- What to do if the device does not work well

- What does it consist of?

- pumping device

- Hydraulic accumulator

- Automation block

- Principle of operation and technical characteristics

- 1 Device design

- 1.1 How it works

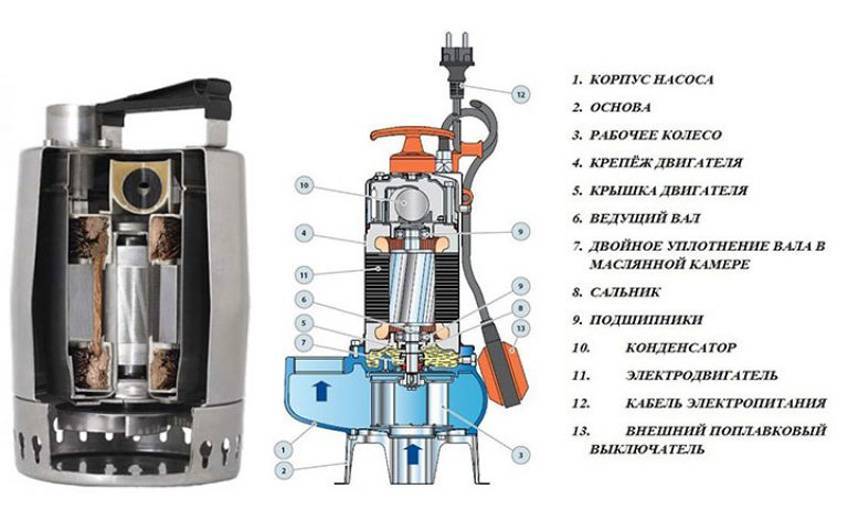

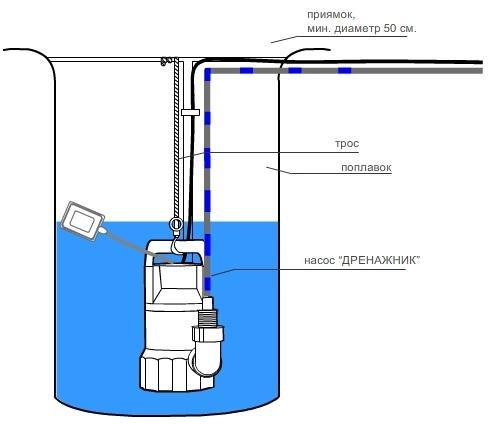

- Features of pumping drainage water

- Device and principle of operation

- Model range and manufacturers

- Vibration pump "Aquarius": characteristics, pros and cons

- Aquarius vibration pumps specifications

- Borehole pumps Aquarius

- Surface pumps Aquarius

- Drainage pumps Aquarius

- Device and principle of operation

- Recommendations for installation and operation

- How to replace the compound

- The main types of malfunctions and their causes

- Electrical faults

- Mechanical breakdowns

- Conclusions and useful video on the topic

What to do if the device does not work well

If the pump does not function well, its power has decreased and there is no pressure, you should try to rinse it with clean water, perhaps the reason is clogging with debris. Disassembly of the "Baby" is required if the causes of the breakdown were not established during an external examination.

Repair includes the following steps:

- It is necessary to unscrew the bolts on the housing connecting the two parts of the device. If they are rusty and cannot be twisted by hand, you can cut them off with a grinder.

- The piston and other internal parts should be cleaned of dirt.The pump coil is treated with a compound, it must be removed from the housing.

- It is necessary to inspect the coil, repair and rewind it. If the rewind is burned out, replace it with a new one.

- An ohmmeter checks the performance of the power cord. In the event of a malfunction, it can be shortened or a new one installed.

- Assembly of the device. Be sure to correctly align the holes through which water passes.

Check the operation of the pump. If there is additional noise, you need to tighten the bolts better.

What does it consist of?

The average pumping station has three main components, namely:

- pumping device;

- hydraulic accumulator;

- automation block.

Now let's look at each element in more detail.

pumping device

Water supply stations are most often equipped with surface pumps, whose names indicate their location. They are installed in specially equipped xenons, or inside residential premises. Pumps with a fairly high power are used, since it is necessary to raise water from wells and transport it to the house.

A small device is enough to service one house

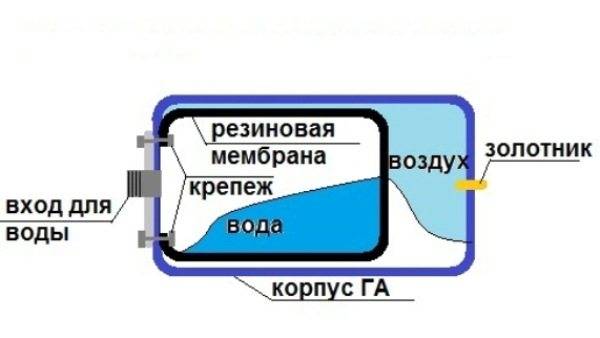

Hydraulic accumulator

A hydraulic accumulator (also called a pressure accumulator) is a metal device whose purpose is to maintain a certain level of pressure on an ongoing basis. The most popular is the model, which is a small metal cylinder, inside which an elastic membrane is installed. During operation, the rubber membrane is deformed to a certain point. When the work stops, it returns to its original position, while displacing the liquid from the cylinder.

Hydraulic accumulator device

Automation block

It is intended for the timely termination of the device. Works like this:

- pressure drops to a certain point;

- the relay starts to operate;

- the pump comes into play, and the accumulator begins to fill with water;

- when the optimum pressure is reached, the operation of the device is suspended.

As you have already noticed, the pumping station is a combination of components and assemblies, the operation of which is possible separately. In most cases, all the main components of the unit are installed on one housing, however, there are also models in which the pumping device is installed on a pressure accumulator. The automatic control device is also located on the same housing.

Pump automation unit

During the entire warranty period, there are practically no problems with the equipment during operation. But this does not mean at all that you will not have to face the need to troubleshoot various nodes. With a long operating period, any part of the mechanism can break, so you need to be prepared for everything that happens. Let's take a look at the possible causes of failure and solutions these problems.

Principle of operation and technical characteristics

A small-sized borehole submersible pump copes with the extraction of water both from the deck shafts and from an open source. Works from a household network, providing a constant inflow of water. The functionality is based on high-frequency oscillations of the working membrane, which supports pressure changes in the working chamber. The simplicity of the device ensures the reliability of the device and a significant operational resource. Subject to the conditions, Rodnichok will last more than one year.

The best mobile application for experienced BPlayers has appeared and you can absolutely free download 1xBet on your Android phone with all the latest updates and discover sports betting in a new way.

The technical characteristics of the pump are few, but the downhole unit is used not only for pumping water for domestic needs, but also for watering the garden. The device parameters are as follows:

- Mains supply 220 V, power consumption 225 W. The downhole pump can work when the central power is turned off, connected to diesel generators or gasoline low-power devices;

- The maximum pressure of up to 60 meters is sufficient to provide a flow of two-three-story buildings;

- Productivity at shallow depth up to 1.5 m3/hour;

- It is desirable to use a water pump for pumping a clean stream, however, Rodnichok can work with water, where there are small inclusions of insoluble or fibrous particles, provided that the size is not more than 2 mm;

- Structurally, the submersible pump is equipped with an upper water intake, which eliminates the ingress of large debris, however, when processing a dirty stream (switching on after floods), conventional filtering equipment should be used, located at the bottom of the well;

- Equipped with a built-in valve does not allow water to drain back;

- Double-circuit isolation of the electrical part of the pump guarantees increased safety of the device;

- It is necessary to connect the downhole unit to a hose or pipeline with a diameter of 3/4 inch.

These specifications position the Rodnichok pump as the most affordable, convenient and acceptable equipment for extracting water from a well, well or open source.

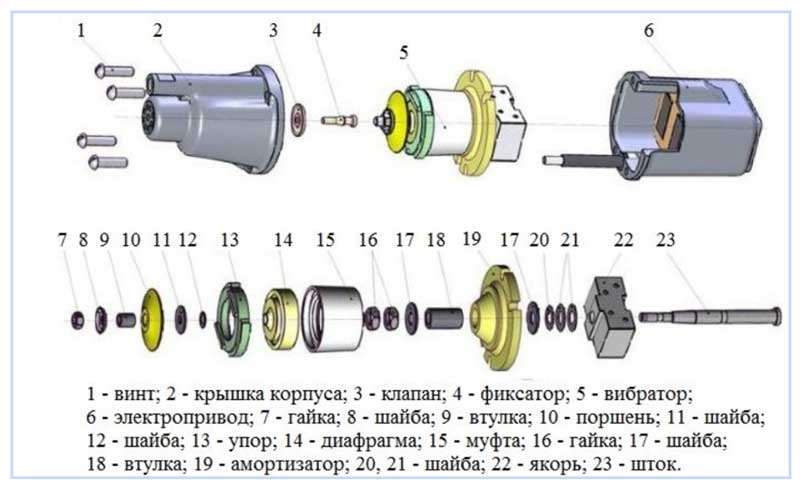

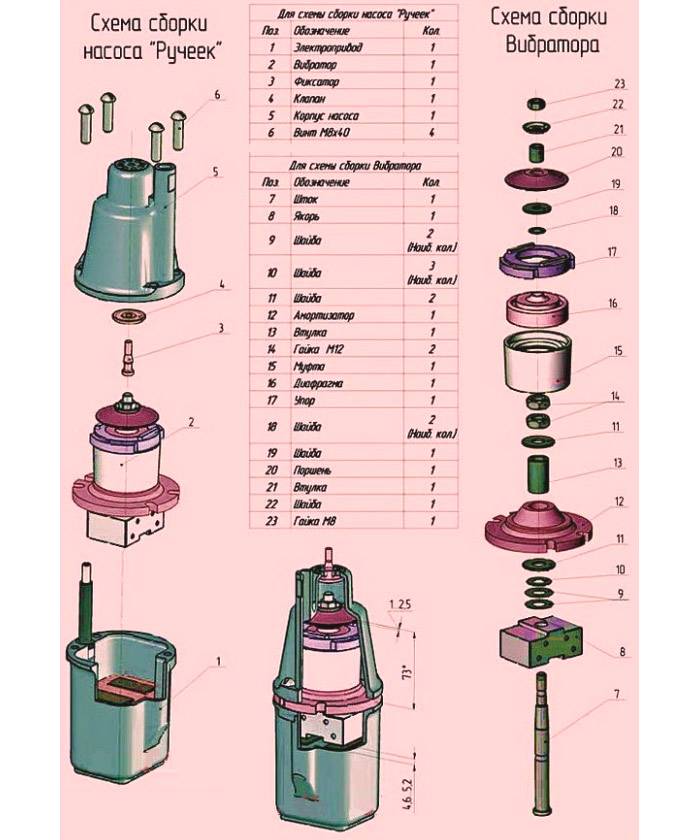

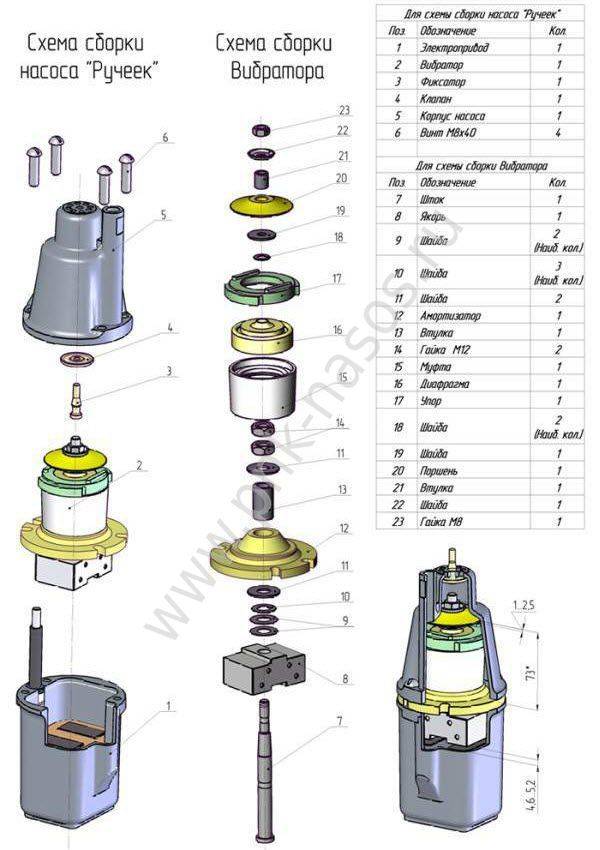

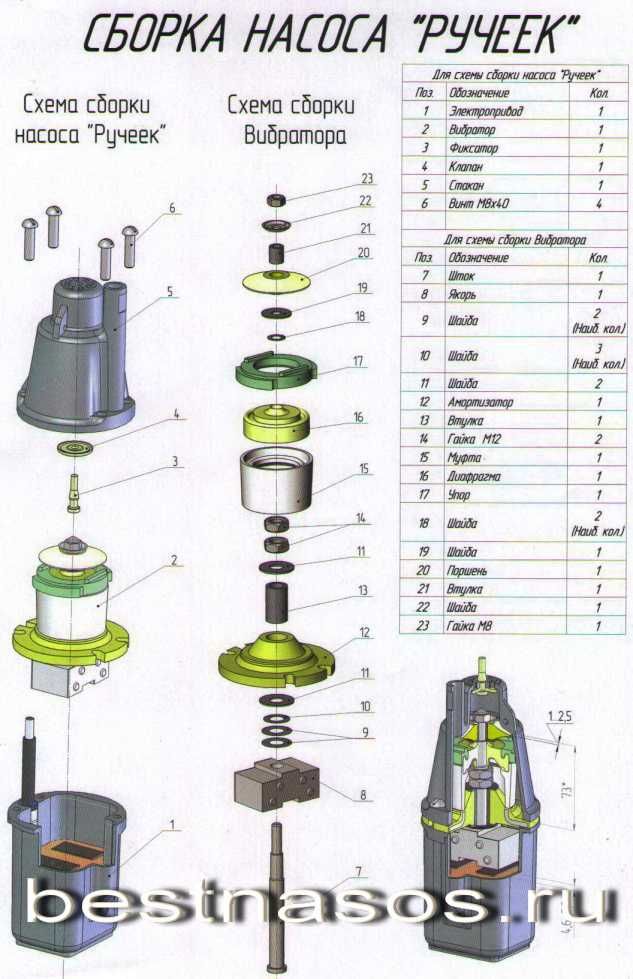

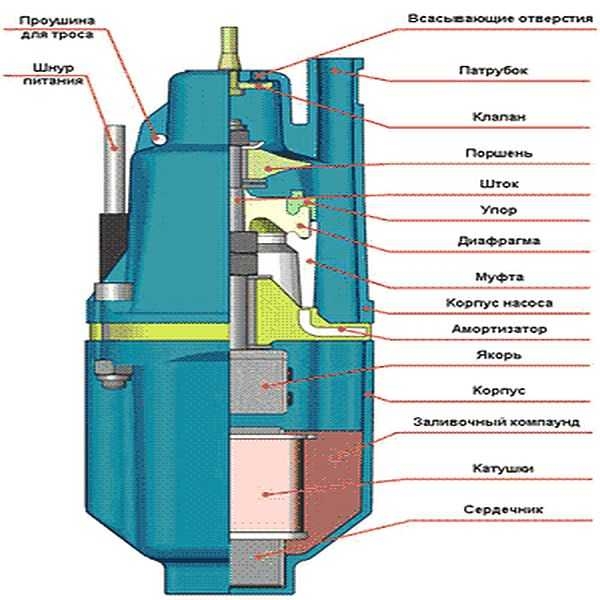

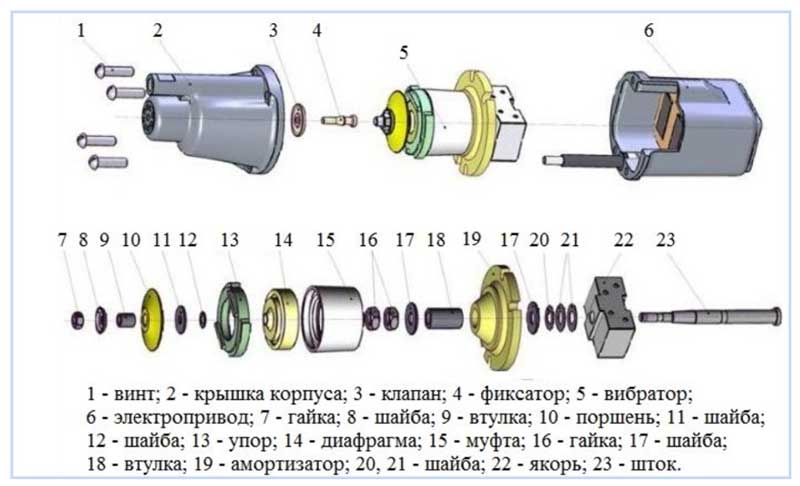

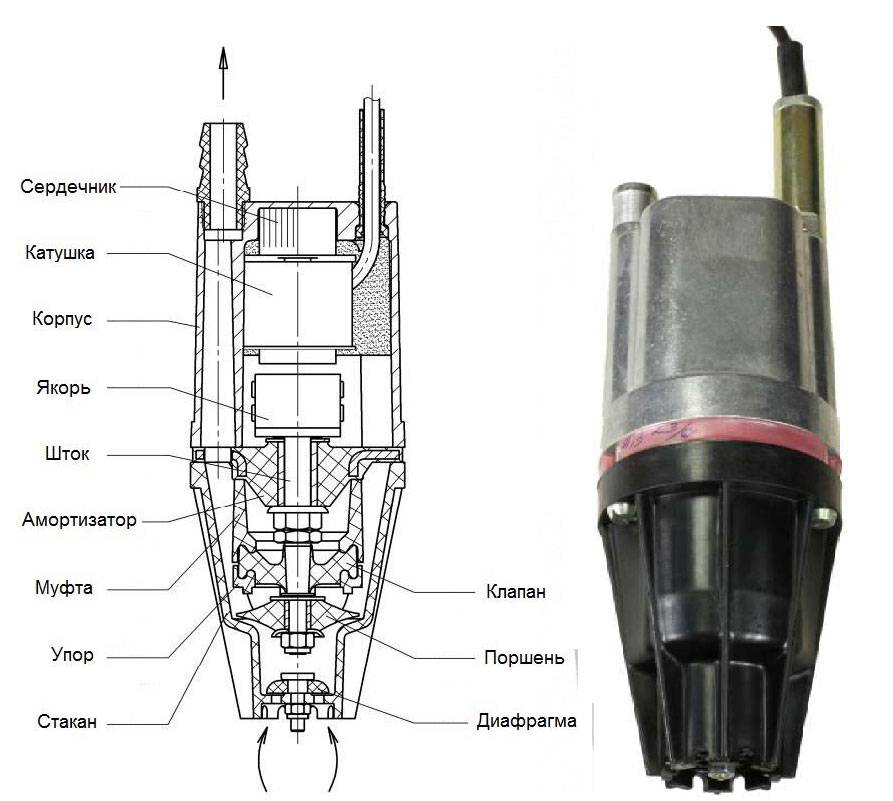

1 Device design

The device of the vibration pump baby is quite simple.It consists of three main parts:

- frame;

- electromagnet;

- anchor vibrator.

The body of the device is made of metal alloys and consists of two halves. The lower part is cylindrical. The top is made in the form of a cone.

The electromagnet of the device consists of a U-shaped metal core, on which several layers of electrically conductive winding are placed. The winding is fixed on the core with a compound (plastic resin). The same material secures the magnet inside the body of the device, isolating the coil from the metal components of the device. The composition of the compound also includes quartz-containing sand, which removes heat from the magnet, preventing it from overheating.

The anchor of the device is equipped with a special rod. With the rest of the nodes, it is attached with a spring, which ensures that the vibrator returns to the neutral position when the magnet ceases to act.

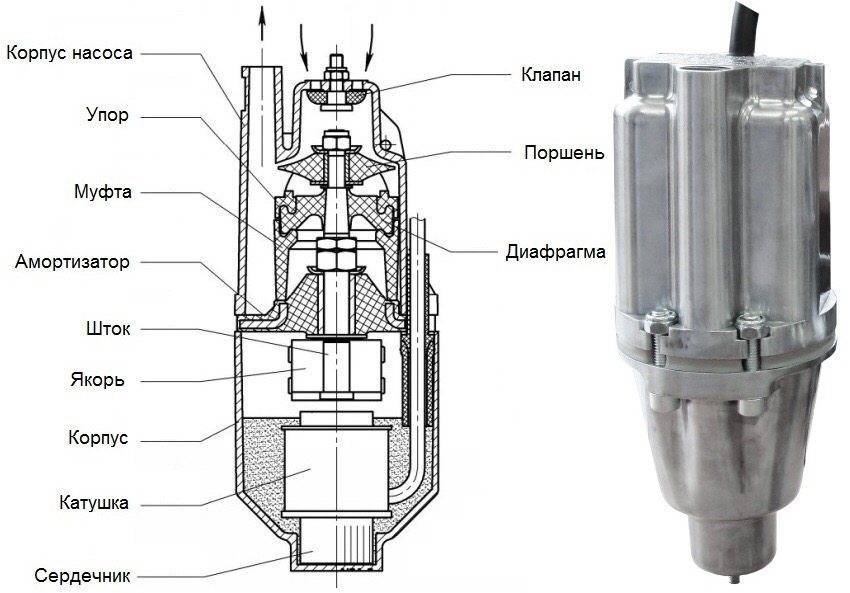

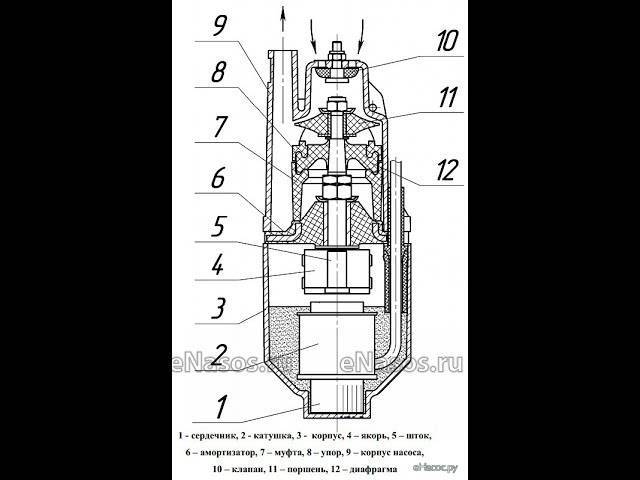

1.1

Operating principle

Proper repair of a vibration pump is impossible without a clear understanding of how the device works. The principle of operation of the pumps, the kid refers them to the inertial type of devices.

Submersible type devices are switched on only after complete immersion in the working environment. The whole algorithm of the device has the following form:

- The pump is connected to the electrical network.

- After connecting, an electromagnet begins to act, which attracts the anchor. The magnet works intermittently, with a frequency of up to 50 inclusions per second. When it is turned off, the anchor returns under the force of the spring.

- When the armature is retracted by the spring, it also retracts the piston attached to it.As a result, a space is formed into which water saturated with air enters. This composition of the liquid provides greater elasticity, and hence susceptibility to vibrations.

- Under the action of the vibrator, the water begins to move. And subsequent portions of liquid from the inlet rubber valve put pressure on the previous liquid, directing the flow exclusively in the direction of the outlet pipe.

This principle of operation provides a high pressure in the tube, which allows you to keep the pressure over a long distance.

Features of pumping drainage water

During the spring flood, situations often arise related to the flooding of basements, inspection pits and other structures below the surface. Usually, such groundwater has practically no impurities, so it is quite possible to pump it out with vibration pumps.

If it is necessary to work with contaminated water, it is necessary to use an additional filter, which will prevent possible damage to the pump. Such a filter has the form of a cap, which is put on the receiving part of the device, and the installation must be carried out after the filter has been preheated, this will greatly simplify the installation process.

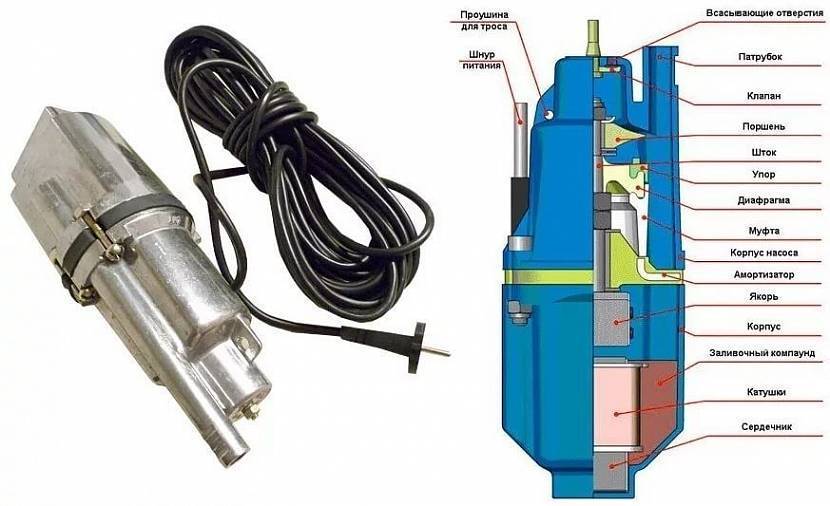

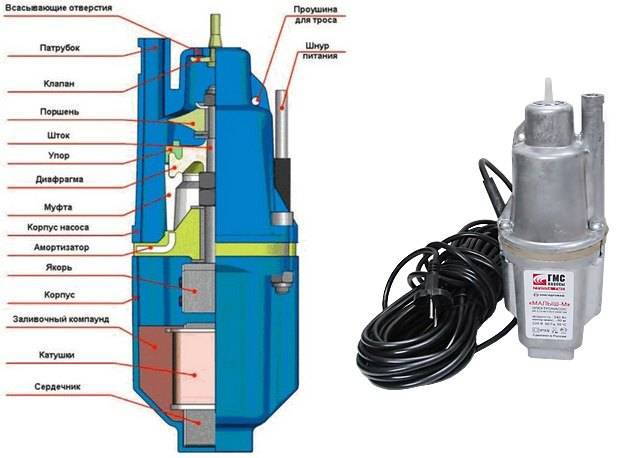

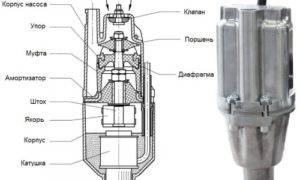

Device and principle of operation

Pump device.

Its body is divided into 2 parts. A yoke is pressed in at the bottom. These are 2 electric coils with a core, filled with a compound (polymer resin), an anchor. In the upper half is the mechanical system. A vibrator with a piston rests on a shock absorber made of elastic rubber. A non-return valve can be installed on the water intake pipe and pumped out.

The principle of operation of the device is simple. When it is connected to the network, the coil creates an electromagnetic field. The heart starts to vibrate.The membrane does not allow it to sway much, and the shock absorber returns to the neutral position. The piston attached to the anchor pushes the elastic mixture of fluid with air, and the water pump starts to work. This creates a movement of fluid in a hose or pipe.

Model range and manufacturers

Initially, "Rodnichok" was developed for industrial purposes. But given that powerful pumps of this type need a lot of electricity, the developers decided to focus on the private consumer.

As a result, a compact model of a vibrating submersible type was created, which is still successfully used in everyday life.

To date, the official manufacturer of the classic Rodnichok pump is UZBI - the Ural Plant of Household Products, which produces two pump modifications:

- "Rodnichok" BV-0.12-63-U - version with an upper water intake;

- "Rodnichok" BV-0.12-63-U - a variant with a lower water intake.

Both models can be equipped with a 10m, 16m, 20m or 25m power cord.

Also, the Moscow plant Zubr-OVK CJSC is engaged in the production of Rodnichok pumps, producing a model called Rodnichok ZNVP-300, which is not much different from the classic electric pumps produced by UZBI.

Vibratory submersible pumps for domestic use, manufactured under the brand name "Rodnichok" comply with GOST and are reliable, safe and durable equipment

Considering that the “Rodnichok” pump is not as well-known and popularly loved as the same “Baby”, it is extremely rare to find its fakes.

The affordable price of the electric pump is explained by the simplicity of its design and the use of only Russian parts for its production.

Image gallery

Photo from

Inexpensive, but extremely durable vibration pumps are ideal for drawing water from country wells. In the organization of permanent autonomous water supply systems, they are used much less frequently.

The installation of the pump unit is extremely simple: a pressure pipe is connected to the pump nozzle (1) through the check valve, a fixing nylon cord is threaded through the lugs (2)

In order to fix the position of the cable, it is attached to the pressure pipe with tape. The first hitch (3) is 20 -30 cm from the nozzle, following every 1.0 - 1.2 m

In order to leave the distance indicated by the manufacturer between the bottom of the well and the bottom of the pump, as well as the top of the unit and the water mirror, a bright mark must be made on the pressure pipe before immersion in water

In order for the vibration pump not to hit the walls of the well during pumping water, it is better to place it in the center of the working

For normal operation of the vibrator in the well, it is necessary that the inner diameter of its casing is 10 cm larger than the maximum diameter of the pump

So that the vibration unit does not hit the well casing during operation, it is equipped with protective rings from a hose or rubber rolled into a tube

The rubber rings working as shock absorbers must be changed periodically, because. they rub against the walls of the well

Vibration pumps in the dacha

Connecting the vibration pump

Power cable couplers with pressure pipe

Pump installation depth mark

Vibrator installation tool

Well for installation of a vibration pump

Pump and Well Protector

Replacing the protective rings on the vibrator

This is interesting: Pump device "Gnome": characteristics and consumer reviews

Vibration pump "Aquarius": characteristics, pros and cons

Vibration pump Aquarius - this is the most reliable assistant in your country house. This brand has firmly established itself in the leading positions of the world market. Firstly, this is due to its affordability, and secondly, the quality of products.

Aquarius vibration pumps specifications

Brand "Aquarius" has a large range of equipment for water supply:

- these are pumps for working with dirty water, in which there is a high content of sand;

- electric pumps, with centrifugal system.

Borehole pumps Aquarius

Downhole pumps include the following models:

- pumps Aquarius 1 BTsPE;

- Aquarius 3 pumps;

- Pumps Aquarius 16.

Aquarius pump BTsPE 0.32 - equipment productivity 0.32 m3 per 1 sec., for 1 hour - this is 3.6 m3 of water. Constant pressure at a height of 40 meters.

Ideal for a private house, as well as a summer cottage. Also suitable for industrial water supply and for extinguishing fires. Silent when on.

Pump Aquarius BTsPE 032-32U - weighs only 10.5 kilograms, has a single-phase electric motor. In addition to supplying drinking water, it can also cope with watering the land. The height of the water pressure reaches 32 meters, and the productivity for 1 hour is 1.2 m3.

Pump Aquarius BTsPE 0.5 - used in wells with a diameter of 120 mm. Equipped with a powerful engine that provides water pressure to a certain height.

The most popular model is the Aquarius BTsPE U 05-32 pump. It is used for a well with a diameter less than 110 mm. Constant water pressure - up to 48 meters.Productivity is 3.6 liters per hour. The price for this model is affordable and is 7000 rubles.

Designed for clean water only. Weight 4 kilograms.

It has a plastic body and a rubber piston. Treated with a compound, which makes such equipment waterproof.

Suitable for shallow wells or reservoirs. There is a remote control to control the pump.

Surface pumps Aquarius

Convenient if there is a body of water nearby. It is not permissible to lower this pump into water, because. all internal systems are not protected, and if moisture enters, they will immediately fail.

Two main models, which in turn have subspecies:

- pump Aquarius BTsPE 1.2 - productivity reaches 1.2 m3 in 1 sec. The pressure of the water column reaches 80 m. The weight of the pump also depends on the chosen model: from 7 to 24 kg.

- Aquarius pump BTsPE 1.6 - pump performance indicator 1.6 m3 in 1 sec. Stable water pressure at a height of 40 m. The weight of the device also depends on the variety.

Drainage pumps Aquarius

Drainage - such a pump is used to pump dirty water from a freshly dug well, or to drain basements.

Filter systems are necessarily built into the drain pumps to prevent solid particles from entering the equipment. The position in which these pumps are used is vertical.

The two-valve vibration pump Aquarius BV-0.14-63-U5 has the following characteristics:

- produced in Ukraine;

- meets all state standards;

- meets all safety requirements;

- submersible with a two-valve water intake system;

- the height of the water column reaches 63 meters;

- designed to work in wells and wells at a depth of not more than five meters;

- installed vertically;

- the diameter of the well should be from 90 mm.

According to reviews, the two-valve vibration pump Aquarius BV-0.14-63-U5 has the following advantages:

- easy to use;

- the equipment itself is light (only 3.8 kg.) and compact, so one person can easily handle it;

- not required, fill with water first;

- made of high quality materials, with anti-corrosion treatment;

- unpretentious at work.

This model is ideal for supplying potable water, and for use in vegetable garden watering. The design of the Aquarius Poseidon pump is unique and made of high quality materials.

Vibration pump Aquarius consists of an electric motor and pumping equipment.

Each pump is accompanied by an instruction manual with operating rules, which reflects the following:

- The temperature of the water in which the pump is located should not exceed 350C;

- The pump control panel must be protected from precipitation;

- There must be a distance of at least 40 cm between the bottom of the well and the pump;

- The switched on pump must be completely in the water;

- Before connecting the pump to the electrical network, it must first be lowered into the water for 10 minutes;

- The pump is intended for pumping clean water only.

Benefits of using Aquarius vibration pump:

On the official website of Vinnitsa you will find a full range of Aquarius vibration pumps.

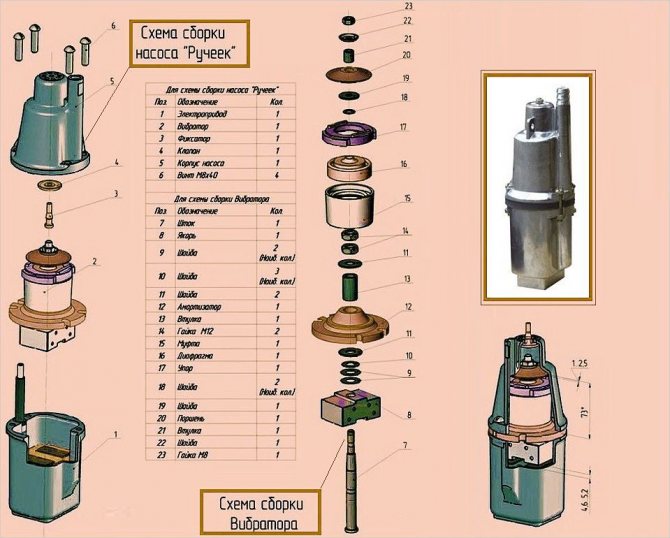

Device and principle of operation

The submersible pump "Brook" consists of the following parts: an electric drive, a vibrator and a housing, which are interconnected with four screws. The electric drive of the unit includes a core with two coils and a power cord. The vibrator consists of a shock absorber, a diaphragm, an emphasis, a coupling and a rod.An anchor is pressed in at the bottom of the rod, and a piston is attached to it at the top.

The pump housing is a casing, in the upper part of which there is a glass with holes for water inlet and a branch pipe that provides water outlet. The existing valve serves to open/close the inlets.

The pump pumps water due to vibrations of the piston and armature. They are actuated by an elastic shock absorber, which converts the alternating current received from the network into a uniform mechanical vibration. The rod transmits the movement to the piston, which, when vibrated, creates a mini-hydraulic shock in the glass with holes. The valve at this moment closes, and the water is pushed out into the outlet pipe.

There are no rotating elements in the design of the pump, which reduces the risk of breakdown, because. friction is the main cause of failure (click to enlarge)

Due to the fact that the water intake takes place in the upper part of the unit, the system is cooled and it does not heat up during operation. Another advantage of the water intake located on top is that sludge from the bottom is not sucked in by the working body. As a result, the unit is much less likely to be clogged with a muddy suspension, because of which the pump should be periodically disassembled and cleaned.

For quick replacement of wearing parts, manufacturers of vibration pumps produce repair kits that include a full set of necessary spare parts.

Recommendations for installation and operation

To reduce the number of problems in the operation of the pumping station, it is important to correctly install the equipment, as well as follow the recommendations for the operation and maintenance of the device. It is necessary to adjust the pumping station in accordance with the technical characteristics of the source and the required water pressure. The pressure standards in the water supply system of a private house and ways to achieve the necessary pressure parameters are given in the article we proposed

We advise you to read useful material

The pressure standards in the water supply system of a private house and ways to achieve the necessary pressure parameters are given in the article we proposed. We recommend that you familiarize yourself with useful material.

of In order to extend the working life of the pumping station, in particular its main unit - the pump, it should not be started with the working part unfilled with water. At least once a month, it is necessary to check the pressure in the gas-filled part of the accumulator with a car pressure gauge. Before checking, it is necessary to drain the water from the pressure pipe. For the stationary installation of the pumping station, it is necessary to choose a heated, dry room. In case of conservation, the unit is stored in a similar place with water completely drained from it. In order to maintain the impeccable technical condition of the pumping station and avoid repairs, air must not be allowed to enter the suction line.

Here are some important points:

- To prevent vacuum compression of the water supply line, it is recommended to use either metal pipes, or sufficiently rigid PVC pipes, or a vacuum-reinforced hose.

- All hoses and pipes must be installed straight, avoiding deformation and twisting.

- All connections must be sealed and sealed, and their condition regularly checked during routine inspections.

- Do not neglect the installation of a check valve on the water supply hose.

- The pump must be protected from contamination by a filter.

- The immersion depth of the hose leading to the pump must exactly match the recommendations of specialists.

- The pumping station should be installed on a level and solid base, using rubber gaskets to dampen the effects of vibration during pump operation.

- To prevent the pump from running without water, a special circuit breaker must be installed.

- In the room where the pumping station is installed, the correct temperature (5-40 degrees) and humidity (no more than 80%) should be maintained.

It is recommended to check the condition of the pumping station at least once every three months. Separately, check the readings and settings of the pressure switch.

Another important preventive step is to bleed the air that is released from the water and fills part of the volume of the liner in the hydraulic tank. On large containers, there is a separate faucet for this. To remove unnecessary air from the membrane of a small tank, you will have to fill it several times in a row and completely drain the water.

How to replace the compound

- We disassemble the device.

- We determine the place where the compound has exfoliated from the body of the submersible pump.This can be done by lightly tapping with a small hammer on the body. In normal areas, the sound will be deaf, in damaged areas - sonorous.

- We remove the assembly with the compound from the vibration pump housing.

- With a grinder, we carefully apply a grid of notches to the inside of the case, up to 2 millimeters deep. We make the same mesh on a node with an epoxy compound.

- We cover both sections with notches with glue for glass surfaces (you can use any sealant)

- We return the assembly with the compound to its original position - we fix it and wait until the sealant hardens.

- We collect the body back.

The main types of malfunctions and their causes

Devices with a lower water intake are more likely to break down, because the engines in them heat up more. The causes of defects due to which the pump does not pump water lie either in its mechanics or in the electrics.

The most common problems of the "Baby":

- loosening nuts due to vibration of the core;

- valve wear caused by abrasive impurities in the water;

- breakage of the core rod.

Electrical faults

Due to strong heating, such breakdowns often occur:

- a short circuit occurs;

- the electrical wire is charred or broken;

- the copper winding burns out in the coil;

- exfoliates from the body of the compound.

Mechanical breakdowns

Most often, such defects are detected:

- clogging of the internal cavity of the pump with mechanical impurities;

- liming parts due to excessive water hardness;

- loosening nuts due to strong vibration;

- damage to the device from impacts on the concrete wall of the well;

- weakening of the properties of the rubber shock absorber;

- loss of valve elasticity;

- piston failure.

Conclusions and useful video on the topic

Video #1Repair of the pump "Sverchok" - a complete analogue of the "Brook":

Video #2 A visual demonstration of the repair of a vibration pump:

The electric pump "Rucheyek" is a simple and reliable unit. In the event of a breakdown, you can fix it yourself, significantly saving on repairs. But the best option would be to prevent the pump from failing. It is not difficult to do this, you must carefully study the operating instructions and carry out timely maintenance and control of the operation of the equipment.

Have questions or a desire to share the experience gained during the countryside vibration pump? Please write comments. Post posts with your opinion and photos on the topic.