- 2 Stages of troubleshooting

- 2.1 Phased work on the repair of the electric motor

- Pump modifications and characteristic differences

- 1 Main Weaknesses of Baby Pumps

- Troubleshooting Algorithm

- Stage 1: careful external examination

- Stage 2: a closer look from the inside

- Step 3: Troubleshooting the electrical problem

- Stage 4: correction of mechanical violations

- How to troubleshoot basic pump problems

- Scope of application

- Elimination of mechanical damage

- Why does equipment break down?

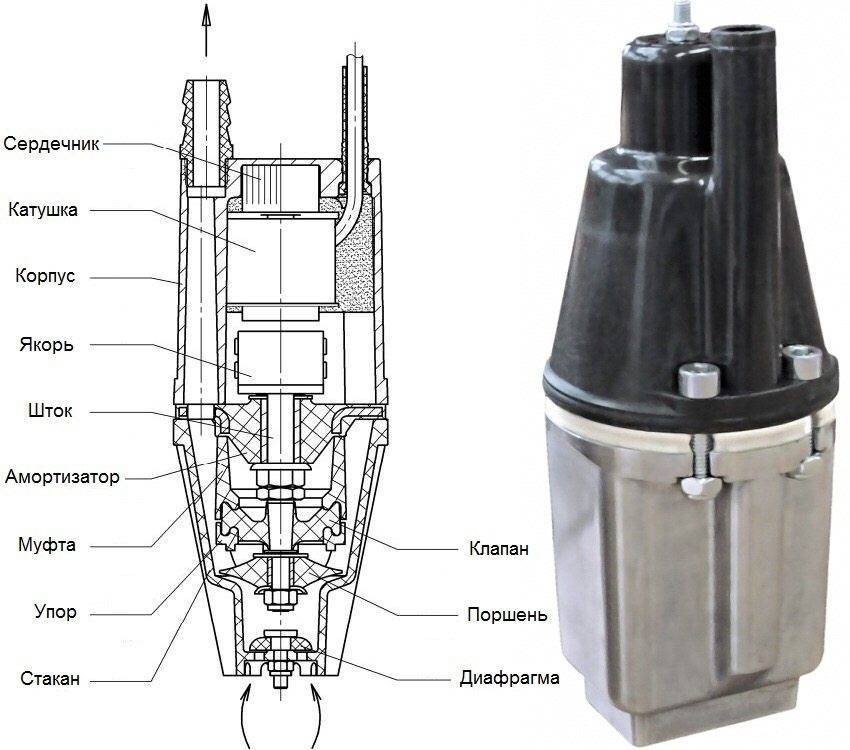

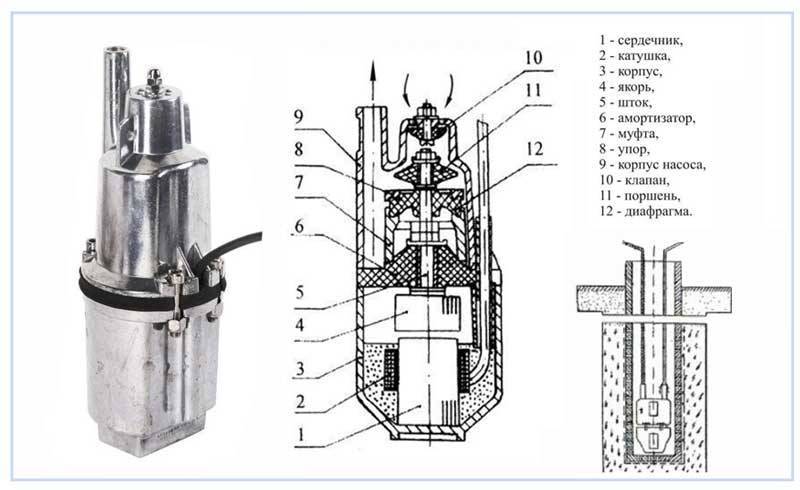

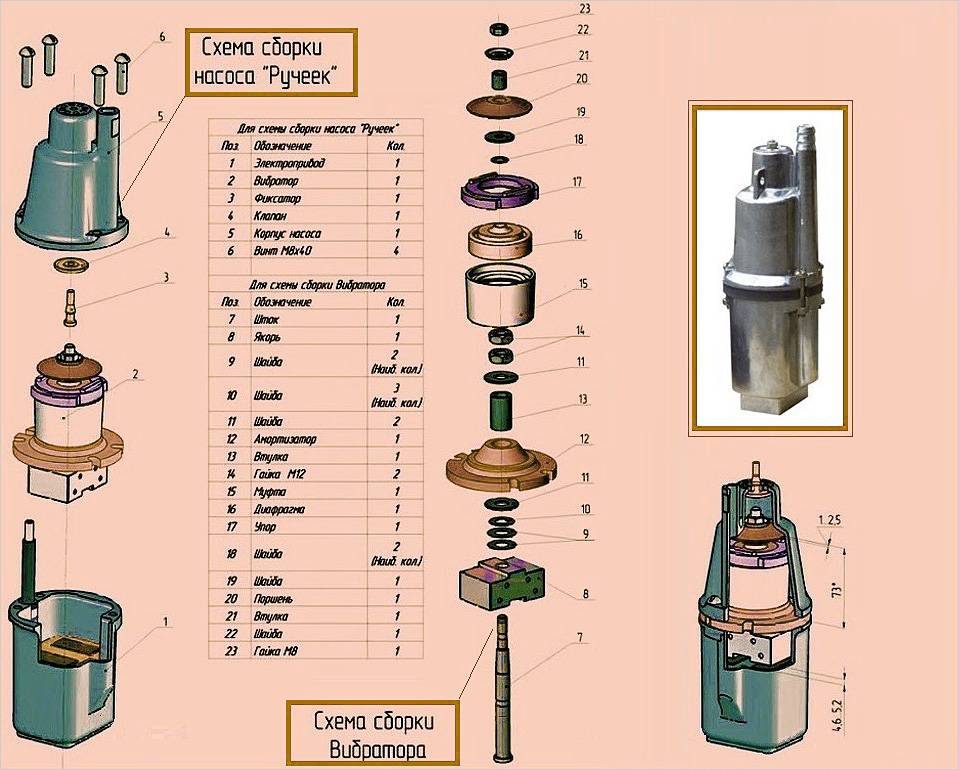

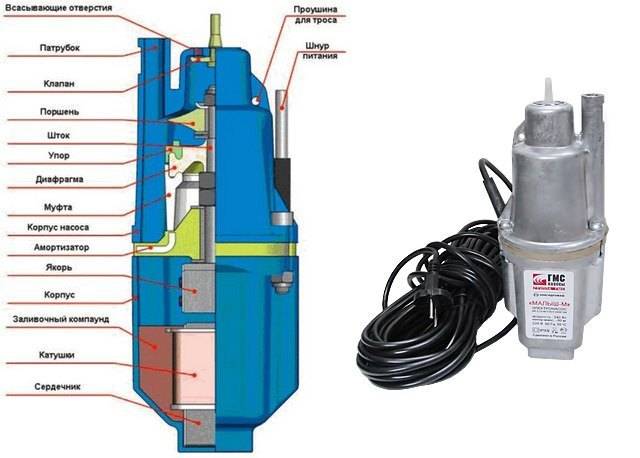

- How the product works

- Pump "Vodomet": do-it-yourself installation and repair

- The pump does not turn on:

- The pump turns on, but does not pump water:

- The pump frequently turns on and off:

- The pump works, but the pressure is weak:

- If the pump is broken

- How to prevent damage to pumping equipment?

- Conclusions and useful video on the topic

2 Stages of troubleshooting

If during operation you notice that the pump does not work as it should, extraneous noise is heard, then immediately you need to take action. First, we recommend checking the devices for minor problems. On such brands of pumps as "Octopus" and "Aquarius", it is initially necessary to check whether a reboot has occurred, due to which the machine is most often turned off, followed by the pumping system.

Aquarius pump and its repair.

To check this, you must first unscrew and disassemble the junction box. Inside this box, you can see a breakdown, and this is blackening or a burning smell. If everything is in order in this area, there is no smell, then we proceed to remove the impeller from the pump motor.

First, it is checked whether the engine is spinning. A smoothing capacitor is connected to the engine, through which the engine starts. We also look around the winding, which should not be broken or torn. The most common failure in these pumps is engine burnout. That's why to see it, the impeller is removed.

After the impeller was removed, we begin to manually scroll the engine (shaft). If the shaft does not spin, then there is a mechanical failure on the face. In other words, the pump motor has jammed. Most often this happens due to the fact that small debris, soil can get into the engine. And this is due to the fact that it does not have a protective filter. If in the future you do not clean the special filter and remove particles on it, then the stator winding may soon burn out in the engine.

2.1 Phased work on the repair of the electric motor

Before you decide to repair the electric motor, it must be placed vertically. If you do not do this, when disassembling the electric motor, an oil leak will occur, without which the pumping system will not work. Then, in a vertical position, the cover is removed, through which the 220 W power wire passes.

Immediately upon removing the cover, it is advisable to diagnose the starting capacitor. To diagnose the starting capacitor, you will need an ohmmeter.This is checked by connecting the terminals to the motor winding. Then we rotate the handle, and it creates a voltage of 250-300 volts.

We disassemble the Gilex pump

If the device shows resistance at the same time, then it is considered that the state of the winding is ideal. But if the ohmmeter device fixes infinite resistance, then there is a problem in the form of a break. Conclusion: the working phase of the motor is not working, there is a break.

If the device shows a small resistance, then we can talk about an interturn circuit. The conclusion from the above - with your own hands, if this happened, it is not possible to fix it. In such cases, it is better to contact specialists. Since in most cases the replacement of parts will not help, but only the replacement of all consecutive parts will help. Especially if the pump winding is not corrected.

When viewed in the future, we look at the pump further. The device shows that everything is in order, we proceed to inspect the starting capacitor. More often than not, it breaks down. In other words, it breaks. When the pump is running, such a problem does not immediately strike the eye, but upon a detailed examination with such a device as an ohmmeter, the breakdown will come out.

At the same time, do-it-yourself repair of the starting capacitor can be done independently, without resorting to the help of a master. But if you fail to do this, then it is better to replace the starting condensate with a new one. Since starting condensate is a fatal failure.

Pump modifications and characteristic differences

Vibratory submersible pumps have been around for a very long time. Back in 1891, Russian engineer V. G. Shukhov used the principle of vibration for a pump. By the way, approximately such a system is involved in an automobile gasoline pump.

Later, the Argentine T.Belloc finalized the scheme - it is used without any changes today.

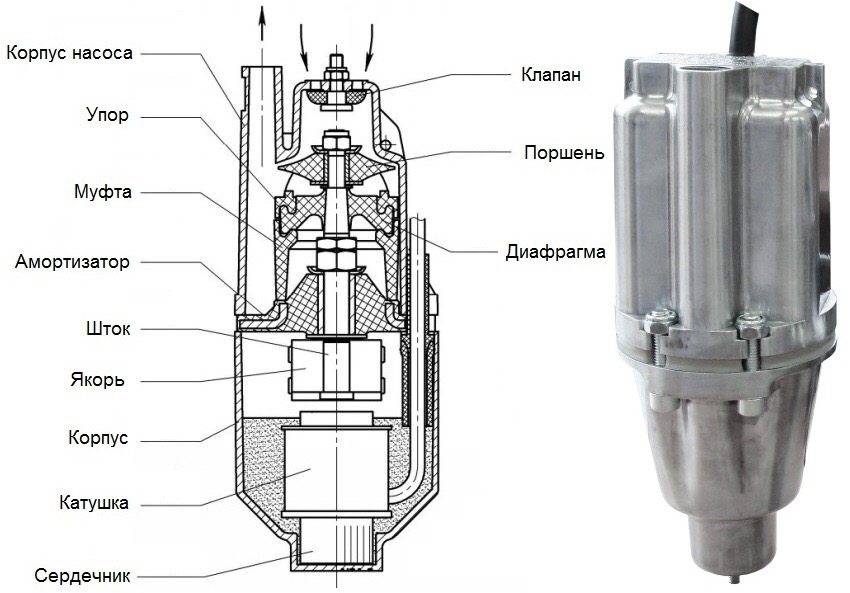

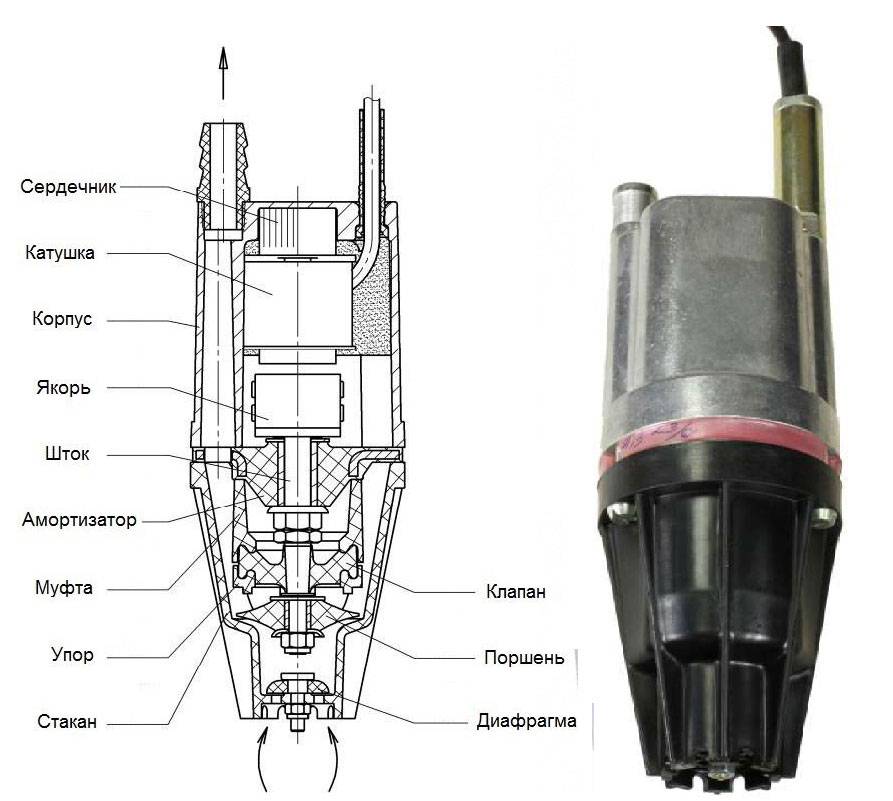

There are a great variety of vibration submersible pumps. But they all have approximately the same device and the principle of their repair is the same.

The Italians were the first to produce such devices for domestic needs. In the USSR, their development in the late 1960s was undertaken by the designers of Moscow under the leadership of M.E. Breitor.

And since 1971, the household vibration pump began to be produced at the enterprises of the USSR - the passion for unification affected.

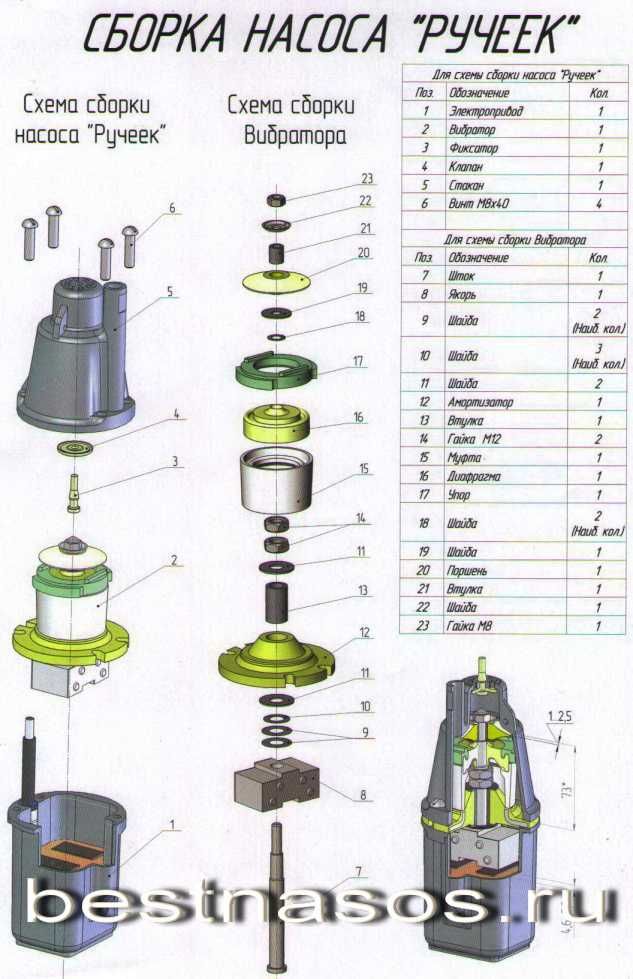

Approximate composition of the repair kit for the Malysh pump and similar modifications

Pumps were produced in Yerevan, Livny, Moscow, Bavleny and many other enterprises. You can name only the most famous brands: "Kid", "Neptune", "String", "Sega", "Brook", "Harvest", "Bosna", "Kashtan".

All of them, in fact, differed in names and body shape. And that is not always the case. This also includes Italian and Chinese designs. For example, "Jerelce".

The Strunok pump will not always be distinguished from the Kid even by a specialist - only by marking

These are all variations of the same pattern. Sometimes the names changed, but the essence remained the same. For example, the now famous "Baby - M" was a little earlier "Sega" and "Brook".

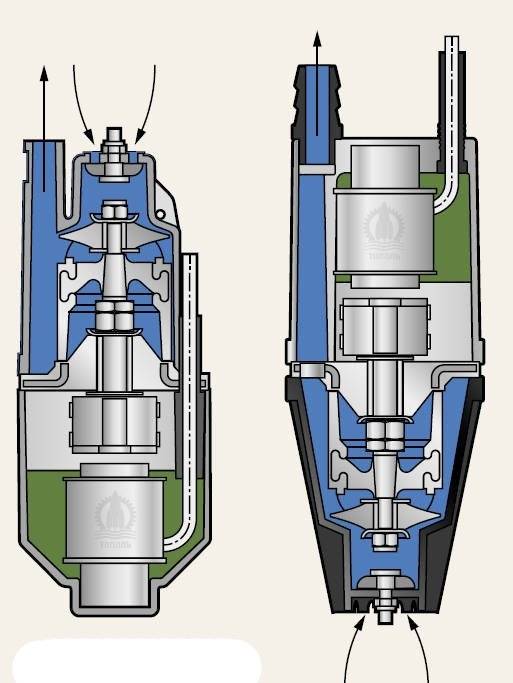

If you ignore the confusion with different names, then briefly all the variations come down to three to four types of submersible pumps:

- “Kid” is a model of a submersible vibration electric pump with a lower water intake. The most powerful modification of all, but poorly suited for bottom work - it can capture dirt or silt from the bottom and fail.

- "Baby - M" option in the upper water intake. Slightly weaker, but does not pick up dirt from the bottom.It rarely fails due to overheating - simply, even if the water level drops and the intake ends, the case still cools - it remains immersed.

- "Baby - K" - a model with a lower water intake, but equipped with a thermal relay and a three-wire ground wire. The presence of a thermal relay has a positive effect on the service life and reliability, but increases its cost. Previously, this modification was exclusively for export.

- "Kid - 3" is a compact model with a diameter of 80 mm for narrow wells.

In any case, vibration pumps are valued for their compactness, low cost and simplicity. In addition, they are quite resistant to water hammer.

When blocking the water line, for example. Although here you should not get carried away - such a frequent practice still disables the pump.

Pumps of even the same model may differ slightly: polishing or powder coating of the casing, for example. But the parts are usually interchangeable.

1 Main Weaknesses of Baby Pumps

First of all, it is necessary to say about the characteristic predisposition of the device housing as a whole and the pump housing to corrosion. Of course, this shortcoming is not critical, and can become a problem for you only after decades. But, do not forget that the pump has direct contact with water resources, which are subsequently consumed by you already with corrosion particles.

After several years of operation, when disassembling the baby pump, you can observe a thin layer of corrosion on almost all metal components. This means that the metal has poor anti-corrosion treatment.Therefore, saving on purchases will not always save you money in the future, so repairing a water pump baby can make you shell out a tidy sum of money.

Also, the repair of the Malysh submersible vibration pump can be complicated due to the potential for rusting of the screws.

We disassemble the pump Kid

Due to the specific principle of operation (due to vibration waves), very often in baby class pumps, destruction of internal fasteners, valve and stem is observed. Seals are also likely to be unusable if broken.

Also, with improper operation and constant reloading work, the baby will need to repair the water pump ahead of time. The consequence of such errors may be the destruction of the metal, which in the future will not allow the submersible pump Malysh to be repaired with his own hands and its key elements.

If you use the pump in too polluted water (silt, sewage, etc.) know that water pump repair baby is "just around the corner". Since this device is not intended for pumping water with a large amount of sand, stones and other solid particles. With regular suction of large particles, the valve of the device becomes clogged, and the working surface in the form of a cover is also destroyed, in which the rubber valve should operate.

The negative impact of the vibration of the brook pump can also be attributed to the poor “survivability” of the thrust ring, which cracks over time, which forces the replacement of this part of the device. Also, quite often there is a problem of violation of the integrity of the winding, which is the reason for the failure of all pump systems.

Do-it-yourself pump repair Kid

But this breakdown should not be confused with a temporary cessation of the pump, due to overheating, under the action of an automatic control system. If more than a few hours have passed since such a shutdown, then the repair of the pump by the baby with his own hands should be aimed at replacing the “burnt out” parts and mechanisms.

Troubleshooting Algorithm

Troubleshooting.

If the unit pumps water weakly or stops working completely, you need to turn it off and lift it up. Then you should disconnect the hose and check for obvious damage to the device.

Stage 1: careful external examination

If microcracks are visible on the surface of the case, it is necessary to replace it. If the integrity of the unit is not broken, the tester should check the resistance of the coils (the norm is about 10 Ohms) and the absence of their short circuit to the metal casing. A burnt coil should be replaced by a specialist.

Then you need to lightly blow into both nozzles of the pump - the air should pass unhindered. With sharp exhalations into the inlet, the valve should close.

Then we immerse the apparatus for 5-6 hours in water with the addition of 9% table vinegar to dissolve limescale. Rinse it again with clean water.

Then, gradually releasing the locknut and the clamping nut on the pump intake, we repair the valve clearances. The norm is 0.5-0.8 mm. At a finely adjusted device, lowered into a container of water without a hose, a fountain appears 0.5-1 m high.

Stage 2: a closer look from the inside

To find a defect, disassembly of the unit is required. You can do it yourself. Necessary:

To find the cause of the breakdown, it is necessary to disassemble the pump.

- Scratch symbols on the case with a sharp object, so that later, during assembly, exactly combine the lower and upper parts along them.

- Loosen all screws at the same timesecuring the pump cover. If they are very rusty, cut off the hats with a grinder.

- Take out the piston, core, rubber gaskets.

Assemble the device in the exact reverse order. In this case, it is necessary:

- exactly fit the piston disc, it must be at least 4 mm from the coil;

- combine the openings of the housing and gaskets, otherwise the unit will be depressurized;

- free from litter all its internal space;

- check the pump in a container with water - if it is in good condition, a fountain 0.5-1 m high should appear.

Step 3: Troubleshooting the electrical problem

If you need to repair an electrician, it is better to contact the factory. A burnt coil is easier and cheaper to replace with a new unit.

If the electromagnet has completely peeled off, you can try to fix this problem with your own hands:

- take out the electromagnet;

- apply on it and on the inner surface of the body with a grinder intersecting grooves up to 2 mm deep;

- lubricate the compound with glass sealant and press the magnet into place using a press;

- after the composition has solidified, assemble the pump.

Stage 4: correction of mechanical violations

Procedure:

- The tearing of the membrane can be eliminated with rubber glue.

- A broken shock absorber should be replaced with a new spare part.

- A worn piston must also be replaced. From it you need to pull out the sleeve and press it into a new part. Between the piston and the body, it is necessary to adjust the gap of 4-5 mm by removing or adding washers.

- The required distance between the anchor and the yoke is achieved by adjusting the washers and locknuts, the final tightening of which is carried out when it is 6-8 mm.

- The projections of the coils and the rod anchor must necessarily match. Adjustment is carried out by loosening the nuts.

- A gap of 0.6-0.8 mm between the new valve and the water intake hole is achieved by tightening the screw.

The operating conditions of the vibration pump must be exactly observed. They are described in detail in the technical data sheet of the device. Then the probability of breakdowns of the "Baby" will be minimal.

How to troubleshoot basic pump problems

Problems in the operation of the vibration pump are indicated either by a loud buzz when the engine is turned on, or by the complete absence of water pressure. Owners may have experienced that the Baby pump is buzzing, but not pumping water.

At the first stage, it is imperative to check the serviceability of the pump check valve - if it is torn or worn, then it can be easily replaced.

The reason may be a breakage or damage to the stem - this element cannot be repaired, so you will have to contact the service or look for another pump of the same quality as a donor

And after you eliminate the first 2 reasons, you should pay attention to the reliability of the pump mounting - the housing is completely disassembled and all nuts are tightened

If at the moment of switching on the cable is charred, and the plugs are constantly knocked out, then it is necessary to test the cable or completely replace the burnt cable winding. In most pump models, the cable can be replaced without problems, but sometimes it may be necessary to extend it with a twist.

If, for a number of reasons, the Malysh downhole pump remains in an empty well, then it will run “dry”, and because of this, delaminations occur in the magnetic part - signs of this are constant overheating and severe vibration. This is one of the most difficult to troubleshoot - the pump will have to be completely disassembled, the electrical part of it is separated, and the magnet is also removed.

You will need to make 2 mm grooves with a cut-off circle in Bulgarian - along, across the magnetic element (compound) and from the inside of the device case. After that, the surfaces at the joints are covered with adhesive or "liquid nails", the magnet is installed in its original place. Then you will need to wait for the created joint to dry completely, and when everything sticks together, the pump is assembled back.

An insufficient amount of clearance inside the pump, in the vibrator, is also indicated by a too weak water pressure. A disadvantage of this type is eliminated quite easily - you just need to supplement the vibrator with the necessary number of washers that provide the required water pressure. You can be sure that after such manipulations the submersible pump will work as well as immediately after assembly.

Scope of application

The primitive design of vibration-type pumps ensures their simple operation. Due to the absence of bearings and rotating elements, they do not need regular lubrication. A slight heating of the mechanism during operation contributes to the slow wear of parts. Vibrating type pumps successfully cope with pumping alkaline water, they are not afraid of the presence of mineral salts in the liquid and are resistant to temperature fluctuations.But before choosing such a unit, it is worth remembering about its property to vibrate. What is the risk?

The vibrations of the pump, due to which the liquid is taken and moved to the pipeline, have destructive abilities. Due to their action, static objects or materials may begin to move, which is highly undesirable. Typically, vibration-type pumps are used for the following purposes:

- Remove liquid from a recently dug well or pump out water for further inspection and cleaning of aquifers.

- Provide water supply from a well for life support.

- The vibration pump is successfully operated for watering the site, pumping water from a lake, river or other body of water.

- Also, using the unit, you can adjust the supply of liquid from a tank or tank.

- A vibration pump will help out if you need to remove water from a flooded basement, free a pit, trench or other volumetric recess.

Comment! The absence in the list of actions for taking water from a well is explained by opposite reviews about this scope. One vibration-type pump serves as an excellent assistant in delivering water from a well, while it harmed others by destroying the well itself and causing deformation of the foundation of the main structure.

Elimination of mechanical damage

When repairing the water pump "Kid" with your own hands, you need to pay attention to the condition of the check valve. It is the most vulnerable part of this mechanism.

When the rubber wears out, it ceases to fit snugly against the housing seat, which is why the pump stops pumping.

In this case, it should be replaced. To repair the unit, you must first carefully disassemble it.Before disassembling the structure, marks are made on both parts of the body. Then the screws are unscrewed, given that the unit is under tension from the spring, which is in a compressed state.

Therefore, the body of the unit is clamped by the flanges in a vice, and then the screws are unscrewed. As soon as the threaded connection is removed, both halves of the body are separated by slowly unwinding the vise.

When the valve is replaced, they begin to set up the equipment. In this case, it is imperative to grind the seat for the valve with sandpaper so that the rubber fits as best as possible. After that, adjust the position of the valve and assemble the pump.

For normal operation of the unit, the gap between the valve and the body should be 0.6-0.8 mm, which allows water to flow out in a free state. After assembly, be sure to check how the vibration pump works.

Why does equipment break down?

The submersible well pump provides convenience and ease of use of the well. It raises water from a great depth to the surface, where it flows through communications to water intake points.

Domestic and foreign enterprises produce household submersible pumps. And although pumping equipment is reliable, breakdowns can occur from time to time during operation.

All elements of submersible pumps are precisely fitted and easily disassembled. If during the assembly process the parts do not fall into place freely, then the order of installation of individual components is violated

The smooth and precise operation of a submersible pump is often violated by the following reasons:

- high (more than 50%) concentration of suspended particles in water;

- dry operation, when the device operates without touching the water;

- voltage drops above the permissible level, which regularly occur in the network;

- poorly fixed cable connections;

- the cable of the unit is not correctly attached in the area of the well head;

- the submarine cable is not fixed properly.

Malfunctions are provoked by the absence of a filter or its excessive contamination, an unstable pressure switch or a poorly functioning accumulator.

In the absence of grounding, electrochemical corrosion affects the metal elements of the equipment. The pump stops pumping water normally and requires immediate service.

If problems arise with a new pump that is under warranty, do not fix them yourself. It is better to take the device to a company service. There, its performance will be restored by professional craftsmen with experience.

Very often, the cause of the malfunction is errors made by users during the installation of the pump and its operation. Manufacturers and service center employees recommend that buyers, immediately before connecting devices, carefully read the instructions and strictly follow everything that is written there. This will avoid many problems and extend the life of the pumping equipment.

How the product works

When the unit is connected to a power supply with a mains voltage of 50 Hz, the armature is attracted to the core. Every half period, it is thrown back by the shock absorber. Thus, for 1 period of the current wave, the attraction of the armature occurs twice. Therefore, in 1 second it is attracted a hundred times.There is also frequent vibration of the piston located on the rod with the anchor.

Stream pump without housing

Due to the volume limited by the valve and piston, a hydraulic chamber is formed. Actions in it are springy due to the elasticity of the pumped medium containing dissolved air, and the vibrations of the piston. While the water is pushed into the pressure pipe, and the spring is unclenched-compressed, the valve ensures the entry of liquid and through the suction holes - its exit.

The Brook pump in the kit has a nylon cable used for its fastening and installation. The cable protects the consumer from electric shock in the event of insulation breakdown, as it does not conduct current.

Pump "Vodomet": do-it-yourself installation and repair

The rise of water from a deep source - a well or a well - is carried out using a pump.

Depending on the type, the pump is lowered below the water level, or mounted on the ground, and a pipe or hose is lowered into the water. Accordingly, such pumps are called submersible or surface.

The operating conditions of a submersible pump are much more difficult, since it is constantly in the water at great depths.

It also complicates maintenance and repair work on the pump, since the pump must be lifted to the surface instead of being completely bundled with pipes, cables and ropes.

For example, consider the Vodomet centrifugal pump, popular with many suburban homeowners.

water jet pump

The pump does not turn on:

- check the power cable going to the pump. Check for mains voltage.

- the mains protection trips too often. It is necessary to check the network for short circuits and current leakage. Call a professional electrician.

- the pump control panel does not function. Call the service department or take the unit to the manufacturer's warranty department.

The pump turns on, but does not pump water:

- The pump turns on but does not pump water. The non-return valve may be incorrectly installed or blocked.

- air lock in the pump. Perhaps the dynamic level has decreased. Lower the pump to a greater depth.

check the pressure in the accumulator

The pump frequently turns on and off:

- check the tightness of the accumulator, pipes, hoses, connections and pump

- check the range of recommended working pressure in the accumulator

- downhole pump installed too high capacity

The pump works, but the pressure is weak:

- the filter screen is clogged.

- decrease in pump efficiency due to the ingress of large amounts of sand.

- heavy wear of the pump mechanism.

- the pump consumes too much electricity

If the pump is broken

What to do if the pump fails?

- if the filter is clogged, it is necessary to disassemble the pump, clean or replace the strainer.

- the pump mechanism is jammed due to the ingress of solid particles. The pump must be cleaned, an additional filter should be installed to protect against solid particles, or the pump should be raised slightly, moving it away from the sand accumulation at the bottom of the well.

steel mesh for filter

- increased power consumption may be due to increased friction between parts due to sand ingress.

- in case of severe wear of the pump mechanisms, it will be necessary to inspect and repair it at a service center to replace individual components, or to replace the entire pump.

How to prevent damage to pumping equipment?

Water lifting equipment for autonomous water supply contains complex mechanical and electronic components.In order for all equipment to work for a long time and without failures, certain requirements must be observed, which the manufacturer usually indicates in the technical data sheet of the product.

Recommendations for the quality work of an autonomous water supply system:

- it is necessary to ground all equipment, to protect the pump from power surges and other negative manifestations of the power supply.

- the pump must hang on a special steel cable, and not on an electrical supply cable or a plastic pipe. When the pump is detached, it will be necessary to carry out complex and expensive work to lift the equipment that has fallen into the well.

steel safety rope

- check, disassemble and repair the pump, as well as other equipment, only when completely disconnected from the mains.

- organize protection of the pump against "dry running" and overheating

- the maximum depth of lowering the pump is 1 m from the bottom of the well. Otherwise, the risk of sand getting into the pump mechanisms increases.

- Eliminate any possible route for sand and other hard abrasive substances to enter the pump.

Subject to all the requirements for the operation of the Vodomet downhole pump and related equipment, the autonomous water supply system will serve you for a long time without failures.

Conclusions and useful video on the topic

A small video tip on repair and diagnostics, which will help to repair:

We always remember safety! And therefore, even after making sure of the integrity of the coils and the absence of a short to the case, we never hold the pump by the case when checking! Always only on a dielectric spring suspension!

And we never use the power cord for such purposes. Security is never superfluous.

Have something to add, or have questions about troubleshooting pumping equipment? Please leave comments on the post. The contact form is in the bottom block.