- Typical malfunctions and repairs

- How to disassemble

- How is the “Water Cannon” arranged and working?

- 2 We repair the pump depending on the manufacturer's model

- 2.1 Do-it-yourself pump repair Dzhileks Vodomet - video

- How the product works

- Device

- Areas of use of pumping equipment

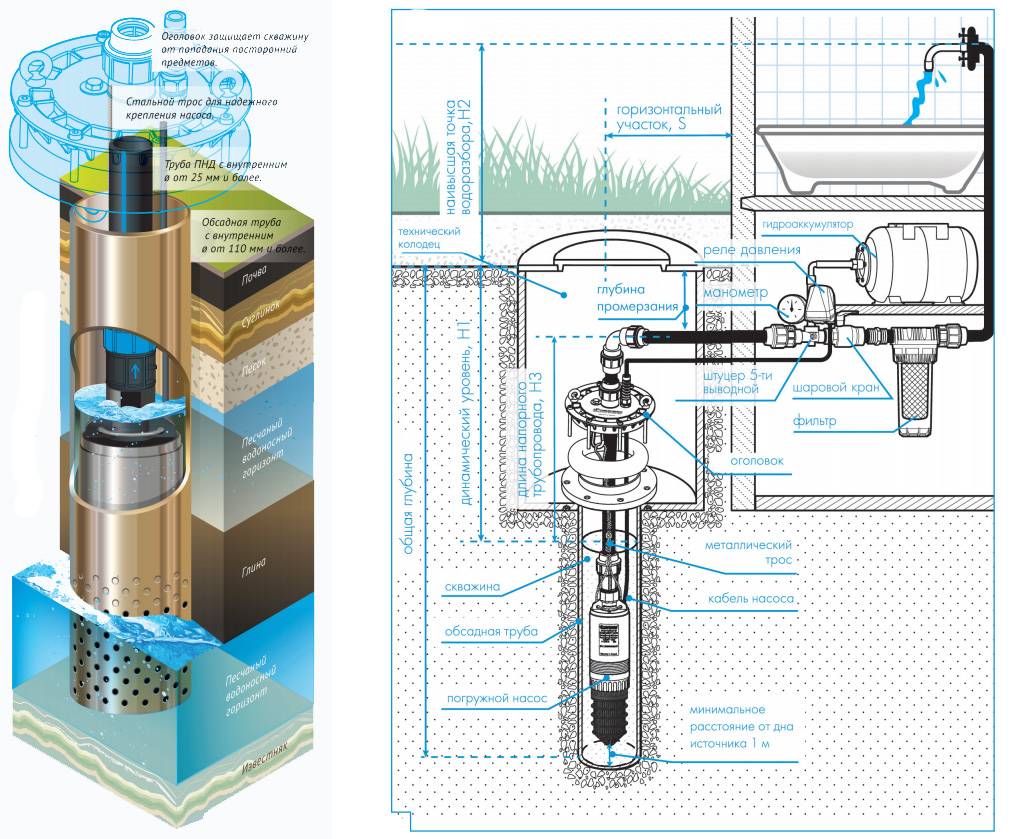

- Water supply from a hydraulic structure

- Temporary replacement

- Filling heating systems

- Fluid pumping

- The main malfunctions of submersible pumps

- The pump is not working

- The pump works but does not pump

- Low machine performance

- Frequent switching on and off of the device

- Water is supplied with pulsation

- The buzz of the machine is heard, but the water does not pump

- The unit does not turn off

- The most common pump failures and how to fix them

- Typical breakdowns of pumps of different brands

- We disassemble the pump "Vodomet" using the example of model 60/52

- Pump disassembly

Typical malfunctions and repairs

If the Vodomet pump is under warranty service, the easiest way to solve all problems is at a service center. But when the deadlines have passed, owners usually prefer to save money and do the repairs themselves. Some operations, such as replacing worn impellers, are easy to perform.

But if you need to rewind the engine, it is better to entrust this matter to specialists.As for spare parts and components, they can be purchased without any problems and at a very reasonable price.

The company "Dzhileks" willingly sells spare parts for its products. They are sold both in specialized stores and in service centers. You can also contact the manufacturer directly.

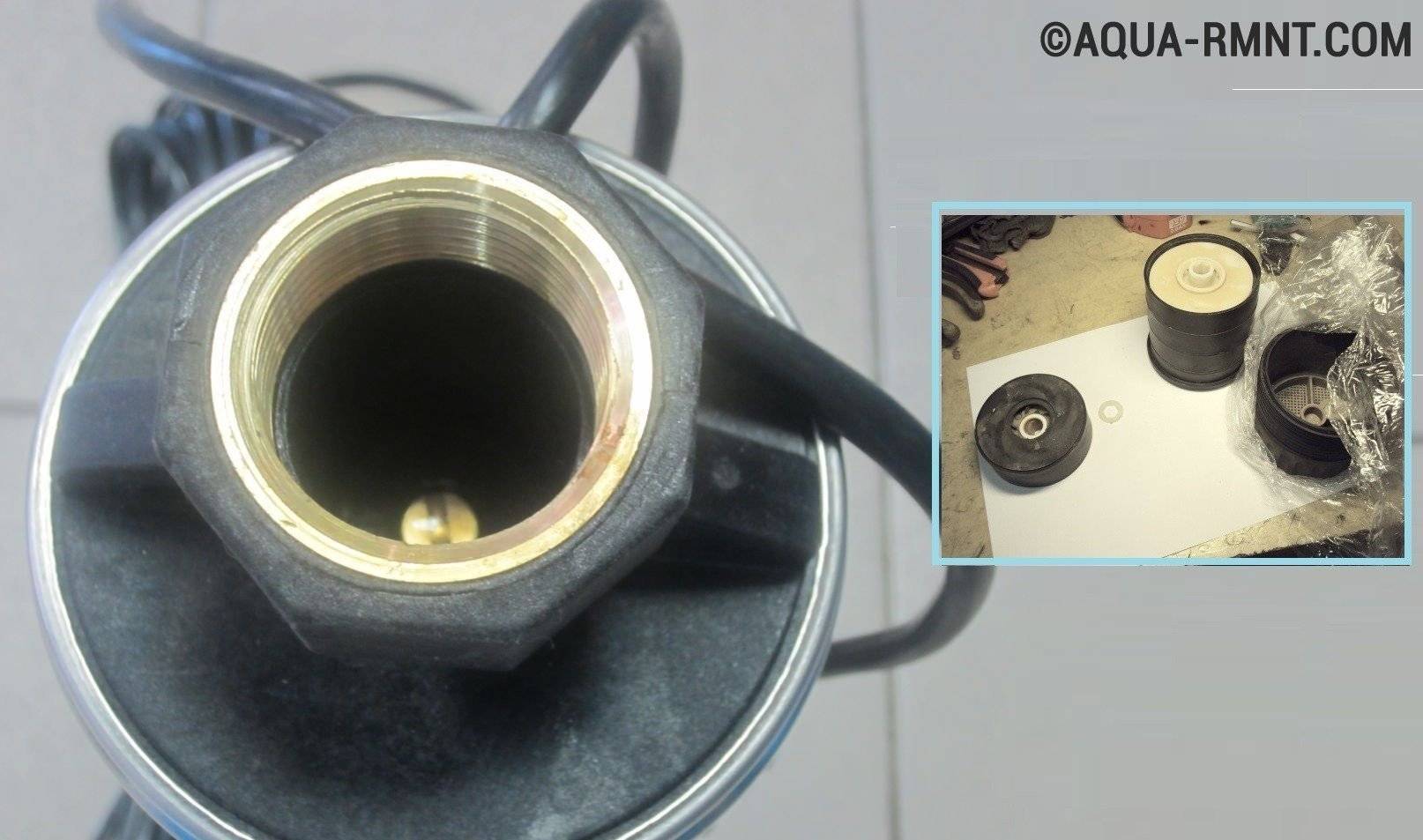

This is how the result of water penetration into the engine compartment looks like, if for some reason the case is poorly sealed - the capacitor is damaged, it should be replaced

By the nature of the breakdown of the device, one can roughly judge what kind of repair work will be needed.

Here is a list of typical problems that owners of Vodomet pumps have to face:

- The device does not turn on.

- The pump housing is energized.

- The pressure of water in the system has noticeably decreased.

- The pump works unevenly, making sounds uncharacteristic for normal functioning.

And here is a list of malfunctions that are typical for these symptoms and ways to eliminate them:

- The motor winding burned out. It will have to be completely replaced.

- Loose contact or broken wire. It is necessary to open the motor housing, restore the connection with the contacts and / or the integrity of the electrical cable.

- The integrity of the engine housing is broken. As a result, the capacitor got wet, it should be replaced with a new analogue.

- The impellers are worn out. It is necessary to disassemble the pump and replace them with new elements.

Of course, if the pump is already removed from the well for repair, it makes sense to carry out a complete diagnosis of the unit. The pump is disassembled, gaskets, washers, glasses, impellers and other elements are inspected. If signs of wear are noticeable, you should immediately take care of replacing such elements.

Then it makes sense to disassemble the engine, test the condition of the contacts and the supply wire. If necessary, locate the damaged cable and reconnect. Sometimes it is worth completely replacing the power cord.

Problems with a damp capacitor are usually obvious even from the outside. Soldering a new capacitor is usually not difficult, but during reassembly, the cause of the malfunction should also be eliminated, i.e. ensure sufficient tightness of the motor housing.

The burnt motor winding, as already mentioned, will be difficult to perform correctly at home. This operation can be ordered at the factory, and all other work can be done independently. This makes repairs cheaper. In some cases, it is easier and more reliable to replace the engine with a new device.

When the engine is depressurized, a situation is observed that experts characterize with the word “emulsion”. This means that water got into the engine case and mixed with the oil, turning it into an emulsion. The oil must be drained and completely replaced.

In no case should this fluid be replaced with some ordinary engine oil. The only suitable lubricant for Vodomet pumps is pure glycerin. The fact is that in the event of a breakdown, oil can get into the well and significantly spoil the quality of the water. It is very difficult to get rid of such pollution.

How to disassemble

First, turn off the power, then dismantle, disconnect the pressure pipeline and disassemble it:

- remove the coarse filter;

- disconnect the motor part from the hydraulic.

Dismantling the hydraulic unit:

- the hydraulic part is clamped with a vice on the pressure pipe;

- the case is unscrewed;

- all parts are removed from the shaft;

- if necessary, change worn or broken;

- the parts are washed, then assembled on the shaft.

Motor disassembly:

- it is installed with the lid up;

- the cover is unscrewed, the sealing gasket is removed;

- oil is drained;

- using a press, the lower cover of the motor is pushed down, the retaining ring is released, then removed;

- with light blows of a mallet on the end of the shaft, the bottom cover with the rotor is knocked out;

- the motor rotor with bearings is removed;

- if replacement is necessary, the bearings are removed from the shaft and the oil seal from the top cover of the motor;

- windings are checked; if necessary, the stator is sent for repair. Assembly is carried out in the reverse order.

How is the “Water Cannon” arranged and working?

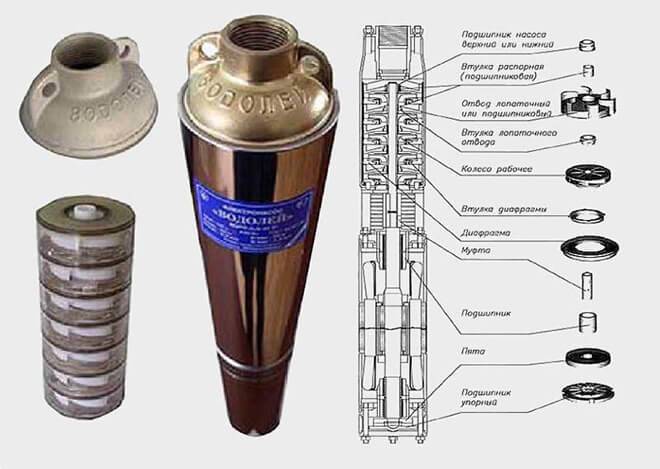

The device of the centrifugal pump "Vodomet" is somewhat more complicated than that of the vibrational "Kid" or "Brook". In the lower part of the unit there is a sealed oil-filled engine, on the shaft of which peculiar glasses are put on - elements with working floating wheels.

Depending on the power of the pump, there may be more or less such glasses. The top cover of the pump presses all these elements and holds them in the correct position. An electric cable comes out of this cover, a pipe for supplying water to the water main and lugs for hanging the pump.

The pump "Vodomet" is a reliable technique with high efficiency. Its design allows you to perform many repairs at home

Floating impellers are the highlight of this unit. At the very beginning of work, they are ground to the structure by grinding a plastic shoulder. As a result, a minimum gap is formed between the static and moving elements of the device. This design ensures high pump efficiency.

Another advantage of floating pump wheels is the ability to pass sand particles that enter the well during natural sanding processes. Pump models of the “Vodojet A” type are arranged in a similar way.

They are additionally equipped with a float switch, which is designed to turn off the device in case of an emergency. For example, if the source has dried up for some reason water (low debit, flooding, etc.).

If the installation and operation of the Vodomet pump was carried out in accordance with the manufacturer's recommendations, there will be no need for premature repairs

The downhole pump "Vodomet", despite the lack of such protection, works quite well, but it is very important to install it correctly in the well. It can turn on/off every three minutes without compromising structural integrity

To prevent the situation with the occurrence of "dry running", which is detrimental to any pump, you should choose the right model, hang it at the right height, etc.

An additional element extends the life of the device, but requires additional space for placement. For this reason, Water Jet A ”is usually used not in wells, but in wells. But this model has to be repaired in approximately the same way as a well pump.

Another feature of the submersible pumps "Vodomet" is bottom water intake. The design allows the pump to be used in a semi-submerged state. If you need to completely empty the container, the Water Cannon will do the job perfectly.

But in a filter well, it is not always useful to place the pump in this way. The device will constantly pick up sand from the bottom.This negatively affects both the quality of water and the condition of the impellers of the device.

To prevent a problem of this nature, home-made nozzles are put on the bottom of the pump to prevent sand from entering the device.

It is necessary to position the unit in the well so that there is at least 1 m between the bottom of the working and the bottom of the pump.

The water cannon is designed for pumping water with temperature from +1 to +35 °C. It is not recommended to violate the temperature regime for its normal operation. And you can’t turn on the unit more than 20 times a day.

In order to avoid premature wear and breakage, it is impossible for the Water Cannon to work without water. The device must be grounded. It is necessary to include an RCD in the network, which turns off the device in case of current leakage more than 30 mA.

This is interesting: Do-it-yourself pumping station repair - popular malfunctions

2 We repair the pump depending on the manufacturer's model

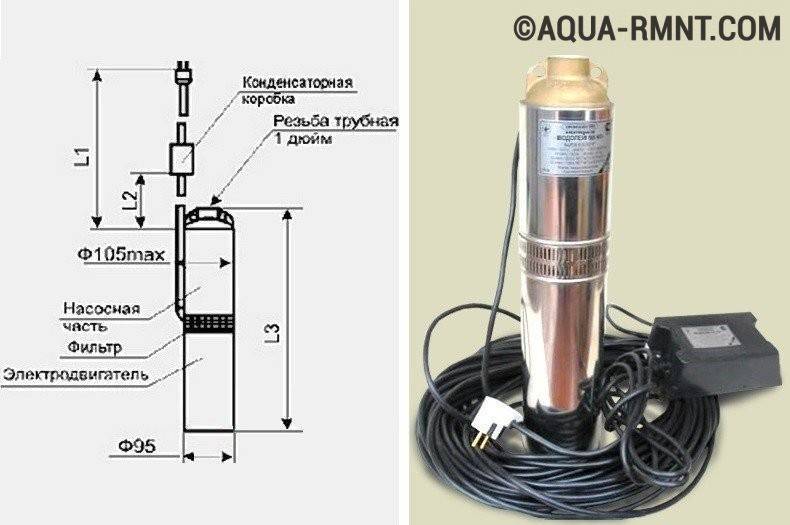

The time has come to consider the actual pumping equipment. Here it is necessary to distinguish between the repair of a submersible pump and the repair of a surface unit. First, consider the common model of the Water Jet pump. Such a pump Water cannon related to the submersible model is available in several positions and configurations.

For example, configurations such as 40/50, 55/35,110/110. The main difference between them is the size and equipment. As a result, they have the same design. You need to start repairing the Water Jet pump by disassembling it. To do this, the Vodomet pump is removed from the well, it must be turned off from the network and only dry it needs to be repaired.

Drainage pump Gileks

Disassembly steps:

- As mentioned above, dry the pump, then carefully remove the housing and cover on the pump.

- Next, using a vice, remove the water intake mechanisms. Everything is done carefully, since the body of the unit is hollow.

- After that, you need to disassemble the pumping part, and if you find a breakdown there, then it will not be difficult for you to fix it at that stage with your own hands. If not, then move on to the engine.

- In order to remove the engine, you need to carefully remove the snap ring, since it is plastic, and it will not be damaged.

- Then, as soon as we got to the engine, we gradually pull out the wires, inspect them for burnt wires.

- After that, if everything is fine, you need to pour non-toxic oil into the engine and assemble the unit in the same order as it was disassembled.

For these cases, glycerin is suitable, it does not pollute the water. And after that, in disassembled troubleshoot pump very easy with your own hands. If you notice broken contacts, then it is better to solder them, or wipe them with an alcohol solution. And if the contacts are broken at all, then it is better to replace them.

If the problem is in the engine, then it is better not to repair it yourself, but to give it to a specialist who can give you a guarantee for its work in the future. As a result, we see that repairing the Water Jet pump is easy and will not be difficult for you. And most importantly, it does not matter what type of Water Cannon you have chosen, since the principle of spare parts and the device are almost the same.

Dzhileks Vodomet downhole pump

According to a different principle of repair, a surface pump of the Gileks Jumbo type operates. Here it is much more complicated, and it is necessary to solve specifically the breakdown. If your pump is malfunctioning, then you definitely need to repair it, remove the housing and check all systems one by one.

Stages of work:

First, you need to turn off the pump and accumulator from electricity 220 watts.

Then drain the liquid that remains in the hose.

We remove the housing by unscrewing the bolts.

Be sure to remove all moving parts of the housing, and only then disassemble the pump chamber.

After that, remove the impeller and seals.

Carefully pull out the engine.

Now let's look at the wires. And after that, if everything is fine, we assemble the pump in the same sequence as we disassembled it .. The advantage of surface pumps is that their body is not solid, and can be removed in parts

Details in it are turned off and not removed sequentially, which is a plus. Did you disassemble the pump and see a problem with the impeller and consumables? They are not repaired, but completely replaced with new ones.

The advantage of surface pumps is that their body is not solid and can be removed in parts. Details in it are turned off and not removed sequentially, which is a plus. Did you disassemble the pump and see a problem with the impeller and consumables? They are not repaired, but completely replaced with new ones.

If you decide to look at the contacts, it is better to get there through the engine's camera. To disassemble the accumulator, the hose is first disconnected, and then the plates are already removed by unscrewing. Pull out the membrane and inspect it.

2.1 Do-it-yourself pump repair Dzhileks Vodomet - video

How the product works

When the unit is connected to a power supply with a mains voltage of 50 Hz, the armature is attracted to the core. Every half period, it is thrown back by the shock absorber. Thus, for 1 period of the current wave, the attraction of the armature occurs twice. Therefore, in 1 second it is attracted a hundred times.There is also frequent vibration of the piston located on the rod with the anchor.

Stream pump without housing

Due to the volume limited by the valve and piston, a hydraulic chamber is formed. Actions in it are springy due to the elasticity of the pumped medium containing dissolved air, and the vibrations of the piston. While the water is pushed into the pressure pipe, and the spring is unclenched-compressed, the valve ensures the entry of liquid and through the suction holes - its exit.

The Brook pump in the kit has a nylon cable used for its fastening and installation. The cable protects the consumer from electric shock in the event of insulation breakdown, as it does not conduct current.

Device

Deep pump device. (Click to enlarge) Before proceeding with repair work, it is necessary to carefully consider the device structure, the principle of operation and the main malfunctions.

This will make it easy to disassemble. For the water supply of private houses, centrifugal and vibration deep pumps are often used.

The first option is often used in wells, while vibration units are used in wells.

Deep centrifugal unit consists of the following elements:

- housing, for the manufacture of which high-strength material is used;

- an electric motor that ensures the operation of the unit;

- an impeller that creates centrifugal force that pushes water into the pipeline;

- bearings;

- cooling system and o-rings.

As for vibration pumps, they consist of the following structural elements:

- body made of the same durable material;

- electric motor;

- working piston;

- high power electromagnet;

- shock absorbers and other small parts.

Each of these units has its own principle of operation. Having information about the structure and principle of operation of the equipment, if necessary, it can be easily disassembled and repaired. Of course, we should not forget about the build quality. Often this parameter is of great importance in the operation and life of the equipment.

Specialist's note: It should be noted that vibration pumps are characterized by low cost and reliability in operation and are capable of pumping water of any quality.

Areas of use of pumping equipment

The submersible pump Strumok is widely used for domestic and household purposes:

- water supply from a hydraulic structure - a well or a well;

- temporary replacement of the main pumping equipment;

- irrigation works;

- filling heating systems before starting work;

- pumping liquid from water receivers;

- organization of an autonomous water supply system using a single water distribution point.

Water supply from a hydraulic structure

Such devices provide timely water supply for a country house, cottage or bath. True, the low performance of the pump will allow you to alternately use the water distribution point - for showering, washing dishes or washing. In this case, the water pressure is determined by the depth of the water intake column, the deeper the structure, the less pressure. You should not connect an electric pump of this type to several buildings at the same time, this can lead to a reduction in the working life and overloads of the system elements.

Temporary replacement

To provide an autonomous water supply system in a private household, the owners install powerful pumps.If the main equipment fails, the repair of which will take a lot of time and money, a simple Creek will become a fallback option. Even the low performance of the device will satisfy the basic needs of consumers.

Filling heating systems

In the process of building houses, the creation of autonomous heating systems is carried out earlier than the supply of water. Compact pumps are used to fill the water pipes. All work is carried out in the following order: a large volume container is filled with water, the first hose is lowered into it to supply water from pumping equipment. The second hose is connected to the tap on the radiator. When the tap is opened, the pump starts and the system is filled. A manometer is used to determine the pressure level.

Fluid pumping

Often, a vibration pump is used to pump liquid and effluent from receivers and flooded technical rooms. The equipment allows you to remove excess water automatically without the involvement of additional equipment.

The main malfunctions of submersible pumps

If failures are noticed in the operation of a submersible pump, then it is not always necessary to remove it from the well for inspection. This recommendation applies only to pumping stations in which a pressure switch is installed. It is because of him that the device may not turn on, turn off or create poor water pressure. Therefore, the operability of the pressure sensor is first checked, and after that, if necessary, the pump is removed from the well.

Water pump malfunctions it will be easier to diagnose if you first familiarize yourself with the most common breakdowns of this unit.

The pump is not working

The reasons that the pump is not working, may be the following.

- The electrical protection has tripped. In this case, disconnect the machine from the mains and turn on the machine again. If it knocks it out again, then the problem should not be sought in the pumping equipment. But when the machine is turned on normally, do not turn on the pump anymore, you must first find the reason why the protection worked.

- The fuses have blown. If, after replacement, they burn out again, then you need to look for the cause in the power cable of the unit or in the place where it is connected to the mains.

- An underwater cable has been damaged. Remove the device and check the cord.

- The pump dry-run protection has tripped. Before starting the machine, make sure that it is immersed in the liquid to the required depth.

Also, the reason that the device does not turn on may lie in the incorrect operation of the pressure switch installed in the pumping station. The start pressure of the pump motor needs to be adjusted.

The pump works but does not pump

There may also be several reasons why the device does not pump water.

- Stop valve closed. Turn off the machine and slowly open the tap. In the future, pumping equipment should not be started with the valve closed, otherwise it will fail.

- The water level in the well has dropped below the pump. It is necessary to calculate the dynamic water level and immerse the device to the required depth.

- Check valve stuck. In this case, it is required to disassemble the valve and clean it, if necessary, replace it with a new one.

- The intake filter is clogged. To clean the filter, the hydraulic machine is removed and the filter mesh is cleaned and washed.

Low machine performance

Advice! If the performance of pumping equipment drops, the mains voltage should be checked first. It is because of its reduced value that the engine of the unit cannot gain the necessary power.

Also, performance degradation causes:

- partial clogging of valves and valves installed in the water supply system;

- partially clogged lifting pipe of the apparatus;

- pipeline depressurization;

- incorrect adjustment of the pressure switch (applies to pumping stations).

Frequent switching on and off of the device

This problem occurs if the submersible pump is paired with a hydraulic accumulator. In this case, frequent starts and stops of the unit can be provoked by the following factors:

- in the hydraulic tank there was a decrease in pressure below the minimum (by default it should be 1.5 bar);

- there was a rupture of a rubber pear or diaphragm in the tank;

- the pressure switch is not working properly.

Water is supplied with pulsation

If you notice that the water from the tap does not flow in a constant stream, then this is a sign of a decrease in the water level in the well below the dynamic one. It is necessary to lower the pump deeper if the distance to the bottom of the shaft allows this.

The buzz of the machine is heard, but the water does not pump

If the pump is buzzing, and at the same time water is not pumped out of the well, then there may be several reasons:

- there was a “gluing” of the impeller of the apparatus with its body due to long-term storage of the device without water;

- defective engine start capacitor;

- dipped voltage in the network;

- the impeller of the pump has jammed due to dirt collected in the body of the apparatus.

The unit does not turn off

If the automation does not work, the pump will work without stopping, even if excessive pressure is created in the hydraulic tank (seen from the pressure gauge). The fault is the pressure switch, which is out of order or incorrectly adjusted.

The most common pump failures and how to fix them

Under the moon, as you know, nothing lasts forever, including submersible pumps. Here are the reasons that most often lead these units to an inoperable state:

- Breakdown of one of the elements of the electromagnet (for vibration pumps): here, as a rule, there is nothing to do with your own hands. The pump needs professional repair.

- Clogging with mechanical contaminants: the water entering the pump often contains grains of sand and other particles that can accumulate in various components. This can lead to wear of some elements or their jamming. If wear has not reached a critical level, rinse the unit well enough.

- Overheating: the reasons for this phenomenon may be the lack of oil or the pumping of a medium with a temperature exceeding the value indicated in the passport (usually 40 degrees). In this case, the method of troubleshooting will depend on the results of the diagnosis.

Most often, failures occur in the operation of a time relay and a safety switch that operates at an over-permissible current value.

A break in the core of the supply cable or an open/short circuit in the motor winding may also occur.

Typical breakdowns of pumps of different brands

The equipment of popular domestic and foreign brands has its own characteristic breakdowns.The devices of the Danish manufacturer Grundfos, despite their reliability and endurance, need regular replacement of mechanical seals. If this is not done in a timely manner, water will penetrate inside and damage the winding.

It is not advisable to service the unit at home. The specific design requires that repairs be carried out by a specialist with experience, ideally an employee of a company service center.

A pronounced buzz and a head that has fallen to a minimum indicate that the impeller has worn out or has shifted along the axis in the pump. The device must be disassembled, cleaned of sand, replaced damaged elements and installed new seals

Gilex units often leak motor fluid. Replacing it is possible, but only with a similar composition.

Some masters believe that it is not necessary to buy an expensive substance. You can get by with glycerin or transformer oil. However, this is not the best advice. The equipment does not tolerate filling with alternative means very well and can completely fail after such an operation.

It is better not to repair the device yourself, but to entrust this task to qualified specialists. They are guaranteed to fill the engine with the original composition and do it in strict accordance with the wishes of the manufacturer. After service, it will work as well as on the first day of purchase.

Wear of the seals is indicated by a low oil level in the pump motor. It is best to replace them as soon as possible. This will keep the motor from overheating.

In devices "Kid" of the Russian enterprise Livgidromash, coils often fail. Provokes this trouble work "dry".A strong noise heard when turned on without pumping out water indicates a break in the central axis, to which the membranes with an anchor are attached. This breakdown is easy to detect after disassembling the unit.

Replacing the axle even at home is not difficult. But finding a part for sale is really a problem.

Aquarius pumps tend to overheat. This disadvantage is especially active when the equipment works in shallow wells. Repairs are expensive and sometimes amount to about 50% of the original cost. Many users in such cases prefer to buy a new device, however, from a different manufacturer.

The same problem is typical for the Brook models. Despite the modern design and compliance with current European standards, they do not tolerate continuous operation.

The manufacturer says that the devices can continuously pump water for no longer than 7 hours. However, almost always such a load leads to overheating. In order to avoid problems, it is better to take breaks and let the equipment rest every 2-3 hours. In this way, the life of the pump can be extended.

Do not start water pumping devices when the shut-off valve is closed. In the future, this will lead to breakdown of pumping equipment. Valve must be opened before turning on.

Pumping equipment "Vodomet" is considered quite reliable and operationally stable. Most of the breakdowns here are due to misuse. Also, equipment in contact with contaminated water quickly becomes clogged with silt and sand. In this case, the pumping part of the unit needs to be replaced.

When a problem that has arisen cannot be solved at home, it is worth seeking help from professional masters of a certified service center. They will quickly determine what happened to the equipment and restore its performance. Or recommend to buy and install a new pumpif the old one cannot be repaired or it is not economically viable

The pump is clogged with sand and does not pump water. How to deal with one of the most common problems of pumping equipment will tell the following video:

We disassemble the pump "Vodomet" using the example of model 60/52

Several models of Vodomet pumps are suitable for wells: if the static water level is not more than five meters, then these are models 60/32 and 150/30, and if from five to twenty-five, then 60/52 and 150/45.

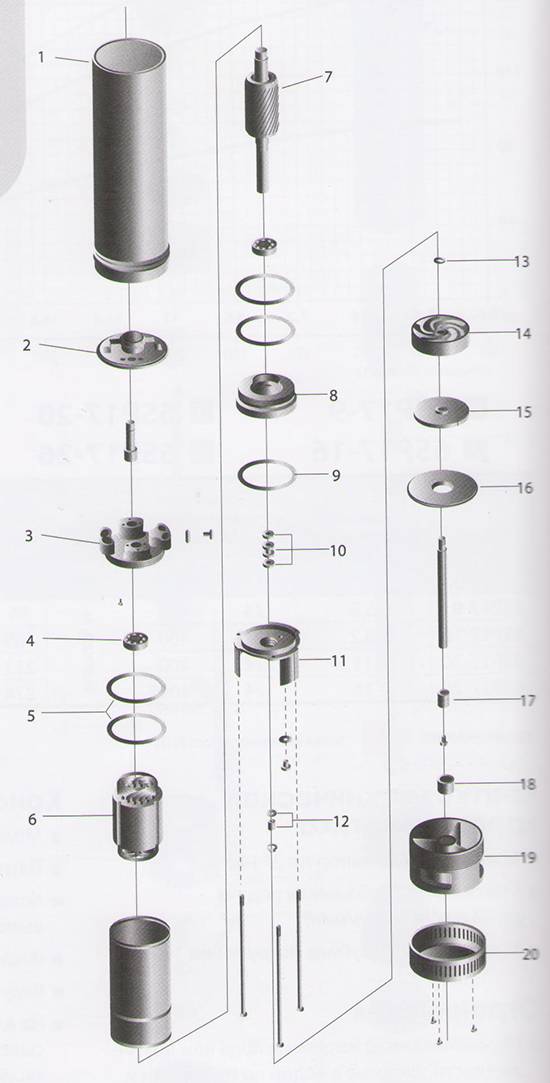

The pump must be disassembled carefully, numbering all the parts along the way and recording the order in which they were installed.

We will analyze the repair procedure using the example of the Vodomet 60/52 pump. We start by disassembling and removing all the parts:

Unscrew the cover with water intake holes

If you have to clamp the body in a vise, you need to do this carefully, since it is hollow inside. It is better to enclose dense rubber on all sides;

We disassemble the pump part (washers, "glasses" with a bottom, an impeller and everything else)

All parts removed from the shaft must be carefully laid out in order to install them later in the same order;

We take out the retaining ring (white plastic) and the engine from the outer "glass". To do this, the pump is placed vertically on the table, which has a hole for the shaft. On the top fitting cover, you need to tap lightly with a rubber mallet so that the engine moves the ring a little.Trying to pull it out through the thread is not worth it, it still will not work. Then we put the pump horizontally, pull the cable a little and pull the engine back. Next, on one side, you need to rest against the white ring with a long screwdriver and hit it so that it moves a few degrees. We unfold it with our hands across the pipe and remove it from the body. In the same direction, you need to remove the engine;

We remove the cover of the compartment in which the wires are located. It is held in place by two rubber bands. We put the engine on its side and, using a wide screwdriver and a rubber mallet, carefully knock it out in a circle.

Only non-toxic oil can be poured into the pump motor so as not to poison the water in the well in the event of an accident. As a rule, glycerin is used. 0.5 liters is enough to replace

Pump disassembly

Disassembly of the pump is usually not very difficult.

After lifting the device from the well, blow out the outlet fitting, removing any remaining water from the pump. All mating parts of the apparatus should be marked with a marker in order to install them in the exact position during assembly. Then we proceed to disassemble the case, holding it in a vice for the ledges near the screws. The screws that tighten the two halves of the body (4 pieces) should be loosened evenly. After removing the cover, a vibrator is removed from the housing - the main working unit of the pump.

By unscrewing the fixing washer located on top of the vibrator, you can disassemble the entire assembly. All components are strung on the central rod one after another, like rings on a children's pyramid. The main thing is to remember the correct sequence of all these parts when disassembling the vibrator. To do this, it is recommended to capture each stage of dismantling on a phone camera.