- Electrician

- Faults in the washing machine

- Washer window seal

- Washing machine filter

- How to clean the washing machine filter

- Functional diagram

- The principle of operation of the washing machine

- Do-it-yourself LG washing machine repair secrets

- Main malfunctions

- Video: do-it-yourself lg washing machine repair

- Porthole and gasket

- Compartment for detergent

- Fault codes for LG washing machines

- Causes of failure and repair of bearings

- We change the heater

- The main malfunctions of LG washing machines

- LG washing machine repair price

- Prevention is easier than cure!

- Features of the repair of washing machines with vertical loading

- water flowing

- Typical breakdowns of household units

- Bearing dimensions

- Summing up

Electrician

Do-it-yourself electrical repairs without sufficient knowledge is difficult. The main steps in this case come down to checking all the wires and terminals in the assembly that go from the control module to all elements, parts and assemblies.

The check is carried out using a multimeter - so you can find out basic information about the status of a particular device. It is also necessary to make a visual inspection. It will help to find torn clamps, fragments of wires that are without insulation, the presence of burning and melting of contacts.All wiring problems are solved by replacing failed conductors or terminals.

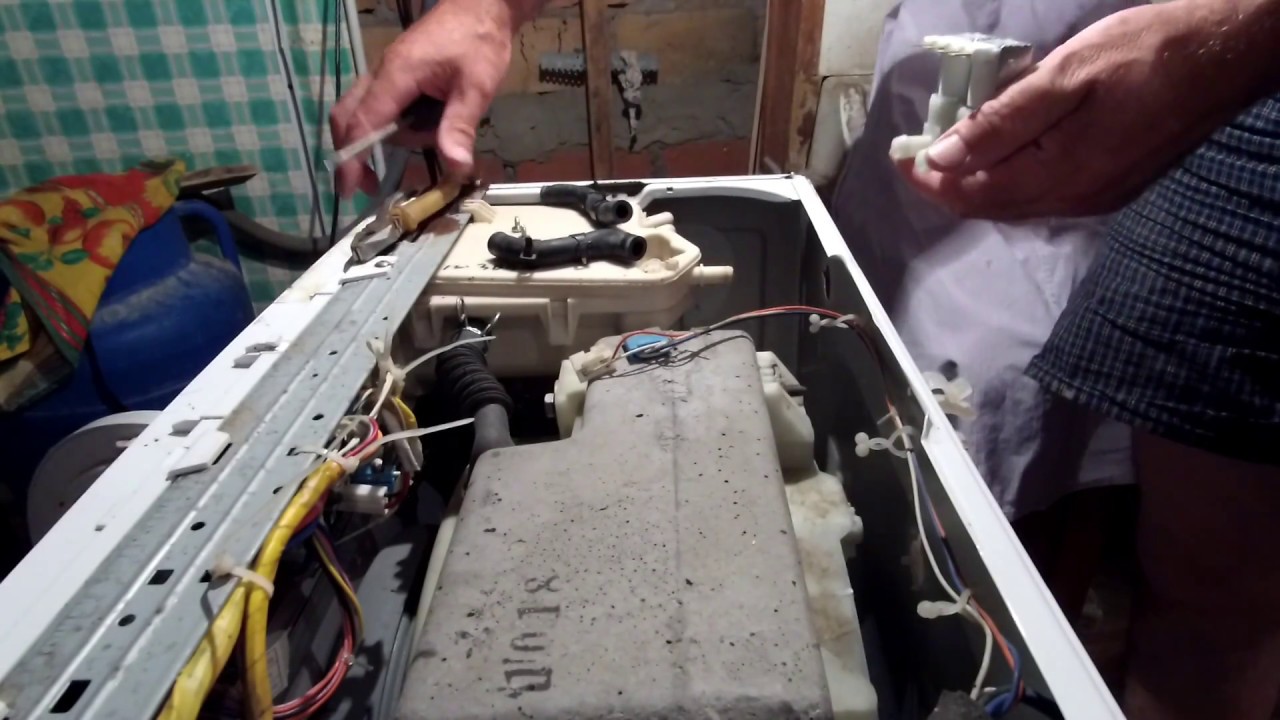

Faults in the washing machine

Among the most common malfunctions of the lg washing machine is the loss of water by any component.

If you see a wet floor under the washing machine, you must first unplug the machine, turn off the water supply and open the back of the cabinet.

After that, you will have to inspect the following components:

- water pipe from the faucet to the solenoid valve;

- an exhaust pipe from the pump to the wall drain connection;

- internal coupling between tank and filter and between filter and pump;

- door seal and filter;

- bath.

The only time you need to call a plumber right away is when you're checking to see if the tank is leaking from a hole in it due to corrosion.

In other cases, it is quite easy to interfere. These pipes and flexible hoses, like all elements made of synthetic material, crack.

Inside the sleeves, which are bellows-shaped to be able to follow bends, limestone is often deposited, which accelerates the destruction process.

After receiving the necessary materials to proceed with the replacement, remove the damaged part. In general, it is a matter of loosening the metal clamps and removing the tubes.

Washer window seal

A very common case where the loss is due to wear on the door seal, which cuts along the folds. Replacement is not difficult.

The gasket is removed by loosening the steel wire clamp that surrounds the door and secures it to the body. Once you have removed the belt, pull the seal outward.

It often happens that the body has rust spots under the seal.

While you're at work, you can do a little bit of rust removal with glass paper and a couple coats of spray enamel. A new seal is applied by putting it in instead, repositioning the metal band and tightening it properly. Many models require the use of a slotted screwdriver with a flexible shaft to loosen and tighten the metal band; in others it is necessary to unscrew the door from the hinge in order to operate easily.

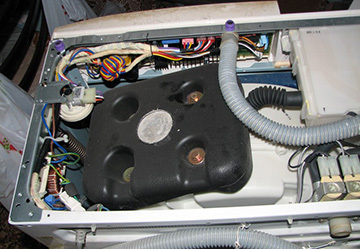

Washing machine filter

Loss can also occur due to a clogged or loose filter: just unscrew it and check.

Some washing machines the filter is mounted directly on the body drain pump: access to it is through the hole in the body of the washing machine.

The filter must be removed and rinsed under running water to remove any deposits.

How to clean the washing machine filter

Every ten to twenty washes, the filter is removed to remove deposits, sand or fluff. It is also necessary to make sure that foreign objects such as coins, buttons or buttons do not get stuck in the filter housing.

Their presence can interfere with the regular flow of water to the pump, stressing and damaging it. The mesh is cleaned by immersing it in a basin of water, removing solid residue with a small or soft brush, and rinsing thoroughly.

The second filter is usually placed at the other end of the water supply pipe that is inserted into the washing machine.

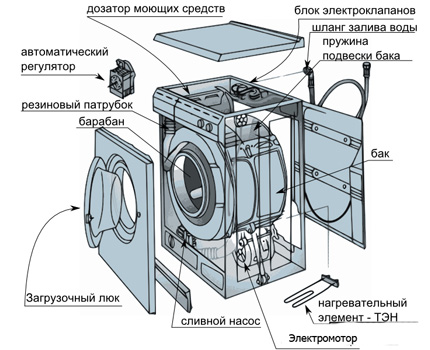

Functional diagram

The LGI washing machine is a complex electromechanical device.

Its functional diagram includes the following components and assemblies:

- water filling system;

- heating system;

- laundry washing system;

- water drain scheme;

- washing system;

- drying system.

In each new model, developers will improve some system or several components.

In order to exclude premature repairs, when installing and connecting the washing machine, it is necessary to strictly follow the rules set forth in the operating instructions.

When loading clothes for washing, you should follow the recommendations for the volume and texture of fabrics.

The principle of operation of the washing machine

What does a washing machine do? In fact, she pours water into the body, heats it up and spins the drum filled with dirty laundry. This happens in a certain way, which ultimately leads to the cleaning of linen from contamination.

Now a little more. As soon as the washing program is started, the first thing to do is open the water inlet valve. Water flows through the dispenser into the tank.

Typical malfunctions for LG washing machines that most often occur during operation are listed in the instructions for the unit.

Important machine parts to know:

- Dispenser - a box for detergents.

- Tank - a plastic container in which there is a drum and a heating element (TEN). Water is poured into it.

- The pressure switch is also a pressure switch. Monitors the water level in washing machines.

- TEN - tubular electric heater. Heats water.

The pressure switch gives the go-ahead to stop the water supply as soon as the required volume is reached. Then the heater turns on. Next to the heating element there is always a water temperature sensor (thermostat). As soon as he reports that the water has heated up to exactly the right temperature, a motor comes into play that rotates the drum.

Toward the end of the wash, the pump starts to work - this is what the water drain pump is most often called. It ends the “production cycle” of the washing machine and begins with the analysis of typical malfunctions of LG brand machines.

Schematic diagram of a horizontal loading washing machine. To start the repair, you need to get acquainted with all the details of their purpose.

Do-it-yourself LG washing machine repair secrets

In order to do the repair of the LG washing machine with your own hands, you need to familiarize yourself with its design features.

Modern household appliances are easy to use and highly reliable.

At the same time, regular loads lead to wear of various components and assemblies.

Today on the market, you can easily choose a washing machine that is suitable in terms of cost and performance.

Before going to the store, it is advisable to read the reviews of people who already use this or that unit.

The next point to pay attention to is the maintainability of the machine.

Main malfunctions

Repair of LG washing machines begins with the identification of possible malfunctions. They occur even in the case of careful use of the device, so the average user needs to know them. Many breakdowns are displayed directly on the built-in displays. Faults are combined into codes, the decoding of which is attached to the technical documentation.

In 90% of cases, you can see the following breakdown codes:

FE - indicates problems with draining water. A possible cause of failure is the failure of the electric controller or drain pump.

IE - the code appears when the water fill level sensor is damaged. In this case, there is little padding. Possible causes include a failed inlet valve or weak water pressure in the pipes.

It should be noted that in the absence of water, a sound notification about the problem is added to the code on the display.

OE is an error code that indicates that an excess amount of water is entering the machine. The cause may be a malfunction of the pump or the electrical controller of the device.

PE - the code that appeared on the display is also associated with water

It indicates a deviation from the norm of its quantity. The cause may be a faulty pressure switch, as well as changes in the pressure of the liquid in the pipes. It is required to eliminate it, since interruptions can lead to a short circuit.

- DE - this code appears when the hatch door is not completely closed. The reason is an excessive amount of laundry loaded or a malfunction in the sensor.

- TE is an error code indicating problems with the sensors. Shows a malfunction in the absence of water heating to the required temperature (set by the program). If the water remains cold, then the main reason is the breakdown of the heating element.

- SE - the problem is related to a non-working electric motor. Feature - a breakdown can occur only in those washing machines that have a direct drive. In this case, the motor remains in the blocked state even if the failure occurred only in the sensor.

- EE - an error code always occurs when you first turn on a new washing machine. Related to service tests and should not appear on subsequent power-ups.

- CE - a code that indicates an overload of the tank, an excess amount of laundry. The weight is controlled by a special fuse and if the norm is exceeded, this code appears on the display. As a result of the operation of the fuses, the rotation of the drum is blocked by the sensor. In this case, repair work is very simple - you should reduce the weight of the laundry.

- AE - indicates improper use, violation of the rules and regulations of operation, which are accompanied by frequent automatic shutdowns of the washing machine.

- E1 - the code is displayed on the display when the sensors signal the detection of a leak.

- CL is a special lock code. It protects against pressing the buttons by children. Unlocking is simple - just press a special combination of buttons.

Up to 90% of all possible malfunctions and breakdowns can be eliminated independently without contacting service centers or workshops. To do this, you need to know how the fault codes that appear on the display are decoded. If the measures taken to restore working capacity did not lead to a positive result, you need to seek qualified help from specialists who will carry out a complete diagnosis of the machine.

Video: do-it-yourself lg washing machine repair

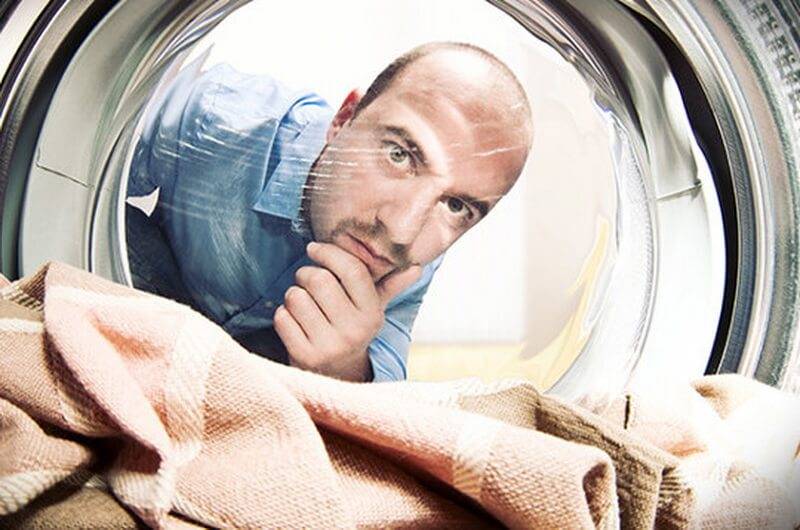

Porthole and gasket

The most common disadvantage is the loss of water due to damage or destruction of the O-ring located between the porthole and the tank of the basket. These vibrations can lead to the loosening of the porthole bolts shown in the photo.

Detaching the leading edge of the gasket from the casing results in a clip that locks the inside edge and identifies the tie bolt.A flexible-blade screwdriver is useful, the head of the bolt is held with an open-ended wrench.

The gasket has been carefully removed to prevent tearing. In the folds of the pad, you can hide metal objects that rust and stain the laundry. Water deposits with detergent corrode the pad: it must be dried after each wash.

To assemble a new bellows, follow the reverse procedure: to facilitate proper installation of the gasket in its housings, it can be lubricated with silicone spray or liquid soap. To secure it, the ends of the metal ring are tightened. If these operations do not solve the problem, the washer must be replaced.

Compartment for detergent

Washing powder is sucked out of the chamber through the supply water and crusts often form that can obstruct the flow of water: it also controls the napkin.

The reaction mixture is poured with vinegar into the detergent dispenser to eliminate limestone encrustations formed over time within the pipelines, it performs a thorough cleaning with warm water. After removing the washing machine tray, wash it in running water, removing deposits deposited in the corners.

Fault codes for LG washing machines

The popular LG washing machines of the Intellowasher series, which includes models such as WD-80250S, WD-80130N, WD-80160N, WD-1090FB and others, have built-in displays. Thanks to intelligent electronic control, all current information is reflected on them, including codes for the most common errors and malfunctions.

| The code | Malfunction |

| F.E. | Overflow of the tank with water caused by a malfunction of the pressure switch, a breakdown of the controller on the board of the electronic control unit (hereinafter also referred to as the ECU), damage to the wiring or filling valve |

| IE | Insufficient or slow filling of the tank with water (it did not have time to fill within 4 minutes). Possible causes - malfunction of the pressure switch, damage to the filler valve, worn wiring, malfunction of the computer, clogged inlet strainer, low water pressure |

| PE | Too fast or too slow filling of the tank with water. Causes - non-working pressure switch, too low or high water pressure in the pipeline |

| OE | Exceeding the water level in the tank due to incomplete drainage (due to blockage in the drain filter or drain pump) |

| CE | Motor overload due to too much laundry in the drum. You need to take out some of the laundry to lighten the drum |

| HE | Malfunction of the heater - heating element. Washing machine does not heat water |

| TE | Mismatch of the water temperature with the indicators of the temperature sensor - thermistor. Reasons - breakage of the thermistor or scale formation on the heating element |

| PF | Power failure, reset CM. Possible causes - wiring malfunction, poor contact in the connectors, breakdown in the computer board |

| OE | Errors in draining water: within 5 minutes the pump was unable to remove water from the tank. The drain filter may be clogged, the pump may be clogged or defective |

Causes of failure and repair of bearings

Malfunctions of LG washing machines may be associated with broken bearings. It happens for two reasons - natural wear and tear, as they experience heavy loads during the operation of the machine, are constantly in motion when programs are running or factory defects.If such a breakdown occurs, then it must be repaired without delay, since the elements attached to the bearings can damage the tank.

Since in 90% of cases, direct drive technology is implemented on the washing devices of this manufacturer, the bearings, motor, pulley last longer. In the case of do-it-yourself repairs, the first thing to do before removing the bearings is to disassemble the tank and, if necessary, remove the belt drive. Next, you need to remove the clamp, which is located next to the spring - it should be picked up to remove the clamp. Only after that the front panel is removed.

It is important to remember that repairs must be carried out carefully, using a special hammer for this purpose, which is equipped with a bronze impact part and has a thin metal rod. Features of extracting bearings - striking at its opposite edges

To do this, you first need to put the rod on one side of the bearing and strike it with a small force. This action is repeated until the old bearing pops out. Then you can put a new element in its place.

We change the heater

Replacing the heating element of a washing machine of this brand will initially require removing the top cover of the washing machine, otherwise it will be impossible to remove the back wall. There should be no problems in order to pull off the top cover, but if you still have difficulties, read the corresponding instructions posted on our website.

Next, you need to get rid of the screws that hold the back wall, and then easily remove it.Now you need to take the phone and take a picture of the position of the wires on the contacts of the heating element, so as not to confuse anything later, otherwise you can easily burn a new part, and at the same time also the control board. The next step is to remove the wires from the contacts of the heating element, as well as the thermistor.

We check the ten with a multimeter. If you have problems with this, read the article called Checking the heating element of the washing machine. It describes the features of the check very well. Next, we do the following.

We check the ten with a multimeter. If you have problems with this, read the article called Checking the heating element of the washing machine. It describes the features of the check very well. Next, we do the following.

- We find a bolt with a nut in the center between the contacts of the heating element, put the head on the nut and unscrew it.

- With a ratchet handle, apply a light blow to the bolt so that it fails slightly.

- Using a screwdriver with a flat working surface, carefully pry off the heating element, or rather its sealing gum.

- After that, we pull the heating element by the contacts gently, but strongly, until it comes out. It is advisable to remove it without breaking off the contacts.

- We examine the old heater and put it aside.

- With our fingers we take out debris and dirt from the bottom of the tank, and then wipe the seat under the heating element with a rag.

- We take a new heating element, lubricate its rubber band, and then insert the part into place.

- We make sure that the part sits tightly, fasten the nut and put on the wires, then assemble and connect the washing machine.

On this we can assume that the replacement of the burnt part was successful. As you can see, this is a simple repair, which is theoretically accessible even to an amateur. However, when repairing an LG washing machine, remember safety precautions. Before performing any manipulations, turn off the water and power supply - be vigilant, good luck!

The main malfunctions of LG washing machines

From time to time, many people have a situation where the washing machine stops working normally. Modern units, including LG, have no problems with diagnostics and error detection. The fact is that on the screen - the display shows codes, each of which corresponds to a particular malfunction. LG washing machines have their own encoding, decoded in the attached technical documentation. It also provides practical advice on troubleshooting.

Deciphering the main fault codes of LG washing machines:

- FE - means the impossibility of draining the waste water within the set time. This problem occurs due to a malfunction of the electrical controller, as well as a malfunction or incorrect operation of the drain pump.

- IE - most often this error appears when the level sensor is damaged. Because of this, the water level in the tank is not detected correctly, and the machine does not receive enough liquid. Sometimes the cause may be a non-working inlet valve or a weak water pressure in the pipes. In the absence of water supply, in addition to the code, an audible signal is given.

- OE is an error code that is absolutely opposite to the previous case. Here, on the contrary, there is an excess of water due to a faulty pump or electric controller.

- PE - this error indicates a deviation from the norm up or down the amount of water entering the machine. The reason may be a faulty pressure switch or the reason is too strong or weak water pressure in the pipes. Sometimes the LG washing machine draws excess water as a result of a short circuit in the electrical network.

- DE - appears when the sunroof sensor indicates that the door is not closed enough.Full closure is often prevented by laundry inside the drum. Sometimes the cause of the error is a faulty sensor.

- TE is an error code that also indicates problems with the sensors. In these cases, the washing machine does not heat the water to the desired temperature or overheats it. Sometimes the water does not heat up at all, which indicates a malfunction of the heating element.

- SE - this error is associated with a non-working electric motor and appears only on direct drive washing machines. If only the sensor is defective, the engine will still remain blocked until the defective element is replaced.

- EE - this code appears during service tests when the LG washing machine is turned on for the first time.

- CE - indicates an overload of the tank. The weight of the laundry is controlled by a special fuse and, if the norm is exceeded, the rotation of the drum is blocked at the command of the sensor. The problem is solved by removing excess laundry from the washing machine.

- AE - indicates improper use of the washing machine, accompanied by frequent automatic shutdowns.

- E1 - this code appears when a leak is detected.

- CL - is a lock code that protects the LG washing machine from pressing the buttons by children. The lock is released with a specific key combination specified in the instruction manual.

Many problems that arise with LG washing machines can be solved independently, in accordance with the decoding of the codes displayed on the display. If the measures taken have not led to a positive result, it is recommended to perform a service test for a more complete diagnosis. Thanks to the information received, the repair of the washing machine can be done independently.Sometimes there are breakdowns that are not provided for by error codes. They also need to be able to identify and eliminate.

LG washing machine repair price

It is impossible to answer this question right away. It all depends on the nature of the breakdown, the complexity of the upcoming work and the cost of parts that are out of order and must be replaced. Therefore, the master will be able to calculate how much it will cost you to repair the washing machine only after determining the cause of the breakdown. After that, you will be able to assess the feasibility of the repair. In some cases, when the main electronic unit fails, repairs are not recommended - replacing the unit costs about 60% of the cost of a new washing machine.

At the same time, keep in mind that the more accurate and reliable information you can give when making a call to the master, the higher the likelihood that the master will immediately take the necessary parts with him and perform repairs promptly. Otherwise, he will have to come to your home several times: for diagnostics and for repairs, respectively. Or it will be necessary to take the washing machine to a service center for further troubleshooting.

Prevention is easier than cure!

Almost any breakdown can be prevented if you handle your washing machine with care and perform periodic maintenance. Do not trust the installation to unverified masters and do not undertake to do it yourself without having sufficient experience and knowledge. A considerable percentage of breakdowns occur precisely because of poor-quality installation. During operation, follow the simple rules of operation. Necessary:

- Control water quality;

- Mains voltage;

- Adhere to the rules and regulations for loading laundry;

- Use high quality washing powder;

- Carefully check the contents of the pockets before sending things to the drum. Doubtful things must first be placed in special bags.

- Periodically clean the filter.

These simple measures will avoid problems, costly repairs and extend the life of the main home assistant.

Order repair of LG washing machines at home: 8(495) 507-58-40

Back to LG

Features of the repair of washing machines with vertical loading

Repair of a vertical washing machine is very time-consuming, fraught with certain difficulties due to the crowding of elements. To get to the broken part, you have to disassemble half the car.

Some types of breakdowns are typical only for top-loading machines and require the knowledge of a professional. This, for example, is the spontaneous opening of the drum flaps during unbalance, which entails the drum stopping and the drive belt breaking.

It is independently possible to replace the top cover, which is subject to corrosion, clean the filters and change the gaskets at the connection points. Other types of top-loading machines are best left to the master.

-

Do-it-yourself bars - a step-by-step master class for making a sports equipment at home (110 photos)

- DIY lamp - 130 photos of original and stylish ideas on how to make a homemade lamp from improvised means

-

Do-it-yourself boiler - the main types of boilers and features of their manufacture. 75 photo and video instructions for beginners

water flowing

If water leaks into the drip tray located under the machine, it will react with the appearance of the code "E1" on the display. There may be several reasons:

- The gasket between the two halves of the tank stopped holding water. This usually happens if the tank was dismantled shortly before. It is necessary to install a new gasket, and before that it should be lubricated with silicone sealant.

- Worn oil seal, which is installed next to the bearings. In LG machines, this gland is sometimes destroyed by a drum that touches it during rotation. The seal needs to be replaced.

- The hose that connects the tank outlet to the pump may burst. "Cure" by replacement.

Due to a design flaw in LG machines, a new oil seal cannot always be put in place. In this case, it is put on a sealant (the composition of the Dyson brand is considered the most reliable).

Water can also flow out through the hatch seal, which in this case is also changed (how to remove the seal was described above).

Worn oil seal

To prevent the seal from wearing out so quickly, wipe dirty water off it after each wash.

Typical breakdowns of household units

To understand the malfunction that has arisen, you need to consider the most common of them and the reasons for their occurrence.

Here is a list of common problems:

- Water is not poured into the tank of the machine - this means that the heating element, or the inlet valve, or the drain pump may be faulty, or the pressure switch may not work;

- The machine does not turn on - the hatch is not closed very tightly, the locking system or the “Start” button does not work, a break in the power cord, poor contact. It can also be more serious problems, such as a breakdown of the heater or engine;

- The drum does not rotate when the motor is running - the drive belt is broken, the bearings or motor brushes are worn out. It is possible that a foreign object has got into the gap between the drum and the tank;

- Water does not drain - this problem means a blockage in the drain hose, either in the filter of the washing machine, or in the sewer system;

- The hatch of the car does not open - a malfunction of the locking system, or the handle is damaged;

- Water leakage - occurs when the seams or parts of the machine are depressurized, as well as the drain hose or pump leaks;

- Self-draining of water - if water is drained before it has had time to accumulate, then this is either a problem with the connection or a malfunction of the control system;

- Problems with spinning - the “Spin off” button does not work, problems with draining or with the electric motor of the washing machine;

- Unusual washing sounds - worn bearings and oil seal. They will have to be changed, and it may also be necessary to replace the drum;

- Large vibration may be caused by a large load of laundry or incorrect installation of the appliance;

- Problems with the control system - the terminals on the buttons are oxidized or the contacts close due to water ingress.

Next, do-it-yourself methods of repairing them will be considered, because it is not always possible to call the master. And for this you need to have a set of necessary tools.

A list of the most common problems that occur in the operation of a Samsung washing machine is in the manual attached by the manufacturer to the product. You can often find a solution there as well.

Before starting repairs, you need to make sure that all the tools from this list are available:

- flat and Phillips screwdrivers or a screwdriver;

- set of wrenches;

- pliers, pliers, wire cutters;

- tweezers - elongated and curved;

- powerful flashlight;

- mirror on a long handle;

- soldering iron;

- gas-burner;

- small hammer;

- knife.

In addition to these tools, you may need a magnet to pull out small metal objects that are inside the machine, a long metal ruler to level the drum, a multimeter or a voltage indicator.

A set of the most necessary repair tools will be needed to carry out repair operations available to a home craftsman. Most of the tools can be found in the household, the rest can be borrowed from friends.

But that's not all, in addition to the necessary set of devices, you will need to purchase the following consumables for repairs:

- sealant;

- Super glue;

- insulating resin;

- materials for soldering - rosin, flux, etc .;

- wires;

- clamps;

- current fuses;

- rust remover;

- tape and tape.

Sometimes a multimeter is not needed, it is enough to turn on the machine and select the high water temperature mode. From the operation of an apartment electric meter, it can be easy to understand whether power is supplied to the heating element.

Bearing dimensions

To fix a breakdown, many men prefer not to call a master at home, but to do all the work of replacing them with their own hands. In order not to make a mistake when buying new spare parts, you need to know that each manufacturer uses different parts that differ in size. So, in Samsung models, bearings are numbered 203, 204. The manufacturer of Atlant models uses components under the numbers 6204, 6205. Bosch completes washing units with bearings of different sizes. Each model is equipped with its own version of the bearing system. So in the model range, you can find bearings from numbers 6203 to 6306. At the same time, each number corresponds to certain indicators.

What bearings are on the Indesit washing machine? In these models, the components 6204-2RSR are installed - inner diameter 20 mm, outer 47 mm, height 14 mm and ZVL 6205-2RSR - inner diameter 25 mm, outer 52 mm, height 15 mm. Which bearing in the Indesit washing machine is installed in a particular case can be found in the instructions supplied by the manufacturer with the technique. In Lg washing machines, components are usually installed with numbers 6204, 6203, 6205, 6206.

Summing up

Considering that the bearing system is the most important unit in the design of washing machines, if this component fails, it is important to replace it. To select suitable components, you need to know the dimensions of the bearings. Most manufacturers use elements similar in size

To determine the exact size, you can study the instructions that came with the unit, or remove the old component from the washing machine and purchase a similar one.

Most manufacturers use elements that are similar in size. To determine the exact size, you can study the instructions that came with the unit, or remove the old component from the washing device and purchase a similar one.