- The main types of faults

- Why does equipment break down?

- Deep well pumps Aquarius for wells technical characteristics

- Equipment disassembly features

- How to clean and make minor repairs to equipment

- How to repair the Aquarius pump yourself

- Very helpful tips

- Causes of failure of the pump in "Aquarius"

- 1 What are the problems with submersible pumps?

- How to carry out regular maintenance of pumps?

- Deep well pumps Aquarius for wells technical characteristics

- Pump Maintenance

- 2 Stages of troubleshooting

- 2.1 Phased work on the repair of the electric motor

- Prevention and diagnosis of breakdowns

- 1 Most common pump failures

- A few good tips

- Repair of Aquarius pumps

The main types of faults

But, non-observance of the operating mode and operating rules often lead to breakdowns of water supply equipment. Fortunately, many pump problems can be fixed without resorting to the paid services of highly qualified professionals.

The most common causes of breakdowns are:

- Long-term pumping of water containing mechanical impurities in a concentration of more than 20 g per liter of liquid.

- Pumping hot water, with t greater than 35 ° C.

- Frequent voltage drops in the mains supply.

- Violations of the tightness of the body of the device.

- No downhole filter.

- Engine overheating due to dry running.

As a result of this, the "Aquarius" may fail, wear out, the impellers of the centrifugal water supply mechanism. It is also likely that there will be problems with the electrical part, up to the combustion of the motor winding. It is very dangerous for the pump and wintering in a freezing reservoir. Water, turning into ice, undergoes a significant expansion. As a result, the pump cavities filled with ice simply burst.

To diagnose a breakdown, the device is taken out of the well and plugged into the network for a couple of seconds. If the pump is buzzing, then most likely the mechanical water supply part has broken. A silent electric motor is already talking about problems with the electrics. You can try to manually rotate the shaft. If it rotates without any effort, then everything is in order with it. When you have to apply force to turn the shaft, then there may be sand inside the pump.

Why does equipment break down?

The submersible well pump provides convenience and ease of use of the well. It raises water from a great depth to the surface, where it flows through communications to water intake points.

Domestic and foreign enterprises produce household submersible pumps. And although pumping equipment is reliable, breakdowns can occur from time to time during operation.

All elements of submersible pumps are precisely fitted and easily disassembled. If during the assembly process the parts do not fall into place freely, then the order of installation of individual components is violated

The smooth and precise operation of a submersible pump is often violated by the following reasons:

- high (more than 50%) concentration of suspended particles in water;

- dry operation, when the device operates without touching the water;

- voltage drops above the permissible level, which regularly occur in the network;

- poorly fixed cable connections;

- the cable of the unit is not correctly attached in the area of the well head;

- the submarine cable is not fixed properly.

Malfunctions are provoked by the absence of a filter or its excessive contamination, an unstable pressure switch or a poorly functioning accumulator.

In the absence of grounding, electrochemical corrosion affects the metal elements of the equipment. The pump stops pumping water normally and requires immediate service.

If problems arise with a new pump that is under warranty, do not remove them yourself. It is better to take the device to a company service. There, its performance will be restored by professional craftsmen with experience.

Very often, the cause of the malfunction is errors made by users during the installation of the pump and its operation. Manufacturers and service center employees recommend that buyers, immediately before connecting devices, carefully read the instructions and strictly follow everything that is written there. This will avoid many problems and extend the life of the pumping equipment.

Deep well pumps Aquarius for wells technical characteristics

Aquarius deep pumps, designed for water supply of country houses, have the following operational and technical parameters:

- Single-phase supply voltage 220 V. for all models, the device remains operational in the range from 198 to 242 V.

- Pumps are designed for pumping clean water with a temperature of not more than 35 C., mineralization should not exceed 1500 g/m. cube

- The nominal volume of supply, depending on the model, ranges from 1.2 to 5.8 m3/h.

- The rated engine power for different brands ranges from 440 to 2820 watts.

- The immersion depth of the unit under water is up to 10 m.

- The pressure of the electric pumps at a nominal flow is 14 - 140 meters.

- The outer diameter of the pump is 96 mm.

Polypropylene pipes: typical mistakes and practical laying tips

Rice. 5 Vibration pump BV, downhole screw NVP and surface pump Vodoley BTs.

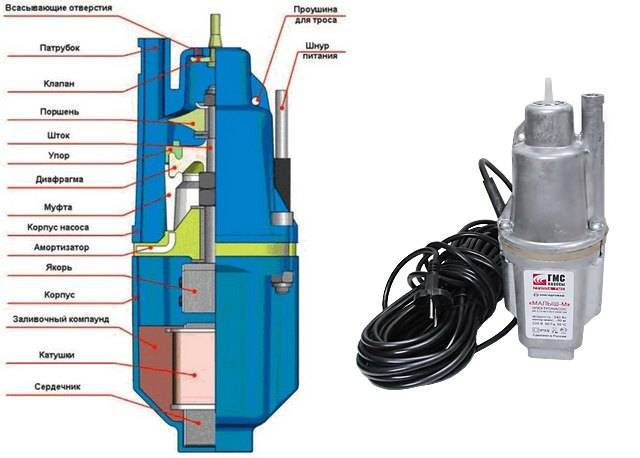

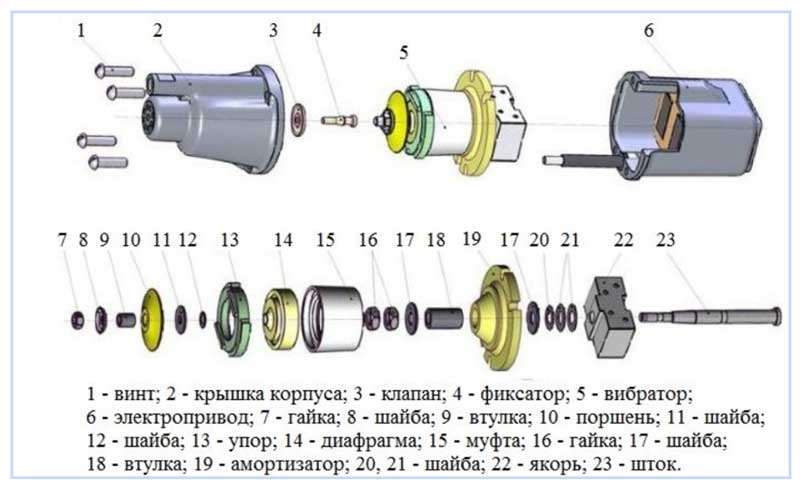

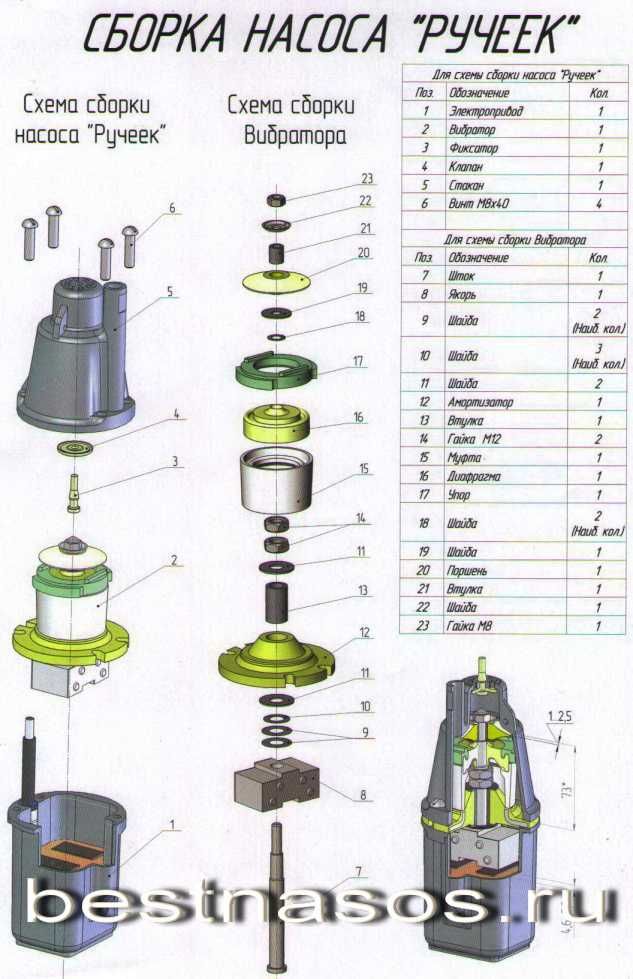

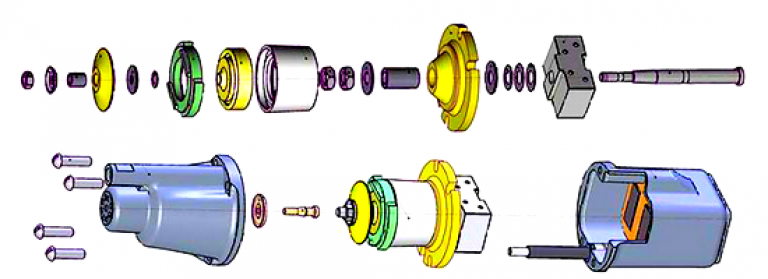

Equipment disassembly features

How to disassemble the Aquarius pump, instructions

The Aquarius pump is disassembled if it becomes necessary to check the condition of all parts and assemblies.

Dismantling of pumps is divided into partial and complete:

- If partial disassembly of the pumping equipment is carried out, then it is disconnected from the electric motor.

- Complete disassembly consists in dismantling the engine or pump or both parts of the installation at once.

- After disconnecting the motor from the pump, the back cover of the motor is dismantled.

- The next step is to remove the rotor from the stator.

- After that, it is necessary to remove the stuffing box from the rotor shaft, which is located under the impeller.

- Next, you need to knock out the rotor with the bearing.

- The next step is to remove the bearing.

This completes the disassembly of the pumping equipment.

How to clean and make minor repairs to equipment

If the Aquarius pump does not pump well, it is necessary to make unscheduled repairs.

A feature of the Aquarius pumping device is that there are no filters inside the equipment, which makes such a device vulnerable to clogging of its working units. If the clogging did not affect the serviceability of important parts, then the pump can be repaired with your own hands (see Repair of submersible pumps: how to do it right). The procedure for cleaning the unit is as follows:

The pump is removed from the source.

The protective metal mesh is removed from the equipment. It can be fixed in different ways. On older pumps, the mesh is attached with two screws. On the latest models, the mesh is fixed with a clip, which is hooked up and removed with a slotted screwdriver. On models with a large cross section, the cable channel is additionally removed, in the form of a metal gutter.

The electric motor of the device is dismantled

Usually it is fixed on four bolts, the head dimensions of which are 10 mm.

Plastic couplings are dismantled, designed to transfer the rotation of the motor shaft to the impellers.

All parts are laid out on a clean horizontal surface.

With a 12 mm socket wrench, the working shaft is carefully turned, while the upper part of the equipment must be held by hand.

After the shaft turns a little on the working part, a jet of water is sent from the hose, which flushes the water pumps, the sand is removed from the device.

By turning the shaft, the washing of the working units with water continues.

If washing the shaft helped, and it began to rotate well, the device can be assembled.

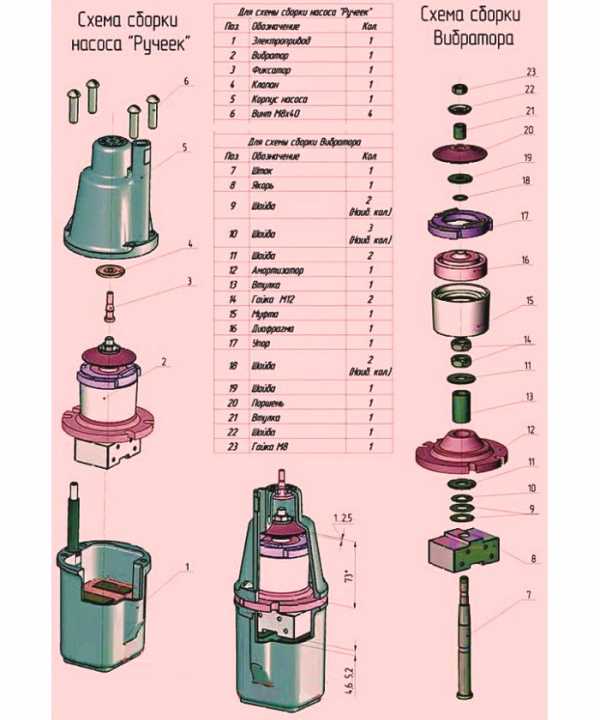

How to repair the Aquarius pump yourself

The order of work is this:

- The device is removed from the source and disconnected from the power supply.

- With great effort, the pump housing is compressed in the upper and lower parts, focusing on its lower edge.

- The retaining ring located in the groove is removed. Compressing the body of the device is necessary to loosen the clamp of the retaining ring.

- All the impellers of the apparatus are gradually dismantled.

- The thrust cover is removed, where the bearing assembly is located.

- If there is a need, damaged items of equipment are replaced with spare parts for the Aquarius pump.

- All parts of the pump are mounted in reverse order, controlling the rotation of the impellers, it must be free.

Very helpful tips

Highly purified vaseline oil is used as a lubricant in Aquarius pumps.

This composition is used in pharmacology for the manufacture of ointments. In this case, the manufacturer hides the name of the company supplying this product.

In total, the Aquarius pump motor contains about half a liter of vaseline oil. But to restore the lubricant, it is better to contact the manufacturer in order to avoid contamination of the well with technical oils. Authorized service centers usually provide this service without any problems.

If the Aquarius pump is supposed to be used in an automated water supply system, it is imperative to install a check valve. The device is not supplied with this element, it will have to be purchased separately.

If the pump will be used only for irrigation, there is no need to buy and install a check valve. In this case, you can block the flow of water into the hose.In this case, the pump will idle, the device is designed for such loads.

If it becomes necessary to replace the capacitor, it will be useful to consider the following information. The Aquarius pumps use devices with a capacity of 14-80 microfarads, designed for 400 V. This is a bipolar dry capacitor made in the Czech Republic, the dielectric component of the device is polypropylene.

AT depending on the model or the time of manufacture of the pump, a capacitor from TESLA, AEG, Gidra, etc. can be installed in it. Models with both wire contacts and petal contacts were used.

All this allows us to conclude that similar models of any manufacturer are suitable for Aquarius pumps, if their characteristics meet the specified technical requirements.

Water pipes in an autonomous water supply system usually use either half-inch or three-quarters of an inch. But the pump or pipe that connects to the pump outlet must be at least one inch in diameter.

These sections of the water supply can be connected using an adapter. When using a smaller diameter pipe, a slight decrease in pump performance can be observed.

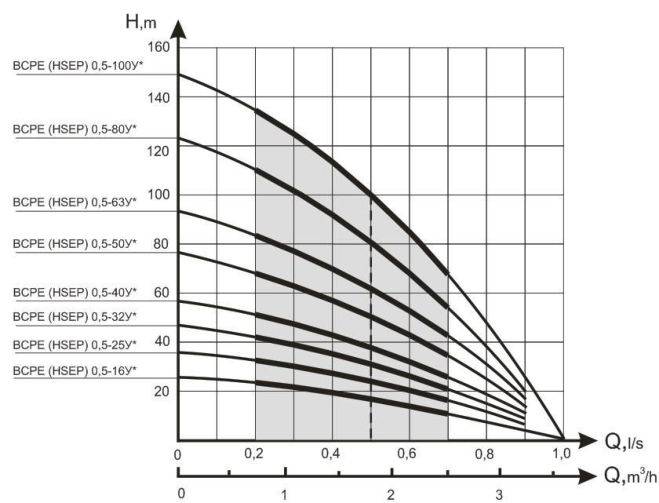

This diagram shows the characteristics of various models. pumps "Vodoley" for the well. This data will help you choose the right pump for your specific situation.

Some amateur craftsmen tried to reduce the performance of an overly powerful pump by removing part of the impellers. Such actions can be fatal for the device. It is best to initially select equipment of the desired performance.

Causes of failure of the pump in "Aquarius"

Despite the functionality and performance, Aquarius pumps have a simple design. This allows you to repair 60% of the components of the device.

The pump is constantly in the water. This causes the device to operate under load. The content of abrasive materials, sludge, too high water temperature, incorrect connection affect the operation of the device. But, despite the negative nature of the impact, these factors lead to gradual wear and tear of mechanisms. As a result, a breakdown can be detected at an early stage, which simplifies repairs.

Blockage of the inside of the deep pump

Negative factors affecting the operation and condition of the pumping device are:

- operation of the device in idle mode without pumping water;

- concentration of sand and other abrasive materials in water over 50%;

- work with liquid, the temperature of which exceeds 40 degrees;

- sudden and frequent voltage drops in the working network;

- incorrect fastening of the ends of the cable at the top of the well;

- incorrect fixation of the device cable;

- Wrong version of submersible electric pump cable connection under water.

Factors that can lead to breakdown and make it necessary to repair the Aquarius pump include frequent removal of the device from the well, and lack of grounding. Lack of grounding leads to problematic breakdowns, as it increases the rate of corrosion of metal parts. In addition, the absence of a filter on the inlet organs of the pump leads to an increased load on the unit and, as a result, its malfunction.

1 What are the problems with submersible pumps?

Due to the fact that the pumping device constantly interacts with water, it is constantly exposed to various negative factors. Fortunately, such negative factors rarely lead to lightning-fast breakdowns, usually the pump performance is broken gradually, gradually and noticeably for the operators.

And this means that if small defects are found, a radical replacement of the deep pump is not necessary, since you can do it yourself. By the way, the replacement of a submersible pump with minor breakdowns is almost never carried out at all. Submersible pumps are even easier to repair, including do-it-yourself, than deep-seated ones.

In the vast majority of cases of breakdowns of deep-well pumps, it is the magnet of the pumping device that fails. Such a breakdown is most often observed in deep pumps of the Sprut and Aquarius brands. Unfortunately, in this case, do-it-yourself repairs will not work, since the equipment for repairing the pump magnet is available only at specialized enterprises. In such a situation, the pump should immediately be taken to a specialist for repair.

Another thing is extraneous noise when the pumping device is running. Here we are talking about a mechanical failure. In the vast majority of cases, a mechanical breakdown can be repaired by hand.

First of all, with extraneous noise, it is necessary to disassemble the pumping device for spare parts. In cases where noises are heard at pumps of the Octopus or Aquarius brand, it is necessary first of all to check the electrical system of the pump, which includes both the engine itself and the automation system.

Deep well pump with connected hose

Pumps of the brand "Octopus" and "Aquarius" have breakdowns most often in these systems, which, however, are quite simple to repair with your own hands. Among other problems that often occur with pumps of the Sprut and Aquarius brands are breakdowns of the time relay and protection systems against short circuits or dry running.

The reasons for such breakdowns can be gradual blockages of the internal pumping system with foreign objects from the well soil. In addition, the operation of the pump in dry mode can also become a serious problem, since such a “stroke” quickly runs out of oil, which leads to uneven and unsteady operation of the internal mechanisms of the pump.

In such a situation, over time, the parts undergo deformation, up to the impossibility of repair in principle. That is why any pumping device, especially the Aquarius and Sprut brands that are especially popular in the CIS, must undergo constant diagnostics for internal problems, preferably by specialists.

The most rare causes of failure of the pumping system include the following reasons:

- overheating of the working fluid when its temperature exceeds 40 degrees Celsius;

- improper anchoring of the submarine cable.

These problems are typical not only for pumps of the Aquarius and Sprut brands, but in general for everyone, since the reasons that led to such problems have nothing to do with the quality of the pump, but directly depend on the professionalism of the pump installer.

How to carry out regular maintenance of pumps?

Pump device option

- Turn on the pump and check for abnormal noise and excessive vibration while operating.

- Check the pressure of the coolant supplied by the pump. It must correspond to the indicators stated in the technical passport.

- Make sure that there is no excessive heating of the electric motor of the device.

- Check the presence of grease on the threaded flanges and, if necessary, restore it.

- Make sure there is a ground connection between the pump housing and the appropriate terminal.

- Inspect the pump from all sides and make sure there are no leaks. Typically, such vulnerabilities are the junction of the pipeline and the housing of the pumping device. Check the level of tightening of the bolts and the normal condition of the gaskets.

- Examine the terminal box. All wires must be securely fixed. The presence of moisture is unacceptable in the node.

Deep well pumps Aquarius for wells technical characteristics

Aquarius deep pumps, designed for water supply of country houses, have the following operational and technical parameters:

- Single-phase supply voltage 220 V. for all models, the device remains operational in the range from 198 to 242 V.

- Pumps are designed for pumping clean water with a temperature of not more than 35 C., mineralization should not exceed 1500 g/m. cube

- The nominal volume of supply, depending on the model, ranges from 1.2 to 5.8 m3/h.

- The rated engine power for different brands ranges from 440 to 2820 watts.

- The immersion depth of the unit under water is up to 10 m.

- The pressure of electric pumps at a nominal flow is 14 - 140 meters.

- The outer diameter of the pump is 96 mm.

Rice.5 Vibration pump BV, downhole screw NVP and surface pump Vodoley BTs.

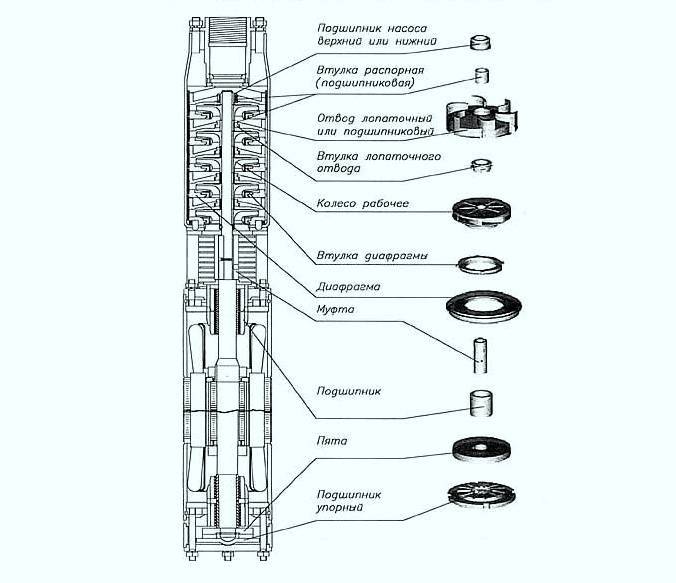

Pump Maintenance

After dismantling the pumping equipment, it is necessary to inspect its condition.

When disassembling the pump, you can find sand that prevents it from working fully.

During disassembly of the pump, the intermediate distance between the following parts of the pump is checked, such as:

- Intermediate and upper bearing.

- Bushings and shafts.

- Bearings and base.

Maintenance of Aquarius pumps consists in lubricating parts such as:

- Rubber-metal bearing.

- Sealing rings.

If during disassembly of the pump you notice wear of the bearing element, then it is necessary to replace it.

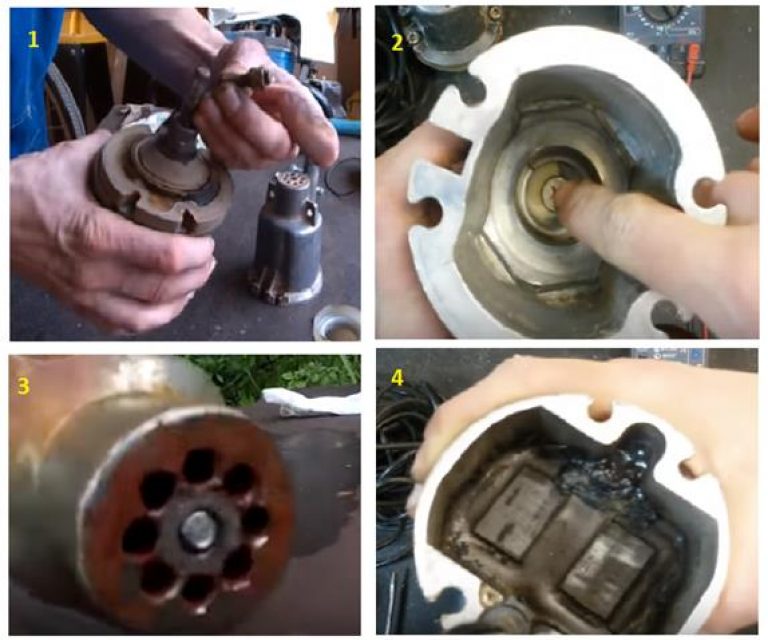

2 Stages of troubleshooting

If during operation you notice that the pump does not work as it should, extraneous noise is heard, then immediately you need to take action. First, we recommend checking the devices for minor problems. On such brands of pumps as "Octopus" and "Aquarius", it is initially necessary to check whether a reboot has occurred, due to which the machine is most often turned off, followed by the pumping system.

Aquarius pump and its repair.

To check this, you must first unscrew and disassemble the junction box. Inside this box, you can see a breakdown, and this is blackening or a burning smell. If everything is in order in this area, there is no smell, then we proceed to remove the impeller from the pump motor.

First, it is checked whether the engine is spinning. A smoothing capacitor is connected to the engine, through which the engine starts. We also look around the winding, which should not be broken or torn.The most common failure in these pumps is engine burnout. That's why to see it, the impeller is removed.

After the impeller was removed, we begin to manually scroll the engine (shaft). If the shaft does not spin, then there is a mechanical failure on the face. In other words, the pump motor has jammed. Most often this happens due to the fact that small debris, soil can get into the engine. And this is due to the fact that it does not have a protective filter. If in the future you do not clean the special filter and remove particles on it, then the stator winding may soon burn out in the engine.

2.1 Phased work on the repair of the electric motor

Before you decide to repair the electric motor, it must be placed vertically. If you do not do this, when disassembling the electric motor, an oil leak will occur, without which the pumping system will not work. Then, in a vertical position, the cover is removed, through which the 220 W power wire passes.

Immediately upon removing the cover, it is advisable to diagnose the starting capacitor. To diagnose the starting capacitor, you will need an ohmmeter. This is checked by connecting the terminals to the motor winding. Then we rotate the handle, and it creates a voltage of 250-300 volts.

We disassemble the Gilex pump

If the device shows resistance at the same time, then it is considered that the state of the winding is ideal. But if the ohmmeter device fixes infinite resistance, then there is a problem in the form of a break. Conclusion: the working phase of the motor is not working, there is a break.

If the device shows a small resistance, then we can talk about an interturn circuit.The conclusion from the above - with your own hands, if this happened, it is not possible to fix it. In such cases, it is better to contact specialists. Since in most cases the replacement of parts will not help, but only the replacement of all consecutive parts will help. Especially if the pump winding is not corrected.

When viewed in the future, we look at the pump further. The device shows that everything is in order, we proceed to inspect the starting capacitor. More often than not, it breaks down. In other words, it breaks. When the pump is running, such a problem does not immediately strike the eye, but upon a detailed examination with such a device as an ohmmeter, the breakdown will come out.

At the same time, do-it-yourself repair of the starting capacitor can be done independently, without resorting to the help of a master. But if you fail to do this, then it is better to replace the starting condensate with a new one. Since starting condensate is a fatal failure.

Prevention and diagnosis of breakdowns

To increase the service life of heating equipment, simple preventive measures will help:

-

Do not turn on the pump without water.

- To prevent oxidation of parts during inactivity, turn on the equipment once a month for 15-20 minutes.

- Regularly conduct a visual inspection, be attentive to the noise that appears, excessive heating of devices, leaks.

Before the start of a new heating season, a technical inspection of the equipment is carried out. Carry out a test run and check the status of the most important components:

- correct connection to the pipeline;

- tightness of connecting elements;

- filter status.

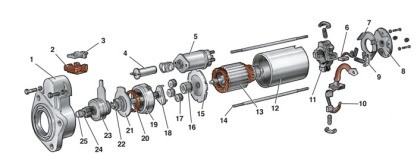

1 Most common pump failures

We all know that a pump is an ordinary device, a mechanism that does not differ in any complexity, but this is a judgment only at first glance.

The pump consists of an engine, an impeller, and also in the middle of the pump there is a shaft, seals and all this closes the housing. The above parts are constantly in operation, which leads to gradual wear.

That is why it is necessary to occasionally repair the pump, since the device is constantly in operation and is in the water. Yes, not all pumps work in water, such as Gilex surface pumps, which work on the surface at the same time as hydraulic accumulators, which can also be installed separately on the surface.

But, Gileks surface pumps also need repairs. Let's take, for example, a submersible pump, from such a well-known manufacturer as Gileks Vodomet. This device is in the water (well or well) constantly. Some of us do not even take it out for the winter, and this is a gross mistake.

The Gileks Water Jet pump has a lightweight design, and it is really easy to repair it yourself. But if you are not an expert in this, you will not only not repair it, but you can even damage the pump even worse. But if the situation is such that there is a slight breakdown of the pump on the face, then you can do it yourself.

We disassemble the Gilex pump

The main thing who is going to repair submersible and surface pumps should understand their design, as well as how they are connected correctly. The most famous pump failures, which we will discuss separately in this article.

Check pumps are very easy and affordable.

For example, if the pump is connected to 220 W and it does not respond, then there is a breakdown with the contacts or with the supply wire. Solving this problem is easy, you just need to have a tester.They check the contacts of the pump

If there is no signal during the test, then the contact is damaged.

You should also pay attention to the contact, it may become damp or change color. If, when connecting 220 W, all mechanisms do not react, then the main cable is interrupted

This is the most common failure in water pumps. Their disadvantage is that their cable is very poorly protected, and is constantly in limbo.

If during operation you notice a hum in the engine, uneven operation is felt, clicks are heard, this indicates that there are problems with the engine and the pump impeller. To finally understand this, you must first disassemble the pump and inspect it. It may be that the pump impeller simply cracked and the bearings flew out or failed. These are the most painful pump problems.

If you see that the engine does not work at all, then the problem is in it. And in this case, you will not be able to fix it with your own hands. Especially such a breakdown occurs in submersible models. If we disassemble a specific model, let's take the Vodomet 50/25 pump engine as an example, then it is not repaired or disassembled at all. In them, the winding can most often burn out. But replacing the winding in such models is a moot point. It is better if you have such a breakdown, replace the engine with a new one, as Gilex manufacturers are constantly replenishing the range of spare parts.

If we talk about Gilex Jumbo, then in such surface pumps the engine often burns out and quickly wears out. And all this happens from the dry running of the pump. Surface pumps are more likely to break down from dry running than, for example, submersible units.

Accessories for the pump Gileks

Let's go back to the Gilex Jumbo pump.In it, breakdowns such as poor water pressure in the system occur. The main reasons for this are: the pressure switch does not work and the accumulator does not work, as well as general problems of the pump as a whole.

First, let's analyze the first breakdown, it is the relay that goes astray.

Its performance is checked easily and simply, and if did you notice that everything is not so smooth with it, it is configured very easily. If we talk about hydraulic accumulators, then there are the following breakdowns:

Rupture of the air membrane. And we can only check this when we disassemble the tank. If there is a large amount of air in the membrane, then the system is completely unbalanced, as a result of which the pressure drops.

Accessories for the pump Dzhileks Vodomet

The pump itself can also react badly, but this happens very rarely. Most often, working elements come out of the pump, and the pump simply does not cope with its task of pumping water. And if the working elements of the pump come out, during operation you notice a hum, the impeller does not rotate well. If there are other signs of a breakdown, then most likely the relay or hydraulic accumulator has failed.

A few good tips

Highly purified vaseline oil is used as a lubricant in Aquarius pumps. This composition is used in pharmacology for the manufacture of ointments. In this case, the manufacturer hides the name of the company supplying this product.

As the inscription on the lid says, do not open it.

If handled carelessly, oil may spill out of the engine. In total, the Aquarius pump motor contains about half a liter of vaseline oil.

But to restore the lubricant, it is better to contact the manufacturer in order to avoid contamination of the well with technical oils.Authorized service centers usually provide this service without any problems.

In total, the Aquarius pump motor contains about half a liter of vaseline oil. But to restore the lubricant, it is better to contact the manufacturer in order to avoid contamination of the well with technical oils. Authorized service centers usually provide this service without any problems.

If the Aquarius pump is supposed to be used in an automated water supply system, it is imperative to install a check valve. The device is not supplied with this element, it will have to be purchased separately. It is recommended to give preference to a valve equipped with a brass damper. Such devices are characterized by increased resistance to wear and a longer service life.

If the pump will be used only for irrigation, there is no need to buy and install a check valve. In this case, you can block the flow of water into the hose. In this case, the pump will idle, the device is designed for such loads.

If it becomes necessary to replace the capacitor, it will be useful to consider the following information. The Aquarius pumps use devices with a capacity of 14-80 microfarads, designed for 400 V. This is a bipolar dry capacitor made in the Czech Republic, the dielectric component of the device is polypropylene.

Depending on the model or time of manufacture of the pump, a capacitor from TESLA, AEG, Gidra, etc. can be installed in it. Models with both wire contacts and petal contacts were used. All this allows us to conclude that similar models of any manufacturer are suitable for Aquarius pumps, if their characteristics meet the specified technical requirements.

Water pipes in an autonomous water supply system usually use either half-inch or three-quarters of an inch. But the pump or pipe that connects to the pump outlet must be at least one inch in diameter. These sections of the water supply can be connected using an adapter. When using a smaller diameter pipe, a slight decrease in pump performance can be observed.

This diagram clearly shows the characteristics of various models of Aquarius pumps for a well. This data will help you choose the right pump for your specific situation.

Some amateur craftsmen tried to reduce the performance of an overly powerful pump by removing part of the impellers. Such actions can be fatal for the device. It is best to initially select equipment of the desired performance.

Repair of Aquarius pumps

If the pump connected to the network is silent, then the main suspicion falls on a malfunction of the electrical part. To find out the exact malfunction, you should “ring” it with an ohmmeter. When the indicator of the device goes off scale, this indicates a clear break in the electrical circuit. When the resistance is extremely low, then the motor winding is closed.

You can try to rewind it, but it is best to purchase and install a new electric motor. In the normal state of the electric motor, a possible reason for the failure of the device lies in the failed capacitor.

If the internal cavities of the device are clogged with sand, as a result of which the shaft turns with difficulty, the repair of the Aquarius pump comes down to flushing. To do this, the electric motor is disconnected so as not to flood the condenser, and a stream of running water is supplied to the shaft with wheels.In this case, the shaft should be forcibly rotated with a 12 socket wrench. The operation continues until the pump mechanism begins to rotate completely freely.

In the event of a drop in the output pressure, attention should be paid to the impeller wheels. When working in sand-saturated water, they are quickly erased, and can no longer provide a normal level of water jet pressure.

The problem should be solved by replacing the wheels with new ones.

HelpfulUseless1