- Ratings

- Which is better to choose a water heated towel rail: manufacturer rating

- Rating of the best wired headphones of 2020

- Rating of the best mobile phones for games

- What to do if the boiler smokes

- Possible malfunctions and do-it-yourself repair methods

- Smells like gas in the house

- Fan not working

- High temperatures

- Sensor failure

- Boiler chimney clogged

- Self shutdown

- A little theory or how it all starts

- The device and operation of the geyser

- Adjustment

- How to flush the heat exchanger of a double-circuit boiler

- Boiler maintenance

- Possible malfunctions and do-it-yourself repair methods

- Smells like gas in the house

- Fan not working

- Boiler chimney clogged

- High temperatures

- Sensor failure

- Self shutdown

- How often should the heat exchanger be cleaned?

- Description of the floating head heat exchanger “TP”

- Which material is better

- Steel

- Aluminum

- Copper

- Gas boilers with cast iron heat exchanger

- Proper operation

- About the dangers of scale in the heat exchanger

- Conclusions and useful video on the topic

Ratings

Ratings

- 15.06.2020

- 2976

Which is better to choose a water heated towel rail: manufacturer rating

Types of water heated towel rails: which one is better to choose, rating of manufacturers and overview of models.Advantages and disadvantages of towel dryers. Features and installation rules.

Ratings

- 14.05.2020

- 3219

Rating of the best wired headphones of 2020

The best wired earbuds for 2019 A brief overview of popular devices designed for a variety of purposes. Pros and cons of budget gadgets.

Ratings

- 14.08.2019

- 2580

Rating of the best mobile phones for games

Rating of the best mobile phones for games and the Internet. Features of choosing a gaming smartphone. Main technical characteristics, CPU frequency, amount of memory, graphics accelerator.

Ratings

- 16.06.2018

- 862

What to do if the boiler smokes

In many models, a problem may arise that when the ignition unit is turned on, soot comes out of it. The reason for this problem is the low concentration of air in the fuel, so the gas does not burn immediately. Eliminate this by adjusting the air on the burner:

- find the adjusting washer and equalize the air supply with the burner lit;

- you should focus on the operation of the burner: if there is a lot of air, noise will be heard and the fire will vibrate; if it is small, then a red flame with yellow dots will appear; with good air concentration, the fire burns evenly and has a grayish color.

Clogging of the gas burner with dust also leads to the appearance of soot. In this case, the element should be cleaned of all kinds of contaminants.

Possible malfunctions and do-it-yourself repair methods

Any malfunction of the gas boiler must be dealt with by a specialist. However, the opportunity to use the services of a master is not always available, and breakdowns are trifling. Consider problems that are solved independently.

Smells like gas in the house

Usually the smell of gas appears when it leaks from the threaded connection of the supply hose. If there is a smell in the room where the boiler is installed, you need to open the window and turn off the boiler. Then proceed according to the instructions:

- Prepare the necessary things: soap solution, FUM tape, open-end or adjustable wrench.

- Apply mortar to all threaded connections. If bubbles begin to inflate, a leak has been found.

- Close the gas valve.

- Expand the connection with the key. Wrap the FUM tape on the external thread and assemble everything back.

- Reapply the solution and restart the gas supply.

- If the leak is fixed and the smell of gas is gone, remove the remaining solution.

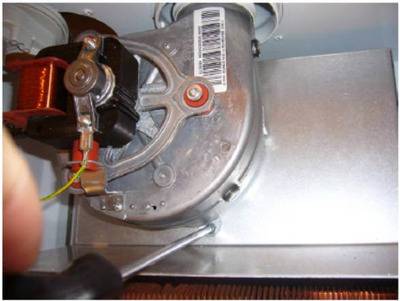

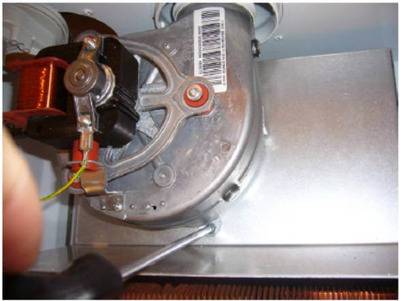

Fan not working

If during the operation of the boiler the sound emitted by the turbine disappears or decreases, this indicates a malfunction of the blowing fan. For repair you will need: a screwdriver, a new bearing, a rag, grease.

- It is necessary to turn off the boiler and turn off the gas.

- Remove turbine.

- Use a cloth to clean dust and soot from the turbine blades.

- Inspect the electric fan coil for blackening. If everything is in order, move on or replace the fan.

- Disassemble the fan housing. A bearing is installed on the turbine shaft inside, it must be replaced. Some fans have a sleeve instead of a bearing. In this case, it must be lubricated.

The turbine may also not work due to low mains voltage or a malfunction of the control board. The first is eliminated with the help of a stabilizer, but the second is only by calling a specialist.

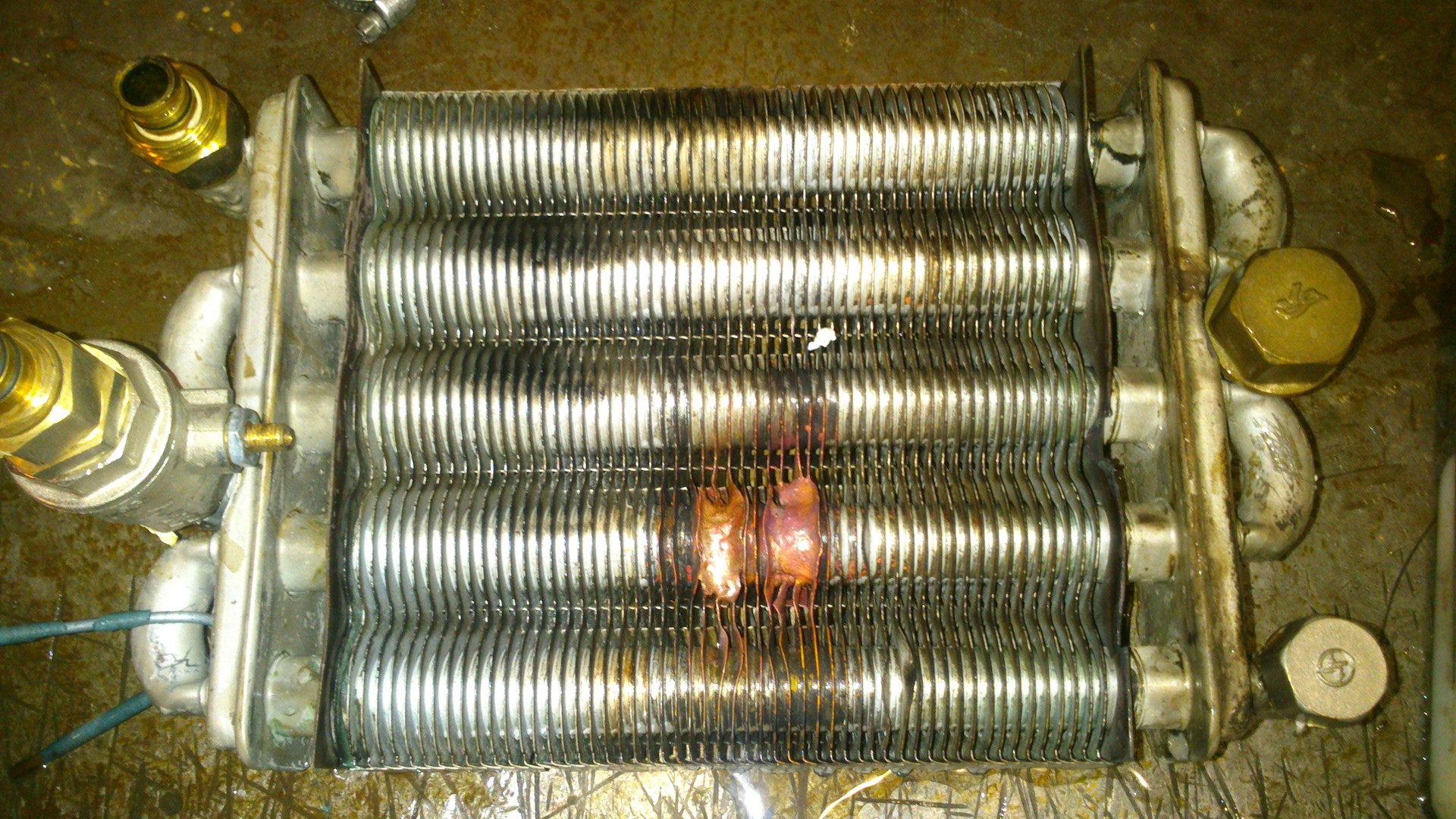

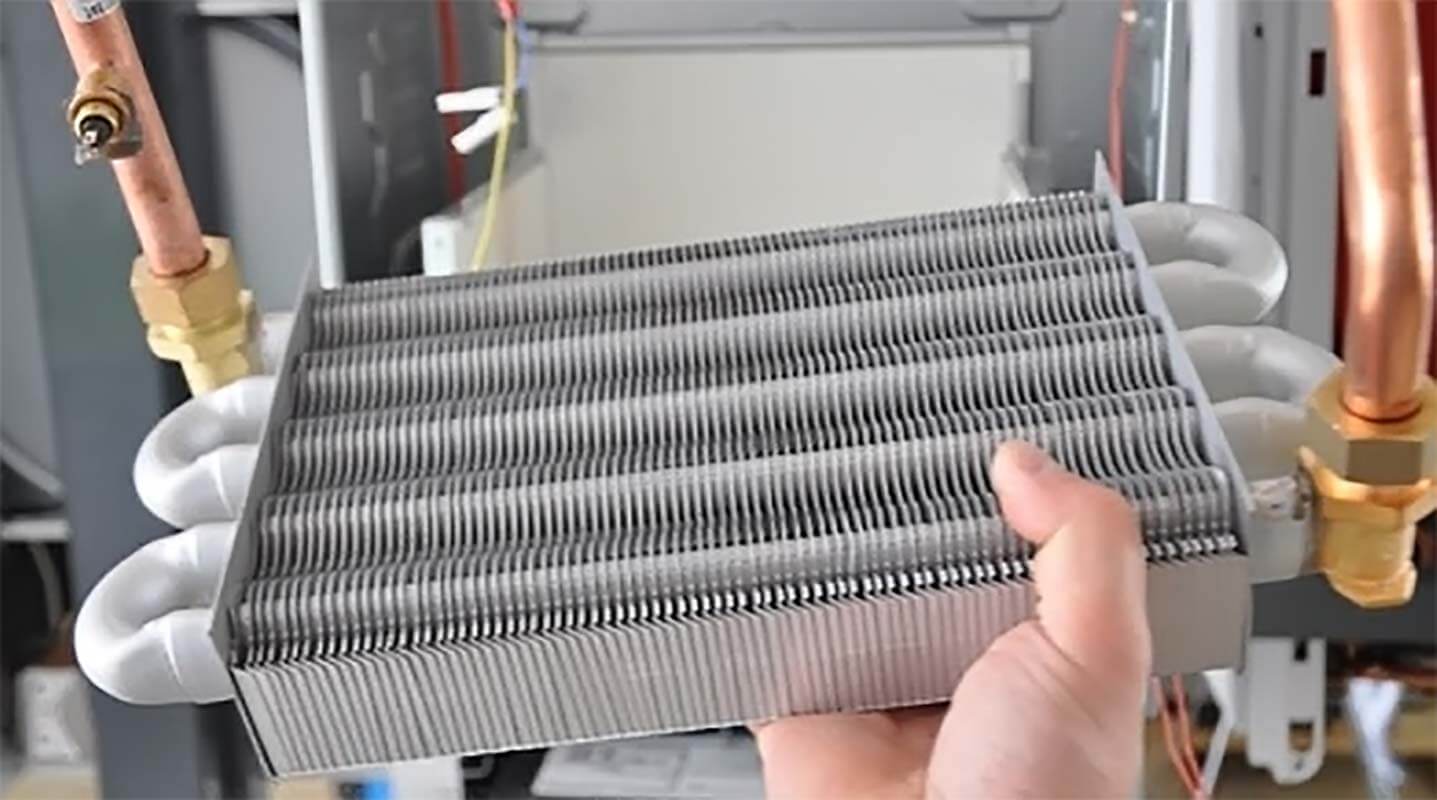

High temperatures

Overheating of the boiler is associated with contamination of the heat exchanger. To clean the device, you will need: a special solution of hydrochloric acid, an adjustable wrench, an FUM tape, a metal brush.Then proceed according to the instructions:

- Turn off the boiler, turn off the gas and water.

- Remove the heat exchanger using an adjustable wrench.

- Clean it with a brush.

- Pour the acid solution into the heat exchanger through the pipe. If foam appears, then there is a lot of scale inside.

- Pour out the solution and repeat the procedure.

- Rinse.

- Install back, after wrapping all threaded connections with FUM tape.

Sensor failure

Problems usually arise with the combustion electrode. If the burner flame goes out after a few seconds, and the boiler gives an error, then the problem is in the combustion sensor. Turn off the boiler, turn off the gas.

To repair the electrode, you will need sandpaper, with which the sensor probes are cleaned without removing it. If the failure remains, the sensor is replaced.

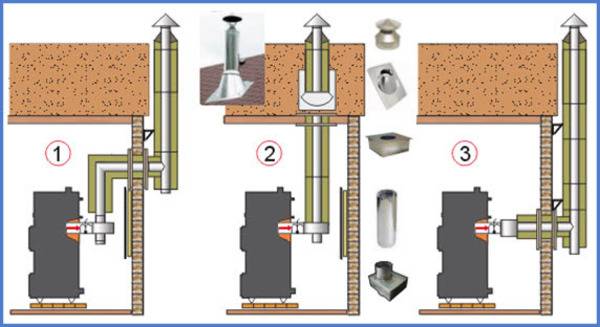

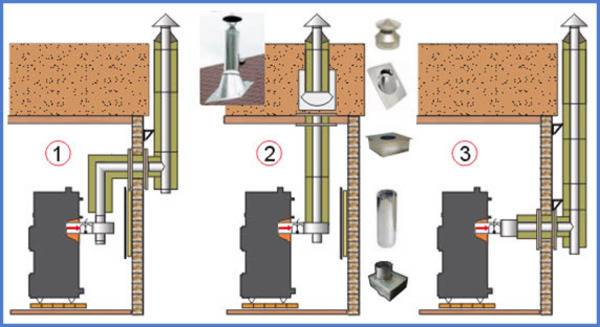

Boiler chimney clogged

Problems with the chimney occur only in floor-standing boilers. This is due to its size and vertical position. Mounted devices do not need to clean the chimney.

The chimney, consisting of metal parts, is cleaned with a metal brush. It must be disassembled and the accumulated soot removed mechanically. The whole chimney is cleaned with special vacuum cleaners or chemicals. But for this you need to call a professional.

Three ways to arrange a chimney for a floor-standing gas boiler. The first option is the hardest to clean.

Self shutdown

There are two problems that lead to spontaneous shutdown of the boiler. The combustion sensor is broken or the chimney is clogged. Repair of both faults is described above in the article.

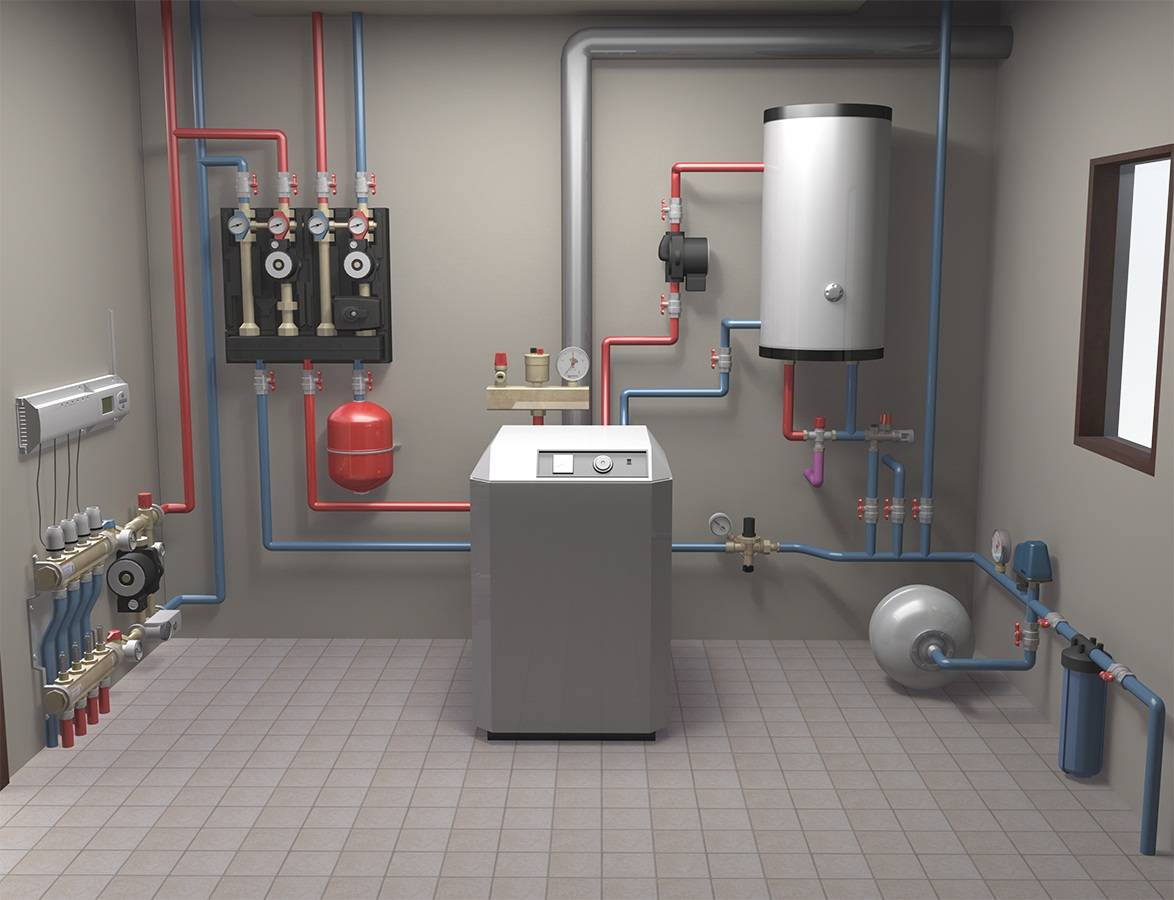

A little theory or how it all starts

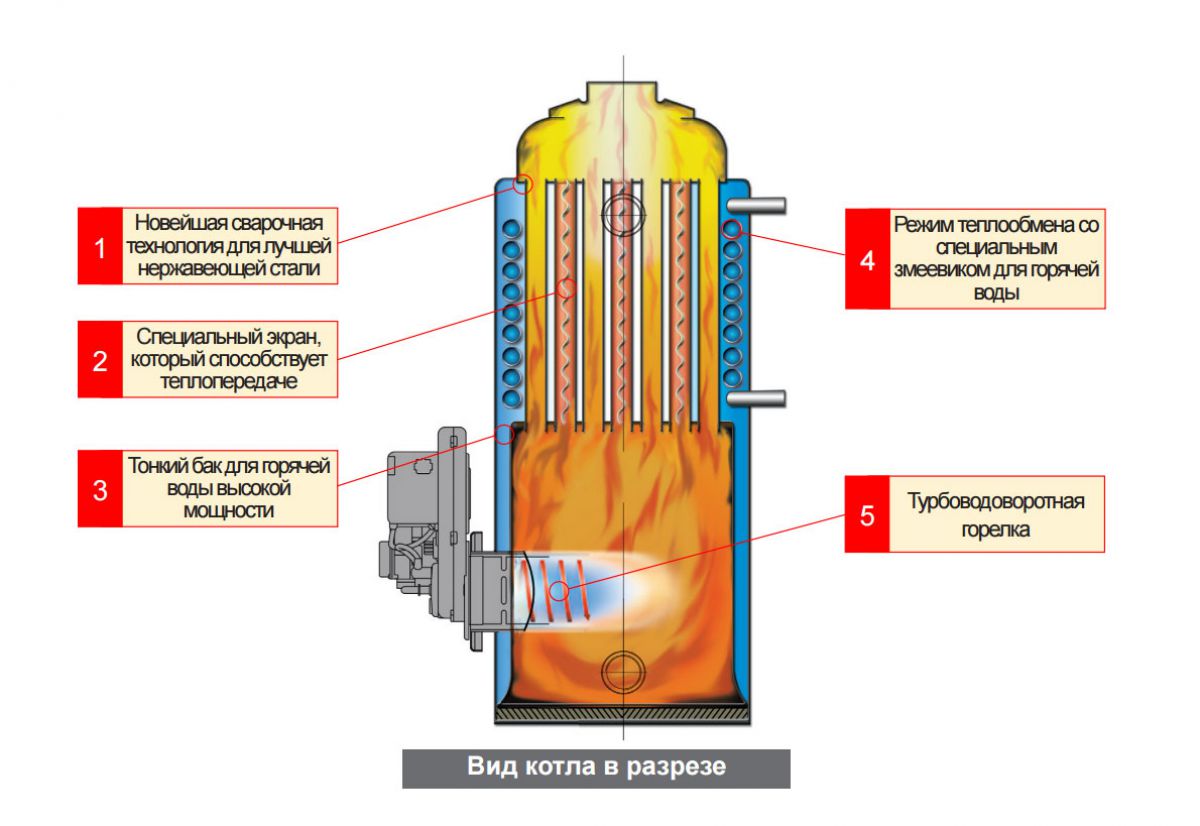

Although the heat exchangers of different heating systems may have some distinctive features, their design and principle of operation are basically the same: a coolant passes through a curved pipe (coil), then the coil heats up with a flame of burning gas, transferring heat to the liquid passing through it, supplied further along pipes to heating radiators. The plate system, in which the tube heated by the flame is located, allows to increase the temperature and make the heating of the coil material more uniform. Outwardly, such a system resembles a radiator installed in a car.

For the manufacture of heat exchangers, materials with good thermal conductivity are most often used. As a rule, these are copper alloys or pure copper.

In order to ensure efficient heating of the coolant in the heating system, it is necessary to monitor:

- Cleanliness of the heat exchanger inside and out

- Cleanliness and absence of blockages in the gas nozzles that release gas to heat the heat exchanger and its surrounding plates

You are unlikely to find specific figures, however, the experience and independent calculations of the owners of individual heating systems indicate that as a result of contamination of the heating system of the coolant, the loss of resources can be quite large.

Overexpenditure in this case, the gas can be 10-15%. When converted into a financial equivalent, the amount lost as a result of the inefficient operation of the heating system can be quite large.In accordance with the advice of professionals, for the efficient operation of the heating system, annual cleaning of the heat exchanger of a double-circuit boiler is necessary, however, practice shows that with soft tap water it is enough to carry out this procedure once every three years.

Scale in kettles and taps indicates a high degree of water hardness, in which case we recommend cleaning the heating system every two years.

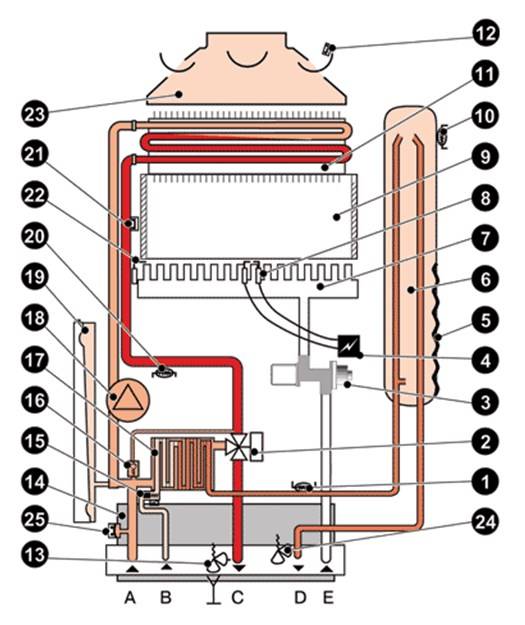

The device and operation of the geyser

The geyser is similar to an ordinary kitchen cabinet. Two burners, a heat exchanger, temperature sensors, regulators and three small pipelines are mounted in this “cabinet”, which are responsible for supplying water, gas and removing heated water from the column. Geysers Beretta, Oasis, Electrolux, neckar, amina, bosch, termet have similar schemes for constructing internal components, so the repair process of this equipment does not have any special differences.

The process of heating water begins as the water tap is opened, after which the valve automatically opens to supply gas to the burner, which is ignited through the installed candle. The combustion process generates heat, which is controlled by a sensor. The accumulated heat is transferred through the heat carriers to the open faucet. The generated gas vapors are removed through the ventilation system. The temperature regime is controlled by a switch, which is located on the outer side of the column body.

Adjustment

After purchase and installation gas column should be adjusted comfortable temperature. This requires:

- set the water and gas supply to the minimum

- open the water and gas supply to the column

- open the hot water supply at the tap, then adjust the water pressure on the gas equipment

- wait a few minutes, then measure the water temperature

- increase the gas supply, thereby increasing the temperature of the water to the indicators you need

- leave all settings and use water at a comfortable temperature

How to flush the heat exchanger of a double-circuit boiler

The method of descaling the DHW path depends on the type of heat exchanger installed in your heat generator. There are only two of them:

- bithermic, it combines the heating of the coolant and water for hot water supply;

- secondary heater in stainless steel.

It is better to clean the units of the first type with the help of a booster, since it can be quite difficult to remove such a unit. The hoses leading from the tank are connected instead of supplying cold water and exiting hot, after which the circulation pump and the boiler itself are started. The heating temperature should be limited to 50-55 degrees.

If there is a secondary heat exchanger in the double-circuit boiler, the latter can in most cases be removed. To do this, the front panel is removed, and then the control unit is unscrewed and moved aside. The secondary heat exchanger is located at the bottom and is fixed with 2 bolts. After removing it, it is immersed in a saucepan with citric acid dissolved in water and boiled on a gas stove, which is described in detail in the video:

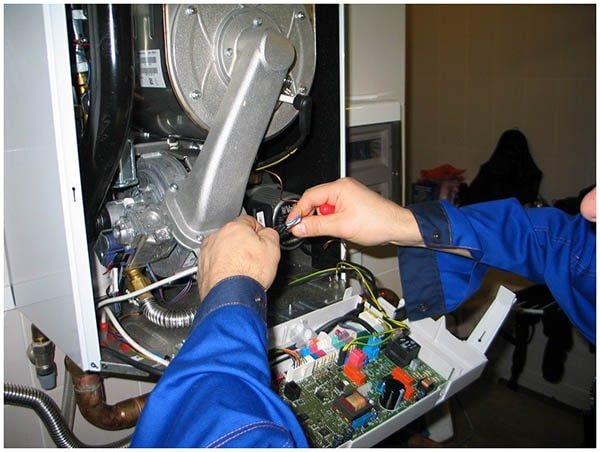

Boiler maintenance

The durability and performance of the heater will depend on how competently and timely its maintenance is performed. With solid fuel boilers, everything is simple, you just need to do the following:

- annually clean the chimney from soot and remove ash from the grate in a timely manner;

- periodically open the safety valve manually to avoid sticking of the plate;

- remove scale from the heat exchanger if untreated water is used (see above).

Maintenance of a gas boiler is a more complex process that requires the participation of a specialist. But it is desirable for the user to know which work must be carried out without fail, and which are imposed in order to unreasonably increase the cost of the service. A specific list of operations is set out in the instructions for the heater, in the general case, the following should be done:

Inspection of the unit, including disconnection and inspection of the burner.

Cleaning the following elements of the burner: retaining washer, igniter electrodes, flame sensor and air sensor, with which the boiler optimizes the composition of the gas-air mixture (it must be thoroughly blown out).

Washing of gas filters or their replacement (if necessary).

Cleaning of carbon deposits from all elements of the heater in contact with the flame.

Gas duct cleaning. Note that we are talking about the flues of the boiler, not the chimney. Cleaning the chimney is not included in the boiler maintenance procedure, but the craftsmen usually perform it for an additional fee. Cleaning of the burner and gas ducts is included in the standard set of maintenance works for a gas boiler. Masters can also adjust the draft in the chimney, but for a fee

Checking electronics, and if necessary, then repairing it.

Boiler regulation in general.

Chemical analysis of combustion products (allows you to determine whether the boiler is correctly adjusted for this type of fuel).

Checking and adjusting the built-in boiler, if any. If a boiler is built into the boiler for supplying hot water, it must also be checked and adjusted.

Checking the functionality of the safety automation

This part of maintenance is extremely important. Almost all the time, emergency automation is inactive and the user may not know if it works at all and whether it can block the gas supply in a moment of danger

The wizard simulates various alarm situations and checks if the sensors are responding correctly. At the same time, he also monitors how quickly and hermetically the automatic valve closes.

At the last stage, an inspection of the gas pipeline section, for which the customer is responsible, is carried out. The tightness of the joints is checked and places damaged by corrosion are identified. If necessary, the pipeline is painted.

Possible malfunctions and do-it-yourself repair methods

Any malfunction of the gas boiler must be dealt with by a specialist. However, the opportunity to use the services of a master is not always available, and breakdowns are trifling. Consider problems that are solved independently.

Smells like gas in the house

Usually the smell of gas appears when it leaks from the threaded connection of the supply hose. If there is a smell in the room where the boiler is installed, you need to open the window and turn off the boiler. Then proceed according to the instructions:

- Prepare the necessary things: soap solution, FUM tape, open-end or adjustable wrench.

- Apply mortar to all threaded connections. If bubbles begin to inflate, a leak has been found.

- Close the gas valve.

- Expand the connection with the key. Wrap the FUM tape on the external thread and assemble everything back.

- Reapply the solution and restart the gas supply.

- If the leak is fixed and the smell of gas is gone, remove the remaining solution.

Attention! When the leak could not be found, turn off the gas, call a specialist

Fan not working

If during the operation of the boiler the sound emitted by the turbine disappears or decreases, this indicates a malfunction of the blowing fan. For repair you will need: a screwdriver, a new bearing, a rag, grease.

- It is necessary to turn off the boiler and turn off the gas.

- Remove turbine.

- Use a cloth to clean dust and soot from the turbine blades.

- Inspect the electric fan coil for blackening. If everything is in order, move on or replace the fan.

- Disassemble the fan housing. A bearing is installed on the turbine shaft inside, it must be replaced. Some fans have a sleeve instead of a bearing. In this case, it must be lubricated.

The turbine may also not work due to low mains voltage or a malfunction of the control board. The first is eliminated with the help of a stabilizer, but the second is only by calling a specialist.

Boiler chimney clogged

Problems with the chimney occur only in floor-standing boilers. This is due to its size and vertical position. Mounted devices do not need to clean the chimney.

The chimney, consisting of metal parts, is cleaned with a metal brush. It must be disassembled and the accumulated soot removed mechanically. The whole chimney is cleaned with special vacuum cleaners or chemicals. But for this you need to call a professional.

Photo 2. Three ways to arrange a chimney for a floor-standing gas boiler. The first option is the hardest to clean.

High temperatures

Overheating of the boiler is associated with contamination of the heat exchanger.To clean the device, you will need: a special solution of hydrochloric acid, an adjustable wrench, an FUM tape, a metal brush. Then proceed according to the instructions:

- Turn off the boiler, turn off the gas and water.

- Remove the heat exchanger using an adjustable wrench.

- Clean it with a brush.

- Pour the acid solution into the heat exchanger through the pipe. If foam appears, then there is a lot of scale inside.

- Pour out the solution and repeat the procedure.

- Rinse.

- Install back, after wrapping all threaded connections with FUM tape.

Sensor failure

Problems usually arise with the combustion electrode. If the burner flame goes out after a few seconds, and the boiler gives an error, then the problem is in the combustion sensor. Turn off the boiler, turn off the gas.

To repair the electrode, you will need sandpaper, with which the sensor probes are cleaned without removing it. If the failure remains, the sensor is replaced.

Self shutdown

There are two problems that lead to spontaneous shutdown of the boiler. The combustion sensor is broken or the chimney is clogged. Repair of both faults is described above in the article.

How often should the heat exchanger be cleaned?

Many Internet sources on this topic indicate very conflicting information regarding the frequency of cleaning the heat exchanger. Some of them advise to follow the manufacturer's instructions, others rely on the opinions of experts.

Maybe they are all right, but the most realistic option would be that the heat exchanger should be flushed when the following signs begin to appear:

- the burner in the gas boiler is on all the time;

- the circulation pump works with a characteristic hum, which indicates an overload;

- heating radiators heating occurs much longer than usual;

- significantly increased gas consumption with the same operation of the boiler;

- weak pressure of hot water in the tap (this feature is applicable for double-circuit boilers).

All these points strongly indicate that there are problems in the functioning of the heat exchanger, and this, in turn, means that it is necessary to start flushing.

Specialist note: irregular cleaning of the device will reduce the efficiency of the gas boiler.

Description of the floating head heat exchanger “TP”

The floating head heat exchanger is one of the popular types of shell and tube heat exchangers and is widely used in refineries, as well as various other industrial enterprises.

The main feature of this device is the presence of a temperature compensator in the form of a so-called “floating head”.

Below are 2 versions of the “floating head”:

- The top figure is a design with the ability to extract the tube bundle without dismantling the head itself, characterized by reduced thermal efficiency due to the presence of bypass flows (designation T according to TEMA).

- The bottom figure is a design that requires disassembly of the head to remove the tube bundle (designation S according to TEMA). Most common in domestic refineries.

In both cases, the presence of a floating head allows the use of a heat exchanger with a large temperature difference between the process media in the tube and annulus of the apparatus.

Thus, this type of apparatus is more versatile than rigid-tube heat exchangers and can be used in a wide range of combinations of various media with a large temperature difference. However, due to the presence of melt. heads, the cost of the heat exchanger also increases. Therefore, the use of this equipment must be technically justified. When specifying the device code, the abbreviation “TP” is used - heat exchangers with a floating head according to TU 3612-023-00220302-01 VNIINeftemash.

By the way, read this article too: Stainless steel analogues

Which material is better

Boiler heat exchangers are made of different metals, the choice of which is made by the manufacturer in the process of designing the heating source.

Basically, modern devices are equipped with heat exchangers made of steel, cast iron, copper and aluminum. They have different heat transfer coefficients, acceptable temperature environment and resistance to corrosion processes. The floor gas boiler with a cast-iron heat exchanger is the most economical and durable.

Steel

The stainless steel heating apparatus is technologically the most simple, both in manufacture and in operation. Therefore, it has the most affordable price, which affects the total cost of the boiler.

Steel has good ductility, so this design in high-temperature hot gases is less susceptible to thermal deformation.

Aluminum

Many Western models are equipped with aluminum heat exchangers, to which experts attribute a great future in domestic heating.

With high ductility, they have a thermal conductivity 9 times higher than that of steel.In addition, they have high functionality with low weight.

In such structures, stress zones are not created during a welded joint, like stainless devices, and, consequently, there will be no hazardous corrosion areas.

Aluminum components are characterized by strong chemical resistance, which is used in low temperature applications or condensing type boilers.

However, aluminum structures will last less if they use hard tap water, they become clogged with scale almost immediately.

Copper

Copper surfaces in boiler heat exchange devices are compact and lightweight, so they are installed on the Navien gas boiler.

Copper essentially does not corrode in aggressive acidic environments. Boilers with similar devices are compact and easy to use. Due to the low inertia, copper devices rapidly warm up and cool down.

There are more advantages to copper heat exchangers than negative qualities. Copper construction owns light weight, compactness, small capacity.

It is not afraid of corrosive processes and requires less gas consumption to heat the coolant. The disadvantages of users include high cost and unreliability in non-standard cold starting conditions.

Gas boilers with cast iron heat exchanger

The cast-iron boiler heat exchanger is considered the most efficient and durable, since it is not subject to corrosion. At the same time, since the material is very fragile, it requires proper operation.

Uneven heating of the structure, which occurs at the time of starting from a cold state or in places of scale formation, leads to the appearance of various cracks in the walls of the structure.

Users of such a device will need to control the quality of the feed water, install a purification system, and when scale appears for gas boilers with a cast-iron heat exchanger, the heat exchanger is flushed.

Usually it is performed once a year before the start of the heating season. If the feed water is pre-treated before being fed into the boiler, then the frequency of flushing is 1 time in 4 years.

Proper operation

Transportation, installation and operation of the heat exchanger are described in detail in the instructions:

- The heat exchanger in the apparatus is placed so that it has free access for inspection and repair.

- Start-up is carried out at stable pressure and temperature values. Do not raise the temperature faster than 10 degrees per minute or increase the pressure more than 10 bar per hour.

- When filling with water, the air valves and valves behind the heat exchanger remain open. After starting the pump, they are closed. Thus, stable pressure is achieved.

- You need to change the heating parameters smoothly. The slower this happens, the longer the seals and the heat exchanger itself will last.

- The device needs to be cleaned periodically. The plate is cleaned right in the frame, then the plates are taken out and washed. Another method is possible: first removal and then cleaning of the plates. Shell-and-tube cleaning is not recommended. For complex blockages, the master puts a plug.

- Before restarting, check the condition of all gaskets. The pressure and temperature are set as for the 1st start.

About the dangers of scale in the heat exchanger

Heating of tap water for a hot water supply system (DHW) in a double-circuit gas boiler or in a gas column is carried out in a flow heat exchanger.

It is known that when heated above 54 °C, crystallization of salts of chemical elements dissolved in water occurs, mainly calcium and magnesium. Solid salt crystals settle on the heating surfaces of the heat exchanger and form a strong crust on them.

In addition to hardness salts, other solid particles that are contained in water get into the composition of scale deposits. For example, rust particles, oxides of other metals, sand, silt, etc.

The amount of salt in water determines the degree of its hardness. Distinguish between hard water, which contains a lot of salt, and soft, with a small amount of salt.

If the source of tap water is a river or other natural body of water, then the hardness of such water is usually small. You are lucky, the water in your house is soft.

Tap water from a well usually contains more hardness salts. And the deeper the well, the more salt in the water.

A hard crust of hardness salts, rust, sand, silt on the heating surface of the heat exchanger prevents heat transfer through its metal walls. In addition, deposits reduce the clearance of the heat exchanger channels. As a result, the heating temperature and hot water pressure gradually decrease, and the walls of the heat exchanger overheat, which reduces its service life.

Internal organization double-circuit gas boiler on the example of Protherm Gepard 23 MTV and Panther 25.30 KTV (Panther). The secondary DHW heat exchanger is located in the lower compartment.

Dual circuit most often gas boilers have two heat exchangers.One is primary, in which water is heated by gas for heating. The other is the secondary DHW heat exchanger, in which the heating water from the primary heat exchanger heats the water from the DHW pipeline.

There are also double-circuit boilers in which both heating water and hot water are heated by gas in one combined bithermic heat exchanger. The bithermic heat exchanger accumulates scale faster, and it is more difficult to clean it from scale.

The geyser has one DHW heat exchanger, in which tap water is immediately heated by gas.

Regular descaling is necessary only for the DHW heat exchanger, in which there is a constant accumulation of deposits of hardness salts.

In the channels of heat exchangers with heating water, scale accumulation occurs only when fresh water is replaced or added to the system. This happens quite rarely and in small volumes.

If there is a filter at the heating water inlet to the boiler, then other dirt from the heating system does not enter the boiler and there may not be a need to clean the boiler coolant channels for the entire period of its service life. Descaling of the primary heat exchanger with the same frequency as the DHW heat exchanger is not required. However, "servicemen" without proper reason often insist on descaling the primary heat exchanger, at the same time, just in case. Naturally, they charge for this.

Secondary plate heat exchanger for hot water supply of a double-circuit gas boiler. Two openings serve for the circulation of heating water through the heat exchanger. Through the other two, cold water enters and heated DHW comes out. Requires regular descaling inside.

Bithermic heat exchanger of a double-circuit gas boiler. On the right side pipes for heating water. On the left - pipes for DHW water. Regular descaling inside and soot outside is required.

Heat exchanger of a geyser of hot water supply. Regular descaling inside and outside soot is required.

Conclusions and useful video on the topic

How to get a heat exchanger from a Baxi boiler, how to clean it:

Cleaning the primary exchanger with reagents, an overview of the means and the end result:

Idea for repairing a broken primary heat exchanger inlet:

We talked about two types of heat exchangers. Primary - above the burner of the combustion chamber and secondary - for heating running water. Now you are better versed in the design of gas boilers and understand the importance of heat exchangers in their work. We also gave two partially similar algorithms for replacing exchangers.

If necessary, you can start soldering this part. You will be able to do home washing. Do not forget also about the quality of materials, if you still have to buy a new part.

Leave comments and ask questions. Tell us about your boiler. Write how many heat exchangers are in it. Have you changed them, and how long have the old exchangers lasted? Write about it in the contact form, which is located under the article.