- Possible malfunctions and ways to eliminate them

- Preparation for operation

- "Continuity" of the insulation value

- Filling oil into the protection chamber

- Checking the correct rotation of the rotor

- Safety in operation

- The most common problems

- Varieties

- mud aggregates

- explosion-proof

- High pressure

- Repair of pump parts “Gnome”

- Bearing replacement sequence

- Impeller replacement

- Repair of impeller shaft and casing

- Adjustment of the gap between the impeller and the diaphragm

- Repair of the electric motor of the pump "Gnome"

- How to repair a drainage pump with your own hands

- The pump works, but the pressure is low

- Peculiarities

- The engine is running but the pump is not pumping water

- Pros and cons

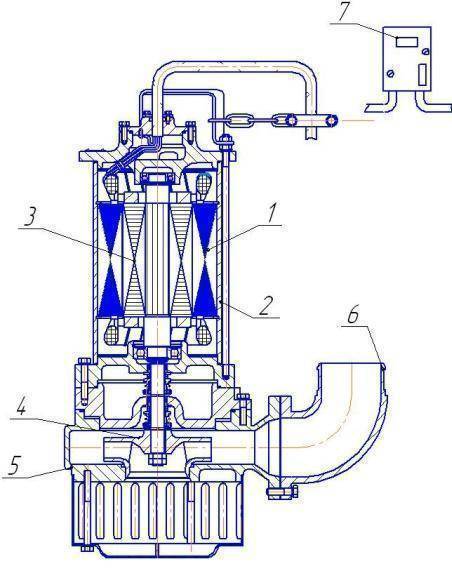

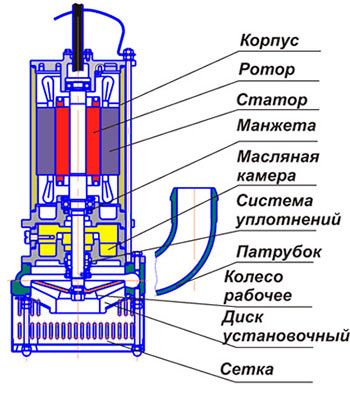

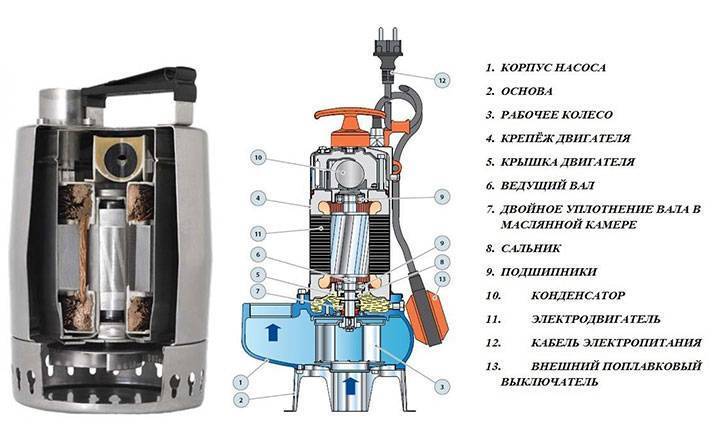

- The device of a typical drainage pump

- Rules for disassembling the unit

- Bearing replacement sequence

- 1 Applications

- 1.1 General characteristics and features

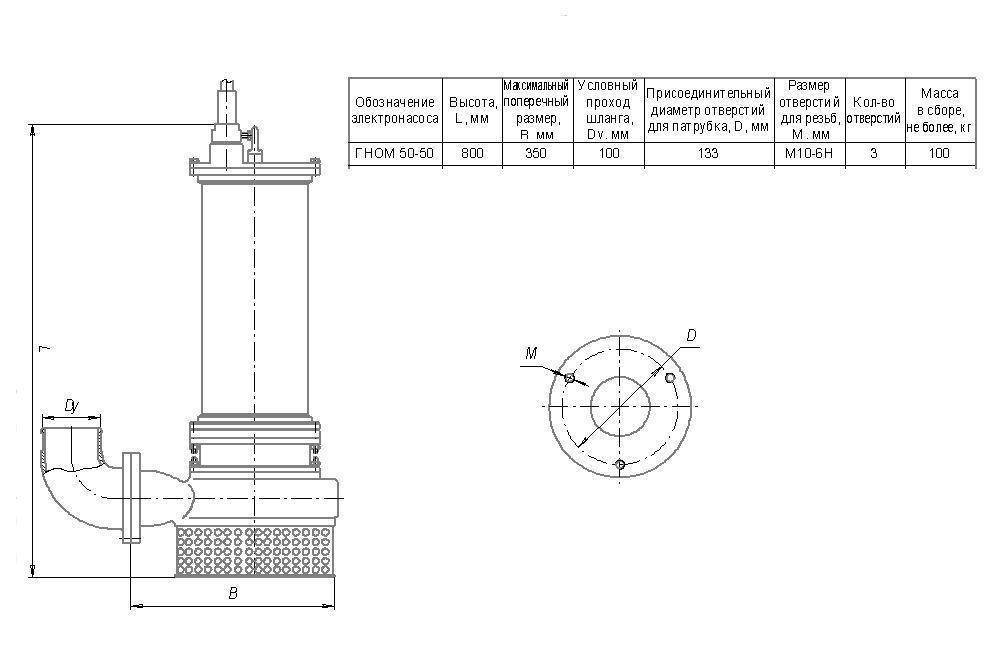

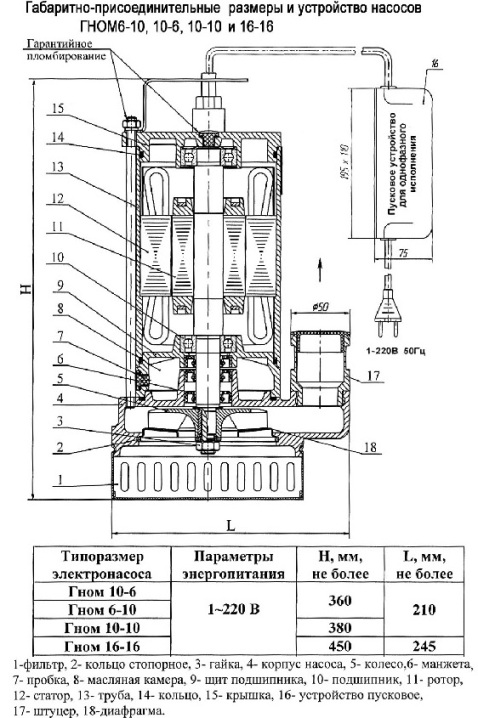

- Pumps Gnome: some technical characteristics

- Submersible or semi-submersible

Possible malfunctions and ways to eliminate them

WATCH VIDEO

The main causes of equipment failure are violations of the rules of operation. To avoid most problems, it is enough to carefully read the attached instructions and follow the recommendations indicated in it.Breaking errors are common and easy to avoid:

- Overheat. Occurs when working without water or when immersed in an excessively hot liquid. Often this situation occurs when trying to pump out water that has flooded the room as a result of a burst of hot water or heating pipes. It is also forbidden to turn on the pump with a blocked suction or delivery opening.

- Voltage fluctuations in the network. Manufacturers recommend using circuit breakers that operate when the voltage deviates from the rated voltage by more than 20%.

- Clogging of the duct or jamming of the wheel mechanism is solved by cleaning. For cleaning, it is enough to remove the strainer and diaphragm.

- Damage to the electrical cable. Carrying is done with a handle, and diving with a cable. It is strictly forbidden to use an electric cable for these purposes.

- The flow or head exceeds the maximum allowable values for this model, which leads to overheating of the engine. It is recommended to select a model whose characteristics correspond to the tasks.

Preparation for operation

Attention! The design of the pump is designed to operate when it is completely immersed in the pumped liquid, in a strictly vertical position.

"Continuity" of the insulation value

Before the first dive after purchase or repair, first of all, it is necessary to perform a "dialing", or determine the amount of insulation:

- Check the insulation between the phase conductor and the housing, as well as the insulation between zero and each phase. To do this, with a 500-volt megger, find the neutral wire according to the diagram and measure the insulation value of each phase, there will be three measurements in total, the insulation value on each is less than 1 MΩ.

- The second part of the test is to determine the breakdown between the motor windings and the housing. To do this, one end of the megohmmeter must touch the body cleaned to the metal and measure the insulation of each phase in turn. The insulation value must be at least 0.5 MΩ.

- And the last procedure is checking the neutral wire. For this, a measurement is made between the “neutral” wire and the insulation housing. the reading should show “0”.

Filling oil into the protection chamber

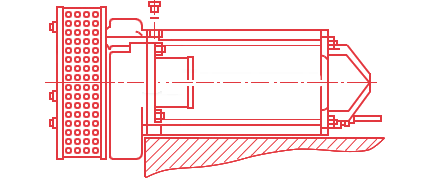

Fig.4. body position when filling oil into the protective chamber.

According to operating requirements, the containment chamber oil should be changed after 200 to 250 operating hours. To change the oil, it is necessary to place the housing on a flat surface with the filler neck up. 14 mm wrench. unscrew the fill plug. The volume of oil in the housing should be approximately 300 - 350 ml. type of oil industrial I-20A or I-40A. Before tightening the filling plug, it is necessary to trace the presence of a rubber gasket. Checking for oil leakage at the seal is done by turning the body down the filler neck. Industrial oil can be replaced with automobile M6z / 10-V, GOST 10541-78.

Checking the correct rotation of the rotor

To do this, lower the pump into the water. And to make a trial run of the pump, while the value of the pumped liquid should be more than the declared one, that is, about 7-8 liters. s., if - this number is much less, then it is necessary to switch the direction of rotation of the impeller, for this it is enough to reverse the phases on the two supply cables. Another practical check of the correct rotation - at the time of start-up, when turned on, the pump should twitch in the opposite direction of the arrow indicated on the housing.

Safety in operation

For the purposes of electrical safety, it is necessary to inspect the supply power cables and cable channels for damage at least once a month. With the prevention of power cables, you can combine the control measurement of insulation according to the above described method. In the event of a downward deviation of the insulation value, it is best to disassemble the pump to dry the windings and find out the cause.

The pump "Gnome" 20 25 can be purchased on specialized Internet resources, or specialized or dealer centers for plumbing equipment. You can also get a free consultation from a sales manager. It is best to visit several stores for this - as very often different stores hold promotions for price reductions or additional accessories.

For more details, please watch the video below.

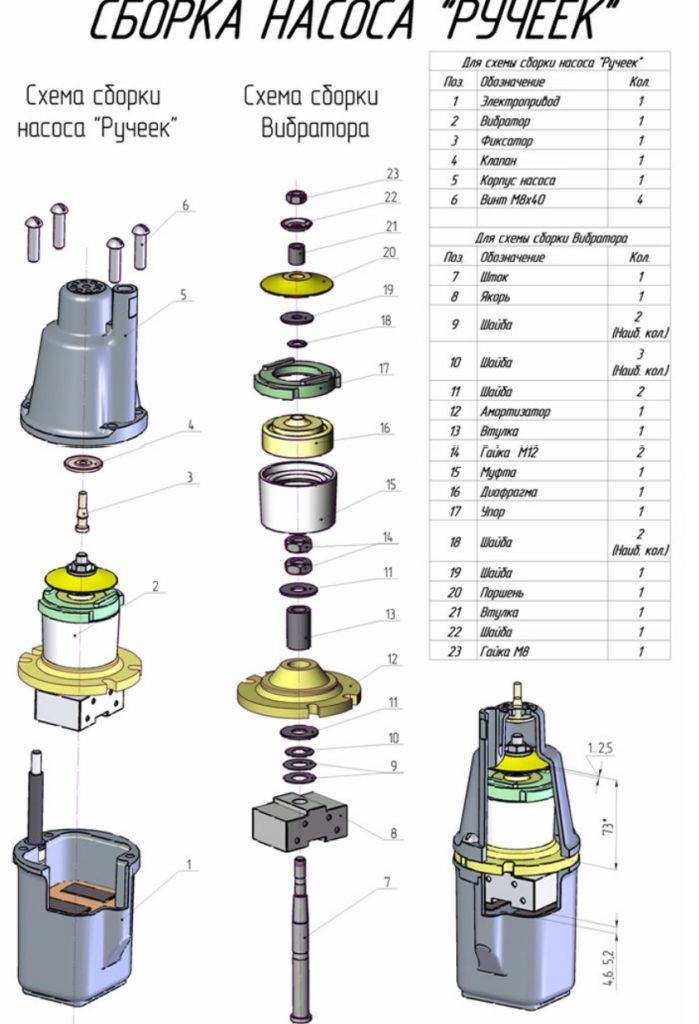

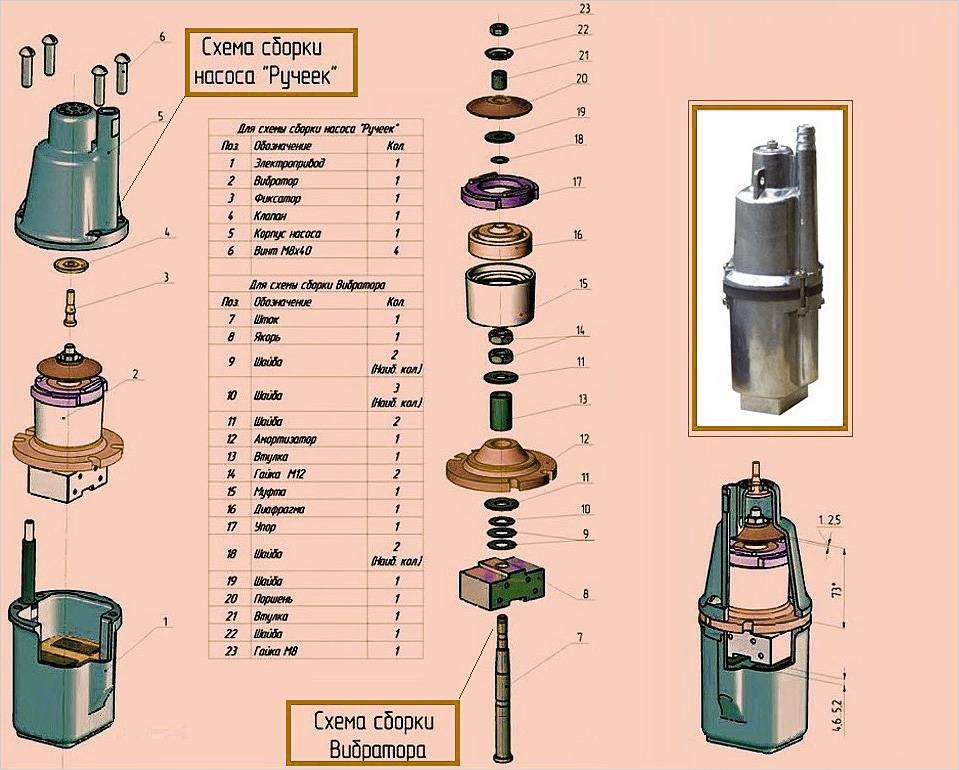

The most common problems

If the fecal pump does not work or repair of Gilex pumps is required, then the following cases may be the probable causes of breakdowns:

- the motor winding burned out, and a characteristic smell may appear;

- the float may be wedged below the launch horizontal;

- the starting capacitor has failed;

- the impeller is wedged due to the ingress of foreign mechanical particles.

It is also necessary to repair the Gilex pump with your own hands, if you hear a rumble from it, but the pumping of water does not go:

- a stem break has occurred;

- the service valve is damaged;

- the fastening of the rod shock absorber loosened;

- damaged power cable.

This list includes the most popular causes of breakdowns, but individual situations occur or several emergency situations occur at the same time.

Varieties

The range of Gnome pumps from various manufacturers includes about a dozen models. At the same time, the marking of the unit has the following form: “Gnome 35-35”. The first number indicates the performance, measured in cubic meters per hour, the second number is the fluid pressure.

Conventionally, all submersible pumps of the Gnome series can be divided into three types:

- Traditional mud pumps.

- Explosion-proof.

- High pressure.

mud aggregates

This is the most popular and numerous series of such pumping devices. This series includes about a hundred modifications of Gnome drainage pumping devices. All of them differ in technical characteristics and features of operation. We list the most popular of them:

- Gnome pumping equipment with the designation 6-10 is a unit with a capacity of 6 m³ / h and a liquid head limit of 10 m. Its power is 0.6 kW.

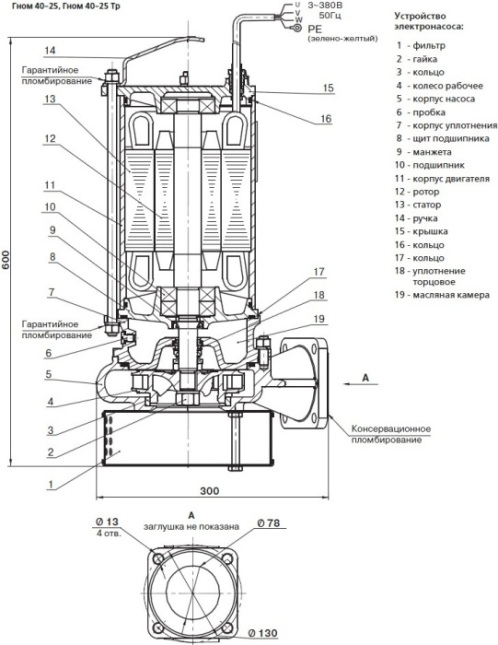

- Dwarf marked 10-10. The performance of this drainage pumping equipment is 10 m³ / h, the allowable head is 10 m. There are models with a power of 0.75 and 1.1 kW on sale. Two versions of this unit are also produced for networks of 220 V and 380 V. This model has a modification for pumping hot liquids marked Tr.

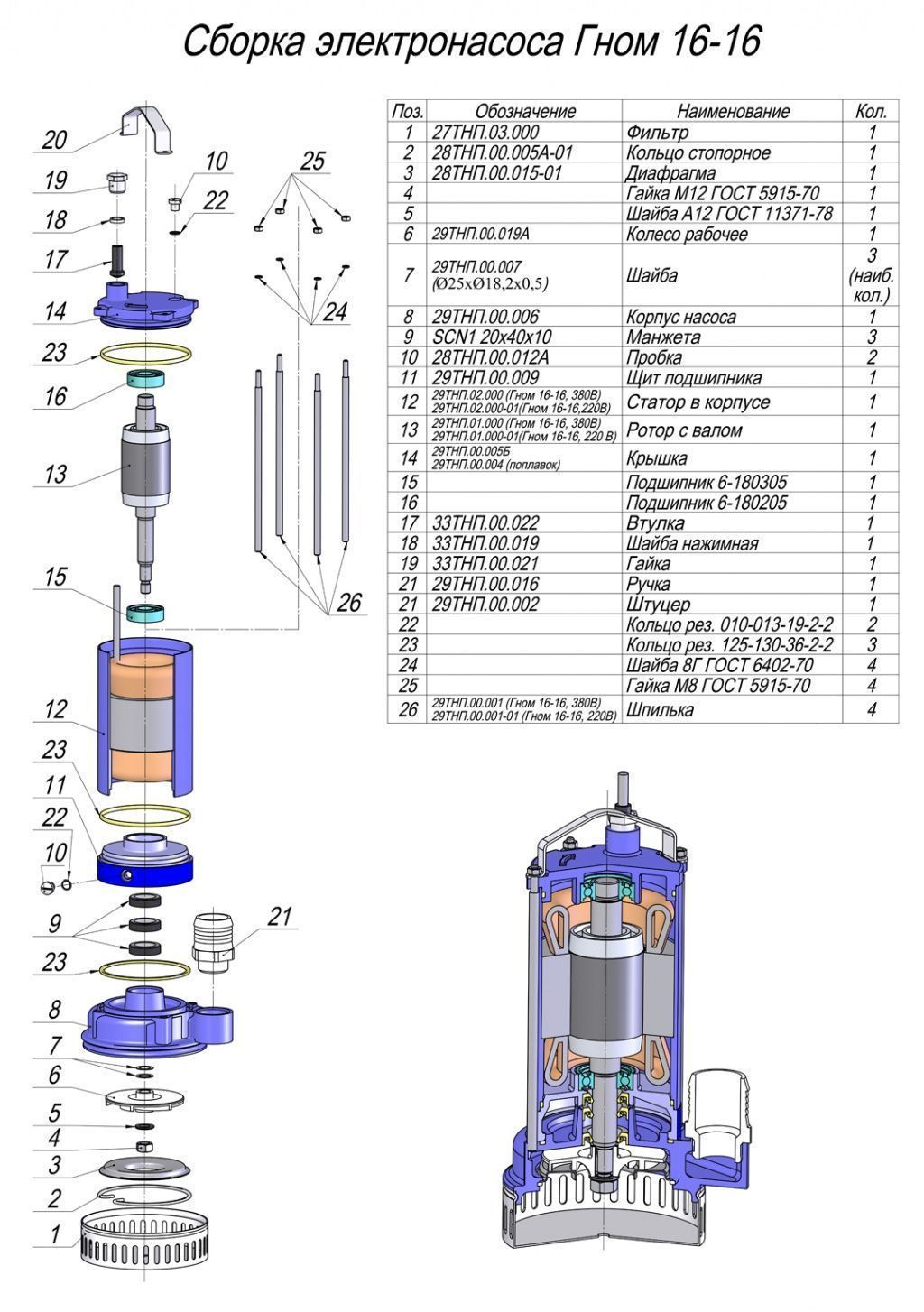

- The Gnome modification electric pump with the designation 16-16 is a model with a head of 16 m and a capacity of 16 m³ / h. There are three variations of this unit with a capacity of 1.1; 1.5 and 2.2 kW.

- Gnome submersible pumping equipment marked 25-20 creates a water pressure of 20 m and has a capacity of 25 m³ / h. The unit is available in three different capacities 2.2; 3 and 4 kW. In this series, you can purchase a model that pumps hot liquids.

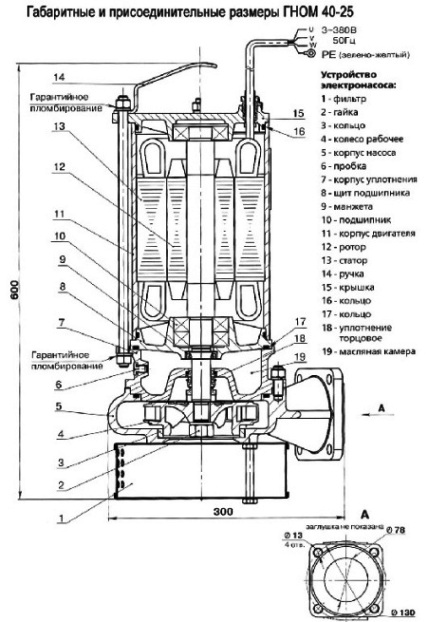

Also, the category of mud pumps should include models with markings from 40-25 to 600-10. Some of these modifications are equipped with control stations. Usually the prices for such devices are 1.5 times higher than for traditional mud models.

explosion-proof

This is not such an extensive series. It has only 10 modifications of Gnome pumps. For domestic needs, this unit is unlikely to be useful, but for industrial and manufacturing enterprises it is simply irreplaceable. To distinguish explosion-proof models from ordinary ones, you should look at the markings. It must contain the letters EX.

The model range of this series includes some of the above models only in a protected hermetic case and with increased power. Three of them are designed to work in a hot environment.

The cost of such models in comparison with traditional mud units increases several times. Therefore, the choice of this pump should be made only if it is appropriate to use it.

High pressure

The category of high-pressure pumping devices includes only seven Gnome modifications. For domestic needs, such pumps are not suitable, because they have very powerful characteristics. As for the parameters of these units, they are as follows:

- The high-pressure unit Gnome 50-80 has a capacity of 50 m³ / h, a maximum head of 80 m. The power of such pumping equipment is 30 kW.

- The Gnome 60-100 pump has a capacity of 60 m³ / h and a maximum head of 100 m. Its power is 45 kW.

- The Gnome 80-70 unit is a high-pressure pump with a power of 35 kW, a capacity of 80 m³ / h and an allowable head of 70 m.

- Pumps with a power of 45 kW are devices marked 160-40, 140-50, 100-80. Their performance and pressure can be judged by the digital designation.

- The unit with a capacity of 40 kW is a high-pressure pump Gnome 110-60.

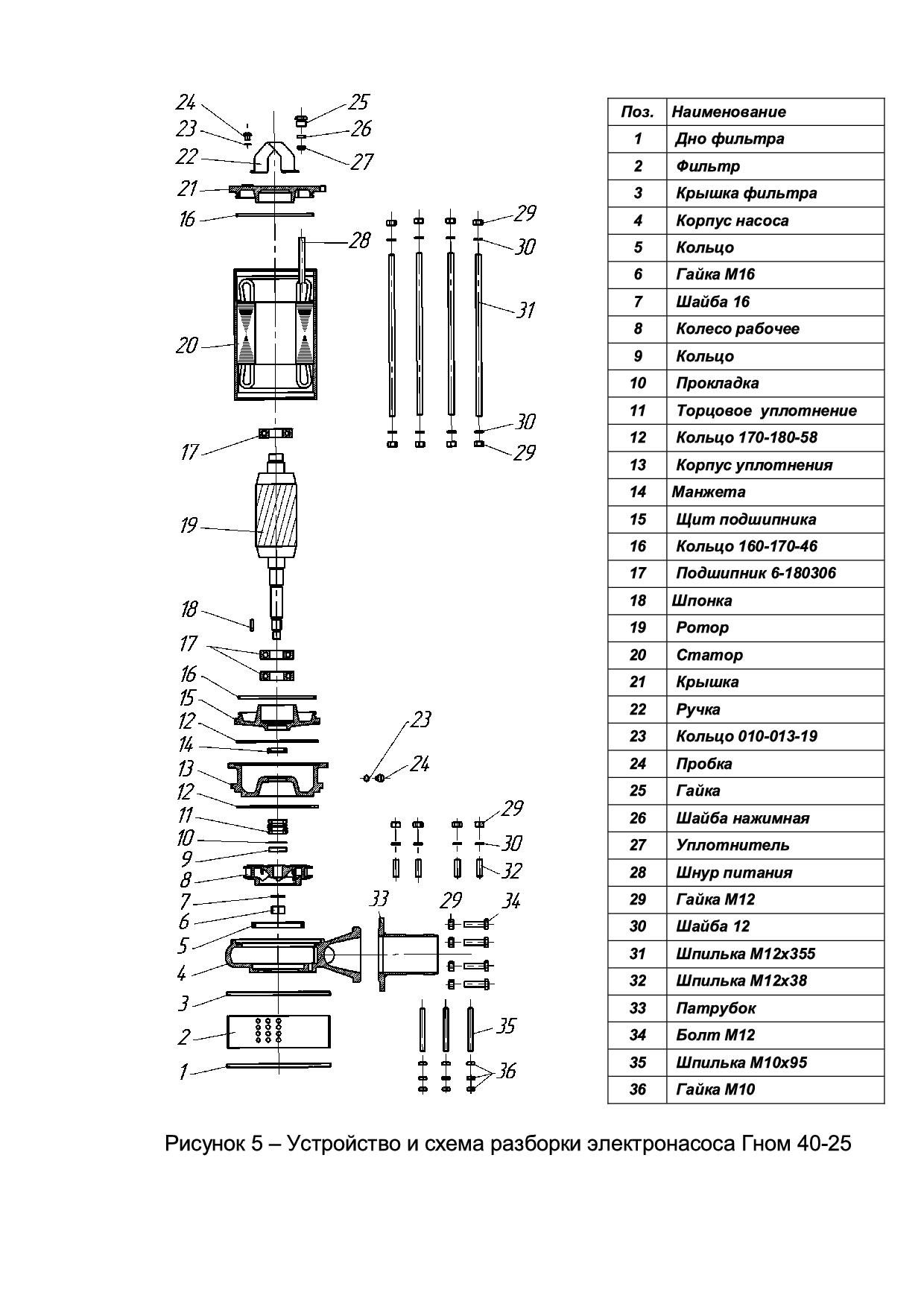

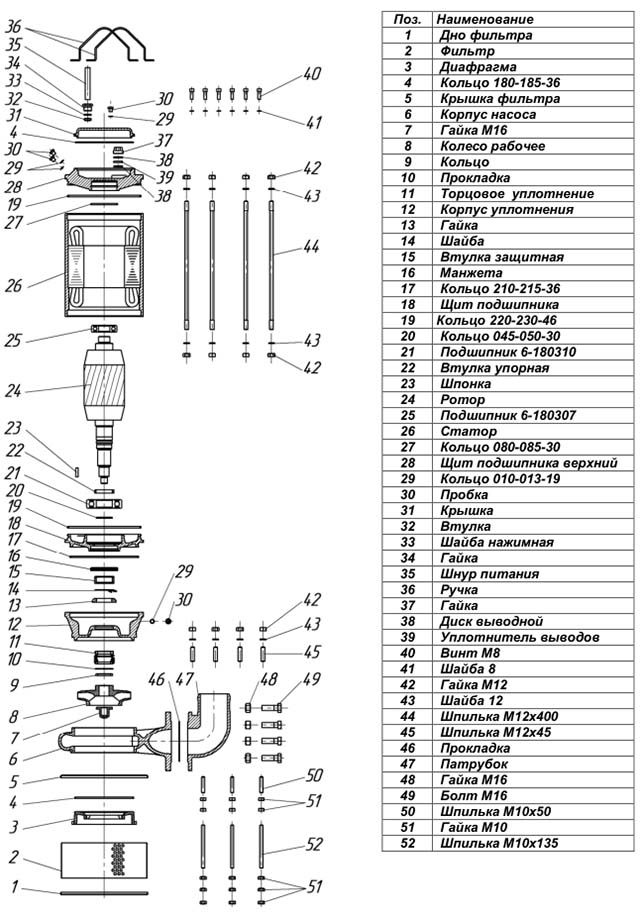

Repair of pump parts “Gnome”

Having considered the causes of malfunctions of pumps of the Gnom brand, you can see that almost all problems are solved by replacing the following parts: bearings, impeller, impeller shaft. Also, some malfunctions are eliminated after adjusting the gap between the impeller and the diaphragm.

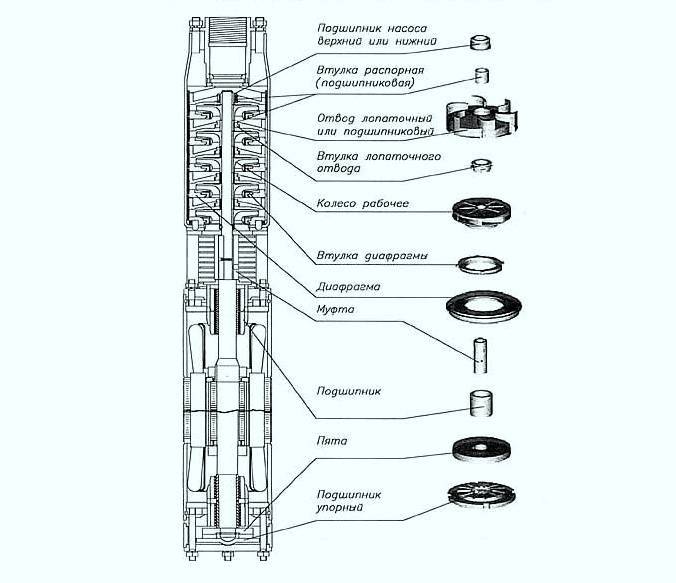

Bearing replacement sequence

If the bearings are worn, the pump may pump water, but make unusual sounds due to friction and swaying of worn bearings. Bearings must be changed if there are gaps of more than 0.1-0.3 mm. This usually happens after 3-6 years of operation of the Gnome electric pump.

The process of replacing bearings is very simple: the pump is disassembled, the bearings are removed and replaced with new ones taken from a special repair kit. Do not use self-made similarity of bearings or from analogues from repair kits of other modifications, because. this can again disable the equipment in the very near future.

Impeller replacement

To replace the impeller, it is necessary to disassemble the Gnome electric pump and remove the impeller. Then install a new impeller and assemble the pump in reverse order. When installing a cover with a setting-moving disk, it is necessary to screw the fasteners onto the studs and tighten them simultaneously until the minimum clearance between the impeller blades and the cover with the disk is reached.

After assembly, it is required to check for tightness and, if it is broken, then refuse to use a permanently damaged electric pump.

In some cases, with experience and appropriate equipment, it is possible not to produce impeller replacement to a new one, and try to fix the existing ring workings with the help of surfacing, followed by processing it on a lathe.

Impeller defects in stainless steel or cast iron can be corrected by electrode welding followed by turning of the welding spot on a lathe

Repair of impeller shaft and casing

If the working shaft is damaged (bent, cracked), it is best to replace it completely. The body of the "Gnomes" is theoretically repairable, but in practice it is almost impossible to carry it out correctly.

In nine out of ten cases, the tightness of the case will be broken, and this defect can only be corrected at the factory or at a service center.

Given that such breakdowns are found in pumps that have worked for a long time, and therefore not subject to warranty service, it is necessary to think about the feasibility of repair. In most cases, it is faster, cheaper and easier to purchase a new submersible pump.

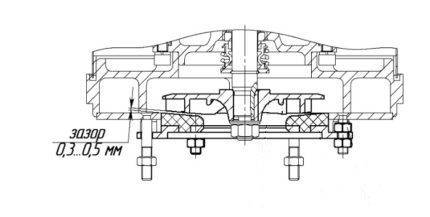

Adjustment of the gap between the impeller and the diaphragm

The main reason for the decrease in pressure and performance of the Gnome electric pump is the increase in the gap between the impeller and the diaphragm during operation. To reduce the gap, you need to adjust it.

To do this, remove the bottom of the filter and unscrew the top nut. Then tighten the parts of the diaphragm with nuts located on different sides until it comes into contact with the impeller.

Then loosen the lower nuts half a turn. With this adjustment, the gap will be 0.3-0.5 mm. The adjusted location of the diaphragm relative to the impeller is fixed with the upper nuts. After completing the adjustment, it is necessary to check the ease of rotation of the impeller, it should rotate without any effort.

Adjustment of the gap between the diaphragm and the impeller is necessary after repair work related to the disassembly of the pump "Gnome"

Repair of the electric motor of the pump "Gnome"

Gnome brand pumps are equipped with a reliable asynchronous electric motor. It is very difficult to repair an electric motor on your own. The maximum that can be done without special stands is to determine the resistance of the motor windings using a household multimeter.

If the resistance indicator tends to infinity, then this indicates that the winding is damaged and needs to be replaced. To replace the winding, a complex disassembly of the electric motor and the presence of a rewinding machine will be required.

But the main difficulty lies in the assembly process - the unit must be assembled in such a way as to provide an impeccable barrier against water penetration into the electric motor. That is why it is better to entrust the repair of the Gnome pump engine to professionals.

The most difficult repair of Gnome pump modifications is the restoration of engine performance. It is not worth taking on this business without skills and auxiliary equipment.

How to repair a drainage pump with your own hands

Of all the listed malfunctions of drainage pumps, only a few can be eliminated with your own hands.Really release the float (here the instructions are unlikely to be needed), remove the jammed impeller mechanical inclusions (you can not tighten the impeller, as in the video below), fix the shock absorber, repair the cable. To fix the shock absorber, you need to disassemble the body and simply tighten the nuts on the mounting bolts, locking the top one. This is the simplest of all. Repairing the cable will take time, but it's doable. In some models, it is easy to replace the capacitor.

Everything else cannot be done without craftsmen, and a torn stock is generally so difficult to fix that it is much more expedient to purchase new equipment. It will not be possible to replace the valve on your own (difficult, unprofitable) and repair the winding - you will need specialized tools. However, this does not apply to cheap Chinese pumps: either take them new or repair them yourself, since highly qualified repairs will cost more.

The pump works, but the pressure is low

The Gnome pump pumps water, but the water pressure is much lower than it was before. Possible reasons:

- Leak on the water supply line (hoses, pipes).

- Low voltage in the mains.

- Contamination of the impeller and insufficient speed of its rotation.

- Wrong direction of impeller rotation.

- Large clearance between the wheel and the movable disk.

- Impeller wear.

If the low head is not due to a low voltage in the network or a leak in the line, then the pump should be disconnected from the power supply, removed from the pumped liquid and disassembled for inspection and repair work.

When the impeller is worn, it is replaced.In case of clogging or improper installation after self-assembly, the unit should be disassembled, cleaned and the wheel installed in the correct position.

Peculiarities

The production of sediments "Gnome" is carried out in Russia. This equipment is characterized by wide functionality, wear resistance and ease of operation. Each such unit is designed to pump out both clean and contaminated liquids. As for pumping out fecal effluents, special models with individual technical characteristics are provided for this purpose.

The main advantages of pumps "Gnome" include:

- a large assortment;

- excellent quality;

- wear resistance;

- ease of repair and maintenance;

- durability;

- affordable cost.

Each pump "Gnome" is designed for full or partial immersion in liquid. These devices operate according to the centrifugal principle, are made in an elongated form with a vertically mounted type of nodes in the inner part of the body. The process of pumping liquids is carried out under the influence of centrifugal forces that occur during engine operation.

Gnome pumps have the following technical features:

- the level of productivity, depending on the type of unit, can be in the range of 7-600 m3 / h;

- the permissible temperature of the liquid during pumping can reach +60 degrees;

- the concentration of impurities can be up to 10%;

- the pressure of the pumped liquid is at the level of 7-25 m;

- the power of the mechanism for each instance is individual, its maximum indicator is 11 kW;

- the mass of devices is within 112 kg;

- the shaft and the impeller of the device are made of durable steel, and the outlet is made of high-quality plastic.

The manufacturer claims that all these features make it possible to use Gnome pumps to solve a variety of tasks both in domestic conditions and in large enterprises.

Basically, they are used for such purposes as:

- drainage of basements flooded during the flood;

- drainage of pits;

- pumping liquid in factories and enterprises;

- irrigation in the rural sector;

- pumping out wastewater from various systems and electrical engineering;

- neutralization of the consequences of accidents.

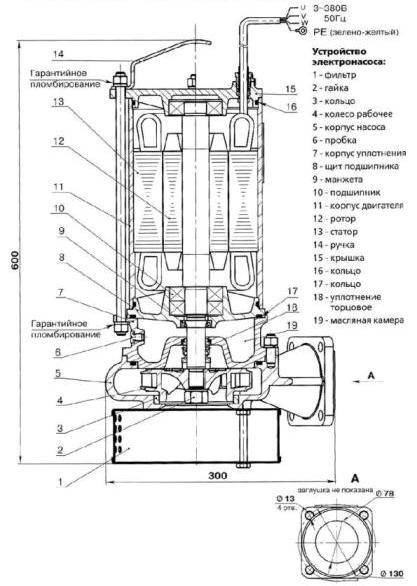

The design of the pumps "Gnome" is made of two parts - the pumping and motor sections, which are harmoniously combined into one block. The engine is cooled directly when pumping liquid, and its tightness on the shaft is ensured by an end seal. Oil is poured inside, which cools and lubricates the bearings of the device, ensuring their full working condition.

It must be remembered that immediately before turning on the unit must be in the liquid at a level of at least 50 cm. After starting the device, the pumped liquid is sucked through an additional mesh into the housing, from where it is pushed out of the pump room under pressure.

The engine is running but the pump is not pumping water

The engine of the pump "Gnome" works, but at the same time it does not pump water. The sound of a running engine may be weaker, uneven. Possible reasons:

- Clogged filter screen or outlet pipe.

- The engine is running with insufficient power.

- Bearing wear and reduced motor speed.

- The pumped liquid is missing or has become too viscous and dense.

- Damage to the water supply line (pipes, hoses).

In this case, you need to make sure that there is no damage to pipes and hoses, there is water in the water source. If everything is in order, then it is necessary to disconnect the equipment from the mains and inspect the inlet filter and outlet pipe. If necessary, clean them and try to start the pump. If the bearings are worn, they will need to be replaced (see below).

Pros and cons

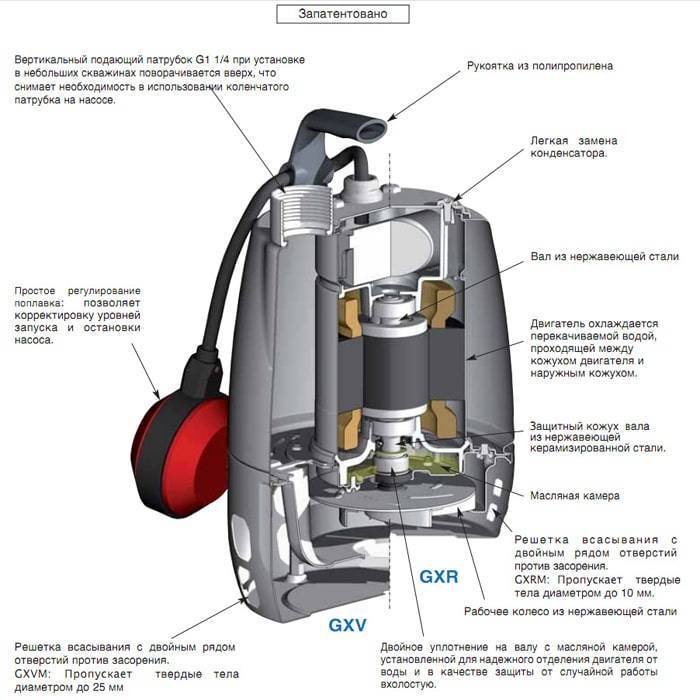

The device of a typical drainage pump

The ability to pump water with fine gravel, large inclusions of sand, organic residues is a very useful quality when you need to pump out water after flooding or drain a pond. Drainage units are designed to work in such conditions, but exceeding the load often leads to breakdowns.

It is better to get acquainted with the internal content of the device immediately after purchase in order to imagine what parts can fail in the event of clogging or breakage. To do this, it is not necessary to open the case or disassemble it - just study the diagram that is attached to the instructions for connecting and servicing the device.

Devices for private use in summer cottages do not differ in high power or complex filling. Unlike heavy industrial equipment, they are compact, relatively light (average weight - 3-7 kg), consist of steel or plastic parts, although cast iron is still used for the production of industrial models and some household ones.

The main components of the submersible mechanism are a pumping unit that pumps water and an electric motor that rotates a shaft with blades. The motor is housed inside a robust case, which is made of stainless steel or reinforced polypropylene and is double.Water circulates between the outer and inner walls, preventing cooling.

Modern models are equipped with thermal protection that is triggered when the device is overloaded. An impeller is attached to the axial shaft - a screw device that supplies liquid into the housing. When the unit is turned on, the impeller begins to rotate, taking in water from the outside and pushing it along the walls to the outlet. The first portion of water is replaced by the next one - and so on until the mechanism stops.

The float switch regulates the frequency of operation. It monitors the liquid level in a tank or natural reservoir, and when it drops sharply, it turns off the device automatically.

As you can see, the drainage pump device is quite simple, and if you have ever disassembled and cleaned a submersible well pump, then you can handle this category of equipment. The fecal aggregate is slightly different, having an additional unit for crushing too large particles.

Rules for disassembling the unit

The design of the Gnome pump is very simple, and the body is quick-release, which allows it to be disassembled without any problems. This does not require special tools. Dismantling begins with detaching the three nuts of the receiving mesh-filter and removing the mesh itself. Then the cover fastening nuts are unscrewed, and it is removed together with the installation-movable disk. The impeller nut is unscrewed, after which the impeller is freely removed.

All parts should be dismantled carefully, without applying excessive force.Symmetrical parts must be numbered and marked (left/right, top/bottom) in order to avoid their incorrect reverse installation during assembly. During the assembly process, it is recommended to replace rubber parts with new ones using repair kits designed for this model.

During the assembly process, it is recommended to replace rubber parts with new ones using repair kits designed for this model.

During long-term operation of the Gnome pump, problems may arise with unscrewing the nuts on the housing, because. they are rusted or covered with a layer of lime sediment. In this case, the nuts can be cut off with a grinder, and when assembling, use new ones that are suitable in shape and size.

When assembling the pump, it is necessary to pay special attention to the seat of the replaced parts, they should not hang out, shrink, their size must strictly correspond to the brand of the pump

Bearing replacement sequence

If the bearings are worn, the pump may pump water, but make unusual sounds due to friction and swaying of worn bearings. Bearings must be changed if there are gaps of more than 0.1-0.3 mm. This usually happens after 3-6 years of operation of the Gnome electric pump.

The process of replacing bearings is very simple: the pump is disassembled, the bearings are removed and replaced with new ones taken from a special repair kit. Do not use self-made similarity of bearings or from analogues from repair kits of other modifications, because. this can again disable the equipment in the very near future.

1 Applications

Gnome drainage pumps are ideal for pumping dirty water with a small, which is very important, content of foreign matter.Moreover, this type of pump can also be used for pumping clean water.

Like any other submersible pump, Gnome pumps are used in a wide range of industries. Most often, a fecal submersible pump is used to clean or pump water from the following sources:

- Industrial water;

- Domestic water from wastewater (with the exception of fecal);

- Ground water, usually from construction trenches or, more rarely, from pits;

- Waters of heavily polluted or marshy reservoirs.

At the same time, the Gnome brand submersible pump is used in the following areas:

- Communal economy. In cases of a pre-accident or emergency flood, pumps of this type are used as a fecal cleaner, for pumping contaminated water from various basements;

- Metropolitan, for pumping fluid in pits or trenches;

- The submersible drainage type pump has proven itself in industrial and civil construction. With it, you can pump out flood waters from pits. In addition, the pump does an excellent job with groundwater;

- In agriculture for land reclamation;

- ONE HUNDRED. The fecal drainage pump Gnome is used at service stations to drain wastewater from various equipment when washing cars;

- The submersible drainage apparatus is used, ultimately, in industrial enterprises. It is necessary in production processes and for the organization of drainage-type treatment facilities.

Drainage pumps Gnome with cable

1.1 General characteristics and features

The technical characteristics of Gnom pumps allow them to work in a liquid medium at temperatures between 0 and +95 degrees Celsius. The permissible pH range is 5 - 10 pH.During the operation of pumps of this type, the content of impurities is not more than ten percent, and the size of impurities, as well as particles with inclusions, should not exceed 5 millimeters.

Considering that the Gnom submersible drainage pump is distinguished by a reliable design and excellent strength of the housing mechanism, while having excellent technical characteristics, this type of pump can be used in difficult and aggressive conditions. In addition, pumps of this type also have the following advantages:

- Easy to remove and clean filter;

- Easy repair. However, given the rugged design of the device, it is rarely necessary to repair it. Moreover, repair is usually required when the pump parts are completely worn out, where repair, as such, is no longer possible and a complete replacement of the part is needed;

- The submersible drainage pump has a long period of maintenance-free operation;

- High-quality materials from which the device is made, and high wear resistance of the device allow it to work in more than aggressive environmental conditions without "whims" for repairs;

- Huge work efficiency;

- Ease of installation and subsequent operation along with maintenance;

- The design of Gnome-type pumping systems allows the simultaneous use of several devices at once. This allows you to perform work more efficiently and, if necessary, carry out repairs right during the operation of the pump.

Pumps Gnome: some technical characteristics

For more detailed information regarding a particular Gnome pump model, it is recommended to refer to the technical specifications. But here are some average values that you can focus on when choosing a pump:

- The temperature of the pumped liquid can be up to plus 60 degrees Celsius. These are the so-called "hot" pumps. Ordinary ones will feel comfortable at a liquid temperature of 35 degrees above zero. Otherwise, rapid overheating of the motor is inevitable;

- You can connect the pump to a regular household network of 220 volts. There are models that can operate at an industrial voltage of 380 volts;

- The performance of the pump depends on the specific model. The manufacturer's assortment includes models that can provide productivity from 7 to 600 cubic meters of water per hour;

- There are models that can provide a pressure of the supplied fluid from 5 to 25 meters;

- As a rule, household models of Gnome pumps have a power of 600 watts. Industrial pumps will be able to show a power of 11,000 watts;

- The mass of the pump can be from 10 to 115 kilograms.

The equipment is available with different types of motor, the pump housing is made of plastic, cast iron or steel, and the impellers and motor casing are made of cast iron.

Such a range of characteristics allows the consumer to choose exactly the model submersible pump Gnome, which will be the best option for solving his particular range of tasks.

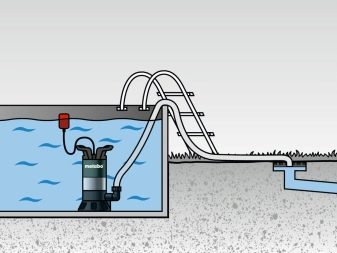

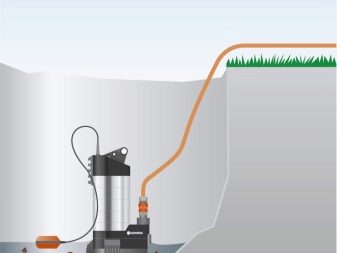

Submersible or semi-submersible

Gnome drainage pumps can be operated in two modes: fully submersible and semi-submersible. As you can guess from the names of these modes, in the first case, the pump housing is completely immersed in the liquid, and in the second - only partially. But it must be taken into account that if it is planned to operate the pump in a semi-submersible state, then a special cooling jacket should be provided on it structurally. Of course, even without it in semi-submersible mode, the pump will last for some time.But then its service life will be significantly reduced.

All Gnome submersible pumps have a sealed housing that prevents even accidental ingress of moisture inside. That is why these pumps are used when it is necessary to pump oil or other combustible substances.

The figure shows a schematic arrangement of submersible and semi-submersible pumps.