- Main types

- Standard Models

- Professional Devices

- Submersible models

- Drainage pumps

- Detailed instructions for disassembling the pump

- The subtleties of disassembling the shaft of the pump section

- Step-by-step process of disassembling the electric motor

- Typical breakdowns of pumps of different brands

- Repair of drainage pumps

- The most common causes of breakdowns

- The subtleties of repairing units of different brands

- Operation of the device and prevention of breakdowns

- Typical breakdowns of pumps of different brands

- How to disassemble "Water cannon"

- Revision of the motor part

- Typical malfunctions and repairs

- Water jet pump repair

- How to do your own repairs

- Pump repair

- DIY repair

- Water jet dzhileks 60 32 unit repair

- The pump does not start

Main types

The company produces several lines of pumps that are distinguished by affordable prices and have long won well-deserved recognition from customers. Pumps designed for use in wells are represented by a rather impressive range. In this product niche, the manufacturer sells three main types of units at once:

- conventional models;

- professional devices;

- ready pumping stations for the house.

Standard Models

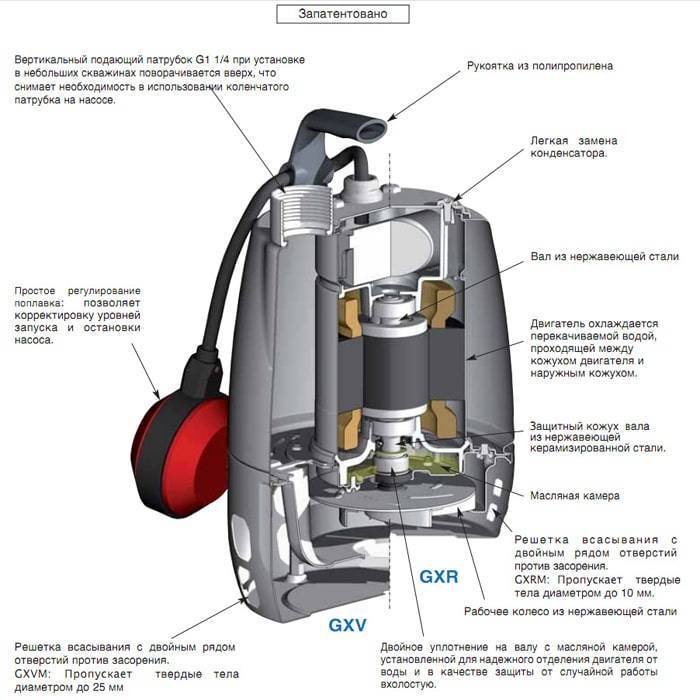

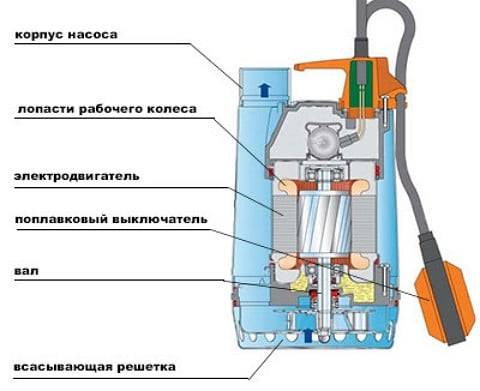

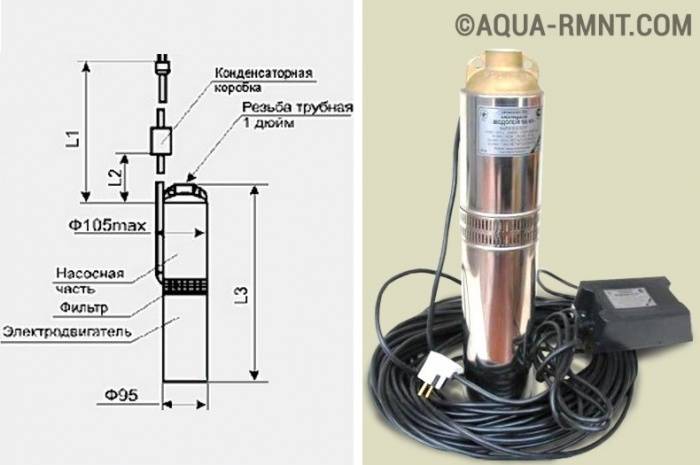

The conventional centrifugal type submersible device has a cylindrical shape and compact dimensions.Its diameter is 9.8 centimeters (suitable for wells larger than four inches). The body is made of stainless steel. Inside are the main mechanical components of the pump and the electric motor. The pumping chamber is located in the housing below the engine - this is a fairly popular technical solution used in pumps from different manufacturers. Cooling occurs due to the circulation of water - the device is reliably protected from overheating. The rowing element (impeller) is made of durable polymer, and the bearings are made of ceramics.

The conventional centrifugal type submersible device has a cylindrical shape and compact dimensions.Its diameter is 9.8 centimeters (suitable for wells larger than four inches). The body is made of stainless steel. Inside are the main mechanical components of the pump and the electric motor. The pumping chamber is located in the housing below the engine - this is a fairly popular technical solution used in pumps from different manufacturers. Cooling occurs due to the circulation of water - the device is reliably protected from overheating. The rowing element (impeller) is made of durable polymer, and the bearings are made of ceramics.

Advantages:

- reliability;

- budget price (up to 17,000 rubles);

- high maintainability;

- the possibility of pumping liquid with impurities up to 3 centimeters in size;

- the presence of a strainer and a check valve;

- can be used at depths up to 30 meters.

Flaws:

lack of an automatic control unit (observed in conventional models);

Professional Devices

For work in wells, reservoirs and tanks, the company produces pump models equipped with a float switch. Their owners are often called barrel pumps, since such a unit is convenient to use in tanks and capacious barrels intended for watering the garden.

Advantages:

- sealed case (can be lowered into water);

- affordable price (from 7,000 to 11,000 rubles);

- can be used in muddy water with a small admixture of sand or other small particles of dirt;

- there is protection against dry running (provided by a float).

Flaws:

more often, use is only available at shallow depths (up to 15 meters).

Submersible models

how to get the pump out of the well

Advantages:

- the system is completely ready for operation;

- guaranteed uninterrupted water supply;

- the electric motor is protected from overload and power surges;

- can be used at a depth of up to 30 meters;

- quiet operation is ensured;

- there is protection against dry start and overheating;

- the specified pressure is maintained in the pipeline.

Flaws:

high cost - up to 39,000 rubles.

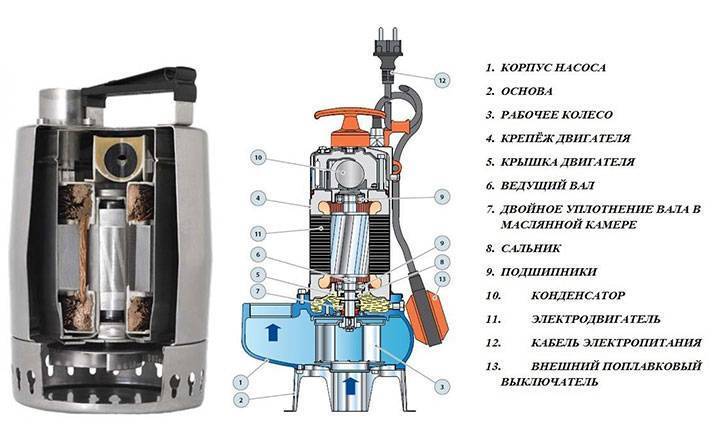

Drainage pumps

Drainage type pumps equipped with a float switch are also available. There are models that work in dirty water. For example, capable of draining a pool or a flooded basement. And units designed to work with strong pollution - the so-called fecal pumps, capable of pumping liquid with solid particles up to 3.5 centimeters in size.

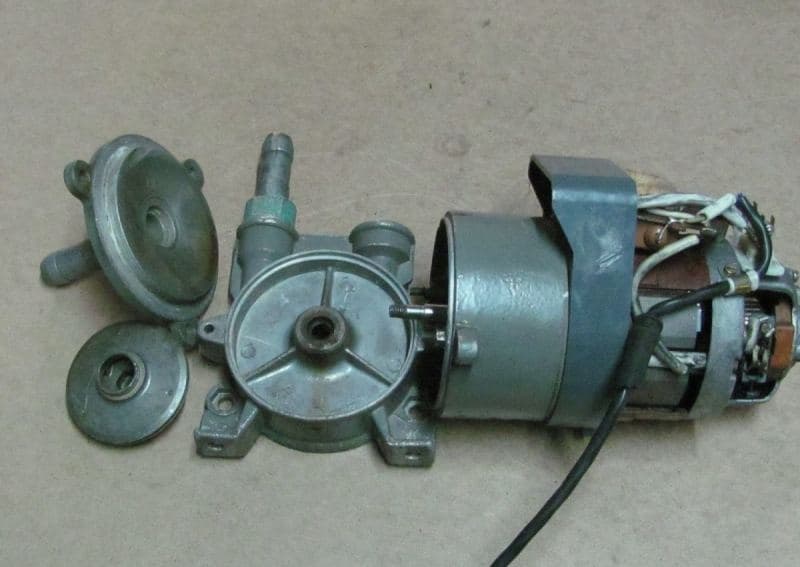

Detailed instructions for disassembling the pump

To determine and troubleshoot a submersible pump, it must be disassembled into its constituent elements. To do this, you will need a spacious workplace and a stable wide table, a vise, Phillips and flat screwdrivers, a set of keys and pliers.

The disassembly process is not difficult, but requires precision, scrupulousness and attention.

It is carried out in stages in a certain order.

When the pumping part and the engine compartment are separated from each other, troubleshooting is much easier and more convenient.

The subtleties of disassembling the shaft of the pump section

To pinpoint the exact location of the problem, try spinning the shaft of the pump section. If this is not possible, then the problem is there.

At the end of the measures related to the repair / replacement / maintenance of the pumping part, reassemble the equipment, carefully following the instructions. Then connect to the engine and return to the workplace.

Step-by-step process of disassembling the electric motor

If the area of the problem could not be identified in the two steps described above, there is a good chance that it lies in the engine. To finally verify this, you need to do the following important steps.

Assemble the engine block following the instructions. Make sure that all the details are in their original places.

Typical breakdowns of pumps of different brands

The equipment of popular domestic and foreign brands has its own characteristic breakdowns. The devices of the Danish manufacturer Grundfos, despite their reliability and endurance, need regular replacement of mechanical seals. If this is not done in a timely manner, water will penetrate inside and damage the winding.

It is not advisable to service the unit at home. The specific design requires that repairs be carried out by a specialist with experience, ideally an employee of a company service center.

A pronounced buzz and a head that has fallen to a minimum indicate that the impeller has worn out or has shifted along the axis in the pump. The device must be disassembled, cleaned of sand, replaced damaged elements and installed new seals

Gilex units often leak fluid from the electric motor. Replacing it is possible, but only with a similar composition.

Some masters believe that it is not necessary to buy an expensive substance. You can get by with glycerin or transformer oil. However, this is not the best advice. The equipment does not tolerate filling with alternative means very well and can completely fail after such an operation.

It is better not to repair the device yourself, but to entrust this task to qualified specialists. They are guaranteed to fill the engine with the original composition and do it in strict accordance with the wishes of the manufacturer.After service, it will work as well as on the first day of purchase.

Wear of the seals is indicated by a low oil level in the pump motor. It is best to replace them as soon as possible. This will keep the motor from overheating.

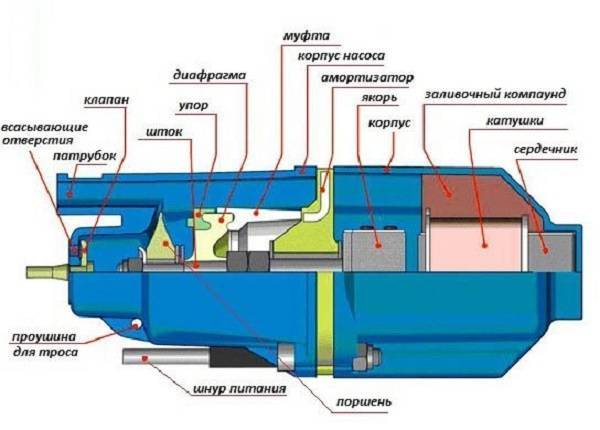

In devices "Kid" of the Russian enterprise Livgidromash, coils often fail. Provokes this trouble work "dry". A strong noise heard when turned on without pumping out water indicates a break in the central axis, to which the membranes with an anchor are attached. This breakdown is easy to detect after disassembling the unit.

Replacing the axle even at home is not difficult. But finding a part for sale is really a problem.

Aquarius pumps tend to overheat. This disadvantage is especially active when the equipment works in shallow wells. Repairs are expensive and sometimes amount to about 50% of the original cost. Many users in such cases prefer to buy a new device, however, from a different manufacturer.

The same problem is typical for the Brook models. Despite the modern design and compliance with current European standards, they do not tolerate continuous operation.

The manufacturer says that the devices can continuously pump water for no longer than 7 hours. However, almost always such a load leads to overheating. In order to avoid problems, it is better to take breaks and let the equipment rest every 2-3 hours. In this way, the life of the pump can be extended.

Do not start water pumping devices when the shut-off valve is closed. In the future, this will lead to breakdown of pumping equipment. Valve must be opened before turning on.

Pumping equipment "Vodomet" is considered quite reliable and operationally stable. Most of the breakdowns here are due to misuse. Also, equipment in contact with contaminated water quickly becomes clogged with silt and sand. In this case, the pumping part of the unit needs to be replaced.

When a problem that has arisen cannot be solved at home, it is worth seeking help from professional masters of a certified service center. They will quickly determine what happened to the equipment and restore its performance. Or they will recommend purchasing and installing a new pump if the old one cannot be repaired or it is not economically viable.

Repair of drainage pumps

The malfunctions listed above for the drain pump cannot always be fixed on their own. You can independently fix a weakened shock absorber, release or replace the float, eliminate mechanical damage that caused the impeller to jam, and replace the supply cable.

The simplest of all this will be fixing the shock absorber. To do this, you will need to disassemble the body of the device and tighten the loose nuts on the mounting bolts. Be sure to lock the top nut so that there is no further loosening. It will take some time to replace the power cable. Replacement of the condenser is possible in some models of drains.

The rest of the malfunctions are almost impossible to eliminate without the involvement of service workshops.For example, with a broken stem, it is easier and sometimes cheaper to purchase new equipment than to disassemble and try to repair. Valve replacement is a complicated and unprofitable undertaking to solve the problem on your own. The replacement of a burnt winding must be carried out in specialized workshops.

Dismantling the drainage pump Belamos DWP CS

The most common causes of breakdowns

If it becomes necessary to repair pumping equipment, it is necessary to find out the probable cause of its breakdown, which are often:

- Failure to comply with the terms of periodic inspection and repair of equipment.

- The equipment has been operated incorrectly. During operation of the device, its operating parameters were exceeded.

- The pumped liquid contains solid impurities larger than required.

- Prolonged use of the pump in dry mode.

- Installation of equipment was performed incorrectly or poorly.

- The hydraulic accumulator, the relay are out of order, there is no filter.

When the first hints of a breakdown appear, the following components of the device should be immediately checked: The ideal distance between the electromagnetic coils and the piston must be set from 0.4 to 0.5 cm.

Drainage of the reservoir with a drainage pump

The piston must not have mechanical damage and defects, its condition must be elastic. The valve closing the inlets must have a clearance between the body of 0.7 to 0.8 mm. Air should flow freely when blown in at the intake side. It often happens that the poor performance of the pump is not related to its breakdown. There may be power fluctuations in the network.

Therefore, before disassembling the device, make sure that the mains voltage matches, which should be 220-240 V. It should be noted that for long-term and reliable operation of pumping equipment, it is necessary to carry out technical inspection and maintenance of the device in a timely manner and follow the rules of technical operation.

The subtleties of repairing units of different brands

Since there are models of pumping equipment from different manufacturers on sale, which are distinguished by their strength and design features, the repair and operation of such devices should be carried out taking into account the model

Since there are models of pumping equipment from different manufacturers on sale, which are distinguished by their strength and design features, the repair and operation of such devices must be carried out taking into account the model. Since you could choose not “Vodojet” or “Whirlwind” as a downhole unit, but a model of another brand, we decided to list the weaknesses of the most common pumping products, as well as the features of their repair:

- Most Grundfos models have special motor insulation and built-in valves. Therefore, sometimes it is necessary to change the thermal insulation seals of the motor. This work can only be done by a professional.

- Gilex brand pumps often encounter fluid leakage from the electric motor. For repair, it is necessary to replace the fluid with a similar product. This can be done only in a special service center.

- The domestic pump "Kid" is the most popular. Although the price of service repairs is quite acceptable, it is easy to repair this device with your own hands. A common problem is that the unit makes a lot of noise after turning on, but does not pump water.Usually this happens due to a rupture of the central axis on which the membrane and anchor are installed. Usually, disassembling the unit allows you to quickly identify the problem. The axle needs to be replaced. You can learn more about repairing the Baby pump from the proposed video:

- The Aquarius well pump overheats quite often during operation. This is especially true for units installed in shallow wells. However, since the repair of such equipment can be about half of its cost, it is easier to buy a new device if an inexpensive pump breaks down.

- Pumps "Vodomet" and "Whirlwind" are quite reliable equipment, which, if used correctly, can last a long time without breakdowns. If used incorrectly, the units can become clogged with silt and sand. For repair, you will need to change the pumping part.

- Pumping equipment "Rucheyok" is also famous for its ability to overheat. And this despite the design in compliance with European standards. According to the manufacturer's instructions, the device can work without stopping for 7 hours, but in practice this will cause overheating. Therefore, the pump is recommended to give a break after 2-3 hours of operation.

Operation of the device and prevention of breakdowns

When choosing equipment for a home water supply system, first you need to decide what power and performance the equipment needs. The necessary parameters can be found in the technical data sheet of the device.

It is necessary when purchasing a pump to pay attention to its size. It is optimal that it be at least a centimeter smaller than the well pipe, otherwise it may jam

You need to pick up a strong cable so that it is convenient to pull out the equipment and immerse it back.

Often, it is not necessary to spend a lot of money to repair a submersible pump.

Inspection of the device for malfunctions should be carried out in several stages:

- Extraction from water;

- Checking the suspension cable and electric cable for damage;

- Inspection of the body for any damage and rust;

- Start the pump to listen for any strange sounds.

If the well is emptying very quickly, it is likely that the productivity was calculated incorrectly. In this situation, either it needs to be changed, or the water consumption should be reduced. Also, the equipment can operate protection against idling. The reason for it is the same, and the device will have to be changed.

Typical breakdowns of pumps of different brands

The equipment of popular domestic and foreign brands has its own characteristic breakdowns. The devices of the Danish manufacturer Grundfos, despite their reliability and endurance, need regular replacement of mechanical seals. If this is not done in a timely manner, water will penetrate inside and damage the winding.

It is not advisable to service the unit at home. The specific design requires that repairs be carried out by a specialist with experience, ideally an employee of a company service center.

A pronounced buzz and a head that has fallen to a minimum indicate that the impeller has worn out or has shifted along the axis in the pump. The device must be disassembled, cleaned of sand, replaced damaged elements and installed new seals

Gilex units often leak fluid from the electric motor. Replacing it is possible, but only with a similar composition.

Some masters believe that it is not necessary to buy an expensive substance. You can get by with glycerin or transformer oil.However, this is not the best advice. The equipment does not tolerate filling with alternative means very well and can completely fail after such an operation.

It is better not to repair the device yourself, but to entrust this task to qualified specialists. They are guaranteed to fill the engine with the original composition and do it in strict accordance with the wishes of the manufacturer. After service, it will work as well as on the first day of purchase.

Wear of the seals is indicated by a low oil level in the pump motor. It is best to replace them as soon as possible. This will keep the motor from overheating.

In devices "Kid" of the Russian enterprise Livgidromash, coils often fail. Provokes this trouble work "dry". A strong noise heard when turned on without pumping out water indicates a break in the central axis, to which the membranes with an anchor are attached. This breakdown is easy to detect after disassembling the unit.

Replacing the axle even at home is not difficult. But finding a part for sale is really a problem.

Aquarius pumps tend to overheat. This disadvantage is especially active when the equipment works in shallow wells. Repairs are expensive and sometimes amount to about 50% of the original cost. Many users in such cases prefer to buy a new device, however, from a different manufacturer.

The same problem is typical for the Brook models. Despite the modern design and compliance with current European standards, they do not tolerate continuous operation.

The manufacturer says that the devices can continuously pump water for no longer than 7 hours. However, almost always such a load leads to overheating. In order to avoid problems, it is better to take breaks and let the equipment rest every 2-3 hours. In this way, the life of the pump can be extended.

Do not start water pumping devices when the shut-off valve is closed. In the future, this will lead to breakdown of pumping equipment. Valve must be opened before turning on.

Pumping equipment "Vodomet" is considered quite reliable and operationally stable. Most of the breakdowns here are due to misuse. Also, equipment in contact with contaminated water quickly becomes clogged with silt and sand. In this case, the pumping part of the unit needs to be replaced.

When a problem that has arisen cannot be solved at home, it is worth seeking help from professional masters of a certified service center. They will quickly determine what happened to the equipment and restore its performance. Or they will recommend purchasing and installing a new pump if the old one cannot be repaired or it is not economically viable

The pump is clogged with sand and does not pump water. How to deal with one of the most common problems of pumping equipment will tell the following video:

How to disassemble "Water cannon"

The device of the “Vodomet” pump cannot be called completely simple and understandable. Before starting disassembly, it is recommended that you familiarize yourself with the features of its design as much as possible. It does not hurt to fix the correct position of each element: record, photograph, film, etc.

You should also pay attention to the correct position of each detail in relation to the concepts of "top" and "bottom". If the wheels were installed incorrectly after repair, the pump will still work, but not very efficiently.

Problems can also arise after rewinding the engine. Not all pump owners remember the correct arrangement of contacts.

Before starting disassembly, the pump, of course, should be disconnected from the power supply and removed from the well. To facilitate the work, it is better to disconnect the water supply pipe from the nozzle and remove the metal cable. When the “Vodomet” pump is in working position, its wetted motor is in the upper part, and the pumping part, consisting of vane wheels and cups with lids, is in the lower part. But when disassembling the pump, it is more convenient to keep it upside down, i.e. engine down.

The first step in disassembling the Waterjet pump is unscrewing the bottom cover. This operation is performed using a sufficiently long screwdriver, threaded through the eyelets for hanging the cable. You need to unscrew it counterclockwise. It may be more convenient to use other devices, for example, gas wrench number three. A device for removing the oil filter cap, well known to motorists, or its equivalent from a strip of durable fabric with a lever for twisting it, is also suitable.

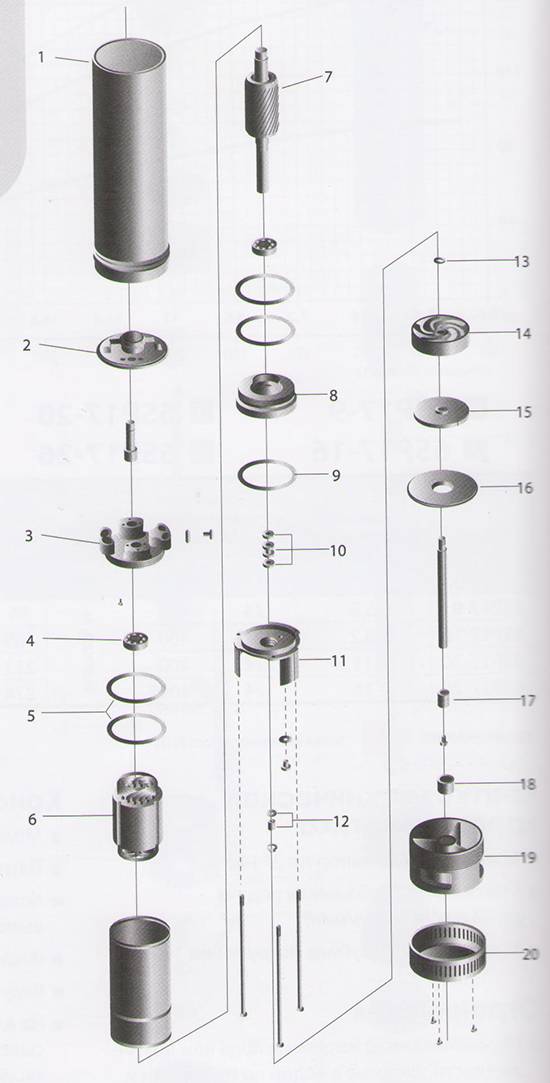

After that, carefully remove the chamber-cups with lids and impellers from the pump housing. Cup covers are numbered from 1 to 3. Usually, all cups with the number “1” are first put on the shaft, then with the number “2”, then with the number “3”. When disassembling the water jet pump, these elements will be removed in the reverse order.It is better to write down the numbering order of the glasses to avoid mistakes during assembly.

It will not hurt to immediately clarify the direction of movement of the shaft. To do this, the pump with the wheels removed is simply turned on for a few seconds. The wheel should stand in such a way that the water is sucked in from the bottom in the center, and the water flows up to the outer part of the ring. In the correct position, the vane ring should be mounted with the widest part towards the engine, i.e. tab down and smooth side up.

The pump shaft is not twisted, as in similar models, but is fixed with two clips. If it needs to be removed, clamp the clips with pliers and remove the shaft. When the impeller cups are removed, it may be necessary to remove the motor as well. This will require some effort, since it is pressed into the body quite tightly.

In order not to bend the shaft, place the pump housing on a support with a hole through which the shaft can be inserted. After that, gently knock the engine out of the housing with a hammer and plank. They hit the end with a hammer, and the plank acts as a shock absorber.

When the position of the motor in the housing changes, you must first remove the ring-shaped fixing gasket. It must be rotated inside the housing by 90 degrees, squeezed a little and removed so as not to damage the internal thread of the housing

You can immediately pay attention to the position of this gasket

It should be facing the engine with the side from which the chamfer was removed. After that, you can remove the engine from the housing. It is closed by the top cover of the pump, which is fixed with two strong sealing rubber bands.

To remove the cover, you need to put the engine on its side.Then the cover is carefully knocked out of the engine housing, hitting it with a wide screwdriver and a rubber mallet. Other suitable tools can be used for this. There is a capacitor under the cover. Sometimes this element fails, but it is not difficult to replace it.

Care must be taken when handling the pump casing. Sometimes it becomes necessary to fix the device in a vise

First, it is recommended to wrap the body at the fixation point with shock-absorbing material. The force must be moderate so as not to deform the product.

Revision of the motor part

Downhole pumps are equipped with a single-phase, mostly brushless asynchronous motor. There is a starting capacitor in the wiring diagram. The stator of the electric motor has a monolithic attachment to the housing, often it is filled with epoxy compound.

In pumps of a monolithic design, the motor must be squeezed out of the glass by pressing on the outlet for connecting the outgoing pipeline with the impellers removed. In rod pumps, the motor part is disconnected when the two halves are undocked, in screw pumps, after the working screw is removed. In all cases, the internals of the motor (capacitor, connecting terminals) can only be reached after removing the tight plug. It is fixed with 2-3 screws on the side surface of the sleeve and a powerful retaining ring. In some types of pump, the plug may require the use of a special puller.

Well pump motor stator

All borehole pump motors are filled with oil, which performs lubricating, cooling and dielectric functions. The oil used is a special food oil, but it is commercially available.Signs of poor quality can be a cloudy color of the oil when mixed with water, darkening or the presence of mechanical impurities, as well as an insufficient level. If the oil is normal, it must be drained into a clean, dry container, leaving the motor housing for 15–20 minutes until the residues completely drain from the walls. Insufficient filling of the engine with oil indicates wear of the stuffing box seals.

In addition to bad oil, worn bearings can be the cause of engine failure, which is determined by play and freewheel noise. If the pump has been operated for a long time in extreme conditions, the shaft may be twisted (twisted), the winding insulation may overheat. Burnt stators are practically beyond repair, but they are quite easy to replace.

Burning of the stator winding due to water ingress into the motor

Typical malfunctions and repairs

If the Vodomet pump is under warranty service, the easiest way to solve all problems is at a service center. But when the deadlines have passed, owners usually prefer to save money and do the repairs themselves. Some operations, such as replacing worn impellers, are easy to perform.

But if you need to rewind the engine, it is better to entrust this matter to specialists. As for spare parts and components, they can be purchased without any problems and at a very reasonable price.

The company "Dzhileks" willingly sells spare parts for its products. They are sold both in specialized stores and in service centers. You can also contact the manufacturer directly.

This is how the result of water penetration into the engine compartment looks like, if for some reason the case is poorly sealed - the capacitor is damaged, it should be replaced

By the nature of the breakdown of the device, one can roughly judge what kind of repair work will be needed.

Here is a list of typical problems that owners of Vodomet pumps have to face:

- The device does not turn on.

- The pump housing is energized.

- The pressure of water in the system has noticeably decreased.

- The pump works unevenly, making sounds uncharacteristic for normal functioning.

And here is a list of malfunctions that are typical for these symptoms and how to fix them:

- The motor winding burned out. It will have to be completely replaced.

- Loose contact or broken wire. It is necessary to open the motor housing, restore the connection with the contacts and / or the integrity of the electrical cable.

- The integrity of the engine housing is broken. As a result, the capacitor got wet, it should be replaced with a new analogue.

- The impellers are worn out. It is necessary to disassemble the pump and replace them with new elements.

Of course, if the pump is already removed from the well for repair, it makes sense to carry out a complete diagnosis of the unit. The pump is disassembled, gaskets, washers, glasses, impellers and other elements are inspected. If signs of wear are noticeable, you should immediately take care of replacing such elements.

Then it makes sense to disassemble the engine, test the condition of the contacts and the supply wire. If necessary, locate the damaged cable and reconnect. Sometimes it is worth completely replacing the power cord.

Problems with a damp capacitor are usually obvious even from the outside.Soldering a new capacitor is usually not difficult, but during reassembly, the cause of the malfunction should also be eliminated, i.e. ensure sufficient tightness of the motor housing.

The burnt motor winding, as already mentioned, will be difficult to perform correctly at home. This operation can be ordered at the factory, and all other work can be done independently. This makes repairs cheaper. In some cases, it is easier and more reliable to replace the engine with a new device.

When the engine is depressurized, a situation is observed that experts characterize with the word “emulsion”. This means that water got into the engine case and mixed with the oil, turning it into an emulsion. The oil must be drained and completely replaced.

In no case should this fluid be replaced with some ordinary engine oil. The only suitable lubricant for Vodomet pumps is pure glycerin. The fact is that in the event of a breakdown, oil can get into the well and significantly spoil the quality of the water. It is very difficult to get rid of such pollution.

Water jet pump repair

How to do your own repairs

In the article presented to your attention, you will learn the principle of the pump device, and you will also be able to deal with the nuances and aspects that you need to know in order to repair the Water Cannon and we will take a closer look at a real example of a real model 60-52. Naturally, you will also get acquainted with possible problems that are indicated in those. passport and the method of their elimination.

Pump repair

Repair of the pump is urgently required, especially for the private sector, it can mean again buckets-watering cans. A significant complication of the situation, if the water supply at the site is organized within the circumference of the well.

Naturally, even someone who is slightly familiar with such matters is able to repair equipment such as "Brook", but restoring the unit's performance is a rather laborious task, which is not easy to perform without certain knowledge in this area.

In the case of unskilled repairs, there is a possibility that oil will penetrate into the well, which will have to be eliminated with the help of highly qualified professional specialists.

Otherwise, you will have to do this work on your own.

DIY repair

Components. Analysis of the components.

Units of this type, specially designed for interaction with wells, have a certain (different) number of stages, based on the model marking. All parts of this type can be freely divided into several typical categories.

The first and third positions are almost identical in their dimensions and are made of high-quality and durable plastic, which together resembles a mushroom in its appearance. The glasses, respectively, are made in the form factor of a cylinder, which are made from black polyamide.

The bottom is essentially a disk, which is made of the same material, and there is a hole in its center. Together with the glass, they form a double bottom. An anti-friction washer will inherently prevent friction of parts, as a rule, when parsing, blue-white color variations are most common. The first few are thinner.

Disassembly 60-52

To repair the water jet, first of all you should unscrew the cover equipped with specialized holes for the subsequent removal of other parts.If you need to clamp the device in a vise, be extremely careful, as the inside of the hollow format. The best solution would be a rubber lining (dense) on all sides.

Next, disassemble the pumping part. The parts removed from the shaft should be laid out in the most accurate way, which will allow them to be returned to their place in the same but reverse order.

Take out the stop ring and the motor. For this action, you will need to install the unit vertically.

Attempting to extract through a thread will fail, as it will not be able to pass through it. After you lay the pump in a horizontal position, pull the cable and pull the motor

Remove the cover of the compartment containing the wires, put the engine on its side and, using a powerful screwdriver and a mallet (rubber), knock out as carefully as possible

Water jet dzhileks 60 32 unit repair

Indicated malfunctions

The units outline the main malfunctions, as well as their causes and methods of elimination.

But in a huge number of cases, a recommendation to contact a specialized service center will simply be indicated.

Two additional breakdowns that are not included in the passport are very often called by experts: there is no water injection at startup, and the device also beats with current without making any sounds.

The first malfunction symbolizes that the impellers and stage covers have worn out. And in the second option, we will talk about a capacitor failure. More than likely, it is caused simply by exposure to moisture, which in a certain way gets through the cable entry directly into the condenser compartment. Naturally, such a part will only be subject to replacement with a serviceable one.

Sufficiently careful and careful handling of the unit will extend its service life without any problems, but from time to time you still have to carry out preventive maintenance either on your own or by contacting a specialized service center.

The difficulty of self-repair will lie not only in the ability to disassemble a somewhat complex device, but also to find the necessary replacement parts, which is even more problematic, why the best solution would really be to contact such a center.

The pump does not start

If the device does not beep and does not function after turning on, the cause is probably the power supply. How to fix such malfunctions, you can watch the video of repairing the circulation pump. However, it should be understood that the reasons are different.

Repair does not always require disassembly of the pump. Should be using multimeter check voltage at the connection points of the unit. Perhaps it does not meet the standards or is completely absent.

There is a fuse in the electronics of the device. If there were power failures, it may have burned out. You should disassemble the device and replace the fuse with a similar one.