driven in between the casing and the ground.

It is important to connect the casing segments to each other reliably, with maximum tightness. Otherwise, mechanical pollutants (for example, quicksand) and perched water will enter the well

Horizons and types of wells: accessible and not very

Before you start preparing for such a large-scale work, you need to find out where to drill, but without conducting geological exploration, you will not be able to find the exact answer.

Horizons have boundaries

Water is located on different horizons, these sources do not communicate with each other. This is provided by layers of impermeable rocks - clay, limestone, dense loam.

- The shallowest source is perched water, which is provided by precipitation and reservoirs. It can start at a depth of 0.4 m and end at 20 m from the surface. This is the dirtiest type of water, it always has a lot of harmful impurities.

- Having drilled a well up to 30 m deep, you can “stumble” on cleaner groundwater, which is also fed by precipitation. The upper boundary of this horizon can be located at a distance of 5 to 8 m from the surface. This liquid is also recommended to be filtered.

- The underground water source, located in the sandy layer, is already filtered with high quality, therefore it is optimal for water supply. It is this horizon that must be reached by those who want to drill their own well.

- Depth from 80 to 100 m is an unattainable ideal with crystal clear water. Artisanal drilling methods do not allow you to get so deep.

Since the occurrence of horizons is influenced by relief and other factors, the boundaries of perched water and groundwater are conditional.

The whole range of wells

Drilling water wells manually depends on the type of future well. The types of structures cannot be called numerous, because there are only three of them:

- Abyssinian;

- on the sand;

- artesian.

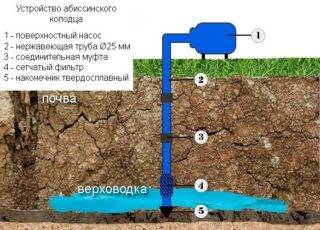

Abyssinian well

This option is optimal when the water in the area is 10-15 m away from the surface. It does not require a lot of free space. Another advantage is the relative simplicity of work, which allows even a beginner who is just learning the science of drilling to cope with the task. This is a well-needle, which is a column constructed from thick-walled pipes. A special filter is arranged at the bottom of it, drilling holes at the end of the pipe. The Abyssinian well does not require drilling as such, since the chisel is simply hammered into the ground. But the most common way to make such a well is still called impact drilling.

Well on the sand

If the aquifer lies at a depth of 30 to 40 m, then it is possible to build a sand well, with the help of which water is extracted from sands saturated with water. Even a 50-meter distance from the surface does not guarantee the purity of drinking water, so it must be given for laboratory analysis. Since in this case there will be no insurmountable obstacles on the way - hard rocks (semi-rocky, rocky), manual drilling of water wells does not imply any special difficulties.

Artesian well

This aquifer can be located at a depth of 40 to 200 m, and water has to be extracted from cracks in rocks and semi-rocks, so it is inaccessible to mere mortals.Without knowledge and serious equipment for drilling, the task of building a well for limestone is an impossible mission. However, it can serve several sites at once, so drilling services ordered together promise significant savings.

Percussion drilling of a well for water

With the deepening of the shaft of more than 10 meters, drilling with the auger method becomes more and more difficult, which takes a lot of effort. The string of rods bends, the axis of the well is bent, it takes a long time to unscrew and screw the rod segments, and the risks of string rupture increase. The drill more and more often encounters stones, which significantly complicate the drilling of the wellbore. Drilling will be facilitated by impact drilling, which is effectively used when performing deep (over 10 m) wells for water.

Order percussion drilling next:

- wellbore basting. A tripod is installed above the prepared (pit laid) drilling site, a block is fixed and a steel cable is pulled. A drill suspended on a rope marks the center of the shaft, followed by drilling to a meter depth;

- drilling with a conical glass. Having fixed the tool on a rope, it is raised to a height of 1-1.5 m and thrown down. Crashing into the bottom of the mine shaft, the glass cuts the soil with its edges, collects it in itself and compacts it. It remains to raise and empty the glass on the surface, taking it away from the developed well and tapping it with a hammer. This tool is the main tool for percussion drilling;

- bailer passage. This drilling tool is necessary for drilling a section of a well in loose or water-saturated (quicksand) soils.Equipped with a valve, the bailer will allow you to remove mobile soil rocks from the mine shaft while lowering the casing pipes, otherwise the rock will fill the well.

Combining two drilling tools - a glass and a bailer - it is possible to prepare a water well with a depth of more than 20 m in a couple of days. If the glass does not collect soil well due to its dryness, hardness, flowability or waterlogging, then in the first two cases, water should be poured into the well, and in the remaining two, some plant soil should be added and slightly moistened with water. It is impossible to make a drill glass and a bailer at home, since both tools require manufacturing according to a certain technology, forging and hardening.

When drilling in hard formations, a special factory-made bit is required, which is dropped with a strong impact. To enhance the impact, a massive rod, weighted with concrete, is needed. It is more convenient to use a composite rod formed by steel bars with concrete filler. Such blanks should be connected into a column with bolts on the flanges, since the threads will collapse after impacts and the blanks will be practically inseparable. The mass of the impact rod with a chisel can reach 500 kg, it should be controlled only by a steel cable.

The nuances of installing casing pipes

It can be metal, asbestos cement or plastic. Each of the materials has its own advantages and disadvantages. Concrete casing pipes are rarely used. This is usually production. The material is heavy, brittle, prone to splitting. Therefore, in the process of drilling wells, either steel or HDPE is used.

The metal oxidizes unless it is stainless steel, which is expensive.Oxide causes deterioration in water quality. Over time, it becomes brown and has a metallic taste. You will have to install a filter and clean the well. Connections are welded. It is they who are the weak point, and after depressurization, groundwater with dirt enters the casing pipe.

Low pressure plastic (HDPE) is lightweight, which simplifies installation. The inner surface is smooth and no deposits appear on it. Corrosion is not terrible, connections are tight. The sections are twisted by means of the provided thread, and no special tools are required for this. The only drawback is the limitation on the depth of the well. This material is not suitable for an artesian well.

How to equip a punched well

Punching/drilling a well is not enough. We still need to raise the water, and this is a completely different story. How to bring water from the well to the house, read here. If you want to make the water supply constant, with normal pressure, so that you can connect household appliances, you will need a pumping station.

For seasonal water supply in the country, you can get by with a more modest set:

- vibration pump;

- check valve, which is installed in front of the pump;

- water container;

- watering hose;

- taps, etc.

Please note that the check valve is installed in front of the pump, and not at the end of the hose submerged into the well. Just like that, this same hose will not break during frosts

Another plus of such a device is that it is easier to dismantle for the winter.

Another tip: the well must be closed with something. In permanent residences, a caisson is made - a concrete or plastic bunker, which is located below the freezing depth. It contains all the equipment.When using water only periodically, the caisson is too expensive. But something needs to close the well. Firstly, some kind of living creature may fall into it, which will not please you in any way. Secondly, "good" neighbors can drop something. A more budgetary way out is to build a house like a well. An even cheaper option is to dig a pit, beat it with a board, and make a wooden cover. Key point: all this should be locked.

Methods for self-drilling

To drill a well for water in a country house, a personal plot, a rural courtyard, it must be taken into account that there are three ranges of depths at which aquifers occur:

- Abyssinian well. Before the water will have to drill from one and a half to 10 meters.

- On the sand. To make a well of this type, you need to pierce the soil to a mark in the range from 12 to 50 m.

- Artesian source. 100-350 meters. The deepest well, but with the purest drinking water.

In this case, each time a separate type of drilling rig is used. The determining factor is the chosen method of drilling operations.

Shock rope

With such drilling of wells for water, the technology of the process involves raising the pipe with three cutters to a height. After that, being weighted with a load, it descends, and crushes the rock under its own weight. Another device necessary for extracting crushed soil is a bailer. All of the above can be bought or made with your own hands.

But before you drill a well with your own hands, you will have to use a garden or fishing drill to make the primary recess. You will also need a metal profile tripod, a cable and a system of blocks.The drummer can be lifted with a manual or automated winch. The use of an electric motor will speed up the process.

Auger

This technology of drilling wells under water involves the use of a drill, which is a rod with a helical blade. A pipe with a diameter of 10 cm is used as the first element. A blade is welded onto it, the outer edges of which form a diameter of 20 cm. To make one turn, a sheet metal circle is used.

A cut is made from the center along the radius, and a hole equal to the diameter of the pipe is cut along the axis. The design is “divorced” so that a screw is formed that needs to be welded. To drill a well in the country with your own hands using an auger, you need a device that will serve as a drive.

It could be a metal handle. The main thing is that it can be disconnected. As the drill deepens into the ground, it is increased by adding another section. The fastening is welded, reliable, so that the elements do not come apart during the work. After the procedure is completed, the entire structure is removed, and casing pipes are lowered into the shaft.

Rotary

Such drilling of a well in the country is not the cheapest option, but the most effective. The essence of the method is the combination of two technologies (shock and screw). The main element that receives the load is the crown, which is fixed on the pipe. As it sinks into the ground, sections are added.

Before you make a well, you need to take care of the water supply inside the drill. This will soften the ground, which will extend the life of the crown. This method will speed up the drilling process. You will also need a special installation that will rotate, raise and lower the drill with a crown.

Puncture

This is a separate technology that allows you to penetrate the ground horizontally. This is necessary for laying pipelines, cables and other communication systems under roads, buildings, in places where it is impossible to dig a trench. At its core, this is an auger method, but it is used for drilling horizontally.

The pit is dug, the installation is installed, the drilling process begins with periodic sampling of rock from the pit. If water in the country can be obtained from a well separated by an obstacle, a puncture is made, a horizontal casing pipe is laid, and a pipeline is pulled. Everything can be done with your own hands.

When is it more profitable to carry out drilling seasonal features

The seasonal peak in demand for drilling is summer and the first month of autumn. Indeed, the conditions are ideal, the ground is solid and it is possible to equip a source of any type, regardless of depth.

In spring and late autumn, demand is minimal, there are no queues. This is due to the large amount of precipitation and the specifics of the technology. In winter, there are more chances to save money: but in cold weather it is better to only drill, and postpone the arrangement until warmer weather.

In the off-season, you can drill artesian wells: in spring or autumn, work is carried out to slaughter deep sources for sand and limestone. Can be drilled:

- If there is a good road to the site.

- When the site is not landscaped.

From surface sources in the off-season, it makes sense to equip an igloo or an Abyssinian well. The casing pipe is installed during drilling, being at the same time a drill - shedding of the walls does not slow down the work. Usually, the slaughter is carried out manually: in wet soil, the passage is facilitated and occurs faster.

Flaws:

- There is severe damage to the area.

- The extracted wet soil is difficult to dispose of; during rains, the dirt spreads throughout the site.

- High risk of errors in determining the depth, difficulties with the installation of equipment.

The best conditions for drilling any well are summer and autumn. The groundwater level is the lowest. The soil is compacted, the equipment is easy to deliver even off-road. After completion of work, only dry soil from the trunk will remain on the site, which is easy to remove.

Advantages:

- It is easier to choose a time without precipitation to organize work.

- There is no risk of collapse or flooding of the trunk with perched water.

- It is possible to carry out work in the complex: drilling with simultaneous arrangement.

- Ideal conditions for all types of sources: surface and deep.

Of the shortcomings, it is worth noting the heavy workload of drilling crews. It is better to order summer drilling in advance: 4-5 months before the planned procedure. It is also better to negotiate the cost in advance and make an advance payment. Increased demand stimulates seasonal price increases. Equipment should be purchased in advance: at the peak of the construction season, prices for materials for arrangement also increase.

The winter period is ideal for slaughtering deep artesian wells. Advantages:

- Clean area after work.

- The lawn is not damaged.

- The integrity of the soil is not violated.

- Drilling will cost less - there is a seasonal decline in demand.

- Minimal risk of depth errors.

The disadvantage of winter drilling is the uncomfortable working temperature for the craftsmen and restrictions on the installation of equipment: it is impossible to install a pipeline and connect pumps at temperatures below -5o.There is a way out: assemble the pump group in an isolated room or basement, or postpone the piping until warmer weather.

In winter, not only heavy equipment works: you can make a sand well without unnecessary dirt and at a bargain price. On the video: how a compact installation works on a landscaped area in winter.

Drilling is a job for specialists. It is not necessary to choose the type of source and the season for work on your own, but after a complete analysis of all the initial data. Masters will tell you which type of water intake will be cheaper, when it is faster and more profitable to carry out

Types of wells

To drill a well, you need to find out the location of aquifers

To drill a well, you need to find out the location of aquifers

On the site, you can equip several types of sources that differ in design. At the same time, it is necessary to clarify at what depth the water is in order to choose the optimal place. Usually, when processing documents, the owners are advised one or another location. In particularly difficult cases, you have to spend a lot of money to get to the water, for example, if the house is located on a hill, the depth of the well automatically increases by a distance equal to its height.

Types of sources that you can do with your own hands:

- Abyssinian well - the simplest design;

- sand well - depth up to 12 meters;

- artesian - a well on limestone.

The Abyssinian well is a pipe up to 4 cm in diameter. It may be even smaller - 2.5 cm. There is a filter and a sharp tip at the bottom, which is why the Abyssinian is also called a needle. Water can be pumped out using a hand pump or a pumping station connected to electricity. Depending on the filling rate of the well, up to 3 cubic meters of liquid is pumped out per hour.

The Abyssinian well is a pipe up to 4 cm in diameter. It may be even smaller - 2.5 cm. There is a filter and a sharp tip at the bottom, which is why the Abyssinian is also called a needle. Water can be pumped out using a hand pump or a pumping station connected to electricity. Depending on the filling rate of the well, up to 3 cubic meters of liquid is pumped out per hour.

Advantages of arranging an Abyssinian well:

- speed - the installation takes several hours and then you can use the source;

- there is no need to buy expensive materials and rent drilling equipment;

- long service life of 10 - 15 years, if the underground water intake is properly equipped.

If the distance to the water surface is more than 8 meters, it is necessary to additionally equip caisson for pumping station several meters below ground level, which will entail additional costs of time and money. The problem is that the station cannot lift liquid from great depths, and the submersible pump does not fit into a very narrow hole in the casing. Before proceeding with the arrangement, you need to find out the depth of the aquifer and determine the type of soil.

Well on the sand

Sandy soil filters the liquid well from large particles, so the water in the well is transparent. As long as the filter is done correctly. The main problem is flowability, so the walls often collapse during well installation. At the same time, drilling rigs easily cope with the soft layer, so the work does not last long.

Sandy soil filters the liquid well from large particles, so the water in the well is transparent. As long as the filter is done correctly. The main problem is flowability, so the walls often collapse during well installation. At the same time, drilling rigs easily cope with the soft layer, so the work does not last long.

Sand wells can be drilled to a depth of up to 35 meters, but they have many disadvantages:

- insufficient natural water filtration, since sand does not remove dissolved substances and wastewater residues, as well as pesticides and other types of agricultural chemicals;

- the well can work no longer than 20 years, then the process of silting occurs and a major overhaul with flushing is necessary;

- sand clogs the filter, which can be cleaned by removing the entire casing;

- the need for regular cleaning of the pump, since its filter element is also clogged with small solid particles.

However, most of the existing wells are sand, as they are much cheaper than artesian ones.

artesian well

Water-bearing limestone can be found at a depth of 50 to 250 meters. In one area, the difference is up to 150 - 200 meters. There is an opinion that artesian water is much cleaner than sandy water. This is not entirely true. It is a bit cleaner as the liquid goes through more layers of soil. The main advantage of an artesian well is a high filling rate and an inexhaustible supply of water. In limestone rocks, the fluid is under high pressure and when drilled, it rises higher. There were cases when the water itself poured over the edge of the neck. In this way, the liquid can be raised to the desired level in order to be able to install a pumping station or a shallow submersible pump.

Water-bearing limestone can be found at a depth of 50 to 250 meters. In one area, the difference is up to 150 - 200 meters. There is an opinion that artesian water is much cleaner than sandy water. This is not entirely true. It is a bit cleaner as the liquid goes through more layers of soil. The main advantage of an artesian well is a high filling rate and an inexhaustible supply of water. In limestone rocks, the fluid is under high pressure and when drilled, it rises higher. There were cases when the water itself poured over the edge of the neck. In this way, the liquid can be raised to the desired level in order to be able to install a pumping station or a shallow submersible pump.

The advantage of an artesian well:

- there are no seasonal fluctuations in the water level, which has a positive effect on the operation of pumping equipment;

- the liquid is cleaner - it can be used raw without boiling;

- dissolved minerals have a positive effect on health;

- no repair and maintenance is required, subject to high-quality installation;

- long service life - more than 50 years.

The deepest artesian well drilled by man reaches a depth of more than 12 km. It is located on the Kola Peninsula and is listed in the Guinness Book of Records. Back in the 13th century, the Chinese manually drilled very deep wells - up to 1.5 km.

Conclusions and useful video on the topic

Drilling a well with a shock-rope method:

The subtleties of making a screw with your own hands:

For those who want to know how to competently drill a water well manually, we have given proven methods in practice.It is necessary to choose the optimal method of drilling, to seriously approach the choice of the necessary equipment, and when drilling, strictly follow the advice of experienced craftsmen.

The result of the efforts made will be a self-equipped source of water supply, providing clean water to all households.

Would you like to tell how you drilled a well in your own area? Have questions or interesting facts about the topic of the article? Please write your comments in the box below.