- External and internal sides

- Main characteristics

- The main malfunctions of submersible pumps

- The pump is not working

- The pump works but does not pump

- Low machine performance

- Frequent switching on and off of the device

- The buzz of the machine is heard, but the water does not pump

- Water is supplied with pulsation

- The unit does not turn off

- Video on installation and start-up of the Agidel pump

- Launch preparation

- Weak water supply

- Agidel pump repair video

- Trademark "Agidel": brand history, product overview

- Pump Agidel M

- Pump Agidel 10

- Features of Agidel pumps

- Construction device

- Fundamentals of pump operation

- Rules for the use of pumps

- Pros and cons of Agidel models

- Advantages and disadvantages of pumps

External and internal sides

When buying a pump, be sure to pay attention to its technical characteristics. They are indicated in the passport and on the packaging. Agidel quality pump 10 or m must be sold in a package with the address of the manufacturer (Bashkiria, g

Ufa), contact numbers that will help you contact the manufacturers in case of any problems, if, for example, you need to perform certain manipulations with the pump or when you need to repair the Agidel pump

A high-quality pump Agidel 10 or m is necessarily sold in a package that contains the address of the manufacturer (Bashkiria, Ufa), contact numbers that will help you contact the manufacturers in case of any problems, if, for example, you need to produce certain other manipulations with the pump or when repair of the Agidel pump is required.

As for the technical characteristics, they are basically universal for pumps of this class, whether it is an agidel m or some other form of pump. Its power is 370 W, the mains voltage is 220 V. The water intake level is 2.9 cubic meters per hour, the pressure is 22 liters.

Speaking about the external characteristics of the pump, it should be noted that it has retained its data since the time when the first such pump was created, which is about 40 years ago. Complete with it are immediately all the necessary components for water intake - nipples and valves.

The color of the Agidel 10 pump remains unchanged for the same huge amount of time, it is represented by a bright brown color, it also has brown, but slightly darker in tone, caps.

As for the type of this technical device, it is a surface vertical centrifugal pump. Its body is aluminum, all materials for parts (both internal and external) are produced exclusively in Russia. Its cap is made of polypropylene, and the inner winding is made of copper wire with a diameter of 5 mm.

Past tests show that this pumping device can operate without interruption for 5-6 hours without shutting down. In order to make it more convenient and safer to work, the pump is equipped with a special thermal fuse.This is necessary so that if a strong overheating suddenly occurs during operation, the pump will automatically turn off. Further, after the device cools down, its operation will continue. An additional advantage of choosing the Agidel pump is that its warranty period is quite significant, it is 30 months.

Main characteristics

Compact device operating on the centrifugal principle. It is placed on the surface in a vertical position. The model without an ejector is designed to lift water from wells up to seven meters deep. And if you use an ejector with this unit, the efficiency of the pump will double, and the owners will be able to receive water from a depth of up to 15 meters.

The movement of water is provided when the electric motor is turned on by rotating the shaft with blades located on the axial sleeve. The liquid inside the pumping chamber is displaced into the pipeline under the influence of centrifugal force. And in the center of the impeller there is a zone of low pressure, which ensures a continuous flow of water from the well through the intake hose.

- a pressure of 20 meters is created;

- productivity - 2.9 cubic meters per hour;

- power - 370 watts.

Advantages:

Advantages:

- low price;

- the possibility of application at a sufficient depth when using an ejector;

- ease of maintenance and operation;

- high reliability;

- low power consumption.

the unit is afraid of dry running (it is necessary to fill in water at the beginning of operation).

The average price is from 4,500 rubles.

This is a more powerful and overall model of a self-priming vortex type. It is placed on the surface in a horizontal position. The main advantage of the unit is the possibility of a “dry start”.That is, at the first start-up, the pump does not need to be filled with water.

Turning on the pump starts the rotation of the impeller (impeller), which creates a vacuum and causes air to be sucked in. The water in the housing is mixed with air. The movement of water and air creates a vacuum zone, which ensures the suction of liquid through the intake hose. The remaining air is removed through a special technical opening. Further, the unit functions as a standard centrifugal pump, the operation of which was described above.

Turning on the pump starts the rotation of the impeller (impeller), which creates a vacuum and causes air to be sucked in. The water in the housing is mixed with air. The movement of water and air creates a vacuum zone, which ensures the suction of liquid through the intake hose. The remaining air is removed through a special technical opening. Further, the unit functions as a standard centrifugal pump, the operation of which was described above.

- pressure up to 30 meters;

- productivity - 3.3 cubic meters per hour;

- power - 700 watts.

- budget cost;

- long service life;

- the unit is not afraid of dry running;

- ease of maintenance;

- reliability.

- can not be used at a depth of more than seven meters;

- relatively high power consumption.

The price is from 6,000 to 7,500 rubles.

If we compare the technical data, it becomes clear that the second pump has better performance and is able to create more pressure. The main advantage of the first type model is low power consumption (370 watts) and light weight. It is allowed to use an ejector with it, which is important for owners of wells and wells fifteen meters deep. If power is not the main choice for owners when buying a pump, you can safely purchase a more economical and compact model. In terms of build quality and service life, the units are no different.

If we compare the technical data, it becomes clear that the second pump has better performance and is able to create more pressure. The main advantage of the first type model is low power consumption (370 watts) and light weight. It is allowed to use an ejector with it, which is important for owners of wells and wells fifteen meters deep. If power is not the main choice for owners when buying a pump, you can safely purchase a more economical and compact model. In terms of build quality and service life, the units are no different.

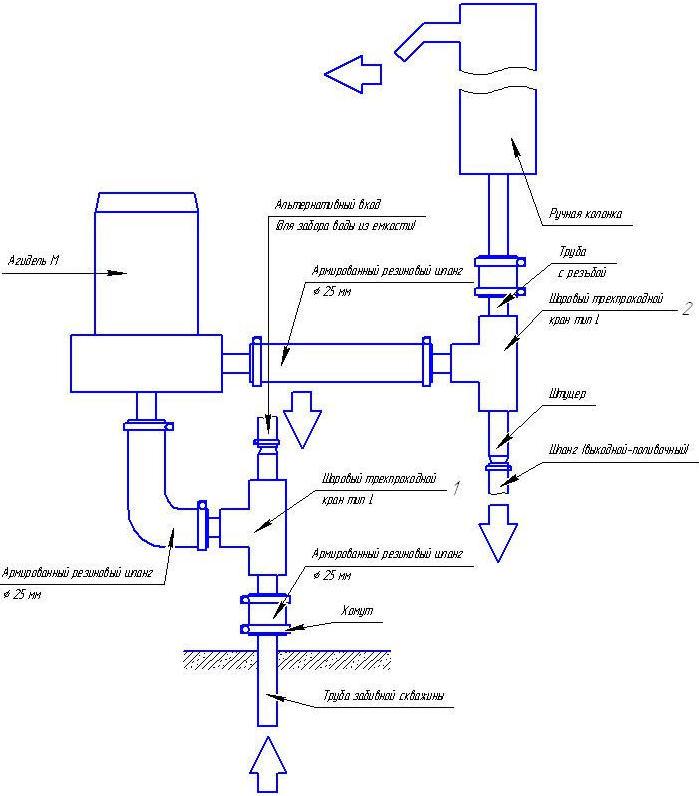

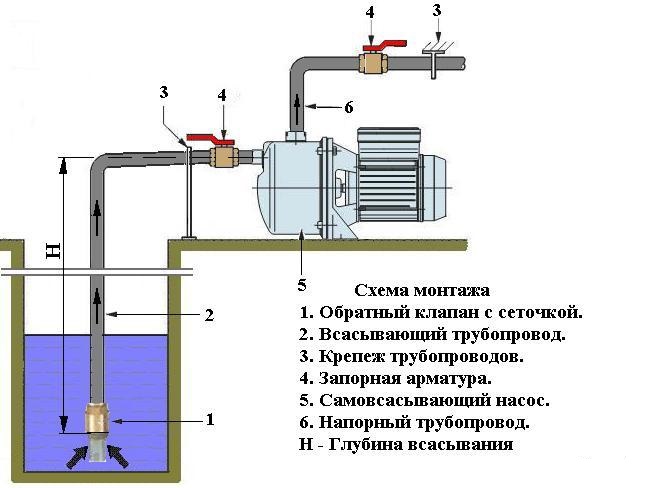

When installing pumps of this brand, three main parameters should be followed:

- positive operating temperature;

- as close as possible to the source of water;

- flat mounting surface.

Obviously, the ideal solution would be to equip an insulated caisson chamber with a flat bottom. In such conditions, the equipment will be able to work even in the winter cold. A close location to a well or well is required due to the sensitivity of the equipment to depth - this is an indicator from 7 to 15 meters, depending on the model and the presence of an ejector.

Obviously, the ideal solution would be to equip an insulated caisson chamber with a flat bottom. In such conditions, the equipment will be able to work even in the winter cold. A close location to a well or well is required due to the sensitivity of the equipment to depth - this is an indicator from 7 to 15 meters, depending on the model and the presence of an ejector.

It is allowed to install directly on the head of the well or the cover of the well (this is a good solution for summer use). The caisson is set up five or ten meters from the house below the freezing point of the soil.

A good solution would be to mount it on a special raft, which is then lowered into the well. But in this case, there will be a problem with connecting the electrical cable. It needs to be extended and waterproofed. The standard cable length is 1.5 meters.

Experts recommend using Agidel-10 for installation in a caisson or mounting on a raft for year-round use. And for seasonal use, Agidel-M should be used - a unit that requires adding water before starting and is extremely sensitive to low air temperatures. It can be installed on a flat surface near the well or attached to a special bracket at the head of the well.

For the winter, the pump is dismantled, dried and stored in a warm room for storage.

The main malfunctions of submersible pumps

If failures are noticed in the operation of a submersible pump, then it is not always necessary to remove it from the well for inspection. This recommendation applies only to pumping stations in which a pressure switch is installed. It is because of him that the device may not turn on, turn off or create poor water pressure.Therefore, the operability of the pressure sensor is first checked, and after that, if necessary, the pump is removed from the well.

Water pump malfunctions will be easier to diagnose if you first familiarize yourself with the most common failures of this unit.

The pump is not working

The reasons that the pump does not work may be as follows.

- The electrical protection has tripped. In this case, disconnect the machine from the mains and turn on the machine again. If it knocks it out again, then the problem should not be sought in the pumping equipment. But when the machine is turned on normally, do not turn on the pump anymore, you must first find the reason why the protection worked.

- The fuses have blown. If, after replacement, they burn out again, then you need to look for the cause in the power cable of the unit or in the place where it is connected to the mains.

- An underwater cable has been damaged. Remove the device and check the cord.

- The pump dry-run protection has tripped. Before starting the machine, make sure that it is immersed in the liquid to the required depth.

Also, the reason that the device does not turn on may lie in the incorrect operation of the pressure switch installed in the pumping station. The start pressure of the pump motor needs to be adjusted.

The pump works but does not pump

There may also be several reasons why the device does not pump water.

- Stop valve closed. Turn off the machine and slowly open the tap. In the future, pumping equipment should not be started with the valve closed, otherwise it will fail.

- The water level in the well has dropped below the pump. It is necessary to calculate the dynamic water level and immerse the device to the required depth.

- Check valve stuck. In this case, it is required to disassemble the valve and clean it, if necessary, replace it with a new one.

- The intake filter is clogged. To clean the filter, the hydraulic machine is removed and the filter mesh is cleaned and washed.

Low machine performance

Also, performance degradation causes:

- partial clogging of valves and valves installed in the water supply system;

- partially clogged lifting pipe of the apparatus;

- pipeline depressurization;

- incorrect adjustment of the pressure switch (applies to pumping stations).

Frequent switching on and off of the device

This problem occurs if the submersible pump is paired with a hydraulic accumulator. In this case, frequent starts and stops of the unit can be provoked by the following factors:

- in the hydraulic tank there was a decrease in pressure below the minimum (by default it should be 1.5 bar);

- there was a rupture of a rubber pear or diaphragm in the tank;

- the pressure switch is not working properly.

The buzz of the machine is heard, but the water does not pump

If the pump is buzzing, and at the same time water is not pumped out of the well, then there may be several reasons:

- there was a “gluing” of the impeller of the apparatus with its body due to long-term storage of the device without water;

- defective engine start capacitor;

- dipped voltage in the network;

- the impeller of the pump has jammed due to dirt collected in the body of the apparatus.

Water is supplied with pulsation

If you notice that the water from the tap does not flow in a constant stream, then this is a sign of a decrease in the water level in the well below the dynamic one. It is necessary to lower the pump deeper if the distance to the bottom of the shaft allows this.

The unit does not turn off

If the automation does not work, the pump will work without stopping, even if excessive pressure is created in the hydraulic tank (seen from the pressure gauge). The fault is the pressure switch, which is out of order or incorrectly adjusted.

Video on installation and start-up of the Agidel pump

Many owners manage to hide pumps inside wells by constructing a raft from a material that is not subject to corrosion. This downhole installation method allows the use of a short suction hose and eliminates the need to constantly monitor the water level. But this will have to increase the length of the electrical cord. Since the pump has a 1.5 meter cord, it is best to install a cord of sufficient length and route it in such a way as to prevent accidental damage.

Before starting installation work, carefully read the instructions in order to take into account all the requirements and recommendations to ensure long and reliable operation of the unit.

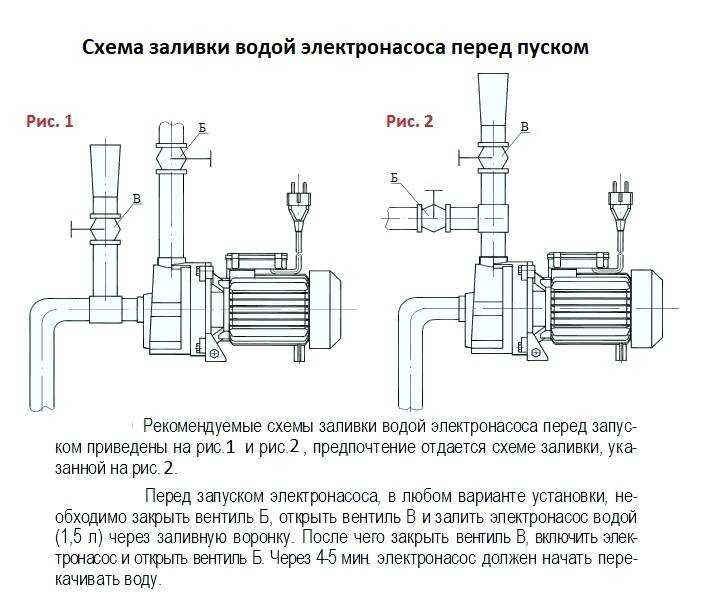

Launch preparation

Model 10 does not require pre-priming of the system. It has enough power to create a vacuum in the supply pipe. When you first turn on the water will not rise through the pipe immediately. After all, Agidel 10 is a self-priming pump and therefore you should wait 3-5 minutes for the system to fill up and water pressure to appear.

Model Agidel M requires pre-filling with water before starting. This must be remembered. Otherwise, there is a risk of damaging the mechanism. Consider the method of filling the unit installed on the manual column:

- The pump tap opens;

- The outlet hose is lowered into a container filled with water;

- We pump water with a column in manual mode to create a vacuum in the well. The liquid from the tank begins to move towards the well, causing the pump impeller to rotate;

- We continue to pump until the water flows out of the column, and we start the unit.

If the pump is installed near a tank or reservoir, then you just need to pour water into the supply hose until it flows from the supply line. Then quickly lower the inlet pipe into the water and turn on the unit.

Weak water supply

One of the main reasons for poor water supply is the quality characteristics of the intake hose. The fact is that a sufficiently powerful vacuum is created inside the hose, which is capable of compressing the walls of the hose. In this case, either a metal or plastic pipe should be used. You can use a special reinforced hose.

The other most common cause of low head is worn or damaged oil seals. In this case, they will need to be replaced. Fortunately, the manufacturer took care of this. Each pump is accompanied by detailed instructions that describe the repair and technical characteristics of the unit.

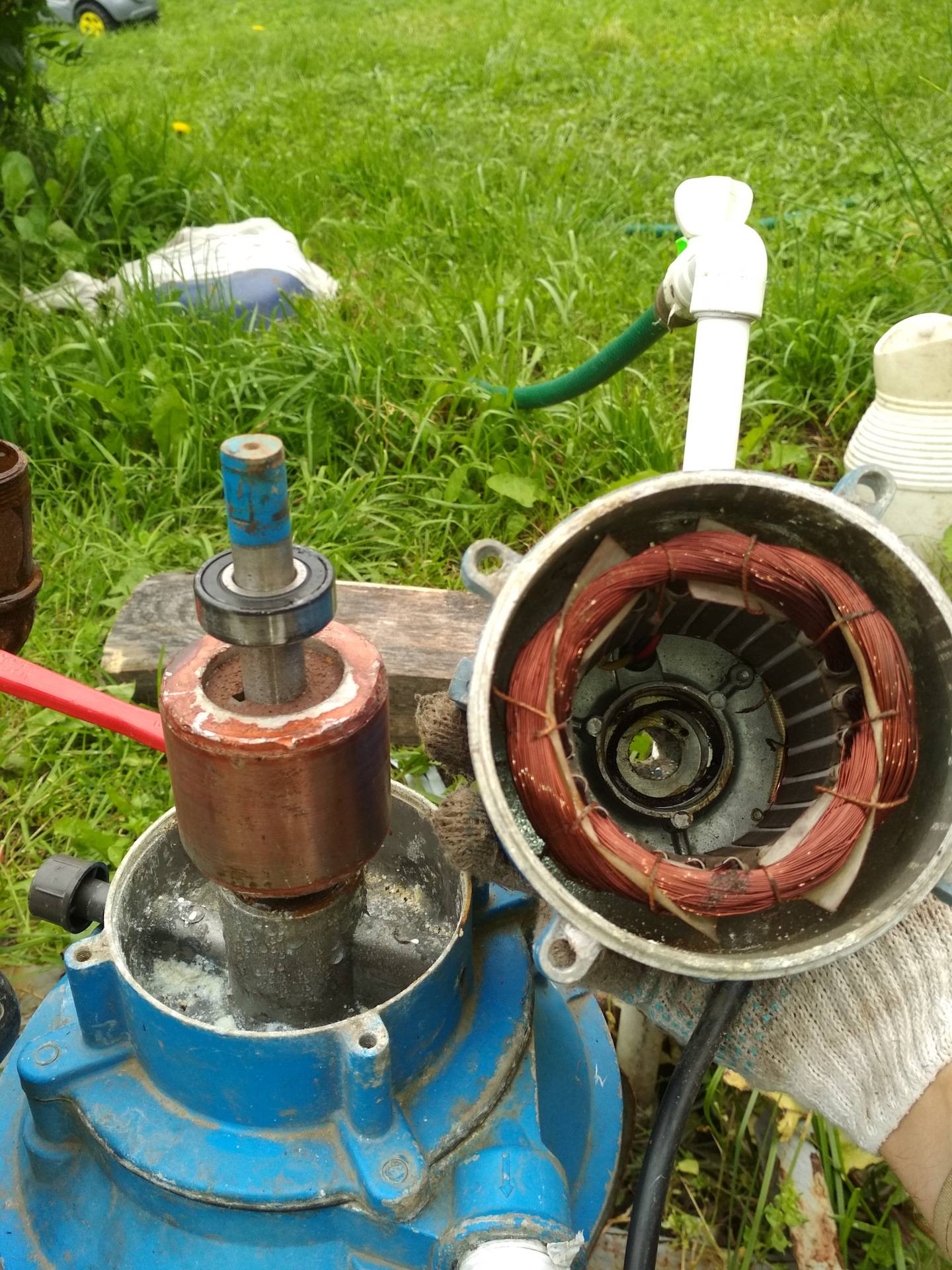

Agidel pump repair video

Procedure for replacing oil seals:

- The upper part of the protective casing of the pump is dismantled;

- The sealing gasket and the injection volute are removed;

- The impeller nut is loosened in order to gain access to the pump armature;

- The armature axis is carefully knocked out of the impeller through a bronze or brass gasket;

- The stuffing box and (if necessary) the sealing gasket is changed;

- Assembly takes place in the reverse order.

The performance of the pump, as a centrifugal unit, depends to a greater extent on the resistance of the pipe system and the height to which water is supposed to be supplied. Therefore, when choosing a pump model for a well or for a reservoir, one should take into account the conditions in which the unit will operate. If you have to work at the maximum, then the performance, of course, will differ from the parameters specified by the manufacturer. With a minimum resistance, both the pressure and the pump performance can be much higher than stated in the passport.

Trademark "Agidel": brand history, product overview

The Ufa Aggregate Production Association (UAPO) has been producing pumps of the Agidel brand since the 70s of the last century. Moreover, many owners of such products still use pumps from the first batch.

Moreover, the manufacture of components, as well as the assembly of the unit, is carried out on the basis of the production facilities of UAPO. That is, Agidel pumps are manufactured in the same workshops that produce complex units for the aviation industry or high-tech equipment for the oil and gas industry.

Agidel pump in operation

In addition, under the Agidel brand, UAPO also produces non-contact ignition systems, candles (incandescent and spark), corundum ceramics. And UAPO itself is a fairly respected brand in narrow circles that produces generators, plasma ignition systems, protected electric motors and components for gas pumping stations.

In a word, the Agidel brand is a very respected trademark founded by a well-known domestic manufacturer whose products are famous in quite specific circles (oil and gas production, aircraft manufacturing, the defense industry, and so on).

Pump Agidel M

The Agidel M device is inferior in power, but has its own characteristics:

The inlet valve of the Agidel m pump should be placed at a distance of no more than 0.35 m from the bottom of the source so that dirt and sand are not sucked in.

It is recommended to install the water pump on a hard, level ground. It is also recommended to build protection for the pump from exposure to rain and sunlight.

Also, the Agidel M system should first be filled with water. This can be done using the manual column.

Pump Agidel 10

The features of this device are as follows:

The scope of Agidel water pumps is not very wide, but sufficient to meet the basic needs:

When using an Agidel pump machine of any model, it should be remembered that the shorter the distance from the pump to the water source, the more efficient the unit will work.

General design:

Features of Agidel pumps

The Agidel water pump does not require complete immersion, it is enough to lower the suction hoses into the water. The device is safe to use because the wires are not in the water.

In the upper part of the pump on the cover there are ventilation holes through which air is exchanged. Under the cover there is a fan impeller designed to cool the electric motor.

The devices are not intended for operation in winter. But if there is no other option for supplying water, it should, if possible, be transferred to a room with a temperature above 0 ° C.You can also dig a hole, concrete it, insulate it and put a pump there.

The body and impeller are made of a special aluminum alloy, which is recommended for food contact. Despite the fact that Agidel pumps are adapted for operation in open water, it is recommended to additionally install a bottom filter. So the device will last longer.

Operating rules

Agidel water pumps should only be used at positive ambient temperatures.

The device must be grounded.

Avoid idling. Water must first be filled.

Do not touch the casing of a running pump.

Make sure that no water gets into the motor.

Do not allow the device to work with chemicals.

Troubleshooting

If the Agidel water pump is under warranty, then if a malfunction is detected, contact the supplier or the place where the device was purchased. If the warranty is over, some malfunctions can be fixed by yourself.

Leakage of water in the drain hole

With this malfunction, the seals should be replaced. To do this, you will need to perform the following steps:

Remove the casing - unscrew the 3 bolts in the upper part of the casing.

Remove the electric motor housing - unscrew 4 bolts.

Disconnect the snail, which is attached, also on 4 bolts.

Remove rubber seal.

Unscrew the impeller fastening nut.

Get the anchor axle.

Find the oil seals in the impeller, carefully remove them and replace them.

Assemble in reverse order.

Weak pressure

If the water supply is weak or intermittent, this may be due to an unsuitable water intake hose.Discharged air can form inside the rubber hoses, which compresses the walls of the hose, which prevents the flow of water. It is recommended to use a reinforced sleeve with a plastic spiral.

Attention! Beware of fakes

Due to the fact that instead of new Agidel pumps, old models or fakes are often sold, the manufacturer points out a number of features in the appearance of the device that you should pay attention to so as not to be deceived when buying:

Package. The original pump is supplied in a hard cardboard box bearing the manufacturer's information.

The color of the original device is dark orange, and the cap is brown.

Pump wire with capacitor box only.

The serial number stamped on the cover must match the number on the warranty card.

The connection bolts are hexagonal at the bottom and slotted screws at the top.

The body must be made of metal, not plastic.

Video about Agidel pump

The pump manufacturer Agidel designates the service life of its devices as 5 years and gives a 30-month warranty. In practice, if the Agidel pump has been operated properly according to the instructions, then only occasionally lubricate the parts and periodically clean the device.

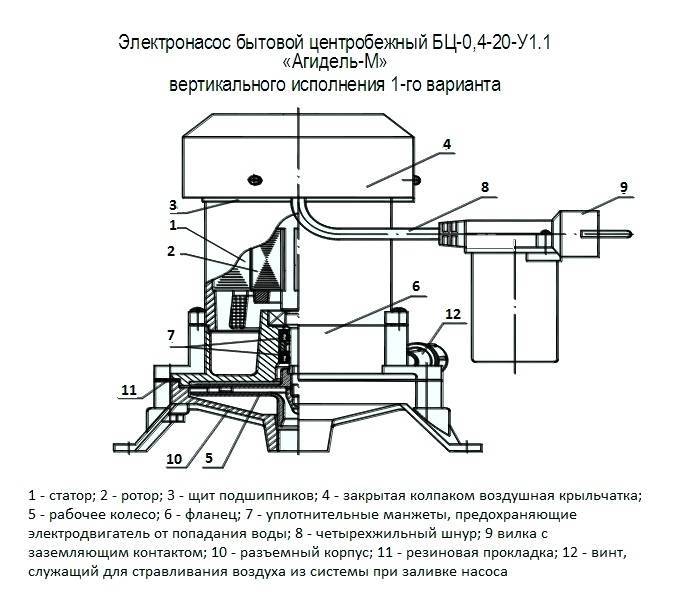

Construction device

Pumps of modification M have two parts of a design: an electric motor with a centrifugal pump. Model 10 additionally has a jet pump. With the help of it, the liquid is self-absorbed, enters the chamber using a centrifugal device.

At the heart of the electric motor device is a stator, which has a built-in thermal fuse. It protects the winding of the device from overheating.The motor also consists of a rotor with a flange and a end shield. During operation, the parts are cooled by a vane fan equipped with a hood.

Fundamentals of pump operation

The principle of operation is based on centrifugal force, which affects the flow of fluid. The force comes from the rotation of the wheel mounted inside the rotor shaft. The flange has sealing cuffs so that water does not get into the engine.

Attention! The main reason for the breakdown of Agidel devices is water that has entered the engine, so the pumps should be well sealed from water. Inside the device, water enters through the valve for receiving, acting as a filter. It prevents the penetration of large elements, pieces of rock

This valve of brand M pumps serves as a shut-off valve when water is poured into the pump before starting.

It prevents the penetration of large elements, pieces of rock. This valve of brand M pumps serves as a shut-off valve when water is poured into the pump before starting.

Inside the device, water enters through the valve for receiving, acting as a filter. It prevents the penetration of large elements, pieces of rock. This valve of the M brand pumps serves as a shut-off valve when water is poured into the pump before starting.

The flange with body connector is equipped with seals made of rubber material. Pumping equipment of modification M is equipped with a screw to release excess air. To mount the pump in a vertical position, fasteners are inserted into the prepared holes. To install horizontally on the rack, special holes are made.

Rules for the use of pumps

Attention! You can install the pump in the basement, but the pressure level of the unit will decrease because the pump will be located far from the well

Pros and cons of Agidel models

Agidel electric pumps are considered reliable devices. They are used for watering the garden, for pumping liquid for domestic purposes. Pumps have many positive properties:

1.Affordable price.

2.easy operation.

3. You can replace individual parts.

4.Low energy consumption when working.

5.The units are reliable, durable.

Among the shortcomings, they note the inability to pump water from wells over 8 meters high. Units should be mounted near wells with water.

Important! There are many Chinese fakes of Agidel pumping devices on the market. They are made of plastic, have a low level of build quality.

Advantages and disadvantages of pumps

The manufacturer has determined the service life of the pump for 5 years. It is after this period that the first replacement of the seals will be required with the correct operation of the device. Do not use devices for pumping dirty water, the impeller may get abrasive wear, and the device will lose pressure.

The advantages of Agidel pumps include:

- simple maintenance and repair;

- low price of products;

- low consumption of electrical energy;

- long service life and adaptability to unstable mains voltage.

Please note that the product in a plastic case is counterfeit.