- The device and characteristics of the main elements

- 2 Model range of equipment

- 2.1 Marina CAM

- 2.2 Marina APM

- 2.3 Typical malfunctions and repairs

- Other causes of failure

- How the pumping station is arranged and works

- The main malfunctions of the pumping station and how to deal with them?

- The pump has stopped working: the first thing to do

- Air pump does not pump water

- Equipment does not turn off

- Features of the device, operating rules

- Why doesn't it work and what to do about it?

- Works often

- Doesn't turn off pump

- Clicking and turning off frequently

- It just doesn't work

- How to troubleshoot on your own?

- Pumping equipment rotates, while water does not flow

- The station pump is turned on frequently, and water is supplied in fits and starts

- The pumping station is working, but the water enters the system jerkily, intermittently

- Troubleshooting

The device and characteristics of the main elements

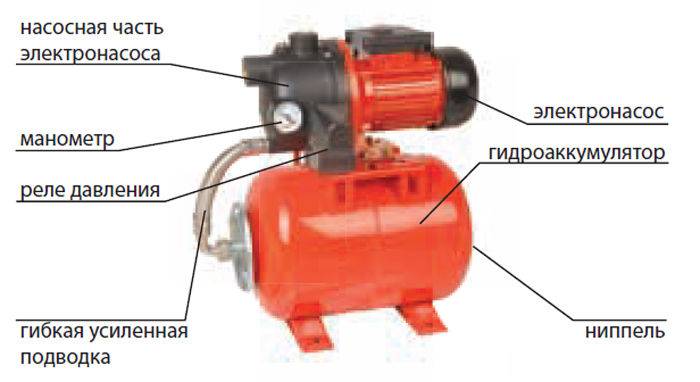

The unit is very different from the submersible in the first place in its volume and principle of operation. Working elements of the complex:

- Powerful pump. It is she who raises the liquid from the depths of the well or well and supplies it to the water supply network. All other elements ensure its correct operation. The first and only purpose is to pump out liquid from an aquifer.

- Hose or pipe.The torque of the impeller creates a vacuum environment inside the hose, and the water rushes up to the impeller. Here it is captured and pushed further into the system.

- Check valve. It is located on the hose near the unit itself or directly in the well. Designed to stop the fluid after the pump is turned off.

- Coarse filter. It has the form of an iron or plastic cork with a mesh base. Detains large and small particles of silt and clay, depending on the size of the cell. Protects equipment from blockage, especially the impeller.

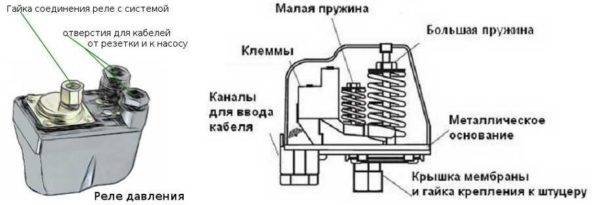

- Relay for measuring pressure in the line. Without this device, the device will not work. The sensor is installed at the base of the expansion tank. When water is drawn in, the pressure in the system drops, the relay registers this process and instructs the pump to turn on. Therefore, the power cable does not go directly to the network, but passes through the pressure sensor. The turn-on step is 1.5–2 points.

- Pressure gauge. Serves as a pressure controller in the system. Shows any changes after turning the unit on and off.

- Expansion tank. Regulates the smooth start of the pump. Without it, the equipment will work jerkily, constantly turning on and off.

This is interesting: Repair of a hydraulic jack - instructions, tools, materials

2 Model range of equipment

The product line of Speroni (Italy) includes 4 series of Marina pumping stations:

- Marina CAM is a budget option for water intake from wells up to 9 m deep;

- Marina APM - pumps for wells up to 50 m deep;

- Marina Idromat - units equipped with a regulator that turns off the pump when running dry.

Let's take a closer look at each of these lines.

2.1

marina cam

The CAM series consists of equipment made in a cast-iron or stainless steel case, with internal fittings made of food-grade polymers. Several models are presented, the power of which varies between 0.8-1.7 kW, and the head is 43-60 m.

The volume of the accumulator can be 22, 25 or 60 liters. These are the most affordable stations for private use, the cost of which starts at 7 thousand rubles.

Among the stations with the best price / quality ratio, we highlight:

- Marina Cam 80/22;

- Marina Cam 60/25;

- Marina Cam 100/25.

The Marina Cam 40/22 pumping station is equipped with a 25 liter hydraulic accumulator, the capacity of which will be enough for a family of 3 people. The capacity of the unit is 3.5 m 3 / hour, the maximum lifting depth is 8 m. The price is 9 thousand rubles.

Marina Cam 100/25 has similar technical characteristics - a tank of 25 liters, a throughput of 4.2 m 3 / hour, however, this model is equipped with a pressure boosting system that significantly increases the delivery head - up to 45 m, compared to 30 m for CAM 40 / 22.

2.2

Marina APM

Well pumps of the APM series have a maximum water intake depth of 25 m (model 100/25) and 50 m (200/25). This is more power and overall equipment, the weight of which can reach up to 35 kilograms. As an example, consider the popular station Marina ARM 100/25.

Specifications:

- head - up to 20 m;

- throughput - 2.4 cubic meters / hour;

- centrifugal motor power - 1100 W;

- the diameter of the supply pipe is 1″.

AWP 100/25 is made in a stainless steel case, the model is equipped with overheating protection and a water level control system in the hydraulic tank.ARM100/25 is designed for pumping clean water, without mechanical impurities, the temperature of which does not exceed 35 degrees.

2.3

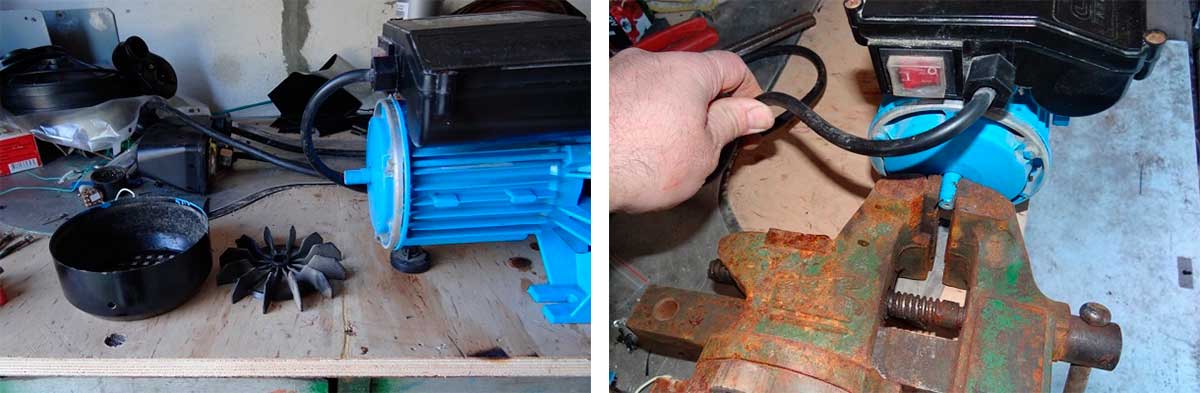

Typical malfunctions and repairs

Marina pumping stations have established themselves as reliable and durable equipment, however, like any other equipment, they are not immune from breakdowns. We bring to your attention a list of the most common breakdowns and ways to eliminate them:

- Lack of water supply when the pump is on, the cause of which may be a loss of tightness in the conductive pipelines and a worn check valve. First check if you forgot to fill the pump body with water. If it is, inspect the check valve and the tightness of its fit to the pump nozzle, and also check the condition of the intake pipe - all damaged components must be replaced. Similar problems are possible if the impeller is damaged, to replace which you will need to disassemble the unit.

- Water is supplied in jerks due to a damaged accumulator. The main malfunction of the hydraulic tank is a damaged membrane. To determine if it is intact, press the nipple (located on the tank body), if water flows from the nipple and not air, then the membrane is torn. It is quite easy to install the membrane, you just need to unscrew the fixing ring from the tank neck, pull out the old part and mount a new one in its place.

- Reduced water supply pressure. The reason for this can be either a faulty hydraulic tank or problems with the pump. In the first case, the depressurization of the tank is most likely to blame - inspect the body for cracks, repair the detected deformations and pump air up to the standard value.If the tank is intact, the problem must be sought in the deformed impeller of the centrifugal wheel inside the pump.

We will separately consider the situation when the pumping station does not want to work in automatic mode - the unit does not turn off when the tank is full and does not turn off when it is empty. The incorrect adjustment of the pressure switch is to blame here - it is usually calibrated at the factory, but there are exceptions.

The above diagram shows a standard pressure switch for Marina pumps. On it, under the plastic cover of the case, there are two springs. Most of them rotate clockwise, it is responsible for the minimum pressure in the tank at which the station turns on. By rotating a small spring, we adjust the maximum pressure, upon reaching which the pump turns off.

Adjustment of the pressure switch must be carried out with the equipment disconnected from the mains. Before starting the calibration, it is necessary to drain the water from the tank, the level of air pressure is also important - it must correspond to the value recommended by the manufacturer.

Other causes of failure

Most often, the pumping station does not turn off due to a reason that may be hidden in the following problems:

- power supply is lost;

- no water enters the pipeline;

- failure of the pump itself;

- breakdown of the hydraulic accumulator;

- malfunction in the automatic system;

- there were cracks in the hull.

There are times when the pumping station does not pump water, but the automation is working properly. The reason for this may be a banal crack in the pipeline. Or the valve that is responsible for the return in the pipeline does not work.In this case, the water will not knock, which leads to a lack of fluid.

The power of the pumping station directly depends on the parameters of the pipes and the goals set

In order for the pumping station to work without interruptions and breakdowns, it is necessary to take into account many nuances that can affect its functionality. Most problems are easy to fix on your own. If the characteristics of the pumping station do not meet your needs, then this can also greatly affect its operation.

Water will not flow to its destination if the power of the station does not match the diameter of the pipes, as well as the length of the entire pipeline

For this reason, you must always pay attention to the power of the equipment. Other reasons why the pumping station does not turn off may be as follows:

- Air in pipes. This is due to improper connection of the pipe and pump. The connection is not sealed. Or the pressure disappears due to a rupture of the pipeline.

- The water runs back. This happens if the tap breaks or the pipe breaks again.

Having discovered such problems, you must immediately stop the pumping station and carefully examine it. In addition, you should check the voltage in the mains.

Filters need to be cleaned regularly

In addition to a pipeline malfunction, the pump may not pump due to the fact that the filter is very clogged. In this case, you need to proceed as follows:

- clean the filter from dirt;

- add liquid to the tank using a separate hole, which is closed with a cork;

- before looking for the cause of the breakdown, the pump and the suction pipe are checked for fullness, only after that the station is started.If the liquid has disappeared after checking and starting, then it is first recommended to inspect the check valve.

- tightness is checked by drying and careful inspection.

- if the impeller of the device is stalled, then you must first turn it and start the entire system.

If the station is working properly, then the engine makes a uniform sound, but if unusual sounds are heard during startup, you need to look at the capacitor. Over time, it will be necessary to replace old parts, since they completely wear out during operation.

The correct setting of the accumulator is of great importance when starting the pumping station. If everything is configured correctly, the system will work for a long time and without interruption. Battery life is directly dependent on normally set pressure limits, tightness of the tank and the ratio of pipes with a branch pipe. In addition, air may enter the system due to the fact that the membrane will be broken.

Care must be taken to ensure that the tank is not covered with rust.

The main causes of a malfunction can be:

- preventive examination is ignored;

- wheel not working

- inappropriate power;

- membrane rupture;

- pressure drop;

- the pump often turns on and off;

- voltage fluctuations.

The battery reservoir rusts over time, dents appear. All these factors need to be eliminated immediately.

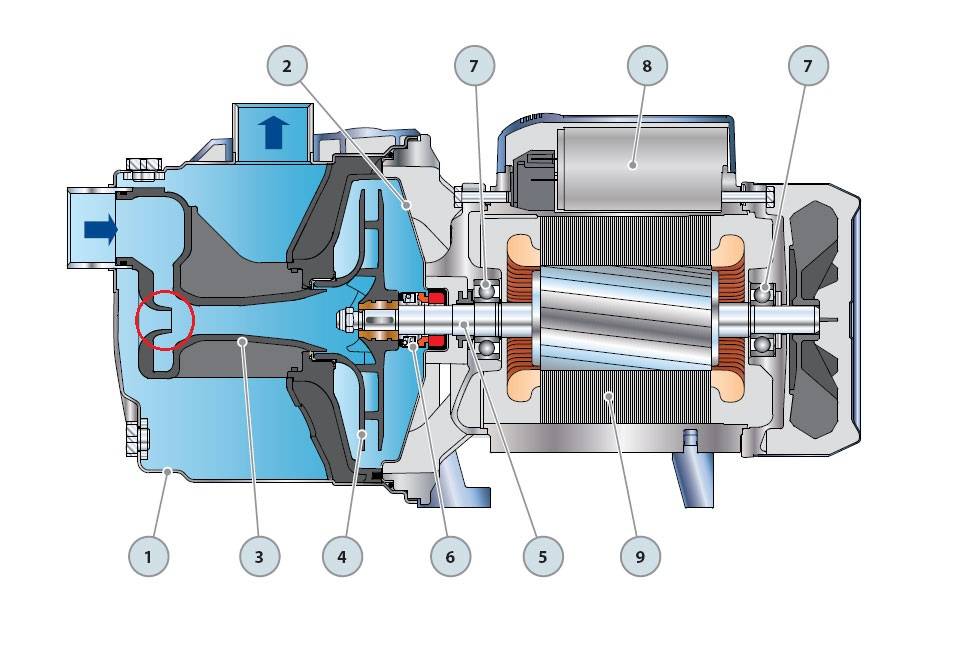

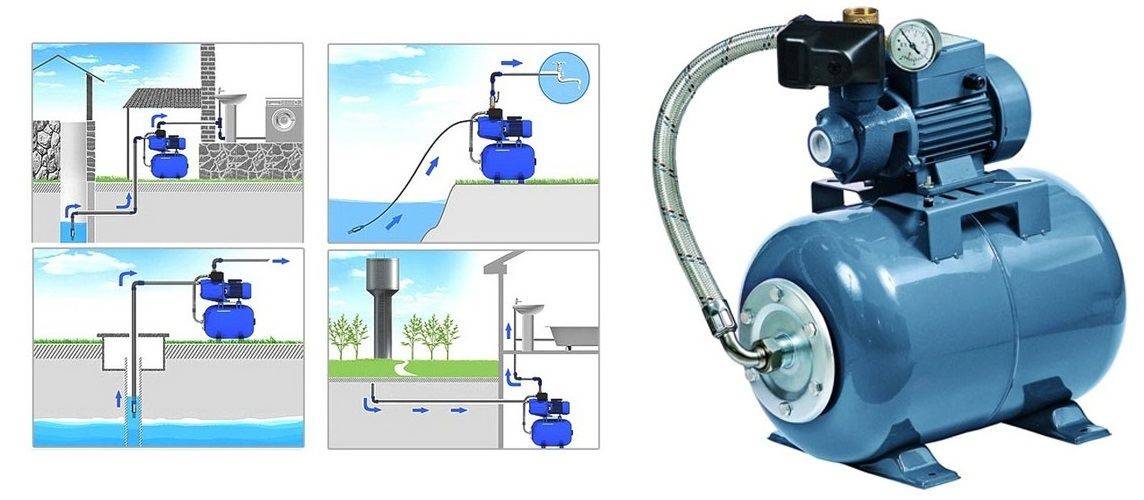

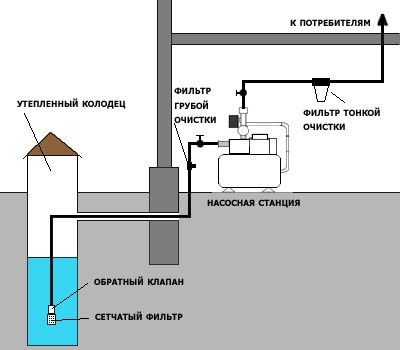

How the pumping station is arranged and works

Installation scheme of the pumping station

Picture positions:

- 1 - support for fixing the line;

- 2 - crane;

- 3 - check valve;

- 4 - pressure control relay;

- 5 - a place for pouring water;

- 6 - feeding part of the system;

- 7 - pump;

- 8 - filter for cleaning the line;

- 9 - line for water suction;

- 10 – hydroaccumulating tank;

- 11 - water for supply to the system;

- 12 - return valve, with a safety net;

- 13 - cover, for closing the nipple;

- 14 - drain hole for water.

Before you repair the pumping station, you need to at least briefly get acquainted with the device and the principle of operation of the system, the purpose of its constituent elements. The main components of the equipment:

- Centrifugal surface pump for station. It consists of an asynchronous single-phase motor and a pumping element.

- The hydraulic accumulator consists of: a steel tank and a replaceable membrane made of ethylene-propylene food grade rubber. A nipple is built into the accumulator, which serves to pump air under high pressure into the device.

- Visual pressure control is provided by a manometer in the water supply system.

- The pressure switch controls its upper and lower values, when they are reached, the pump turns off and on.

- The pumping station is connected to the power network through a cable with a plug on which a grounding contact is built-in, and sockets with the same contact.

The instruction indicates the approximate order of operation of the equipment:

- After installation and connection of the equipment, water fills the accumulator and the entire water supply system.

- After reaching the highest limit of water pressure in the system, the electric pump is switched off.

- The water tap opens, at the first moment water begins to be consumed from the accumulator.

- As the water flow increases, the pressure in the system begins to drop to the lower limit to which its relay is set, then the electric pump turns on again.

- Water begins to flow to the consumer and at the same time fill the accumulator.

- Reaching the liquid pressure of the upper limit value, to which the pressure switch is set, the system is switched off again.

- The cycles of turning the device off and on are repeated until the water is taken out of the system.

The main malfunctions of the pumping station and how to deal with them?

It happens that the pressure switch does not turn off the pump, a leak has formed in the hydraulic accumulator of the pumping station, the equipment constantly clicks, does not turn on the pump, etc.

Of course, it is easier to throw out a faulty water pump and put a new one in its place. But, not everyone can afford such returbations, therefore, let's look at the main breakdowns of pumping systems, and deal with their elimination.

The pump has stopped working: the first thing to do

If the water pump is on, but does not show "signs of life" - check the voltage in the mains. Try disconnecting and reconnecting the power cable. It's trite, but many are faced with just such a problem.

Is there still tension? Then check the reliability of all electrical connections.

Does the pump turn on for the first time since purchase? Check if the connections are correct. Nothing happened? Then the reason may lie in the breakdown of the wheel or relay. Your actions are as follows:

- power off the device;

- try turning the motor shaft with your hands;

- if it does not spin, the problem is in the starting capacitor;

- the way out is to replace it. You will need a soldering iron, a similar capacitor and skillful hands.

Air pump does not pump water

In what situations does this happen:

- air has entered the housing of some elements.Check the tightness of all containers, turn off the device, and use a special valve (it must be unscrewed) to let excess air out;

- a similar problem occurs when the water level is low. Check the water level at the water intake point, and the compliance of the pump installation with the recommendations in the passport;

- the problem may lie in the breakdown of the check valve or clogging of the ejector nozzle. Clean the valve.

Equipment does not turn off

Is the pump equipped with a hydraulic accumulator and does not turn off? The pressure switch might not work properly. Usually the reason lies in the incorrectly set pressure or low water pressure, due to air entering the sealed parts of the device.

The constant operation of the pump may be due to clogging of the fiver - due to too hard water. The way out is to remove and clean the relay, install a special filter to “soften” the water.

If the pump worked and then stopped abruptly, the problem may be hiding in the motor overheating. It is necessary to disconnect the device from the mains, find the cause of overheating and eliminate it. Here you will need experience or the help of a master.

It is necessary to connect all elements of the pumping station very carefully. If you have any problems, then immediately contact the masters!

Do not forget that the water flow with your own hands was done correctly, and never let you down, you need considerable experience, tools and the “right” hands.

Features of the device, operating rules

Household pumping stations allow you to organize water supply in a private house, which for some reason cannot be brought to the central highway. Stations are needed to solve such problems as:

1. provide automatic water supply to the house from a water supply source.

2. Organize a stable fluid pressure in the water supply system.

3.Protect pipes from water hammer.

4. make water supplies in case an emergency happens.

In some cases, pumping stations are delivered ready-made, this implies a lightweight installation of the structure. You can also assemble the equipment yourself, selecting individual spare parts of the right quality, it all depends on individual needs.

Attention! If the well has a great depth, then instead of a surface pump, the station should be equipped with a submersible device. If you understand the principle of operation of the station for pumping water, then repairing equipment will seem easy.

The design is based on a container with a rubber liner inside, it is called a hydraulic tank. Water enters the membrane compartment of the tank through the pump. On the other hand, the membrane is filled with air, in rare cases, pure nitrogen is filled in hydraulic tanks

If you understand the principle of operation of the station for pumping water, then repairing the equipment will seem easy. The design is based on a container with a rubber liner inside, it is called a hydraulic tank. Water enters the membrane compartment of the tank through the pump. On the other hand, the membrane is filled with air; in rare cases, pure nitrogen is filled into hydraulic tanks.

If you understand the principle of operation of the station for pumping water, then repairing the equipment will seem easy. The design is based on a container with a rubber liner inside, it is called a hydraulic tank. Water enters the membrane compartment of the tank through the pump. On the other hand, the membrane is filled with air; in rare cases, pure nitrogen is filled into hydraulic tanks.

This creates a certain level of pressure in the tank. On one side of the tank there is a nipple, as in a car, with the help of which air is pumped in or excess air is released. On the other side of the tank, a piece of pipe is placed, to which a fitting is attached, equipped with five outlets. The remaining parts of pumping equipment are mounted to them in the form of a pressure gauge, a pressure switch, a pump hose, a water supply pipe.

A hydraulic tank is brought to the water pipe of the house. When you turn on the water in the tap, the container becomes empty, the pressure in it drops. When the liquid level reaches the minimum mark, the device itself starts to work, the accumulator is filled with water to the maximum level, and the pressure will not return to normal.

Using a special relay, the pump is turned off and on. The relay is connected to a hydraulic accumulator, a pump. The hydraulic tank, as a buffer, serves as protection against water hammer.

Attention! The pump is only switched on when necessary when the pressure switch is activated. It makes the service life of the equipment longer

Attention! It is necessary to choose a station, taking into account the parameters of the well, the location of the water intake units

Why doesn't it work and what to do about it?

If the diagnostics showed that the pumping station itself is working, then you should pay attention directly to the pressure switch. The algorithm of actions will depend on how the malfunction of this unit manifests itself.

Works often

With a stable pressure in the hydraulic tank, the main reason for the spontaneous frequent switching on of the pump is a failure of the automation settings. A pressure gauge must be connected to the system for adjustments.

The RDM-5 relay is most in demand in the local water supply, with preset settings for the operation thresholds:

- lower pressure - 1.4 atm.,

- top - 2.8 atm.

Step by step, this standard relay is adjusted as follows:

Step by step, this standard relay is adjusted as follows:

- Remove the block cover.

- By right-hand rotation of the larger spring nut, raise the shut-off pressure to the desired, for example, 3.8 atm. At the same time, the lower limit of the launch will also rise.

- Set the desired pressure delta by turning the smaller scroll knob to the left.

Spirals, especially the smaller one, are very susceptible to adjustments, so they should be adjusted very carefully, with gradual tightening of the nuts in 45o turns.

Doesn't turn off pump

The most common reasons for the failure of the relay to turn off the pump include:

- Sticking and, in severe cases, with powerful starting currents, melting of the breaker contacts. If the contacts are not damaged, then the defect is eliminated by cleaning them with fine-grained sandpaper, a fine file or a nail file.

- The difference between the relay thresholds is too high. You should set the settings recommended by the manufacturer or optimal for a particular pump.

It is desirable to maintain the pressure delta in the range from 1.2 to 1.6 atm.

Clicking and turning off frequently

In practice, you can meet with another malfunction of the automation unit responsible for water pressure - periodic clicking.

In practice, you can meet with another malfunction of the automation unit responsible for water pressure - periodic clicking.

If the reason is not related, as described above, to a breakdown in the water supply system itself (more often - airing) or a lack of pressure in the hydraulic tank (the membrane is torn), then the matter is in the automation.

Summarizing numerous opinions on this problem on engineering forums, we can conclude that there is only one possible solution to it - to try to eliminate the frequent operation of automation (clicking) by increasing the difference in relay thresholds.

If the problem is not solved by this, then only the replacement of the block.

It just doesn't work

The relay may not close on for the following reasons:

- Insufficient voltage in the network - automation is demanding on this parameter.

- Oxidation of the contact group - it is necessary to disassemble the device and clean the contacts.

- The automatic cut-off pressure limit has been set too high.

- Lime and other deposits in the five-pin fitting with a pressure gauge that connects the relay to the pump (pyatnikovy), or the opening of the membrane compartment is clogged - it is necessary to remove the relay and clean the part.

- The ingress of sand into the membrane part of the block, which interferes with the action of the diaphragm on the piston. The latter is often observed if the pump has pumped sand. It is necessary to disassemble the relay, carefully clean and rinse everything.

How to troubleshoot on your own?

Now we will sequentially consider the most common malfunctions in pumping stations, their causes and methods used to eliminate them.

Pumping equipment rotates, while water does not flow

If the owner turned on the station, the pump impeller began to rotate, and no water enters the pipeline, then this may happen due to certain factors.

If the owner turned on the station, the pump impeller began to rotate, and no water enters the pipeline, then this may happen due to certain factors.

To deal with this problem, you must first check how tight all the connecting pipelines are. You also need to make sure that there is really no water in the system. If no fluid is present, this may indicate a bad check valve. It is located between the inlet pipe of the station and the head of the well

The closest attention should be paid to it. You need to check its status.

Failure of this element is possible if foreign objects get into it.

A special spring controls the operation of the check valve. Sometimes it breaks down, which leads to the failure of this element. In some cases, the valve becomes dirty.To solve the problem, it must be removed and cleaned well. If the valve is faulty, then in this case it is necessary to replace it with a new one.

If the equipment has been idle for a long time, then water may disappear in the area between the well and the pump. In this case, a special filling hole must be used to fill the inlet section.

The lack of water in the system may occur due to the depletion of the well. In order to compensate for the seasonal drop in the water level, the owner can lower the inlet circuit of the pumping equipment deeper into the well shaft. However, this may lead to a risk of contamination. Therefore, in order to avoid this, it is necessary to equip the inlet pipe of the station with a filter.

If there is no water in the pipeline, while the station is working, the pump rotates, then one of the reasons for this may be insufficient voltage of the electrical network. In this case, despite the rotation of the rotor, its rotational speed will not be enough to move the water coming from the well to the desired distance. To check the voltage in the electrical network, you should use a special device - a power tester.

The station pump is turned on frequently, and water is supplied in fits and starts

The reason may be the incorrect operation of the automation unit. Such in pumping stations is a manometer. The main function of this instrument is to measure pressure. Working in jerks, you can observe how the readings of the pressure gauge can change, rising to large values, and then falling sharply.

The reason may be the incorrect operation of the automation unit. Such in pumping stations is a manometer. The main function of this instrument is to measure pressure. Working in jerks, you can observe how the readings of the pressure gauge can change, rising to large values, and then falling sharply.

The reason for this deficiency may be damage that has occurred in the membrane in the accumulator.You can get to the membrane through the nipple, which is located on the back of the accumulator housing. By pressing this part, air should flow from it. If, instead of air, water comes out of it, then this indicates that it is time to change the accumulator membrane. To perform this operation, it is necessary to disassemble the accumulator housing, for which the bolts are unwound, and then the membrane is replaced.

Another reason for the operation of the station in jumps may be the pressure drop in the air cushion located behind the membrane part of the accumulator. The manufacturer usually pumps into this part of the device pressurized air 1.8 atmospheres. If the tightness is broken, then the air will leave and the accumulator will cease to perform its functions. The nipple located under the back of the device can increase the pressure.

If there are traces of rust or microcracks in the body of the device, then the only way out here is to seal the seams. To perform this operation, you must use cold welding. Or you can spend money and replace the body or accumulator.

This malfunction can also occur due to a breakdown of the automatic adjustment unit. It cannot be repaired, so you will have to replace the faulty device with a new one.

The pumping station is working, but the water enters the system jerkily, intermittently

This problem can occur if air is partially drawn into the pipeline. Such suction can occur in the segment, which is located in the area from the suction pipe with a filter to the outlet pipe of the station. To eliminate this shortcoming, it is necessary to ensure the tightness of pipelines and their connections.In addition, it is necessary to achieve a deeper immersion of the suction pipe into the well.

Troubleshooting

Consider ways to troubleshoot:

The first problem can be caused by damage to the tight characteristics of the conductive pipeline, improper functioning of the check type valve, lack of water in the area of the pump or pipeline. To eliminate the breakdown, first of all, you need to make sure that there is water in the latter. In a situation of its absence, you just need to add the missing volume. After that, the integrity of the structure of the check valve and the level of butt tightness are checked, and then the elimination of the detected problems.

In the absence of the desired effect after performing the above series of actions, it can be assumed that the pump is damaged due to the ingress of abrasive components together with water, for example, in the form of sand

Under such conditions, it is important to disassemble the pump and replace its impeller or casing. Occasionally, it may be necessary to install a new pump.

The second problem: too frequent switching on of the pumping station is often provoked by damage to the hydraulic tank

Due to these circumstances, the pumping station does not build up pressure. To prevent such a breakdown, it is first necessary to press the nipple, which is located on the back of the tank. If water flows through it, we can talk about a torn membrane, which must be replaced.

The third problem is represented by the failure of the pump. The prerequisites for this are the missing power supply. The problem is solved by checking and, probably, cleaning the contacts of the pump water pressure switch, which are burnt.

Fourth problem: the pump does not rotate when it is on. This is facilitated by a faulty capacitor, or an “glued” impeller to the pump housing. In such a situation, to start the impeller that is blocked, it is enough to scroll it several times by hand. With a broken capacitor, the only way out is to replace it.

Fifth problem: non-shutdown of the unit, its continuous operation. Caused by malfunction of the pressure switch. It is solved by configuring this part.

To identify the reasons that provoke the mechanism not to turn off, it is imperative to check the condition of the inlet on the relay in question. It may be dirty and need to be cleaned.

You may also be interested in the article on household pumping stations for summer cottages.

Read an article about setting up and adjusting a pumping station with your own hands here.

Thus, if you have the necessary spare parts, possessing certain knowledge and skills, repairing a pumping station at home will not be difficult.

Watch the video, which explains the main malfunctions and how to repair the pumping station with your own hands: