- Do you need to restore the bath?

- Acrylic liner

- BATH RESTORATION WITH ACRYLIC - WHAT YOU NEED TO KNOW?

- Why do bathroom restorations with acrylic?

- How is acrylic bath restoration done?

- What material is used for this procedure?

- Acrylic restoration is the best alternative to a new bathtub.

- Preparatory work

- Care

- Advantages of liquid acrylic

- Procedure execution technology

- Acrylic bath restoration

- Cons of the acrylic restoration method

- Application of acrylic

- Bath restoration

- How to prepare the composition?

- Some Helpful Tips

- Price

- What is Liquid Acrylic?

- Conclusions and useful video on the topic

Do you need to restore the bath?

Before proceeding directly to the consideration of the relevant technology, let's see if it makes sense to restore the bath, and is it not easier to replace it with a new one.

Restoration of bathtubs in general and bulk acrylic, in particular, has a number of undeniable advantages. Firstly, there is no need to disturb existing repairs, whether it be tiles or wallpaper. This not only greatly simplifies the process, but also makes it possible to significantly save on restoring the bathroom finish. Secondly, the restoration of even the most “killed” bathtub will cost much less than replacing it, even with the cheapest analogue.And finally, the restoration will take much less time than the replacement, since the procedure does not require shutting off the water and other “plumbing complications”.

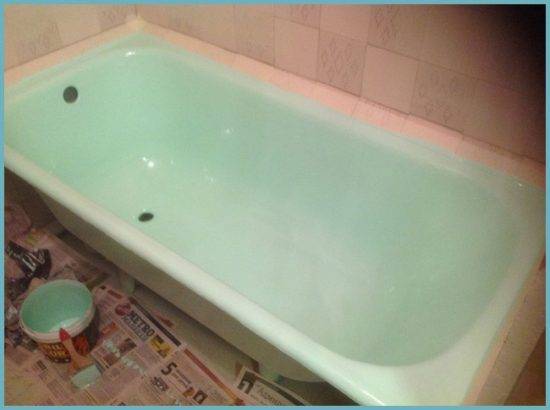

Liquid acrylic allows you to save even the most "killed" bath

Acrylic liner

For each particular bath, the liner must be selected individually. This is understandable. It is necessary that the shape of the insert be as close as possible to the shape of the base on which it will rest. The master measures the object being repaired, discusses with the customer the desired color for him, and based on these data, an insert is made.

Acrylic insert for bathtubs

Acrylic insert for bathtubs

The technology of its installation in general terms looks like this. The inside surface of the tub is cleaned and degreased. Glue is applied to the base and liner, after which the acrylic insert is placed inside the bathtub and pressed well. At the same time, it is necessary to ensure the complete coincidence of the drain holes, and to exclude a gap in this place so that water does not get between the liner and the bath. The pressure, which must be maintained for the entire period of glue hardening, is created by water filling the restored product.

BATH RESTORATION WITH ACRYLIC - WHAT YOU NEED TO KNOW?

From this article you will learn:

- why do the restoration of bathtubs with acrylic;

- how the process takes place;

- what materials are used;

- why it's better than buying a new bath.

Why do bathroom restorations with acrylic?

Bath restoration with acrylic is done in order to restore the enamel coating of an old or damaged bath. Over the years, bathtub enamel loses its appearance. If nothing is done in time, then it will be unpleasant to swim in it, as it will be unpleasant to show it to guests.And perhaps it will become unusable at all, for example, if a hole forms in it.

If some people in such cases change the bath, then others decide to restore it with acrylic.

How is acrylic bath restoration done?

In the process of such restoration, liquid acrylic is applied to the previously prepared surface of the bath. It can be white or colored, if you add color to it first. Acrylic is literally poured onto the surface, so this restoration method is called a pouring bath. And liquid acrylic, which is used for this procedure, is often called bulk acrylic.

The convenience of this method of updating the bath is that it does not need to be dismantled and transported somewhere. The whole process is carried out at the client's home, in the bathroom and lasts from 2 to 5 hours. In the end, its surface is covered with a thick layer of acrylic enamel, especially at the bottom, and strong enough after curing. And although this enamel is acrylic, it is very different from the usual, fragile acrylic from which acrylic bathtubs are made. After hardening, it is dense as a stone, so it holds securely for up to 20 years.

What material is used for this procedure?

The phrase "restoration of bathtubs with acrylic" speaks for itself - the procedure is performed using liquid acrylic or, more precisely, acrylic enamel. Acrylic enamels of different brands are used for restoration with acrylic. Therefore, there are often heated debates about which acrylic is better to restore a bathtub. However, as it is repeatedly noted on our website in various articles, the brand of liquid acrylic does not determine the quality of the restoration.It mainly depends on the professionalism of the master and his attitude to the performance of the work, or in other words, on how conscientiously he will perform it. Subject to the technology in the process of work, any of the following materials can make the bath new and reliable.

Among the common brands of bulk acrylic for restoration in Ukraine, Stacryl Ecolor (Stacril Ecolor), Plastol (Plastall), EcoVanna and FinnAcryl (FINNACRYL) are used.

Liquid Acrylic for Baths

There is also Fiber Glass. But this acrylic is fictitious and is used as German in order to artificially increase the cost of restoration. In fact, ordinary acrylic is poured into buckets with the corresponding brand image, usually one of the above.

When choosing a bath restoration contractor, we recommend focusing not on the material he works with, but on his professionalism and recommendations, if any.

Acrylic restoration is the best alternative to a new bathtub.

There are several reasons, why acrylic bath restoration is better buying a new one.

- Price. Restoring a bathtub with acrylic is cheaper than buying a new one. When buying a new bath, you overpay not only for the accessory itself, but also for its delivery, installation, as well as the replacement of plumbing fixtures and, often, tiles. And that's not all that can pull additional costs.

- Quality. The quality of the enamel of a professionally restored bathtub, old, USSR or modern, differs significantly from the enamel of most new bathtubs. Although acrylic enamel, like factory ceramic, cracks with a strong impact, it is more durable.

- Reliability. Old bathtubs are very durable and reliable.And this applies not only to cast iron, but also to steel bathtubs. Such a bath will not bend or burst under the weight of its owner. It holds heat better, and after applying a layer of acrylic, its thermal insulation is enhanced even more.

- Design. When restoring a bath with acrylic, you can fantasize with its color, which is almost impossible when buying a new one. In most cases, you can choose the color of the new enamel to match the bathroom renovation.

Restoration of a bathtub with acrylic allows you to update the look of an old or damaged bathtub at no extra cost. Restoration is carried out with liquid acrylic, and its quality depends mainly on the professionalism of the master. After restoration with acrylic, the bathtub will look like new. It will be very reliable and will last up to 20 years. Then, if desired, the restoration can be repeated.

Preparatory work

How to cover the bathtub with acrylic correctly? The main thing is careful pre-treatment of the surface:

- Sandpaper cleans off the old coating. To speed up the process, you can use a grinder with an abrasive disc or a drill with a round nozzle.

- Enamel residues and dust are completely removed by hand with abrasive powder.

- Then, the surface is degreased with a special solution and completely dried.

- The faucet and drain will need to be insulated with a film so that drops do not damage the metal structure.

- It is better to disconnect the siphon in order to avoid getting a hardening mixture into it. You can put a bowl or bucket under the drain hole.

If any of these actions are performed poorly, then the new acrylic will begin to peel off almost immediately.

Care

After completion of all stages of work and complete polymerization of the material, you become the owner of an almost new bathtub, which has a durable and smooth coating, and possibly a new color. Caring for such a font is not particularly difficult: all dirt from the surface of the bath can be easily removed with soapy water and a sponge. It should be remembered that the acrylic coating is not recommended to be treated with abrasives and aggressive chemical detergents. In order for the white bathtub not to turn yellow during operation, it is not recommended to soak laundry with washing powder in it for a long time, and after each use, the surface of the font must be washed with soapy water and, preferably, dried with a soft cloth.

During the operation of the restored bath, you should try to protect it from bumps and falls into the bowl of sharp or heavy objects so that cracks, scratches and chips do not form, which will then be quite difficult to eliminate, and you may have to call a specialist to re-repair the damaged surfaces. However, you can remove small coating defects on your own, and abrasive polishing will help you do this.

To polish small defects in the acrylic bathtub, you will need the following materials:

- synthetic detergent;

- lemon juice or table vinegar;

- silver polish;

- fine-grained sandpaper;

- abrasive mixture for polishing;

- soft fabric, foam sponge.

The process of polishing an acrylic bathtub at home is not difficult to perform - it is enough to follow a certain sequence of actions.

- Before starting work, the font must be thoroughly washed with a sponge and a soapy solution of synthetic detergents, and then rinsed with clean water. At the same time, as mentioned earlier, it is not recommended to use those detergents that contain chlorine, oxalic acid, acetone, as well as granular washing powder.

- Now you need to carefully examine all the chips and scratches and carefully sand them with fine-grained sandpaper.

- If, when examining the surfaces, you see severe contamination that could not be removed with a soap solution, apply a little ordinary toothpaste or silver polish to them and gently treat the desired area.

- With the appearance of hard-to-remove limescale, lemon juice or acetic acid will help you cope with the task. To do this, apply any of these products to a small piece of cloth and wipe the contaminated areas.

- Now you can apply an abrasive polish on the surface of the bath and gently spread it evenly over all areas with a soft cloth. To fix the polish, it is washed with a soapy solution prepared from a synthetic detergent.

Sometimes a small crack or chip needs to be repaired on an acrylic coating. This can be done with the same liquid acrylic that was used to restore the bath.

The technology for performing this small repair consists of several steps.

- If you need to remove a crack, first of all, it must be slightly expanded with sandpaper or a knife blade so that a small depression is obtained.

- Now you need to degrease the surface with a detergent, which is applied to the sponge and treated with the area necessary for work, and then rinsed with clean water.

- Next, you need to prepare an acrylic mixture by mixing the base with a hardener. You need to act according to the instructions attached to the specific material.

- Acrylic is applied to the prepared and dried area, completely filling the chip or crack groove so that the composition is flush with the main surface of the bath wall. If you apply a little more acrylic, this is not a problem, since after the polymerization process is completed, you can sand off the excess with fine-grained sandpaper.

- After the composition polymerizes, completely hardens and dries, the restored surface must be polished with sandpaper having a grit of 1500 or 2500 to smooth out all, even very small, scratches, and then treated with an abrasive polish to a shine.

Advantages of liquid acrylic

Restoration of a bathtub by applying acrylic enamel is considered one of the most popular and simple ways. Acrylic has many positive properties in comparison with other finishing materials, the price of which is often unreasonably high:

- With proper observance of operating conditions, the service life will be up to 15 years.

- The time for complete solidification of 3 days is not so much, given that complete solidification will occur without any defects.

- Covering the bathtub with acrylic ensures that there are no stains.

- Acrylic enamel practically does not smell, so all work can be carried out without burdening yourself with additional protection.

- Air bubbles, drops, smudges and lumps do not form in the uncured material.

Procedure execution technology

This method of restoration is very fast, but it generates a lot of dust, so you need to protect your respiratory system.

We proceed according to the following plan:

After cleaning the old coating, it is important to sand the surface with sandpaper, large defects are closed with a hermetic substance.

After grinding, the object is degreased using a specific solvent (this is any dishwashing substance).

After drying, you need to close the tap with a polyethylene film, close the walls near the bathtub with tape, remove the siphon. A container is put in place of the siphon .. As the preliminary work is completed, restoration can begin

For this:

Once the preliminary work is completed, restoration can begin. For this:

- Mix the acrylic base and hardener to get a homogeneous substance in accordance with the instructions. If you need to get a certain color, then add a special pigment.

- Pour the prepared solution into a container with a thin nozzle.

After that, you can cover the bath with pouring:

- The procedure starts from the top and goes along the perimeter, you need to watch that the product flows evenly, so you should get an even coating.

- If divorces, stains have turned out somewhere, they are not touched - they will resolve themselves.

- At the bottom of the plumbing, the substance is leveled with a spatula, and the excess is removed through the drain.

After that, the procedure is considered complete, and the product must be left to dry.

Acrylic bath restoration

Acrylic bath restoration is a reliable and durable option. Consider all the pros and cons.

Application of liquid acrylic on the surface of the bath

Application of liquid acrylic on the surface of the bath

The advantages of this method include:

- Easy to apply acrylic. No need for a brush or roller, leaving streaks and villi.

- Long service life.

- Elasticity and excellent adhesion, providing tight adhesion to the surface of the bath.

- Low thermal conductivity, which means that the water will stay hot longer.

- Smooth surface that does not retain dirt.

- The ability to give the bath any color.

Bathroom refurbishment is much cheaper than buying a new one.

Bathroom refurbishment is much cheaper than buying a new one.

Cons of the acrylic restoration method

The first and, perhaps, the last argument given when talking about the shortcomings of the acrylic bath restoration method is its cost. At first glance, it may seem that this is true - indeed, such restoration costs a little more than, for example, the enamel restoration method. But hasty conclusions are not always correct.

liquid acrylic

liquid acrylic

By paying more for the material and for the work, you will get a bath that fits perfectly into the interior of the room, and most importantly, its shine will not disappear after 1-2 years, but will delight you for about a decade and a half. So consider whether the restoration cost you dearly or not. In addition, it is not necessary to invite masters - the simplicity of the technology allows you to do everything yourself.

Application of acrylic

Now consider the most important thing - how to cover the bath acrylic at home. To begin with, it is necessary to pour very hot water into it so that it warms up. Application should be carried out by progressive pouring of the mixture around the entire perimeter and distributing it evenly with a spatula. Excess can be removed through the drain hole.

Particular attention should be paid to the area in the area of the drain hole, here the acrylic layer must be well sealed.The bottom should be formed immediately, not allowing the mass to harden

It is better to apply it for a certain amount of time in accordance with the ambient temperature:

- 15-20 degrees - 50 minutes;

- 25 degrees - 40 minutes;

- More than 30 degrees - 30 minutes.

Bath restoration

The process itself takes about two hours for professionals, so without experience it may take 3 or even 4 hours.

For restoration you will need:

- A 1–1.5 liter container that will be used for casting acrylic.

- Wooden stick for mixing liquid acrylic. It is not recommended to use a construction mixer. Acrylic is mixed from two substances that will turn into a homogeneous mass only with manual mixing.

- Actually, liquid acrylic. In hardware stores, it is sold in plastic buckets. The main size is 3.5 kilograms of polymer base and 0.5 liters of hardener. This volume is sufficient for bathtubs up to 1.7 meters in size.

And now a step-by-step instruction for casting liquid acrylic for restoration:

- Mix the two components of liquid acrylic until smooth. This will take at least 10 minutes to avoid unhardened lumps.

- For the top layer, you will need 1–1.5 liters of the mixture, which must be separated into a container with a spout so that it can be conveniently used for casting.

- The casting process itself starts from the corner where the bath is adjacent to the wall surface. Pour a 4 mm layer of liquid onto this corner, which should flow quietly into the bath.

- Pour further along the perimeter of the top of the tub. At the same time, do not allow excessive pouring and do not prevent the liquid from flowing down freely.

- When the entire perimeter is passed, stop without climbing onto the already applied layer.

- Start the second layer already from the middle of the walls of the bath and go the whole circle around the perimeter in the same way.

- Finally, excess liquid will remain at the bottom of the bath, which must be drained into the hole with a spatula.

- Once the coating is ready, close the bathroom to prevent dust and insects from entering the surface.

The layer of bulk acrylic will dry for at least a day. If you use a long-drying composition, it will take about four days to completely harden. By the way, long-drying compositions are more reliable and durable, so it is advisable to use them.

How to prepare the composition?

Liquid acrylic is a two-component polymer composition consisting of a base and a hardener. It is possible to combine the base and hardener only when the restored surface of the bathtub is fully prepared for acrylic coating. It is impossible to mix the components in advance, since the resulting mixture is suitable for application in a limited period of time, which is only 45-50 minutes. At the end of this period, the polymerization process begins in the mixture, and the entire composition literally becomes thick before our eyes, its fluidity, necessary for the performance of work, is lost. After polymerization, the composition for application to the surface is unsuitable.

It is best to mix the base and hardener, which are part of liquid acrylic, with a smooth wooden stick, always remembering that the uniformity of the composition will largely determine the final quality of the restoration work. If the volume of the composition is large, then to speed up the process of preparing the mixture, you can use a special nozzle fixed in the chuck of an electric drill

When mixing the components of liquid acrylic with an electric drill, it is important to take into account the fact that you need to work with the tool only at low speeds, otherwise the entire composition will be sprayed around you on the walls and ceiling

Liquid acrylic can be made colored. For this, there are special tinting additives of various colors. When adding a tinting shade, it should be borne in mind that its maximum volume should not exceed 3 percent of the total volume of the acrylic mixture. If you increase the percentage in the direction of increasing the content of the tinting composition, this will reduce the strength of the acrylic material after the polymerization process, since the verified balance of ingredients will be disturbed and the polymer bonds will not be strong enough. For liquid acrylic, only additives specially created for this purpose can be used. If a tinting pigment containing a solvent is added to the polymer composition, this will lead to the fact that you will spoil the entire material and it will be unsuitable for work.

Some Helpful Tips

There are situations when a coating of liquid acrylic is applied not in one layer, but twice. For example, this is done if the damage to the base is extensive and needs additional repairs. In this case, it should be remembered that the filling of the second layer should be done only after the initial coating has completely dried.

This means that the repair time will increase by several days. Otherwise, the technology for pouring the second layer of liquid acrylic is carried out in the same way as when applying the first layer.

The white acrylic finish looks very attractive, but the design of the bathtub can be slightly modified if desired.If, when mixing the material, a little tinting paste is added, it will acquire a certain shade.

A special tinting paste, introduced into liquid acrylic during mixing, allows you to give the surface the desired shade. But the amount of color should be no more than 3% of the total volume of the material

The color palette is quite diverse, but the amount of dye in the total mass of liquid acrylic should be no more than 3%. if you add too much tinting paste, it will degrade the performance of the coating, make it less durable.

The following article will acquaint you with the technological rules for painting a cast-iron bath, which describes in detail the steps for performing a difficult job.

Care of the new coating is recommended to be carried out according to the same rules as for a solid acrylic bathtub. For regular cleaning of the acrylic surface, it is enough to use a sponge and soapy water. But do not use cleaning agents containing abrasive particles, as they can scratch the enamel.

Caution does not hurt when using acidic or alkaline cleaners. Acrylic coating does not always tolerate contact with such aggressive chemistry well.

It is believed that the acrylic coating perfectly resists mechanical damage. It really is. But still, enamel should be handled carefully, trying not to drop heavy objects on its surface. Compliance with these simple recommendations can significantly increase the life of the bath.

Price

You can buy liquid acrylic in many hardware stores. The cost of the product depends on the size of the bathroom bowl and the quality characteristics of the composition.The capacity of a plastic bucket with contents is usually at least 3.5 kg.

This is enough to cover a bath up to 1.7 m long with a new layer. The price of liquid acrylic is on average 1100 - 2000 rubles per bucket. The hardener is sold separately in 1.5 liter bottles. If there is no certainty that it will be possible to restore it on your own, then calling specialists will cost another 1000 - 1500 rubles.

Following the instructions helps to achieve excellent results. Feedback on the restoration of the bath with liquid acrylic is usually positive. The popularity of the tool is growing due to the versatility and durability of the restoration. Consumers note the improvement in quality characteristics and the wonderful appearance of the new bath.

What is Liquid Acrylic?

Liquid acrylic is a special polymer substance that is in a liquid state before use.

After application to the surface, the material is evenly distributed over the treated surface and hardens as it dries. The result is an even, smooth and durable coating that reliably protects the bathtub from damage.

Usually liquid acrylic is a two-component composition. Before use, it must be mixed in strict accordance with the manufacturer's instructions. Some manufacturers supply a ready-made composition that does not need to be mixed.

Among the most popular varieties of liquid acrylic can be mentioned:

- Plastrol - is considered one of the highest quality materials for the restoration of bathtubs, does not have an unpleasant odor characteristic of such materials.

- Stakryl is a two-component composition that allows you to complete all restoration work within 3-4 hours.

- Ecobath is a good formula that allows you to get a quality coating, but the work will be accompanied by a characteristic unpleasant odor.

These brands of bulk acrylic are constantly being improved. In addition, more and more new varieties of acrylic bulk compositions with improved characteristics appear on the market.

Bulk acrylic is usually sold as two components: an acrylic semi-finished product and a hardener. The components must be thoroughly mixed and do not forget about the life of the finished composition

Conclusions and useful video on the topic

Acrylic enameling of a bowl previously painted with other enamel and requiring puttying of individual sections:

Video instruction for restoring the bathtub finish with liquid acrylic from the manufacturer of Plastol restoration compositions:

The following video describes the process of installing the strapping, dismantled before applying the acrylic enamel:

Guided by the instructions in the article, you will restore the enamel coating of the bath yourself. An updated container will last as long as it has been carefully repaired.

Note that the finish of bulk acrylic requires careful cleaning. It is impossible to use abrasive agents, only liquid ones, and substances containing a solvent will not work either.

Share with readers your experience of restoring an old cast-iron bath. Please leave comments on the article, ask your questions, participate in discussions and attach photos of the updated plumbing. The feedback form is located below.