- Device Capabilities

- Hydraulic supply

- Pump replacement

- Application in a slowly filling source

- How to successfully restore a clogged well?

- Pumping water from flooded premises

- New heating system

- Pump disassembly

- The main types of malfunctions and their causes

- Electrical faults

- Mechanical breakdowns

- Technical indicators of pumps Rucheek

- How to avoid pump failure?

- How to rewind a reel

- Features of pumping drainage water

- Device and principle of operation

- Principle of operation and device

- Setting up a submersible pump “Ruchek”

- Principle of operation and technical characteristics

- Specifications

- Prevention of breakdowns of the pumping unit

- Kinds

- Self troubleshooting

- Weak water supply

- Oil seal replacement

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

Device Capabilities

Of course, this pump will not solve your global problems in a fundamental way in the water supply of a large suburban area, since on average it has a power of one hundred and fifty to two hundred and twenty-five watts. But the owner of a country house will effectively help to deal with many processes.

Hydraulic supply

In the house, this unit copes with the necessary supply of natural water.True, at the same time you will not be able to calmly bathe in the bathroom, wash the accumulated dishes and wash, as the pump only produces up to seven liters per minute.

But if you use it skillfully and economically enough, then it will be enough to take a warm summer shower and wash the accumulated things. Water pressure directly depends on the depth of a particular water resource. The larger the number, the smaller the feed, respectively.

It is undesirable to connect the pump to your country house, bathhouse and other important outbuildings at the same time, as an unwanted automatic reboot of this system may be caused.

Pump replacement

Some private owners of country houses, who use more powerful and expensive equipment in their home water supply, buy this budget pump as insurance. After all, absolutely anyone, even the best imported device, can break down, and until you repair it from specialists and get it back, a lot of time will pass.

And in any case, the pump will come in handy on the farm. And then, to meet the vital needs, it is the "Brook" that will come in handy for you. It is a kind of lifesaver for the owners of country houses and will not leave you alone in difficult trouble, which are so many in the daily life of every person who owns a country house.

Application in a slowly filling source

When carefully digging a well or well, it is difficult to guess in advance how quickly the proper water level will be restored with repeated use. One source will do it instantly, and the second will need long days for the long-awaited update.

But when buying a device, few people think about it, and it happens that the unit pumps out water very quickly, rather than being replenished. In such a situation, the system may shut down automatically and require a prompt restart. With a quick intake, the chances of getting muddy water increase.

It is best to take the Brook, as it works more stably and has a low intake intensity.

How to successfully restore a clogged well?

You can develop a system using the "Brook". The quality of water, of course, will not change, but the volume will increase significantly, you will immediately notice this for yourself.

Turn on the pump and lower it as close as possible to the required filter. Thanks to the vibrating mechanism, numerous layers will be knocked out, and then rise to a flat surface. Several such successful attempts, and the well will begin to come into full order.

During operation, it is not necessary to stand right next to your well. In any case, the water pump will not completely pump out the water. So you can take care of your accumulated household chores. For example, you can water a country garden. You will immediately notice if the water quality and volume change.

Pumping water from flooded premises

In the spring, basements and cellars are very often flooded with summer residents. Carrying out water with the help of small buckets is very problematic and takes a lot of precious time. Here you will be perfectly helped by a pump with good quality from a Belarusian domestic manufacturer.

New heating system

When building a new house, the heating system is done first of all, rather than connecting to the water supply. You need to somehow fill all the pipes.

The scheme is as follows: you bring water in a huge barrel, insert this pump into it, and connect the second hose to the drain valve of the battery. Next, the tap gently opens and this unit starts. While the system is carefully filled, look carefully at the special pressure gauge in order to determine when the pressure is at the level you need.

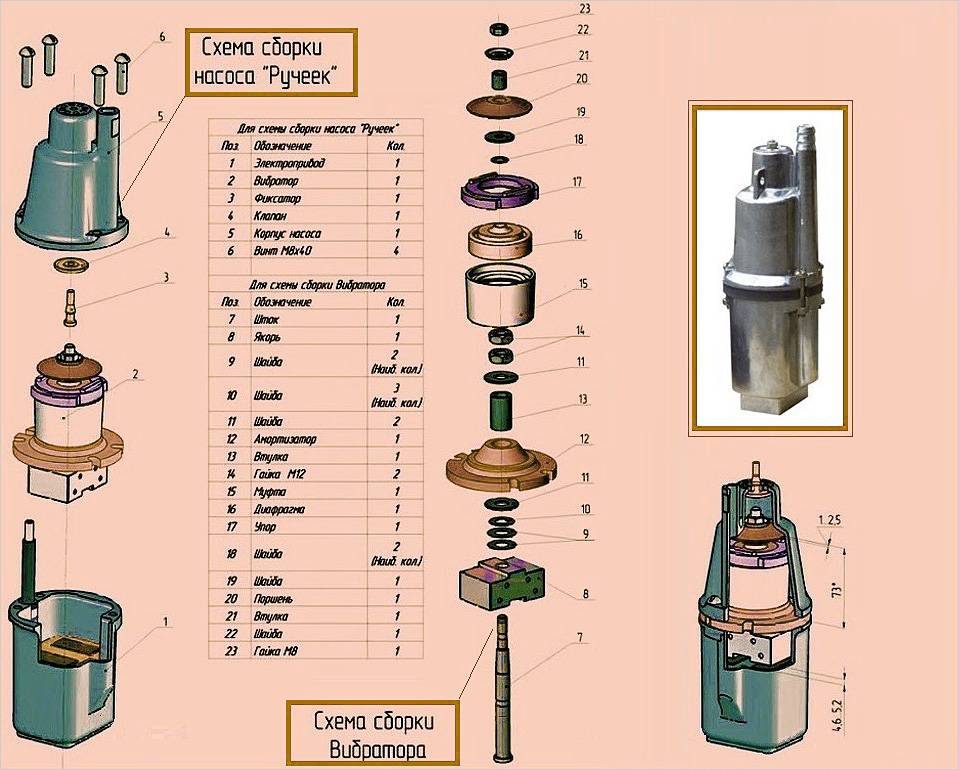

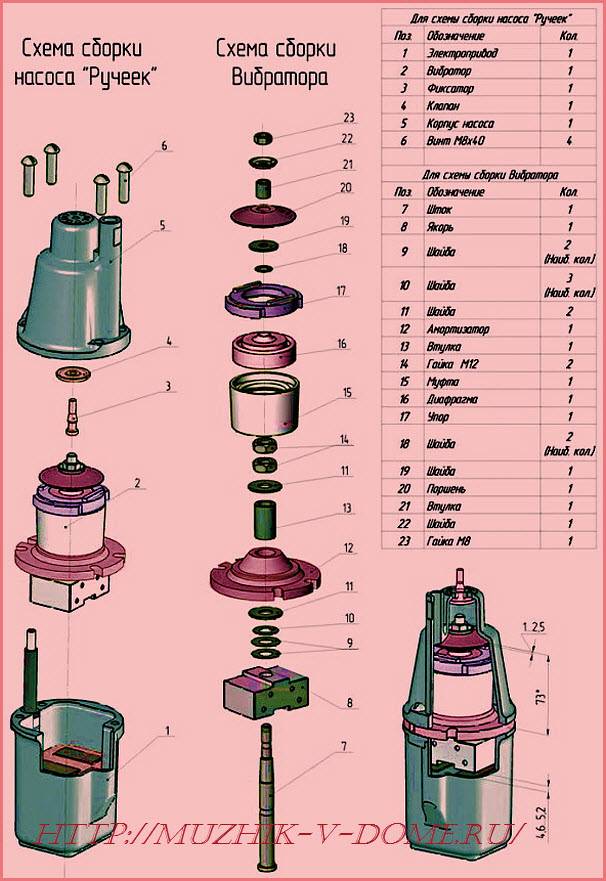

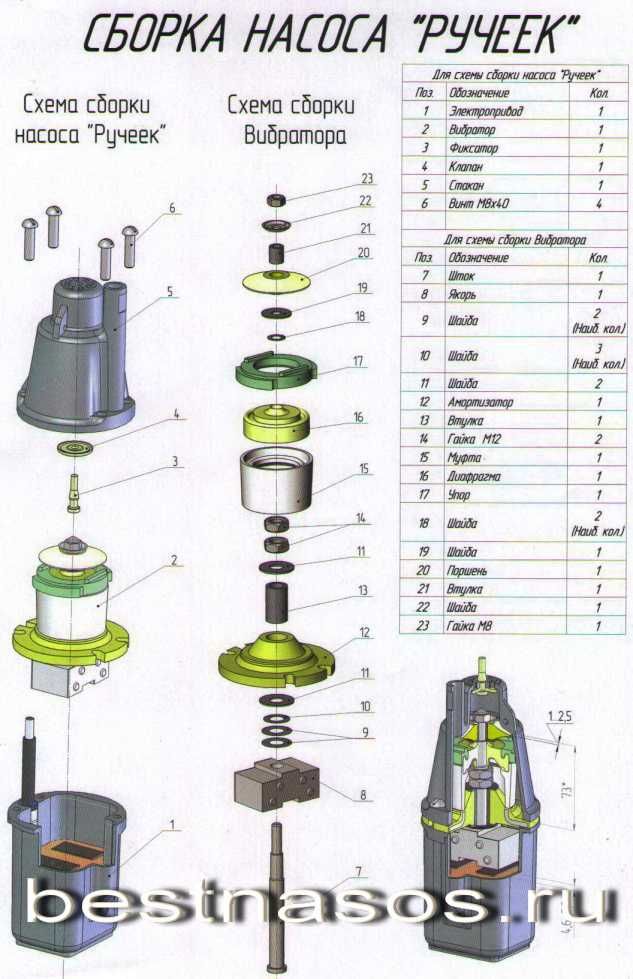

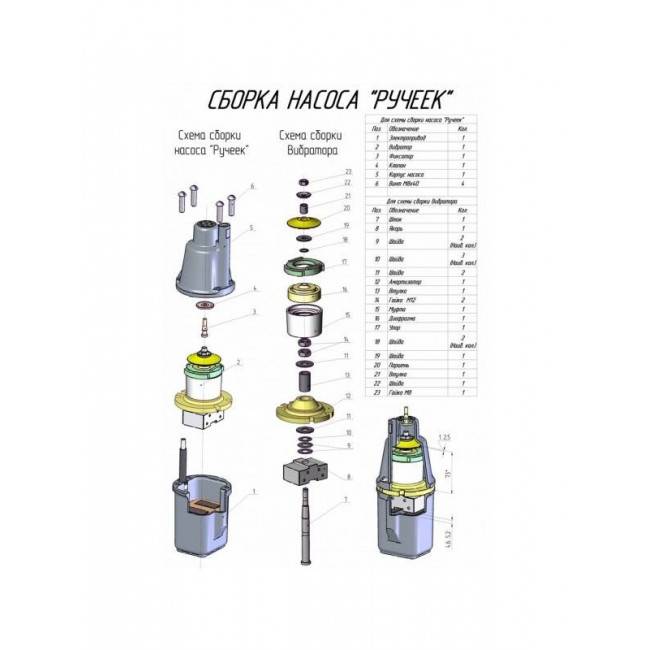

Pump disassembly

After lifting the device from the well, blow out the outlet fitting, removing any remaining water from the pump. All mating parts of the apparatus should be marked with a marker in order to install them in the exact position during assembly. Then we proceed to disassemble the case, holding it in a vice for the ledges near the screws. The screws that tighten the two halves of the body (4 pieces) should be loosened evenly. After removing the cover, a vibrator is removed from the housing - the main working unit of the pump.

By unscrewing the fixing washer located on top of the vibrator, you can disassemble the entire assembly. All components are strung on the central rod one after another, like rings on a children's pyramid. The main thing is to remember the correct sequence of all these parts when disassembling the vibrator. To do this, it is recommended to capture each stage of dismantling on a phone camera.

The main types of malfunctions and their causes

Devices with a lower water intake are more likely to break down, because the engines in them heat up more. The causes of defects due to which the pump does not pump water lie either in its mechanics or in the electrics.

The most common problems of the "Baby":

- loosening nuts due to vibration of the core;

- valve wear caused by abrasive impurities in the water;

- breakage of the core rod.

Electrical faults

Due to strong heating, such breakdowns often occur:

- a short circuit occurs;

- the electrical wire is charred or broken;

- the copper winding burns out in the coil;

- exfoliates from the body of the compound.

Mechanical breakdowns

Most often, such defects are detected:

- clogging of the internal cavity of the pump with mechanical impurities;

- liming parts due to excessive water hardness;

- loosening nuts due to strong vibration;

- damage to the device from impacts on the concrete wall of the well;

- weakening of the properties of the rubber shock absorber;

- loss of valve elasticity;

- piston failure.

Technical indicators of pumps Rucheek

Of the vibrating devices, the Brook surpasses other pumps in terms of performance. The pump is adapted to work in wells and wells, it is lowered to pump pools, flooded pits.

Characteristics of the pump Brook indicated in the passport:

- power consumption - 225 W;

- maximum depth of liquid rise - 80 m;

- head / flow - 20 m / 950 l / h, 30 l / 720 l / h, 40 m / 430 l / h;

- dimensions - height 300 mm, diameter 99 mm;

- cable length corresponds to the numbers in the marking.

The general assembly of the submersible pump is made on a sealant. For non-contact work with the walls of the well, shock-absorbing rings are used.

The apparatus is lowered into the depth on a nylon cable. The electric magnet in the case must always be under the bay for water cooling.

How to avoid pump failure?

By following the operating rules recommended by manufacturers, you will minimize the risk of breakdown of pumping equipment, and it will serve you for many years. Basic rules of operation:

- Do not allow the pump to run without water.

- Do not use the pump in the presence of unstable mains voltage.

- Do not operate the pump with a damaged power cord or casing.

- Do not move the unit by the power cord.

- Do not pinch the hose to increase the pressure.

- Do not pump water with dirt, impurities, debris.

When installing the pump in a well, it is necessary to put on a protective rubber ring on it, which will protect the equipment from hitting the walls.

The unit can only be switched on/off using a mains plug or a two-pole switch embedded in the fixed wiring system.

During the operation of the vibration pump "Rucheyok" it is necessary to carry out a preventive inspection in a timely manner and monitor the quality of the pumped water. If the water is dirty, then the pump must be turned off and its position relative to the bottom checked.

How to rewind a reel

To rewind the vibration pump coils, you will need the following materials:

- Copper wire with a diameter of 0.65 m (PETV brand);

- Epoxy resin, plasticizer, hardener.

Tools:

- winding machine;

- soldering iron

- Electric stove;

- A hammer;

- Screwdriver;

- Protective gloves.

Repair of the vibration pump is recommended to be carried out outdoors or in a well-ventilated area, since epoxy resin will have to be melted to rewind the coils, and it releases toxic substances, the inhalation of which is harmful to the body.

Pump Baby, ready to install and connect

First, we disassemble the submersible pump. We remove the flooded electromagnet from the device. To do this, you will have to melt the epoxy compound.

For this, an electric stove is best suited, on which you need to put the body of the unit.Wait until the epoxy warms up to a temperature of 160-170 degrees (this is indicated by the characteristic smoke coming from it - this smoke is toxic, try not to inhale it).

Next, we need a wooden log, on which it will be possible to knock out the electromagnet from the body. After the compound has warmed up, put on protective gloves, and beat the body against the block (the electromagnet should look down), until the electromagnet changes its position so that you can pry it with something and remove it.

While the body is hot, clean it of epoxy residue with a metal brush or a flathead screwdriver.

Now you need to knock the electromagnet out of the coil with a hammer. To do this, use a small wooden block as a wedge. It is recommended to do this with an assistant who will hold the reels while you shoot. If you fix the coil in a vice, then, most likely, the repair will end with the deformation of its frame.

Once the core of the electromagnet has been knocked out, unwind the coil and clean its frame of epoxy residue. Place the spool frame on the winder and wrap the spool completely (approximately 8 layers). This can be done without a special machine, but it will take much more time.

Connect the beginning and end of the wire to the main part using a soldering iron. We put the electromagnetic core back into the coil frame. We pass the cable for connecting to the mains through the seal inside the case. We separate the cable and clean its ends by 2-3 cm.

We solder the cable to the beginning of the winding of the coils. Gently lower the coils inside the case.In order for the coils to sit tightly in their place, attach a small wooden block to the electromagnetic core, and gently tap them to give them the desired position.

Now you need to make an epoxy compound. Fix the body of the unit in a vise. In a metal bowl, mix the epoxy, plasticizer and hardener.

Fill the coils with the resulting mixture up to the upper edge of the electromagnet. Wait 10-15 minutes for the compound to fill all the gaps. If after the epoxy has sank into the voids, its level has decreased, then add additional amount of the mixture.

Features of pumping drainage water

During the spring flood, situations often arise related to the flooding of basements, inspection pits and other structures below the surface. Usually, such groundwater has practically no impurities, so it is quite possible to pump it out with vibration pumps.

If it is necessary to work with contaminated water, it is necessary to use an additional filter, which will prevent possible damage to the pump. Such a filter has the form of a cap, which is put on the receiving part of the device, and the installation must be carried out after the filter has been preheated, this will greatly simplify the installation process.

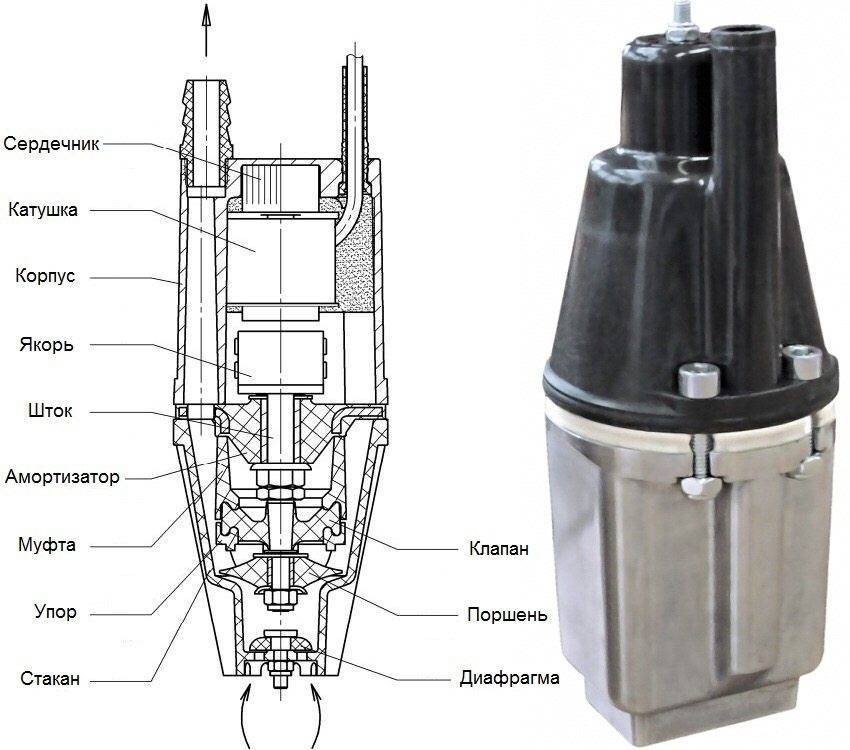

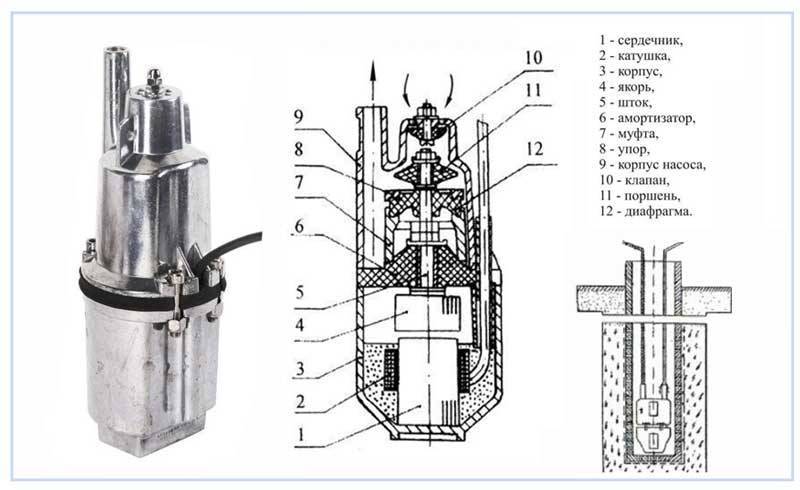

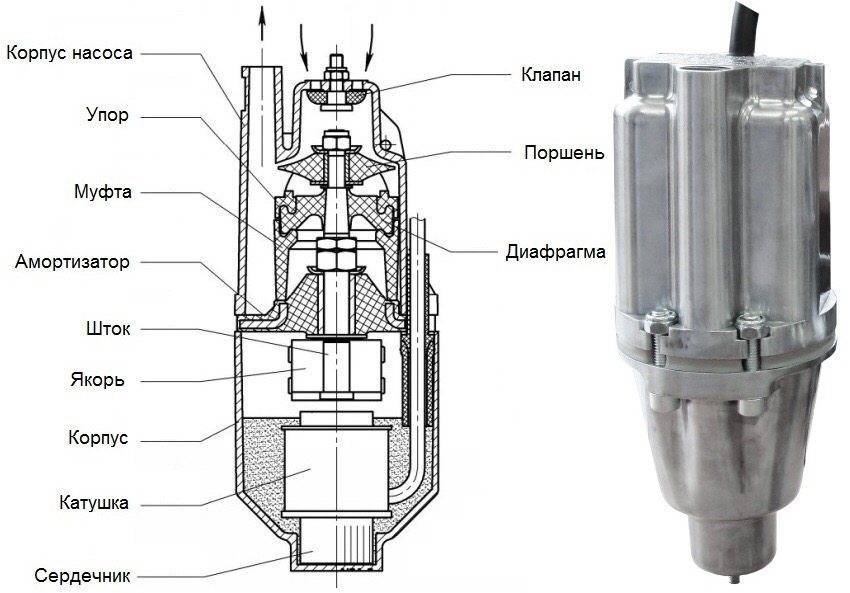

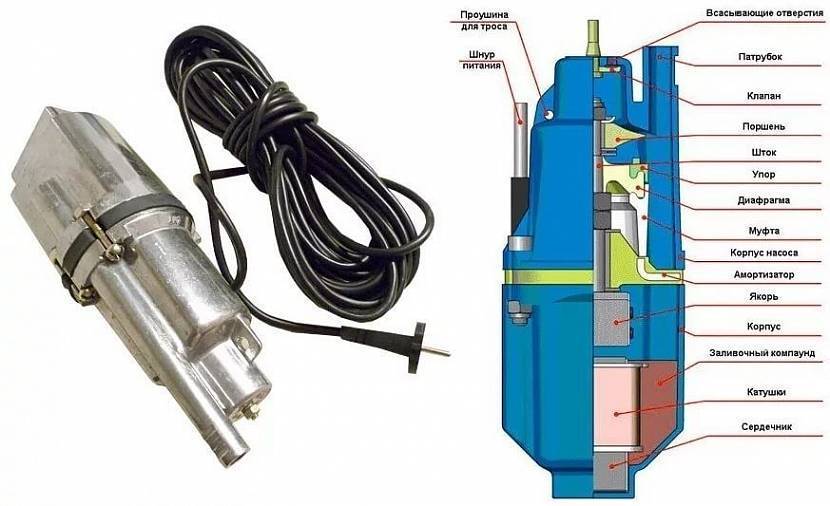

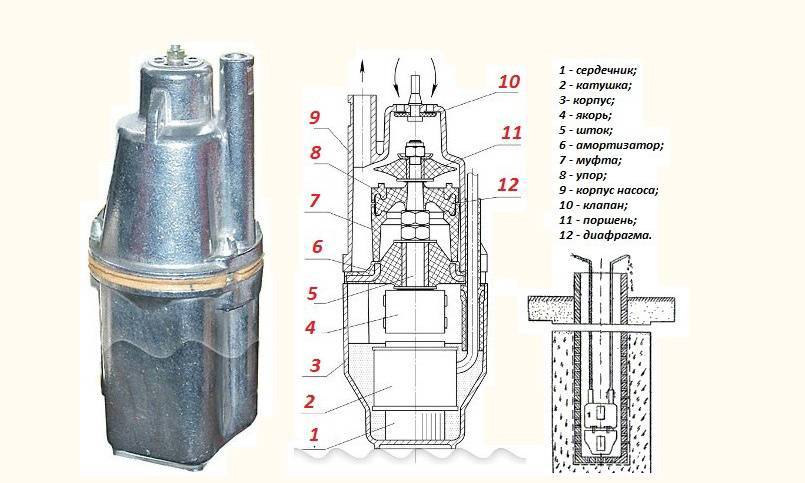

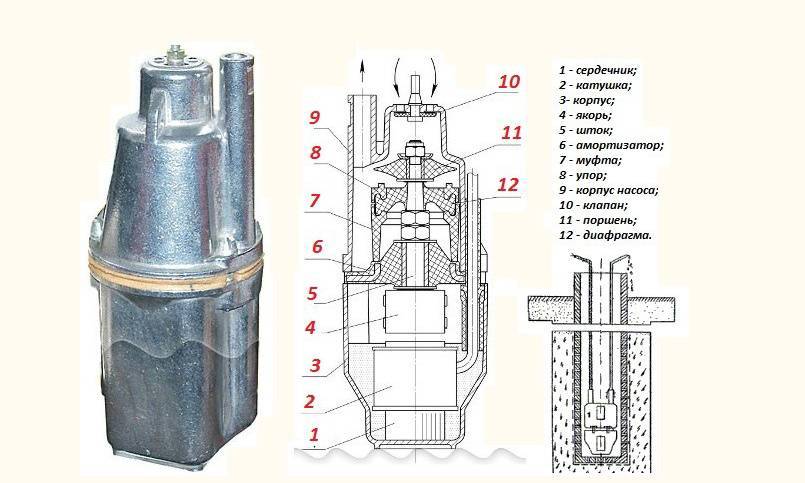

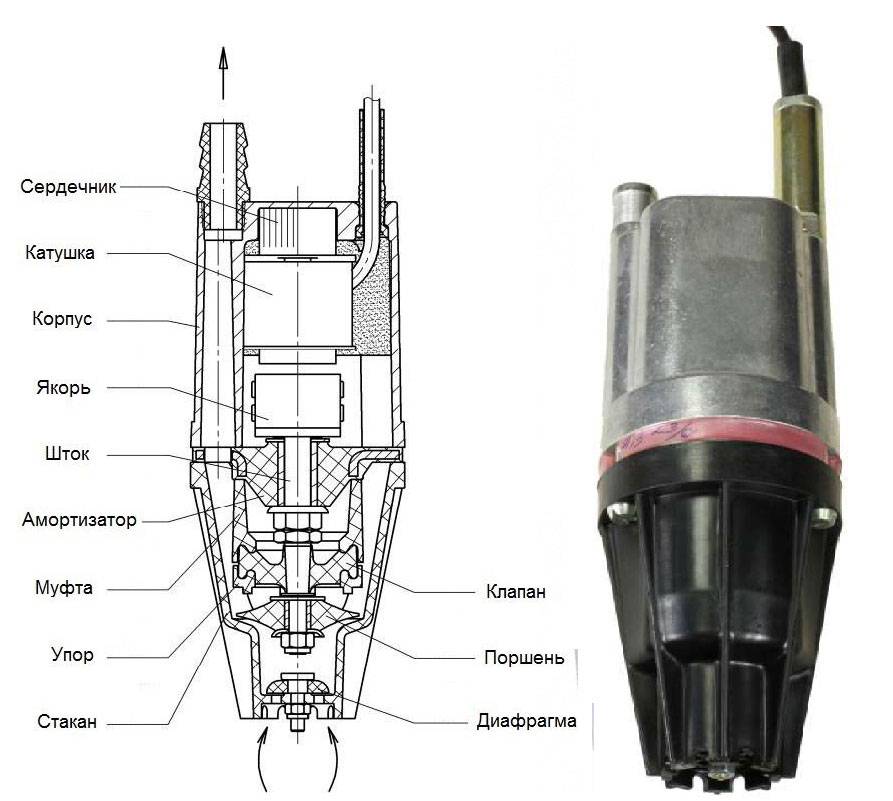

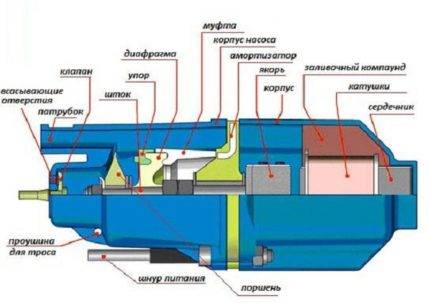

Device and principle of operation

The submersible pump "Rucheyok" consists of the following parts: an electric drive, a vibrator and a housing, which are interconnected with four screws. The electric drive of the unit includes a core with two coils and a power cord.

The vibrator consists of a shock absorber, a diaphragm, an emphasis, a coupling and a rod. An anchor is pressed in at the bottom of the rod, and a piston is attached to it at the top.

The pump housing is a casing, in the upper part of which there is a glass with holes for water inlet and a branch pipe that provides water outlet. The existing valve serves to open/close the inlets.

The pump pumps water due to vibrations of the piston and armature. They are actuated by an elastic shock absorber, which converts the alternating current received from the network into a uniform mechanical vibration.

The rod transmits the movement to the piston, which, when vibrated, creates a mini-hydraulic shock in the glass with holes. The valve at this moment closes, and the water is pushed out into the outlet pipe.

There are no rotating elements in the design of the pump, which reduces the risk of breakdown, because. friction is the main cause of failure (click to enlarge)

There are no rotating elements in the design of the pump, which reduces the risk of breakdown, because. friction is the main cause of failure (click to enlarge)

Due to the fact that the water intake takes place in the upper part of the unit, the system is cooled and it does not heat up during operation.

Another advantage of the water intake pipe located on top is that sludge from the bottom is not sucked in by the working body. As a result, the unit is much less likely to be clogged with a muddy suspension, because of which the pump should be periodically disassembled and cleaned.

For quick replacement of wearing parts, manufacturers of vibration pumps produce repair kits that include a full set of necessary spare parts.

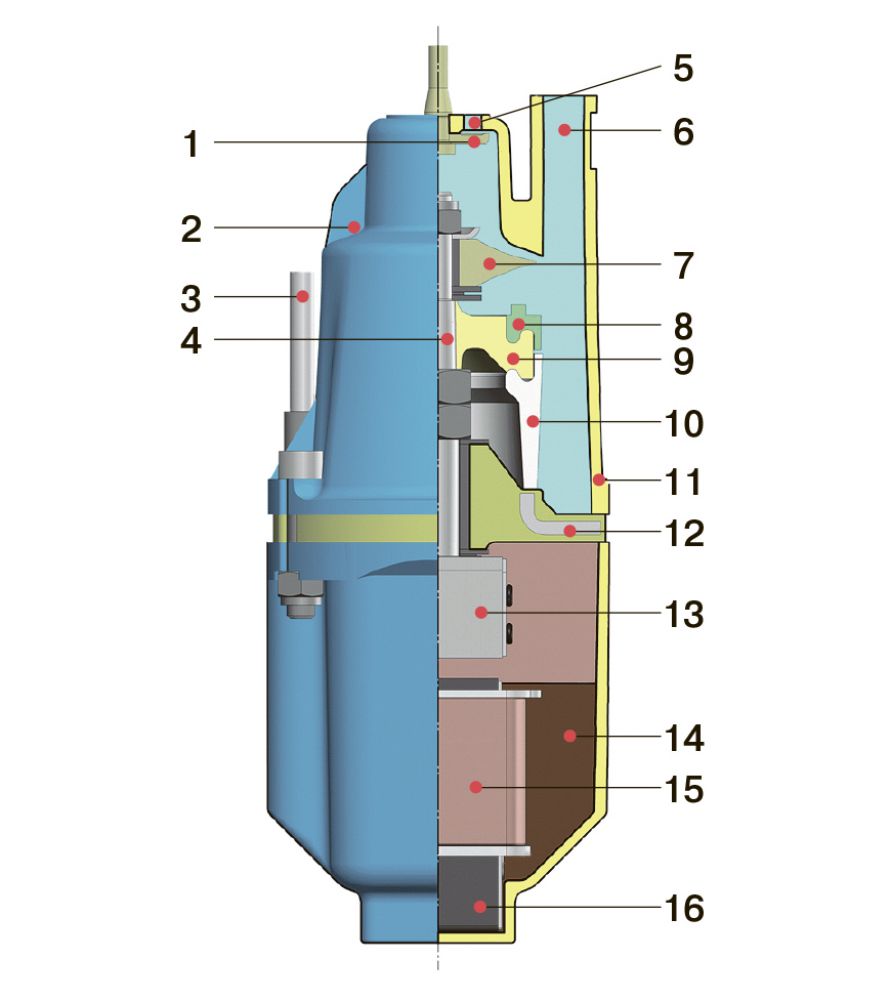

Principle of operation and device

The Brook pump is one of the most popular vibration type pumps. The central part of the design of this unit is the membrane. When the pump is turned on, it is attracted and repelled under the influence of an electromagnetic coil built into the pump.

The oscillatory movements of the membrane create a pressure difference in the pump housing, which allows you to move water to a sufficiently high height.

“Trickle” is a submersible pump, that is, for operation it must be lowered on a cable into the water. The device is relatively small, weighing only 4 kg. The performance of the standard model is usually rated at 450 l/h.

Technically, the pump is designed to pump clean water, so the product warranty does not cover damage caused by working in difficult conditions.

The "Rucheyok" pump has compact dimensions, low weight and performance, which is able to provide water to one or two points of water intake at the same time.

A special rubber ring is installed across the durable metal pump housing. It protects the well casing from impacts during descent or excavation of the device.

To suspend the pump, you can use a nylon cord or a fairly strong twine, since the weight of the unit is small. Of course, you should securely fasten the cable to the string so that it does not fall into the well.

Modern models of the "Rucheyok" pump are equipped with a special sensor. It detects the temperature of the device and turns off the device when it reaches critical values. Most often, such situations arise if, for some reason, the pump is out of the water column.

Protection against the so-called "dry run" prevents equipment breakdowns and extends its life.

Technical parameters of the pump "Brook":

- temperature of the pumped water - no more than 35°С;

- power - 150-270 W, so its operation will not increase the overall energy costs too much;

- immersion depth - within 40-60 m;

- average productivity - about 7 l / min.

It should be remembered that the deeper the pump is suspended, the lower its performance. If the pump is submerged only one meter or less, it can pump water at a rate of 1500 l/h.

The performance of the unit is quite modest. Residents of the house will have to turn on the water intake points in turn: first wash the dishes, then take a shower, then turn on the washing machine. For all the needs at once, the performance of the “Brook” may not be enough.

For work with sea water “The stream is not intended.

Setting up a submersible pump “Ruchek”

The Brook pump is considered reliable equipment. With proper operation and timely maintenance, it rarely breaks. In some cases, troubleshooting can be done by adjusting the pump.

All vibration type pumps are arranged in almost the same way. They are characterized by common breakdowns, and methods for restoring the working capacity of devices are similar (+)

All vibration type pumps are arranged in almost the same way. They are characterized by common breakdowns, and methods for restoring the working capacity of devices are similar (+)

To do this, first of all, an idle or unstable pump must be removed from the well (well) and suspended without a hose in a container of water. Next, you need to turn on the device in the network and check the voltage, it must be at least 200V.

If the voltage in the network is correct, then turn off the pump, drain the water from it and blow through the outlet. Blowing can be done by mouth without using any special tools.

A properly tuned “Brook” pump is blown through without problems, and if you blow harder, you can feel the piston stroke inside.The air must also flow in the opposite direction. If this does not happen, then it is necessary to configure two parameters of the unit, having previously disassembled it.

Dismantling of the household pump "Brook" is carried out with the help of a vice, which compresses the ledges on the body, located next to the screws. You need to loosen the screws gradually, in turn. At the first disassembly, it will not be superfluous to replace the screws with similar screws with a convenient hex head, this will greatly facilitate assembly and disassembly during the next repair.

Before disassembling the submersible pump, it is recommended to make marks on the joined elements, this will speed up the assembly and ensure its correctness.

It follows from the principle of operation of the “Brook” pump described above that the two parameters are configured in the following order:

- Piston position adjustment. It must be parallel to the rest of the unit. Parallelism is controlled using a caliper. Misalignment of the piston body may occur due to the gap between its metal sleeve and the rod. To eliminate it, you need to wind the stem with foil until it is completely parallel.

- Checking the alignment of the axes of the rod and piston. When they are displaced, the inlet glass usually “fidgets” along the gasket. To eliminate it, it is necessary to disassemble and reassemble the assembly, temporarily securing the glass to the gasket with pieces of adhesive tape during assembly.

- Setting the distance between piston and seat. It should be approximately 0.5 mm. Adjustment is made by changing the number of washers 0.5 mm thick, mounted on the stem. This indentation is necessary so that the air during blowing, and subsequently water, passes into the outlet pipe without obstacles, and when the pressure increases, the outlet is blocked by a piston.

As the number of washers increases, the piston approaches the seat, so air will not pass when blowing through the mouth. Only with suction in both versions, the air must circulate freely.

It happens that the piston rod is bent. It's unlikely to be fixed. However, if this did not affect the operation of the unit, you can slightly correct the position by turning the gasket relative to the rod by 180º.

A properly configured and assembled vibration pump without a hose, when immersed in a container of water, should give a head of 0.2-0.3 m and work smoothly at normal voltage in the mains 220V plus / minus 10V. If, after adjustment, the equipment does not work or does not work satisfactorily, then it is necessary to establish the cause of the breakdown and eliminate it.

It is necessary to tighten the screws after assembly gradually and in turn, in order to avoid distortion of the case, it is better to do this with an assistant

Principle of operation and technical characteristics

A small-sized borehole submersible pump copes with the extraction of water both from the deck shafts and from an open source. Works from a household network, providing a constant inflow of water. The functionality is based on high-frequency oscillations of the working membrane, which supports pressure changes in the working chamber. The simplicity of the device ensures the reliability of the device and a significant operational resource. Subject to the conditions, Rodnichok will last more than one year.

The best mobile application for experienced BPlayers has appeared and you can absolutely free download 1xBet on your Android phone with all the latest updates and discover sports betting in a new way.

The technical characteristics of the pump are few, but the downhole unit is used not only for pumping water for domestic needs, but also for watering the garden. The device parameters are as follows:

- Mains supply 220 V, power consumption 225 W. The downhole pump can work when the central power is turned off, connected to diesel generators or gasoline low-power devices;

- The maximum pressure of up to 60 meters is sufficient to provide a flow of two-three-story buildings;

- Productivity at shallow depth up to 1.5 m3/hour;

- It is desirable to use a water pump for pumping a clean stream, however, Rodnichok can work with water, where there are small inclusions of insoluble or fibrous particles, provided that the size is not more than 2 mm;

- Structurally, the submersible pump is equipped with an upper water intake, which eliminates the ingress of large debris, however, when processing a dirty stream (switching on after floods), conventional filtering equipment should be used, located at the bottom of the well;

- Equipped with a built-in valve does not allow water to drain back;

- Double-circuit isolation of the electrical part of the pump guarantees increased safety of the device;

- It is necessary to connect the downhole unit to a hose or pipeline with a diameter of 3/4 inch.

These specifications position the Rodnichok pump as the most affordable, convenient and acceptable equipment for extracting water from a well, well or open source.

Specifications

Vibration pump "Brook" according to the technical characteristics is considered to be a fairly high-quality equipment. In many respects, it surpasses the products of other manufacturing companies.Often, devices have a water lifting height of 40 m. Pumps with this indicator of 60 m are more practical.

Before installing the vibration pump Brook, you should watch the training video

Before installing the vibration pump Brook, you should watch the training video

The equipment can be submerged to a maximum of 7 m. If the device is used for a well, then its diameter must necessarily exceed the size of the pump itself. Usually its diameter is 10 cm. The main thing when choosing a pump is its performance. It is determined by the number of liters of water that the equipment pumps per hour of operation.

Varieties of pumps "Brook" in terms of performance:

- Small is 360 l/h;

- Average indicators - 750 l / h;

- High allows you to pump 1500 l / h.

Power is in the range of 225-300 watts. In this case, the voltage for all models is 220 V with a current frequency of 50 Hz. The equipment can work uninterruptedly for 12 hours.

Other characteristics include the type of pump. This is usually an immersive vertical view. The unit is aluminum, with one check valve. The weight is 4 kg. At the same time, models with different cable lengths can be found - from 10 to 40 m. The diameter of the hose varies between 18-22 mm. Water, depending on the model, can penetrate both from below and from above.

Prevention of breakdowns of the pumping unit

By following the operating rules recommended by manufacturers, you will minimize the risk of breakdown of pumping equipment, and it will serve you for many years.

Basic rules of operation:

- Do not allow the pump to run without water.

- Do not use the pump in the presence of unstable mains voltage.

- Do not operate the pump with a damaged power cord or casing.

- Do not move the unit by the power cord.

- Do not pinch the hose to increase the pressure.

- Do not pump water with dirt, impurities, debris.

When installing the pump in a well, it is necessary to put on a protective rubber ring on it, which will protect the equipment from hitting the walls.

The unit can only be switched on/off using a mains plug or a two-pole switch embedded in the fixed wiring system.

Kinds

Pump Brook V-40 The simplicity of the design is reflected in the number of types of pumps Brook, although the number of modifications produced is quite large. This is due to the principle of water intake from the reservoir (reservoir):

model with the upper position of the non-return valve (upper water inflow).

Creek-V-10, V-15, V-25, V-40. The pump is constantly in the water and the situation with overheating does not threaten it;

with the lower position of the valve (lower water inflow).

Creek-N-10, N-15, N-25, N-40. It is possible that the pump, having pumped out the maximum water, will be in the air, which threatens with inevitable overheating. To avoid this, it is equipped with a thermal relay that protects it from overheating.

In terms of design and technical characteristics, both types of pumps differ little from each other. Numerical indicators for all modifications indicate the length of the supply cable - from 10 to 40 meters.

Self troubleshooting

Some problems can be fixed without the help of specialists.

Weak water supply

Poor supply (weak or jerky flow) is most often caused by using the wrong inlet hose. When liquid is sucked from the well, rarefied air is formed inside the rubber hoses, which causes compression of the walls. This interferes with the normal flow of water. A hose reinforced with a plastic spiral is recommended for the unit.

For water intake, a hose reinforced with a plastic spiral is used.

Oil seal replacement

The current repair of the pump is associated with the replacement of seals, because if they fail, then leaks begin in the drainage hole.

Consider how to replace them with your own hands.

In the diagram, red dots indicate the location of the bolts that should be unscrewed.

- We unscrew the three bolts located on top of the case, and remove the casing.

- We unscrew 4 bolts in the electric motor.

- Remove the motor housing.

- Disconnect the snail by unscrewing 4 bolts.

- Remove the rubber pad.

- We unscrew the nut that holds the impeller.

- We take out the armature axis from the impeller (if it doesn’t get it, “help” by hitting the armature axis with a hammer).

- When the armature with the bearing comes out of the housing, find the oil seals in the impeller.

- Take them out so as not to damage the insert between them.

- Install new oil seals, separating them with an insert, and assemble the unit in reverse order.

If Agidel pumps are used in accordance with the instructions, they work stably and require only periodic cleaning and lubrication of parts.

Conclusions and useful video on the topic

A little video tip for repair and diagnosticsto help you repair:

p>Always remember safety! And therefore, even after making sure of the integrity of the coils and the absence of a short to the case, we never hold the pump by the case when checking! Always only on a dielectric spring suspension!

And we never use the power cord for such purposes. Security is never superfluous.

Have something to add, or have questions about troubleshooting pumping equipment? Please leave comments on the post.The contact form is in the bottom block.

Conclusions and useful video on the topic

Here you can see practical example of work pump of this brand:

The video clip shows a diagram of the pump device, its technical parameters, as well as the features of using the “Brook”:

Pump "Brook" - a tireless worker and faithful assistant for all owners of cottages and private lots.

Of course, its performance is not too great, and it is not designed to solve global cleaning tasks. But where you need to pump water or clean a well, "Brook" can be the best option.

Do you have experience with a submersible pump? Tell us for what purposes you use the unit, share your impressions about the operation of the equipment with our readers. You can ask questions and leave to the article in the form below.