- How a well is repaired by professionals

- How to determine what exactly is out of order?

- Cleaning work in the well

- Video description

- Cleaning work with a bailer

- Cleaning work with a vibration pump

- Cleaning work with two pumps

- Preparing for a long downtime and pumping after it

- Restoration of wells with a decrease in production rate: do it yourself or invite specialists

- Common well failures

- The most common methods of resuscitation

- gelling

- Application of ultrasound

- Reopening of wells

- Four ways to clean a well

- Method #1 - flushing with a pump

- Application of ultrasound

- Production casing replacement

- Four ways to clean a well

- Method #1 - flushing with a pump

- Method # 2 - cleaning with a vibration pump

- Method # 3 - using a bailer

- Method # 4 - flushing with two pumps

- In what cases is it necessary to restore a well

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

How a well is repaired by professionals

Determining exactly the problems that have arisen with a filter that is deep is almost impossible.

To solve the problem, you can use one of the methods:

- Cleaning the filter mechanically: with a special metal brush.This is the most gentle method, it is used in the first place.

- Flushing the device with chemicals.

- Water hammer. In this case, water is pumped into the well at high pressure.

Well flushing

How to properly drill a well for water, repair it if necessary, is clearly visible in the video. This article provides a quick introduction to device wipe.

How to determine what exactly is out of order?

The cost and effectiveness of the measures taken to restore the wells depend on how correctly and on time the diagnostics are performed.

If there is no water in the water supply system as such, the automatic unit failed most quickly or the pump failed.

A decrease in water pressure can occur as a result of a breakdown in water distribution equipment. It is imperative to check the impermeability of the joints of the pipeline, make sure that the hydroaccumulation tank is in good condition, etc. If no problems are found, it is worth moving on to inspecting the well.

Carefully inspect the caisson or pit and assess the condition of the casing. If there is a curvature of the casing, you can talk about the presence of big problems. If everything is fine here, the fastest thing to do is to clean or change the filter, wash the well column from sludge.

Key ways to restore water wells:

Hydraulic:

- cleaning of the filter area,

- swabbing,

- cleaning the filter and pipe walls.

- Pulse:

- electrohydraulic shock,

- tdsh explosion,

- pneumatic explosion,

- implosion.

Reagent (cleaning takes place using neutralizers, oxidizing agents and complexing agents).

Vibrating:

- electrovibration,

- hydrodynamic vibration finish,

- ultrasonic finishing.

When performing well workover, the following activities are carried out:

Removing sand plugs:

- gelling,

- cleaning with metal ruffs,

- cleaning with air mixture,

— Airlift cleaning.

Replacement of oil seals and filter columns:

— increase in the diameter of the well,

- replacement of seals

— replacement of the filter column.

Cleaning work in the well

If the location of the well is supposed to be in a summer cottage, used only for weekends in the summer, then it is not worth it. Too laborious and costly. It will be quite enough to have imported (brought) water for a couple of days.

It is quite another matter if agricultural work on growing vegetables is carried out on the site, there is an orchard or a flower garden. Or it is used for long-term residence. In this case, the presence of a constant source of fresh water is simply necessary, because. it is supposed to water the beds, cook food and use it for hygienic purposes.

Own well allows the owner to:

- do not depend on the central water supply;

- always have an uninterrupted supply of water in the required volume;

- use clean water that has passed through natural filters and is saturated with essential trace elements.

Video description

Which option of a well for water to choose can be found here:

However, the presence of these advantages will require the owner of the site to carry out periodic preventive maintenance to clean the clogged device. As a rule, this cleaning is carried out in several ways:

- with the help of a bailer;

- pumping the well with a vibration pump;

- using two pumps (deep and rotary).

The use of these methods presupposes both their separate use and their joint use in turn.It all depends on the weediness and depth of the well.

Cleaning work with a bailer

The bailer (metal pipe) is fixed with a strong iron cable or rope and smoothly lowers to the bottom. When it reaches the bottom, it rises (up to half a meter) and drops sharply. The blow of the bailer under the influence of its weight is able to lift up to half a kilogram of clay rock. Such a well cleaning technique is quite laborious and long-term, but inexpensive and effective.

Cleaning the well with a bailer

Cleaning work with a vibration pump

This option for cleaning the well will be the simplest and fastest. That is why it is considered the most common and has found application even in mines with a narrowed receiver, which is why the use of a conventional deep pump is not possible.

Vibration pump cleaning

Cleaning work with two pumps

This method is characterized by the fact that it does not actually require human participation in the process. The flushing of the well takes place using two pumps that do all the work themselves, but the time spent on this is simply enormous.

Preparing for a long downtime and pumping after it

If a visit to the summer cottage in the winter (or for another long period) is not expected, and the well will not be used either, then you should take care of this in advance. It is necessary to consider preparing the device for inactivity and how to pump the well after a winter or a long downtime.

Preparation comes down to installing a heating cable inside or using any materials at hand to insulate the device.

Well pumping after winter is carried out by standard methods, which are described above, and are used only if necessary.

An example of well insulation for the winter

A private well on your own site is a useful and absolutely necessary thing. However, it will require some periodic maintenance work on cleaning and buildup. The above describes what buildup is, why it is used, which pump to pump the well after drilling, how to do it correctly and in what way, and what are the features of using one or another option. The issues of preparing the device for a long downtime (wintering) and restoring performance after this period are also mentioned.

Restoration of wells with a decrease in production rate: do it yourself or invite specialists

The service life of water wells is limited. Artesian will last longer than a well "for water", but also not indefinitely. It is extremely rare for a source of water to dry up completely and suddenly. A similar phenomenon is associated with the disappearance (drainage) of the aquifer, and in this case, one cannot do without an expensive deepening of the well. But much more often we are talking about a gradual regression of the source: a noticeable drop in productivity, deterioration in water quality. In this case, it is likely that it can be reanimated. There are companies that provide similar services, but you can try to restore the well with your own hands.

Common well failures

If you abandoned a well because you no longer needed a large amount of water, then such a well is the easiest to restore.To do this, you will need to conduct water tests, flush and clean the well and, if necessary, use a special chemical reagent.

If your well broke down, and for lack of funds or time you abandoned it. First of all, it is better to contact specialists who will conduct a complete survey of the well and diagnostics of all systems. They can easily determine the cause of the failure of the hydraulic structure and offer you solutions. The most common breakdowns are:

- blockage;

- Pump malfunction;

- Wear of well string pipes;

- Errors about the installation or design of the well.

First of all, you need to find out the cause of the breakdown.

First of all, you need to find out the cause of the breakdown.

To solve these problems on your own, you first need to diagnose and determine what kind of malfunction caused the entire system to fail.

The most common methods of resuscitation

gelling

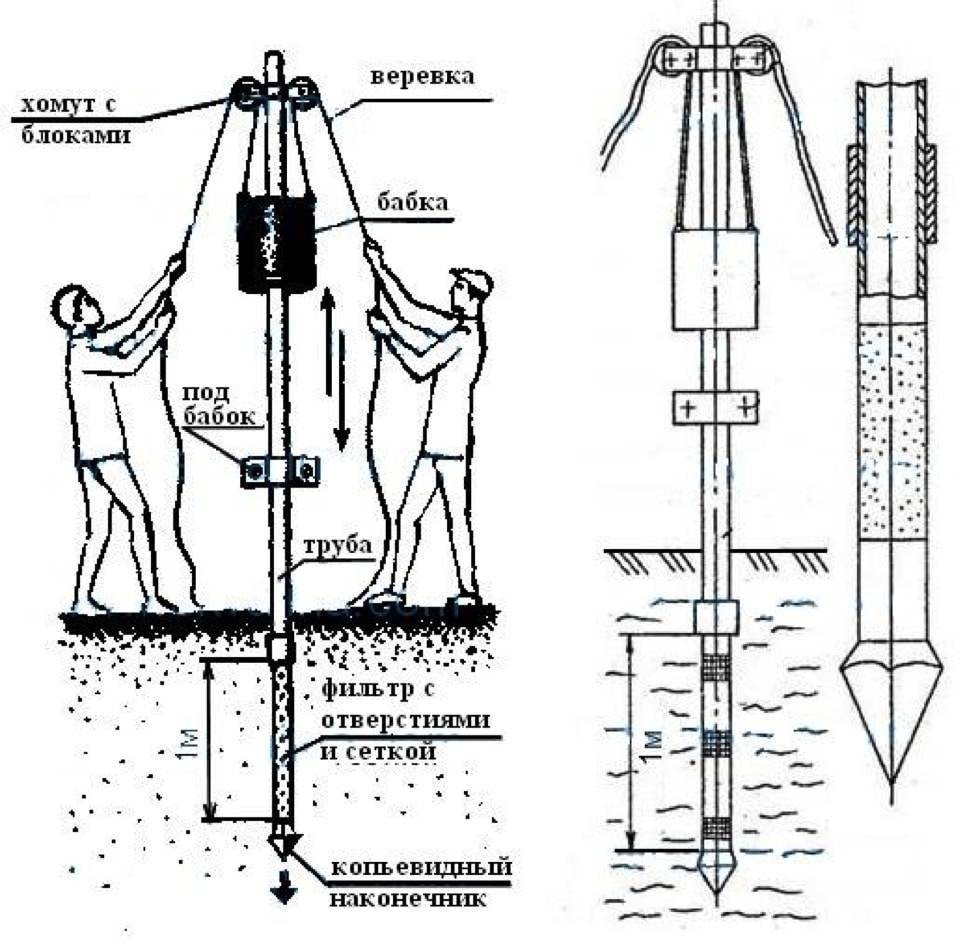

The easiest and easiest way to remove a sand plug is by gelling. The bailer is a steel pipe with a length of 1 to 3 meters with a diameter somewhat inferior to the circumference of the water intake pipe. Sharp baking powder and a check valve are mounted in the lower part of the bailer.

To clean the well, the bailer is lowered to the bottom, then raised (about half a meter) and thrown down again. Actions are repeated several times. As a result, the sand fills the device, which is then raised to the surface and cleaned.

The procedure lasts until the maximum possible amount of silt and sand is extracted. Then it will be pumped with a standard borehole pump until clean water appears.Such a repair is valuable in that all the devices necessary for its implementation can be made with your own hands.

If, after cleaning the well, it was not possible to restore the debit of incoming water, additional manipulations will be required. Most likely, you will have to clean the filter (with a brush, reagents and / or other methods).

Application of ultrasound

Acoustic cleaning of the well is carried out at a frequency of 1 to 20 kHz. It significantly reduces downtime and reduces the cost of filter decolmation. The maximum effect is achieved when using reagent-ultrasonic treatment. It combines the advantages of acoustic and chemical resuscitation.

The trunk of the production string is cleaned before chemical-acoustic treatment using airlift pumping, using a ruff. Then a reagent is fed into the well (through a hose or column), and only after that the pipes with an ultrasonic projectile are lowered. When it descends to the bottom of the filter, ultrasonic treatment and pumping with the help of an airlift begin. The duration of the process (at each interval) is at least 10 minutes. As a rule, as a result, the debit increases by 1.5-2.5 times.

Reopening of wells

Conservation of wells is carried out for the environmental protection of the source. It guarantees a temporary cessation of well operation with the possibility of subsequent restoration of its operation. The conservation act, which is drawn up at the end of the process, belongs to the list of mandatory documents that the owner of the water source must keep.

The reactivation of wells is carried out in agreement with Gosgortekhnadzor. It is produced in the following order:

- Handwheels are mounted on the valves of the X-mas tree;

- Branch pipes - depressurize, pressure gauges - install;

- Remove plugs from flanged valves;

- Christmas trees are tested at pressure and checked for compliance with operating conditions;

- Then the well is washed and put into operation.

Four ways to clean a well

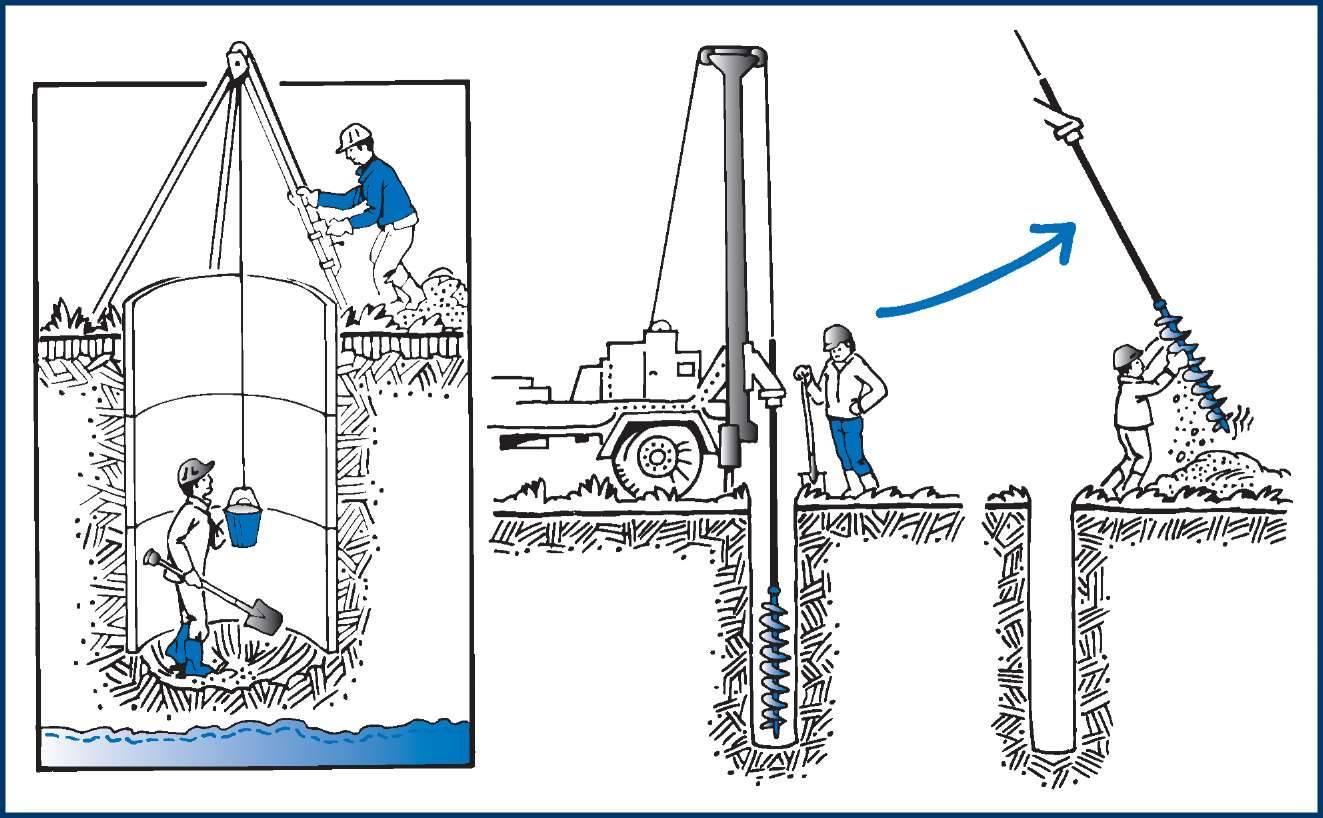

If during the diagnosis it turned out that the problems arose due to silt, then the well can be cleaned independently. To do this, it is washed with water or blown with a compressor.

The easiest option is to pump water. The process takes a lot of time and effort, but the result is worth it. If the filter is not destroyed, but simply contaminated, then it is quite possible to completely restore the productivity of the source.

Method #1 - flushing with a pump

You will have to stock up on clean water in advance. If your own well works poorly, this can become a whole problem, you will need to turn to neighbors for help. Water will require a large container and pump, and finding them can also be difficult.

If these issues are resolved, then you can get to work. The hose is connected to the pump and lowered to the bottom of the well

It is important that it reaches not just to the mirror of water, but almost to the very bottom.

The pump is turned on for pumping water, and it lifts silt and sand from the filter. The wellbore quickly overflows with water, and it begins to gush uncontrollably. Pollution particles are thrown out with water.

Application of ultrasound

Acoustic cleaning of the well is carried out at a frequency of 1 to 20 kHz. It significantly reduces downtime and reduces the cost of filter decolmation. The maximum effect is achieved when using reagent-ultrasonic treatment.It combines the advantages of acoustic and chemical resuscitation.

The trunk of the production string is cleaned before chemical-acoustic treatment using airlift pumping, using a ruff. Then a reagent is fed into the well (through a hose or column), and only after that the pipes with an ultrasonic projectile are lowered. When it descends to the bottom of the filter, ultrasonic treatment and pumping with the help of an airlift begin. The duration of the process (at each interval) is at least 10 minutes. As a rule, as a result, the debit increases by 1.5-2.5 times.

Production casing replacement

One of the most unpleasant breakdowns is the wear of the production pipe. Its replacement is a complex and time-consuming process that requires considerable financial investments. It is best to entrust the work to professional drillers. For self-fulfillment, it is desirable to have the appropriate skills, because. replacing a well pipe is even more difficult than installing a new one when drilling a well.

It is easiest to work if the casing and production structures consist of two pipes of different diameters. In this case, only the production pipe is changed, without touching the casing. If everything is done carefully, performance wells will be restored.

It is better not to start repairing a well with asbestos-cement pipes, because. the material is destroyed under additional loads. This is the case when it is worth immediately starting the construction of a new hydraulic structure. But it is quite possible to replace a metal pipe, even if the material is very rusty.

To dismantle the pipe, it is captured with a loop loop or a special clamp and pulled out using any available lifting mechanism - a railway jack, a truck crane, etc. The main thing is that the device provides the necessary force for lifting.

When the pipe is removed from the shaft, a new one is installed - metal or plastic. Do not use asbestos cement. The material is impractical and potentially hazardous to health. This is confirmed by data from the World Health Organization.

New pipes can be connected with threads or nipples. You should choose high-quality connecting elements with a special anti-corrosion coating. If plastic pipes are chosen, then a strong nippleless connection is provided here. When choosing pipes, you should not save. This is fraught with new breakdowns.

When replacing a production string, a new pipe is selected based on well depth, future loads, material durability, and chemical resistance.

Four ways to clean a well

If during the diagnosis it turned out that the problems arose due to silt, then the well can be cleaned independently. To do this, it is washed with water or blown with a compressor.

The easiest option is to pump water. The process takes a lot of time and effort, but the result is worth it. If the filter is not destroyed, but simply contaminated, then it is quite possible to completely restore the productivity of the source.

Method #1 - flushing with a pump

You will have to stock up on clean water in advance. If your own well works poorly, this can become a whole problem, you will need to turn to neighbors for help.Water will require a large container and pump, and finding them can also be difficult.

If these issues are resolved, then you can get to work. The hose is connected to the pump and lowered to the bottom of the well

It is important that it reaches not just to the mirror of water, but almost to the very bottom.

The pump is turned on for pumping water, and it lifts silt and sand from the filter. The wellbore quickly overflows with water, and it begins to gush uncontrollably. Pollution particles are thrown out with water.

This is one of the fastest and most reliable ways to clean a silty source. If you can’t do the restoration of the well with your own hands, then you can turn to hydrogeologists and sewers. The former will calculate the required water hammer power, while the latter will help with a large volume tank to remove excess water.

Method # 2 - cleaning with a vibration pump

A shallow well can be cleaned of silt and sand using a vibration pump. Small-diameter equipment is often used, for example, devices of the Malysh brand. The pump is lowered into the shaft to the level of the filter, the well is turned on and gently rocked.

The device will lift solid particles, and they, along with water, will come to the surface. Such flushing of the well may take several days, but it will be effective only if the pollution is not severe.

During well cleaning, the working parts of the pump may become clogged with dirt, and the electric motor may overheat. Therefore, it is advisable to take breaks and clean the device from contamination.

The advantage of this method is its simplicity and low cost. Everything can be done by hand, no complicated equipment is required.

Method # 3 - using a bailer

This method is only suitable for shallow wells - no more than 30 m. Assistants, a winch and a bailer are required for work. It is a piece of metal pipe with a mesh top and a washer bottom. The bailer is attached to a long strong cable.

The device is lowered to the very bottom of the well, after which it is raised by about half a meter and sharply lowered again. After several such manipulations, the bailer is removed from the well and cleaned of sand. Usually it is recruited about 0.5 kg.

Not all well owners consider this method of cleaning effective, but most still agree that the bailer helps to cope with silting. The main advantage of cleaning with a bailer is cheapness. If you make a device with your own hands, you can remove the sand almost for free.

Method # 4 - flushing with two pumps

The method is similar to flushing with a pump, but has some differences. Two pumps are required - submersible and surface. Not far from the well, a large water tank (from 200 cubic meters) should be installed, and in it - a home-made filter made from a bucket with a mesh or a women's stocking. A hole is made on the side and bottom of the tank through which water will be pumped using a surface pump.

With the help of a deep pump, contaminated water is pumped into the tank, passing through a filter. The surface pump takes the purified water from the tank and pumps it back into the well. The bucket is periodically freed from sand and silt. The procedure is carried out until clean water without impurities flows from the well.

In what cases is it necessary to restore a well

The decrease in the characteristics of the source can be caused by both improper operation of the well and natural causes. Let's consider what kind of troubles may lie in wait for the owners of wells during their operation, what are their causes, how to avoid or delay them.

The deterioration of water quality in the source can occur for the following reasons:

Contaminants got into the casing (working string) from the surface. This happens when storm or melt water penetrates into a caisson that is not sufficiently protected from the external environment or into an unequipped well.

Water can become cloudy from mechanical impurities, in which case it is enough to pump the source for several hours. Worse, if harmful microorganisms from the surface have penetrated into a clean underground environment. For example, iron oxide bacteria. They and other unwanted "guests" give the water a very unpleasant taste and smell. The infected source will have to be "treated". It helps to disinfect the well with the help of traditional antiseptics: potassium permanganate, hydrogen peroxide. They put the “medicine” in, wait for several hours, wash the well. After a couple of days, it becomes clear whether the desired result has been achieved. As a last resort, if repeated washings do not help, use products containing chlorine. There are also special preparations for disinfecting water pipes, but they are not cheap. At the end of the treatment, the well must be thoroughly washed out for several days.

As a result of corrosion of the steel casing, particles of rust and even soil get into the water if the connections have become loose.Water, as a rule, is transparent, but small solid particles come across in it. Installing a filter from mechanical impurities will help.

To make a more accurate "diagnosis", a laboratory analysis of water should be done. It will allow you to determine the nature of the measures for the "treatment" of the source, to choose the right filter system.

If the problem is not a decrease in the flow rate of the source, but a deterioration in water quality, start well resuscitation activities with a laboratory water analysis

A shallow well, arranged on a perch, can completely dry out during the dry season. After heavy rains or snowmelt, water will reappear. Well productivity "on sand" can also fall depending on the season, but not significantly. If a previously normally operating submersible pump began to “grab air” during long-term drawdown, or dry running protection is triggered, there is cause for concern. The well flow rate is falling and the regression is likely to continue. Up to the point that the source completely becomes unusable. The deterioration of well performance can occur for the following reasons:

Incorrect operation. The well must be pumped regularly. If no one lives in the house and does not constantly use the water supply, several hundred liters of water should be pumped out of it at least once a month. In the case when the source has been idle for many months, the soil in the water intake zone, as well as the filter, begins to clog with tiny particles, “silt up”. Calcium salts settle in hard water, the well is "calcified". Small particles, being motionless, accumulate and are compressed, forming rather solid layers.The pores in the soil and the holes in the filter are clogged, silt can accumulate in a rather thick, indelible sediment at the bottom of the casing. Water stops flowing into the column. For a year or two of insufficiently intensive use, the source can be spoiled. Silting and calcination also occurs naturally, even with proper well operation. But usually this process is lengthy, stretching for decades.

If the filter at the bottom is missing, poorly made or damaged, sand can enter the casing from below. Sand and dirt can also get inside due to leaks in the work string pipe connections resulting from corrosion.

In the case when the reason for the decline in the flow rate lies not in the disappearance of the aquifer, but in the contamination of the source, there is a chance that it will be possible to restore the well with your own hands.

Conclusions and useful video on the topic

Video #1 Demonstration of well silting and presentation of the process of its pumping on its own:

Video #2 How to clean a well with a simple homemade bailer:

Unfortunately, you can never be sure that after restoration, the well will work fully and smoothly.

There are cases when the resuscitation of the well is generally impossible, especially if it is placed on sand, and the filter is not removable. Then it is easier to arrange a new source than to bring the old one back to life, because in the end, the forces and means for this will be spent approximately the same.

If there are problems with a new well, it means that it was originally built incorrectly. The contract with the drilling company usually specifies a warranty period, so you can get its employees to determine the cause of the problem and eliminate it, if possible.

Problems with the pump, filter, silt - this is solvable. But replacing a completely destroyed filter or worn barrel pipes will lead to serious costs with an uncertain result. Here you will have to decide what is more profitable - the restoration of the old well or the construction of a new one.

Tell us about your own experience gained during the restoration of the well, share only the nuances of the work known to you. Please write comments in the box below. Ask questions, post photos on the topic of the article.

Conclusions and useful video on the topic

Video #1 Demonstration of well silting and presentation of the process of its pumping on its own:

Video #2 How to clean a well with a simple homemade bailer:

Unfortunately, you can never be sure that after restoration, the well will work fully and smoothly.

There are cases when the resuscitation of the well is generally impossible, especially if it is placed on sand, and the filter is not removable. Then it is easier to arrange a new source than to bring the old one back to life, because in the end, the forces and means for this will be spent approximately the same.

If there are problems with a new well, it means that it was originally built incorrectly. The contract with the drilling company usually specifies a warranty period, so you can get its employees to determine the cause of the problem and eliminate it, if possible.

Problems with the pump, filter, silt - this is solvable. But replacing a completely destroyed filter or worn barrel pipes will lead to serious costs with an uncertain result. Here you will have to decide what is more profitable - the restoration of the old well or the construction of a new one.

Tell us about your own experience gained during the restoration of the well, share only the nuances of the work known to you. Please write comments in the box below. Ask questions, post photos on the topic of the article.