- The toilet is leaking: what to do?

- The mechanism and principles of the system

- How to get rid of noise when filling the tank

- Features of the internal device

- The device of modern models

- Drain cisterns with button

- Common drain tank failures

- Troubleshooting the "two-button" tank

- Drain mechanism

- Seat stabilization

- rusty hinges

- Types of fittings for flush cisterns

- Separate and combined options

- Materials for the manufacture of devices

- Place of water supply

- The water in the toilet bowl does not shut off. What can be done

- Typical malfunctions of flush mechanisms for typical toilet bowls

- The device and operation of the drain tank

The toilet is leaking: what to do?

First of all, don't panic. If we exclude mechanical damage to the toilet bowl (various chips and cracks), then there will be two reasons that water pours onto the floor:

- Poor quality toilet bowl bolts;

- Wear of the rubber seal, which is located between the drain tank and the toilet bowl.

To eliminate this trouble, try to start by simply tightening the mounting bolts a little more. However, be careful: with excessive force, you risk damaging the tank and cracking it. Tighten them gradually, periodically checking whether there is a leak or not.

If, after tightening the fasteners, water continues to ooze onto the floor, you will have to remove the tank and change the sealing ring on the drain channel. Do not be lazy, and if you have already removed the tank, immediately change the washers that fix the mounting bolts and rubber gaskets, and it is best to treat all joints with silicone - this will give an additional guarantee against leakage.

In tanks with a lower wiring, the problem of water leakage may be associated with a worn seal where water is poured. In this case, you will also have to change the seal that has become unusable and fix everything with silicone sealant.

The mechanism and principles of the system

Before you repair a toilet flush tank, you should understand the general principle of its operation and have a good idea of \u200b\u200bthe device from the inside.

Drain tank device

Drain tank device

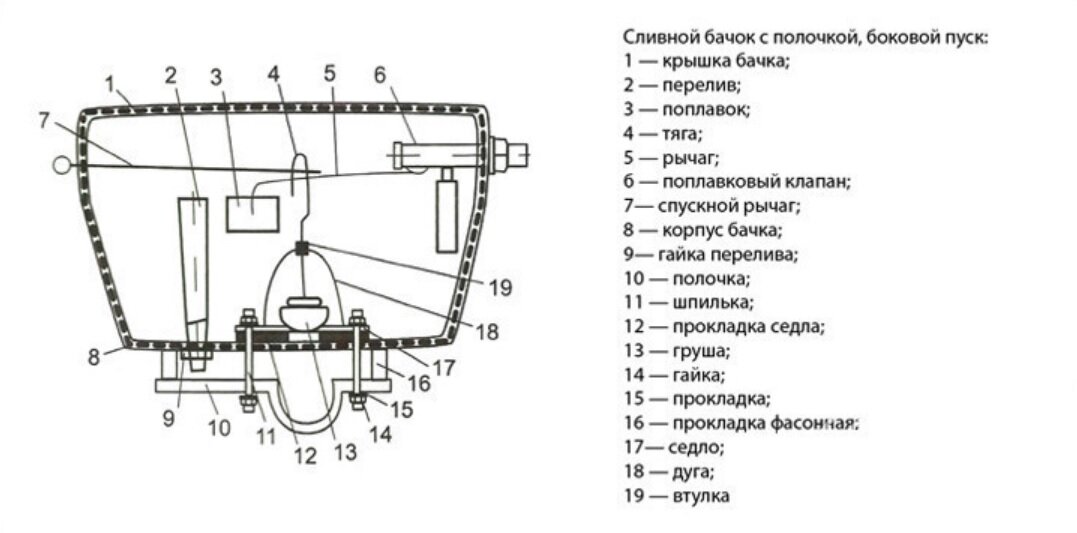

Today, there is a large selection of different designs for draining water into the sewer, but they all have the same mechanism and principle of operation. The main components of such structures are a device for collecting water and for lowering it into the toilet bowl. For flushing on tanks, a button or lever is usually provided. It may be located on the cover or side of the device.

The flush tank is sometimes installed at a certain vertical distance from the toilet. In this situation, the container is connected to the plumbing using pipes. This type of design allows you to increase the flow of flushed water.

In some models, the elements of the sewer system for draining are hidden behind a special decorative screen or combined in one design with a bowl. At the same time, no matter what configuration the drain tank has, its device remains unchanged.

Toilet cistern

Toilet cistern

The main functions of the product are as follows:

- water is drawn into the system to a certain mark or level, malfunctions in the details of this device are often the reason that water is not drawn into the toilet bowl;

- the water must be drained into the bowl in full or in part.

The main points of operation of the device while filling it with water:

- So that after the descent of water, its flow into the tank resumes, the float, which is fixed at the end of the lever, must work effectively.

- After pressing the button, the float lowers, opening a special hole for water supply.

- When water completely fills the system to the desired level, the float rises again and closes the liquid inlet channel.

Today they produce devices in which water is supplied from below. This is very convenient, as it significantly reduces the noise level during filling the tank. However, such designs have a more complex device and are much more expensive than conventional budget counterparts.

In old-style devices, a similar drain principle was used. The hole for draining the water was closed by a piece of rubber like a pear or a special valve. The lever protruding beyond the structure was connected to the body with a chain. To flush, it was necessary to press the lever and it opened the drain hole.

Cistern. Inside view

Cistern. Inside view

If you're wondering why in the toilet cistern no water is drawn or dials very slowly, first of all, you need to check this component for a malfunction. Sometimes a significant amount of liquid simply flows out through a drain that is not tightly closed. Further in our article we will consider ways to solve this problem.

Such designs are simple, they do not have a large number of small moving parts.If this system breaks down, you can easily repair it yourself. The toilet bowl in your bathroom will work like new again.

However, in newer models of toilets, a different kind of locking mechanism is installed. Such fittings have the function of adjusting the flush force or the volume of drained water. Externally, the device is a double button, each half of which allows you to release water with a different pressure.

Details of the double button flusher

Details of the double button flusher

How to get rid of noise when filling the tank

Most designs to reduce the level of water noise provide for the installation of a special downpipe, through which water is discharged to the bottom of the tank when filling.

First of all, check its installation. If the tube is asleep, then put it on the fitting near the filling hydraulic valve. In that case, such a tube is missing, then try to find the required diameter and install it.

Another way to get rid of loud noise when filling is to reduce the flow rate of the supplied liquid. This can be done by turning off the faucet on the water connection line or by installing a constriction washer on the hose fitting.

Features of the internal device

The basis of the flush tank for the toilet includes 2 systems - an automatic water intake system and a water drain mechanism. If you know the principle of operation of either system, then it is easy to troubleshoot the problems that have arisen. To make it easier to understand the mechanism of the flush tank, you should first familiarize yourself with the diagram of the old toilet cisterns, since their systems are more understandable and simpler than modern mechanisms.

The device of the old barrel

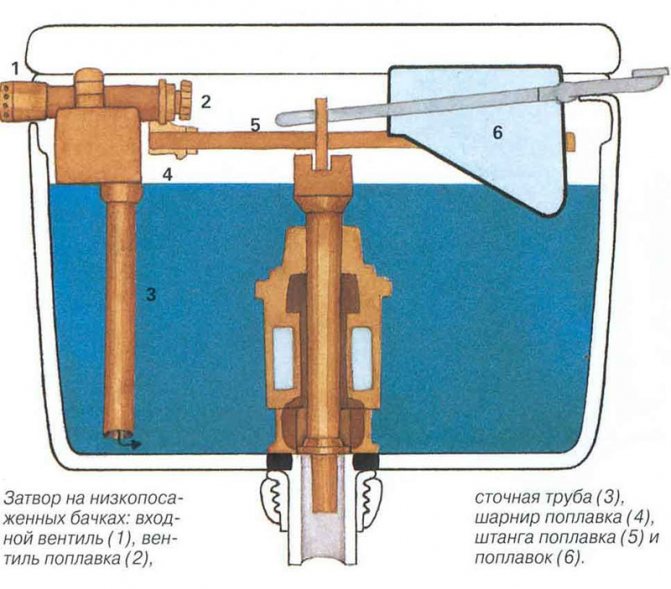

Tanks of old designs consist of elements for supplying water to the tank, as well as a drain device. An inlet valve with a float is included in the water supply mechanism, and a lever and pears are included in the drain system, as well as a drain valve. There is also a special tube, the function of which is to remove excess water in the tank without using the drain hole.

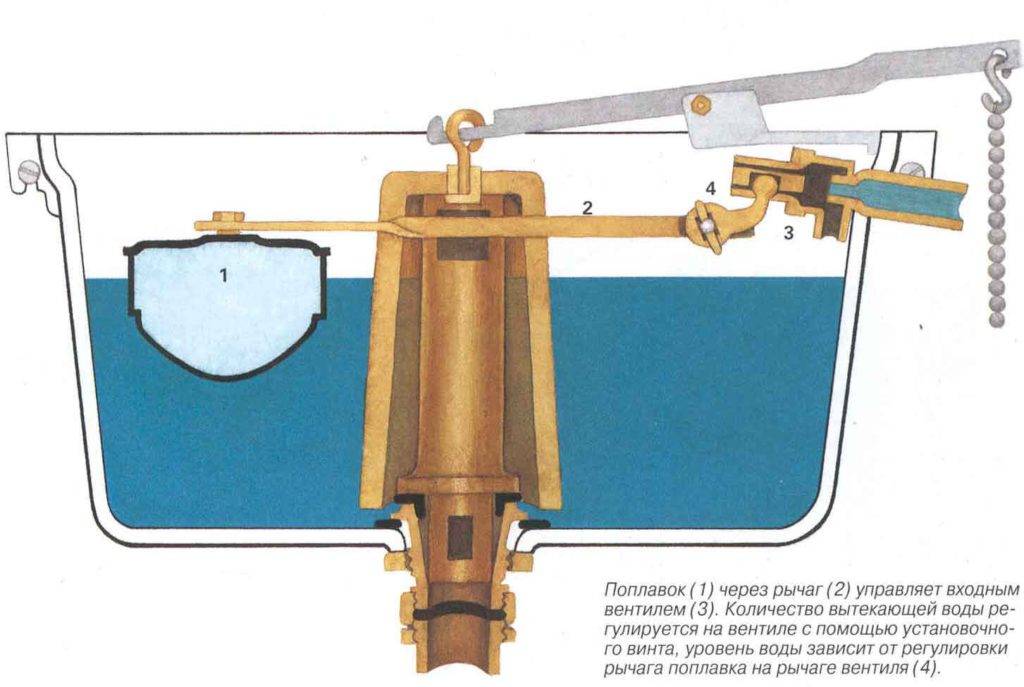

The normal operation of the entire structure depends on the reliable operation of the water supply elements. In the image below, you can see in more detail the scheme of automatic water supply. The inlet valve is connected to the float using a curly lever. One end of this lever is connected to a piston that either shuts off the water or opens the water.

Float mechanism device

When the water in the tank is missing, then the float is in its lowest position, so the piston is in the depressed position and water enters the tank through the pipe. As soon as the float rises and takes its extreme upper position, the piston will immediately shut off the water supply to the tank.

This design is quite simple, primitive, but effective. If you partially bend the curly lever, you can adjust the level of water intake in the tank. The disadvantage of the mechanism is that the system is quite noisy.

Water is drained from the tank using another mechanism, which consists of a pear blocking the drain hole. A chain is connected to the pear, which in turn is connected to the lever. By pressing this lever, the pear rises up and the water immediately flows out of the tank. When all the water has drained out, the pear will drop down and close the drain hole again.At the same moment, the float drops to its extreme position, opening the valve for supplying water to the tank. And so every time, after draining the water from the tank.

Toilet bowl device | Operating principle

Watch this video on YouTube

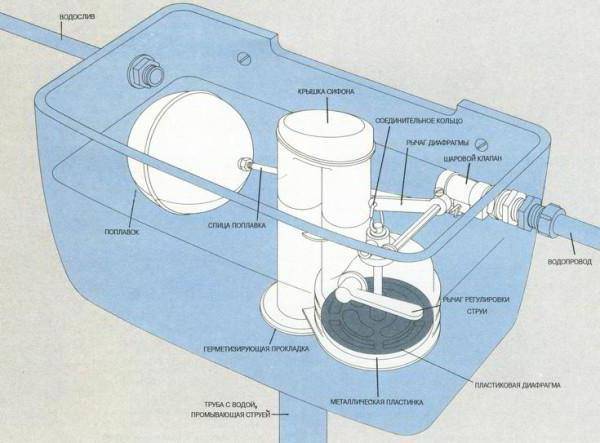

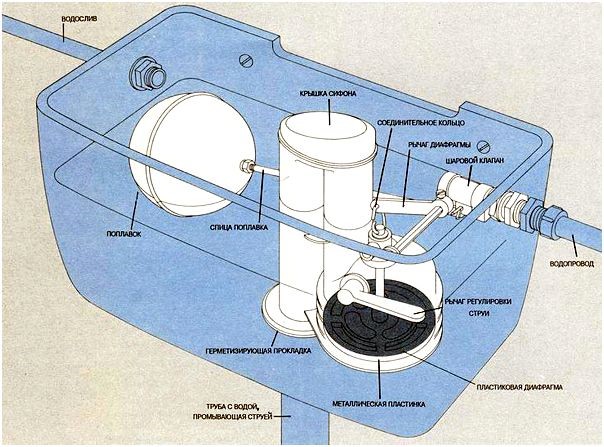

The device of modern models

Tanks that have a lower water supply to the tank make less noise. Therefore, we can safely say that this is a more modern version of the device. The inlet valve is hidden inside the tank, which is a tube-shaped structure. In the photo below, this is a gray tube that is connected to the float.

Construction of a modern cistern

The mechanism works in the same way as in older systems, so when the float is lowered, the valve is open and water enters the tank. When the water in the tank has reached a certain level, the float rises and blocks the valve, after which water can no longer flow into the tank. The water drain system also works in the same way, since the valve opens when the lever is pressed. The water overflow system functions in a similar way, but the tube is led into the same hole to drain the water.

Drain cisterns with button

Despite the fact that a button is used as a lever in these tank designs, the water inlet mechanism has not undergone major changes, but the drain system is somewhat different.

With button

The photo shows a similar system, which is mainly used in domestic designs. It is believed that this is a fairly reliable and not expensive system. Imported cisterns use a slightly different mechanism. As a rule, they practice a lower water supply and a different drain / overflow device scheme, which can be seen in the photo below.

Imported fittings

There are several options for such systems:

- With one button.

- The water drains when pressed, and the drain stops when pressed again.

- With two buttons responsible for different amounts of water releasing into the drain hole.

And although the mechanism works in a completely different way, its principle of operation remains the same. In this design, by pressing the button, the drain is blocked, while the glass rises, and the rack remains in the mechanism itself. This is precisely the difference in the design of the mechanism itself. Drainage is regulated using a special rotary nut or a special lever.

Drain mechanism for a ceramic tank manufactured by Alca Plast, model A2000

Watch this video on YouTube

Common drain tank failures

The most common failure is the continuous filling and leakage of water from the tank. The reason for this is the following factors:

- float tilt;

- the float mechanism does not work;

- loose shut-off valve, old rubber seal.

The easiest way to solve the first problem, because in this case the toilet will not even require repair of the drain tank - just open the lid and adjust the float. Also, sometimes the shut-off valve does not fit into place, it is also enough just to put it manually into the recess.

The next problem is that the water fills the tank to the limit and does not stop. To check the mechanism, lift the float up to the stop. If the water does not stop, then the float mechanism will need to be replaced.

And the last point is the old sealant. It is very simple to determine such a breakdown: you just need to press the valve with your hand. If the water stops, you will have to replace the seal. Also, sometimes this is due to the too low weight of the locking mechanism.In this case, weights are added inside to make it heavier.

Another common failure is associated with a worn float. Its tightness is broken, and it does not float well, so the water in the tank does not rise to the desired level. You will need to replace the fittings of the drain tank, but you can also fix the float with your own hands. To do this, its hole is sealed with sealant, glue, heated plastic or any other material at hand. You can also look into a plumbing store, perhaps there will be an analogue of this float.

Not very often, but there are such breakdowns with the tank as: leakage of the tank mounting bolts and failure of the water supply valve. To eliminate them, it is enough to change the gaskets and buy a new valve.

The video shows how to repair a toilet cistern with your own hands:

Usually, repairs come down to a maximum of replacing fittings, and this can be done on your own without calling a plumber. The main thing is to choose a quality product and the right size, and then the sound of dripping and gathering water will not interfere.

Troubleshooting the "two-button" tank

Currently, in order to save water, modern models of tanks are equipped with fittings that have two drain modes - economical, full. At the same time, each of the buttons is equipped with a separate drive to the drain valve.

Consider the most common problems with two-button drain fittings.

- Button drop. To fix this problem, you need to remove the cover of the device, set the button to its original position.

- Separation of the lever mechanism of the buttons. Namely, after pressing the device, there is no water drain. To eliminate the breakdown, it is necessary to install the reinforcement parts with hooks to their original position.

- Constant outflow of water.In this case, the membrane needs to be replaced.

- Leakage at the junction of the cistern, toilet bowl. The cause of the defect is the wear of the sealing gasket. To fix the problem, you need to replace it. First of all, you should disconnect the resource supply pipe from the drain system, and also remove the fixing screws. Next, the old gasket must be replaced with a new one. In this case, the dimensions of the connecting elements must completely match.

Remember, in order to avoid aggravating the breakdown of the toilet drain system, it is necessary to eliminate the problem as soon as possible.

Drain mechanism

The flush mechanism allows you to release water into the toilet bowl to flush sewage into the sewer. It is activated by pressing a lever or button.

Toilet bowl with top cistern and lever

Drainage devices differ in design, but in most cases they are interchangeable if they are designed for installation in tanks of standard dimensions, with holes of standard sizes. The general principle of the mechanism is as follows:

- the drain hole is blocked by a valve retaining water;

- when you press the button or lever, the valve rises, and water rushes into the bowl with a powerful stream;

- valve falls into place.

The design includes an overflow pipe with an open top. Water that has risen above a predetermined level flows through it into the toilet bowl - this eliminates the overflow of the tank, prevents water from leaking through the edges of the tank to the floor.

Seat stabilization

Inexpensive rubber bushings and stabilizers seats will help repair the toilet on long years. Remove the nuts from the toilet seat and insert the rubber bushings.Wrap the rubber band around the toilet seat and center the stabilizers so that they touch the inside edge of the toilet.

Wrap the rubber band around the toilet seat and position the stabilizers so that they touch the inside edge of the toilet. Drill a hole for the starter and secure the stabilizers with the screws provided. Then install the toilet seat stabilizer kit. This will eliminate the looseness caused by side to side movement.

rusty hinges

The screws on the toilet quickly rust and ruin the whole look. To prevent this, coat the screw heads with clear varnish. If the screws are already rusty, lubricate them with sealant or degrazer first.

Types of fittings for flush cisterns

The principle of operation of a conventional tank is not complicated: it has a hole through which water enters and a place where water is discharged into the toilet. The first is closed by a special valve, the second - by a damper. When you press the lever or button, the damper rises, and the water, in whole or in part, enters the toilet, and then into the sewer.

After that, the damper returns to its place and closes the drain point. Immediately after this, the drain valve mechanism is activated, which opens the hole for water to enter. The tank is filled to a certain level, after which the inlet is blocked. The supply and shutoff of water are regulated by a special valve.

A cistern fitting is a simple mechanical device that draws water into a sanitary container and drains it when a lever or button is pressed.

There are separate and combined designs of fittings that collect the volume of water necessary for flushing and drain it after activating the flushing device.

Separate and combined options

The separate version has been used for many decades. It is considered cheaper and easier to repair and set up. With this design, the filling valve and the damper are installed separately, they are not connected to each other.

The shut-off valve for the tank is designed in such a way that it is easy to install, dismantle or change its height.

To control the inflow and outflow of water, a float sensor is used, in the role of which even a piece of ordinary foam is sometimes used. In addition to a mechanical damper, an air valve can be used for the drain hole.

A rope or chain can be used as a lever to raise the damper or open the valve. This is a typical option for models made in retro style, when the tank is placed quite high.

In compact toilet models, control is most often carried out using a button that needs to be pressed. For those with special needs, a foot pedal may be installed, but this is a rare option.

In recent years, models with a double button have been very popular, which allow you to empty the tank not only completely, but also halfway to save some of the water.

The separate version of the fittings is convenient in that you can repair and adjust individual parts of the system separately.

Combined type fittings are used in high-end plumbing, here the drain and inlet of water are connected into a common system. This option is considered more reliable, convenient and expensive. If this mechanism breaks, the system will need to be completely dismantled for repair. The setup can also be a little tricky.

The fittings for the toilet cistern with side and bottom water supply are different in design, but the principles of setting up and repairing them are very similar

Materials for the manufacture of devices

Most often, toilet fittings are made of polymeric materials. Usually, the more expensive such a system is, the more reliable it is, but this method does not give clear guarantees. There are fakes of well-known brands, and quite reliable and inexpensive domestic products. An ordinary buyer can only try to find a good seller and hope for good luck.

Fittings made of bronze and brass alloys are considered much more reliable, and it is much more difficult to fake such devices. But the cost of these mechanisms will be much higher than that of plastic products.

Metal filling is usually used in high-end plumbing. With proper configuration and installation, such a mechanism functions smoothly for many years.

In bottom-fed toilets, the inlet and shut-off valve are very close. When adjusting the valve, make sure that the moving parts do not touch.

Place of water supply

An important point is the place where water enters the toilet. It can be carried out from the side or from below. When water is poured from the side hole, it produces a certain amount of noise, which is not always pleasant for others.

If the water comes from below, it happens almost silently. The lower water supply to the tank is more typical for new models released abroad.

But traditional cisterns of domestic production usually have a lateral water supply. The advantage of this option is the relatively low cost. The installation is also different. The elements of the lower water supply can be installed in the tank even before its installation.But the side feed is mounted only after the tank is installed on the toilet bowl.

To replace the fittings, they are selected taking into account the option of supplying water to the sanitary tank, it can be side or bottom

The water in the toilet bowl does not shut off. What can be done

29 comments

Hello, such a problem, in the tank at the outlet of the valve, water is leaking all the time. Those. it seems that the float does not press hard enough and the valve does not close, I tried to slightly bend the float so that it pressed harder, but this did not give the desired effect. The toilet bowl is old soviet.

I think that the valve is clogged, I did not check it myself. If it's really a problem with the valve, is it possible to how to fix it yourself??

I ask you to answer quickly, otherwise there is no drain in the toilet and it is possible to call the owner’s door from below)))))

I'll start by answering the question & where does the water drain &. If you look at the photo below, you can see that a tube sticks out in the tank. This tube is the overflow into which water is drained if the supply valve does not close. Thus, the water does not flow to the floor, but to the toilet.

If there is no such overflow tube, then another drain valve may be installed, and the overflow tube is made inside the valve itself. See photo below, arrows show

where does the water go.

If there is no overflow, which is extremely rare, then it is necessary to turn off the water and disassemble the supply valve.

Let's say that you have already unscrewed the flexible hose and removed the supply valve from the tank.

Next, remove the plastic plug:

After that, straighten and remove the &splint& with pliers:

Next, with this hand hold the valve body, and with the other hand, pull the float holder out of the valve body as shown in the photo:

It can be seen that the "lever" with a rubber gasket has pulled out, which locks the water.

If you now look into the valve body, you will see a through hole:

Water passes through this hole into the toilet bowl. And it is this hole that locks the "lever" from which the rubber gasket fell out.

Now we have the task of cleaning this hole if it is clogged. To do this, you will need a thin knitting needle, a large needle, or a suitable wire:

After cleaning, we look at our "lever" with a gasket:

Please note that the gasket is already pressed through. Usually such a gasket can no longer lock water. There are several ways to solve this problem:

There are several ways to solve this problem:

4. Replace the valve.

3. Replace gasket

2. Level the dented area with a knife or sandpaper and carefully stick on a rubber band that can be cut out of a bicycle inner tube.

1. Turn gasket over. This is the easiest method and should be done first.

We take out the gasket from the holder

And turn it over

As you can see, on the other hand, the gasket is even and it will serve for some more.

Now reassemble everything in reverse order and don't forget to insert the &splint& or locking wire.

Here is such a simple thing.

The situation becomes more complicated when the float holder, inside the valve, rots. Then you can not do without replacing the supply valve.

It is not necessary to buy exactly the same, you can buy, for example, this one:

The most important thing when buying is to take a valve with a side feed and not with a bottom one. And then you can't take it all back. )

Typical malfunctions of flush mechanisms for typical toilet bowls

— Water flows and flows without filling the tank. What happens:

- a) the simplest is the skew of the float. In such cases, the float lies at the bottom of the tank. Eliminated easily - a simple adjustment of the toilet flush mechanism is necessary. Often it is enough just to move it in different directions.

- b) but the water continues to flow into the bowl, which means that the shut-off valve or seal does not keep it in the tank. Well, the valve also sometimes warps, let's fix it.

As a rule, these small problems, which occur in 9 cases out of 10, are eliminated without any tool at all - it is enough to remove the lid of the drain tank and fix either the valve or the float by hand.

|  | |

| toilet flush device on the picture | CAREFULLY moved, moved from the "dead center" and earned. HURRAH! |

But even with such simple operations, care must be taken not to break the shut-off valve of the flush mechanism in the toilet. It happens that it is completely worn out and easily broken off gives out an uncontrolled flow of water under pressure

To avoid such a problem, it is necessary to turn off the water supply valve to the toilet bowl.

This is done differently in every apartment. Who has a separate valve for each plumbing fixture, and who has one for everything. .

| Therefore, before disassembling the drain mechanism, it is necessary to check the operation of this valve. After repairing the apartment, these taps work fine, but be careful in old houses. If the faucets are very old, they themselves are the source of the flood. Start spinning it and it won't close. Toilets are distinguished by fastening the tank lid, before removing it, figure out how to do it carefully |

TANK Lids ARE NOT SOLD SEPARATELY! SAVE THEM!

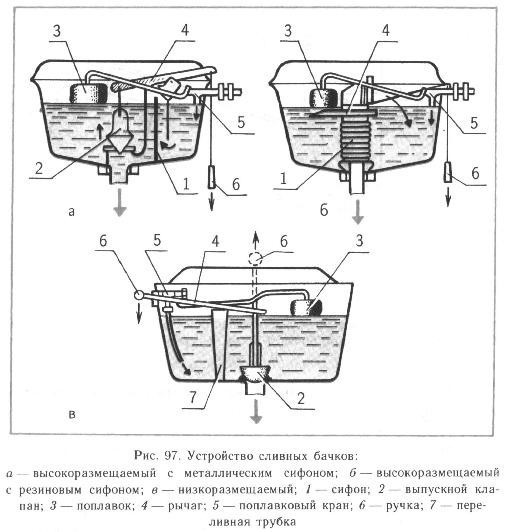

The device and operation of the drain tank

Minor difficulties sometimes occur only with improved modern models, in such cases it is worth contacting specialists. Basically, almost any repair of the toilet cistern can be done by hand.

The device of the toilet cistern is quite simple, and almost anyone can cope with its repair, because. it does not require any special skills

The device of the toilet cistern is quite simple, and almost anyone can cope with its repair, because. it does not require any special skills

In many ways, drain tanks of various designs are similar. The main difference is in the installation method:

- Hanging tanks. Structures of this type are attached to the toilet bowl at a low height and connected with a pipe.

- Toilet bowl compact. The compact cistern is attached directly to the toilet bowl without connecting pipes.

- Built-in tank. Structures of this type are installed in the wall, they are used with hanging toilets.

Regardless of the models, the designs of the cisterns are very similar. Modern devices are convenient in that they can be repaired without disassembling the modules and replacing them entirely

The water supply to the drain tank is carried out either from below or from the side. The side feed device is most often found in domestic-made toilets. Its advantage is a relatively low price, which affects the cost of the entire toilet bowl as a whole.

Bottom water supply is often found in modern domestic and imported designs. Usually these are slightly more expensive models.

Various types of mechanisms can be provided for draining: buttons, rods, levers, chains. The most common option is a button.

It can be located at the top of the structure, and in models with a hidden tank - on the wall.To drain the water, just press it.

Push-button models can only be disassembled after the push-button has been removed. How to remove the lid from a tank of this design is shown in detail in the video:

Buttons in which the water is completely drained after a short single press are called automatic.

Those in which water is drained only while the button is pressed are mechanical. The former are more convenient to use, while the latter save water when flushing the toilet.

There are single and dual-mode push-button drain mechanisms. In models with two buttons, it is possible to drain only half the volume of the tank.

However, there are designs with one button, which in the same way can drain either the full volume of water or half. If the push-button mechanism is equipped with a special auger that causes the water to rotate during the descent, then the toilet bowl is washed more efficiently.

Mechanisms with two buttons are a little more expensive, but the overpayments pay off, because draining in economy mode can reduce water consumption by 20 cubic meters. in year

Mechanisms with two buttons are a little more expensive, but the overpayments pay off, because draining in economy mode can reduce water consumption by 20 cubic meters. in year