- Gas stove maintenance

- The air conditioner works, but does not cool - this is often called the most common symptom

- Water is leaking from the air conditioner - no less common situation

- Overview of major breakdowns

- Doesn't turn on

- Electrical part

- Remote control or receiving module

- Protection system

- Part wear

- Shutdown after a short period of operation

- Room temperature

- Dry mode

- Compressor overheating

- Control board failure

- Safety relay failure

- Elimination of leaks of the indoor unit

- Mechanical damage to the case

- Bad smell

- Gorely

- Plastic

- Dampness and mold

- Wrong sounds

- Uneven noise

- clatter

- squelching

- Inefficient work

- Clogged filters

- Clogged heat exchanger

- Adaptation to severe frosts

- Wrong choice of power

- Outdoor unit icing

- Automatic diagnostics

- Compressor and clutch problems

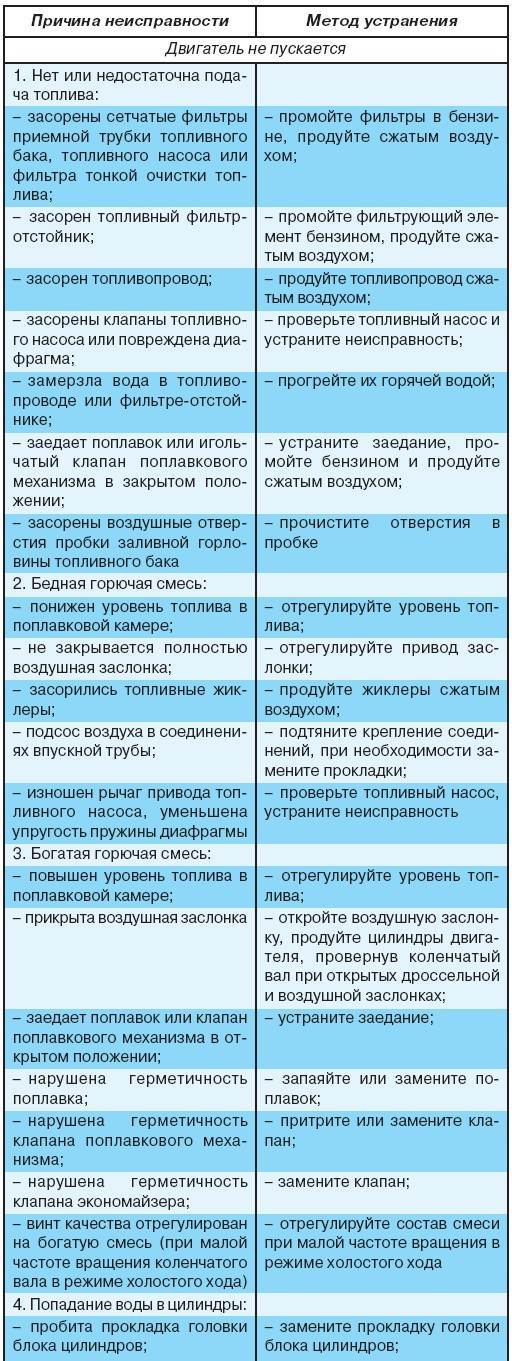

- Possible malfunctions

- Cleaning the indoor unit

- Cleaning the air filters

- Fan cleaning

- Removing dirt from vents

- Cleaning the heat exchanger

- Removing bad odor

- Cleaning the drainage system

- 1 Air conditioner does not heat in severe frost

- Basic Troubleshooting

- Insufficient traction

- Noise

- Filter system

- The main reasons for the failure of the split system

- Our Air Conditioning Service includes:

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

Gas stove maintenance

In order to maintain the kitchen equipment in good condition, it is necessary to regularly inspect the product.

After using the appliance, daily clean the burners and the hob of the unit from dirt.

Cast iron burners can be cleaned with a fine-bristled metal brush. At the same time, for effective removal of contaminants, a teaspoon of baking soda can be added to the detergent. Special products should be used to clean metal plates.

After carrying out preventive maintenance, the device should be wiped dry.

If during the operation of the plate, the adjusting knobs began to sink or turn hard, it is necessary to lubricate the plugs of the levers, as well as clean the rods from contamination. To do this, it is necessary to dismantle the plastic elements of the taps and the front panel of the gas appliance. Then, unscrewing the mounting studs that fix the stem, one by one, remove the valves. After that, pull out the spring and cork mechanisms, carefully cleaning them from dirt.

In order to avoid damage to the element and, as a result, gas leakage, it is strictly forbidden to remove dirt from the plug with sharp objects.

Cork mechanism, after cleaning, can be treated with graphite grease

However, in the process of performing this procedure, extreme care must be taken not to close up the passage holes of the element. After the restoration of the cork, it is necessary to clean the stem from contamination.The assembly of the control valve should be done in reverse order.

Namely: insert a plug into the tap, then a spring, securing the stem with a pin

The assembly of the control valve should be done in the reverse order. Namely: insert a plug into the tap, then a spring, securing the stem with a pin.

After carrying out the maintenance of the plate, the plastic levers and the front panel of the device should be installed in their original place.

Thus, the above recommendations will help to identify and eliminate problems that often arise in the process operation of gas equipment. At the same time, many malfunctions can be eliminated with your own hands. However, if it was not possible to fix the breakdown on your own, you should contact the service center for help.

The air conditioner works, but does not cool - this is often called the most common symptom

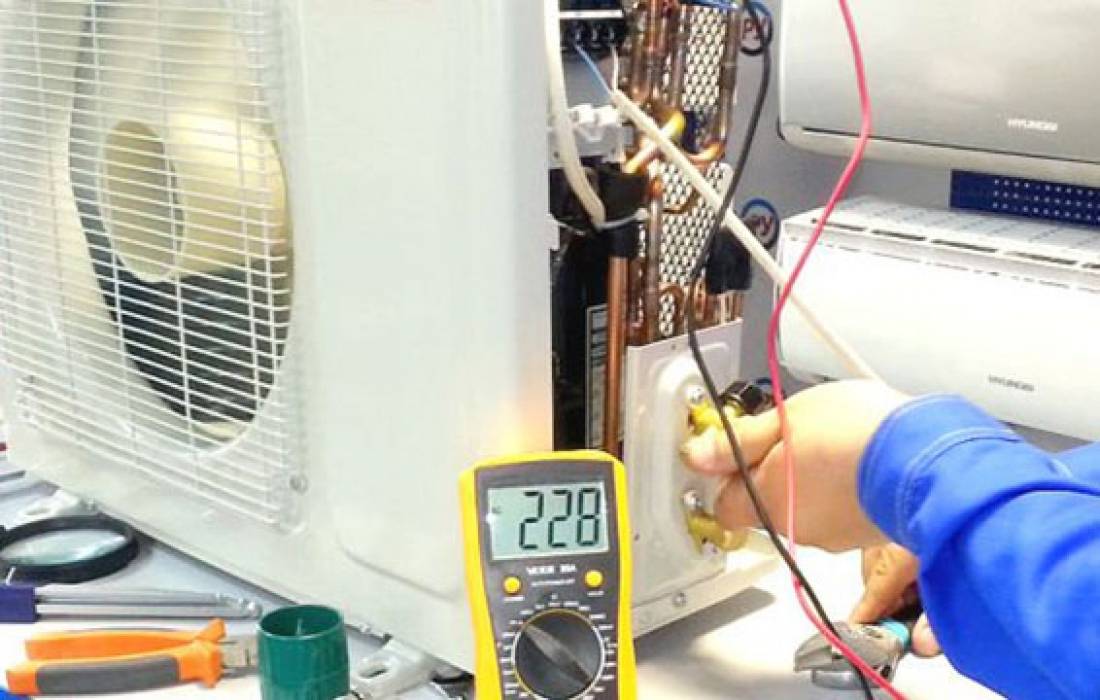

The first step is to make sure that the air conditioner is set up correctly and that all operating conditions are met !!! In order to understand at this stage where to go next, you need to find out if the compressor is working.

During operation, it should “buzz” a little and vibrate:

- if the compressor is running, then the reason is most likely a lack of refrigerant (freon). To verify this, you need to check the pressure (connect pressure gauges). In most cases, the leak occurs at the copper pipe connections of the indoor and outdoor units. Only 4 such connections that need to be checked and, if necessary, eliminate the leak (poor-quality rolling or a cracked nut, as in the photo). Often in the "sore spot" there is oil, on which dust sticks. Read the signs of a lack of freon in a separate article.

- if the compressor does not start, then without special preparation it will not be possible to eliminate the problem. Because there can be many reasons. The main ones are:

- Compressor start capacitor not working

- burned out compressor power contacts;

- temperature sensors are faulty;

- the compressor itself is out of order;

- failure in the control board.

Water is leaking from the air conditioner - no less common situation

The reason for this phenomenon often lies in the clogging of the drainage tray or drainage hose. It is necessary to disassemble the indoor unit and thoroughly clean the drainage system. To do this, you can read the detailed instructions "how to clean the air conditioner."

I came across air conditioners with defects in the condensate collection system. Water periodically flows from the block due to structural imperfections. I will not "burn" models. In this case, it is difficult to find the cause. You have to disassemble the indoor unit and in the process of its operation, study how the condensate flows. And as luck would have it at these moments, the drainage system is functioning normally!

Overview of major breakdowns

Having familiarized yourself with the main malfunctions, it will be easier to carry out repairs.

Doesn't turn on

The problem with turning on the air conditioner is the most common. The cause is natural wear or internal breakdown.

Electrical part

When the equipment is turned on, the sensor sends a corresponding signal. A breakdown in the electrical part does not allow the sensor to work correctly.

Remote control or receiving module

The remote control controls the air conditioner. Due to malfunctions of the remote control or receiving sensor, the equipment cannot be turned on.

Protection system

Air conditioners are equipped with a system of protection against improper operation.In the event of a system failure, the air conditioner does not start.

Part wear

Long-term operation leads to wear of the components. As a result of natural wear and tear, failures occur when switching on.

Shutdown after a short period of operation

Spontaneous shutdown indicates a breakdown. The problem may be due to a violation of the operating rules and internal malfunctions.

Room temperature

Air conditioners with automatic control function can be switched off by themselves. This happens when the room is sufficiently cooled.

Dry mode

In dry mode, cooling is performed so that the heat exchanger of the indoor unit reaches the lowest temperature. When this mode is enabled, the fan runs at minimum speed.

Compressor overheating

Due to overheating, the air conditioner may turn off spontaneously. It will be possible to start the equipment only after the compressor has cooled down.

Control board failure

A board failure disrupts communication between the outdoor and indoor units. Most often, a replacement board is required to solve the problem.

Safety relay failure

The protective relay fails when the contacts are stuck or the winding is broken. In the event of a malfunction, the air conditioner is not able to work properly.

Elimination of leaks of the indoor unit

Condensation forms in the outdoor unit when the air conditioner is running. Due to a breakdown, some of the water begins to leak.

Mechanical damage to the case

Liquid can also leak through cracks in the case. You can fix minor defects with waterproof glue.

Bad smell

When using the conditioner, a pronounced smell often occurs. Depending on the specifics of the smell, you can understand the problem.

Gorely

The smell of burning is often due to burnt wiring. Smelling the smell, you need to turn off the air conditioner and call a specialist.

Plastic

As a rule, the smell of plastic occurs in cheap equipment. High-quality equipment is made from safe material without a pronounced odor.

Dampness and mold

The presence of bacteria inside the unit causes a musty smell. To eliminate the smell, you need to process the case from the inside.

Wrong sounds

By the sounds emitted, you can determine the cause of incorrect operation. The presence of extraneous noise is often associated with an internal breakdown.

Uneven noise

Partial clogging of the filter or through hole creates uneven noise. In this case, cleaning of the equipment is required.

clatter

The first time after starting, clicking is the norm. The sound is associated with a change in the temperature of the case and the expansion or contraction of parts.

squelching

By analogy with the previous problem, squelching occurs when water is not properly drained. Also, the cause is often damage to the case.

Inefficient work

In some situations, the air conditioner does not work effectively. To use the maximum opportunities, you need to eliminate the cause of the problem.

Clogged filters

The accumulation of dust and dirt on the filter does not allow air to pass freely. Cleaning the filter helps to correct the situation.

Clogged heat exchanger

The role of the heat exchanger is to convert heat into cold air. Clogging reduces cooling efficiency.

Adaptation to severe frosts

Some models of air conditioners are unable to work at very low temperatures outside. Forced activation can cause damage.

Wrong choice of power

To quickly cool the room, you need to select the appropriate mode. Incorrect selection can lead to slow reaching of the required temperature.

Outdoor unit icing

Ice covering the outdoor unit will interfere with the operation of the unit. In winter, it is worth knocking down the icy crust.

Automatic diagnostics

Factory defects, poor installation and improper operation are the main reason that the internal parts of the air conditioner fail prematurely. Almost nothing can be done with a factory defect, in the other two cases there is a chance to improve.

The inscriptions on the display and the blinking of the lights will help you find out in time that certain problems have appeared.

in the air conditioner, they usually talk about breakdowns of the following nature:

- Broken thermistor, due to which there is no additional temperature control.

- Throttle valve problems.

- Problems inside the fan.

- Power surges at the outdoor unit.

- Exceeded parameters related to energy consumption.

- Cable or circuit problems due to communication.

- Lack of overvoltage protection.

- Work goes both on heat and on cold.

- Malfunction in the thermistor of the outdoor part.

- Faulty internal thermistor.

The instructions give a precise definition for those who are interested in deciphering the emerging codes and designations. This allows you to quickly determine what exactly happened.

But not every code has a decryption for users. Most of the information is handled by wizards related to a particular service center.

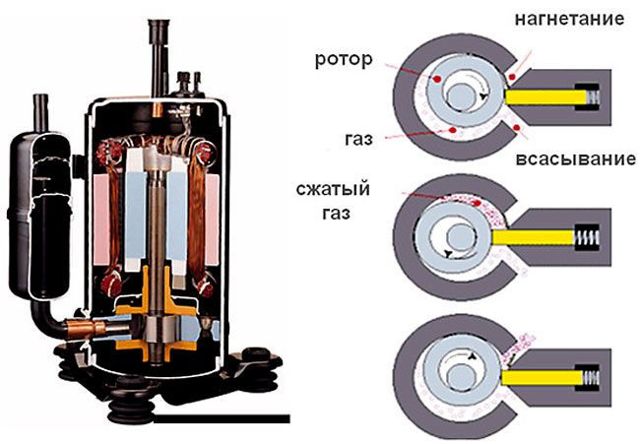

Compressor and clutch problems

If the radiator on the outdoor unit is clogged with dirt, this part of the structure may overheat. Heat dissipation becomes more difficult, the load on the device increases. A separate check requires the level of pressure in the lines. Excess refrigerant must be bled off if the indicator is above normal.

They never exclude the possibility that the fan at the external unit has become faulty. A blockage in the capillary tubes is another common reason why malfunctions appear in the future. Replacing one of the tubes often solves the problem.

There are other signs that speak specifically about breakdowns in this part:

- Compressor failure to start when .

- The presence of oil leaks on the compressor.

- The creak of the compressor drive belt.

- Extraneous noises.

- Decreased performance.

Complete compressor replacement and repair are complex operations, so it is recommended to contact specialists immediately.

But noise can tell both about problems in the compressor and about malfunctions in the drive. The pulley bearing is very likely to be the source if the noise is heard even when the appliance is turned off.

If the compressor fails to start, they also look at several details of the mechanism:

- Coupling.

- Relay.

- Fuse.

A blown fuse is the easiest to deal with; in case of breakdowns, it is simply replaced with a new one. The electromagnetic clutch is studied next if the previous steps did not give any result.

As for the compressor itself, there are several reasons for its breakdowns:

- Reduced coolant level.

- System clogging.

- Complete blockage.

Repair and replacement of a compressor is a rather expensive undertaking, therefore it is recommended to treat the part with care as much as possible during operation.

When you turn on and instantly turn off the device, the reason is more likely to lie in the sensors - evaporation or temperature. Data from temperature sensors is associated with the operation of the control board. If the system is faulty, no information is available. And the device considers that the current mode of operation does not need an adjustment for this indicator.

Compressor overheating and shutdown are often due to fan failure. This usually happens if the rotation speed of the device is less than certain specified parameters.

Dirt and dust can also appear in some other parts:

- Dryer filter.

- Outdoor Radiator.

- capillary tubes.

In such situations, the compressor stops turning on and working normally.

Possible malfunctions

Many users of such complex equipment as air conditioning are interested in the question: is it possible to repair the device on their own without resorting to the help of a specialist? Our answer is of course yes. However, before you start repairing household appliances, you need to know the cause of the breakdown, as well as what the air conditioner consists of. Below are the main malfunctions of air conditioners:

- the amount of cold (heat) produced decreases;

- condensate begins to flow due to clogged drainage;

- the air conditioner does not turn on and does not respond to a signal from the remote control;

- there was an unpleasant smell during the operation of the equipment.

All of the problems listed above can be fixed on your own without resorting to the help of a wizard. How to do this you will learn further. But if you doubt your abilities, then you can call a master who will diagnose and make an inexpensive repair of air conditioners in Moscow.

Cleaning the indoor unit

After you get access to all the components of the indoor unit of the split system, you can start cleaning them. For this, it is not recommended to use hard brushes or metal objects that can damage the heat exchanger or the freon line.

Cleaning the air filters

It is not difficult to clean the filter in the air conditioner with your own hands, the main thing to remember is that this procedure should be carried out regularly, at least once a week. To remove accumulated dirt, it is recommended to soak the filter elements in water with detergent foam for 30 minutes. And then rinse thoroughly with clean water and dry well before installing in the air conditioner.

Cleaning the air filters from dust

It should be noted that it is difficult to clean the air filters of duct, cassette or ceiling type air conditioners, because the indoor unit of such devices is located in the ceiling.

Fan cleaning

The fan of the indoor unit of the air conditioner also needs to be cleaned regularly. It is a roller that drives cool air into the room. To complete the task, you can dismantle the fan or wash it without removing it from the case. If the second option is selected, to remove dirt, the blades should be treated with soapy water, and then turn on the split system at minimum power.

Be prepared for the fact that the debris accumulated on the blades will fly to the floor, so first cover the part of the apartment under the air conditioner with old newspapers. After 15 minutes, turn off the device and remove any remaining dirt with a soft sponge or brush.

Removing dirt from vents

The top panel of the indoor unit is equipped with holes for air to enter the split system. You can clean them with a cloth dampened with soapy water.

Cleaning the heat exchanger

If the owner of the air conditioner has decided to monitor the cleanliness of the device on his own and perform its maintenance without calling the master, do not forget about regular maintenance of the heat exchanger. It is necessary to remove accumulated dirt from this part of the device at least once a year.

To get to the heat exchanger, you will have to remove the grate. After this, dirt can be easily removed with a vacuum cleaner or a cloth dampened with soapy water.

But you need to do this carefully, as you can easily damage the heat exchanger or injure yourself.

Cleaning the heat exchanger

During cleaning, special attention should be paid to the appearance of the heat exchanger. If signs of corrosion are found, it is necessary to contact the service center, since such damage is dangerous due to freon leakage.

Removing bad odor

To eliminate the unpleasant odor that may eventually appear from the air conditioner, it is necessary to carry out antiseptic cleaning. To do this, 0.5 liters of alcohol-based liquid antiseptic (can be bought at a pharmacy) is poured into a spray bottle and sprayed near the radiator with the air conditioner turned on. Small drops are drawn in and after ten minutes the unpleasant odor disappears.

Cleaning the drainage system

The drainage system of the air conditioner also needs to be cleaned. Otherwise, the device will leak and the outgoing air will acquire a putrid odor.

The cause of a clogged drain tube can be both dust and mold. To clean it, use one of the following methods:

- a soapy solution is passed through the evaporator, which washes away dirt and dissolves grease;

- purge the disconnected tube (drainage) with a vacuum cleaner, however, this option is applicable only if the drainage system is not very clogged;

- the completely disconnected drain pipe is washed and blown along the entire length, treated with a disinfectant (this is the only way to clean the system from heavy contamination).

To disinfect the tube, various agents are used, such as chlorhexidine.

To check the quality of cleaning, you can pour 1.5 liters of water into the drainage system. With a positive result, the liquid will flow out unhindered.

The video below will help owners of air conditioners clean the indoor unit from contamination:

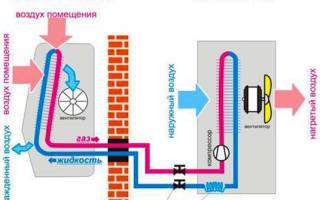

1 Air conditioner does not heat in severe frost

Why does the air conditioner not blow warm air when it is very cold outside? There is a perfectly logical explanation for this. For some models, operation in heating mode is not allowed below the set temperature. This leads to freezing of condensate, the formation of an ice crust and, if the device is not turned off, the compressor will fail due to overload. Before operating such a complex device as a split system, be sure to read the instructions. Manufacturers clearly prescribe the conditions under which the split system can work for heating. Many models must not be operated at temperatures below 5 degrees Celsius. Exceeding the permissible modes of operation of the air conditioner threatens with serious damage to the device.

The exception is inverter type air conditioners.What type of compressor can operate at 20 degrees below zero. The inverter system of the air conditioner is equipped with the option of soft start of the heating mode. Malfunctions in the operation of the air conditioner during the heating function can occur for various reasons. Let's consider some of them:

- If, when the air conditioner is turned on, the compressor runs, and unheated air comes out of the indoor unit, but does not turn on in heating mode, then the cause of the malfunction is more likely to be the failure of the four-way valve. This small detail plays a very important role in the device of the air conditioner. It is thanks to this valve that the transition from heating to cooling and vice versa is carried out. And accordingly, if the valve is out of order, there will be no heating.

- In cases where an air jet enters, which indicates that the fan is working, but the compressor is not working, the cause lies in the compressor malfunction. The way to eliminate such a breakdown is to replace or repair the compressor.

- Sometimes the lack of operation of the air conditioner for heating may be due to the freezing of condensate if a dehumidifying filter is not installed in this model. In this case, the air conditioner will work fine in cooling mode, but will not give warm air. This happens when the outside temperature is too low (Fig. 1).

Rice. 1 Outdoor unit icing

- Problems with the power supply of the electric coil can also cause a lack of operation in heating mode.

- Mechanical contamination of the filter and fan blades can cause the heating function to fail (Fig. 2). The air conditioner filter requires regular cleaning and maintenance. If this is not done, a dirty filter will lead to malfunction of many components, causing malfunctions of the device.

Rice.2 Mechanical contamination of the air conditioner

Why the air conditioner does not heat up will be exactly told by the service center master after the diagnosis. There are cases when a breakdown can only be repaired by repair engineers using special equipment. Such breakdowns include problems with freon. Freon is a gas used as a refrigerant and circulating in the evaporator system, which is the indoor unit of the air conditioner.

Why does the air conditioner not want to heat if the breakdowns described above are not observed? Most likely the reason for the failure is a problem with freon. The most common failures are:

- One of the reasons for the failure of freon circulation may be the failure of the electrical board responsible for the circulation of the refrigerant. In this case, the board needs to be replaced or repaired. It won't work without a specialist.

- The operation of air conditioners in adverse conditions at low temperatures is prohibited by the manufacturer. If this condition is neglected, ice may form in the freon circuit of the air conditioner and ice plugs. It is very difficult to melt the cork just like that, sometimes you have to wait for favorable weather conditions for natural thawing.

- Damage to the freon circuit and gas leakage. This happens if cracks and defects appear in the freon circuit of the air conditioner, accompanied by a refrigerant leak. The fact that a freon leak has occurred can be understood by examining the junction between the blocks. Freon leakage is indicated by the appearance of ice on the fittings of the outdoor unit. The lack of freon in the circuit leads to an overvoltage of the compressor, which can cause it to break.The compressor is a very expensive part of the air conditioner, its replacement cost is half of the device itself. Therefore, you need to be very careful and timely refuel freon, as well as periodically conduct a technical inspection of the entire air conditioner. In cases of such a malfunction, the air conditioner requires refueling of freon, for which you will have to call a wizard who will refuel freon and eliminate damage to the circuit.

Basic Troubleshooting

Insufficient traction

The following signs (one or more) may indicate a malfunction of air exchange:

- the room smells of dampness, rot or diaper rash;

- on the windowsill, walls, in the crevices, mold begins to actively multiply, a fungus is visible, which is concentrated both in open areas and in hard-to-reach places (under the plinth, behind cabinets, carpets and peeled off wallpaper);

- condensation is visible on the surface of the walls, wallpaper and even on furniture;

- the rooms are constantly cool, dampness, mustiness are felt;

- the supply of oxygen ceases to be replenished, which is expressed in the rapid breathing of the residents, the desire to go outside;

- extraneous sounds are heard in the ventilation system in the form of hum, noise, creaking;

- a burning smell comes from the air duct.

Rooms are usually made as airtight as possible. The natural ventilation system works through cracks in doors and windows. Decorative gratings are used to cover large gaps. With a difficult hood, which is forcibly installed in the bathroom, kitchen, toilet, the reasons may be corrosion in the system and impaired integrity of the parts.

To eliminate the problem, it is necessary to replace the damaged soft inserts, wafer seals. In this case, it may be necessary to replace duct elements with visible defects. To achieve tightness of the joints, they need to be adjusted.

Attention

The problem may be the increased resistance of the veterinary channels. Contaminants can accumulate in the air duct, resulting in low filter efficiency.

The maximum cleaning of the ventilation duct from debris will be required. It must be well dried, washed from dirt. Sometimes it's better to change to a new one.

Noise

A loud noise from the ventilation duct is evidence of clogged valves. There may be other reasons for increased noise:

- Small insects, rodents and even birds can enter the pipeline. The problem is solved by installing a protective mesh on the sockets of the outlet channels. It is fixed with screws.

- Noise can occur due to insufficient lubrication of moving parts of the equipment and, finally, due to strong wind. At least 4 times a month, you need to remove the grate and lubricate the moving parts with special grease.

- To get rid of wind noise, you can wrap the pipe with soundproofing material. You should choose a reliable one that is not affected by temperature and moisture. In addition, you can put several silencers that will absorb extraneous sounds.

Noise can be mechanical or aerodynamic. The first appears due to poor depreciation, unsatisfactory condition of the nodes, friction and violation of the balancing parameters. The second - as a result of the operation of electric motors, fans (read how to repair a kitchen hood engine with your own hands). The following steps will help reduce noise:

- install the fan on special vibration-isolating bases;

- balance rotating elements, parts;

- firmly fix the movable valves, gate valves and clamps;

- install a removable soundproof casing;

- between the channel and the fan, you can insert canvas pads or rubber ties;

- Facing the internal surfaces of the air ducts with durable materials that absorb sounds (mineral felt, fiberglass) will also help;

- you can lubricate the moving parts of the compressor.

Advice

An effective way to dampen vibrations is to build a concrete frame around the duct on the roof. If technical reasons do not allow such an operation, the channel is wrapped with insulation.

Filter system

Filters can be constantly clogged with dust, fine debris and kitchen grease

It is important to carry out a scheduled cleaning every 4-6 months. If the filter system is finally clogged, does not allow the air duct system to function normally, then the following steps must be performed:

- prepare a stable ladder, table or chair and put on protective gloves on your hands;

- after removing all the ventilation grilles, they must be thoroughly cleaned and washed with detergent;

- when parts are worn out, which will be visible at first glance, they are replaced with new, better ones;

- with a spatula, they clean the inner walls of various types of settled dirt;

- You need to be very careful not to damage the surface of the protective mesh.

The deep channel needs to be cleaned well. To do this, use a long stick with a solid base wound around its end, preferably a damp terry cloth. You need to move inward gradually, with rotational movements.At the end of the work, a final check of thrust is made with a sheet of paper or an anemometer.

here

The main reasons for the failure of the split system

- There is a blockage in the drainage water supply - this breakdown is manifested by dripping water during the use of climate technology and the formation of condensate. This phenomenon may occur due to the start of the cooling mode at low temperatures outside;

- The air conditioner filter becomes clogged and as a result, the air conditioner starts to cool the room poorly. And in this case, the cause of the malfunction may be excessive dustiness of the room, or the presence of carpets with small villi in the room;

- The compressor stops working - in this case, the device simply will not turn on. This problem occurs due to the burnout of the starting capacitor.

Before you start self-repair, you should know exactly what can break down, and detailed diagnostics of climate technology will help in this as well as possible. This procedure is facilitated by the presence in many modern models of a diagnostic system that notifies of a particular problem by flashing a special LED on the panel of the air conditioning unit. As soon as some kind of breakdown is detected, the LED will report this with a certain number of blinks.

Our Air Conditioning Service includes:

Indoor unit:

- cleaning of air filters, evaporator and air intake panel,

- fan cleaning,

- checking electrical contacts, connecting cables,

- drainage system check

- checking fan bearings,

- fan balancing check,

- checking the operation of the evaporator,

- check all modes of operation of the air conditioner.

Outdoor unit:

- checking electrical contacts and connecting cables, /li>

- freon leak check, /li>

- control of condensing pressure and suction pressure of the refrigeration unit of the air conditioner, / li>

- checking the fastening and balancing of the fan impeller, / li>

- checking fan bearings, /li>

- cleaning the intake grille and condenser fins, /li>

- current control./li>

If you need to repair or service the air conditioner (split system) - call us by phone

Conclusions and useful video on the topic

The method of restoring the power supply of the humidifier:

The humidifier does not produce steam - how to deal with the problem at home. Recommendations from the user:

How to properly use a humidifier so that it does not break:

The air humidifier is a reliable device designed for a long service life. Its electronic system fails as a result of a voltage drop, short circuit or contact with water. Almost all other malfunctions occur due to improper operation or falling, contamination of internal parts and untimely replacement of consumables.

Most of the problems can be fixed at home, and it is better to entrust complex repairs to the masters from the center for the restoration of climate equipment. They will diagnose, identify the problem area and quickly restore the device to working capacity.

Do you have questions about diagnosing the causes of a broken humidifier? Ask them to our experts - the feedback block is located below.Also here you can share your own experience of repairing a humidifier, take part in the discussion of ways to restore its performance.

Conclusions and useful video on the topic

How to clean the ventilation duct from dust and dirt with your own hands:

How to eliminate noise and vibration in the exhaust fan: detailed instructions for disassembling the device and lubricating parts:

Analysis of one of the typical fan malfunctions: what to do if the fuse is blown:

Faults are easier to prevent than to fix. Therefore, it is worth testing the ventilation in the bathroom annually, keeping the ventilation grilles clean, and periodically cleaning the accessible areas at the inlet of the ventilation duct. It is also advisable to take measures to improve the circulation of air masses - ventilate the premises, install window or wall valves.

If the ventilation stops working, try to determine the cause of the problem and use one of the appropriate methods to repair and optimize the system. In case of serious breakdowns, contact the specialists of the management companies.

Would you like to supplement the above information with useful comments? Or if you still have questions about troubleshooting the hood, ask our experts and other site visitors - the feedback form is located below the article.