- Designs of modern tank models

- Scheme and details

- How the drain system works

- Types of cisterns for the toilet

- Damage not related to rebar

- Preventive measures

- Briefly about the main

- Button jamming

- Internal organization

- Modern models with lever drain

- With button

- Ways to repair the tank mechanism on your own. Inlet valve replacement. Bleed valve replacement

- How to disassemble the installation of the toilet

- Types of fittings for flush cisterns

- Separate and combined options

- Materials for the manufacture of devices

- Place of water supply

- Replacing cistern fittings

- Preventive measures

- Reasons for the breakdown of the drain tank

- Dual flush

Designs of modern tank models

The descent mechanism and characteristic breakdowns depend on the configuration of the tank.

Structurally, it is a bowl with 1 or 2 buttons that start the process of water discharge.

Scheme and details

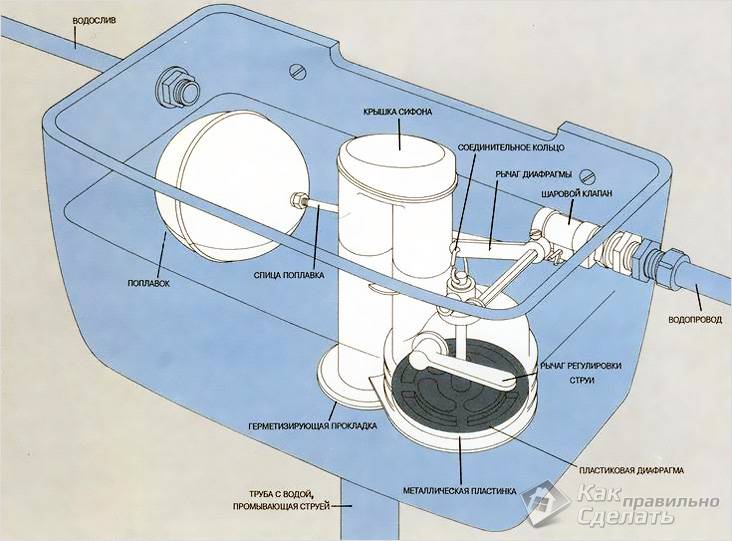

The tank scheme consists of several nodes:

- Water dump system. It consists of a drain pipe, a release mechanism and a valve that stops the water supply to the bowl immediately after discharge. The fixed parts of the mechanism are fixed with metal fasteners and elastic seals. Movable elements can change position. They can be recognized by the presence of divisions and notches on the surface.

- Overflow system (float module). This part of the mechanism includes a float valve and a shut-off valve. The float is made in the form of an inverted glass or a hollow container. When taking on water, the air inside makes it easy to push it to the surface.

- Button mechanism. Depending on the complexity of the scheme, it can be double or single. The 2-button system allows you to separate the full and economical escapement. In simple designs, the flush ends arbitrarily (after draining the entire mass of water), and in more complex designs, after the second press of the button.

In older side mechanism designs, the push button and float are connected by a lever or linked through an overflow system. When the container is full, the water pressure on the inlet valve increases, stopping its supply inside.

Tank diagram.

The part that blocks the flow of liquid from the tank is in the form of a pear or a standard bath stopper. It is connected to the overflow system and rises when the shutter button is pressed.

The toilet can be made in the following configurations:

- Monoblock. It is a single faience form of 2 combined bowls.

- Compact. Is the most common option. The tank is attached to the seat using special holes and long screws.

- Separated. Hanging or built-in container is not fixed on the toilet. An outer pipe is connected to the bowl, through which a jet of water is supplied.

How the drain system works

The principle of flushing is based on the expulsion of the float module. When you press the button, the drain valve rises, and all the liquid from the tank is dumped into the bowl in one gulp. After emptying the tank, the float sinks to the bottom following the water level.

The drain system works on the principle of pushing the float module.

Changing the position of the module opens the check valve, allowing access to the hose connected to the piping system. When the liquid level rises, the tap again shuts off the water supply.

Types of cisterns for the toilet

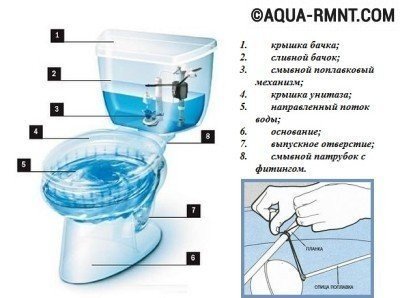

The flush tank is a container with a lid, equipped with a water supply mechanism and a drain device. According to the place of installation, the tanks are divided into three types:

- suspended;

- built into the wall;

- compacts.

The hanging tank is mounted on the wall above the toilet at a certain height and connected to the bowl with a drain pipe. A chain with a handle is attached to the lever of the flush device. The top location of the tank provides a high pressure of water when draining.

The built-in tank is a flat container made of high-strength polymer. She is equipped with hanging toilets. The container is hidden behind a decorative finish, only flush control buttons are mounted outside.

The compact cistern is installed on the back shelf of the toilet bowl. It is equipped with a lever or push-button mechanism. Water supply is carried out from the side or from below.

Classic toilet-compact with bottom water connection

Damage not related to rebar

It is important to know how to repair the cistern or the toilet itself if there are cracks in the body. Leaked water can cause a flood, so if you find a problem, you should act immediately.

Glue for ceramics will help to close the crack, but in the near future the plumbing will have to be replaced.

A leak can also occur if:

- The nuts on the bolts with which the tank is attached to the toilet pan have loosened. Fasteners must be carefully tightened with a wrench.If it is necessary to replace the seals, the tank will have to be dismantled and reinstalled.

- The connecting cuff between the tank and the toilet shelf is deformed or damaged. It must be replaced, but as a temporary measure, the resulting gaps can be sealed with silicone sealant.

How to quickly close a crack in the tank

Preventive measures

To avoid problems associated with leaks, with excessive consumption of water constantly flowing into the toilet bowl from the reservoir, it is important to know the design of the flush tank, to be able to adjust and repair the mechanisms. Recommended systematically:

Recommended systematically:

- check the condition of the flexible piping, connection node;

- inspect the fittings inside the tank, clean it from lime deposits and other contaminants;

- check the tightness of the connecting collar and bolt fasteners with a paper towel;

- inspect the tank and toilet for cracks.

Preventive measures allow you to extend the life of the mechanisms.

Briefly about the main

The cause of the breakage of the flush tank is usually worn or damaged fittings, improper adjustment, deformation and contamination of the seals or the drain valve. Knowing how to fix a drain tank, you can fix or adjust the water supply mechanism, return the functionality of the drain device, completely replace the fittings, or replace damaged elements, including seals.

Source

Button jamming

With such a breakdown, the drain is fixed in one position. So the toilet tank is leaking. What to do in this situation? The cover is removed, it is checked because of which the mechanism is jammed. Often the drain mechanism is checked for the following features:

- System blockage. Cleared from plaque.

- Stuck stock. The cause of jamming is identified and eliminated. If necessary, change to a new one.

- The return spring has weakened (the connecting ring on the lever has deformed). To be replaced.

- Broken or deformed traction system. It can be made from improvised means, for example, wire. But this will be a temporary solution to the problem. Because during subsequent operation, the wire will bend over time and you will have to repeat the procedure again.

Of course, before the breakdown is repaired, the water supply system should be turned off, the liquid should be drained from the drain tank.

Internal organization

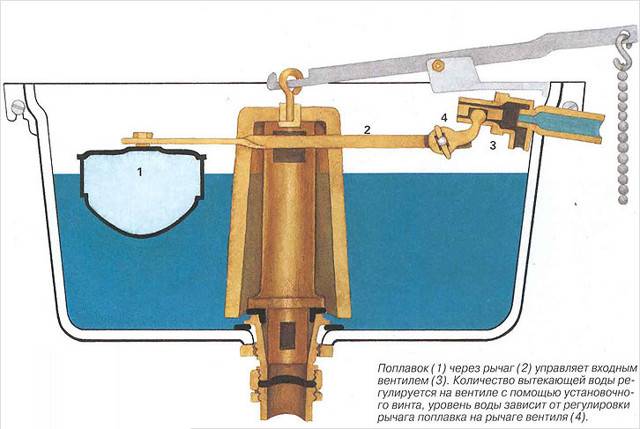

The toilet cistern consists of two simple systems: a set of water and its discharge. To troubleshoot possible problems, you need to understand how everything works and works. First, consider what parts the old-style toilet bowl consists of. Their system is more understandable and visual, and the operation of more modern devices will be clear by analogy.

The internal fittings of a tank of this type are very simple. The water supply system is an inlet valve with a float mechanism. The drain system is a lever and a pear with a drain valve inside. There is also an overflow pipe - through it excess water leaves the tank, bypassing the drain hole.

The device of the drain tank of the old design

The main thing in this design is the correct operation of the water supply system. A more detailed diagram of its device is in the figure below. The inlet valve is connected to the float using a curved lever. This lever presses on the piston, which opens / closes the water supply.

When filling the tank, the float is in the lower position.Its lever does not put pressure on the piston and it is squeezed out by water pressure, opening the outlet to the pipe. Water is gradually drawn in. As the water level rises, the float rises. Gradually, he presses the piston, blocking the water supply.

The device of the float mechanism in the toilet bowl

The system is simple and effective, the filling level of the tank can be changed by slightly bending the lever. The disadvantage of this system is a noticeable noise when filling.

Now let's look at how the drain of water in the tank works. In the variant shown in the figure above, the drain hole is blocked by a bleed valve pear. A chain is attached to the pear, which is connected to the drain lever. We press the lever, lift the pear, the water drains into the hole. When the level drops, the float goes down, opening the water supply. This is how this type of cistern works.

Modern models with lever drain

They make less noise when filling the cistern for toilet bowls with a lower water supply. This is a more modern version of the device described above. Here the tap / inlet valve is hidden inside the tank - in a tube (in the photo - a gray tube to which the float is connected).

Drain tank with water supply from below

The mechanism of operation is the same - the float is lowered - the valve is open, water flows. The tank was filled, the float rose, the valve turned off the water. The drain system remained almost unchanged in this version. The same valve that rises when you press the lever. The water overflow system has not changed much either. This is also a tube, but it is brought out into the same drain.

You can clearly see the operation of the drain tank of such a system in the video.

With button

Models of toilet bowls with a button have similar water inlet fittings (there are with a side water supply, there are with a bottom one).Their drain fittings are of a different type.

Tank device with push-button drain

The system shown in the photo is most often found in toilet bowls of domestic production. It is inexpensive and reliable. The device of imported units is different. They basically have a bottom water supply and another drain-overflow device (pictured below).

Imported cistern fittings

There are different types of systems:

- with one button

- water drains as long as the button is pressed;

- draining starts when pressed, stops when pressed again;

- with two buttons that release different amounts of water.

The mechanism of work here is slightly different, although the principle remains the same. In this fitting, when you press the button, a glass rises, blocking the drain. The stand remains stationary. In short, this is the difference. The drain is adjusted using a swivel nut or a special lever.

Ways to repair the tank mechanism on your own. Inlet valve replacement. Bleed valve replacement

Let's move on to the section: ways to repair the tank mechanism on your own.

Through the upper hole in the tank, the entire mechanism of the drain valve is visible. It may have the following faults:

- Uncontrolled drain mechanism.

- The tank is constantly leaking.

- There is no water pressure at the inlet.

It depends on how the repair will be done. toilet cistern, the causes of these malfunctions may be different.

The regulator does not shut off the water supply. The serviceability of each element of the device is checked: rods, fasteners, inlet valve, float. Due to the presence of an overflow tube, at the same time, the tank will never overflow. The failed part is replaced or the float mount is simply tightened.

Weak pressure through the intake valve.This can be avoided by cleaning or installing a filter in front of it. As a rule, this is done if it becomes clogged.

The plug (pear) does not fit snugly against the drain hole. By pressing the stem with a little force, the possibility of repair can be checked. To avoid this, you should purchase high quality plumbing. If at the same time the water does not flow, the cork can be slightly weighted with an additional load or the rod can be leveled. The liquid constantly flows into the bowl, it is also necessary to periodically clean the seal from rust and salts, due to which the tightness is broken.

Leak from the tank into the room. It may have a crack or the tightness of the gaskets is broken.

Particular attention should be paid to the quality of the connection of the current tank with the bowl. And if this does not help, the rubber gasket changes, it must be tightened. The seal is changed to a new one, having cleaned the connection of contaminants and treated the surfaces with a sealant

Another cause of leakage may be the wear of the cuff in the joint between the bowl drain and the sewer pipe.

_

Repair - a set of operations to restore the serviceability or operability of an object and restore the resource of a product or its components. (GOST R 51617-2000)

Detail - a product or its component part, which is a single whole, which cannot be disassembled into simpler components without destruction (reinforcing bar, washer, spring, window sill board, etc.).

room - a unit of a complex of real estate (a part of a residential building, another real estate object associated with a residential building), allocated in kind, intended for independent use for residential, non-residential or other purposes, owned by citizens or legal entities, as well as the Russian Federation, subjects of the Russian Federation and municipalities. ; - the space inside the building, which has a certain functional purpose and is limited by building structures. (SNiP 10-01-94); - the space inside the house, which has a certain functional purpose and is limited by building structures. (SNiP 31-02-2001)

rule — a clause describing the actions to be performed. (SNiP 10-01-94)

Crack - a cavity formed without removal of material by two surfaces connected inside the body, which, in the absence of stresses in it, are separated from each other by distances many times less than the length of the cavity itself. (GOST 29167-91); - a slot, a narrow recess located on the surface of the product, more than 1 mm wide. (GOST 474-90)

Now let's consider intake valve replacement.

Turn off the water supply faucet before repairing the toilet. It connects to the pipeline from the riser. In the future, after the flexible hose is unscrewed from the intake mechanism. If the fastening is loosened, it can be easily removed. Assembly is in reverse order. Instead, a new one or a repaired one is installed. And a fluoroplastic tape is wound onto the brass one, the plastic thread does not require sealing.

Next, consider drain valve replacement.

The main reason is the wear of the sealing ring under the valve.To replace it, you need to remove the hardware and install a new gasket. In the future, after the assembly takes place in the reverse order.

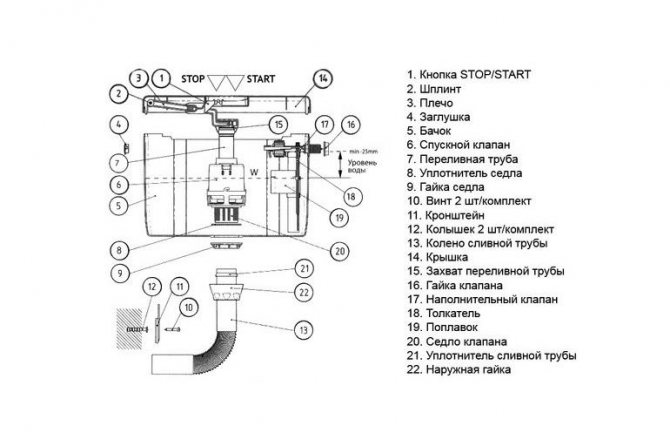

How to disassemble the installation of the toilet

For repair or maintenance, you do not need to disassemble the wall. To get to the details of the toilet installation, disassembly is carried out in the following sequence:

- By pressing the bottom of the button, move it upwards to remove it from the mounts.

- To remove the frame from the sides, the bolts are unscrewed, after removing the clamps, plastic pushers are taken out.

- Disassemble the brackets to which the button is attached.

- The partition is removed after pressing the latches.

- Shut off the water.

- After dismantling the filling valve, the rocker arms are removed.

- When you press a pair of petals in the upper part, the drain valve is released from the latches.

- Due to the large size, it will not be possible to get it through the revision window. Therefore, the drain assembly is disassembled on site. Unscrew the upper part, followed by bending the second rod.

After dismantling, the parts are washed with running water, the condition is assessed. Faulty and worn components are replaced. After completion of the repair, the assembly is carried out in the reverse order.

Types of fittings for flush cisterns

The principle of operation of a conventional tank is not complicated: it has a hole through which water enters and a place where water is discharged into the toilet. The first is closed by a special valve, the second - by a damper. When you press the lever or button, the damper rises, and the water, in whole or in part, enters the toilet, and then into the sewer.

After that, the damper returns to its place and closes the drain point. Immediately after this, the drain valve mechanism is activated, which opens the hole for water to enter.The tank is filled to a certain level, after which the inlet is blocked. The supply and shutoff of water are regulated by a special valve.

A cistern fitting is a simple mechanical device that draws water into a sanitary container and drains it when a lever or button is pressed.

There are separate and combined designs of fittings that collect the volume of water necessary for flushing and drain it after activating the flushing device.

Separate and combined options

The separate version has been used for many decades. It is considered cheaper and easier to repair and set up. With this design, the filling valve and the damper are installed separately, they are not connected to each other.

The shut-off valve for the tank is designed in such a way that it is easy to install, dismantle or change its height.

To control the inflow and outflow of water, a float sensor is used, in the role of which even a piece of ordinary foam is sometimes used. In addition to a mechanical damper, an air valve can be used for the drain hole.

A rope or chain can be used as a lever to raise the damper or open the valve. This is a typical option for models made in retro style, when the tank is placed quite high.

In compact toilet models, control is most often carried out using a button that needs to be pressed. For those with special needs, a foot pedal may be installed, but this is a rare option.

In recent years, models with a double button have been very popular, which allow you to empty the tank not only completely, but also halfway to save some of the water.

The separate version of the fittings is convenient in that you can repair and adjust individual parts of the system separately.

Combined type fittings are used in high-end plumbing, here the drain and inlet of water are connected into a common system. This option is considered more reliable, convenient and expensive. If this mechanism breaks, the system will need to be completely dismantled for repair. The setup can also be a little tricky.

The fittings for the toilet cistern with side and bottom water supply are different in design, but the principles of setting up and repairing them are very similar

Materials for the manufacture of devices

Most often, toilet fittings are made of polymeric materials. Usually, the more expensive such a system is, the more reliable it is, but this method does not give clear guarantees. There are fakes of well-known brands, and quite reliable and inexpensive domestic products. An ordinary buyer can only try to find a good seller and hope for good luck.

Fittings made of bronze and brass alloys are considered much more reliable, and it is much more difficult to fake such devices. But the cost of these mechanisms will be much higher than that of plastic products.

Metal filling is usually used in high-end plumbing. With proper configuration and installation, such a mechanism functions smoothly for many years.

In bottom-fed toilets, the inlet and shut-off valve are very close. When adjusting the valve, make sure that the moving parts do not touch.

Place of water supply

An important point is the place where water enters the toilet. It can be carried out from the side or from below.When water is poured from the side hole, it produces a certain amount of noise, which is not always pleasant for others.

If the water comes from below, it happens almost silently. The lower water supply to the tank is more typical for new models released abroad.

But traditional cisterns of domestic production usually have a lateral water supply. The advantage of this option is the relatively low cost. The installation is also different. The elements of the lower water supply can be installed in the tank even before its installation. But the side feed is mounted only after the tank is installed on the toilet bowl.

To replace the fittings, they are selected taking into account the option of supplying water to the sanitary tank, it can be side or bottom

Replacing cistern fittings

In the old toilet bowl, we dismantle the old fittings that have become unusable and install a new water supply and drain system. We purchase universal fittings suitable for all toilet cisterns. For economical use of water, we buy a two-button drain mechanism that allows you to change the amount of drain depending on the type of human waste being washed off.

In such fittings, the manufacturer uses:

- dual-mode push-button mechanism;

- manual adjustment of the volume of small and large water discharge;

- drain mechanism rack adjustable to the height of the tank;

- changing the thrust by reinstalling the lever in one of the existing holes;

- clamping nut with rubber gasket;

- a valve that closes the drain hole in the toilet bowl.

The mechanism for economical draining of water from the tank, carried out using two keys, which are activated by a blue or white pin at the moment one of the buttons is pressed

We will replace the old fittings. To do this, unscrew the button holding the toilet lid and pull it out of the socket. Let's take the cover off. Turn off the water supply to the tank. Disconnect the flexible hose. Unscrew the screws holding the flush tank to the toilet bowl. Remove the reservoir and place it on the seat cover. Remove the rubber seal, and then unscrew the clamping plastic nut by hand. Then we remove the old drain mechanism.

Next, we put a new drain mechanism, after removing the rubber seal from it and unscrewing the clamping fixing nut. After installing the drain mechanism in the hole of the tank, we fix its position with the removed parts. When installing the tank on the toilet, do not forget about the sealing ring that is placed on top of the plastic nut. Then we insert the pins of the tank into special holes in the bowl, screwing the wing nuts on them from below. We tighten the fasteners evenly from both sides, avoiding distortion of the installed part. If necessary, replace the fasteners with new parts with sealing gaskets.

With the help of two fasteners, the tank is securely attached to the toilet bowl. From the bottom of the bowl, wing nuts are screwed onto the screws, thin gaskets are first put on

When connecting the water hose to the side inlet valve, we hold the part inside the tank from turning. Tighten the nut with a special wrench or pliers. Install the tank lid, tighten the button. If necessary, adjust the rack, rearrange the lever.

The two-button button has two pins, with which the desired drain mechanism is activated. The length of the pins reaches 10 cm. They are shortened to the desired length, depending on the height of the tank.Screw into a button. Insert into the cover and fix the position of the button from the inside with a nut. Install the lid on the tank. Turn on the water supply. Press a small part of the button, about 2 liters of water are drained. Press most of the button, about six liters of water are drained.

Preventive measures

To avoid problems associated with leaks, with excessive consumption of water constantly flowing into the toilet bowl from the reservoir, it is important to know the design of the flush tank, to be able to adjust and repair the mechanisms. Recommended systematically:

Recommended systematically:

- check the condition of the flexible piping, connection node;

- inspect the fittings inside the tank, clean it from lime deposits and other contaminants;

- check the tightness of the connecting collar and bolt fasteners with a paper towel;

- inspect the tank and toilet for cracks.

Preventive measures allow you to extend the life of the mechanisms.

Reasons for the breakdown of the drain tank

Sooner or later, each person is faced with the problem of improper functioning of the water release mechanism. There are many reasons that contribute to the occurrence of leakage or lead to the failure of the drain system.

The most common of them are:

- mechanical damage to the structure;

- frequent use of a plumbing fixture;

- low-quality manufacturing materials.

Before proceeding with troubleshooting, you should familiarize yourself with the structure of the drain system, which, in turn, depends on the design of the toilet bowl

In addition, it is important to block the inlet in advance, as well as prepare the necessary equipment, consumables

Consider the most common models of the toilet cistern, their possible defects, and ways to eliminate breakdowns.

Drain tank device

Dual flush

The working volume of the toilet bowl is 4 or 6 liters. In order to save water, flushing mechanisms have been developed with two modes of operation:

- in the standard version, the entire volume of liquid from the tank is drained into the bowl;

- in the "economy" mode - half the volume, i.e. 2 or 3 liters.

Management is implemented in different ways. It can be a two-button system or a one-button system with two pressing options - weak and strong.

Dual flush mechanism

The advantages of a dual-mode drain include more economical water consumption. But we must not forget about the disadvantage - the more complex the mechanism, the more elements it contains, the higher the risk of breakage and the more difficult it is to fix the malfunction.