- Malfunctions of ventilation in apartments

- Ventilation in the bathroom

- Hood in the kitchen

- About the codes of standard breakdowns

- Do-it-yourself ventilation restoration: pros and cons

- Deadlines for eliminating accidents in housing and communal services: standards for malfunctions, accidents, breakdowns

- About major faults

- In case of poor cooling in the room

- Short cycle unit

- Condensate leakage from the indoor unit

- The need for inspections

- The principle of operation of the air conditioner

- Ventilation repair

- The device is very noisy

- The main reasons for the failure of the stove fan

- Furnace brushes worn out or out of order

- The fan runs at maximum speed or does not switch.

- How to perform a resistor test?

- The automatic control heating system does not function.

- Troubleshooting Methods

- 4.1 Characterization of raw materials and finished products in terms of toxicity

- 3.3.6 Coupling defect repair method

- Air duct malfunctions

- Violation of tightness and elimination of leaks

- Duct pollution

- Ventilation chambers, air intake and exhaust shafts

Malfunctions of ventilation in apartments

Exhaust built-in fans are much simpler in terms of design. But their cost is low and it is often easier to buy a new one than to look for parts that have disappeared from circulation.Poor ventilation of the premises may not be due to the operation of the device itself, but to errors in the organization of the exhaust system.

Ventilation in the bathroom

If the ventilation in the bathroom is not working, the air becomes humid and not ventilated, the laundry does not dry well, mold may appear.

Normal ventilation pattern

The reasons may be the following:

- the ventilation hole is clogged with dust and cobwebs;

- foreign objects in the mine;

- the exhaust fan is set to draw air instead of exhaust.

The correct solution to the problem would be to contact the management company. Specialists lower a load into the ventilation shaft to the very apartment in order to break through all the obstacles. In especially neglected cases, a camera is lowered into the mine to determine the location of obstacles. The ventilation shaft is opened from the side of the entrance. You may have to go around the neighbors in the riser and check if they have improperly installed fans that interfere with the hood.

Hood in the kitchen

Exhaust ventilation is designed to remove unpleasant odors and stale air from the apartment. However, if the construction technology is violated or due to other reasons, air begins to enter the apartment from the exhaust opening, despite the fan running.

Air shaft contamination

Because of this, extraneous odors appear in the apartment. Cooking products are not removed from the kitchen. The reasons may be the following:

- defects in the design of ventilation shafts and channels create reverse thrust;

- strong gusts of wind in one direction blow air currents into the mine;

- accumulation of steam masses and frosty air in ventilation;

- pollution of the mine with snow and waste.

As a result, the axial fan draws air masses from one shaft to another and the hood starts to work silently in the opposite direction.

To solve the shortcomings, it is better to invite specialists. They will assess the rationality of using the equipment in accordance with the documentation and conduct a high-quality examination of the installation and operation of the ventilation system. The resulting report will indicate all the shortcomings of the existing system and measures to correct them. Employees of the Criminal Code are required to clean the ventilation shafts from foreign objects. Also get rid of the backdraft effect in hood install a deflector for smoke suction and the creation of through air currents in the kitchen.

About the codes of standard breakdowns

First of all, you need to watch how many times the sensors flash. If it "blinks" only once - most likely, the problem lies in the thermistor, which is installed on the indoor unit of the split system. Two beeps indicate that there is a problem with the outdoor unit. With three flashes, the system starts to work simultaneously for cold and heat.

Overload protection is disabled if the lamp flashes four times. Five times the signal is switched on means the appearance of errors between the blocks in the process of information exchange. Six blinks means that the level of consumption is significantly higher than the norm. It is recommended to carry out additional testing in different parts of the device.

With ten flashes, the travel valve was definitely broken. Finally, switching on 10 times indicates a thermistor that has failed. no longer performs temperature control. Most brands and models of devices experience roughly the same problems.Each device has its own codes, which indicate errors. The instruction will help to identify the malfunction, set the correct settings for stable operation.

Do-it-yourself ventilation restoration: pros and cons

Like many other works, the restoration of arranged ventilation can be done by yourself, or you can trust the hands of professionals. Fortunately, offices that provide such services are not uncommon. And yet, with regard to self-maintenance of ventilation, it is highly undesirable, unless you are an employee of the mentioned offices. The success of a layperson's work is not guaranteed. Not only that, your modest attempts may have a negative impact on your neighbors. It is unlikely that they will let you get away with such inconvenience. And subsequently, your material costs will double.

The only thing that depends on you in this situation is the correct use of the system itself, which prevents the occurrence of such problems.

Deadlines for eliminating accidents in housing and communal services: standards for malfunctions, accidents, breakdowns

- If the drainage systems are subject to leaks (drain tanks, water taps, etc.), then the problem must be eliminated within no more than 1 day.

- Accidents in drainage systems, at pipe junctions, etc. must be repaired immediately upon discovery.

- if the electrical cable, which is the main conductor of energy to the house, is damaged, then such a problem must be eliminated within no more than 2 hours;

- in cases of breakdowns and accidents that can cause the collapse of walls, ceilings, the whole house, employees of special services are given no more than 5 days according to the standards to cope with the problem;

- to correct the operation of a failed elevator, specialists are given 1 day;

- in case of clogging and other malfunctions of garbage chutes, specialists must eliminate the problem no later than after 1 day;

- deadlines for restoring the integrity of glass in the windows of entrances, vents, balconies, etc. make no more than 1 day in winter and 3 days in summer;

- immediately after the occurrence of any problems, the master must begin work in case of accidents on the pipeline and pipe mates, as well as in cases of short circuits in electrical networks;

- any problems with the entrance driveway must be fixed within no more than 1 day.

About major faults

It is not recommended to repair the damage that has occurred on your own. If repairs are made by oneself, and then problems arise, the manufacturer is likely to refuse warranty obligations.

In case of poor cooling in the room

This is usually due to the following reasons:

- Weak power.

- The appearance of internal breakdowns.

Sometimes it happens that the power of the air conditioner is not enough to maintain the temperature in a particular room. An example is due to a sudden change in the climate in which the operation is carried out. The average temperature range is from -7 to +40 degrees. These are the main indicators that apply to all devices.

In other situations, the problem is related to internal breakdowns of the device. It is recommended to immediately contact for technical service, it is also difficult to solve something here on your own.

Short cycle unit

First, the device is turned on, but it stops working literally after 15-20 minutes.

This problem is due to several reasons:

- Dirty radiator.

- Broken thermostat.

- Broken control board.

- Settings failure.

External radiators are exposed to various mechanical damages and loads, especially in the summer. When foreign objects get inside, overheating of the entire system begins. Because of this, all work stops. The problem is eliminated by flushing the radiator, with water and strong pressure. This will help eliminate other breakdowns of air conditioners.

Refrigerant imbalance may occur after charging. It is enough to measure the working pressure of the compressor to understand how severe the problem has become. If there is an overload, excess fluid is simply disposed of.

Condensate leakage from the indoor unit

This is also one of the signals of faulty equipment. This can happen due to a clogged condenser tube.

The fix involves a few simple steps:

- Turning off the air conditioner. You have to wait 10 minutes.

- Disconnecting the plastic drain tube.

- Cleaning and drying.

- Returning the structure to its original position. This often helps if the air conditioner is broken.

The need for inspections

Constant monitoring and scheduled checks of the condition of the ventilation and air conditioning systems are necessary for the timely detection of technical problems, adjusting their functioning according to the required parameters, and for the planned replacement of consumables. Just like a complex system of ventilation ducts of an industrial building, a domestic air conditioner must be regularly and efficiently serviced.This is an essential condition for the operation of ventilation and air conditioning systems, since equipment failure or improper operation can endanger people's health and result in the loss of large amounts of money.

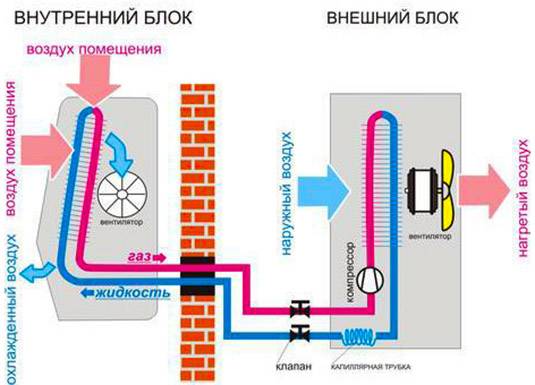

The principle of operation of the air conditioner

To repair modern mobile air conditioners, a different scheme is used compared to wall-mounted climate systems, when it is necessary to restore their performance. For mobile devices, the evaporator and condenser are in the same housing, and split systems always consist from two separate blocks. They are interconnected by an electric cable and copper tubes of different diameters:

- The refrigerant moves through the copper tubes (freon, the brand of which depends on the model of the air conditioner). The gas phase moves along a pipeline of a larger diameter, and liquid freon moves along another route. Each of the pipes during installation is necessarily insulated, since the metal has a high thermal conductivity. At the same time, copper pipelines are durable, easy to bend, solder and straighten without problems.

- The electrical cable is laid simultaneously with copper pipes and drainage. With its help, power is supplied to the outer part of the air conditioner. The cable cross section is selected depending on the performance of the equipment.

- The drain tube is usually made of plastic. Less commonly used rubber product. If necessary, connect the drainage element using adhesive tape or fum-tape. Often, the drainage is additionally equipped with a special heating cable, which is practically indispensable in the winter, since an ice plug can form in the tube.It is she who will prevent the removal of condensate from the indoor unit.

The principle of operation of the air conditioner

The principle of operation of the air conditioner

The condenser and evaporator in the indoor and outdoor units are coils. They are blown with air. To do this, the design has fans. If the air conditioner is operated in winter, then the compressor crankcase of the outdoor unit is equipped with heating, since standard lubricants do not work simultaneously at negative and positive temperatures. So that self-repair of a wall-mounted air conditioner does not have to be carried out too often, a decrease in speed is performed. In winter, when additional space heating is required, the outdoor unit acts as an evaporator. Therefore, in this case, the refrigerant takes heat from the cold outdoor air. However, not all devices are capable of operating in this mode.

The outdoor and indoor unit of the air conditioner have a similar structure. The internal element of the system is additionally equipped with an infrared receiver. It is necessary for the operation of the remote control. The outdoor unit also has a control and monitoring system.

The compressor is always located in the outdoor element. This arrangement allows you to reduce the noise level and carry out heat removal to the street.

A vacuum is formed in the evaporator during the operation of the air conditioner, as the compressor pumps the refrigerant out of it. As a result, the transition of freon into the gas phase is much easier. The gas entering the compressor is compressed. After that, it moves to the condenser. Here, the refrigerant passes into the liquid phase and gives off heat. Heat exchange on the coils of the outdoor and indoor units is accelerated by the presence of fans.At the same time, temperature control is carried out by sensors, the signals to which come from the electrical circuit of the equipment.

Ventilation repair

RESTORATION OF THE VENTILATION BOX

Restoration of ventilation in the apartment is carried out only if there is a certificate of housing and communal services.

This certificate is mandatory for companies involved in the repair of residential and non-residential premises. Includes items of permitted services.

Upon completion of work on the restoration of the ventilation duct (vent block), a copy of it is issued, with the seal of the contractor, an agreement, an act of hidden work and a copy of the certificate of admission to such work. Work on the repair and maintenance of ventilation is carried out only with non-combustible materials. We use a foam block - thickness 50mm (standard wall thickness of the ventilation block). The accelerating tube (satellite-channels) are restored from it. The design is strong and stable enough - at the end of the restoration of the ventilation duct, many apartment owners mount a TV on the ventilation unit, for example.

How to beat the ventilation duct in the apartment

View full album

Photos of works, examples, articles. Comments, discussions, recommendations.

At the moment, groups work in VK and OK.

Publications (articles, photo works) are being prepared in . Come in, all publications and photos are available without registration.

Reviews about our work

Our certificate of housing and communal services No. 7.15.65.17

Group numbers for ventilation and chimney services

(Items in Appendix No. 1 of the Housing and Public Utilities Certificate)

Restoration of ventilation: the cost of work

Partial restoration of the L-shaped air duct - 8,500 rubles.The cost is fixed, includes material costs (delivery, foam block), disassembly-collection (including cutting floor tiles, removal of floor screed at the site of restoration). Taking out the trash.

Works not directly related to ventilation (electrical sockets, dismantling of furniture, switches, etc.) are paid separately, at a contractual cost.

Partial cutout, up to the ceiling (column) - from 10,000 rubles. Depends on the difficulty. There is a cutout on the side of the sink (two walls are mounted) and a cutout on the side of the front door of the kitchen (three walls are mounted).

Completely dismantled ventilation unit - from 14,000 rubles. It also depends on the complexity of the restoration work. The cost may vary depending on the design ventilation unit. The dimensions of the boxes (94X44, 70X35, 90X34) are standard in different series of houses, respectively, a smaller size will be cheaper to restore.

TV cutout - from 3000 rubles. Discussed when calling. The size of the cutout, as a rule, is different for everyone.

The device is very noisy

Since the propeller of the unit, the main task of which is to create an air flow, is made of plastic (not always of high quality), the probability of deformation of the latter is high. This usually happens if the unit is left for a long time in direct sunlight, or near a source of high temperature. When deformed, the balance between the blades is disturbed, which causes strong vibration and noise during normal air flow.

Also, the vibration of the shaft may appear due to the bushing of the plain bearing loosened from long-term operation.

Often, when the device falls, when the blades are spinning, the protective grille is deformed. If a rotating propeller hits it, one of the blades may break.

Summing up, we can say that in different models of fans, the main components and control elements may look different. But the principles of diagnostics and troubleshooting do not change from this.

The main reasons for the failure of the stove fan

There are many more reasons for a breakdown, they arise for a variety of reasons, we will consider the most basic causes of failure, which even an ordinary motorist who is not engaged in professional repairs can eliminate.

Furnace brushes worn out or out of order

In such a situation, you need to disassemble the stove motor and be sure to replace the brushes. To do this, the impeller is removed from the body of the electric motor (it is usually fixed on latches). If the necessary brushes are not in the auto parts catalog, then you can unsolder the old analogues and replace them with identical ones in size. In extreme cases, graphite-copper brushes are filed with a needle file.

Naturally, soldering brushes cannot be done without solder, rosin and a soldering iron. After replacing the brushes, when assembling the electric motor, it is necessary to clean its insides from the wear product of obsolete brushes.

If squeaking or noisy sounds occur during the operation of the fan, it is necessary to lubricate the bushings with a solution of lithol during its repair. To do this, a small portion of the lubricant is placed on the sleeve (its end) and then heated to ensure that it flows inside. With silent operation of the fan, lubrication of its bushings is excluded, since the lubricating solution, retaining dust, turns it into a viscous paste, which makes it difficult for the fans to work.

The fan runs at maximum speed or does not switch.

If the fan only runs at maximum speed, or it is not possible to switch to one of its speeds, this problem is due to bad series resistors used in the electrical circuits on most machines.

How to perform a resistor test?

Additional resistors are checked using a multimeter. The diagnostic process consists in measuring the resistance value of the terminals of this electrical element, as well as comparing the obtained values \u200b\u200bwith the resistor indicators indicated in the instructions for a particular machine. In this case, it is worth checking the condition of the thermal fuse, which can burn out in the event of a short circuit. Sometimes there is a problem associated with soldering the resistor due to its strong heating. A new resistor with identical parameters is selected on the radio market.

The automatic control heating system does not function.

The sources of the problem are the temperature sensor, the sensor that fixes the position of the air-type dampers, the control electrical circuit, and the automatic electronic control module unit. Using the above information, you can easily determine the cause of the failure of the stove fan, and if you have experience with electricity, you can repair this element yourself.

Troubleshooting Methods

In relatively simple systems, a failed component is found based on the results of conventional visual inspection of the condition of the equipment. It is not always possible to detect a malfunction in complex pneumatics, consisting of tens or even hundreds of elements, by a simple inspection. Plus, it takes a lot of time.

Therefore, special industrial techniques are used to search for faulty elements in technically complex pneumatic systems. Their use reduces the duration of defect detection. According to modern approaches, there are two main methods for localizing faulty parts of a pneumatic system.

- Tabular.

It consists in analyzing the pneumatic circuit diagram and compiling a table containing a listing of all elements. According to this table, depending on the nature of the violations, the most correct sequence for checking the system is determined. The use of this method is useful when troubleshooting distributed pneumatic systems.

- Algorithmic.

It involves the execution of a predetermined set of actions or an algorithm, which is compiled based on the results of an analysis of cases of failure of pneumatic systems similar in structure. The method is used for violations of the functioning of typical pneumatic devices, in respect of which the relevant statistics have been collected. The indicated algorithm is usually described in the accompanying document for the device in the "Possible malfunctions" section.

4.1 Characterization of raw materials and finished products in terms of toxicity

Rubber - synthetic butadiene, hazard class - 2; solid and thermoflowing mass from light to brown shades. During processing, acrylic acid is released (Affects the nervous system), melting point 42 degrees Celsius. Work according to safety requirements with the current supply and exhaust ventilation in overalls.

Sulfur - hazard class-2 solid mass of gray color in the form of scales, oily to the touch, melting point 62-69 degrees Celsius; work in biological gloves with the supply and exhaust ventilation turned on.

Technical carbon (soot) — hazard class-3; black powder, highly polluting the skin, work in respirators, goggles, rubber gloves when the supply and exhaust ventilation is turned on, does not burn.

3.3.6 Coupling defect repair method

Couplings are repaired in case of wear or breakage of any part, but most often they are dismantled due to the need to revise or repair the machine. Coupling halves are removed from the shaft using a screw or hydraulic puller. With repeated removal of the coupling halves, the hole for the shaft is gradually worn out, as a result of which the tightness of the fit is violated, which can lead to non-concentricity of the coupling half and the shaft. The initial size of the mounting hole is restored by surfacing by electric welding, followed by boring. With a lot of wear or a small hole diameter, it is bored, a new bushing is pressed in and then bored to the desired size.

When boring, it is necessary to take measures to ensure the concentricity of the hole for the shaft and the circumference of the centers of the fingers or the outer cylindrical surface of the coupling half.

Coupling halves often have finger holes. The following main ways to correct this defect are recommended: reaming holes for fingers of a larger diameter; drilling new holes in the gaps between the old ones if this does not weaken the coupling half (otherwise, the old holes are clogged with plugs and welded).

Coupling cams are repaired by surfacing followed by planing on a machine, milling or manual filing. Worn fingers are replaced with new ones. Minor defects in gear couplings in the form of burrs and dents can be corrected by manual filing. Couplings with heavily worn fingers are completely replaced.

Air duct malfunctions

Air ducts are an integral part of ventilation systems, which are also subject to routine inspections, repairs and cleaning, depending on their technical condition. The main malfunctions of air ducts are a violation of their tightness, as well as a decrease in the cross-sectional area due to dirt sticking to the inner walls of the air line. Maintenance of air ducts is reduced to the elimination of leaks and cleaning of contaminants.

Violation of tightness and elimination of leaks

The duct network consists of many individual units: straight sections and fittings connected by flanges. During the operation of ventilation systems, vibration is inevitable, causing a breakdown in the connections of individual nodes, which leads to the spread of noise and unpleasant odors through the air ducts. This creates an unfavorable microclimate in rooms where people are located. Leaks in the air ducts reduce the efficiency of the entire ventilation system. To eliminate leaks and restore air duct tightness, damaged soft inserts, interflange seals are replaced, damaged sections and elements of the air duct are repaired or replaced.

Duct pollution

During operation, air ducts, filters and other parts of the ventilation system become covered with dust and grease.Moisture condensing on the inner walls of the air duct, in contact with fatty deposits, forms a dense layer of dirt that is difficult to remove. Such a layer can be so thick that it begins to affect the aerodynamic characteristics of the ducts. The deterioration of these characteristics adversely affects the performance of the ventilation system, increases the load on the fan motors, leads to their overheating and increased wear.

Due to pollution of air ducts, the quality of air deteriorates when it is recirculated in the ventilation system. Dirt deposits on the walls of air ducts are an excellent breeding ground for microorganisms such as bacteria, fungi, and pathogens. Microorganisms are not visible to the naked eye, but the risk of disease for people working in rooms with air recirculation is not reduced by this.

The next danger posed by polluted air ducts is the risk of fires starting and spreading through air ducts throughout all rooms of the building. This is especially true for ventilation systems of public catering enterprises (restaurants, cafes, etc.)

Ventilation chambers, air intake and exhaust shafts

Inspection:

checking the tightness of connections of transitions

from the fan to the chamber, as well as

tightness of building structures

with checking of all bolt fastenings;

detection of dents, holes, corroded

seats, color check, thermal and

sound insulation;

checking the tightness of the entrance door;

checking the operation and status of bypass

channels and valves, as well as insulated

valves in supply chambers;

checking the status of the grounds on which

installed ventilation units;

checking the general condition of mines (painting,

thermal insulation, fastenings, detection

damage);

checking the condition of grids, shutters

gratings and umbrellas over mines;

checking the condition of mine passages

through the roof

cleaning grids and louvres on

mines;

checking the condition of the noise suppression devices.

Maintenance:

tightening loose connections with

replacement of flanges and bolts;

replacement of individual places of fencing

chambers in mine structures with repairs

sound and thermal insulation;

rehinging and sealing doors in

cameras, replacement of faulty grids and

shutters in mines;

bypass troubleshooting

channels and valves in chambers and shafts

with repair of thermal insulation and insulated

valves;

replacement of an umbrella over a shaft;

cleaning chambers and shafts from pollution and

rust;

repair of places where shafts pass through the roof;

painting or plastering

repaired places in the cells and

mines, as well as elements, the need

painting or plastering of which

established by inspection.

Overhaul:

replacement or repair of more than 50% of all

structural elements of chambers and shafts;

replacement of bypass and intake valves;

repair of noise suppression devices;

complete painting of the chamber and shaft.