- Pipe cutting at 45 and 90 degree angles

- Large Diameter Pipe Cutting Methods

- 45 degree cutting

- Making a template for trimming a metal profile

- DIY pipe cutting miter box

- Changing the configuration of pipes made of non-ferrous metals

- How to bend copper and brass pipes?

- Aluminum tube bending

- Pipe cutter for steel pipes

- How to cut straight pipe lengthwise

- General recommendations of experts

- Bulgarian

- Roller pipe cutter

- gas cutting

- Plasma cutting

- Using a laser

- Cutting pipes at an angle: advantages and disadvantages of different methods

- 1. Methods for marking pipes at an angle of 45 degrees

- 2. Marking pipes at an angle of 90 degrees

- 3. Marking pipes at other angles

- How to cut a pipe in a "collar" way?

- How to cut along

- Kinds

- Video instruction: how to work with a pipe cutter.

- Video review of one of the models

- How to cut a metal pipe straight

- Cutting pipe at a 90 degree angle

- Cutting pipe at a 45 degree angle

- Use a sheet of paper or cardboard

- Square marking

- Safety when cutting a gas pipe

- Conclusions and useful video on the topic

Pipe cutting at 45 and 90 degree angles

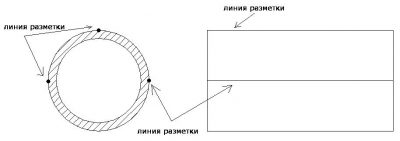

If you need to cut the pipe at an angle of 45 degrees, which is often required when laying water and heating pipes. Often used steel, cast iron pipes, which have a cylindrical shape.In installation work, rectangular or shaped pipes are used. However, you should correctly cut the pipe with a grinder, so that you can easily connect it later. Therefore, you should carefully mark the pipe.

Some masters try to mark the place of the cut with a tape measure, but we warn you that the result will most likely turn out to be negative. And for a positive result, consider the following recommendation of professionals.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe, where you plan to cut evenly. The edges of the paper must absolutely match each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark the cut line in a circle.

If you need to cut straight at a 90-degree angle, then solve the problem quickly with the help of paper or masking tape again. Wrap around the pipe so that the ends match up. Make an even markup and saw off.

How to cut a profile pipe straight?

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and turn and mark with smooth movements. After the action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to perform the action with a grinder, so the cut will be smoother.

How to cut cast iron pipe?

When working with cast iron pipe, keep in mind that this is a fragile material. Therefore, we will direct a method with which it will be possible to cut such a metal without damage.

Before starting work, make marks for the cut, as with steel pipes. Place a wooden beam for support. Walk the grinder around the circumference of the pipe, making small cuts.Then take the chisels, insert into the groove and hit hard with a hammer. Be aware that Bakelite cutting discs are used to cut cast iron pipes.

If there is no grinder at hand, to cut a cast-iron sewer pipe or other purposes, use a hacksaw, chisels or special pipe cutters.

How to cut a gas pipe?

Cutting a gas pipe is dangerous, so it's best to leave it to the professionals. But if you are confident in your abilities, then take a grinder, welding, hacksaw, gas welding to cut metal.

Trimming instruction:

- Shut off the gas supply before work. Then release the rest of the gas from the pipe. To do this, set fire to the gas in the burners and wait for it to go out.

- After the actions taken, cut. Using the welding method, the metal base burns out when exposed to high temperature. The result is fast and efficient. But remember that cutting or rooting gas pipes again requires experience.

Large Diameter Pipe Cutting Methods

For cutting large diameter pipes, such as sewers, there are a number of reliable tools available. Let's take a look at some of them in detail:

Bulgarian is an inexpensive and affordable option, but it is considered not the safest in working with such materials. Once you decide to use this method, then be careful and use protective equipment.

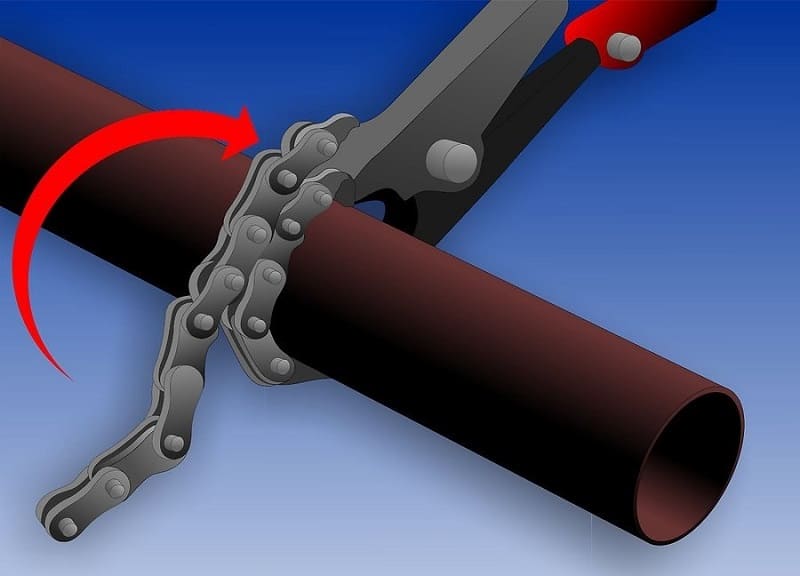

A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and material removal begins. The clamping force is adjusted by means of mechanical devices

It is important to note that machine models differ in shape, so consider the size relationship with the pipe before use.

Flame cutting is the most popular option for cutting larger diameter pipes and sheet metal. The cut occurs due to the action of a high-intensity flame, the metal melts and exits the cut zone with a gas flow

This method is convenient and efficient.

How to cut a pipe lengthwise correctly?

A quick way to cut a pipe lengthwise with a grinder:

Focus on the markup. Use for this case a paint thread, which has found distribution when marking walls.

Before starting work, fix the pipe and with small movements, carefully saw the pipe.

It is better not to rush, but delicately and slowly process the parts of the pipe, so the cutting disc does not come off the marking lines. Remember safety precautions.

How to cut thin wall pipes?

Thin-walled pipes are made of non-ferrous metals: aluminum, copper. Such work should be done delicately, as there is a high probability of deformation of the material. For cutting, fillers are used, for example, sand. Actions can be carried out using a grinder, a special machine.

45 degree cutting

But, if you still need to cut a round pipe from steel or various types of plastics, then for this you will need a template for cutting pipes at an angle, the shape of which is calculated manually or by machine. The task is greatly simplified if at an angle of forty-five degrees it is necessary to cut off a square metal profile.

For quick trimming, you can use a regular sheet of paper folded diagonally, with which you mark the surface for the future cut. Using folded paper, proceed as follows:

- carried out on a straight surface of the profile in the place where the cut is performed, strictly perpendicular to the line;

- apply a diagonally folded sheet of paper to the side surface with a sharp end to the line so that the upper edge of the paper triangle is flush with the upper side of the metal profile.

Rice. 2 Homemade template for cutting a pipe at 45 degrees

draw a line with a pencil along the side of the sheet at an angle of 45 degrees, after which the paper corner is applied to the other side and circle it with a pencil (it is better to use a thin marker).

For sawing, you can use a grinder with a disc for metal, drawing a thin line along the marking at the beginning, and then gradually deepening it until the edges are completely separated.

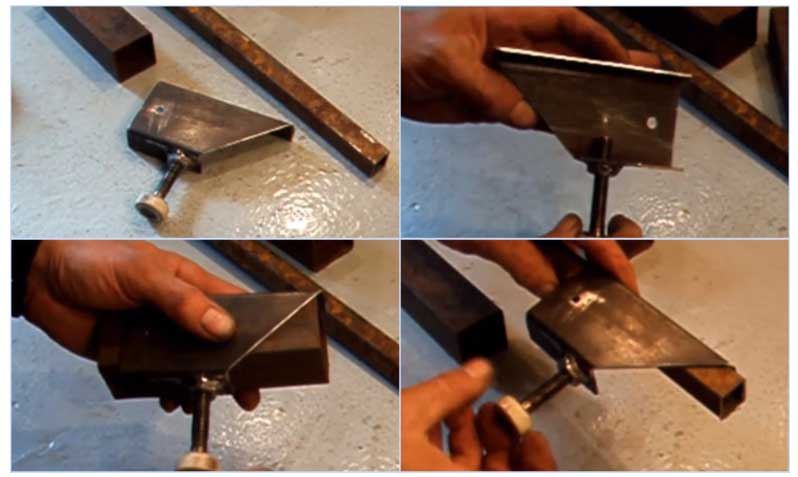

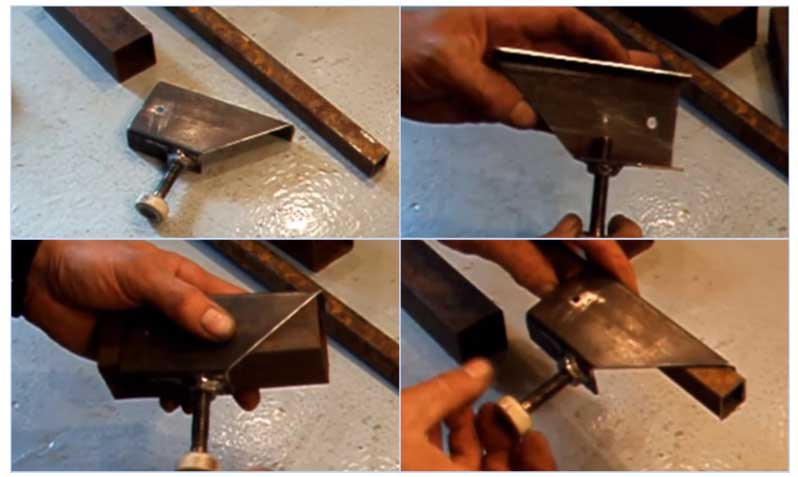

Making a template for trimming a metal profile

If you need to cut a large number of pipes, you can make a template from a metal profile of a larger diameter on a paper sheet using the above method. The angle of inclination is checked with a protractor or a construction square - in this case, the two edges of the trimmed parts of the template are connected.

When working on the part to be cut, a template is put on in the right place and pressed tightly, the marking is applied with a sharply sharpened scriber when tracing the template contour. The part is cut in several passes with a gradual deepening of the groove.

Rice. 3 Cutting a metal profile with a miter box

DIY pipe cutting miter box

Using a template is not very convenient - you have to make a cut along the line, holding the grinder on weight, which leads to large errors. If you have a welding machine, you can make a simple miter box - guides for the grinder disk, preventing it from going to the side.

To do this, use the previously made template, in the side of which a hole is drilled and a nut is welded. When working, a home-made miter box is put on the profile, a bolt is screwed into its nut and the device is pressed against the profile surface. A grinder with a disk for metal cuts, slightly pressing the disk against the side surface of the device. It is clear that during prolonged work, the edges in the miter box gradually grind off, and although the process occurs simultaneously on all edges, some errors will appear over time. Therefore, the device is better to be made of hard wear-resistant metal in order to increase its service life and get a more accurate tool.

Fig.4 An example of a cut at an angle of 90 degrees

Changing the configuration of pipes made of non-ferrous metals

There is a very useful property of non-ferrous metals - high ductility. However, they are not strong enough. During the bending process, as a result of the application of compressive and tensile forces, collapse or rupture of the pipe can be observed. To prevent this from happening, you need to follow the technology exactly.

How to bend copper and brass pipes?

For bending copper and brass pipes, both hot and cold methods are used. When choosing the first, sand is chosen as an internal filler, and molten rosin is chosen as the second. The bending technology is the same as for steel pipes.

Tubular products made of copper and brass before cold bending are subject to annealing followed by cooling. The temperature range for both materials is the same - from 600 to 700⁰С. The difference is in the cooling medium - copper is placed in water, and brass is cooled in air.

After the process is completed, the rosin is removed by smelting it. In order to prevent pipe rupture, the process should by no means be started from the middle of the pipe, only from the ends. As devices for bending, both simple tools and complex machine equipment are used.

Manual pipe benders work due to the physical efforts of a person, and hydraulic ones reduce these efforts to a minimum. Both those and others are equipped with interchangeable nozzles for the possibility of selecting the desired diameter.

The minimum radius for bending copper and brass pipes is regulated by GOST 617-90 and GOST 494-90, respectively. Experts do not recommend using this radius without special need. It's always better to get by with more of it

It is much easier to work with copper and brass pipes than with steel pipes, but the deformation of the metal during bending occurs according to the same laws of physics. In the bending section, the outer surface experiences tension, as a result of which the walls become thinner.

Inside the pipe, the reverse processes occur - the wall contracts and becomes thicker. There is a risk of turning a circular section into an oval and reducing the conditional passage, therefore it is impossible to start bending without taking measures to prevent these phenomena.

Aluminum tube bending

The main methods for bending aluminum pipes are the same as for brass or copper pipes:

- pushing between rollers;

- rolling;

- rollback;

- pressure.

Before deciding how and in what way to bend aluminum pipes, you need to familiarize yourself with each. The first method is used for thin-walled pipes with a maximum diameter of 10 cm, when it is necessary to obtain a gentle bend with little accuracy requirements. Here the minimum radius is strictly regulated.Its value is 5-6 pipe diameters.

The curvature of the section determines the position of the deflecting roller. In this way, decorative elements of the interior are most often made. In the second way, large-diameter pipe material is bent, for which 3-roller pipe benders are used. The pipe is pulled between drive rollers, the orientation of which determines the bending radius.

The photo shows a stationary electric 3-roller pipe bender, but there are also manual mobile equipment models. On it, the workpiece moves through the rollers and bends at a given angle along its entire length. On such a machine, you can change the configuration of the pipe by bending it with a ring, a spiral, or making an arc of a large radius

The accuracy of this method is even lower than the previous one, but the part can be subjected to repeated bending and repeat the process until the desired geometry is obtained.

Bending of aluminum thin-walled pipes can be done manually, having prepared properly:

The rollback method does not provide for the presence of an internal filler, therefore it is not used to obtain small radii. It will not work when choosing this method to fulfill the strict requirements regarding the ovality of the section at the bend.

For deformation of an aluminum pipe by pressure, presses are used with stamps installed on them with a matrix of the desired shape. The given geometry is obtained as a result of the influence of pressure exerted from the outside.

In some cases, the pressure can be internal, when the pipe is placed in a mold and liquid is supplied inside with a pressure sufficient to press it against the walls.

It is not easy to bend duralumin pipes, because. this material is quite hard and springy.To facilitate the process, they are fired immediately before the bend at a temperature of 350 to 400 ° C, then they wait until the pipes cool naturally in air.

Pipe cutter for steel pipes

When using steel pipes of different diameters, craftsmen often face difficulties during their fitting and cutting. In this case, a specially made pipe cutter is best suited. Before buying a tool, it is advisable to study the nuances of all varieties of such ready-made devices.

The first thing you need to pay attention to is the diameter of the pipe and the material for which the tool must be designed to cut. There are three types of cutters:

There are three types of cutters:

- for thin-walled pipes;

- for ceramics;

- for very large jobs.

It is important to note that only electric cutters are designed for heavy loads. The operation of such tools is almost completely automated.

They can cut pipes made of cast iron or steel, having a diameter of up to three hundred millimeters.

Consider the main professional cutting mechanisms, which differ in features and design.

- The roller pipe cutter is used for cutting steel products. Movie groups are included in the outline of this tool. Some carry out the cutting of the material itself, while others are designed to guide the pipe during operation. A roller pipe cutter, which has one roller in its design, can cut products up to fifty millimeters in size.

- A pipe cutter cuts plastic pipes with a diameter of up to one hundred millimeters. Such a cutter looks like a steel clip with discs adjustable to the desired diameter. The incision itself is made with the same discs.

- Chain pipe cutter.This tool is used very rarely, because it is intended exclusively for cutting fragile ceramics or concrete.

Pipe cutters are also divided into manual, electric, hydraulic and pneumatic.

- The manual pipe cutter is easy to use. To make a cut with this tool, you need to fix the device on the pipe in the right place and make a few turns with the handle or the pipe cutter itself. One of the main advantages of manual cutting equipment is the easy control of the entire process, since the cut is the result of the application of physical forces that you can control. The disadvantages of such cutters are the physical fatigue of the master with a large amount of work and the small diameter of the pipes being cut.

- Using an electric cutter, you can complete large volume jobs in a fairly short amount of time. The advantage of such a cutter is the very high quality of the materials used in its production. The strength of this tool will allow you to repeatedly perform numerous cutting actions without worrying about the wear resistance of the tool. Of the advantages of such a device, one can also note the ease of cutting performed by an electric motor. There is practically only one minus for such a tool - the high cost of the cutter. Therefore, such a purchase for one-time work is impractical.

A milling machine is also used to cut pipes. Waterjet cutting is one of the fastest and most efficient cutting methods. Metal processing is performed by a jet of liquid that comes out of a special nozzle at high speed and pressure.

How to cut straight pipe lengthwise

» Miscellaneous » How to cut exactly the pipe along

In domestic households, profile pipes are widely used in the manufacture of greenhouses, greenhouses, sheds to protect automotive equipment from atmospheric precipitation and other structures. When working with this material, it is useful to know how to cut a profile pipe along a line or across with the most accurate angle.

Among a large number of construction cutting tools for metal, the leader in speed, ease of cutting and economy is an angle grinder (grinder), which is often present in the tool kit of any home craftsman. To cut a profile steel pipe with a grinder, you will need an ordinary metal disc and strict adherence to safety regulations - breaking the disc into segments at high rotation speed can lead to serious injury.

Fig.1 Profile pipes in the household

General recommendations of experts

Bulgarian

The use of a grinder is a very popular mechanical method that is used both at home and in production.

Cutting with a grinder requires maximum care from the master. Care should be taken to protect hands and eyes with gloves and goggles.

It is also important to adhere to the following rules:

work with the grinder must be carried out by a master with experience in handling this tool;

it is important to fix the equipment tightly;

it is impossible to process concrete or stone with a disk that was originally designed to cut metal;

in order to avoid “popping out” of the disk, it is necessary to control the direction of movement of the angle grinder, it must coincide with the direction of rotation of the disk;

the tool must be closed with a protective cover, otherwise work cannot be carried out.

Roller pipe cutter

In this tool, rollers are the active components. They carry out the cutting, moving in the clip, installed in place of the future incision. The pressure with which the rollers will be pressed against the material is controlled by screws. To do this, rocking movements up and down are made, at the same time the rollers are pressed against the material.

gas cutting

This method is best for cutting large pipes. When burned, the fuel melts the metal and removes it with a gas jet, blowing it out of the cut. When laying highways from pipes of very large diameter, the use of manual equipment turns out to be absolutely inefficient and costly. In such cases, large machines are used.

Plasma cutting

The temperature at which metal products can be melted is created by the flow of matter brought to the state of plasma. Air is used to form plasma. Enrichment with ions is produced by the action of an electric discharge. As a result, this process generates a high temperature. Plasma cutting of pipes is considered one of the best.

Using a laser

The laser machine is a fully automatic system. With this tool you can cut, mill, drill, edge.

This tool can process pipes of the following parameters:

- diameter (maximum) - one hundred and fifty millimeters;

- length (maximum) - six and a half meters.

Cutting pipes at an angle: advantages and disadvantages of different methods

During installation and plumbing work, it is often necessary to cut workpieces at a certain angle.Changing the direction of the cut line is necessary for further joining and welding with other pipes of the same configuration, or for the installation of shut-off and control valves.

It should be borne in mind that the accuracy of the cut at the desired angle is necessary to obtain a high density of metal-rolled joints. To do this, you need to have the necessary tools, a quality pipe cutter and have the appropriate experience in pipe processing.

In this article, we will look at the techniques for cutting pipes at various angles.

1. Methods for marking pipes at an angle of 45 degrees

Cutting pipe blanks at an angle of 45° is most in demand during the installation of heating mains, sewer networks, gas pipeline systems. For these purposes, pipes made of ferrous metals and stainless steels of cylindrical section, small and medium diameter - 20-500 mm are used.

One of the main tasks when cutting pipes at an angle of 45 degrees is the accuracy of measuring the angle and the evenness of the cut of the pipe, so that when joining the connected elements, they coincide with an accuracy of a millimeter. This is especially true for thin-walled pipes - with the slightest cut error, the walls of the connected pipes will not be able to connect in the desired configuration

Therefore, close attention must be paid to the accuracy of cutting

Marking of pipes of round section

In the absence of a production template, you can use a pattern from a square-shaped paper sheet. To perform pipe marking, perform the following steps:

Fold the square sheet strictly diagonally, aligning opposite corners. The length of the diagonal of the pattern should be equal to the size of the circumference of the workpiece.

The folded sheet wraps around the pipe

It is important to ensure that the side of the pattern, which is closer to the end of the workpiece, is strictly perpendicular to the central axis.

A dashed marking is performed at the place of the future cut.

The next step is to cut the pipe.

Marking of square and rectangular pipes

To make a pattern for marking a profile pipe, it is more expedient to use a similar blank of only a larger section. Marking on the workpiece is performed once using an engineering ruler or protractor. A profile is inserted into the cavity of the finished template, marking is performed and subsequent cutting.

2. Marking pipes at an angle of 90 degrees

Marking the pipe at an angle of 90 degrees is quite easy. If necessary, you can use a sheet of paper: the sheet is wrapped around the pipe, fixed and marked

It is important to ensure that the edges of the sheet coincide along the entire circumference, then the cut will be even.

How to cut a profile pipe at an angle of 90 degrees?

For cutting a square or rectangular pipe, it is preferable to use a triangle. This device alternately marks with a marker on each side of the profile. After drawing the dotted line, the pipe is cut.

3. Marking pipes at other angles

To cut pipes at an angle of other values, you will need patterns with the appropriate values. You can prepare a template using Excel or other computer programs by entering the values of the pipe diameter, the desired angle, etc. in the corresponding interface.

In the calculation programs, you can calculate the cutting of pipes of any diameter and at any angle. But most often this method is used to create patterns for cutting pipes of small and medium diameter.For cutting large diameter pipes and in large volumes, it is preferable to use programmable cutting machines.

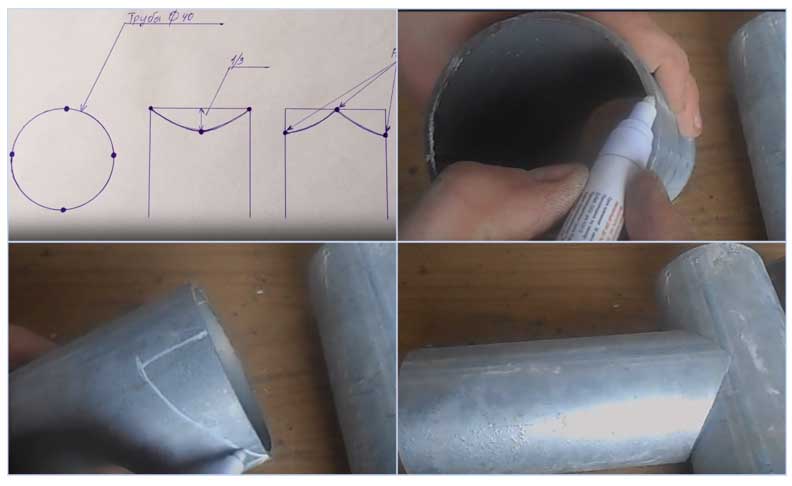

How to cut a pipe in a "collar" way?

Often, when installing water supply networks, pipe blanks are required that have a cut at the end in the form of a triangle. This pipe configuration is required to connect to another round pipe at a right angle.

To perform a collar cut, proceed as follows:

- Measure the circumference of the pipe.

- The pipe is cut at a 90 degree angle.

- At the end of the pipe, equidistant points are marked, which are relative to each other at angles of 90 and 180 degrees.

- Calculations are performed: the diameter of the pipe is divided by three.

- From two diametrically located points, the value obtained is set aside and marked with dots.

- These points are connected to other smooth arcs.

- After cutting with a pipe cutting tool, semicircular segments are separated, which are ready for subsequent welding work.

How to cut along

Another frequently asked question is how to cut the pipe evenly with a grinder along. Here the algorithm of actions will be approximately the same as for transverse cutting

It is important to pay attention to marking. You can, for example, use paint thread, which is usually used when marking walls. In this case, it is necessary to firmly fix the pipe

The sawing process itself must be done carefully and slowly, since when sawing long elements, there is a high probability of the cutting disc slipping off the marking line

In this case, it is necessary to firmly fix the pipe.The sawing process itself must be carried out carefully and slowly, since when sawing long elements, there is a high probability of the cutting disc slipping off the marking line.

Kinds

Varieties of pipe cutters are classified depending on the objects of cutting and the features of the cutting element. Accordingly, the following types of tools are distinguished:

- Cutter cuts pipes up to 100 mm in diameter. Suitable not only for steel pipes, but also for plastic pipes. It has several steel discs.

The chain is different in that it can cut pipes made of dense materials (cast iron, concrete, ceramics), since it has a mechanism for tightly fixing the cutting object, made on the basis of a conventional chain and rotary levers.

Video instruction: how to work with a pipe cutter.

- The roller one is equipped with cutting rollers (from 1 to 3) and guide elements, and the diameter of the pipes that it can cut directly depends on the number of rollers: a device with 1 roller cuts pipes up to 50 mm, and with 3 rollers - up to 100 mm and even more .

Telescopic has a carriage, roller and guides, which can optimally fix the pipe, depending on the required cutting angle. It copes well with cutting pipes of large thickness or from durable materials, because due to the configuration it can create strong pressure on the surface of the object being cut.

The ratchet pipe cutter is portable and can cut thin pipes. Its design is the simplest among devices of this class - 2 handles and a cutting blade.

Electric equipped with an electric motor

due to which the efforts of the worker to cut the pipe are minimal - it is only important to set up the tool correctly, he will do the rest of the work almost independently

At the same time, it is a tool of universal action - it cuts pipes of any diameter and from any material. Application is limited only by engine power. However, such a pipe cutter also has a significant drawback - it will be inconvenient to use it in hard-to-reach areas of work (for example, sewer pipes).

With its help, it is possible not only to carry out mechanical cutting of pipes, but also to carry out work on their facing, chamfering with blunting, as well as from the outer surface of the pipe.

Video review of one of the models

Guillotine got its name because of the design of the cutting mechanism. His knife performs a perpendicular incision of pipes of small diameters (up to 30 mm). The pipe is fixed in the frame, and the screw pushes the guillotine and makes a clear cut at an angle of 9 degrees. The tool is suitable for cutting pipes of different thicknesses and structures (single-layer, multi-layer, reinforced).

Pneumatic pipe cutter is driven by the pressure of rarefied air. This device is used in production for cutting pipes with a very large diameter (up to 1500 mm). At the same time, it copes well with cutting dense material (cast iron) and light plastic.

Orbital pipe cutters are designed not only for mechanical cutting of pipes, but also for chamfering thin-walled pipes. To do this, they are equipped with special chamfer cutters.

Often, various types of pipe cutters are offered with add-ons that allow you to provide the safest conditions for working with pipes.So, with the help of the quick crimping mechanism, large pipes can be quickly fixed in the device without using a special screw. Also, the pipe cutter can be equipped with additional removable cutting elements oriented to pipes of various thicknesses, and rollers that move the device around the pipe.

How to cut a metal pipe straight

The use in the production and installation of metal structures is associated with the need to cut across, along and at an angle. And not always at hand there is special equipment. How to cut the pipe evenly with the help of improvised means, we will describe in this article.

There are several ways to saw off a pipe or cut it into pieces. Of the available tools, the grinder is the best at this task. But the biggest problem remains the need to correctly mark the cut lines. They can be different, most often you have to maintain either a right angle relative to the axis of the pipe, or 45 degrees. The techniques vary somewhat depending on which products need to be cut:

pipes for laying water supply, gas and for heating distribution;

profile products for assembling gates, canopies, other metal structures;

pipes of large diameter - as a rule, this is rarely needed at home, where the widest gap is only in the sewer;

pipes made of steel, cast iron, thin-walled non-ferrous metals and soft alloys.

Both tasks are solved quite simply even without the use of a special pipe angle pattern.

Cutting pipe at a 90 degree angle

To mark the cut at a right angle, you can use a sheet of standard A4 paper, wide electrical tape or construction tape.If you wrap a sufficiently wide material around the pipe so that its edges coincide exactly when applied, you will get a perfect cut line. If the tape or tape is firmly stuck to the metal, you can walk straight along the edge.

It is important to be able to use the grinder correctly, hold it with a certain effort and follow safety rules. The described technique is the simplest, it is also suitable for cutting a large diameter pipe

Cutting pipe at a 45 degree angle

Most often this has to be done when installing plumbing and heating and assembling frame structures. You can cut the pipe at 45 degrees with a grinder according to the markings, which are made either with a sheet of paper of the same A4 format, or use an ordinary school (drawing) isosceles square.

Use a sheet of paper or cardboard

With the sheet, you will have to do several operations to get the desired angle. If you don't want to get tangled up in the folds, just make it square and fold it diagonally to get the right angle. You can do the same with any sheet, as long as its sides are equal to each other. The method is convenient in that it can be applied to a pipe with a large diameter, and to.

Square marking

If there is a square at hand, then you must first determine the exact line of the end of the pipe, including the profile one. Having attached the tool and smoothly shifting it over the surface, we get a cut line of 45 degrees. The same technique is used with a square at 30 degrees.

Accurate sawing and trimming of pipes depends not only on well-executed markings. The material is also of great importance - metal of different thickness and hardness is cut with different efforts and side effects.To properly cut a cast-iron pipe, it should not be cut all the way through. Cast iron is a brittle metal, so several cuts are usually made, and then a specialist beats a piece on them with one precise blow of a chisel.

To work with thin-walled pipes, you will have to very accurately align the position of the angle grinder. In this case, the master must choose the right one. In industrial conditions, special pipe cutters, gas cutters and welding machines can be used to perform the same tasks.

Safety when cutting a gas pipe

When working with gas pipes connected to the main, it is important to observe safety measures. First turn off the gas supply valve, then make sure that there is nothing in the pipe

To do this, it is enough to open the burners of the stove and light the gas - when it runs out, the flame will go out.

In domestic households, profile pipes are widely used in the manufacture of greenhouses, greenhouses, sheds to protect automotive equipment from atmospheric precipitation and other structures. When working with this material, it is useful to know how to cut a profile pipe along a line or across with the most accurate angle.

Among a large number of construction cutting tools for metal, the leader in speed, ease of cutting and economy is an angle grinder (grinder), which is often present in the tool kit of any home craftsman. To cut a profile steel pipe with a grinder, you will need an ordinary metal disc and strict adherence to safety regulations - breaking the disc into segments at high rotation speed can lead to serious injury.

Conclusions and useful video on the topic

Video review of a manual pipe cutter for plastic pipes:

Video instruction on how to use the pipe cutter. The video shows how to properly process steel products of medium diameter with a pipe cutter:

Having familiarized yourself with the types and types of pipe cutting equipment, choosing the right tool will not be difficult at all. If there are doubts, consultants of construction and hardware stores will be happy to come to the rescue and suggest which device is best to purchase.

Have questions about the topic of the article, found flaws in the material, or can you provide valuable information? Please leave your comments in the box below.

![How to cut a pipe evenly with an improvised tool [4 marking methods]](https://fix.housecope.com/wp-content/uploads/6/0/0/600fc6b2fd87bd9a3892ea1404a78e1a.jpg)