- Auger Drilling Tool

- The principle of operation of the installations

- Equipment

- Drilling methods

- Manual way

- rotary method

- Shock-rope method

- screw method

- column method

- Varieties of drilling rigs

- Drilling technique

- Types of drilling methods

- Well Depth Determination

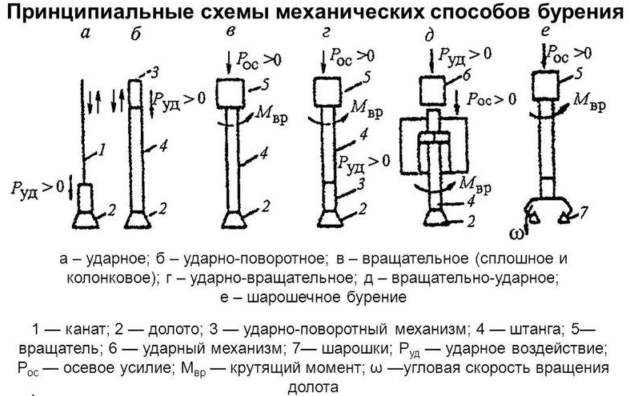

- Classification and general characteristics of drilling methods

- 1 What are the features of rotary drilling technology?

- 1.1 Work equipment

- Pros and cons of the method

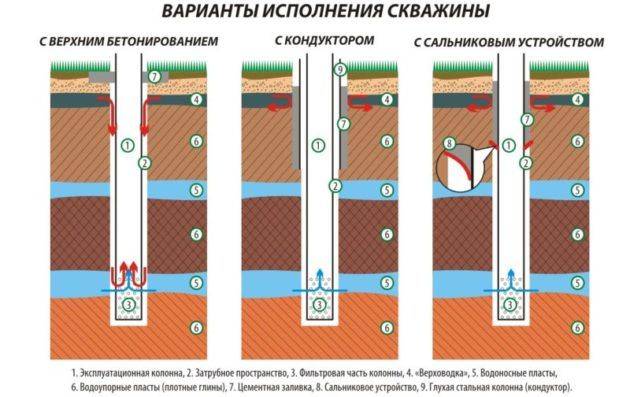

- Types of wells

- Abyssinian well

- sand well

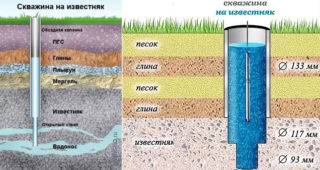

- limestone wells

- Stages of work

- Process

- With direct feed

- Backfeed

- Drilling Options

- Tripod

- Drill and casing

Auger Drilling Tool

Tools for auger drilling according to the type of construction, they are distinguished by the number of turns and the geometry of the cutting part. For driving in hard and semi-solid sandy loams and loams, drilling tools are often used, the edge of which is equipped with additional cutters.

Most often, for driving a water intake for private traders, only one starting auger is used without any additions, because. sedimentary cohesive and non-cohesive rocks are to be drilled. When deepening, the tool is simply increased by drilling rods.

In this case, the projectile is removed from the wellbore every 0.5 - 0.7 m in order to clean the drill itself and the bottom from the destroyed rock. This is a more economical, but also more labor-intensive drilling option.

To drill boulders and pebbles that can be found in sedimentary soils, they switch to the shock-rope method. As a rule, a chisel made of tool steel is used for this. This drill, pointed at the lower end, is “thrown” with effort at the bottom until the “solid barrier” is destroyed.

After the destruction of a pebble or boulder, the fragments are removed to the surface with a glass (column pipe) or bailer. Then they switch back to the screw method. Most often, for sinking a working, it is necessary to use several drilling methods in combination.

When drilling loose sands and soft loams, drilling auger shells are used with blades turned to the bottom at an angle of 30-60º, and for drilling in cohesive clay rocks - 90º.

Structurally, the screw is a pipe or a long solid rod / rod with a wound spiral

Structurally, the screw is a pipe or a long solid rod / rod with a wound spiral

This spiral is obtained by winding a high-strength steel tape with a diameter of 5-7 mm on a screw mandrel. It is stretched on a pipe / rod, after which it is welded.

The larger the diameter of the base pipe, the lower the conveying capacity of the screw. However, the diameter of a long product is limited by the mechanical strength of the screw, as well as by the technology of its production.

Today, two types of screws are made:

- With a central hole, that is, hollow;

- Weighted - no hole.

To minimize the wear of the screw conveyor when drilling in abrasive formations, a steel strip is wound on the outer edge or a layer of metal is deposited on the surface.

At high speeds of auger drilling, a special adapter with a two-start winding of strip steel is fixed above the projectile. In this case, the bulk of the rock falls on the screw conveyor without grinding.

At the end of the pipe with a wound spiral, the connection elements must be welded. There are two types of auger connections: threadless and threaded. In the first case, the augers are connected by coupling locks and held by metal pins with locks, in the second case, by screwing.

The threaded connection of augers in the drill string makes it possible to mechanize their connection and disconnection when performing tripping operations, when supplying fluid to the bottomhole. But there is also a significant minus - there is no possibility of reverse rotation of the screws in this case. Therefore, the threadless connection has become more widespread.

Special drilling rigs, as a rule, include a set of augers of different diameters.

The most efficient are augers with a central hole through which air or water is supplied to the bottom. This makes it possible to reduce the friction of the rock on the surface of the screw conveyor.

The most efficient are augers with a central hole through which air or water is supplied to the bottom. This makes it possible to reduce the friction of the rock on the surface of the screw conveyor.

Hollow augers with a threaded type of connection are used when drilling with a purge, for pumping water when driving cylindrical workings in the earth's crust, for installing a charge in geophysical wells, for pumping concrete into holes for piles. They can also be used as a casing string.

When drilling with a solid face, the central channel is blocked with a drilling tool on a rope.

The principle of operation of the installations

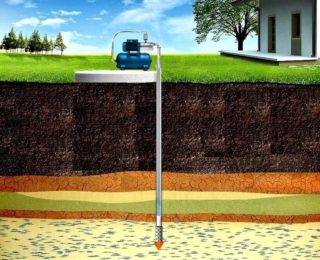

Rotary drilling is an ideal method for shaping a well or extracting water if the result is the possibility of consuming large amounts of clean drinking water. Such a well should work for a long time and uninterruptedly.

To achieve good results will allow such a hydraulic structure as a rotary plant.

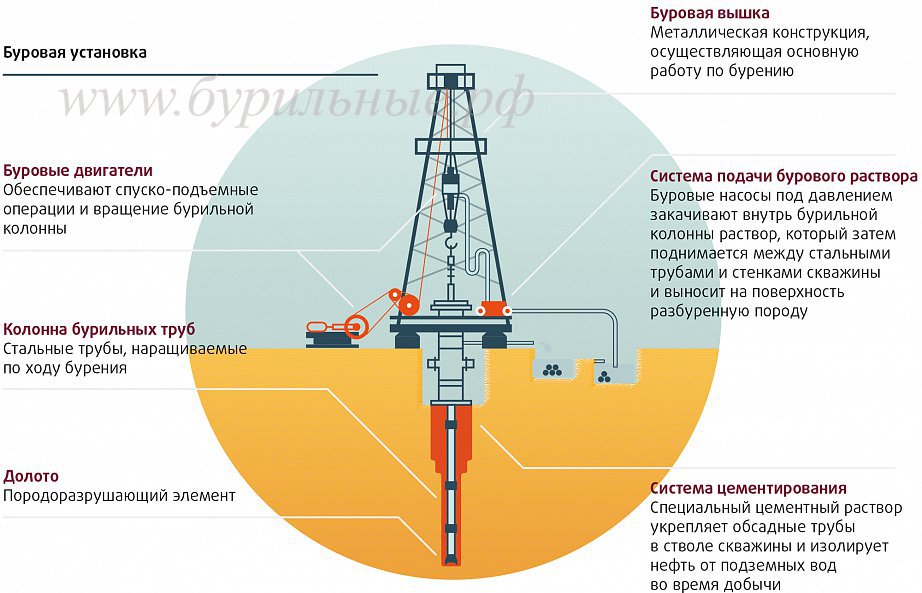

Scheme of the drilling rig

Scheme of the drilling rig

It is able to drill a very deep well, the water from which is enough not only for drinking purposes, watering the site, pool, but also for other domestic needs.

In rotary drilling, the technology is quite simple. A shaft with a tip, which is a chisel, is lowered into the drill pipe. The process of rotation begins, and with the help of a chisel, the rock is destroyed. The rotation process itself is carried out using a hydraulic installation. In order for the destroyed rock to leave the well, a flushing solution is used. There are two ways to submit it:

- Direct flush. It is pumped into the drill pipe using a pump, and squeezed out through the annulus.

- Backwash. Everything happens opposite to direct flushing: first, flushing fluid is supplied to the annulus, and then, using pumps, it is pumped out together with the rock from the drill pipe.

Direct flushing relative to reverse flushing is inexpensive, which allows owners of country houses to use this method. When drilling on an industrial scale, for example, in the development of oil wells, the backwash method is more rational, although more expensive.

The cleaning system itself also consists of several elements:

- gutter;

- vibrating sieve;

- hydrocyclones.

Rotary controlled system

Equipment

Rotary drilling cannot be carried out without special equipment, which includes the following devices and mechanisms:

- tower;

- rotor;

- driven drilling rig;

- piston type pumping equipment;

- drilling swivel;

- mechanisms and equipment for cleaning with a washing solution;

- traveling system, consisting of a crown block;

- gutter;

- vibrating sieve;

- hydrocyclones (usually used in oil drilling).

The mobile version of the rotary drilling rig has all of the above components, except for the cleaning system with a flushing solution.

Drilling methods

Drilling methods are classified according to two parameters.

Depending on the mechanism used, drilling can be:

- mechanical;

- Manual.

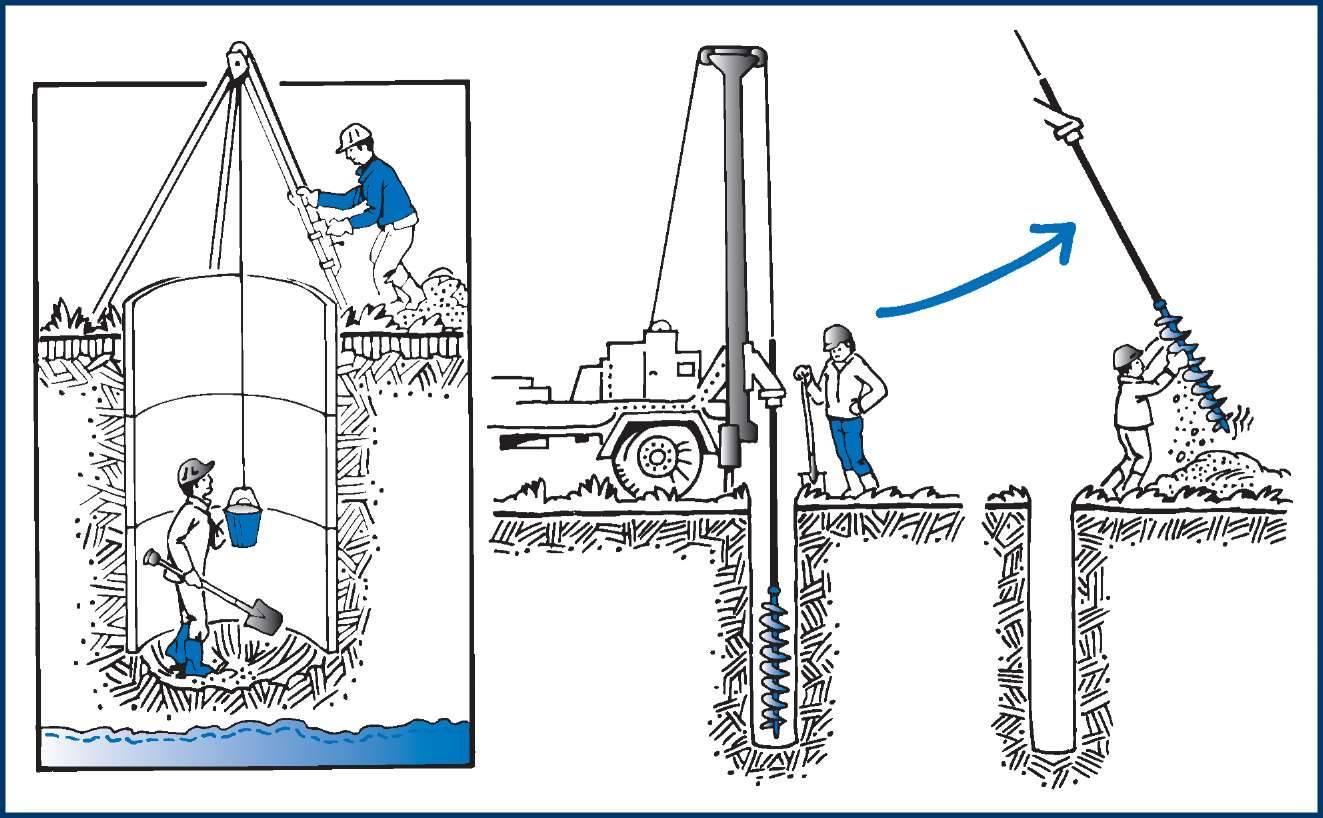

Well options

Well options

Depending on the principle of operation of the drill:

- Shock-rotational method;

- Shock;

- Rotational.

Consider what is remarkable about each water well drilling technology and how it is performed.

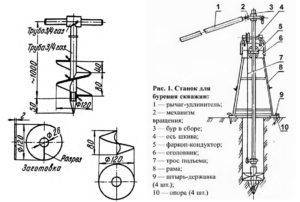

Manual way

Manual drilling of a well is quite suitable for self-performing the process with all the necessary tools. Such a well will be no more than thirty meters, the soil is pierced until the water layer is reached.

To do this, you will need casing pipes, rods, a winch and drill heads of various parameters. When creating a deeper well, a drilling rig is needed to raise and lower the drill.

If the rod was not found, you can make it by connecting the pipes with veneer or thread. A drill head is attached to the end of the lower rod. The process looks like this:

Auger-drill and do-it-yourself well drilling machine

Auger-drill and do-it-yourself well drilling machine

- Above the site of the proposed well, a tower is placed so that it is slightly higher than the length of the rod.

- Dig a small hole for the drill with a shovel.

- Insert the drill into the recess and rotate it. You may need help, because as you go deeper, the movement of the drill will be more difficult.

- Having broken half a meter, stop, take out the drill and clean it from the adhering earth.

- When you reach the water layer, pump out three to four buckets of ground water.

The last action is necessary to eliminate dirty water and can be done with a submersible pump.

rotary method

This is the rotary method most commonly used in deep hole drilling. To do this, you need a special installation equipped with a pipe. This pipe has a rotating shaft and a chisel. The impact on the bit is performed by hydraulic installation. The soil from the drilled well is washed out with a special solution.

Thus, the pipe is located above the drilling site and, when the shaft and the chisel rotate, it breaks through the soil. The liquid can be fed down the wellbore from top to bottom, then the solution, washing out the earth, goes out through the annulus. This method is called direct flushing.

Backwashing can also be used, in which the solution flows by gravity into the annulus and, after punching, is pumped out by a submersible pump.

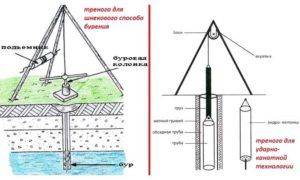

Shock-rope method

The method is based on the fall of the heaviest tool, usually a driving glass, from a derrick at the location of the proposed well. If you want to independently apply shock-rope technology, you will need:

- Durable rope;

- Downhole glass - usually a strong metal pipe suspended on a rope;

- Soil cleaning tools.

Technology and sequence of actions:

Shock-rope method - drilling technology

Shock-rope method - drilling technology

- They make a tower in the form of a tripod from steel pipes or strong logs. The height depends on the length of the downhole glass and must exceed it by 1.5 meters.

- The downhole glass is made of a steel pipe, at the end of which there is a cutting device.

- A cable is attached to the top of the glass.

- By adjusting the cable, the glass is quickly released to the breakdown site.

- The earth is removed from the glass every half a meter drilled.

To create a deep well, installations of the UGB-1VS type are involved.

screw method

Drilling a well with an auger

The method takes its name from the main tool used - the auger or Archimedean screw. It looks like a drill rod, to which the blades are welded helically. Rotating such an auger, the earth is brought to the surface and collected.

For a deeper well, you will need to rent a small-sized, easily transportable drilling rig, since a self-made auger drills no more than ten meters deep.

It should be noted that the auger method is only suitable if the soil is rich in sandy rock. In addition, if the auger collides with a stone on its way, you will have to look for another place to break through the soil and stop work.

column method

Core technology is less and less used these days for drilling wells under water. It is often used for hydrogeological studies. For this, equipment of the ZiF-650 type is used, which extracts a column of soil, creating a so-called column.

Scheme of a core bit for drilling a well under water

The destruction of the soil is carried out in a ring way, then it is washed out.The speed of such an arrangement is quite high, in addition, it allows breaking through hard rocks, but it requires high costs for renting serious geological equipment.

Varieties of drilling rigs

Mini drilling rig

The aggregates under consideration are classified according to the peculiarities of well drilling methods.

So, when percussion-rope drilling is performed, the soil is destroyed by a heavy load tied to a support frame, the ribs of which in most cases are connected into a pyramid. The load is simply lifted up and thrown down as many times as it takes to create a recess of the desired size.

Drilling wells by shock-rope method

Rotating drills are both simpler and more difficult to handle. Such equipment requires much less physical effort on the part of the performer, but the design of such drilling rigs is more complex - many of the components of the system simply cannot be made by hand without special equipment and appropriate skills.

Well drilling scheme

As a result, some of the necessary elements have to be bought or ordered. However, the cost of this is still significantly lower when compared with the cost of installing a factory assembly.

In general, there are 4 main types of drilling rigs, namely:

- units operating according to the shock-rope method. Externally, this design has the form of a frame with a triangular base. A strong cable with a bailer is attached directly to the frame;

-

screw type installations. In the case of using such equipment, excavation is carried out using a special auger. The recess in the ground during the drilling process is not washed;

-

rotary units.Operate using the principles of hydraulic drilling;

-

rotary hand mechanisms. The easiest type of installation. The design does not include an electric motor - physical force is used instead. It requires irrationally large labor costs, therefore it is used extremely rarely.

Drilling technique

Offshore drilling with a subsea wellhead is different from similar work on land. A special technology is used here, consisting of separate step-by-step actions.

Initially, a pile is driven into the seabed to act as a drilling direction. Then the bottom plate is installed in this place. Subsea wellhead equipment is mounted on it. Its mass can be up to 175 tons, height - up to 12 m. The underwater part is connected to the floating equipment, where special tension systems and floats are installed.

The underwater complex includes a diverter unit, a control system, a block of preventers, an emergency acoustic system.

The cost of one offshore well under normal conditions can reach up to 6 million dollars, in arctic conditions - up to 50 million dollars.

Types of drilling methods

Previously, drilling of aquifers for personal use was carried out mainly by hand. It was a laborious and lengthy process, so not every owner of a plot or cottage could boast of having his own source of water supply.

Gradually, mechanized drilling replaced manual methods due to the significant simplification and acceleration of the process.

Today, almost all water-bearing wells are drilled in a mechanized way, which is based on the destruction of the soil, supplying it to the surface in one of two ways: dry, when the waste soil is removed from the well using mechanisms, and hydraulically, when it is washed out with water supplied under pressure or gravity.

There are three main methods of mechanical drilling:

- Rotational (the soil is developed by rotation).

- Percussion (bursnaryad destroys the ground with blows).

- Vibrating (the soil is developed by high-frequency vibrations).

The rotational method is considered the most highly productive, 3-5 times more efficient than the impact method and 5-10 times more vibratory. In addition, the rotary method is the most inexpensive and affordable, it is often used as the main method of manual drilling.

Mechanical rotary methods of drilling water wells have replaced inefficient manual methods

In turn, the rotary drilling method, widely used for the construction of water wells, is divided into four main types of drilling:

- core;

- auger;

- shock-rope;

- rotary.

Each type of rotary drilling has its own characteristics and is performed by equipment specially designed for this purpose. Let's consider these types of drilling in more detail, determine what their differences are and what method should be used in each specific case.

Well Depth Determination

A medium-deep well (up to seven meters) will allow you to have drinking water. To make a drilling rig with your own hands, in addition to the drill, you will need a shovel and time to equip the pit. A pit measuring 2x2x2 meters is used to facilitate the process of drilling to great depths.To facilitate the work, it can be fixed with boards or plywood. After completion of work, the pit falls asleep. Water is taken in by a pump.

A deep well (more than seven meters) will make it possible to fully cover the need for water for all residents of a cottage or private house. Moreover, there will be enough water not only for individual use, but also for technical purposes, irrigation, sanitary requirements, maintenance of a pond or pool.

In general, the choice of the type of water intake will be determined after a geological survey of the well construction site. We propose to study in more detail the last option - the construction of a deep well with your own hands, as the most difficult of those described.

Classification and general characteristics of drilling methods

The drilling process consists of the destruction of the rock at the bottom of the hole (well) with a drilling tool and the removal of destruction products (drilling fines) from it.

With all drilling methods, the following main operations are performed: preparation and installation of the drilling machine to start work, drilling (destruction of rock) with cleaning the bottom of the well from destruction products, building up the drilling string to achieve the required drilling depth and disassembling it after completion of work, changing worn out drilling tools and moving the machine to a new hole or well drilling site.

At present, rotational, shock-rotary, shock-rotational and rotational-impact methods of drilling holes and wells (mechanical drilling methods), as well as fire and combined drilling are used.The effectiveness of the use of explosive energy in explosive drilling of wells, as well as high-voltage electrical discharges in electric pulse drilling, is investigated.

During rotary drilling, the tool rotates around an axis coinciding with the axis of the hole or well and simultaneously with a certain force is fed to the bottom. The magnitude of the force is set from the condition of exceeding the ultimate strength of the rock for indentation on the area of contact between the cutting blades of the tool and the rock. In this case, successive destruction from indentation and chipping of rock particles from the bottom occurs. Destruction products are removed using twisted rods (when drilling holes), augers (when drilling wells), flushing the bottom with water or blowing with air.

At mining enterprises, they use: rotary drilling of holes with cutters using hand and core drills; rotary (auger) drilling of wells with cutters and diamond tools using drilling rigs.

In the percussion method of drilling, the tool (chisel or crown) strikes the bottom and destroys the rock under the blade. After each impact, the tool rotates through a certain angle, which ensures the consistent destruction of the entire bottomhole area and obtaining a round section of the hole or well.

During rotary percussion drilling with conventional and submersible drill hammers (perforators), the tool rotates intermittently only in the intervals between blows by a rotary device mounted in the hammer. In some designs of hammer drills, the rotation of the tool occurs during the period when the piston strikes the tool.

In percussion-rotary drilling with down-the-hole hammers and drill hammers with independent rotation, impacts are applied to a continuously rotating tool.The destruction of the rock with these drilling methods occurs only as a result of the introduction of the drill bit during impacts.

In rotary percussion drilling, impacts are applied to a tool that is continuously rotating under a large axial force. Destruction occurs both as a result of the introduction of the tool during impacts, and as a result of rock chipping during the rotation of the tool.

Drilling with cone bits is performed both in the percussion method with pure rolling bits and in the rotational percussion method with sliding bits, in which the teeth, along with rolling along the bottom, cut the rock with a sliding motion along the surface of the bottom.

During fire drilling, the destruction of rock at the bottom of wells occurs due to thermal stresses that occur when the rock surface is rapidly heated by hot gas flows (2000 ° C) emitted from the burner nozzles at supersonic speed (2000 m/s or more).

During explosive drilling, the destruction of rock at the bottom of wells occurs by successive explosions of small explosive charges. Two methods of explosive drilling are known: cartridge drilling, using cartridges of liquid or solid explosives that explode at the bottom from a blow or detonator, and jet drilling, in which liquid explosive components (fuel and oxidizer) are fed through the drill to the bottom and a liquid flat charge is formed. The explosion of this charge is caused by injecting a drop of an initiating compound (a eutectic alloy of potassium and sodium).

During electric pulse drilling, the destruction of rocks at the bottom of the well occurs due to electrical breakdown of its section by a high-voltage (up to 200 kV) discharge.Instantaneously released energy in the breakdown channel destroys the rock, which is removed from the bottomhole by a dielectric flow circulating in the well (solar oil, water, etc.).

Combined drilling methods are being developed, in which there is a joint effect on the bottomhole of a percussion tool and a cutter (percussion-cone method), cutters and cones (cutting-cone method), cutters and a fire burner (thermo-cone method), a fire burner and a percussion tool ( thermal shock method).

1 What are the features of rotary drilling technology?

Rotary well drilling is a technology suitable when it is necessary to obtain a large volume of the most environmentally friendly water, with a stable, durable operation of the entire system. In such conditions, the rotary drilling method is out of competition.

In general, rotary drilling rigs during their operation have the following advantages over analogues:

- Extraction of water in large volume;

- Rotor drilling has a long service life;

- Large volumes of water are supplied consistently, without interruptions or problems;

- High quality of produced water.

The rotors of drilling rigs are capable of extracting from a source such an amount of water that it will be enough not only to supply water to the house, but also to fill various reservoirs (such as a swimming pool), watering and for the needs of a couple of other buildings. Thanks to this, it is possible to be in cooperation with neighbors, thereby not spending huge amounts of money on arranging water intake.

Rotary drilling technology has proven to be durable and stable.By following all the instructions for working with a rotary drilling system, and the operation of plastic pipes in its design, the user can be sure that the service life of such a system will be at least two decades.

If it is necessary to drill deep wells for water, rotor drilling is usually used. The mechanism of operation of such a system looks like this: a rotating shaft is loaded into the drill pipe, which has a strong tip - a bit (for example, a PDC bit). The weight on the bit is achieved by the operation of the hydraulic unit.

Thanks to this mechanism of operation, it is possible to reach any depth of the well for water production. The well is washed from the soil in it with a special drilling fluid, which is supplied through pipes in two different ways:

Drilling process

- It is pumped into the drill pipe using a special pump, and then it flows out by gravity through the annulus (the so-called “direct flushing”);

- The solution passes by gravity into the annulus, and then with the help of a pump it is pumped out together with the soil from the drill pipe (the so-called "backwash").

Rotor drilling by such methods is used even in oil wells.

At the same time, backwashing is good in that thanks to it, a greater well flow rate is produced, because the aquifer is opened with the highest quality. However, one cannot do without the involvement of the most complex and high-tech equipment with this method of work, and such rotor-drilling will be very costly in terms of money.

Rotor-drilling with direct flushing is somewhat cheaper than the first option, and that is why for the majority of owners of their data sites, the method is the most acceptable and adequate in terms of price.

1.1 Work equipment

The equipment used in rotary drilling includes the following components:

- Tower;

- Drilling rig and drive to it;

- Rotor;

- piston pumps;

- Drilling swivel;

- Travel system from crown block;

- Cleaning system with special liquids;

- vibrating sieve;

- Gutter;

- Hydrocyclones (necessary most often for oil wells).

It is important to note that there are not only stationary rotary installations (such as in oil well production). There are also mobile versions that are equipped with a special platform mounted on a trailer.

Compact Rotary Drilling Rig

At the same time, all the listed equipment is present in the mobile version except for the liquid cleaning system. Thanks to this version of the rotary unit, which has maneuverability and the ability to change its position in the shortest possible time, you can save money at the stage of choosing the right well.

Pros and cons of the method

Among the drilling methods of water wells, the rotary method is considered one of the most popular. This technique is widespread throughout the world.

The advantages include the following:

- Dimensions. The whole structure for rotary drilling takes up little space.

- Ability to transport equipment. Due to its small size, the unit can be placed on special platforms for further movement.

- Versatility. Rotary drilling can be used under a wider range of conditions than impact technology, since many nozzles can be used. Due to this, it will be possible to process any type of soil layers.

- Rapidity.Due to the peculiarities of rotary drilling, labor productivity is much higher than that of the percussion method.

But there are also some disadvantages. The following problems may occur:

- When the soil freezes, it prevents rotary drilling. In this case, it is best to use the impact technique, which is also suitable for work in winter conditions.

- The clay content of the solution. It provokes the appearance of difficulties during the study of layers.

- Power change. The value depends on the performance of the rotor, a rather vulnerable part in the entire structure.

Types of wells

The task of the well is to connect the water carrier with the water consumer. An exploratory well is drilled to determine the depth of the water layer and its parameters. Reducing the cost of work is achieved by using drills of reduced diameter. When developing top water, it is enough to install a drill with a diameter of 10 cm, for deeper deposits - 20 cm. The depth is determined using special probes.

Abyssinian well

The main advantages of the wells under consideration are: low costs, the possibility of self-manufacturing, the speed of arrangement, the ability to install almost anywhere (even in the basement of a house). The service life is estimated at 25-35 years. Among the shortcomings, the following is noted: the impossibility of equipment on especially hard ground, a surface pump can only be used at a depth of no more than 6 m.

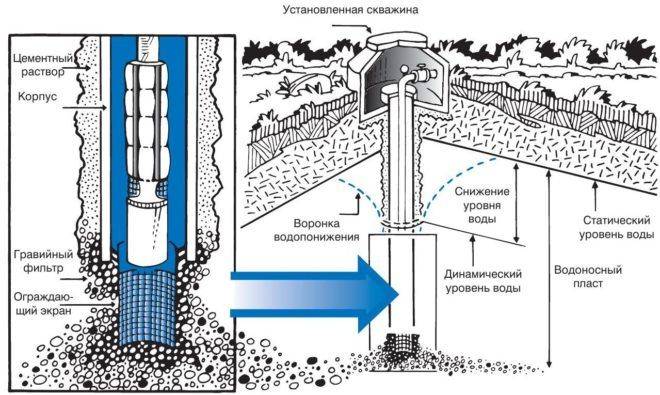

sand well

A filter well is drilled when developing a sandy aquifer located at a depth of up to 40-45 m. It is drilled using special equipment and immediately equipped with a casing string to prevent shedding of the wall.Metal, plastic or concrete pipes with a diameter of 13-20 cm are used for the column. A filter is installed at the bottom. The rise of water is provided by a submersible pump.

Advantages of a sand well: use of small-sized equipment for drilling, which reduces costs; you can install a pump of small power; a well is drilled in 1-2 days. Disadvantages: low productivity (up to 2 cubic meters per hour), dependence of water quality on many factors and its instability, dependence of the level of water occurrence on the season.

limestone wells

Advantages of artesian wells: high purity of water, constant level of occurrence of the water carrier, increased productivity (up to 9-10 cubic meters per hour), durability (more than 40 years). Disadvantages: increased costs for drilling and development, manufacturing time (5-8 days), the need for a site for the operation of large-sized equipment.

Stages of work

The use of augers makes it possible to create wells for various purposes in a vertical or horizontal direction. If necessary, during drilling, casing pipes or the technology of plugging the walls of the hole with concrete from the surface under pressure are used.

The workflow includes several steps:

- geological exploration with the help of special equipment, ensuring the correct choice of a site for a future hydrological structure;

- digging a pit for subsequent dumping of cuttings at a distance of about 1 m from the intended well development site (its volumes are calculated based on the size of the hole);

- preparation of equipment, its installation on a stable platform (for a drilling rig placed on a chassis, reference points are created to prevent its mobility during work);

- deepening the first auger drill into the rock, extracting it to the surface and returning to its original position (these operations are carried out to prevent soil sticking to the working mechanism);

- connecting a new section to the working tool to achieve the required depth.

Upon completion of all work, the screw is removed in stages with the obligatory observance of special technological regulations in order to avoid damage or loss:

- the column of the mechanism is raised to such a level that the upper part of the tool is completely above the surface, and the subsequent section rises above it by about 15%;

- to fix the structure under the spiral, a channel is installed;

- metal fastening brackets are removed, the drill is dismantled.

Process

In rotary rotary drilling, two schemes are used that determine the applied mode, the speed of passage, and the economy of the process. If wells are made in a limited space of private land ownership, direct flushing is used, and if operating conditions require, reverse current flushing is used.

With direct feed

The composition is fed directly through the pipes to the bottom of the created well, and then rises up through the gap between the pipe shell and the wall. After reaching the surface, it is sent to the sump, where it is again filtered and put into motion for a new cycle.

Backfeed

The process is the other way around - it goes down through the annular space, along the walls of the well, and returns up through the drill pipes.Rarely, but sometimes a combined method is used, in which there is one and the second type of washing. Since the invention, motors have been improved, the main components have been modified, different fluid compositions have been used. But the principle of work as a whole remained unchanged.

Currently, it is used both in the construction of oil and gas wells, and in the digging of artesian wells in a limited space of a personal or summer cottage. For the owner of a private land plot, located far from the source-reservoir and from the central water supply, there is only one opportunity to acquire water - an artesian well obtained by rotary drilling.

In the next video you can take a look at rotary drilling.

Drilling Options

Tripod

new entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives makeSecrets of growing seedlings from the Japanese, who are very sensitive to the land

The tripod can be made of wood (knots are not allowed) or a profile pipe. The length of the pipe or beam should be about 4.5-5.5 m.

Then a mechanical winch with a cable is fixed to the tripod, where the drill glass is attached.

This drilling rig is quite small and has a sufficient margin of safety. The principle of operation of the mechanism is quite simple: the glass, sinking into the ground, absorbs the soil. Taking into account the composition of the soil in one blow, you can get 0.30-1.2 m of land. You can simplify the work by pouring water into the drilling site. Periodically, the drill glass must be cleaned of stuffed earth.

The casing pipe can be installed simultaneously with the passage to the depth or after all the work done.

Drill and casing

When doing work, it is necessary to constantly monitor the humidity of the earth being removed so as not to miss the aquifer (otherwise it can simply be closed with a pipe).

Then, when an aquifer is found, the dirty water must be pumped out to determine if there is enough water in that layer. What is a manual or submersible pump used for? If, after pumping out several buckets of dirty water, clean still has not gone, then it is necessary to drill further to a more capacious core.