- How to proceed

- Check power supply parameters

- Check grounding

- Check the potential on the metal part of the boiler

- Check boiler settings

- Check more

- Supply voltage

- Burner status

- Chimney

- Electronic board

- Error E10

- Flame control sensor malfunction (baxi e01)

- Frequent malfunctions and measures for their elimination

- Characteristics of Baksi boilers

- Important nuances

- Advantages and disadvantages

- Varieties of models

- Step 1

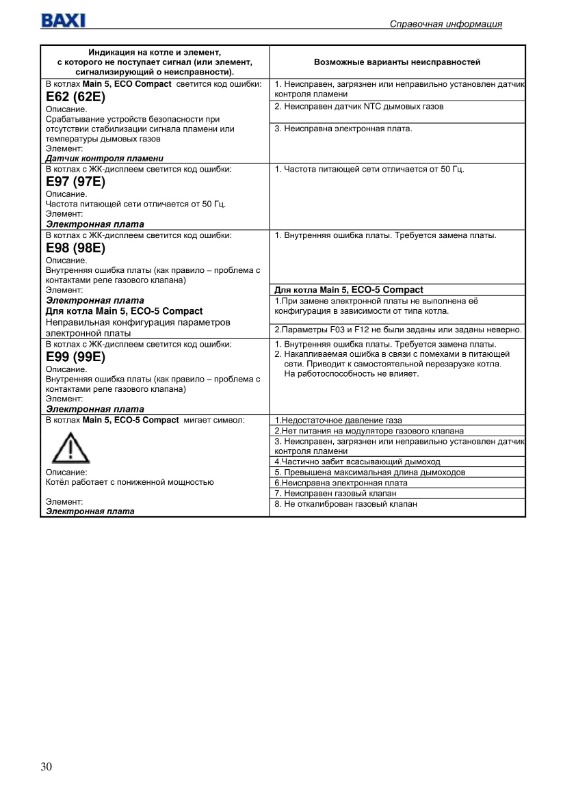

- Error e98 on the baxi boiler how to fix it?

- Operating principle

- How to proceed

- Start with the simplest action - restart the boiler

- Perform gas path diagnostics

- Check the chimney

- Diagnose the Baxi boiler.

- What could be the reasons for the error?

- Error e35 on the baxi boiler how to fix

- What to check

- Presence of condensate

- Solution:

- Mains parameters

- grounding

- gas valve

- Electronic board

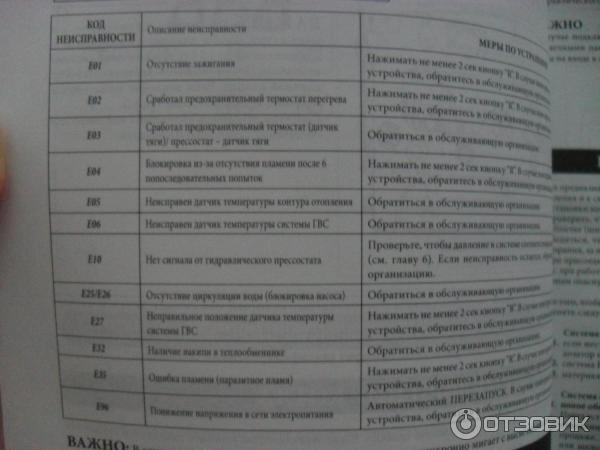

- BAXI gas boiler errors

- How to repair the BAXI gas boiler heat exchanger

- Flushing the boiler heat exchanger

- Posted 1 comment

How to proceed

Check power supply parameters

Imported boilers are sensitive to U, f. Manufacturers do not take into account the nuances that we constantly encounter: power surges, increased / decreased values, phase imbalances and other “surprises”.With an autonomous electric / supply, the error e98 of the Baksi boiler is caused by incorrect operation, source failures (diesel, gas generator). Check, make adjustments - for this, the owner of the object does not need the help of a service master.

Uninterruptible power supply SKAT

Check grounding

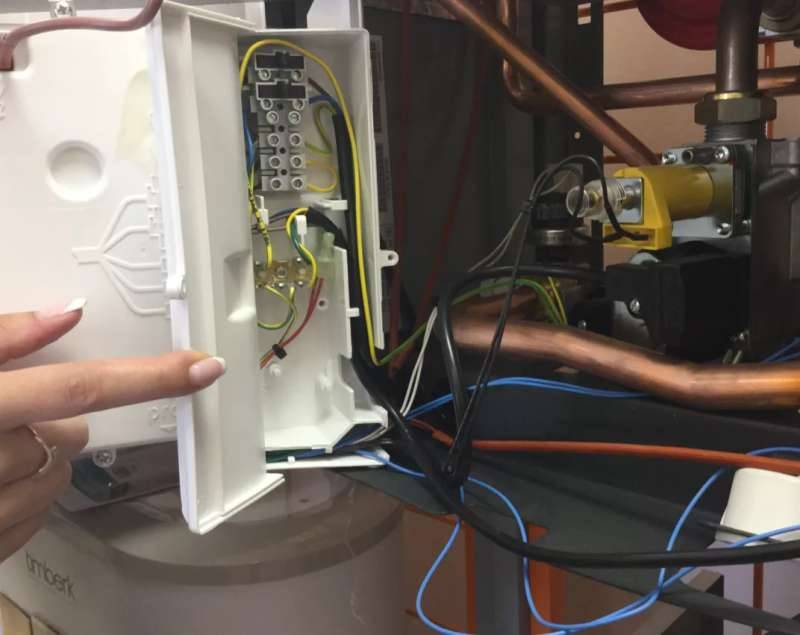

This is the main reason for the appearance errors e98 boilers Baksiinstalled in apartments. In houses built according to old projects, grounding is not provided. It is easy to make sure by removing the cover from the outlet: two wires enter the nozzle box - phase and zero.

In the private sector, loop testing is carried out with a device - a megaohmmeter. When measuring resistance, R should show no more than 4 ohms.

Grounding the baxi boiler

Check the potential on the metal part of the boiler

Error e98 may be associated with pickups (stray currents). They appear for various reasons (power lines are located nearby, a powerful source of radiation, the insulation of the power cable is damaged, or otherwise), but the result is the same: where there should be no potential, it is present.

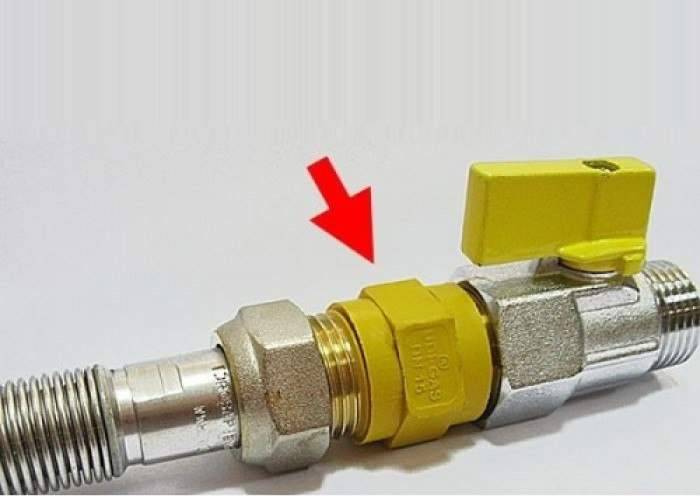

Advice. The gas pipe is a metal, laid in the ground, therefore, the energy leaving the ground is “collected” on it. To exclude the influence of pickups on the electronic board, it is necessary to install a dielectric coupling on the line (between the shut-off valve and the Baksi boiler). Helps to get rid of the e98 error and a number of others.

Connecting the Dialectic Clutch

dielectric coupling one

Check boiler settings

One of the reasons for the e98 error after replacing the Baxi electronic board. The code appears if the parameters are entered incorrectly (F03, 12). To correct the configuration, you do not need to call the service wizard - the instructions describe in detail the method of settings.

Check more

Supply voltage

Network failures are the main cause of heating unit errors. Using a multimeter, it is easy to measure the voltage supplied to the Baksi boiler. The manufacturer has set: 230V/1f. If the value deviates by ±10%, an emergency stop of the unit is possible.

Burner status

Often the e04 error is caused by untimely, unprofessional boiler maintenance. The Baksi burner needs regular cleaning from dust and soot that clogs the nozzle holes. The accumulated dirt prevents the normal passage of gas into the chamber, hence the weak flame that causes the e04 error. Toothbrush, vacuum cleaner, 10 minutes of operation - the fault code will disappear after starting the Baksi boiler.

Chimney

Error e04 may be due to a violation of thrust when combustion products enter the chamber

It happens when weather conditions change, if during the installation of the boiler the wind rose at the point where the pipe exits the building is not taken into account. Other errors indicate malfunctions of the fan (for turbocharged Baksi boiler models)

The nuance is that they are formed on the basis of signals from the corresponding sensors, characterized by a response threshold. Therefore, the code e04 can be caused by a decrease in thrust, which negatively affects the combustion process.

Electronic board

An independent search for the cause of the e04 error is unlikely to give a positive result. If suspicion falls on the control module of the Baksi boiler, you need to contact the service workshop. Diagnostics is carried out on the stand, using special equipment, based on the manufacturer's guidelines. An ordinary user, not having diagrams, tables, devices at hand, is not able to accurately determine the faulty element of the board.

Error E10

Despite the serial number, error E10 ranks second in terms of frequency of occurrence, but unlike error E01, it can often be eliminated by the user on his own. The error is reported by a sensor that controls the pressure in the heating circuit. The heating system should be fed periodically - this is the most likely cause of error E10. As the owner of the BAXI ECO FOUR boiler, I can say that I do this about once a year. If you have to do this much more often, then you should think about finding leaks in the heating system. We have already described a complete list of possible malfunctions in a separate article on error E10.

Despite the serial number, error E10 ranks second in terms of frequency of occurrence, but unlike error E01, it can often be eliminated by the user on his own. The error is reported by a sensor that controls the pressure in the heating circuit. The heating system should be fed periodically - this is the most likely cause of error E10. As the owner of the BAXI ECO FOUR boiler, I can say that I do this about once a year. If you have to do this much more often, then you should think about finding leaks in the heating system. We have already described a complete list of possible malfunctions in a separate article on error E10.

Flame control sensor malfunction (baxi e01)

In general, some manufacturers claim that the “igniter” is a consumable. Personally, I have a baxi eco four boiler in my apartment and I have never changed it (the boiler is already in its sixth year). But nevertheless, it all depends on the specific operating conditions, gas quality and air pollution. Therefore, it is necessary to carry out an inspection, if necessary, clean the electrode with an alcohol solution and check its correct position and gap relative to the burner body according to the instructions (it may be different for different models). A case from practice: a client complains about the Baxi boiler error e01. They changed the board - the boiler worked for a day and again the same error. What did you do before the error appeared with the boiler? Bent the electrode - made a gap of 1 mm. On what basis? Somewhere someone told, showed ...

In Baxi boilers, the ignition electrode also performs the function of controlling the flame. Flame control is one of the most important functions of the boiler safety system. It is needed so that the boiler immediately shuts off the gas supply in the event that the flame on the burner goes out for some reason.The gap must be set exactly to the value indicated in the instruction manual for the device!

The fact is that the principle of flame control is to register a small current that begins to flow through the electrode during combustion. And the structure of the flame has an air gap at the base, and if the gap is too small, the flame will not be registered and the boiler will go into an accident when operating at certain power modes.

In no case do we recommend bending the electrode - it is very fragile and most likely to break off.

Alternatively, carefully bend the attachment point.

Frequent malfunctions and measures for their elimination

The flame of the burner does not reach its maximum power during the operation of the boiler

This malfunction of the gas boiler may occur due to incorrect pressure settings in the heating system. Also, such a breakdown can also occur with a faulty gas valve modulator. Another reason for its occurrence is the breakdown of the diode bridge.

Remedy: it is necessary to adjust the system parameters using the boiler operating instructions.

Boiler starts but stops immediately

This malfunction of the gas boiler may occur due to low pressure in the gas pipeline.

Remedy: it is necessary to adjust the gas pressure downwards to 5 mbar.

Weak heating of the coolant in the heating system

Remedy: Perform a pressure test on the gas valve. It is highly likely that the min and max values have failed.

modulation not working

To eliminate the problem, the valve must be replaced.

Temperature sensor values become inaccurate

To fix this problem, replace the old sensor with a new one.

Weak heating in the hot water system

The cause of this malfunction may be the incomplete opening of the three-way valve. In some cases, its appearance is associated with a breakdown of such a valve. In order to accurately establish that the cause of the malfunction lies precisely in the valve, it is necessary to wait a while until the system cools down. Then the shut-off valves of the heating system will need to be closed. When this is done, the boiler should be switched on to hot water mode. A confirmation of a valve malfunction will be heating in the heating system.

When the unit is ignited, "pops" are heard

Noise can appear for several reasons:

- Insufficient gas pressure;

- The changed distance from the gas supply to the igniter due to careless transportation of the Baksi boiler.

To eliminate this malfunction, you should adjust the gap. It should be set within 4–5 mm.

How to adjust the gap between the burner and the igniter

The temperature of the coolant in the circuit has dropped sharply

The main cause of this malfunction is clogged filters. They need to be removed and cleaned. In some cases, they may need to be replaced. The reason may be damage to the radiators or pipes. If these heating systems are frozen or clogged, then repair is necessary in this case. The area where the defect was found should be cleaned or replaced.

How to clean the primary heat exchanger with your own hands

The pipes of the device should be connected to the heating pipes of the Baxi boiler

Within a few hours on the device, we switch in manual mode the direction of the flushing liquid. When two hours have passed, the device must be turned off. Next, turn off the tap to drain the water. Then you need to remove the hoses. But before that, you need to make sure that the liquid is glassed back into the device. Next, we connect the boiler to the system. After that, it must be filled with coolant. After cleaning the boiler, its parts must be cleaned of scale. And this will eliminate the clogging of the system and its failure.

Do-it-yourself cleaning of the secondary heat exchanger (heating circuit)

Before installing the boiler, it is necessary to consult a specialist. You should also contact him if the boiler needs repair. Baksi gas equipment, like any other, has its own tensile strength, so at some point the boiler will need to be repaired.

Characteristics of Baksi boilers

The equipment of this manufacturer can be used both in a small apartment and in a spacious country house. But the space in which the heating system will be installed must meet certain criteria:

- The size of the room should not be less than 15 m³.

- Ceiling height - at least 2.2 m.

- Good ventilation is required to withstand heavy loads.

This is important: maintenance of Baxi boilers. In this video you will learn how to flush the heat exchanger:

In this video you will learn how to flush the heat exchanger:

Important nuances

In addition to grounding, other factors must be taken into account when installing equipment. Consider the following:

- For the boiler to function properly, 170-250 V is required. At a lower voltage, the device will turn off, and at a higher voltage, the varistor will burn out.

- The equipment is very sensitive to voltage fluctuations. Professionals advise installing additional devices that stabilize the voltage. It is not necessary to use a UPS when installing gas boilers.

- The connection must be made through a separate functionality.

- For phase-dependent varieties, the correspondence between phase and zero should be observed.

Advantages and disadvantages

Baxi is a leader in the heating equipment market.

The following advantages of the equipment of this manufacturer can be distinguished:

- environmental friendliness and safety;

- ease of operation and flexible adjustable settings;

- reliable frost protection;

- automatic diagnostic function;

- profitability;

- a wide range of models, the ability to choose a unit for any requirements;

- stylish thoughtful design.

Of course, any equipment has its drawbacks, Baksi products are no exception. The cons are:

- Sensitivity of technology to voltage drops. For the device to work reliably, you need to connect it through a stabilizer.

- Installation is quite complicated, so it is best to entrust it to a professional.

- High price compared to models from other manufacturers.

In this video, you will learn about the main malfunctions of Baksi boilers:

Varieties of models

The company has a wide range of wall and floor heating systems. Wall mounted boilers are ideal for private homes. They are available in three series: Luna, Prime and Eco3.

Models from the Luna line have built-in automatic diagnostics and electronic modulation. Such units are distinguished by the presence of two temperature controllers, which is very convenient. These are two-circuit devices with an acceptable cost.

Equipment from the Prime line is high-quality and reliable economy class boilers.They have a closed combustion chamber and are made of special composite materials. The devices operate almost silently. Models of this series are condensing and have a biothermal heat exchanger. As a result, they work very economically.

The Luna-3 Comfort and Eco Four models are very popular on the Russian market. Both systems can be presented with both open and closed combustion chambers. Eco Four has a capacity of 14-24 kilowatts. It can be connected to a thermostat or timer. This boiler is equipped with high-quality sensors and reliable protection against temperature changes. Among all Baxi devices, it has the least power.

In addition, models from the Main line are in great demand. The most famous in the Russian market was the Main Four 240, which was discontinued in 2017. It was replaced by Main Five, made using new technology. This system is similar to the previous one, but it contains additions, such as a draft system in the chimney.

How to repair the gas boiler control board:

Step 1

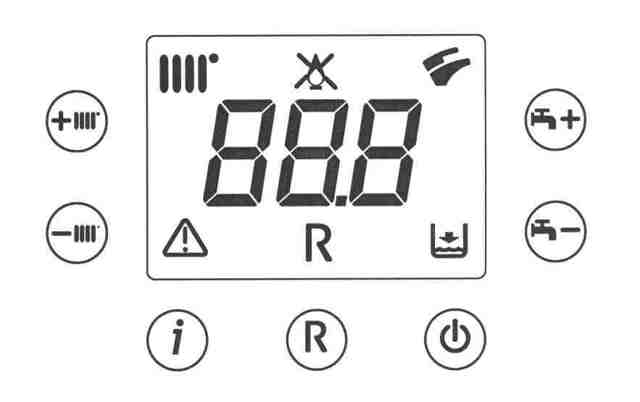

To eliminate the error e25 of the Baxi boiler, press the RESET (R) button and hold it for at least 2 seconds, as stated in the factory instructions.

How to reset the boiler Baxi LUNA 3 comfort reset button

If the malfunction is caused by the accumulation of air bubbles in the coolant, they will be removed by scrolling the pump at idle (without ignition of the burner). This action quickly solves the problem with the e25 error. During the operation of the boiler, the liquid is heated to a high temperature, which contributes to intensive gas formation. Often occurs when the heating unit is operating at elevated modes. If this does not solve the problem, you need to look for the cause in the heating circuit and the Baksi boiler.

Error e98 on the baxi boiler how to fix it?

In the vastness of our Internet, I came across an article about how one of the users independently localized the malfunction, and with the participation of a fellow electronics engineer, the BAXI FOURTECH board was restored (baxi e98 error) and I periodically receive calls with requests to sell “some kind of detail”, which a friend of mine soldered to us and sent to find. This approach is obviously wrong. It must be clearly understood that malfunctions are different and they can be corrected in different ways.

Only original components must be used for repairs. Compliance with the installation rules affects the further service life of the component. It must be remembered that the board controls high-risk equipment and repairs should only be carried out by a qualified specialist. Negligence can lead to disproportionate costs.

instructions

If it is interesting, we have an article on our website with a complete list of error codes for baxi boilers.

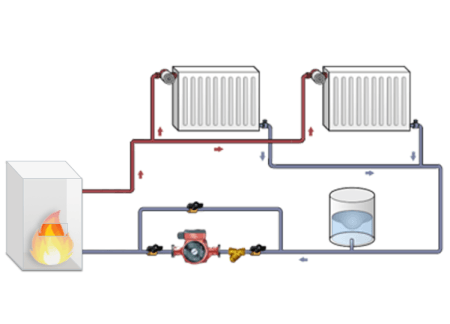

Operating principle

The combustion chamber of baxi boilers is made of metal. Outside, it is covered with a layer of thermal insulation. A copper heat exchanger is placed above the combustion chamber, and the burner is located under the combustion chamber.

When the air temperature in the room changes, the thermostat automatically starts, transmitting a switch-on signal to the pump, which creates a vacuum in the return pipe. At the same time, heated water begins to flow into the supply line of the heating system under a pressure of no more than 0.45 bar (in the event of an increase in pressure, the microprocessor sends a signal to the relay, the contacts close, and the burner ignites).The operation of the boiler starts at a low power, which gradually increases until the temperature of the heat carrier reaches the set temperature. After that, the heating mode changes to the modulation mode. As soon as the temperature of the coolant deviates from the set value in the direction of decrease, a signal is received from the temperature sensor, the inlet fuel valve opens, the burner ignites again and heats the water.

In the event that the boiler output is too high at the beginning of operation, the burner automatically turns off and the system can only be restarted after three minutes.

When there is no need for heating, the boiler is switched on to the DHW mode. In this case, cold water through a three-way valve that shuts off the heating line enters the secondary circuit. From the gas valve, fuel is fed into the burner, gradually increasing power. When the water heats up, the temperature control mode turns on.

How to proceed

Start with the simplest action - restart the boiler

(Press and hold the Reset – R button for 2 seconds). This is also stated in the factory instructions. If error e41 is caused by a short-term failure, it will disappear.

Restart the baxi boiler with Error e 41 on the control panel

Perform gas path diagnostics

Error e41 of the Baksi boiler appears when the pressure at the inlet to the heating unit is below critical or there is no supply of "blue fuel" due to channel blockage.

Assessing the gas pressure in the pipe, its entry into the house is easy with the help of a stove. All burners are kindled, and a conclusion is made according to the intensity of combustion, the height of the flames. If they are small, the Baksi boiler fittings will not react, error e41 will appear. At low pressure, you need to check all the equipment mounted on the highway.

-

The position of the control valves. The supply tap was accidentally closed, the shut-off valve worked during a power outage - common causes of the error e41 of the Baksi boiler.

-

Serviceability, condition of technical devices: meter, reducer (with autonomous gas supply), main filter, tank filling level (gas tank, cylinder group). If error e41 occurs at low temperatures due to a drop in pressure, it is necessary to insulate the tanks with "blue fuel", entering the pipe into the building.

Gas pipe shut-off valve

Check the chimney

A blockage that reduces the Du of the channel, icing of the head, frost on the filter is enough to cause an e41 error. With regard to Baxi with an open chamber, it is necessary to ensure a good flow of air into the room. Code 41 often appears when turning on a powerful exhaust device in the adjacent room. No wonder the manufacturer does not recommend mounting such equipment near the Baksi boiler.

An unpleasant picture when a mouse is found in the chimney

Diagnose the Baxi boiler.

His e41 error is not necessarily the result of a serious breakdown. To start, to save time, you need to visually inspect the inside.

What could be the reasons for the error?

Here are the most likely reasons for the lack of thrust in a gas boiler:

-

insufficient diameter of the outlet channel (chimney) - design error, clogging with dirt, icing of the inner wall. The diameter of the chimney has decreased - the draft is insufficient.

-

exceeding the permissible length of the flue pipes. It is necessary to familiarize yourself with the manufacturer's recommendations for installing the boiler, check compliance with the necessary requirements. Too long a horizontal section of the flue pipe will result in the absence of the necessary draft.

-

defective pneumatic relay - thrust sensor. It is checked by the presence of a characteristic click when a vacuum is created in the supply tube (you can simulate it yourself).

-

missing or poor contact of the sensor with the board

-

Faulty venturi device (melted or clogged)

-

the presence of condensate in the tube connecting the pneumatic relay with the Venturi device (valid for boiler models without a special condensate collector)

-

incorrect connection of tubes with pneumatic relay

For turbocharged boiler models:

fan malfunction. May be due to clogging of the fan impeller, lack of sufficient lubrication on the fan shaft (does not develop the required speed)

lack of normal contact between the control board and the fan

repair of gas boiler control boards

Also on our website, instructions for many models of Baxi boilers are available for download.

Next, we will analyze in more detail the possible options for eliminating the error.

Error e35 on the baxi boiler how to fix

Restart boiler. On the Baxi panel, the Reset (R) button: after pressing and holding for 2 seconds, the false error e35 will disappear. If the code reappears, the following procedure is recommended.

Restart the boiler boiler Baxi

What to check

Presence of condensate

Dampness is the cause of the e35 gas boiler error. If Baxi is in an unheated room, after a long downtime, the appearance of the 35th code is expected: you need to evaluate the condition of the ionization sensor. From it, in conditions of high humidity, a false signal of the presence of a flame is received even when the valve on the pipe is closed. Located in the chamber, it serves to fix the current between the metal of the boiler burner and the sensor electrode; in some models, Baxi is combined with an ignition device.When the unit is not working, in damp conditions, it gives a spurious signal to the board, which generates an e35 error.

Boiler ionization sensor Baxi

Solution:

-

dry the combustion chamber with a stream of warm air (building hair dryer, air heater or the like);

-

if the Baksi boiler is installed in the kitchen, organize an effective hood. The reason for the e35 error is high humidity.

Mains parameters

Deviation from the value specified in the instructions for Baxi (~ 230V) initiates malfunctions in the electronics, causing the boiler to stop with an error.

Tips. If a power line is located near the object, another source of powerful EM radiation, the error of the Baksi e35 boiler is not uncommon. Under such conditions, the operation algorithm of the electronic board is violated, a false fault code is generated. Incorrect functioning of the external stabilizer also causes the 35th code.

Recommendation. One way to get rid of the e35 error is to put a cut-off fitting (dielectric coupling) on the gas pipe between the boiler and the tap. It will prevent the influence of stray currents, pickups on Baxi's electronics. Power lines, tram lines, electrified railway tracks and the like in case of random breakdowns become sources of interference. Electricity "dumped" into the ground, passing to the metal of the gas main, affects the "brain" of the boiler, causing an e35 error.

dielectric coupling one

Connecting the Dialectic Clutch

Wiring diagram for a dielectric coupling

grounding

This is faced by users involved in piping the Baksi boiler on their own, and owners of apartments in high-rise buildings. The connection must be checked during the initial start-up of the unit.It is not for nothing that the violation of the grounding procedure, its non-compliance with the requirements of the PUE is the basis for removing the heating installation from the factory warranty.

Grounding the baxi boiler

This is specifically stipulated in the manufacturer's instructions, which, unfortunately, not everyone carefully studies. Poor connection of the Baxi boiler to the circuit causes malfunctions in the control board, emergency stop and error e35 on the display. At home, reliability, grounding efficiency is easy to determine using an indicator screwdriver by the absence of glow at the moment the probe touches metal parts, assemblies, the body of the Baksi boiler.

gas valve

Its leakage is the cause of the e35 error. If the solenoid valves, after removing the opening command, do not completely block the gas path, the Baksi boiler ionization sensor detects the burner flame. Its repair is a separate issue, but it is more rational to replace it: the defect is associated with the development of a resource.

Electronic board

If error e35 is present, after the measures taken, this node must be checked. Baksi boilers (depending on the year of manufacture, series) are equipped with different boards. With identical functioning, they differ in their response to external factors (power supply, interference, grounding). Honeywell boards are the most "sensitive" to dampness.

How to proceed

Rinse the surface. To remove dust, which becomes a conductive layer when moistened, isopropyl alcohol and a brush (with medium-hard bristles) are used, in laboratory conditions an ultrasonic bath is used. After removing the contamination of the electronic board and drying it, the e35 error will disappear.

Put a new node in the boiler. On this issue, it is worth consulting with a professional - not all boards are interchangeable.Product specification (numbers, letters) is indicated on the panel

When ordering (selecting) an electronic assembly, this code must be taken into account - there will be no error. The owners of Baxi mainfour should be aware that these boilers have boards of 3 options: one differs in circuitry and is not interchangeable.

BAXI gas boiler errors

Error e96 baxi boiler

Error e96 (or 96E) is quite rare and is practically not documented anywhere. The main reason is the low voltage of the boiler power supply network.

baxi boiler error e25 how to fix

Error e25 on the baxi boiler occurs when the temperature rise in the heating circuit occurs too quickly. The automation of the boiler captures the dynamics of temperature changes using sensors, and if the temperature increase exceeds 1 degree per second, it blocks the operation of the boiler.

Baxi boiler error e01 (baxi error 01e) and others. Elimination methods.

Gas boilers every year replenish the list of household appliances of each apartment or country house, have already become an integral part of the modern heating system. In almost every new building, a wall-mounted gas boiler has already been installed according to the project.

The most typical boiler malfunction of absolutely any manufacturer, which is probably why it is indicated by the first serial number.

Error E01 occurs when it is impossible to properly ignite the gas burner of the boiler.

Error e98 and e99 on the Baxi gas boiler. Reasons for appearance. How to fix.

Error e98 (or e99) on the Baxi boiler indicates that the self-diagnosis system fixes an internal error in the operation of the board itself. In the repair manual for fixing this error, the only recommendation is to replace the board.

Gas boiler baxi error e26 (e26 baxi)

The logic of error baxi e 26 is to exceed the set coolant temperature by more than 20 degrees, compared with the value set by the control board. The causes of the error will most likely be similar to error e25, according to which the boiler automation logic registers a too rapid increase in the temperature of the coolant.

Baxi boiler error e04 (baxi e04)

Error 04 on the Baxi boiler is connected to the flame control electrode, which checks the presence of current through the flame, and if the value is registered below the minimum value more than 6 times, the security system considers the combustion process to be incorrect - the boiler stops working.

Heating system temperature error (error e05, error e25)

Error e05 and e25 baxi informs the user about the failure of the temperature sensor of the heating circuit or about exceeding the permissible temperature.

Boiler baxi error e06 what to do and how to fix (error e06 baxi)

The Baxi gas boiler error code e06 informs the user about a breakdown in the temperature sensor of the hot water supply circuit or about exceeding the permissible temperature. . In different series of baxi boilers, different sensors can be installed: submersible, overhead, mounted in a sleeve. The figure shows NTC sensors for various models of BAXI boilers.

How to repair the BAXI gas boiler heat exchanger

In order to start repairing a gas boiler, it must be disassembled, the algorithm is as follows:

- After carefully studying the diagram, you can begin to remove the front cover that protects the inside of the boiler. To do this, it will be necessary to unscrew 4 bolts, this should not be a problem.

- Unscrew the protection from the combustion chamber. At this stage, you will need a vacuum cleaner, well clean the combustion chamber from dust and debris.

- After unscrewing the two screws and removing the wires with the terminal, remove the fan.

- Wipe the burner with nozzles with a damp cloth, if you see clogged nozzles, you can use a brush, but not a metal one, so as not to damage or break the burner elements.

- Now you need to remove the heat exchanger, it's quite simple. Turn off all the sensors. Remove the clips from the tubes and gently rock the heat exchanger up

When the boiler is completely disassembled, you can begin to repair it or carry out maintenance work.

Often, replacing the heat exchanger helps solve the problem of improper operation.

Flushing the boiler heat exchanger

Flushing should be done both inside and outside.

To do this, pour clean water into the basin, add special products to it that help fight scale, rust - place the heat exchanger in it for a while. After this time, using pressurized water, remove scale and rust residues from inside and outside the heat exchanger.

After completing all the described procedures, you can begin to assemble the gas boiler. Follow the described algorithm in reverse order. As you can see, even an inexperienced master can repair baxi, and you can independently diagnose and repair your gas boiler, which will serve you for quite a long time.

Posted 1 comment

In the absence of experience in handling the units or in the absence of special tools, it is better to entrust the repair of the boiler to a competent master.

This site uses Akismet to fight spam. Find out how your comment data is processed.

Baxi is a line of gas boilers from an Italian manufacturer. The best option for maintaining a comfortable temperature in the room.

Gas boilers of this company are safe, environmentally friendly, durable, almost silent, durable and economical, have high performance and are quite easy to operate, in addition, they are distinguished by an affordable price. Even if the network will mark gas pressure reduction, the boiler will not stop working. Baxi boilers run on liquefied natural gas. Modern design allows you to organically arrange the boiler in the interior of any room.

![How to fix the error e04 boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/1/a/b/1ab07f9f41ba83c659b0f963b6b3981a.jpg)

![How to fix the error e35 gas boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/4/d/2/4d26791f2e279d8863c4b61a2dc1212b.jpg)

![How to fix the error e35 gas boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/7/f/3/7f3bda6e51dff86f514116b3f8474ab2.jpeg)