- Types of malfunctions and repairs

- How to open the washer

- After an emergency stop

- With horizontal loading

- Top loading

- If the handle is broken

- Emergency opening cable

- Wire or rope

- Pliers

- During washing

- "Samsung"

- "Atlant"

- Electrolux and AEG

- LG and Beko

- Bosch

- "Indesit"

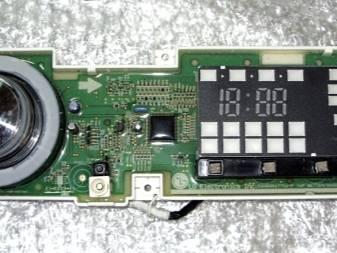

- The device and operation of washing machines

- The machine took on water, but does not wash

- Causes of breakdowns and ways to eliminate them

- No water coming in

- Symptoms

- Process Features

- Front loading machine

- With vertical

- Washing machine does not spin

- Hatch door won't open

- The car is making noise

- water flowing

- How to check?

Types of malfunctions and repairs

If the Samsung washing machine is constantly in use, then over time there will come a moment when it will not turn on. The cause of the problem may be hiding in the water pump, which will need to be removed. Therefore, it is advisable for each owner of the unit to know how to check and change the pump, as well as clean and replace the filter.

In the case when an unusual crack of the unit is heard, you need to try to disassemble it. To carry out this procedure, it is worth knowing the device of the equipment, the nuances of the connection, only then it will be possible to repair the case or correct the situation when the impeller flies.

Depending on the washing mode, the pump may turn on and off several times. Due to the high load, this element may fail. Samsung pump malfunctions include the following:

- frequent connection of thermal protection on the winding of the electric motor;

- clogged impeller, which often causes interruptions in work;

- impeller blades broken by mechanical action;

- wear of the bushing, which is located on the motor shaft;

- scrolling and falling out of the impeller;

- occurrence of short circuits;

- breakage of turns that are located on the motor.

Each of the above breakdowns can be the basis for repairing the pump. It is often recommended to carry out repair procedures when minor damage is detected, for example, debris getting into the impeller, minor damage to the blade. All other problems require washing pump replacement car.

Since the pump is located in the lower half of the machine, under the tank, it can be reached through the bottom or after dismantling the front panel. The replacement of the pump in Samsung technology must be carried out through the bottom.

Dismantling the pump includes the following activities:

- disconnecting the machine from the electricity network;

- blocking water before performing procedures;

- neat laying of the machine on the side - so that the pump is located on top;

- release of the bottom of the equipment from the protective panel - for this, snap fasteners are removed;

- dismantling of the protective cover;

- unscrewing the nodal fastening screws that are near the valve;

- careful pulling out of the pump;

- disconnecting the power wires of the pump;

- loosening the clamps that secure the hoses that are located above the prepared container;

- detaching the snail, if any.

The assembly of the unit should be carried out in the reverse order. The process of replacing a technical unit Samsung washing machine will take a long time. You can do all the work with your own hands or by contacting a specialist. According to the advice of professionals, when replacing a pump, it is worth using original parts, since others can not only not eliminate the malfunction, but also cause irreparable damage to the machine.

In order for the pump to work for a long time and without interruption, it is necessary to regularly monitor its condition and follow these recommendations:

- before washing, you need to check all the pockets in the clothes to prevent the ingress of various objects into the pump;

- use only high-quality special detergents that contain anti-scale additives;

- install a filter on the water supply, which will limit the penetration of rust particles into the unit;

- Soaking is recommended before washing heavily soiled items.

The pump of the washing machine is the heart of the unit, the quality of washing, rinsing and spinning depends on its operation. All owners of Samsung equipment should remember that as soon as the machine starts to work worse or there are noticeable signs of breakdown, you need to immediately start repairing it.

Samsung washing machine pump repair is presented in the video below.

How to open the washer

It is recommended that you familiarize yourself with the main features of opening the blocked hatch of the washer.

After an emergency stop

Opening the hatch for machines with horizontal and vertical loading has certain features that you need to familiarize yourself with.

With horizontal loading

Most people use models with a horizontal load of dirty things. Unlocking such washers is carried out in several successive stages.

Power off

First you need to completely de-energize the washer. To do this, you must urgently stop washing and unplug the cord from the outlet. Connect the machine to the power source only after unlocking the hatch.

Draining

After detaching from the outlet it is necessary to clean the machine from remaining inside the water. You will have to disconnect the drain hose from the sewer pipe and place its end in an empty bucket. If the water does not drain, you will have to clean the hose.

Emergency opening cable

When there is no water left in the drum, you can proceed to open the door. To do this, pull out a special cable on the front panel. If you pull on it, the hatch will open and you can get the washed things.

If it's not there

However, some models are not equipped with such cables. In this case, you will have to manually remove the top panel of the washer and tilt it to get to the front wall. It has a special latch that unlocks the closed door.

Top loading

For machines with a vertical method of loading things, unlocking the doors is a little different.

Disconnection from the network

Sometimes, to unlock the doors of vertical machines, it is enough to unplug the power cable of the device from the outlet. For some models, after disconnecting from the outlet, the latches that block the sunroof stop working.

Reset program

If the door does not open due to a frozen software, you will have to reset the program yourself. This is done in two ways:

- Through the power button.During washing, you must press the button responsible for turning on the machine. When it stops washing, press the button again and hold for 2-3 seconds. The washing machine should turn off, drain the water and unlock the door.

- Through an outlet. To reset the program, just unplug the machine from the outlet and turn it on again after 20-30 seconds.

Manual way

Sometimes resetting the software does not help and you have to open it manually. In this case, you can use a cable for emergency unlocking of the hatch or contact the master.

If the handle is broken

Sometimes the handle breaks at the door and because of this it is much more difficult to open them. This will require special tools.

Emergency opening cable

Often, a cable is used to unlock the washer, which is used to open the door in an emergency. It is located near the filters, in front of the machine.

To open the door, gently pull on the cable

Wire or rope

A thin rope or wire will help unlock the washer door. To do this, you need a product with a length of 10-12 centimeters and a diameter of about 5-6 millimeters

It is carefully dragged into the free space between the hatch and the hull and the latch is pressed down.

Pliers

Washers often use pliers to open the hatch. They can grab a piece of a broken handle and turn it to open the door.

During washing

Sometimes the door is blocked during washing, which complicates its further opening.

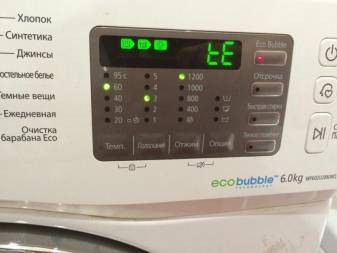

"Samsung"

If the Samsung washing machine has blocked the hatch, you will have to wait until the washing of things is over and try to open it with one of the methods discussed earlier.For people who have not previously been involved in unlocking the hatch, it is better to call the master.

"Atlant"

For most models of Atlant washing machines, blocking occurs due to electronics malfunctions. Therefore, it is enough to simply reset the program.

Electrolux and AEG

These manufacturers took care of unlocking the hatches and installed special cables near the doors. Therefore, to open the locked door, it is enough to use the cable.

LG and Beko

For washers from Beko and LG, the lock rarely fails. However, if the hatch is blocked and cannot be opened, you will have to reset the washing machine or use a cable.

Bosch

In older Bosch models, the latch often breaks, which leads to blocking of the hatch. To release the lock, you will have to remove the top panel and manually unfasten the latch.

"Indesit"

For equipment from the manufacturer Indesit, problems with the operation of the hatch may appear due to the wear of the lock. Therefore, to fix the problem, you will have to call the wizard to replace it with a new one.

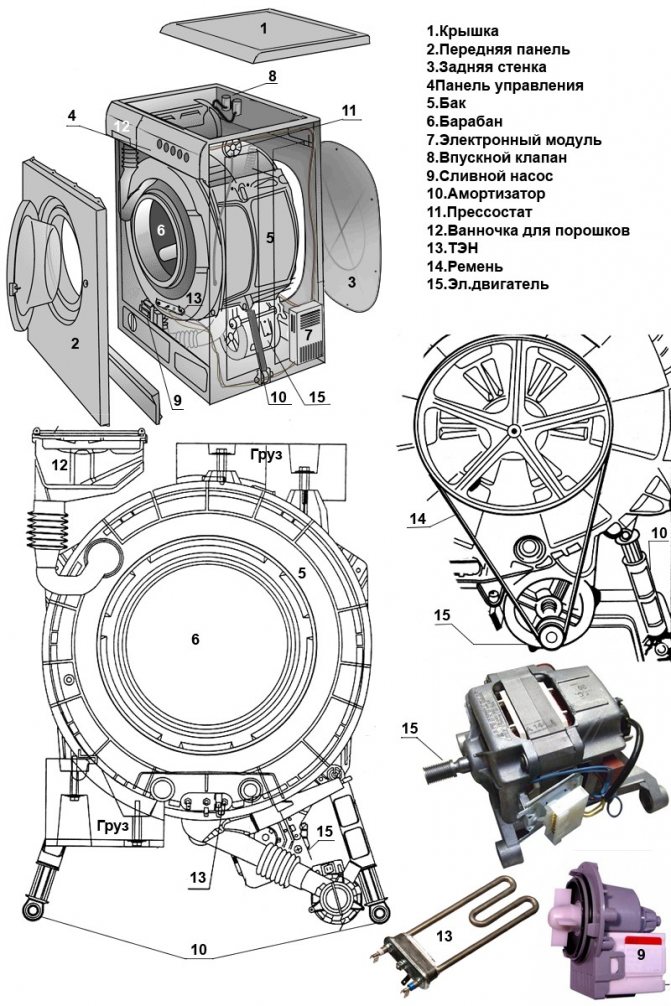

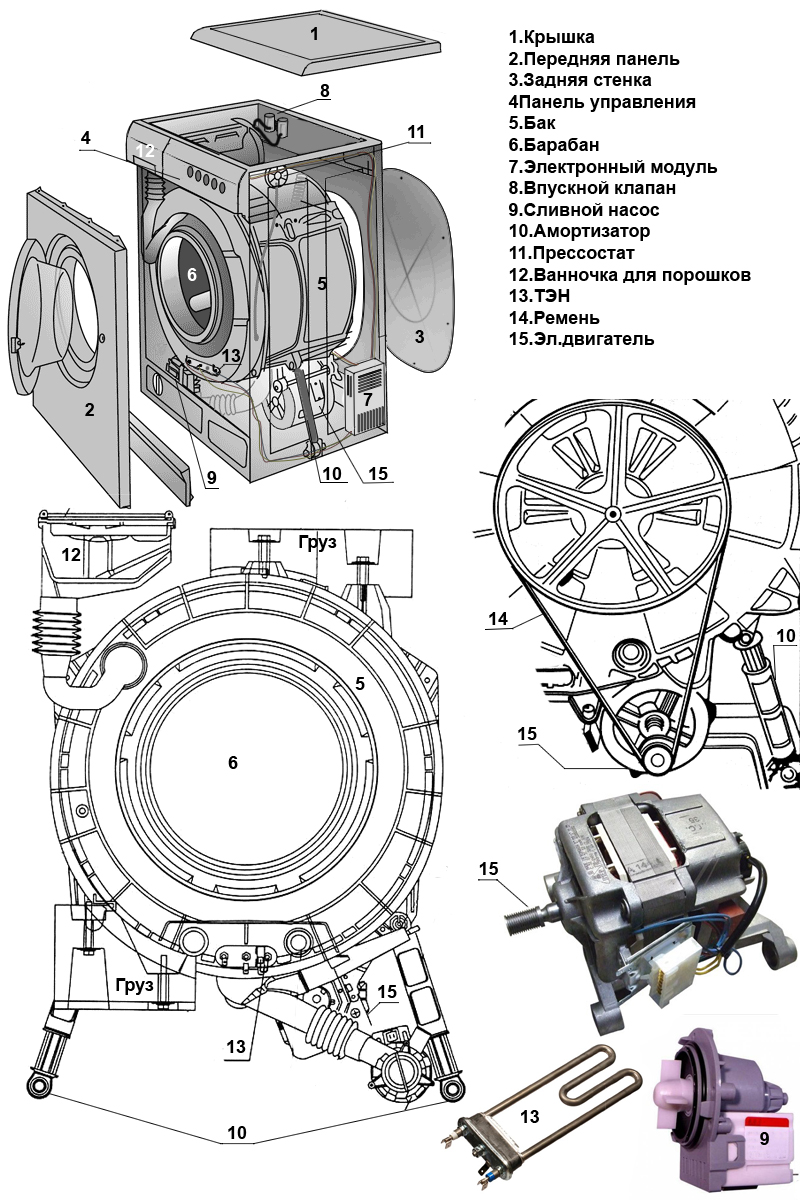

The device and operation of washing machines

Unfortunately, not all housewives follow an important rule - before loading the machine, carefully check and empty the contents of pockets. As a result, coins, paper clips, buttons and other objects get into the filter compartment. As a result, coins, paper clips, buttons and other objects get into the filter compartment.

As a result, coins, paper clips, buttons and other objects get into the filter compartment.

The filter is traditionally placed under the front panel, on the right side.

On some models, to get to it, you need to remove the entire bottom panel. This is easy to do by prying it with a screwdriver from the side.

But more often, the filter is hidden behind a small hatch, which can also be removed with a screwdriver or a coin.

But even after that, some of it will remain in the system.

Before opening the filter, it is advisable to tilt the machine back a little and put a rag or container under it.

Excess is removed from the compartment, the filter itself must be thoroughly rinsed.

Then we inspect the impeller, which is located deep in the compartment. Sometimes, threads, rags or loose pile from clothes are wound around it. All this must be carefully removed.

The filter is installed in place and you can check the drain. Sometimes this is enough, but what if it doesn't work?

Check if the pump itself is working. To do this, unscrew the fixing screws, remove the back cover. The motor, after the electronics and all relays, is supplied with 220 volts AC.

If the impeller does not spin, the problem is found. Remove the pump for a sample and go to the hardware store for a new one. What if the pump is working, but there is still no drain? Disconnect the hoses and fittings and check if there are any foreign objects in them.

Front-loading and top-loading automatic washing machines have a similar structure. Regardless of the brand (LG, Zanussi, Candy, Ariston), the unit has a metal case, consisting of a top, rear, front wall and, almost always, a base. The internal structure of the machine consists of 20 main elements:

- Control Panel.

- Electronic module.

- Water hose.

- Water tank (fixed).

- Powder dispenser.

- Drum for clothes (rotating).

- Drum rotation sensor.

- Tank springs (spirals).

- Water level sensor.

- Motor (conventional or inverter).

- Drive belt (for a conventional engine).

- Tubular electric heater (TEN).

- Drain pump.

- Collector.

- Drain hose.

- Connections (for example, the connection connecting the detergent drawer to the tank).

- Support legs.

- Hatch door.

- Rubber door seal.

- Latch-lock.

The principle of operation of all washing machines is almost the same. After turning on the unit, the inlet valve opens, through which water passes through the hose to the powder compartment and from there into the tank. The liquid level is controlled by a water level sensor. As soon as the required volume is reached, the control module sends an appropriate signal to the valve and it closes.

Next, the machine heats the water using a heating element, while the temperature is controlled by a timer and a special sensor. Simultaneously with the heating of the water, the engine starts, which rotates the drum in both directions at short intervals in time. After the completion of the main stages of washing, the used water is drained and clean water is taken in for rinsing.

After getting acquainted with the structure and principle of operation of the mechanisms, repairing an automatic washing machine no longer seems an impossible task. Before starting work, do not forget to prepare a minimum set of tools: screwdrivers, keys, pliers, wire cutters and other accessories.

Despite the variety of washing machines, each of them consists of 20 nodes:

- Water valve.

- Inlet valve.

- Program selection knob.

- Inlet hose.

- Buck is stationary.

- Detergent dispenser.

- The drum is rotating.

- Water level regulator.

- Suspension springs.

- Tan.

- Engine.

- Drive belt.

- Pump.

- Collector.

- Drain stand.

- Drain hose.

- Legs.

- Door seal.

- Door.

- Door latch.

- The inlet valve opens and through it water enters the drum of the machine.

- After the water level regulator operates, the valve closes.

- Water heating starts. In machines without a temperature sensor, a timer is activated that turns off the heating element.

- Simultaneously with the heating of water, the engine starts to work. But his work is not at full speed. He begins to scroll the drum in different directions for short periods of time.

- After that, the dirty water is drained and the clean water tank is filled for rinsing.

- At the end of the rinse, the engine turns off and the water is drained.

- The last stage is the spinning of linen at high speeds. At each stage of the wash, the pump remains on.

The machine took on water, but does not wash

The reasons for this phenomenon may be the following:

- TEN burnt out. If the heater does not function, the washing algorithm goes astray and the machine does not function. Miracles do not happen: the heating element will have to be replaced.

- The belt drive has worn out and broken. To notice this breakdown, you will have to disassemble the unit completely.

- Broken temperature or water level sensors.

- The processor has failed. The machine does not receive commands and has no idea what exactly it needs to do. In this case, only a qualified craftsman can repair a Samsung, Beko, Indesit washing machine or any other. As a rule, the control unit needs to be replaced.

- The inlet valve is broken. It is possible that it is clogged, and therefore it does not open or close well. The situation is saved by cleaning the valve and installing an additional filter for water purification at the inlet.

- Electric motor burnt out. Of all the breakdowns, this is the most unpleasant, fraught with costly repairs. If you do not have experience in rewinding electric motors, you will have to contact a service center.

Causes of breakdowns and ways to eliminate them

- the washing machine does not turn on;

- water is not collected;

- water is drawn very slowly;

- water remains cold throughout the wash;

- the washing machine turns off during the wash cycle;

- the drum does not rotate;

- water does not drain;

- the machine is very noisy;

- water flows from the machine;

- the washing machine vibrates very strongly;

- the door does not open.

- Wrong program selected.

- The door is not locked.

- No power supply. (Check the electricity in the apartment, directly the socket, whether the plug is inserted into the socket).

- Check if water is getting into the machine.

- Breakage of electrical wiring in the machine. It is necessary to de-energize the machine, remove the back cover and check the terminals, if they are oxidized, you need to clean them. Check wires for breaks.

- Sometimes the timer can be the cause. To check whether this is so, you need to select different programs, if the washing machine works on one of them, then the timer needs to be replaced.

No water coming in

- Check that there is water in the water supply and that the taps are not closed.

- Check the integrity of the inlet hose and whether it is clogged.

- Check the intake filter for cleanliness. To do this, turn off the water supply, unscrew the inlet hose and unscrew the filter with pliers. Rinse thoroughly under running water and put everything back in place.

- Intake valve blockage. Dirt that has passed through the filter can damage the valve. In this case, you need to find the inlet pipes and replace the valve.

- The water regulator is broken.

When the required amount of water has accumulated, gas is compressed in the compartment with the pressure regulator. The switch is activated, the water supply stops and its heating begins.In fact, this is a tube, if it clogs or breaks, then the machine will not work.

Repair:

- First you need to check how the tube is mounted on the switch. If the end has hardened, then you need to cut it off a little and put it on again.

- To check the switch itself, you should blow into the tube, if a click is heard, then the switch is working.

- There is a hose between the pressure chamber and the tank, you need to check the clamp on it, loosen it a little if necessary.

- Wash the camera and check it for damage.

- The water level regulator is broken. If it is faulty, then the machine does not understand that the water has already accumulated in the right amount and does not turn on the heater. The regulator should be checked and replaced if broken.

- Scale on the heating element. Due to hard water, the heater becomes covered with plaque over time, you need to periodically descale the machine. If this is not done, then you will have to completely unwind the machine and clean the heating element directly.

- Breakage of wires leading to the heater. The wires are checked for breaks and the terminals are cleaned.

- Thermostat failure. If it's faulty. It is possible that the heater is turned off too early.

There can be many reasons: power outage, water supply, blockage in the drain or inlet hose, the pump, thermal relay, heating element, timer, engine broke down.

In this case, you need to check the supply of electricity and water, if this is not the case, then the machine is disconnected from the water supply and electricity. The water is drained manually and all other nodes are checked.

- Drive belt loose or broken. You need to spin the car and check the integrity of the belt. A normally tensioned belt should move 12 mm when pressed. If the machine is equipped with a belt tension regulator, then the engine moves down a little and the bolt is tightened.If there is no such function, then you will have to change the belt.

- If the door latch is broken, the drum will also not rotate.

- Broken engine.

- Check if delayed wash or pause is selected.

- Check drain hose for blockages or kinks.

- Check exhaust filter. If clogged - clean, if broken - replace.

- Check pump. You need to remove it and check for the presence of foreign objects. Before removing it, you need to put a rag for water, release the clamps that attach the hoses to the pump. Check how the impeller rotates, if it is very tight, then loosen it a little. Check if the threads are wound on the rotating shaft. If there are no blockages, then it needs to be replaced.

- Check fluid regulator, timer.

In case of leaks, you need to check the integrity and fastening of the hoses, the door seal.

The reasons:

- Overload.

- Uneven distribution of things.

- The machine is on uneven ground and not level.

- The ballast has loosened.

- Suspension springs broken or weakened.

- Check tank for small items. The most common reason is forgotten coins in pockets.

- Check door latch.

- If a squeal is heard during operation, then the belt is slipping. It needs to be tightened or replaced.

- Crack. Most likely the bearings are broken.

Instructional video

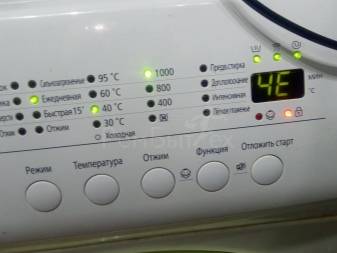

Symptoms

You can understand that something is wrong with the board by the following signs.

- The washing machine does not wring out things, along with this, the control panel freezes, and it does not respond to user actions at all, the error code is not displayed on the display.

- All the LEDs on the control panel blink in turn and all together, at the same time it is impossible to activate any washing program.

- The program for removing contaminants is installed and launched, at the same time, water is either not drawn into the tank, or the water is immediately drained on its own, besides, after that the machine “freezes”, and only reloading helps out. Along with this, after the second start-up, washing can be carried out in the normal mode.

- The machine, with any washing program, works for 3-4 hours in a row without stopping, without switching to rinsing and spinning. The drain pump makes no effort to pump water out of the tank. After a long period, the unit stops.

- After connecting, when trying to set up a contaminant removal program, the machine hangs and turns off.

- The dirt removal program is set, the washing process is displayed on the display, but in practice nothing is done, no water is drawn into the tank, the drum does not rotate - nothing happens.

- The electric motor changes the speed of the drum arbitrarily often, despite the fact that the speed change is not predetermined by the program. The drum turns in turn and for a rather long time in one direction, then in the other.

- The thermoelectric heater of the washing machine either overheats the water or leaves it cold, neglecting the readings of the temperature sensor.

Process Features

Depending on the type of load, the methods for disassembling washing machines will differ. If the procedure is performed for the first time, you must strictly follow the instructions so as not to damage the device.

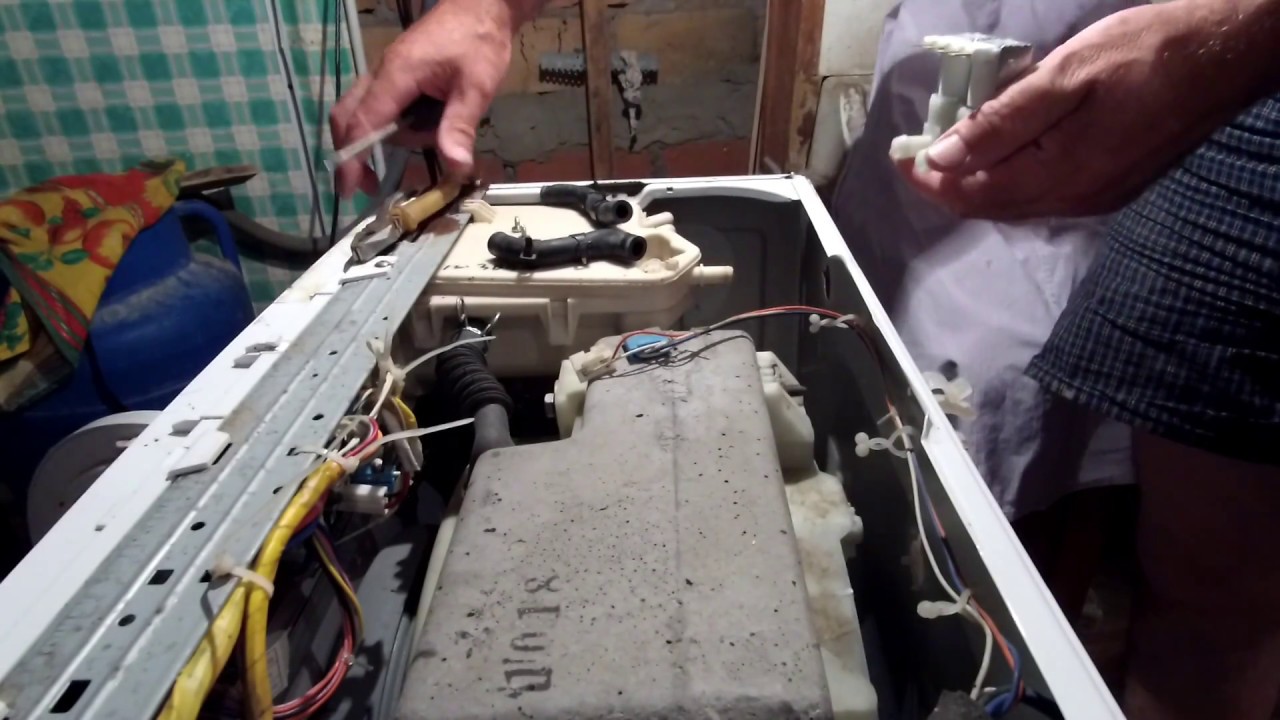

Front loading machine

You need to start disassembly by removing the top cover. To do this, unscrew the 2 screws that are located on the back of the device. The lid is pushed back 15 cm and lifted.

Further algorithm of actions:

Dismantling of the hopper and control panel. First you need to remove the detergent dispenser hopper. To do this, press the latch located at the base of the hopper and pull the container towards you again. It comes out easily and doesn't require much effort. Fasteners holding the control panel can be found behind the hopper. They are unscrewed: there are 2 screws in front and 1 screw is on the right. Separate the panel with a screwdriver, prying it on the left side.

Removing the front panel. It must be pulled on the bottom edge to release it from the top latches. Then the panel is gently pushed back, but without sudden movements. Behind you can find a lot of wires, you need to pull them out one at a time, snapping off the latches.

Removing the bottom panel. It is fixed with 3 latches. It is convenient to pry it with a slotted screwdriver, inserting the tool into the existing slot. First, it is pushed away in the center, and then along the edges, after which the panel easily moves away.

Removing the front panel on which the door is located. It is fixed with 2 screws on the bottom and 2 screws on the top. They are twisted. As a result, the panel will be held on small hooks.

Removing the seal. If you open the door, you will find that it is connected to the rubber piece. The fixing ring of the cuff is hooked with a flat screwdriver and slightly pulled towards you. Behind it there will be a tightening metal clamp in the form of a spring. You need to find its latch and open it with a flat screwdriver.

Then they pass it around the entire circumference of the ring to disconnect it

The tool must be handled with care. Otherwise, the torn cuff will have to be changed.

Removing the rear panel

This process will not be difficult.It is enough to remove the 4 screws with which it is screwed.

Disconnecting hoses. They lead to the tank of the machine (filling and draining), to the pressure switch and to the powder tray.

Disconnecting the wires leading to the heating element and the temperature sensor. The heater itself is located in the front lower part of the tank, under the drum. To remove it, you need to unscrew the nuts. After that, the heating element will easily come out of the socket. When removing the wires, it is necessary to mark their location with colored markers.

Dismantling counterweights. There are 2 of them in the washing machine: above the tank and below it. They are fastened with bolts. Since the loads are heavy, they must be removed carefully.

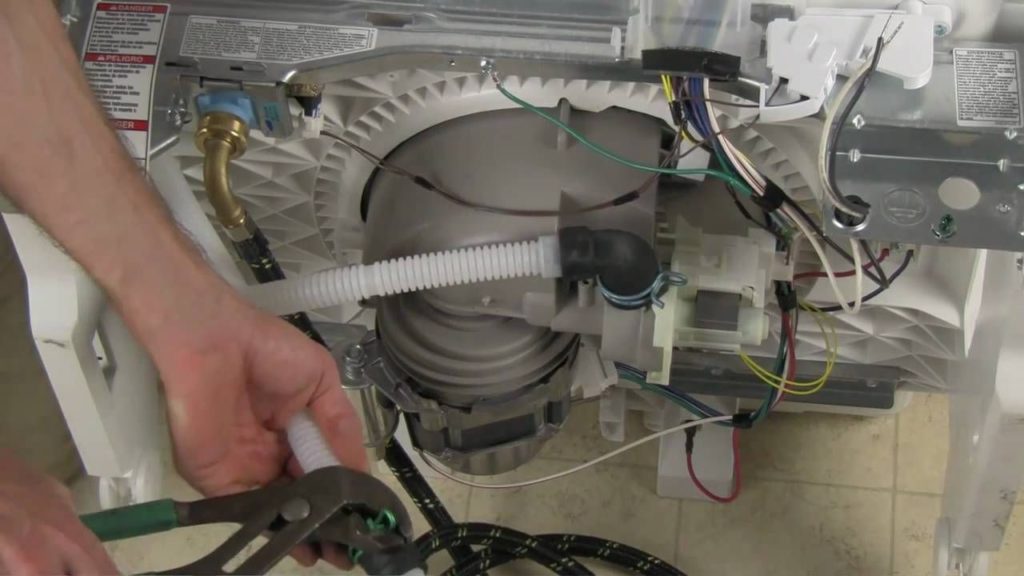

Assistance is required to remove the tank. It's hard to do it with just one pair of hands. First you need to disconnect the shock absorbers, and then carefully remove the tank from the springs and pull it out. After that, remove the belt and motor. At the end, the pulley is dismantled by unscrewing the middle bolt. If it is rusty, it is lubricated with WD-40.

There are bearings inside the drum. To remove them, the tank must be disassembled. If it is soldered, it is sawn with a hacksaw. This process is very laborious and not all craftsmen undertake such work. In this case, it is easier to purchase a new drum. Provided that the tank is collapsible, replacing the bearings will not be difficult.

By following the indicated sequence of actions, you can completely disassemble the washing machine.

With vertical

Disassembling a top-loading machine is more difficult. Such devices are rare in Russia.

Disassembling a top-loading machine is more difficult. Such devices are rare in Russia.

The procedure is as follows:

- unscrew the screws located on the sides;

- move the block to your side;

- disconnect all wires;

- remove the washing machine panel.

Further analysis of the device is carried out according to the same type as the front-loading washing machine: remove the tray, panels, clamp.The process ends with the removal of the drum, the replacement or repair of failed parts.

Washing machine does not spin

There can be several reasons for this problem, ranging from banal inattention to quite serious breakdowns.

Before diagnosing the unit, you must:

Make sure that the "No spin" mode is not set or the speed has not decreased to 0. Make sure that the selected mode of operation comes with spinning, for example, in the "Hand wash" or "Wool" program, only water draining can be provided

Pay attention to any imbalance. If you put too much laundry in the drum (for example, 6 kg instead of 5 kg maximum load) it can be poorly distributed and stray into a lump

In an attempt to straighten things, the machine may freeze during the spin phase. Here you should unload the tank and restart the machine.

Sometimes the reasons for the lack of spin are much more serious:

- Drain unit problem. In this case, the unit “gets stuck” even at the washing stage, the process simply does not reach the spin cycle.

- The pressure switch is out of order - a sensor that controls the water level. In the event of a breakdown, it can give the control module an incorrect signal about a high water level, at which the device will not start spinning. If it is out of order, water can be drawn continuously or vice versa, absent in the tank. Replacing the sensor is very simple - it is located immediately under the top panel of the tank.

- Faulty tachometer. In this case, the drum can rotate, but the number of revolutions will not correspond to the specified ones.

- The motor or control module has failed. These breakdowns are rare, it is quite difficult to eliminate them without resorting to the help of a specialist.

The listed parts (except for the motor and board) can be easily replaced by yourself.

Hatch door won't open

This situation can happen for a number of reasons:

- there is water left in the tank;

- the handle of the lock is broken;

- a water leak has occurred and a safety interlock has been triggered;

- child protection is on;

- an unplanned power outage has occurred and a temporary blockage has been triggered.

To troubleshoot, you should:

- Turn off the appliance from the mains, drain the water through the drain tube or filter. Wait half an hour.

- Try to open it, if it doesn't work out, restart the device to restart the program.

If the proposed methods did not help, you can open the lock manually using an emergency cable (it has a bright yellow or orange color, located behind the rear panel) or wring it out by removing the top panel.

The car is making noise

The most likely cause of noise is bearing wear. You can replace them yourself, however, this process is quite time-consuming. Schematically, it looks like this:

Remove the front, rear panel and cover one by one to gain full access to the device, remove the engine by unscrewing the mounting bolts. The tank of the LG WD washing machine is disassembled, having previously disconnected: pipes (drain and water level sensor), filler valve, shock absorber mounts, counterweights, wires. The drum is disassembled, the bearing is carefully knocked out, the seat is cleaned

Apply grease, carefully hammer the bearing, assemble the structure

Bearings that are not replaced in time can jam. A breakdown will damage the engine and lead to costly repairs.

water flowing

The cause of the malfunction is a violation of the tightness of the device. Possible causes of leakage:

- the cuff of the hatch is torn;

- leaky drain or inlet hose;

- skip pipes;

- tank cracked.

The exact location of the leak can be determined by visual inspection. It remains only to replace the worn part with a new one. The only exception is a cracked tank, which can only be repaired at a service center.

How to check?

Determining problems in the control module is not so difficult.

There may be several signs that the control board needs to be repaired, namely:

- the machine, having filled with water, immediately drains it;

- the device does not turn on, an error is displayed on the screen;

- on some models, the panel LEDs flicker or, conversely, glow at the same time;

- programs may not work properly, sometimes there are failures in executing commands when you press the touch buttons on the display of the machine;

- water does not heat up or overheats;

- unpredictable engine operation modes: the drum either spins very slowly, then picks up maximum speed.

To inspect for a breakdown in the "brains" of the AGR, you need to pull out the part and carefully examine it for burns, damage and oxidation, for which you will need to manually remove the board as follows:

- disconnect the unit from the mains;

- shut off the water supply;

- remove the cover by unscrewing the screws at the back;

- pressing the central stop, pull out the powder dispenser;

- unscrew the screws around the perimeter of the control panel, lift up, remove;

- disable chips;

- unfasten the latch and remove the block cover.