- The pump does not draw water

- 2 Model range of equipment

- 2.1 Marina CAM

- 2.2 Marina APM

- 2.3 Typical malfunctions and repairs

- How to troubleshoot on your own?

- Pumping equipment rotates, while water does not flow

- The station pump is turned on frequently, and water is supplied in fits and starts

- The pumping station is working, but the water enters the system jerkily, intermittently

- Pump "Vodomet": do-it-yourself installation and repair

- The pump does not turn on:

- The pump turns on, but does not pump water:

- The pump frequently turns on and off:

- The pump works, but the pressure is weak:

- If the pump is broken

- How to prevent damage to pumping equipment?

- Equipment does not start

- Self-employment or professional help?

- The purpose of the pumping station

- The composition of the pumping station

- The composition of the pumping station and the purpose of the parts

- The principle of operation of the pumping station

- How to protect the station from breakdowns

- Pump repair

- Impeller replacement

- Oil seal repair

The pump does not draw water

When it turned out that the pump does not pump water, one of the reasons may be that the pressure in it is not adjusted correctly. Troubleshooting is carried out according to the scheme:

- the pumping station is turned off from the mains;

- water is drained from the water tank;

- the air pressure in the tank is measured through the nipple with a car pump with a pressure gauge or a compressor, its optimal value is 90-95%;

- air is pumped into the water supply system.

- water is poured into the station;

- joins the network with pressure control.

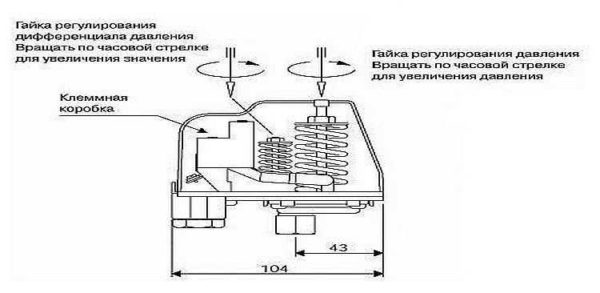

The air in the water supply system is pumped as follows. The cover from the pressure switch is removed by removing the plastic screw and changing the tightening force of the existing assembly springs. Turning one nut turns on the lower value of the pump. Rotation by the hour hand contributes increasing pressure, while turning counterclockwise causes the pressure to drop.

Turning the other nut adjusts the pressure range between the lower and upper limits. The range limits are changed by rotating the element clockwise to expand it, counter-clockwise to decrease it. After the steps taken, the pumping station is connected to the mains, and its performance is checked.

2 Model range of equipment

The product line of Speroni (Italy) includes 4 series of Marina pumping stations:

- Marina CAM is a budget option for water intake from wells up to 9 m deep;

- Marina APM - pumps for wells up to 50 m deep;

- Marina Idromat - units equipped with a regulator that turns off the pump when running dry.

Let's take a closer look at each of these lines.

2.1

marina cam

The CAM series consists of equipment made in a cast-iron or stainless steel case, with internal fittings made of food-grade polymers. Several models are presented, the power of which varies between 0.8-1.7 kW, and the head is 43-60 m.

The volume of the accumulator can be 22, 25 or 60 liters.These are the most affordable stations for private use, the cost of which starts at 7 thousand rubles.

Among the stations with the best price / quality ratio, we highlight:

- Marina Cam 80/22;

- Marina Cam 60/25;

- Marina Cam 100/25.

The Marina Cam 40/22 pumping station is equipped with a 25 liter hydraulic accumulator, the capacity of which will be enough for a family of 3 people. The capacity of the unit is 3.5 m 3 / hour, the maximum lifting depth is 8 m. The price is 9 thousand rubles.

Marina Cam 100/25 has similar technical characteristics - a tank of 25 liters, a throughput of 4.2 m 3 / hour, however, this model is equipped with a pressure boosting system that significantly increases the delivery head - up to 45 m, compared to 30 m for CAM 40 / 22.

2.2

Marina APM

Well pumps of the APM series have a maximum water intake depth of 25 m (model 100/25) and 50 m (200/25). This is more power and overall equipment, the weight of which can reach up to 35 kilograms. As an example, consider the popular station Marina ARM 100/25.

Specifications:

- head - up to 20 m;

- throughput - 2.4 cubic meters / hour;

- centrifugal motor power - 1100 W;

- the diameter of the supply pipe is 1″.

AWP 100/25 is made in a stainless steel case, the model is equipped with overheating protection and a water level control system in the hydraulic tank. ARM100/25 is designed for pumping clean water, without mechanical impurities, the temperature of which does not exceed 35 degrees.

2.3

Typical malfunctions and repairs

Marina pumping stations have established themselves as reliable and durable equipment, however, like any other equipment, they are not immune from breakdowns.We bring to your attention a list of the most common breakdowns and how to fix them:

- Lack of water supply when the pump is on, the cause of which may be a loss of tightness in the conductive pipelines and a worn check valve. First check if you forgot to fill the pump body with water. If it is, inspect the check valve and the tightness of its fit to the pump nozzle, and also check the condition of the intake pipe - all damaged components must be replaced. Similar problems are possible if the impeller is damaged, to replace which you will need to disassemble the unit.

- Water is supplied in jerks due to a damaged accumulator. The main malfunction of the hydraulic tank is a damaged membrane. To determine if it is intact, press the nipple (located on the tank body), if water flows from the nipple and not air, then the membrane is torn. It is quite easy to install the membrane, you just need to unscrew the fixing ring from the tank neck, pull out the old part and mount a new one in its place.

- Reduced water supply pressure. The reason for this can be either a faulty hydraulic tank or problems with the pump. In the first case, the depressurization of the tank is most likely to blame - inspect the body for cracks, repair the detected deformations and pump air up to the standard value. If the tank is intact, the problem must be sought in the deformed impeller of the centrifugal wheel inside the pump.

We will separately consider the situation when the pumping station does not want to work in automatic mode - the unit does not turn off when the tank is full and does not turn off when it is empty.The incorrect adjustment of the pressure switch is to blame here - it is usually calibrated at the factory, but there are exceptions.

The above diagram shows a standard pressure switch for Marina pumps. On it, under the plastic cover of the case, there are two springs. Most of them rotate clockwise, it is responsible for the minimum pressure in the tank at which the station turns on. By rotating a small spring, we adjust the maximum pressure, upon reaching which the pump turns off.

Adjustment of the pressure switch must be carried out with the equipment disconnected from the mains. Before starting the calibration, it is necessary to drain the water from the tank, the level of air pressure is also important - it must correspond to the value recommended by the manufacturer.

How to troubleshoot on your own?

Now we will sequentially consider the most common malfunctions in pumping stations, their causes and methods used to eliminate them.

Pumping equipment rotates, while water does not flow

If the owner turned on the station, the pump impeller began to rotate, and no water enters the pipeline, then this may happen due to certain factors.

To deal with this problem, you must first check how tight all the connecting pipelines are. You also need to make sure that there is really no water in the system. If no fluid is present, this may indicate a bad check valve. It is located between the inlet pipe of the station and the head of the well

The closest attention should be paid to it. You need to check its status.

Failure of this element is possible if foreign objects get into it.

A special spring controls the operation of the check valve. Sometimes it breaks down, which leads to the failure of this element. In some cases, the valve becomes dirty. To solve the problem, it must be removed and cleaned well. If the valve is faulty, then in this case it is necessary to replace it with a new one.

If the equipment has been idle for a long time, then water may disappear in the area between the well and the pump. In this case, a special filling hole must be used to fill the inlet section.

The lack of water in the system may occur due to the depletion of the well. In order to compensate for the seasonal drop in the water level, the owner can lower the inlet circuit of the pumping equipment deeper into the well shaft. However, this may lead to a risk of contamination. Therefore, in order to avoid this, it is necessary to equip the inlet pipe of the station with a filter.

If there is no water in the pipeline, while the station is working, the pump rotates, then one of the reasons for this may be insufficient voltage of the electrical network. In this case, despite the rotation of the rotor, its rotational speed will not be enough to move the water coming from the well to the desired distance. To check the voltage in the electrical network, you should use a special device - a power tester.

The station pump is turned on frequently, and water is supplied in fits and starts

The reason may be the incorrect operation of the automation unit. Such in pumping stations is a manometer. The main function of this instrument is to measure pressure.Working in jerks, you can observe how the readings of the pressure gauge can change, rising to large values, and then falling sharply.

The reason for this deficiency may be damage that has occurred in the membrane in the accumulator. You can get to the membrane through the nipple, which is located on the back of the accumulator housing. By pressing this part, air should flow from it. If, instead of air, water comes out of it, then this indicates that it is time to change the accumulator membrane. To perform this operation, it is necessary to disassemble the accumulator housing, for which the bolts are unwound, and then the membrane is replaced.

Another reason for the operation of the station in jumps may be the pressure drop in the air cushion located behind the membrane part of the accumulator. The manufacturer usually pumps air under a pressure of 1.8 atmospheres into this part of the device. If the tightness is broken, then the air will leave and the accumulator will cease to perform its functions. The nipple located under the back of the device can increase the pressure.

If there are traces of rust or microcracks in the body of the device, then the only way out here is to seal the seams. To perform this operation, you must use cold welding. Or you can spend money and replace the body or accumulator.

This malfunction can also occur due to a breakdown of the automatic adjustment unit. It cannot be repaired, so you will have to replace the faulty device with a new one.

The pumping station is working, but the water enters the system jerkily, intermittently

This problem can occur if air is partially drawn into the pipeline.Such suction can occur in the segment, which is located in the area from the suction pipe with a filter to the outlet pipe of the station. To eliminate this shortcoming, it is necessary to ensure the tightness of pipelines and their connections. In addition, it is necessary to achieve a deeper immersion of the suction pipe into the well.

Pump "Vodomet": do-it-yourself installation and repair

The rise of water from a deep source - a well or a well - is carried out using a pump.

Depending on the type, the pump is lowered below the water level, or mounted on the ground, and in water is lowered by a pipe or hose. Accordingly, such pumps are called submersible or surface.

The operating conditions of a submersible pump are much more difficult, since it is constantly in the water at great depths.

It also complicates maintenance and repair work on the pump, since the pump must be lifted to the surface instead of being completely bundled with pipes, cables and ropes.

For example, consider the Vodomet centrifugal pump, popular with many suburban homeowners.

water jet pump

The pump does not turn on:

- check the power cable going to the pump. Check for mains voltage.

- the mains protection trips too often. It is necessary to check the network for short circuits and current leakage. Call a professional electrician.

- the pump control panel does not function. Call the service department or take the unit to the manufacturer's warranty department.

The pump turns on, but does not pump water:

- The pump turns on but does not pump water. The non-return valve may be incorrectly installed or blocked.

- air lock in the pump. Perhaps the dynamic level has decreased.Lower the pump to a greater depth.

check the pressure in the accumulator

The pump frequently turns on and off:

- check the tightness of the accumulator, pipes, hoses, connections and pump

- check the range of recommended working pressure in the accumulator

- downhole pump installed too high capacity

The pump works, but the pressure is weak:

- the filter screen is clogged.

- decrease in pump efficiency due to the ingress of large amounts of sand.

- heavy wear of the pump mechanism.

- the pump consumes too much electricity

If the pump is broken

What to do if the pump fails?

- if the filter is clogged, it is necessary to disassemble the pump, clean or replace the strainer.

- the pump mechanism is jammed due to the ingress of solid particles. The pump must be cleaned, an additional filter should be installed to protect against solid particles, or the pump should be raised slightly, moving it away from the sand accumulation at the bottom of the well.

steel filter mesh

- increased power consumption may be due to increased friction between parts due to sand ingress.

- in case of severe wear of the pump mechanisms, it will be necessary to inspect and repair it at a service center to replace individual components, or to replace the entire pump.

How to prevent damage to pumping equipment?

Water lifting equipment for autonomous water supply contains complex mechanical and electronic components. In order for all equipment to work for a long time and without failures, certain requirements must be observed, which the manufacturer usually indicates in the technical data sheet of the product.

Recommendations for the quality work of an autonomous water supply system:

- it is necessary to ground all equipment, to protect the pump from power surges and other negative manifestations of the power supply.

- the pump must hang on a special steel cable, and not on an electrical supply cable or a plastic pipe. When the pump is detached, it will be necessary to carry out complex and expensive work to lift the equipment that has fallen into the well.

steel safety rope

- check, disassemble and repair the pump, as well as other equipment, only when completely disconnected from the mains.

- organize protection of the pump against "dry running" and overheating

- the maximum depth of lowering the pump is 1 m from the bottom of the well. Otherwise, the risk of sand getting into the pump mechanisms increases.

- Eliminate any possible route for sand and other hard abrasive substances to enter the pump.

Subject to all the requirements for the operation of the Vodomet downhole pump and related equipment, the autonomous water supply system will serve you for a long time without failures.

Equipment does not start

Most often, the unit does not turn on and does not draw water due to the fact that there was a break in the power supply. To determine the location of the break in the circuit, you will have to use a tester. First of all, it is necessary to check the communications through which the pump pumps water, as well as the pressure switch, on the contacts of which oxide can collect and cause them to malfunction. To clean the contacts, you can use fine-grained emery or a needle file.

If the pump does not pump water and does not turn on, and no network breaks are found on the segment from it to the source, then it is necessary to check each node of the pumping equipment, namely the winding and contacts.

Sometimes the pump does not draw water and does not start due to a breakdown of the starting capacitor. In this case, you will have to replace it yourself.

If, after starting the unit, a characteristic noise appears, but the impeller and other rotating parts do not start to move, then there may be several reasons:

- If the device has been in storage for a long time and has not been used, then most likely the impeller has stuck to the body. To eliminate the malfunction, it is enough to turn the impeller manually several times.

- Sometimes the cause of such a problem can be a breakdown of the capacitor. In this case, it will have to be replaced.

- If the parameters of the electrical network have changed, that is, the voltage is lower than the nominal voltage, then the unit will not work.

Video instructions for repairing pumping equipment for water supply of a country house:

Self-employment or professional help?

Given submersible pump malfunctions allow you to deal with problems on your own, without the involvement of a master. However, even in these cases, one must be well aware that without knowledge of the technique, the problem that has arisen and minimal skills, it is quite difficult to cope with the repair.

Before searching for any malfunction, you must familiarize yourself with the design. First of all, you need to carefully study the instructions for the unit, its diagram. In order not to get unnecessary details later, you need to remember the sequence of actions during disassembly. When working with any unknown device, it is recommended to photograph every step you take.

The price of a submersible pump plays a big role. Small "liberties" are allowed when repairing simple, inexpensive models, since in this case it will be more or less easy to assemble and disassemble the structure.Expensive imported (European) models have a longer warranty period, so the best way out in this case is to contact a service center.

The purpose of the pumping station

The pumping station is the "heart" of your autonomous water supply system. A well-designed autonomous water supply system necessarily includes a well that provides sufficient water production to meet the needs of one or more households. In the vast majority of cases, water from such a well has to be raised. Since the water in the wells lies at great depths, it is necessary to raise it from there by pumping devices. So that the pumps are not activated every time you turn on the water tap in your house, so that there is always constant pressure in the plumbing system of your house, a pumping station is needed.

Pumping station in the house

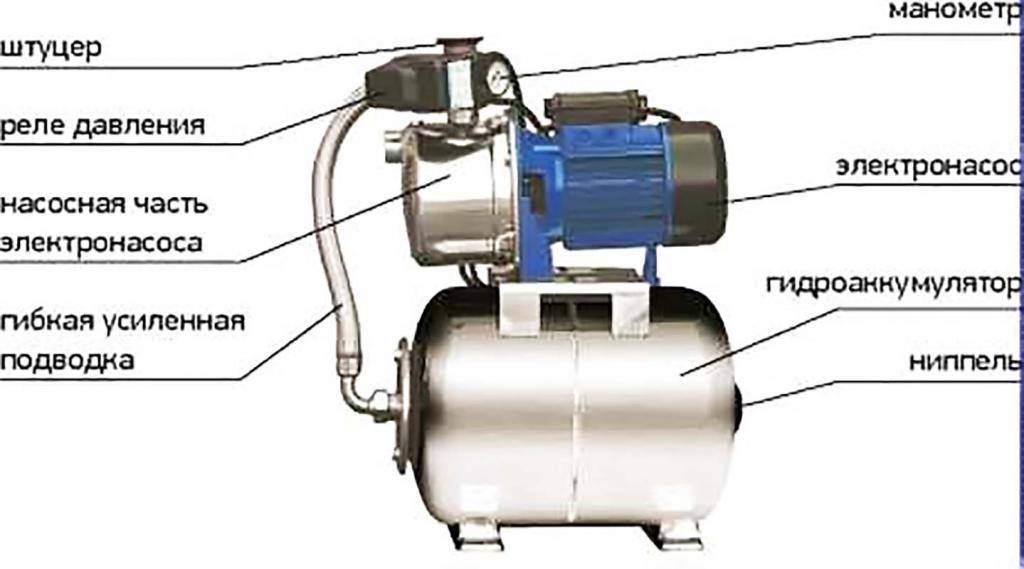

The composition of the pumping station

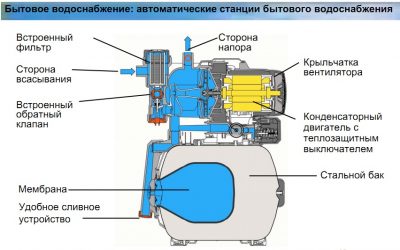

A classic pumping station consists of the following main elements.

-

Actually, the pumping device. Usually, pumping stations use surface pumps, which are installed either in the utility rooms of the house, or in specially equipped caissons. The peristaltic pump must produce enough power to lift water from the well, move it to the house and raise it to the highest point of your home's water intake.

Water supply pump

-

Pressure accumulator or hydraulic accumulator. This device is a strong metal container that maintains a constant pressure in the water pipelines of the system.The most common pressure accumulator model is a metal cylinder with an elastic rubber membrane inside. During operation of the pumping device, the membrane is stretched to a certain level. When the pumping device stops working, the membrane, trying to return to its original position, displaces water from the tank.

Hydraulic accumulator (pressure accumulator)

-

In order for the pumping device to turn on and off when certain pressure parameters in the system are reached, an automation unit is required, which is equipped with a pressure sensor. When the pressure in the system drops to a certain level, the relay is activated, the pump turns on and water begins to fill the pressure accumulator. When the maximum pressure in the system is reached, the pumping device is turned off.

Pump station pressure switch

As you can see, the concept of "pumping station" is only a set of components and equipment that can be used on their own. In industrially produced pumping stations, all main units can be assembled in a single building, however, most often a finished pumping station is a pumping device installed on a pressure accumulator. Also, an automatic control device is fixed on a single frame.

During the warranty operation, problems in such equipment, as a rule, do not arise. In any case, malfunctions that occur at this time can be fixed at service centers. However, with a long period of operation, various components of the pumping station may fail.Let's try to figure it out and find out how you can independently eliminate the most common malfunctions of pumping stations.

The composition of the pumping station and the purpose of the parts

A pumping station is a collection of separate devices interconnected. To understand how to repair a pumping station, you need to know what it consists of, how each of the parts works. Then troubleshooting is easier. The composition of the pumping station:

Each of the parts is responsible for a certain parameter, but one type of malfunction can be caused by the failure of various devices.

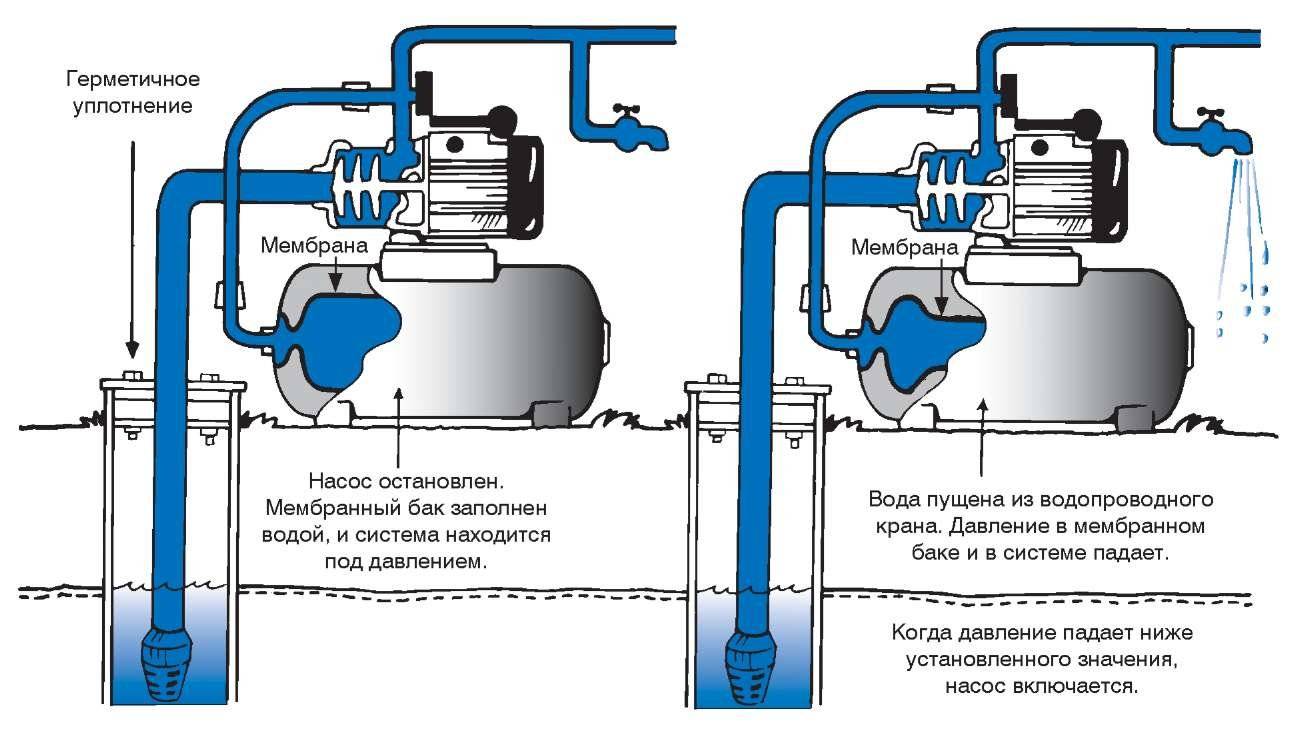

The principle of operation of the pumping station

Now let's look at how all these devices work. When the system is first started, the pump pumps water into the accumulator until the pressure in it (and in the system) equals the upper threshold set on the pressure switch. While there is no water flow, the pressure is stable, the pump is off.

A faucet was opened somewhere, the water was drained, etc. For a while, water comes from the accumulator. When its quantity decreases so much that the pressure in the accumulator drops below the threshold, the pressure switch is activated and turns on the pump, which pumps water again. It turns off again, the pressure switch, when the upper threshold is reached - the shutdown threshold.

If there is a constant flow of water (a bath is taken, watering the garden / vegetable garden is turned on), the pump works for a long time: until the required pressure is created in the accumulator. This happens periodically even when all taps are open, since the pump supplies less water than flows out of all points of analysis.After the flow has stopped, the station works for some time, creating the required reserve in the gyroaccumulator, then turns off and turns on after the water flow appears again.

How to protect the station from breakdowns

If the problem is already there, then after the repair you need to check whether everything was done correctly at the stage of arranging the source. So, pipes and hoses should not be bent or deformed, which leads to a decrease in throughput.

The system includes a check valve that prevents the reverse flow of fluid through the pipeline. Check if the pump power is correct. To do this, the calculation includes the depth of water in a well or well, the distance of the source from the house, the number of consumers. The flow rate of the source cannot be less than the capacity indicated in the technical passport for the pumping station.

Any leaky connection can cause air leakage, which causes interruptions in the water supply. And attempts to save money by excluding any of the nodes from the system always leads to the fact that it works inefficiently. But all this can be fixed if you correctly select all the components and mount them in the right sequence.

The procedure is simple if you approach the issue with due attention.

Helpful39Useless1

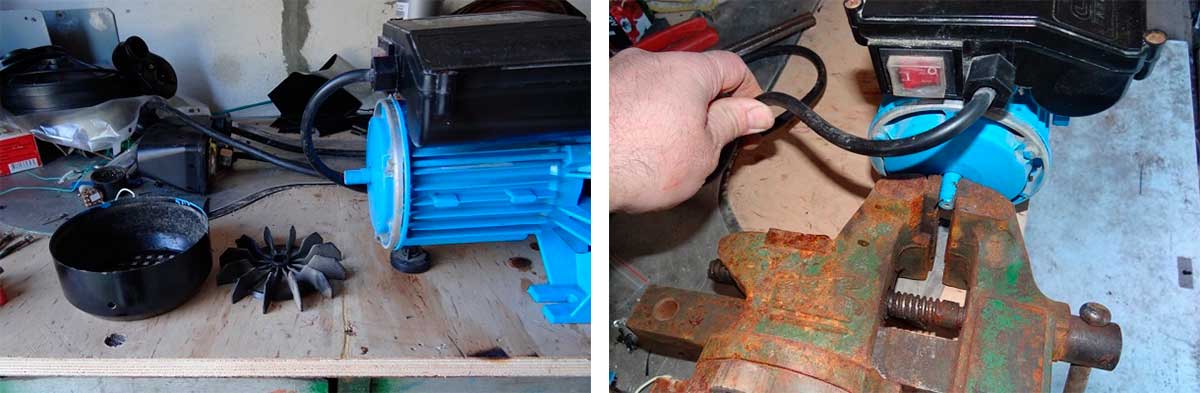

Pump repair

Unfortunately, repairing the pump with your own hands is not so simple. It's still an electrical appliance. After a long operation and if the pumping station did not work for a long time, for example, it was mothballed for the winter period, then sometimes when turned on, the pump starts to buzz, and its rotor does not rotate. The main reason for this malfunction is that the motor bearings are jammed because moisture has penetrated into them.During long-term storage, corrosion has formed on the surfaces of the bearings. She prevents them from spinning.

Pump station details

The easiest way to start the pump is to move its rotor. What can be done for this.

- It is necessary to remove the back cover of the unit, where the impeller is installed to cool the device.

- You can try to spin the impeller by hand. If she succumbed, then you also need to spin the motor shaft by hand, and then turn on the pump itself by pressing the "Start" button.

- If it didn’t work out by hand, then you will have to remove the impeller from the motor shaft and try to spin it with an adjustable, but better gas wrench.

Of course, it would be better to open the pump motor and lubricate the bearings. But with your own hands, if you have never done this, it is better not to open anything and not disassemble the design of the device. And even more so to engage in the replacement of the bearing of the water pump.

Impeller replacement

Exactly the same situation, that is, the motor hums and does not rotate, may occur due to jamming of the impeller, which is also called the impeller. It is located inside the working chamber, and there is a very small gap between it and the pump housing. It is after a long storage of the working unit that rust growths form in this gap, which cause the rotor to jam.

You can solve the problem by spinning the shaft, as is the case with bearings. But if this did not help, then it means that the impeller has firmly stuck to the body. And it is best to replace it with a new one. How to replace the impeller of a pumping station?

- The working chamber of the pump consists of two parts, which are interconnected by four bolts. Therefore, they must be unscrewed and disconnected from one part to another.How the impeller is removed

- The impeller is mounted on the motor shaft. To remove it, unscrew the clamping nut that holds it.

- Since the shaft rotates in bearings, the bolt cannot simply be unscrewed. It is necessary to fix the rotor itself.

- Therefore, it is necessary to remove the back cover and the fan impeller.

- Then clamp the rear end of the shaft, for example, with the same gas wrench, and on the other side, unscrew the nut with an adjustable wrench.

- After tapping lightly on the impeller with a hammer, you need to pry it off with a screwdriver and pull it off the shaft.

- A new impeller is installed in its place, and all operations are performed from the reverse order.

This is how you can answer the question of how to remove the impeller from the pumping station. Let's face it, the complexity of this operation lies in the fact that during long-term operation, the impeller can stick to the shaft. Therefore, before dismantling it, it is necessary to lubricate the connection point, for example, with technical oil or plain water.

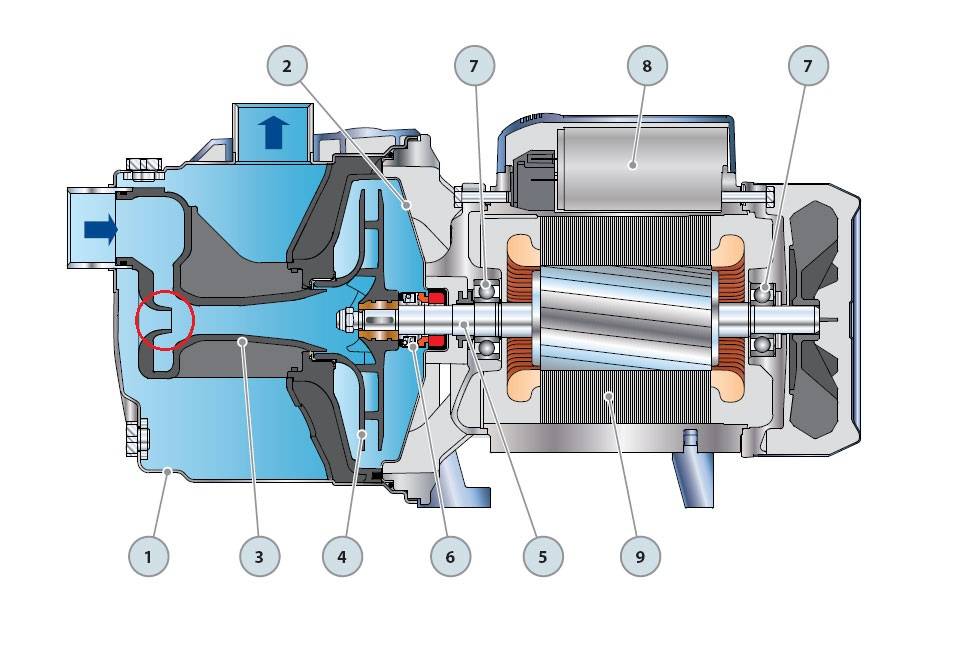

Oil seal repair

By the way, when replacing the impeller, it is necessary to repair the stuffing box of the pumping station. If the working chamber is already open, then it is worth checking everything in it thoroughly. The weak point in this part is the stuffing box, which separates the working chamber from the compartment where the electrical parts of the pump motor are located. It consists of two parts: one is located inside the working chamber, the second in the electrical compartment.

Seal in the pump

Therefore, the first part is first removed, for which it is necessary to remove the retaining ring, which the stuffing box supports. The rubber element itself is removed by hand.

The second part is more difficult. You will have to pull the rotor of the electric motor out of the stator.To do this, unscrew the four bolts from the back of the motor, remove the cover along with the rotor. Just pull it towards you, holding on to the cover.

Next, the second part of the gland is removed.

Assembly is done in reverse order.

It is very important here when pulling out and inserting the rotor into the stator not to damage the copper winding.

As you can see, do-it-yourself repair of a pumping station (replacing the stuffing box, impeller) is not the easiest process. But if you understand it, then you can do without a master. By the way, if you have already opened the electric motor, then immediately lubricate its bearings. But most often in these designs, the bearings have a closed design, so if they work poorly, it is better to change the parts.