- Cuffs for the toilet in St. Petersburg

- Why is the cuff replaced?

- Some Tips

- Types of eccentrics

- corner release

- Installation instructions for cuffs of various types

- #1: Installing the rubber seal

- #2: Quick Rules

- #3: Installing the pleated cuff

- Types of sealing products

- Seal form

- Material

- Toilet cuffs: features, varieties

- Toilet cuff: concept, features, advantages and disadvantages

- The main types of cuffs for the toilet, their characteristics

- Practical Tips

- How to replace the toilet cuff yourself: repair tips

- What is a toilet cuff

- Why is the cuff replaced?

- Replacement procedure

- How to solve the choice problem

- How to change the gasket between the toilet and cistern

- Dismantling the old device

Cuffs for the toilet in St. Petersburg

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

On the seller's website, "One-Click Order" is available. Click "Shop" to go to the site

Related article: Drain tank float device with bottom connection

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

On the seller's website, "One-Click Order" is available. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

On the seller's website, "One-Click Order" is available. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

On the seller's website, "One-Click Order" is available. Click "Shop" to go to the site

An "Online Consultant" is available on the seller's website. Click "Shop" to go to the site

An "Online Consultant" is available on the seller's website. Click "Shop" to go to the site

An "Online Consultant" is available on the seller's website. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

An "Online Consultant" is available on the seller's website. Click "Shop" to go to the site

A free 8-800 number is available on the seller's website. Click "Shop" to go to the site

On the seller's website, "One-Click Order" is available. Click "Shop" to go to the site

Why is the cuff replaced?

The main task that a rubber cuff for sewage should perform is a reliable and tight connection.If water is suddenly detected during operation, it means that the part has ceased to perform its main function. More often, the problem is detected when flushing water from a reservoir.

For diagnostics, place your hand under the connection when draining water. If it is wet and dripping, then it needs to be repaired or replaced.

The causes of failure can be different: displacement of the part due to mechanical stress or a crack due to long-term operation. In the first option, try to restore the tightness by eliminating the offset and tightening the nuts of the connecting screws. If this does not help, the sewer coupling must be replaced.

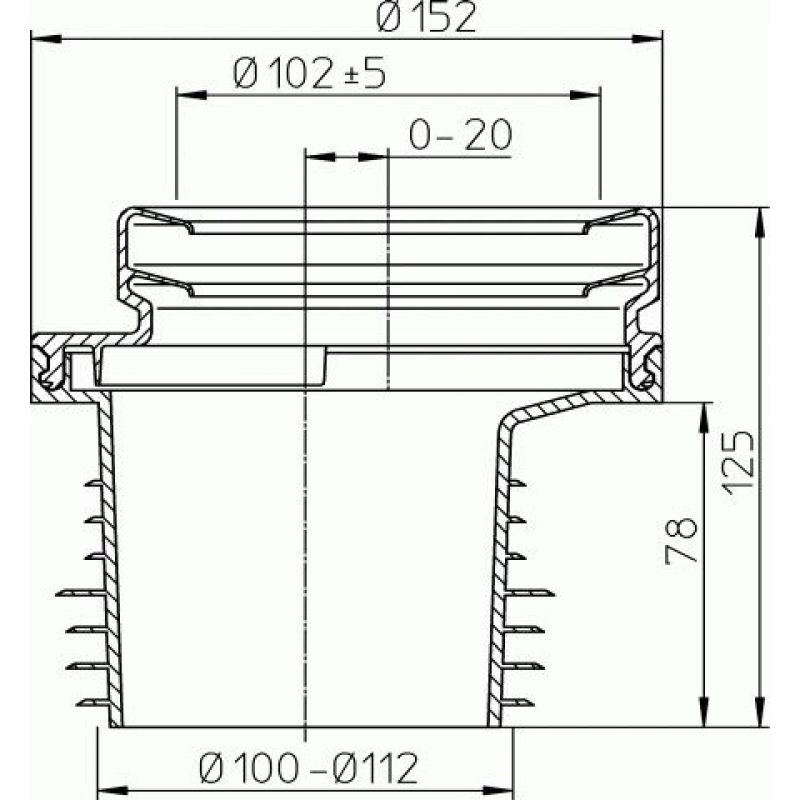

HL WC outlet with infinitely variable adjustment

Some Tips

Depending on the placement of the equipment, a suitable cuff model is selected.

The recommendations of experts will help you to cope with the installation of the adapter faster and better:

- The device must exactly match the features of the installation of the toilet. Before buying it, you should measure the distance and determine the connection principle.

- During installation, you need to carefully turn the corrugation, preventing it from stretching. Otherwise, subsequently, a cavity will form in the sagging part, where impurities will accumulate, which will lead to its depressurization.

- Installation of the toilet bowl involves the preparation of tools: adjustable wrenches, a drill, a fixing fabric, a strip or tow, hoses leading to communications with cold water, a tape measure, accessories and fasteners. Wire, rubber band for temporary repairs may come in handy.

- The sealant is effective only on internal surfaces, it is useless when processing the outside.

An eccentric is required to connect to the inlet of a tee located at the same or different levels with a drain pipe.

For complex fastenings, special types of devices are made of corrugated material.

Such devices allow you to independently carry out hermetic fixation of the device with any displacement.

Types of eccentrics

The fixture is required when installing the toilet for the first time. But it may also be required for emergency repairs. The signal that the device is out of order is the flow of different intensity behind and below the plumbing.

There are several reasons for failure:

- poor quality connection

- rupture of a dry rubber eccentric;

- broken plastic.

In order to connect a suitable eccentric to the sewer, it is important to know which part is needed for a particular connection. Toilet connected to the sewer with an oblique outlet

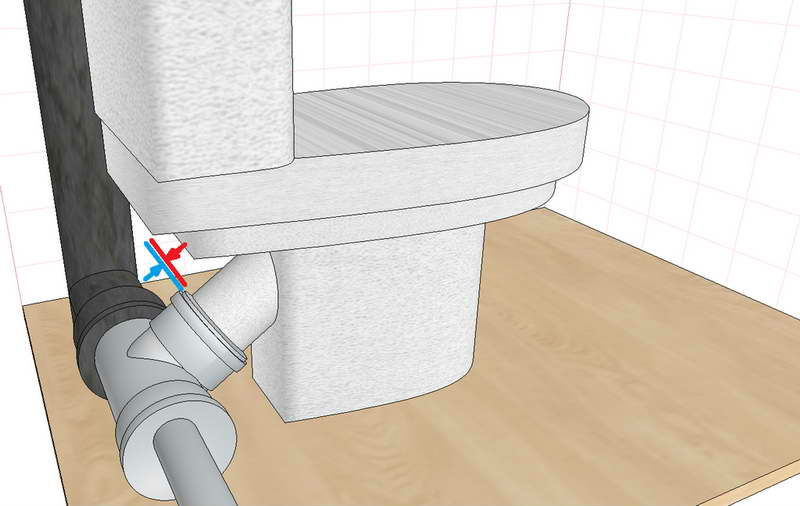

Toilet connected to the sewer with an oblique outlet

Toilet connected to the sewer with an oblique outlet

There are three types of cuffs:

- A straight or tapered element has standard parameters and configuration. Its function is the usual docking of a plumbing fixture with a sewerage system with a tightness condition.

- An offset eccentric is designed to align the toilet with the riser when the inlet and outlet are at different levels.

- Corrugation is a more complex spare part with specific shapes. It has flexibility and elasticity, allows you to connect anywhere. Its versatility lies in the fact that the bowl can be moved and mounted at the required angle, regardless of the location of the internal elements.

The corrugation is reinforced and simple.In the first case, a high level of rigidity is provided due to the introduction of an anti-corrosion wire with a small diameter.

corner release

In old houses, where the pipes have never been changed, the toilet is installed using a rubber cuff. This is most often a conical cuff for the toilet. It is connected to a cast iron pipe. If the entry / exit axis is displaced, then an eccentric is acquired. Suitable smooth or with corrugated tube. With a significant distance to the pipe, you can use the corrugation, stretching it to the desired length. An eccentric is also needed to get a more tight connection.  The principle of mounting products made of rubber or plastic, corrugated or smooth parts is very similar. But there are some nuances. Next, we will consider three options for connecting the toilet.

The principle of mounting products made of rubber or plastic, corrugated or smooth parts is very similar. But there are some nuances. Next, we will consider three options for connecting the toilet.

Installation instructions for cuffs of various types

The principle of fixing rubber or plastic, smooth or corrugated parts is similar, but the process itself may differ. nuances - from the choice of installation site toilet bowl before using additional methods of fastening. Consider three common connection options.

#1: Installing the rubber seal

Rubber cuff - this is a short dense element that is not pulled from the outside, but inserted into the socket of a cast-iron pipe. This is a kind of seal or gasket that creates a tight connection between the drain hole and the plumbing fixture.

In addition, it protects the sanitary ware from chips and damage in case of unintentional violation of the stability of the installation.

Procedure for installing the rubber cuff:

If the toilet outlet enters the socket freely, then the soap solution is not needed. On the contrary, it is necessary to create a tighter abutment.

To do this, they usually use the traditional modern method - a sealant is applied over the entire surface of the adjacent parts. After hardening, it forms a dense hermetic ring.

#2: Quick Rules

You will find out that you need an eccentric at the stage of choosing a place to install the toilet. If the plumbing outlet outlet and sewer pipe socket will not be strictly opposite each other, a simple plastic connector is not enough. Axis offset requires a curved part.

High-quality rubber or polypropylene eccentrics are sold in plumbing stores and can cost from 100 to 250 rubles, depending on the manufacturer

Before installation, it is necessary to put the plumbing fixture in place, measure the length to the sewer drain and once again make sure that the toilet eccentric model is selected correctly. To check, you can simply attach the part to both holes.

The eccentric can be used if drain hole located just above the toilet outlet. If the height difference from the outlet to the socket is more than 5 cm, flushing problems may occur - in this case it is better to replace the pipes and install them lower

Work order:

- we clean the sewer inlet from old deposits;

- we put the cuff with a wide end (110 mm) on the sewer socket, smearing the junction with sealant;

- we attach the second end to the oblique or horizontal outlet of the toilet bowl, also using a sealant;

- we carry out a test descent of water;

- if no leaks are found, we fix the toilet in a pre-prepared place with bolts.

The problem arises when, during installation, it turns out that the eccentric is not matched correctly. To avoid an uncomfortable situation, instead of a rigid structure, you can immediately buy a part with an elastic corrugated middle.

As required, the accordion eccentric can be slightly shifted to the right / left or slightly stretched, while maintaining its functional qualities.

A variant of the cascading use of eccentrics when the toilet model is incorrectly selected. If the pipes are located below, close to the floor or at its level, it is better to purchase a plumbing fixture with an oblique outlet

Moving parts are also relevant when there is a risk of loose toilet seating. Simply put, when the plumbing fixture is rocked, the tightness of the rigid connection will immediately be broken, while this does not threaten the corrugation.

#3: Installing the pleated cuff

When the installation of the toilet bowl is difficult due to the inappropriate form of the outlet or the difficult location of the sewer, an elastic corrugated pipe is often used. Its advantage is that it can easily change shape and length, therefore, it is suitable for almost all types of releases.

The only thing to consider when buying is the diameters of the fixing cylindrical ends. They can be 110mm/90mm, 110mm/80mm, etc.

It is the corrugation that is used for temporary installation of the toilet during repairs, with strong displacements relative to the central axis of the inlet / outlet (instead of the eccentric) and during the installation of the plumbing fixture at a distance of up to half a meter from the drain hole

The principle of replacing or installing corrugations is the same as for other types of cuffs:

- removal of the old worn out element;

- cleaning of inlets from dirt and deposits;

- inserting the sealed end into the sewer socket;

- fixing the second end on the outlet of the toilet bowl;

- test descent of water, elimination of shortcomings.

Experienced plumbers recommend not stretching the corrugation to the maximum, because as a result, it loses elasticity and fails faster.

It is better to choose a longer model or try to move the toilet closer to the sewer outlet. Another option is to buy a combined cuff, consisting partly of rigid elements.

Types of sealing products

Known types of sealing products differ both in their configuration and in size and material from which they are made. Each of these features has its own characteristics.

Seal form

In accordance with this feature, cuffs for toilet bowls are divided into the following groups:

- oval, resembling a regular ring;

- trapezoidal seals;

- cone products;

- gaskets of complex multi-circuit configuration.

O-rings for toilet bowls are the most common type of cuffs used to articulate the bowl and tank.

They are used in most classic old-style designs. In modern models, gaskets of a more complex shape, resembling a truncated cone, are usually installed.

Recently, trapezoidal seals have become increasingly common in foreign-made products, resembling a triangle with cut-off corners.

In addition to the shape of the cuffs, all of them are characterized by another important property that determines the performance characteristics of the product. It involves classification according to the type of material used in the manufacturing process.

Material

On this basis, all known samples of seals are divided into the following types:

- elastic cuffs, belonging to the category of the most popular and cheapest products;

- silicone blanks, characterized by increased elasticity and higher cost;

- polyurethane seals, which are the most expensive in their class.

Rubber cuffs are easy to manufacture and have a relatively low price. You have to pay for this with poor wear resistance and the need for frequent replacement. In contrast, expensive polyurethane products are very elastic, retain their shape well and have a long service life.

Toilet cuffs: features, varieties

Modern dwellings are quite difficult to imagine without a sanitary room equipped with everything necessary. In simple words, a bathroom or a toilet (if the bathroom is separate). Whichever toilet model you choose among the variety of different options, its main goal is always the same - the drain of waste products into the general sewer system

In order for this to happen quickly and efficiently, it is important to choose high-quality structural elements for home plumbing, including toilet cuffs. Today we will talk about what cuffs are (stepped, conical), give their general characteristics: features, size according to GOST, diameter, etc.

Toilet cuff: concept, features, advantages and disadvantages

Cuff - an element of drain fittings, which is a kind of adapter between the toilet bowl and the sewer system. This part is made of heat resistant polypropylene/polyethylene.The main purpose of this element is to provide a tight connection between parts of the system for efficient draining.

The outer diameter of the cuff attached to the toilet is 13.4 cm, the inner diameter is 7.5 cm. The part installed on the sewer pipe has a diameter of about 11 cm.

On the one hand, the cuff can be considered a practical element of the sewer system, since it is very convenient to move the toilet if necessary. But, on the other hand, this element is quite fragile - the slightest mechanical load is enough for damage to appear.

Nevertheless, the cuff is used quite often when mounting the toilet due to some of its advantages:

- makes it possible to install a toilet bowl if the diameter of the outlet and the inlet socket of the sewer pipe do not match;

- suitable for mounting in open areas;

- differs in aesthetic appearance;

- durable with proper use.

- easy to maintain and install;

- has an acceptable price.

But in addition to the advantages, the toilet cuff also has some disadvantages:

brittleness of the material (therefore, the part should be handled very carefully);

the presence of low-quality products in trade construction networks;

if the cuff length is incorrectly selected, it may sag during operation and, as a result, blockages in the sewer pipe may appear.

A few words should be said about the criteria for choosing a quality toilet cuff. Firstly, you should not save money by choosing the right model for your home, since the cuffs are not very expensive anyway.

It is also worth paying special attention not to ordinary plastic cuffs, but to those in the design of which not only plastic is presented, but also reinforced wire made of metal. This will make the cuff more durable and practical.

Advice. When choosing a suitable cuff for a toilet bowl in a small bathroom or in a combined bathroom, it is better to give preference to a corrugated pipe with a branch.

The main types of cuffs for the toilet, their characteristics

There are two main types of toilet cuffs:

- Cuff eccentric. A part of this type most often has a standard straight shape, but sometimes it can be presented in the form of two small pipes tightly connected to each other at a certain angle. The first option is designed to connect a standard configuration toilet bowl with a sewer pipe. The second is ideal for domestic waste systems in which the outlet pipe and plumbing are located at different levels. The eccentric is of two types: long and short (depending on how the place for mounting the element looks like).

Practical Tips

Finally, take on board some useful tips from professionals that will help you avoid possible problems when installing the cuff or preparing for it. First, try to minimize the distance between sewer pipe and socket. If this is not technically feasible or practical, try to strengthen the corrugation as best as possible. This can be done with the help of special props.

When using a sufficiently short cuff, you should not stretch it until it is mounted into the system, since you can randomly stretch it and during installation it will simply sag.

Advice

When it comes to using a cuff in the sewer system of a private building, pay attention to the presence of tailed "guests". If any are present, it is better to use the standard option - a cast-iron elbow

On this, our acquaintance with the existing types of cuffs for toilet bowls comes to an end. Enjoy the shopping!

How to replace the toilet cuff yourself: repair tips

Reliable plumbing is one of the main aspects of home comfort. Replacing and repairing a toilet bowl requires promptness, since this device cannot be taken out of service for a long time. However, the speed of the work performed should not affect the quality. Especially when it comes to connecting to the sewer.

In this article we will talk about cuffs for sewer pipes.

What is a toilet cuff

The cuff on the toilet is an important part of the design of the plumbing fixture, which is responsible for the tight connection between the toilet outlet and the entrance to the sewer system.

It consists of two cylinders, one of which is connected to the outlet of the toilet bowl, and the other to the communication pipe. Between the components is a smooth or corrugated pipe.

Manufacturers provide different features of the location of the toilet. The toilet sleeve is available in several lengths, from short to long, with the ability to bend and maneuver during installation.

There are three types of detail:

- Straight or tapered. It is used if the level of waste output and the entrance to the sewer are at the same height and does not have any fundamental features in the design. With the right choice, it connects holes of any diameter.

- Cuff-eccentric.It is used in the case when the connection is located at a different output-input level. To do this, the cylinders are offset relative to each other.

- Corrugated. A universal connection that allows you to install the toilet at any point in the restroom and not depend on the entrance to the sewer network. Thanks to the accordion of the corrugations, installation is carried out at any angle, regardless of the specific shape or non-standard size.

Various materials are used in the production of the connecting part. Most stores offer:

- rubber sealing cuffs;

- polyethylene compounds;

- polypropylene options.

The first material is now used less frequently. He perfect for earthenware connections with cast-iron pipes. Many residents have already carried out major repairs and replaced pipes with polyethylene ones, therefore, the second and third types of material are used more often.

Polymer compounds have important advantages over rubber competitors:

- The joint between the body and the nozzle does not need to be sealed due to the tight fit of the part.

- In the absence of special mechanical action, the service life of polyethylene is longer than that of rubber.

- The flexibility of plastic is higher, so it is used for solving specific problems, for example, when transferring a toilet bowl to another part of the restroom.

Why is the cuff replaced?

The main task that a rubber cuff for sewage should perform is a reliable and tight connection. If water is suddenly detected during operation, it means that the part has ceased to perform its main function. More often, the problem is detected when flushing water from a reservoir.

For diagnostics, place your hand under the connection when draining water.If it is wet and dripping, then it needs to be repaired or replaced.

The causes of failure can be different: displacement of the part due to mechanical stress or a crack due to long-term operation. In the first option, try to restore the tightness by eliminating the offset and tightening the nuts of the connecting screws. If this does not help, the sewer coupling must be replaced.

Replacement procedure

The installation of the coupling is a relatively simple plumbing work, so it is easy to do it yourself. Instructions will help to cope with the task.

Preparation at work

Before replacing the rubber cuff for the toilet, prepare the workplace:

- Get the right part in advance. Be mindful of the level between the connection points and make the right choice: toilet cone or eccentric.

- Thoroughly clean the installation site. The outlet of the toilet bowl and the entrance of the sewer system are cleaned of dust and debris. If the sealing collars required repair for a long time, the joint of the installation requires cleaning from salts.

- Dry the surface. If moisture remains on the pipes, the joint cannot be made airtight.

- The sealing cuff for the sewer must be treated with a silicone plumbing sealant. This will increase the reliability of the connection.

For installation, the connecting rubber sleeve is put on one end of the toilet drain outlet. Now let the silicone harden. So stop working.

When the sealant is firmly set, repeat the action with the other end of the part and insert it into the sewer pipe.

How to solve the choice problem

Before buying a corrugated connector, you should clarify the dimensions of the holes with which it will be connected. The probability of errors will be less if the corrugation is bought at the same time as the toilet. The second important indicator is the length of the pipe. There are models of different types and purposes.

For example, for a small shared bathroom a very convenient option can be a corrugation with a branch, which allows you to connect two objects to one sewer outlet at once. Sometimes it is more convenient to use a special rubber cuff for the toilet.

To connect the toilet to the sewer system, you can use not only the corrugation (2), but also a special rubber cuff (1) and a plastic outlet (3)

It makes no sense to buy cheaper corrugations, since the cost of even the most expensive option is low. Let the connector be a little more expensive, but meet the expected level of quality. Imported products are distinguished by good characteristics in terms of strength and durability.

Western manufacturers additionally strengthen their products with reinforcing metal wire. Such models are more rigid, they sag less and better resist mechanical stress.

To install the corrugations, you may also need the following items:

- coupling, straight or eccentric, for connection to the sewer pipe of the toilet bowl, which is located next to it;

- a pipe with a cuff or a plastic outlet designed to install a toilet bowl, the position of which is offset relative to the entrance to the sewer system;

- the corrugation is rigid or soft, allowing you to bypass small obstacles that prevent the direct connection of the toilet bowl to the sewer.

When choosing a suitable corrugation for the toilet, it should be remembered that problems can arise not only when using an element that is too stretched. It is also not recommended to use an excessively short pipe.

Strong compression or sharp bending will soon lead to breakage.

With such a bend of the corrugation installed on the toilet, liquid will probably accumulate below. You need to change the position of the toilet or choose a different connection method

How to change the gasket between the toilet and cistern

Installing a gasket between the cistern and the toilet involves removing the cistern from it. The whole procedure consists of several stages:

- The water supply to the toilet is shut off.

- The cover is removed.

- All water is drained from the tank. It is advisable to dry the bottom with a towel.

- Inside the tank, it is necessary to disconnect the water supply pipe.

- Next, the lock nut is unscrewed that holds the siphon inside the toilet bowl.

- The bolts that secure the tank to the toilet are unscrewed.

- The tank is carefully removed from its place.

On older toilets, the bolts connecting the toilet and cistern may be made of metal. Unlike polymer studs, which are used on more modern plumbing fixtures, the metal gradually corrodes. Sometimes it comes to the point that it is simply impossible to unscrew the rusted bolts. In such cases, it is recommended to use WD-40 fluid, which should be sprayed onto the bolts. Even more impressive results are achieved by using kerosene.

On older toilets, the bolts connecting the toilet and cistern may be made of metal. Unlike polymer studs, which are used on more modern plumbing fixtures, the metal gradually corrodes. Sometimes it comes to the point that it is simply impossible to unscrew the rusted bolts. In such cases, it is recommended to use WD-40 fluid, which should be sprayed onto the bolts. Even more impressive results are achieved by using kerosene.

When the cistern is removed from the toilet, further replacement of the gasket involves the following steps:

- The old cuff is removed.

- Before you put the gasket, you need to prepare the place of its installation.On the toilet bowl and on the tank, the installation site is cleaned of dirt and other deposits, dried with a rag.

- The new gasket is installed in place of the old one.

- To achieve maximum tightness, it is recommended to lubricate the surface of the installed gasket with silicone sealant.

- The tank is installed in its original place and fixed with screws. The screws must be tightened very carefully so as not to damage the toilet. One of the bolts is tightened only a few turns, after which the second bolt is also tightened. If only one bolt is tightened tightly, the installed gasket may warp or the tank will burst.

- The internal fittings of the drain tank are connected, which is fixed with a lock nut.

- The water supply hose is also connected to the tank, but the water does not open.

- After 2 hours, necessary for the silicone sealant to harden, if one was used, the water supply to the tank opens. The reservoir is checked for external leaks.

As you can see, replacing a worn seal between the tank and the toilet is not particularly difficult. All work can be done independently, with minimal use of plumbing tools. Inspect your toilet regularly to determine if there is a problem. Then the damage from the occurrence of a leak will be minimized.

Dismantling the old device

Before starting work, prepare a bucket and rags. Turn off the supply valve first. water in the sump. Drain the water and unscrew the water pipe from the tank. Now we disconnect the tank from the bowl, most likely the fastening bolts are rusted and oxidized or stuck with deposits.Use a hex wrench, if you can't unscrew it, then try to tighten the bolt slightly. With translational movements back and forth, the nut should turn. Do not be too zealous so as not to split the tank. If this does not help, then spray the nut with WD-40, kerosene or turpentine. After a day, try to unscrew it again by rocking it.

Disconnecting the cistern of an old toilet

Now you can move on to unscrewing the toilet. Fasteners can be an anchor bolt with a nut or a dowel. If the toilet was installed many years ago, then it is most likely that it was installed on cement mortar. In this case, it is unlikely that it will be possible to keep it intact, especially if the drain is fixed with oil paint with rags or cement coating. The easiest way to start is with the drain neck. Hit the neck with a short hard blow, it will split and detach from the sewer pipe. You can not hit the sewer, cast iron is a very brittle metal, it can crack or split, adding additional problems.

Toilet demolition work

Use a chisel and hammer to beat off the cement mortar at the base of the toilet. Try to swing the device, then tilt the toilet back, drain the water from it into the sewer. Make sure that the fragments do not fall into the sewer pipe. Now, using a screwdriver, carefully clean the neck of the sewer pipe from a solution of other dirt and insert the adapter eccentric collar, previously well lubricated with sanitary sealant. We plug the hole with a rag so that the dangerous and unpleasant smell of sewer gases does not spoil your mood and health.

![[instruction] do-it-yourself toilet installation | video](https://fix.housecope.com/wp-content/uploads/e/0/5/e05c3aaa569c15a65a76abf551b1139c.jpg)