- Types and causes of breakdowns

- The main causes of pump failure

- The most common breakdowns

- Repair of drainage pumps

- Video: Gileks drainage pumps

- Possible causes of malfunction

- Preventive measures

- No water comes out while the pump is running

- Recommendations for the installation and operation of pumping stations

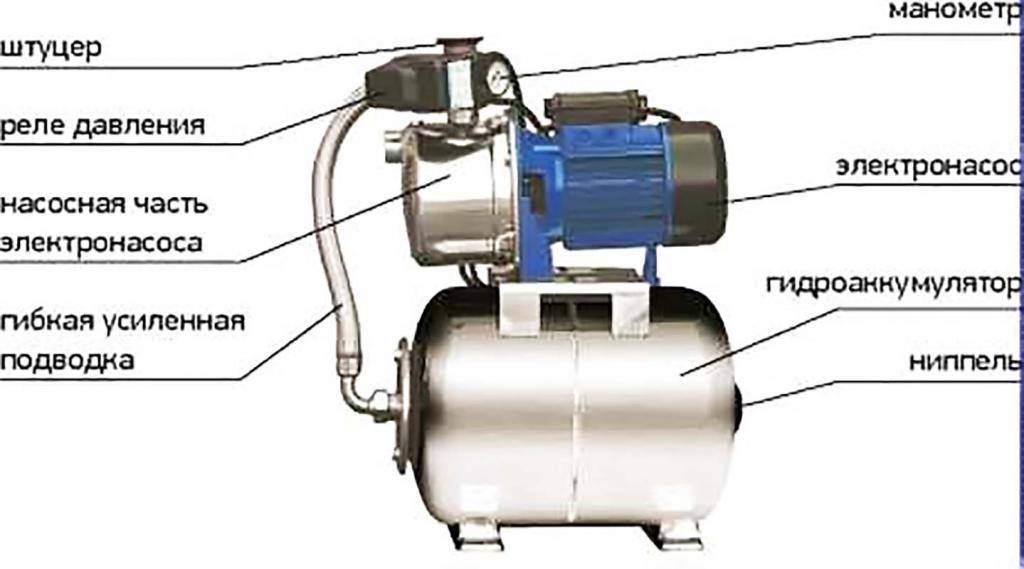

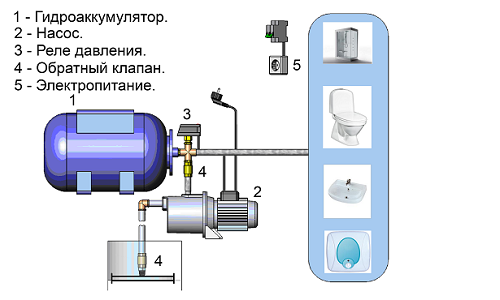

- The device of a complex of pumping equipment

- What is a pumping station?

- A little about relay adjustment

- The purpose of the pumping station

- The composition of the pumping station

- How to find out the cause of a malfunction of a submersible pump?

- What do they do first?

- Where might the problem lie?

- Pressure switch adjustment

- Stages and rules of repair

- 2 Model range of equipment

- 2.1 Marina CAM

- 2.2 Marina APM

- 2.3 Typical malfunctions and repairs

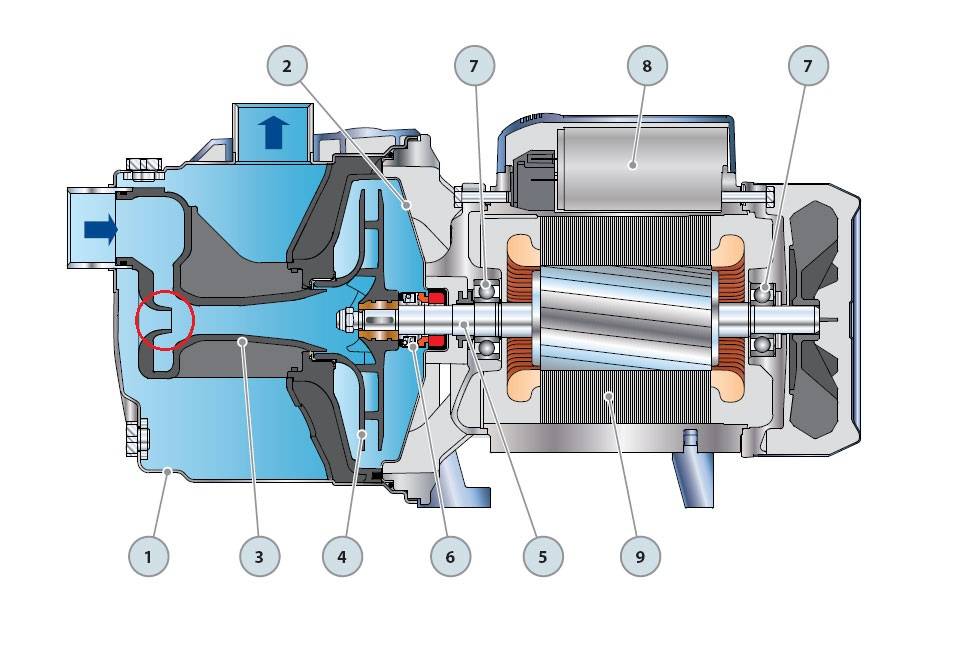

- Principle of operation

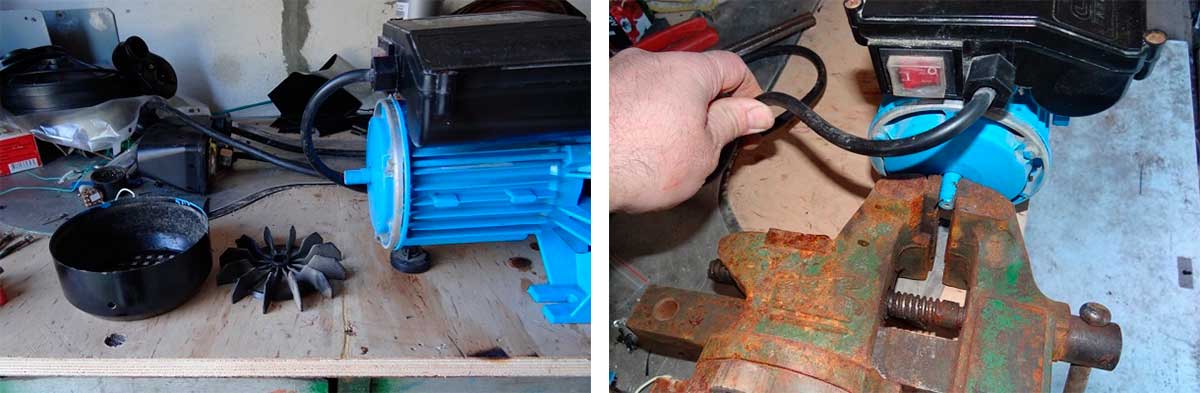

- How to disassemble the pumping station

- The pumping station is running (the pump is spinning), but there is no water:

- Conclusion

Types and causes of breakdowns

To better understand how to repair a borehole pump with your own hands, it is worth understanding the causes of certain malfunctions and understanding the most typical problems. Of course, anything can break during use, but there is a certain set of so-called “diseases” that manifest themselves most often.

The main causes of pump failure

We note right away that most often the unit fails due to the owners' own negligence. Many of them, when purchasing a pump, do not even read the instructions, which spell out the rules for use and basic safety measures.

Moreover, the vast majority of users do not get out of there until it breaks, and this could be avoided by removing it for inspection at least once a year.

But even with a responsible attitude, malfunctions can occur, consider the most common of them:

- Dry running of the equipment, this occurs if the pump is suspended too high or falls too much in the process. The mechanism must work with water - it serves as a coolant and lubricant, without it, overheating and jamming, and sometimes melting of plastic parts, occur.

- Using a pump that is too powerful, in this case the intake is too intense, and sand is sucked from the bottom, which can severely damage the main pumping part - the pump impeller.

- Fluctuations and surges in power supply can render the capacitor and other electrical parts unusable. Voltage stabilizers should be used.

- And, finally, the banal wear of the nodes can serve as the cause of breakdowns.

The most common breakdowns

The most common causes of failures are:

- Accumulator and non-return valve malfunctions - these components are not included in the system, but if they do not work correctly, the pump is not protected from pressure drops and will most likely receive a water hammer.

- Erosion and damage to impellers, shafts and other moving parts.

- Winding and capacitor faults.

- Clogging of the system with sand and silt.

Repair of drainage pumps

Most often this happens:

- improper operation when the operating parameters of the device are exceeded;

- a long period between maintenance;

- long operation of the device in the "dry" mode;

- very large solids in the pumped liquid (then the drainage pump does not pump water);

- poor-quality installation of the pump;

- manufacturing defect.

When the device is inexpensive, the drainage pump is disassembled and repaired by oneself, subject to the skills of handling such units.

If the first signs of improper functioning of the submersible pump appear, you need to check the performance and condition of individual elements:

- the piston must be flexible and cannot be mechanically damaged;

- it is necessary that the air blown in at the place of fluid intake pass freely on both sides;

- the optimal distance between the piston and the coils of the electromagnet is from 0.4 to 0.5 centimeters. If the gap is larger, the coils are beating, and when it is smaller, the motor overheats;

- between the valve that closes the inlets and the body, the gap should be from 0.7 to 0.8 millimeters.

Often the cause of poor performance of equipment is not a breakdown of individual elements, but a voltage drop in the mains. Before you disassemble the drainage pump and start repairing it yourself, you need to check the voltage in the network, which should be 200-240V. If this parameter is normal, you can proceed to disassembly by making special notches on the joined sections of the device.

If the drainage pump that is in working condition does not pump, then the possible reasons are as follows:

- air got into the intake part;

- insufficient immersion depth of the unit;

- the intake element is not covered with liquid.

Only under the condition of timely troubleshooting of the drainage pump will it ensure its operation for a long time without serious problems.

Do-it-yourself repair of a drainage pump, alas, is not always possible. Certain malfunctions can only be eliminated by specialists in a specialized workshop. Some breakdowns cannot be fixed at all - even replacing a part will not save, you will have to buy new equipment. The list of self-repaired faults is short, but still worthy of consideration.

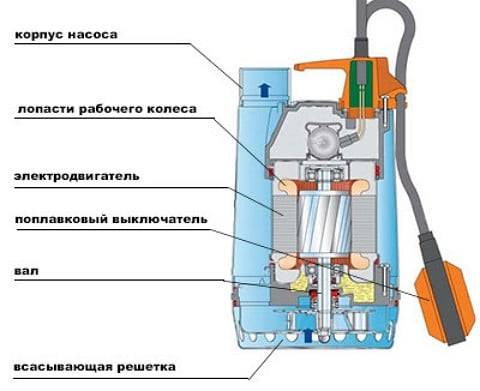

- the motor drives the impeller mounted on the shaft;

- impeller plates disperse the liquid inside the pump casing;

- under the action of centrifugal force, the liquid enters the outlet;

- the vacated space is immediately occupied by the liquid entering through the inlet.

The holes are located at different levels. It depends on the type of pump: submersible, surface. Submersibles take water from below, not from the side.

Drain pump diagram

Video: Gileks drainage pumps

Unplanned do-it-yourself repairs or in the workshop will not be needed if you follow the simple rules for operating the equipment, which are detailed in this video clip of the manufacturer. It also talks about the principle of operation of devices.

Possible causes of malfunction

Even if the owner has purchased a branded high-quality pump, the possibility of its failure cannot be ruled out. Since the operation of all water structures is usually associated with water, such a device is constantly prone to negative impact.

Of course, it is possible to learn how to repair the unit, but it is better to operate it correctly from the very beginning, conduct its regular inspection, and do preventive maintenance.

Often the cause of pump failure is worn parts.

Possible causes that led to the breakdown of the device:

- Work on "dry", water hammer;

- Power surges;

- Pumping of very contaminated liquid;

- Operation in the winter;

- Poor quality cable connection;

- Submarine cable is fixed incorrectly;

- The working fluid exceeds its level by 40%;

- No oil;

- Lack of grounding leading to corrosion;

- The pressure switch is out of order;

- The magnet is broken;

- The hydraulic tank is not working properly.

All of the above factors, to one degree or another, cause the device to malfunction. In some cases, you can make repairs with your own hands, but there are also such breakdowns that can be fixed only with the help of specialists.

Preventive measures

Preventive measures include the following: instrument inspection, cleaning, operation. The unit should be inspected once a quarter. This will be enough to identify any damage or malfunctions.

If you comply with all operating conditions and carefully control the equipment, you can enjoy the smooth operation of the pump for a long time.

It is recommended to repair the pump with the pump disconnected from the pipes

Periodic check of device operation:

- All connections must be checked for leakage, if necessary, change seals or gaskets;

- Grounding is visually checked;

- The sound of the pump must be clear;

- The pressure is checked;

- Absence of strong vibration in the engine;

- The body must be clean and dry.

If any failure occurred in the operation of the pump, it is necessary to immediately make a diagnosis and identify the cause. If it indicates a malfunction of the device, it must be repaired independently or in a special workshop.

Not a single private arrangement of a site or a house is complete without a water pump. It is imperative to monitor its work in order to prevent serious damage to the device.

No water comes out while the pump is running

The lack of water pressure during stable operation of the station may indicate the appearance of several negative factors. First of all, it is necessary to check the liquid level in the source - a well or a well. The amount of contaminants is also controlled. They can clog the pre-filter, thereby blocking the flow of water.

In addition, failure is often associated with the following circumstances:

- The state of the check valve located in the source. Its clogging is a common cause of lack of pressure.

- Lack of water in the line between the well and the pumping station. Some models can only work when completely filled with water. In its absence, the protective automation is activated.

- Non-working condition of coarse and fine filters.

It is recommended to constantly check the source for the amount of abrasive contaminants. If their number is large enough, you need to equip additional filters between the pump and the well.

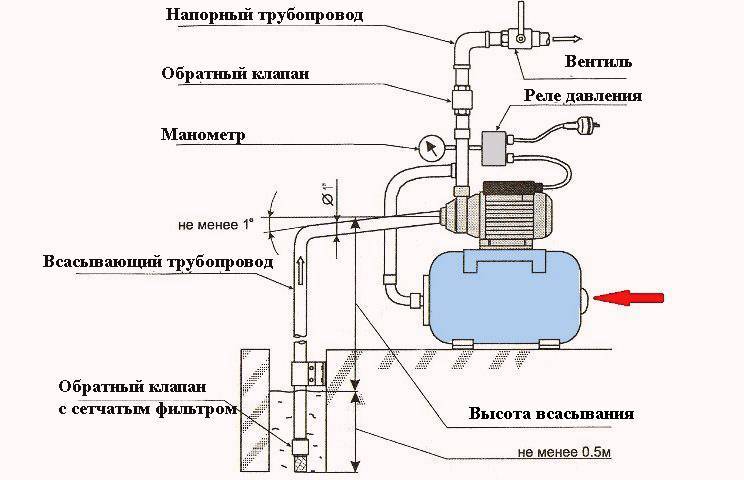

Recommendations for the installation and operation of pumping stations

If the installation of the station is carried out in accordance with the recommendations, then less breakdowns will occur during operation.

Tips:

- Pipelines are made of plastic, so during installation they should not be twisted so that their throughput is not reduced.

- All docking points are checked for tightness.

- As a detachable connection, it is recommended to use an "American", which has proven itself well.

- The installation of a check valve is mandatory. It is advisable to provide the unit with a protective mesh to prevent dirt from entering.

- The pipeline drops below the surface of the water level in the well by 30 cm. The distance to the bottom should remain 20 cm so as not to capture dirt from below.

- Pipe diameters are laid larger if water is transported from a distant source. The maximum depth of the liquid level should not exceed 4 m.

- It is better to mount protection against dry running in the system.

During maintenance, the device does not require human intervention. The exception is the hydraulic accumulator. Here, the air pressure level is checked monthly and pumped if necessary. The excess is bled off so that the useful volume of the tank area does not decrease. The relay is periodically inspected, the contacts are cleaned, and accumulated dirt is removed.

In the presence of a pumping station, so that it causes less trouble, regular maintenance should be carried out. First of all, it concerns the accumulator. Constantly monitor the tightness of the system. Troubleshoot minor faults and, if necessary, carry out major repairs with your own hands.

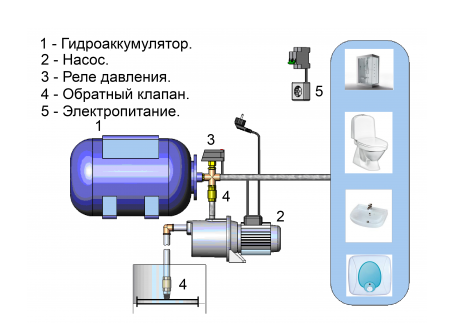

The device of a complex of pumping equipment

In order to understand what malfunctions can occur in the complex of pumping equipment during the organization of pumping water supply, how to fix them, it is necessary to know the composition of the devices and the procedure for their operation.

Pumping stations consist of the following units:

- actually pumping equipment. Depending on the characteristics of the water supply source, pumps can be submersible or surface. They can have different modes of operation and power;

- hydraulic pressure accumulator. This knot is a container, which is divided into two parts by a flexible but durable rubber partition. During the operation of the pumping device, the container is filled with water and the rubber partition is stretched. When the pump stops, the partition tends to return to its original position and returns the water accumulated in the tank to the pipes, maintaining the pressure in the water supply pipelines at a constant level;

- control block. This assembly consists of a manometer that measures the pressure in the system. The mechanical parts in the control unit set the minimum and maximum pressure values. When the minimum indicators are reached, the unit gives a command to turn on the pump, and when the maximum indicators are reached, the pumping equipment is turned off.

What is a pumping station?

Owners of their own water supply system on the territory of a private house or cottage often encounter various kinds of malfunctions. Basically, pumping stations contain the following elements:

- water pump;

- hydraulic accumulator;

- relay;

- manometer.

The main task of the water pump is to draw water from the right source.Popular among consumers are surface pumps installed either in special rooms of the house, or in caissons adapted for this. The pump must have sufficient power to lift water from the well, move to the house and raise it to the upper draw-off point of the dwelling.

An important component is a hydraulic accumulator (storage tank) with a capacity of 20 liters or more. A hydraulic accumulator is a metal container, the task of which is to keep constant pressure in the pipelines of the station. A successful battery model in the form of a metal cylinder with a rubber membrane inside. The membrane stretches and goes back to its previous position, depending on whether the pumping station is working or not.

The relay turns the pump on and off, determining the need for its operation by the water level in the tank. The pressure gauge is designed to indicate the pressure level in the water supply system. The presented set of components and equipment of the water supply station can work as a single system, and each individual element can also work on its own. In the market niche, ready-made pumping stations are presented in the form of a pumping device installed on a pressure accumulator. A single frame also contains an automatic control device.

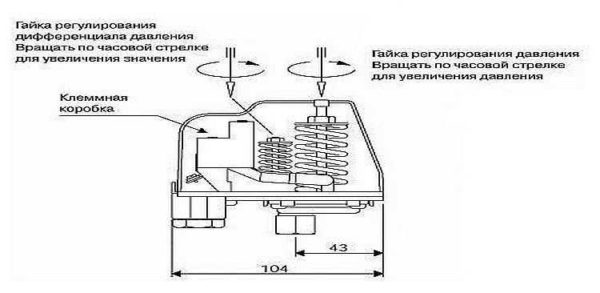

A little about relay adjustment

Do not forget about the seriousness of adjusting the relay - this is a delicate procedure, which must be treated with extreme caution. One minor misadjustment can damage the entire system, wasting time and money on repairs.

In addition, the warranty does not provide for a breakdown of the unit in such cases.

How the pressure switch is adjusted

Initially, it is necessary to achieve the optimal pressure in the accumulator. This can be done by disconnecting the pumping station from power and draining all the accumulated liquid in the tank. Now, using a special compressor with a sensor, create an optimal pressure level in it. Then remove the cover over the relay, while gaining full access to the small and large adjusting spring.

Setting the minimum pressure is achieved by turning the large spring: to increase the indicator - clockwise, to decrease it - counterclockwise.

As you can see, with most of the faults you can handle with your own hands, without resorting to the help of specialists. This will help you save money and, most importantly, give you a new experience in working with pumping stations.

The purpose of the pumping station

The pumping station is the "heart" of your autonomous water supply system. A well-designed autonomous water supply system necessarily includes a well that provides sufficient water production to meet the needs of one or more households. In the vast majority of cases, water from such a well has to be raised. Since the water in the wells lies at great depths, it is necessary to raise it from there by pumping devices. So that the pumps are not activated every time you turn on the water tap in your house, so that there is always constant pressure in the plumbing system of your house, a pumping station is needed.

Pumping station in the house

The composition of the pumping station

A classic pumping station consists of the following main elements.

-

Actually, the pumping device.Usually, pumping stations use surface pumps, which are installed either in the utility rooms of the house, or in specially equipped caissons. The peristaltic pump must produce enough power to lift water from the well, move it to the house and raise it to the highest point of your home's water intake.

Water supply pump

-

Pressure accumulator or hydraulic accumulator. This device is a strong metal container that maintains a constant pressure in the water pipelines of the system. The most common pressure accumulator model is a metal cylinder with an elastic rubber membrane inside. During operation of the pumping device, the membrane is stretched to a certain level. When the pumping device stops working, the membrane, trying to return to its original position, displaces water from the tank.

Hydraulic accumulator (pressure accumulator)

-

In order for the pumping device to turn on and off when certain pressure parameters in the system are reached, an automation unit is required, which is equipped with a pressure sensor. When the pressure in the system drops to a certain level, the relay is activated, the pump turns on and water begins to fill the pressure accumulator. When the maximum pressure in the system is reached, the pumping device is turned off.

Pump station pressure switch

As you can see, the concept of "pumping station" is only a set of components and equipment that can be used on their own.In industrially produced pumping stations, all main units can be assembled in a single building, however, most often a finished pumping station is a pumping device installed on a pressure accumulator. Also, an automatic control device is fixed on a single frame.

During the warranty operation, problems in such equipment, as a rule, do not arise. In any case, malfunctions that occur at this time can be fixed at service centers. However, with a long period of operation, various components of the pumping station may fail. Let's try to figure it out and find out how you can independently eliminate the most common malfunctions of pumping stations.

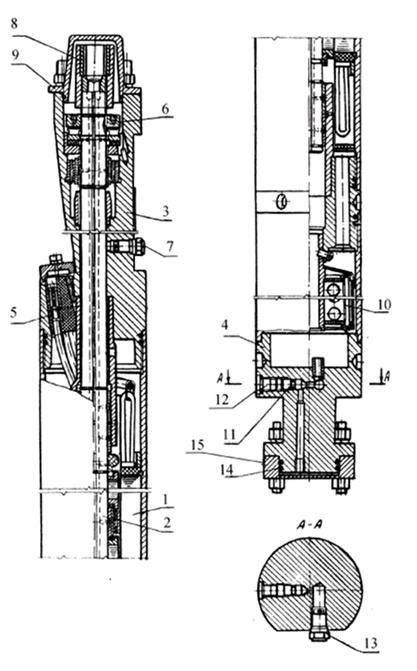

How to find out the cause of a malfunction of a submersible pump?

To lift or not to lift equipment from the well? The simplest option is to analyze the operation of the equipment using indirect signs, without additional manipulations. After identifying all possible culprits, they act by elimination, leaving the most likely cause. But this way is not ideal. It is not always possible to count on the fact that the failure is caused by a simple reason that is easy to fix: for example, reconfiguring the accumulator - changing the operating pressure range.

Therefore, it is better to immediately assume that the malfunction is caused by more serious circumstances, which means that the “naughty” pump will have to be “extracted” from the well. In this case, the owners have a good opportunity to prevent a serious accident, which in the future may require expensive repairs. The first step is to check the power supply. If the voltage is normal (200-240 V), then interruptions in the operation of the equipment due to surges are excluded.

What do they do first?

To find out the exact cause of the device failure, proceed as follows:

- stop, turn off the water supply system, then raise the structure to the surface;

- remove the top cover from the case, then disassemble the mechanism, referring to the instructions;

- conduct a thorough inspection of each part: look for signs of wear or breakage, friction (abrasive, wet, dry), cracks, accumulation of dirt, etc .;

- the electric motor is tested in the same way, the valve, filters, HDPE pipe, and the integrity of the power cable are checked for defects.

Lastly, the sensors, relays, control unit, installed protection units are examined.

Where might the problem lie?

If the operation of the device is no longer satisfactory, then check the status of all the main nodes.

- Piston or impeller. They must be absolutely perfect, not have any damage, or even a hint of the slightest deformation.

- Distance between piston and coil magnets. Ideal - 4-5 mm. Smaller values will lead to overheating of the electric motor, larger ones will cause the coils to beat.

- Optimum distance between valve and body. It is 7-8 mm. In this case, water will flow freely without problems in the absence of pressure.

Such a check, carried out periodically, will reduce the risk of almost any malfunction of the submersible pump, and will help prevent serious equipment malfunctions.

Pressure switch adjustment

Adjustment of the pressure switch is practiced in cases where it is necessary to set the levels of upper and lower pressures to the specified values. For example, you want to set the upper pressure to 3 atmospheres, the lower - 1.7 atmospheres. The adjustment process is as follows:

- Turn on the pump and pump water into the tank to the pressure on the pressure gauge of 3 atmospheres.

- Switch off the pump.

- Open the relay cover and slowly turn the small nut until the relay operates. Turning the nut clockwise means an increase in pressure, in the opposite direction - a decrease. The upper level is set - 3 atmospheres.

- Open the tap and drain the water from the tank to the pressure value on the pressure gauge of 1.7 atmospheres.

- Shut off valve.

- Open the relay cover and slowly turn the large nut until the contacts actuate. The lower level is set - 1.7 atmospheres. It should be slightly higher than the air pressure in the tank.

If high pressure is set to turn off and low to turn on, the tank fills with more water and it is not necessary to turn on the pump frequently. The inconvenience arises only because of the large pressure difference when the tank is full or almost empty. In other cases, when the pressure range is small, and the pump often has to be pumped up, the water pressure in the system is uniform and quite comfortable.

In the next article, you will learn about connecting a hydraulic accumulator to a water supply system - the most common connection schemes.

Choosing a water supply system for a private house: an overview of existing systems A water supply system for a private house from a well: recommendations for creating Technology for flushing and pressure testing a heating system What water pressure should be in the water supply and ways to increase it

Stages and rules of repair

Repair of the Sololift pump, as well as repair of the Grundfos pumping station for any purpose, can be done independently, having previously identified the source of the problem.

Equipment diagnostics involves several stages:

- start the pumping station, evaluate the level of noise and vibration;

- check the pressure indicators;

- make sure that the motor does not overheat during operation;

- check the presence and quality of lubrication of nodal connections;

- make sure the integrity of the structure and the absence of leaks;

- inspect the box for secure fastening of the terminals.

If you are sure that the malfunctions are not caused by lime deposits and pollution, overloads or operation at maximum capacities, the pump can be disassembled. When planning to repair the Grundfos pump with your own hands, make sure that water is drained from the pipelines and turn off the system. Disassembly begins with the junction box and a visual assessment of the components. As a rule, such an inspection makes it possible to immediately detect a burnt or worn part. If not, we will continue to disassemble the installation.

The engine must be in a vertical position during disassembly. This will prevent the risk of oil leakage. To diagnose the trigger mechanism, an ohmmeter must be connected to the engine. This tool, when the handle is rotated, generates a voltage in the range of 200-300 V, sufficient to take readings on the resistance determination device. Too high diagnostic data, reaching infinity, indicate a break in the working phase, too low - an interturn circuit. Self-adjustment of operating parameters with such deviations is not possible.

2 Model range of equipment

The product line of Speroni (Italy) includes 4 series of Marina pumping stations:

- Marina CAM is a budget option for water intake from wells up to 9 m deep;

- Marina APM - pumps for wells up to 50 m deep;

- Marina Idromat - units equipped with a regulator that turns off the pump when running dry.

Let's take a closer look at each of these lines.

2.1

marina cam

The CAM series consists of equipment made in a cast-iron or stainless steel case, with internal fittings made of food-grade polymers. Several models are presented, the power of which varies between 0.8-1.7 kW, and the head is 43-60 m.

The volume of the accumulator can be 22, 25 or 60 liters. These are the most affordable stations for private use, the cost of which starts at 7 thousand rubles.

Among the stations with the best price / quality ratio, we highlight:

- Marina Cam 80/22;

- Marina Cam 60/25;

- Marina Cam 100/25.

The Marina Cam 40/22 pumping station is equipped with a 25 liter hydraulic accumulator, the capacity of which will be enough for a family of 3 people. The capacity of the unit is 3.5 m 3 / hour, the maximum lifting depth is 8 m. The price is 9 thousand rubles.

Marina Cam 100/25 has similar technical characteristics - a tank of 25 liters, a throughput of 4.2 m 3 / hour, however, this model is equipped with a pressure boosting system that significantly increases the delivery head - up to 45 m, compared to 30 m for CAM 40 / 22.

2.2

Marina APM

Well pumps of the APM series have a maximum water intake depth of 25 m (model 100/25) and 50 m (200/25). This is more power and overall equipment, the weight of which can reach up to 35 kilograms. As an example, consider the popular station Marina ARM 100/25.

Specifications:

- head - up to 20 m;

- throughput - 2.4 cubic meters / hour;

- centrifugal motor power - 1100 W;

- the diameter of the supply pipe is 1″.

AWP 100/25 is made in a stainless steel case, the model is equipped with overheating protection and a water level control system in the hydraulic tank. ARM100/25 is designed for pumping clean water, without mechanical impurities, the temperature of which does not exceed 35 degrees.

2.3

Typical malfunctions and repairs

Marina pumping stations have established themselves as reliable and durable equipment, however, like any other equipment, they are not immune from breakdowns. We bring to your attention a list of the most common breakdowns and how to fix them:

- Lack of water supply when the pump is on, the cause of which may be a loss of tightness in the conductive pipelines and a worn check valve. First check if you forgot to fill the pump body with water. If it is, inspect the check valve and the tightness of its fit to the pump nozzle, and also check the condition of the intake pipe - all damaged components must be replaced. Similar problems are possible if the impeller is damaged, to replace which you will need to disassemble the unit.

- Water is supplied in jerks due to a damaged accumulator. The main malfunction of the hydraulic tank is a damaged membrane. To determine if it is intact, press the nipple (located on the tank body), if water flows from the nipple and not air, then the membrane is torn. It is quite easy to install the membrane, you just need to unscrew the fixing ring from the tank neck, pull out the old part and mount a new one in its place.

- Reduced water supply pressure. The reason for this can be either a faulty hydraulic tank or problems with the pump.In the first case, the depressurization of the tank is most likely to blame - inspect the body for cracks, repair the detected deformations and pump air up to the standard value. If the tank is intact, the problem must be sought in the deformed impeller of the centrifugal wheel inside the pump.

We will separately consider the situation when the pumping station does not want to work in automatic mode - the unit does not turn off when the tank is full and does not turn off when it is empty. The incorrect adjustment of the pressure switch is to blame here - it is usually calibrated at the factory, but there are exceptions.

The above diagram shows a standard pressure switch for Marina pumps. On it, under the plastic cover of the case, there are two springs. Most of them rotate clockwise, it is responsible for the minimum pressure in the tank at which the station turns on. By rotating a small spring, we adjust the maximum pressure, upon reaching which the pump turns off.

Adjustment of the pressure switch must be carried out with the equipment disconnected from the mains. Before starting the calibration, it is necessary to drain the water from the tank, the level of air pressure is also important - it must correspond to the value recommended by the manufacturer.

Principle of operation

The main difference between a pump and a pumping station is the automatic maintenance of water pressure in the central water supply system. The main factors supporting the full operation of the pumping station are the availability of electricity and the required amount of water in the well.

Pumping station

The principle of operation and the device of the pump with a storage tank

A pumping station with a storage tank is considered an old model, although today such options are still found.The reason is that the tank itself is a very bulky structure. The presence of water and pressure in it is controlled by a float, and when the level drops, the sensor is triggered, starting its pumping. Such a system has several disadvantages:

1. Large dimensions;

2. If the water level sensor fails, water may overflow into the room;

3. Complexity of installation;

4. Low pressure due to the fact that the water flows by gravity;

5. The installation of the tank must be carried out above the level of the station.

The principle of operation and the device of the pump with a hydraulic accumulator

A pumping station with a hydraulic accumulator is considered the best option in autonomous water supply. Such a system contains a relay, through which the maximum air index is controlled. In this case, in the accumulator, it decreases in volume due to water pressure.

The pumping station, after being put into operation, begins to take water from the well and, due to pressure, sends it to the accumulator. As soon as the user of the house turns on the water, the pressure in the system gradually decreases. When the pressure drops to a certain level, the relay will turn on the pump, which will pump water into the tank and thereby increase the pressure to the required level. Then the relay turns off the pump. If the water demand is small, then the pump itself will not turn on, so liquid from the tank will begin to flow into the tap.

General completeness

Regardless of the type of station - with a battery or with a tank, it is additionally equipped with:

1. By cable;

2. Pump unit;

3. Pressure gauge;

4. Terminals for grounding;

5. Membrane pressure tank;

6. Connector for connection.

How to disassemble the pumping station

The pumping station should be disassembled on its own, based on the manufacturer's instructions. In general terms, the scheme for disassembling the equipment looks like this:

- The first step is to disconnect the device from the mains, and drain the water from the pipeline.

- Then the expansion tank is disconnected and the pump is dismantled.

- All bolts on the housing are unscrewed, after which the outer casing of the pump is removed.

- Remove the cover and fan impeller from the rear of the engine.

- We remove the fixing screw of the pump impeller, after which it is removed from the rotating shaft.

- After removing the impeller, you can dismantle the stuffing box. To do this, remove the mounting ring and pull out one part of it.

- Then the engine is disconnected from the console and the second half of the gland is dismantled.

After replacing the failed part, you should assemble the pump and start it.

The pumping station is running (the pump is spinning), but there is no water:

The steps to troubleshoot this issue are as follows:

- First of all, you need to check the check valve, which is located in the water in the well or well. It often happens that sand or debris gets into it, and the valve does not close. In this case, the water does not rise through the pipes to the pump.

- Secondly, check for water in the pipeline between the well and the pump. The pump must also be filled with water; if there is no water, fill it through the filler hole.

- Very large output between impeller and pump housing. The pump just works for itself. The reason for this may be the high content of abrasive substances in the water, such as sand. In this case, you should change the housing and impeller, if they are on sale, or the entire pump (but not the entire station!).

- The well/well ran out of water.The way out is to try to lower the suction pipe or hose deeper. But remember: the distance from the water level in the well to the pump should not exceed that indicated on the pump, usually 8-9 m.

Conclusion

In the article, we have listed the main malfunctions that submersible and surface drainage stations have and possible how to repair them. To fix breakdowns on your own, you need to have at least basic skills in working with devices, otherwise it is better to contact a service center. What is a sump pump for? Properly ensuring a comfortable life in a country house or cottage. But the repair and maintenance of such devices should be handled by specialists. If you like to tinker with various devices with your own hands, then inexpensive models will be the best option for you, but it’s better not to take on the repair of expensive devices.