- Disassembly of the pump Kid

- Model range and specifications

- Possible breakdowns of the "Brook" and how to eliminate them

- Hull depressurization

- Valve replacement

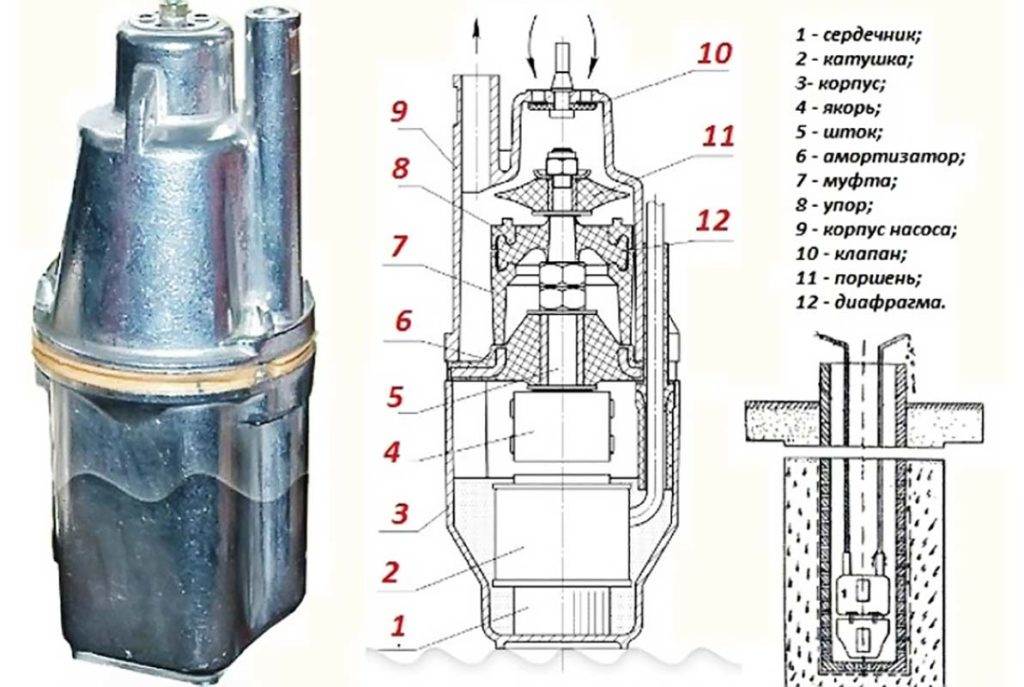

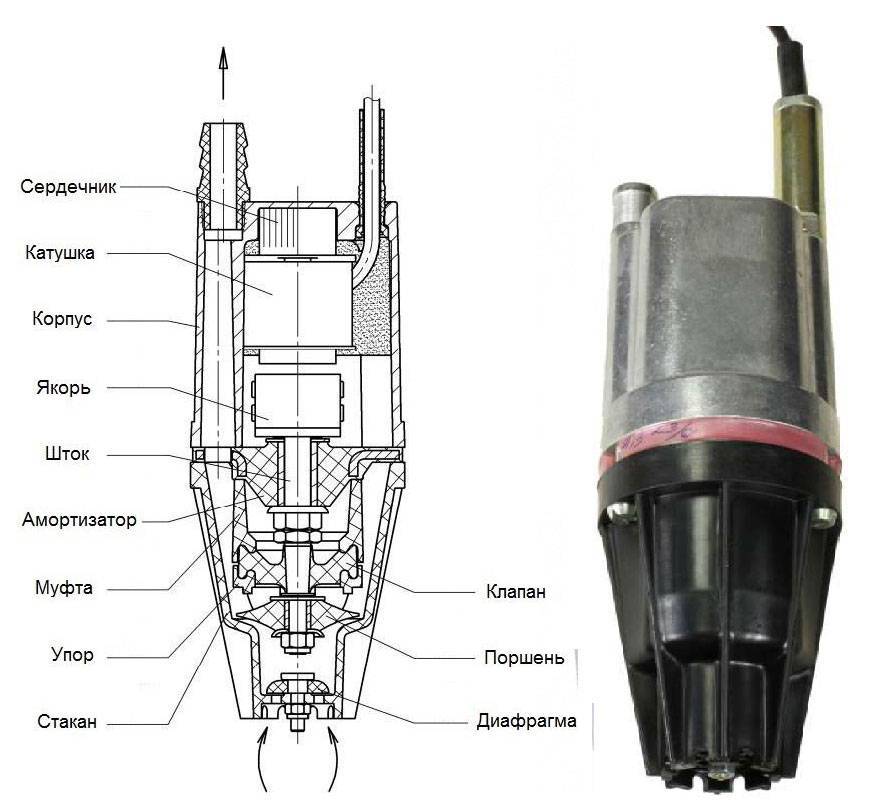

- Device and principle of operation

- The principle of reliable operation of the pump "Kid"

- Competent do-it-yourself repair

- The main types of malfunctions and their causes

- Type #1 - electrical failures

- Type #2 - mechanical failures

- Device design

- Operating principle

- Disadvantages of the Vibratory Pump "Brook"

- The main types of malfunctions and their causes

- Type #1 - electrical faults

- Type #2 - mechanical failures

- Device and principle of operation of the unit

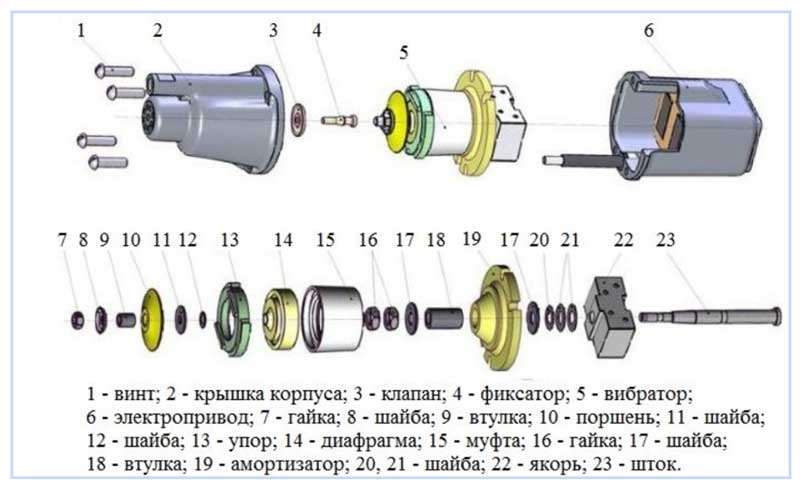

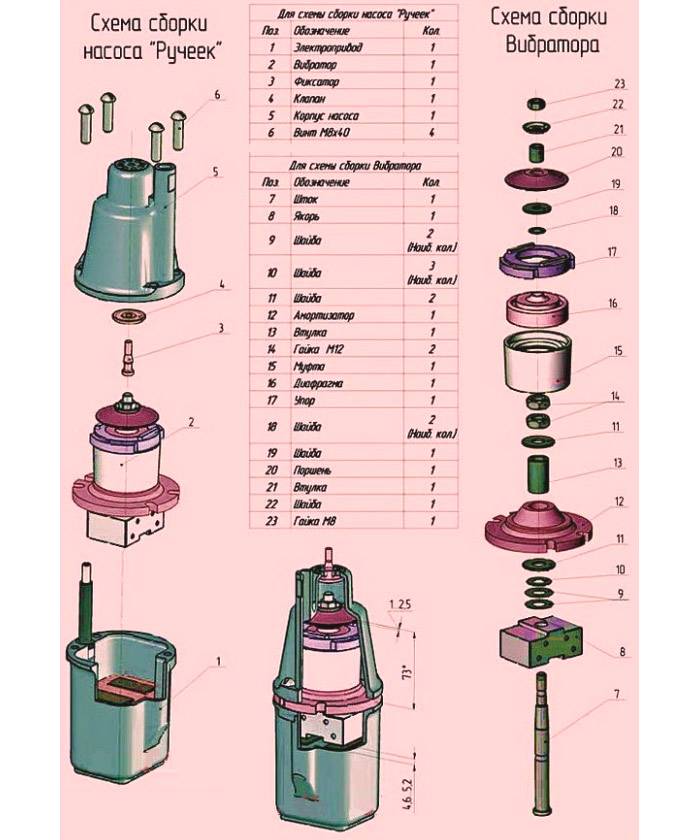

- Assembly

- Specifications and selection criteria for the unit

- Do-it-yourself pump repair "Kid"

- The first step is disassembly and assembly

- Compound replacement

- How to check the correct position of the pump elements

- Device design

- Operating principle

- Briefly about the main

- Device with lower and upper water intake

- Conclusions and useful video on the topic

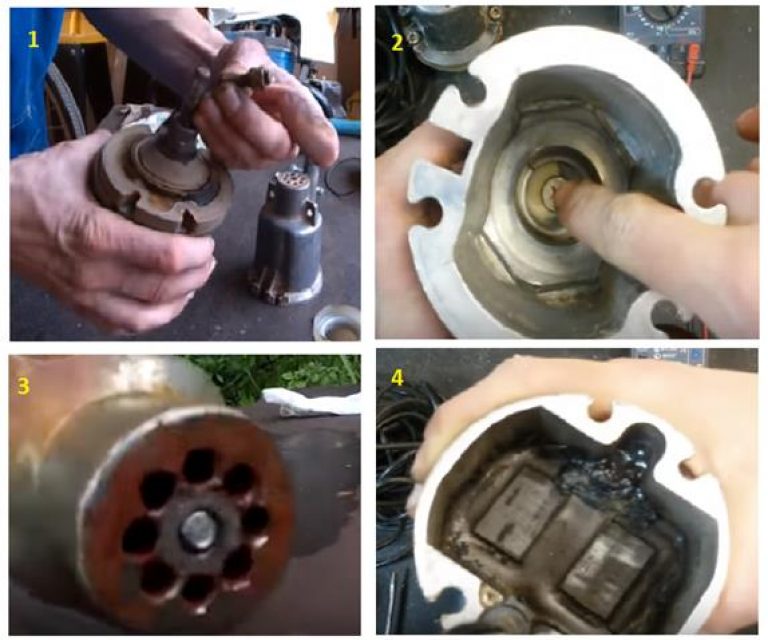

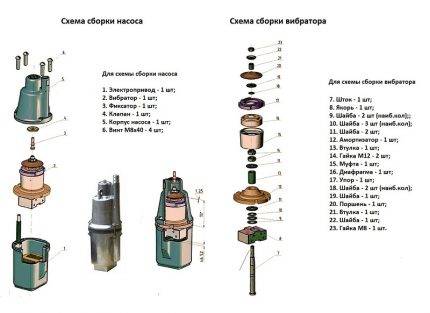

Disassembly of the pump Kid

Before repairing the Baby pump, it must be properly disassembled. The main thing in this matter is not to damage the whole parts, and remember the procedure in order to properly assemble the mechanism after repair. Before disassembly, drain the water from the pump and turn it off.Next, you need to use a sharp object or a marker to apply marks on the two halves of the case in order to properly dock them during assembly.

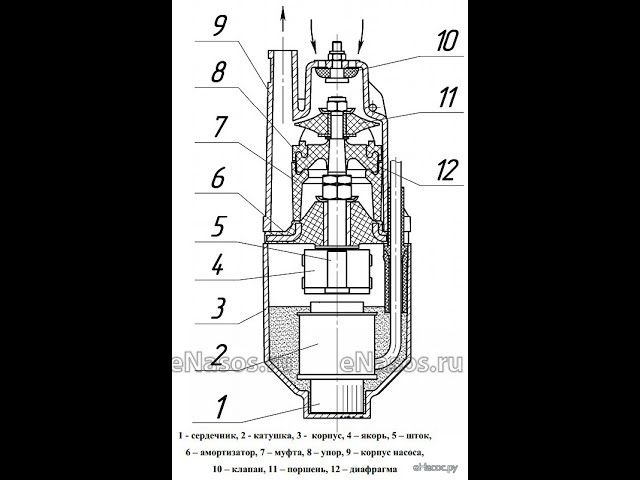

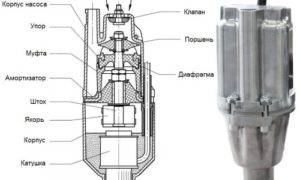

Then the body of the "Kid" is clamped in a vice in a vertical position, just below the butt joint of the upper and lower parts. All fixing bolts are unscrewed, and the upper part of the mechanism case is removed. Next, we unscrew and remove the fixing nut from the vibrator bushing, and remove all the parts put on the rod. The main components of the vibration pump:

- Piston.

- Focused diaphragm.

- Electro coupling.

- shock absorber.

- Anchor.

All of the above parts are strung on the central rod, and washers and locknuts are installed between them.

Model range and specifications

There are three modifications of Malysh pumps on the market:

- Standard (aka basic). Has a lower water intake.

- Model marked "K". Performs the same functions as the basic modification of the device. But it is additionally equipped with protection against overheating.

- The pump the Kid with marking "P". Here, with the same technical characteristics as the previous models, the difference is only in the body material. It is made from polymer.

The Malysh-M and Malysh-3 pumps have an upper water intake.

Technical characteristics for all modifications of the Malysh unit are identical:

- Productivity - 430 l / h when lifting liquid from a depth of 40 m. The shallower the depth, the higher the pump performance. Sometimes this value reaches 1050 l / h if the water is raised from 1 m.

- Pressure - 40 m.

- Engine power - 245 watts.

- The maximum diving depth is 5 m.

- The period of continuous work is 2 hours.

Possible breakdowns of the "Brook" and how to eliminate them

Hull depressurization

When taking water from wells or wells, it is necessary to control that the body of the stream does not come into contact with the walls. The vibrating pump, touching them, will receive blows equivalent in strength to hammer blows. And there will be about a hundred of them per minute. Naturally, the case will not withstand such an overload: it will heat up and the filling will peel off from the magnet inside. The same will happen if the pump is left running out of water, dry.

To repair the pump, it is necessary to open the housing and remove the electrical part

Let's try to repair the brook pump with our own hands. To do this, you need to separate the electrical part, take out the magnet, cut shallow grooves over the entire surface with a small grinder, lubricate with sealant, which is used to insert glass in cars, put it back into the case using a press, and wait until it dries. Then assemble the pump in reverse order.

Valve replacement

When pumping out drainage water from basements, make sure that small pebbles or sand do not get inside. To do this, an additional filter is bought, which is pulled in a heated form onto the receiving part like a cap. They are not very convenient to use, but they are cheap. More expensive filters are like glasses that fit the entire pump. It is with them that it is recommended to pump out spring waters.

From the ingress of small pebbles or sand, the rubber valve wears out - part number 4

If, nevertheless, the pebble managed to get inside the mechanism, then it will pass through the grid of the built-in filter and get stuck at the valve. And since the valve is rubber, after a while it will tear apart.

It is not difficult to repair a submersible brook pump: instead of a valve, you can take a cork from medical bottles. In it, the rubber is thick enough, so it will easily fit into place of the valve.

Having bought a "Streamlet", summer residents will make it easier for themselves to water and pump out drainage water, and they will also always have drinking water in the house.

2014-02-23 09:59:05

Author, learn geography! The Belarusian enterprise (as it is written in the article) JSC "Livgidromash" is located in the ancient Russian city of Livny, Oryol region. In Russia, Livny is also popularly known by the so-called harmonica "livenka" - a kind of Russian accordion, which appeared in the city of Livny in the 60-70s of the XIX century

2014-04-26 12:41:56

I do repairs like this (I disassemble the pump and put the parts in order, I look at their wear):

1) I remove the cap and look at the suction valve;

2) unscrew the nut, remove the piston;

3) I unscrew both nuts and look at the state of the shock absorber;

4) When assembling, you need to check the gap between the magnet and the rod assembly. To do this, take 2 balls of plasticine, put on a magnet

and install a rod without a piston. Then we close the lid with 2 bolts, clamp, remove and check the thickness of the plasticine

caliper - should be 4-5 mm. We adjust this gap with thin washers;

5) to check the correct installation of the piston, you need to assemble the piston and close the cover with 2 bolts. Into the outlet tube

you need to blow with your mouth - if the air passes freely back and forth, you need to add a gasket. Should be when blowing through the passage

air is slower than back. Adjustment completed;

6) check and install the suction valve

When blown, the air must not pass back;

You need to collect on the sealant, especially pay attention to the wire - water can pass there too

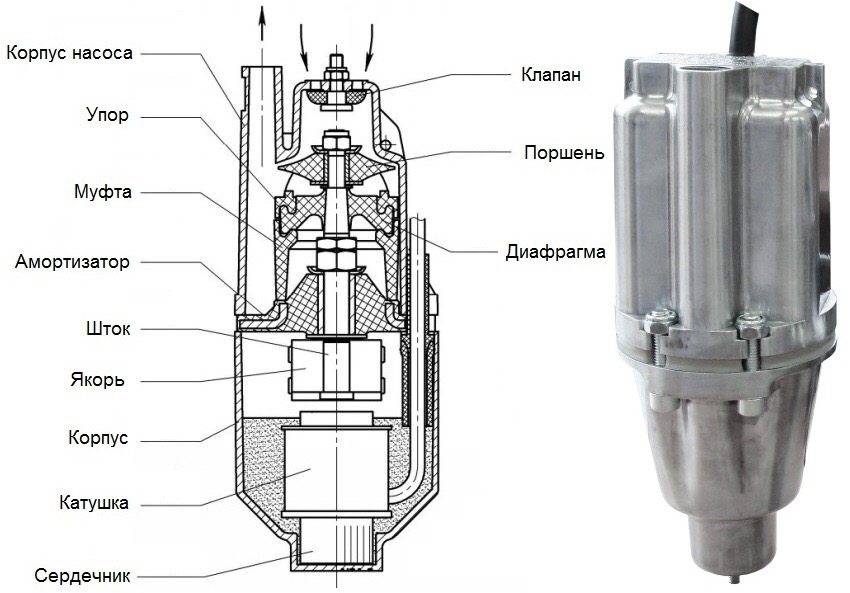

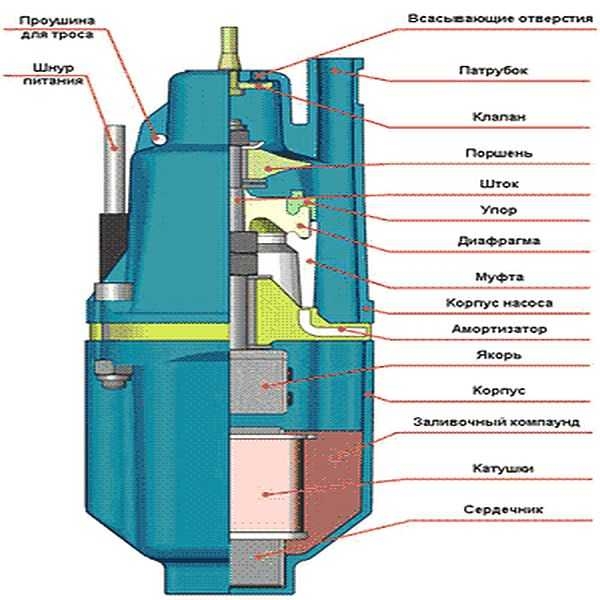

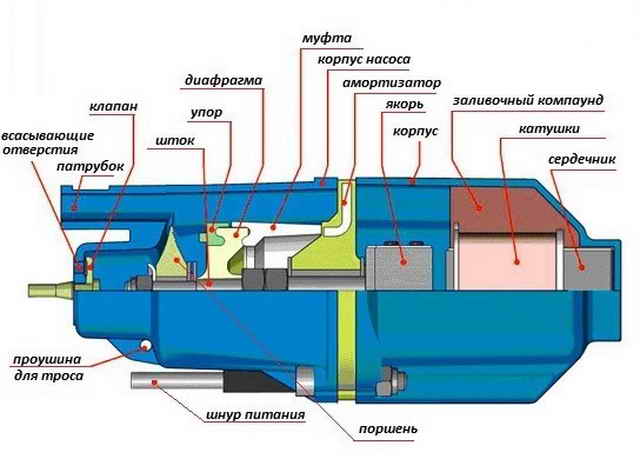

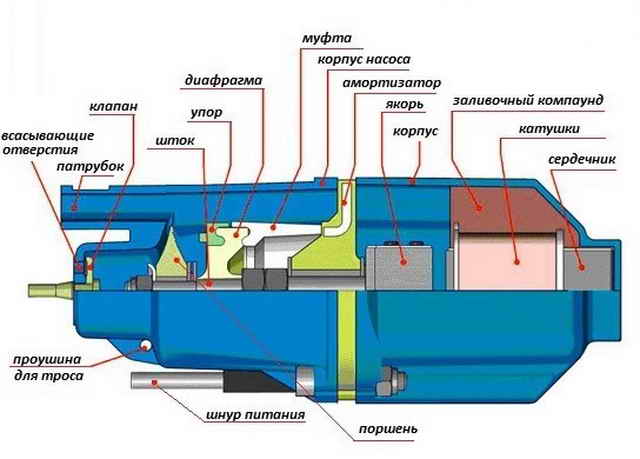

Device and principle of operation

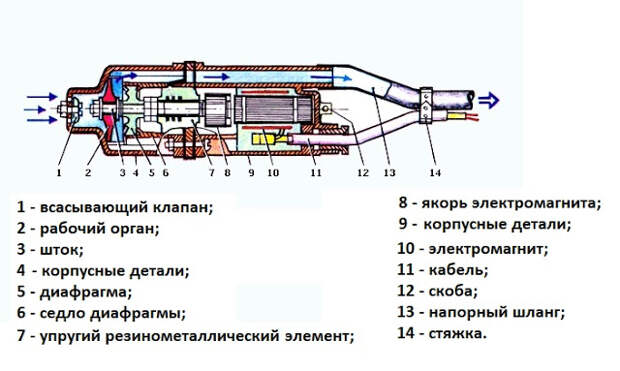

Pump device.

Its body is divided into 2 parts. A yoke is pressed in at the bottom. These are 2 electric coils with a core, filled with a compound (polymer resin), an anchor. In the upper half is the mechanical system. A vibrator with a piston rests on a shock absorber made of elastic rubber. A non-return valve can be installed on the water intake pipe and pumped out.

The principle of operation of the device is simple. When it is connected to the network, the coil creates an electromagnetic field. The heart starts to vibrate. The membrane does not allow it to sway much, and the shock absorber returns to the neutral position. The piston attached to the anchor pushes the elastic mixture of fluid with air, and the water pump starts to work. This creates a movement of fluid in a hose or pipe.

The principle of reliable operation of the pump "Kid"

In order to understand how to repair a vibration do-it-yourself water pump kid, you need to know its device, understand the principle of operation of the vibration pump and its control. Knowing all the nuances of this "Baby", disassembling and assembling the pump with your own hands before and after repair will be easy.

The best mobile application for experienced BPlayers has appeared and you can absolutely free download 1xBet on your Android phone with all the latest updates and discover sports betting in a new way.

So, a water vibration pump of the “baby”, “streamlet”, etc. type works on the principle of creating oscillations in the aquatic environment. The liquid, driven by a submersible water pump, enters a hose attached to the pump and moves in a given direction.

This vibratory motion is generated by a vibrator built into the pump casing.The vibrator itself comes into a movable state as a result of exposure to an electromagnetic field. At the same time, we note that all working elements and components are located in the aluminum case of the device. Outside, only a hose of the required diameter is connected.

Thus, the vibrator in the form of an anchor moves up and down in the pump housing, additionally fixed by a rubber spring. During the operation of the “baby” or “streamlet” submersible pump, the vibrator makes up to 50 oscillations per second, changing its position. Thanks to this movement, water mixed with air enters the mechanism through the valve of the unit and already exits through its nozzle, ensuring the transport of fluid through a hose or pipe. As a result, the pump pumps water well.

Competent do-it-yourself repair

Breakdowns can occur in the electrical and mechanical parts. Equipment may fail partially or completely. A partial malfunction of the device can mean both a breakdown of internal parts and a violation of the adjustment.

Most often, due to the operation of the device without water, it overheats, and the automation fails. For the same reason, the insulation can overheat, the filling is stratified, and the yoke falls out of the body. In this case, the pump buzzes, does not pump liquid, the body of the product may be damaged. It is possible to avoid the occurrence of such malfunctions by observing the rules for operating the pump.

Mechanical failures of the vibration pump occur quite often.

Consider the most common causes of breakdowns:

- Limescale on parts;

- Housing depressurization due to mechanical damage;

- Clogging of the insides with dirt;

- Loose bolt connections.

If you suspect a malfunction of the device, you need to disconnect it from the mains and pull it out of the water. Before disassembling the pump, it should be inspected. Disconnect the supply hose and inspect the device from above for damage. Violation of the integrity of the body is eliminated only by its complete replacement. If everything is in order with him, the tester needs to check the resistance of the coils. If the contacts close, it is necessary to change the coil.

Repair of the pump should be carried out when it is turned off

The next step, if the coil is working, is to purge the pump. If the air enters freely or with a sharp breath into the inlet, the valve closes, then everything is in order with the pump. The device also needs to be shaken, the presence of extraneous sounds indicates a breakdown inside.

The main types of malfunctions and their causes

All faults can be reduced to two types:

- electrical part;

- mechanical part.

In turn, each of them can be divided into two subgroups. This is a complete inoperability and a partial disruption of work.

Partial loss of pump performance does not necessarily mean a violation of the regulation. Sometimes the reason lies in the failure of its individual parts. But let's start in order.

Type #1 - electrical failures

The most common malfunction is the failure of the coil. Complete burnout or breakdown of insulation on the case. Less commonly, delamination from the body of the compound occurs. There is only one reason for malfunctions - running “dry”, without water, which causes the coil to overheat.

Then the insulation burns, the compound burns, and, due to the difference in thermal expansion of various materials, the filling is delaminated and the yoke falls out of the body.

Sometimes the pump stops pumping at all, but it can also break the case. This is the most unpleasant breakdown, which can only be avoided by observing the rules of operation.

When troubleshooting, you will have to disassemble it. Thanks to the simple design, it will be possible to independently disassemble it into its constituent elements.

Type #2 - mechanical failures

There is a wide variety of causes and consequences:

- Liming details. It comes from pumping hard water. This is a white limescale deposit like scale in the kettle. In operation, this is not particularly felt, but after long-term storage, for example, in winter, the lime may jam the piston. The malfunction is rare, as a rule, it only makes disassembly difficult and slightly reduces the performance of the pump.

- Violation of the integrity of the hull. Impression, accurately cut with a file or router. Usually the top edge of the hull. The reason is simple - contact with the concrete surface of the well during operation.

- Clogging of the working cavity of the pump. For example, sand. Sand and pebbles, branches, algae - all this violates the tightness of the valve to the bed. Not critical, but unpleasant - the pump does not develop the required power.

- Loosening of threaded connections. It comes from vibration, happens infrequently. For example, the nuts securing the piston are untwisted. The consequences can be the most deplorable - up to the destruction of the hull.

- Violation of the properties of rubber. Leads to reduced pump power. In rare cases, there is a complete cessation of performance.

The most capricious and sensitive to the weakening of the properties of rubber detail, oddly enough, is a massive shock absorber. Too elastic rubber contributes to the breaking of the core, too hard - to reduce the amplitude of vibration and loss of power.

In addition, when turning the core in the shock absorber, the projection of the base of the rod (a part called an anchor is pressed onto the rod) does not completely coincide with the yoke and is less attracted to it. A rigid piston moves water worse. Broken piston does not pump at all.

The valve with a loss of elasticity works worse, but the pump does not fail at all. We also observe when the valve adjustment is violated.

Sometimes there is just a loss of power. Often the reason is to turn the pump on again without immersion in water. Most often this happens due to neglect of the rules of operation.

For example, suspension of the pump on a steel cable and without a shock absorber - the pump mount must be shock-absorbing! Therefore, the kit includes a fishing line or nylon cord and a shock-absorbing ring for fastening.

Knowing the device of the Malysh series pumps, you can do it yourself with the repair of units without any problems

Knowing the device of the Malysh series pumps, you can do it yourself with the repair of units without any problems

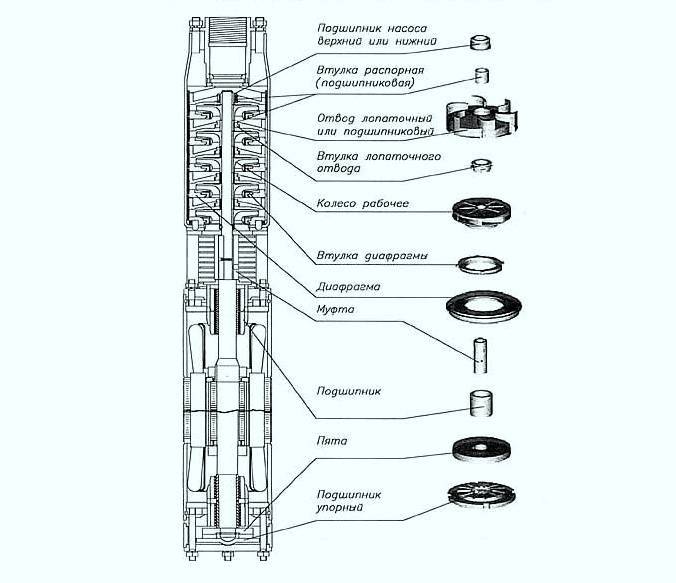

Device design

The device of the vibration pump baby is quite simple. It consists of three main parts:

- frame;

- electromagnet;

- anchor vibrator.

The body of the device is made of metal alloys and consists of two halves. The lower part is cylindrical. The top is made in the form of a cone.

The electromagnet of the device consists of a U-shaped metal core, on which several layers of electrically conductive winding are placed. The winding is fixed on the core with a compound (plastic resin). The same material secures the magnet inside the body of the device, isolating the coil from the metal components of the device. The composition of the compound also includes quartz-containing sand, which removes heat from the magnet, preventing it from overheating.

Vibration pump device Kid

Vibration pump device Kid

The anchor of the device is equipped with a special rod. With the rest of the nodes, it is attached with a spring, which ensures that the vibrator returns to the neutral position when the magnet ceases to act.

Operating principle

Proper repair of a vibration pump is impossible without a clear understanding of how the device works. The principle of operation of the pumps, the kid refers them to the inertial type of devices.

Submersible type devices are switched on only after complete immersion in the working environment. The whole algorithm of the device has the following form:

- The pump is connected to the electrical network.

- After connecting, an electromagnet begins to act, which attracts the anchor. The magnet works intermittently, with a frequency of up to 50 inclusions per second. When it is turned off, the anchor returns under the force of the spring.

- When the armature is retracted by the spring, it also retracts the piston attached to it. As a result, a space is formed into which water saturated with air enters. This composition of the liquid provides greater elasticity, and hence susceptibility to vibrations.

- Under the action of the vibrator, the water begins to move. And subsequent portions of liquid from the inlet rubber valve put pressure on the previous liquid, directing the flow exclusively in the direction of the outlet pipe.

This principle of operation provides a high pressure in the tube, which allows you to keep the pressure over a long distance.

Disadvantages of the Vibratory Pump "Brook"

One of the disadvantages of the Brook vibration pump is a loud sound during operation. If you use it only for watering, you can put up with it.But if you use the pump to operate a fountain, overflow or circulate water in the pool, then the hum of the pump will interfere and annoy. For these purposes, it is better to use pumps of a different type.

With the help of "Stream 1" you can download only part of the water above the suction hole. It will not be possible to completely pump out water from the tank.

Adapters and quick-release fasteners are not provided for connecting the hose. The hose connector has a round section (some models have notches), so the hose often disconnects due to vibrations. You have to crimp it with a knitting wire or a clamp. Disconnecting the hose is then problematic.

The pump device does not provide for automatic shutdown. The user himself has to monitor the water level. "Brook" is cooled by the water in which it is located. If the pump runs idle, it quickly heats up and fails.

Float device for automatic shutdown can be purchased separately. Many owners make their own.

Of course, it will not be possible to solve all problems with its help. To pump water and other liquids in large volumes, you will need a more powerful pump.

The water supply of a country house and the provision of high-quality irrigation of the area adjacent to it is a topic that excites any person who spends part of his life outside the city. For this purpose, various devices and devices are used, including the Rucheek submersible pump, known since Soviet times, whose technical characteristics are quite consistent with many modern and "advanced" analogues.

With its low power, averaging 225-300 W, and the minimum price (1300-2100 rubles, depending on the model), the Brook water pump is quite capable of providing water to a small family of 2-3 people, as well as watering a summer cottage with an area of 6 -12 acres.

The vibration pump can also be used for purposes such as:

Pumping water from pools, basements and various containers.

Most often, the problem of flooding of premises located on the lower tiers of residential buildings and utility structures occurs during the spring flood, when groundwater rises especially high. Since they practically do not have solid impurities in their composition, they can be pumped out using a submersible vibration pump Brook.

The filter for the pump Brook is a special device that has the shape of a cap, which is worn on the receiving part of the pump. This procedure is best done after the pump has warmed up.

Filling the heating system before starting it.

This manipulation is carried out in the absence of the possibility of connecting to a centralized heating system at this stage of construction. The process itself looks like this:

- Water is delivered to the house in a barrel, into which a hose from the pump is inserted.

- The second hose connects to the radiator drain cock.

— The tap opens at the same time as the pump starts.

- The system is filled using a pressure gauge until the pressure in it reaches the desired level.

The main types of malfunctions and their causes

All faults can be reduced to two types:

- Electrical part.

- Mechanical part.

In turn, each of them can be divided into two subgroups. This is a complete inoperability and a partial disruption of work.

Partial loss of pump performance does not necessarily mean a violation of the regulation. Sometimes the reason lies in the failure of its individual parts. But let's start in order.

Type #1 - electrical faults

The most common malfunction is the failure of the coil. Complete burnout or breakdown of insulation on the case. Less commonly, delamination from the body of the compound occurs. There is only one reason for malfunctions - running “dry”, without water, which causes the coil to overheat.

Then the insulation burns, the compound burns, and, due to the difference in thermal expansion of various materials, the filling is delaminated and the yoke falls out of the body.

Sometimes the pump stops pumping at all, but it can also break the case. This is the most unpleasant breakdown, which can only be avoided by observing the rules of operation.

When troubleshooting, you will have to disassemble it. Thanks to the simple design, it will be possible to independently disassemble it into its constituent elements.

Type #2 - mechanical failures

There is a wide variety of causes and consequences.

- Liming details. It comes from pumping hard water. This is a white limescale deposit like scale in the kettle. In operation, this is not particularly felt, but after long-term storage, for example, in winter, the lime may jam the piston. The malfunction is rare, as a rule, it only makes disassembly difficult and slightly reduces the performance of the pump.

- Violation of the integrity of the hull. Impression, accurately cut with a file or router. Usually the top edge of the hull. The reason is simple - contact with the concrete surface of the well during operation.

- Clogging of the working cavity of the pump.For example, sand. Sand and pebbles, branches, algae - all this violates the tightness of the valve to the bed. Not critical, but unpleasant - the pump does not develop the required power.

- Loosening of threaded connections. It comes from vibration, happens infrequently. For example, the nuts securing the piston are untwisted. The consequences can be the most deplorable - up to the destruction of the hull.

- Violation of the properties of rubber. Leads to reduced pump power. In rare cases, there is a complete cessation of performance.

The most capricious and sensitive to the weakening of the properties of rubber detail, oddly enough, is a massive shock absorber. Too elastic rubber contributes to the breaking of the core, too hard - to reduce the amplitude of vibration and loss of power.

In addition, when turning the core in the shock absorber, the projection of the base of the rod (a part called an anchor is pressed onto the rod) does not completely coincide with the yoke and is less attracted to it. A rigid piston moves water worse. Broken piston does not pump at all.

The valve with a loss of elasticity works worse, but the pump does not fail at all. We also observe when the valve adjustment is violated.

Sometimes there is just a loss of power. Often the reason is to turn the pump on again without immersion in water. Most often this happens due to neglect of the rules of operation.

For example, suspension of the pump on a steel cable and without a shock absorber - the pump mount must be shock-absorbing! Therefore, the kit includes a fishing line or nylon cord and a shock-absorbing ring for fastening.

Knowing the device of the Malysh series pumps, you can do it yourself with the repair of units without any problems

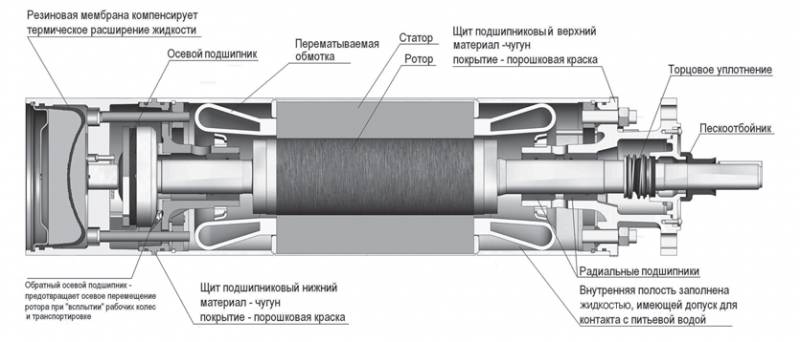

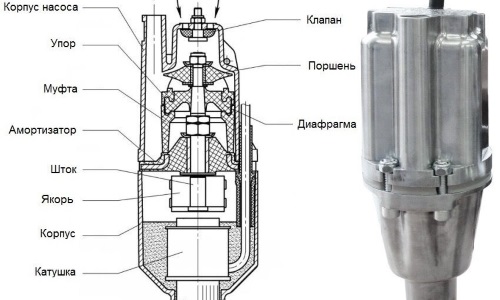

Device and principle of operation of the unit

Pump device.

Its body is divided into 2 parts. A yoke is pressed in at the bottom. These are 2 electric coils with a core, filled with a compound (polymer resin), an anchor. In the upper half is the mechanical system. A vibrator with a piston rests on a shock absorber made of elastic rubber. A non-return valve can be installed on the water intake pipe and pumped out.

The principle of operation of the device is simple. When it is connected to the network, the coil creates an electromagnetic field. The heart starts to vibrate. The membrane does not allow it to sway much, and the shock absorber returns to the neutral position. The piston attached to the anchor pushes the elastic mixture of fluid with air, and the water pump starts to work. This creates a movement of fluid in a hose or pipe.

The core performs 50 vibrations per second. With a similar speed, the piston makes forward-return movements. The portions of water regulated by the valve rush in the set direction and pour out from an outlet branch pipe.

Assembly

Reassembly must be done with the utmost care.

- It is necessary that all holes in the housing coincide with each other and are installed in the same way as before disassembly. If the assembly is not correct, and at least one of the devices inside is in the wrong place, the pump will not function.

- The screws must be pulled crosswise alternately, gradually. The twist must be very tight.

The process of assembling the pump Baby must be carried out in stages

- When the pump housing is assembled, the tightness is checked by immersion in a bucket of water.

- Be sure to measure the resistance.

- If all is well, then you can release the pump to a depth. You have checked.

Experts recommend doing a preventive inspection and cleaning of the pump once a year. In this case, the device will function for a long time without losing power and without breaking.

Assembled pump

Specifications and selection criteria for the unit

According to the technical parameters of the vibration pump, its capabilities are judged. Therefore, knowledge of the characteristics of the unit will help to make a competent choice:

- The performance is selected taking into account the capabilities of the water intake source, which must exceed the parameters of the pump. There are three performance categories of vibration-type units: low, medium and high, which are characterized by the ability to pump 360, 750 or 1500 liters per hour, respectively.

- An important indicator is the height of the water rise. The minimum pressure is 40 m, models designed for 60 m are optimal in operation, units with a lifting capacity of up to 80 m are used less often.

- All vibration type pumps have the same immersion depth - 7 m.

- The outer diameter indicator varies from 76 to 106 mm, it is important when operating the mechanism in the well. In this case, the pipe diameter must exceed the dimensions of the unit.

- There are pumps with upper and lower water intake, which is an important point during operation. The top arrangement excludes hit of sand in the mechanism. Install it 0.3 m above the bottom of the source. The lower location is convenient when using a vibration-type unit for pumping a well or well, removing water from the basement. Install a similar model above the bottom by 1 m.

Attention! The installation of thermal protection will help to eliminate overheating of a vibration-type pump with an upper water intake.Such an element is important in any type of unit, as it stops its operation in an emergency, such as a power surge or piston jamming

Such an element is important in any type of unit, as it stops its operation in an emergency, such as a power surge or piston jamming.

Do-it-yourself pump repair "Kid"

The repair process, in fact, consists of some mandatory steps, the implementation of each of which plays an important role in the end.

The first step is disassembly and assembly

Dismantling the vibration pumping device "Kid" has its own characteristics, without taking into account which, you will spend a lot of time on subsequent assembly.

- Before proceeding with disassembly, it is necessary to put marks on the body, thereby indicating the positions of the parts.

- The screws must be unscrewed sequentially, loosening each of them in turn. If possible, replace the screws with similar ones, but with slots on the head. This will greatly simplify the subsequent disassembly and assembly of the device.

- The location of the piston disc must be parallel to the seat. If the nut is out of parallel, a grover may form, which may take additional time to adjust. The correct position of the disc can be adjusted using a caliper, measuring the distance from the gasket to the edge of the piston.

- So, it's time to assemble the pump "Kid". Here you should be very careful: look for the holes in the gasket (top of the case and in the center) so that they match. Due to their symmetry, it is easy to make mistakes with the sides of the gasket.

- By dipping the assembled device into a bucket of water, check its functionality.Good work will be accompanied by a 25 cm jet emitted from the outlet.

Compound replacement

Common breakdowns of the Malysh pump can also include the detachment of the compound from the metal case. This defect occurs as a result of uneven expansion of the body during the operation of the "Baby".

- Disconnect the device by removing it from the well first.

- Disassemble the device (how to do this - see above).

- Calculate the places of possible detachment of the compound by lightly tapping the body with a hammer. A characteristic sonorous sound will tell you the places of detachment.

- Remove the working unit with the compound from the housing.

- Make small notches on the inside of the body and on the knot itself. For this you need a grinder. The depth of the notches should not be more than two millimeters.

- Cover the assembly with the compound and the inside of the aluminum case with a small layer of sealant.

- Install the compound with the compound in place, pressing it down with great force.

- After the sealant is completely dry, reassemble the pump.

How to check the correct position of the pump elements

After disassembling the pump (especially if you did it for the first time), it is imperative to revise the correct installation of its main elements.

- Check clearance between solenoids and piston. It should be within 5 mm.

- Inspect the valve for mechanical damage.

- Also check the piston assembly.

- To be sure, you can disassemble the sleeve block. To do this, remove the piston assembly and remove the adjusting washer (although it may not be one).Having dismantled the stop ring with a rubber membrane, you should see an aluminum cylinder. It must also be removed by pressing the sleeve assembly inward. Reassembly will allow you to adjust the gap, which should be 0.5 centimeters. If you don't know how to make adjustment: this is done by removing or adding washers on two sides.

- Place the device in a bucket of water, disconnecting the hose first. After turning on the power, check the voltage level - it should be in the range of 220-240 V.

- Drain the accumulated water in the device by first turning it off.

- Test the valve by blowing air through it. This can also be done by mouth. When the pressure rises, the valve should gradually close - you will definitely feel it.

Important: If there are problems with blowing the pump, you can reduce the operating voltage using a transformer. Set the voltage in the range 170-200V.

Device design

The device of the vibration pump baby is quite simple. It consists of three main parts:

- frame;

- electromagnet;

- anchor vibrator.

The body of the device is made of metal alloys and consists of two halves. The lower part is cylindrical. The top is made in the form of a cone.

The electromagnet of the device consists of a U-shaped metal core, on which several layers of electrically conductive winding are placed. The winding is fixed on the core with a compound (plastic resin). The same material secures the magnet inside the body of the device, isolating the coil from the metal components of the device. The composition of the compound also includes quartz-containing sand, which removes heat from the magnet, preventing it from overheating.

The anchor of the device is equipped with a special rod. With the rest of the nodes, it is attached with a spring, which ensures that the vibrator returns to the neutral position when the magnet ceases to act.

Operating principle

Proper repair of a vibration pump is impossible without a clear understanding of how the device works. The principle of operation of the pumps, the kid refers them to the inertial type of devices.

Submersible type devices are switched on only after complete immersion in the working environment. The whole algorithm of the device has the following form:

- The pump is connected to the electrical network.

- After connecting, an electromagnet begins to act, which attracts the anchor. The magnet works intermittently, with a frequency of up to 50 inclusions per second. When it is turned off, the anchor returns under the force of the spring.

- When the armature is retracted by the spring, it also retracts the piston attached to it. As a result, a space is formed into which water saturated with air enters. This composition of the liquid provides greater elasticity, and hence susceptibility to vibrations.

- Under the action of the vibrator, the water begins to move. And subsequent portions of liquid from the inlet rubber valve put pressure on the previous liquid, directing the flow exclusively in the direction of the outlet pipe.

This principle of operation provides a high pressure in the tube, which allows you to keep the pressure over a long distance.

Briefly about the main

There are several options for the Baby pump on the market. All its modifications, like any other devices, are subject to breakdowns. They are observed in the electrical or mechanical part. Also a common reason why the Kid does not pump the pump is the deformation of the housing and its liming.

You can deal with problems on your own. To do this, you need to study the structure of the device and sequentially disassemble it. Checked electrical and mechanical. Quality assembly completes the process.

It is recommended to check the readiness of the Kid for work in a small container before diving to a depth.

Device with lower and upper water intake

"Baby" is one of the simplest and most affordable submersible devices today. It has been produced for a long time and has established itself as a high-quality and reliable device.

Materials for repairing the Baby pump can be bought at a specialized store and on the Internet

With its small dimensions, it can easily perform the following tasks:

- Provide water supply from sources with a diameter of up to 11 centimeters and reservoirs with a water temperature of less than 36 ° C;

- Pumping water from open reservoirs;

- Transport it from containers to domestic water supply;

- Fill the pools with water, drain it from there;

- Pump out liquid from flooded areas, such as basements.

It must be taken into account that the "Kid" pump can pump water with an extremely small amount of mechanical impurities.

"Baby" has three varieties that differ in technical characteristics and are used for various purposes:

- Classical. The water intake of this model is lower, so it can easily cope with the supply of water from open sources located at a great distance. They can also drain flooded rooms, and pumping occurs to a minimum level. The ingress of dirt particles into the pump can damage it. The advantage of the device is the thermal protection function. The relay in the unit turns it off in case of overheating.On such a pump put the marking in the form of the letter "K". There are models marked "P". They differ in that their upper body is plastic. This is the most budget option. Models without this marking are made of aluminum. This is a higher quality and durable material.

- "Kid-M". This is a top suction model. It is convenient for pumping from a well or wells. The advantage is that it can be used in polluted waters. This is due to the fact that during its operation, the debris will remain at the bottom and will not clog the unit. The engine in these devices cools better, this avoids overheating of the equipment.

- "Baby-Z". This pump is also a top suction model. It is used for the same purposes as "Kid-M", but it is smaller and has less power and pressure. These properties allow it to be used for pumping water from shallow wells and small wells.

Conclusions and useful video on the topic

A small video tip on repair and diagnostics, which will help to repair:

We always remember safety! And therefore, even after making sure of the integrity of the coils and the absence of a short to the case, we never hold the pump by the case when checking! Always only on a dielectric spring suspension!

And we never use the power cord for such purposes. Security is never superfluous.

Have something to add, or have questions about troubleshooting pumping equipment? Please leave comments on the post. The contact form is in the bottom block.