- Mounting options for seat cover

- First aid in case of breakdowns

- The help of the online store Satoshop.ru in the repair of microlifts of toilet lids consists in the proposal to replace the old simple and not reliable cover with a microlift with a modern product - the SATO electronic bidet lid.

- Toilet closer repair

- Replacing broken bolts

- Pulling loose supports

- Elimination of other breakdowns

- The nuances of the correct painting on glass

- Innovations in plumbing: we disassemble and repair the microlift

- Seat cover replacement

- Cover selection

- What are lids made from?

- Variety of shapes and sizes

- Availability of additional functions

- Cap manufacturers

Mounting options for seat cover

The type of toilet shelf plays a fundamental role in the installation process, since the overhead copy, popularly referred to as “eared”, will require more employment and attention than a one-piece model. This is due to the need to fix the cover in the same holes where the water tank is attached. Before you attach the lid to the toilet with "ears", you need to purchase auxiliary equipment - polyethylene clamps. They will be needed to fix the bolts holding the entire structure.

Mounting brackets for toilet lid

A few tips to make the process easier:

- optimal fastening of the toilet lid is plastic or brass;

- when screwing in brass parts, it is advisable to use intermediate washers made of plastic (otherwise you can easily break the entire toilet bowl);

- you should not choose steel elements for new designs and, if possible, replace them with old toilets;

- if, after installing a new seat, the toilet shelf shifts and water begins to leak, you need to check the rubber cuff (for this you need a flashlight and looking under the rim: if the structure just squinted, it is enough to fix it with wire, and if there is a gap or dilapidated element, a complete replacement will be required).

Mounting the toilet lid

Manipulation to replace the cuff is simple, but it still takes time. First you need to shut off the water supply, then disconnect the drain tank, and then remove the cuff itself. Before installing a new part, it is advisable to thoroughly clean the attachment point from lime and plaque. And then proceed with the installation:

- the narrow part of the product is put on the toilet shelf;

- the water tank returns to its rightful place;

- the cuff is straightened and thrown over the wide part of the body bell;

- by draining the water, the reliability and absence of leaks are checked.

Mounting the toilet lid on metal fasteners

On a solid shelf, fasteners for a toilet seat are installed as easy as shelling pears: in such options, separate mounting holes and special clamps for the “clamp” are already prepared.

First aid in case of breakdowns

It is not uncommon for a toilet seat lid or seat to break.There can be a lot of reasons for this: a long service life and regular wear, careless handling of the owners, a blow with something heavy, too much load on the surface of the product (for example, if you stand up with your feet), and many other options. If there is no opportunity or desire to purchase a new model, you can try to "reanimate" the old one.

Screw on the lid tightly

Acetone or dichloroethane will help to eliminate a crack on the surface of a plastic seat: just drop a little liquid on the accident site and tightly join the edges, then let it dry thoroughly.

Damaged polypropylene or polyethylene elements are subject to fire: the fracture points must be carefully melted to a soft state, connected and allowed to cool. And then sand lightly. With care, the joints will become almost invisible.

The "eared" toilet bowls have a characteristic unpleasant feature: with an erroneous initial installation, the weight is unevenly distributed during use and for the most part there is an emphasis on the plastic structure. Sometimes it’s enough just to lean harder on the tank or carelessly touch the product with your foot so that the surface of the lid or seat bursts and the “ears” fall off. The easiest fix is to buy a new cover and install it carefully. However, you can fix everything with your own hands.

This will require:

- thoroughly clean the damaged area from dirt and plaque;

- dry thoroughly (you can resort to using a hair dryer);

- completely degrease (for example, acetone, gasoline);

- mix epoxy resin and hardener in any not too valuable container;

- gently smear the cleavage points with the resulting composition, while it is very desirable to remove the excess mixture immediately, since the composition quickly hardens and is difficult to remove;

- evenly connect the edges of the chips and press firmly against each other.

After the final hardening, you can put everything in place, while it is advisable not to forget about the cause of the damage and put up supports or correct the entire structure. Otherwise, after some time, the same problems will be revealed, but on a larger scale, which will require a complete replacement of the structure.

Plumbing, like any other technique, breaks down sooner or later. However, in most cases, it is not difficult to fix these breakdowns on your own. In this article, we will look at how to dismantle and install the seat cover.

The help of the online store Satoshop.ru in the repair of microlifts of toilet lids consists in the proposal to replace the old simple and not reliable cover with a microlift with a modern product - the SATO electronic bidet lid.

The SATO electronic bidet is multifunctional and, in addition to a very reliable microlift mechanism, allows you to transform your ordinary toilet. The bidet cover will wash you after toilet procedures, and then dry you. If necessary, it will heat the seat and make a water massage. There are types of washing for everyone: bidet - for women, general washing - for everyone, including men. Warranty for all SATO bidet models is 5 years!

Handmade owners who prefer to independently carry out all repairs in the house can seek help from the website of the online store Satoshop.ru

. We specialize in selling the products of the main manufacturer of electronic bidet covers for toilet bowls of the South Korean corporation SATO.

If you have installed plumbing equipment of this brand, there are malfunctions in the operation of microlifts, on our website you can at any time get advice from professional experienced specialists. They perfectly know all the nuances of the device of this equipment, they will give qualified advice, recommendations for repair. On our site you can purchase all the necessary parts, mechanisms for SATO devices.

We know that many consumers prefer to do without the help of specialists. A do-it-yourself video posted about repairing a micro-lift cover will allow you to understand the intricacies of this process. The site contains a detailed description of all the work that is required in regular maintenance: replacing filters, cleaning nozzles, etc. This will extend the life of the structures and ensure their flawless operation.

The functionality of plumbing is constantly growing. Another novelty is of interest - a toilet lid with a microlift.

At first glance, it seems that this is not such an important part of a plumbing fixture. But sometimes it is not always possible to hold the lid when lowering, as a result of which it falls down, causing irritation. Doing so may crack the plastic or leave scratches on the surface of the toilet. In such a situation, a cover with a microlift helps.

Toilet closer repair

In the event of a microlift breakdown, it is better to contact qualified craftsmen with the proper experience. They will help determine the cause and type of malfunction, as well as professionally make a replacement and fully restore the functionality of the “smart” system.

Work on self-repair of the built-in mechanism should be carried out with extreme caution, having thoroughly studied the instructions for the product before starting work.

This is especially true if you have to deal with a design that is equipped with several additional functions at once.

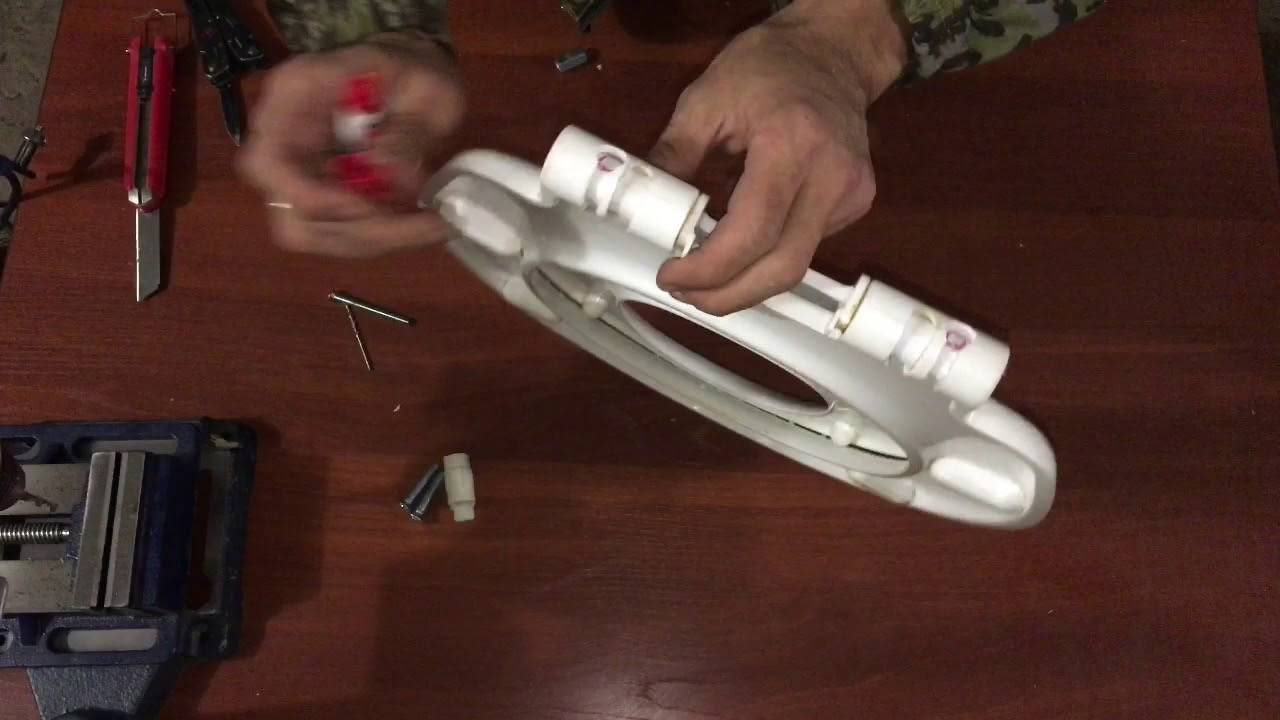

Replacing broken bolts

The most common malfunction that can be fixed on your own is disconnecting the base with an elevator from the toilet, which entails turning it. It can occur if the bolts break.

The work to eliminate the defect is performed in the following sequence:

- Dismantling the device. The standard design model consists of a stem that holds the cover, and a spring that slows down its rotation. The operating mechanism is simultaneously attached to both the plumbing cover and the seat frame.

- Replacing broken bolts, screwed on the reverse side with nuts, which connect the back of the cover to the elevator mechanism.

- Assembling the system in the reverse order with strict adherence to the installation of each part in its original place.

Nuts are screwed onto plastic bolts from the underside of the toilet bowl.

Work is carried out carefully so as not to damage the fasteners.

If you have to screw in brass parts to prevent damage to the surface, you should use intermediate plastic washers that soften the pressure of the fastener

If it is necessary to disassemble the right and left microlift, it is convenient to remove the holders with a conventional screwdriver.

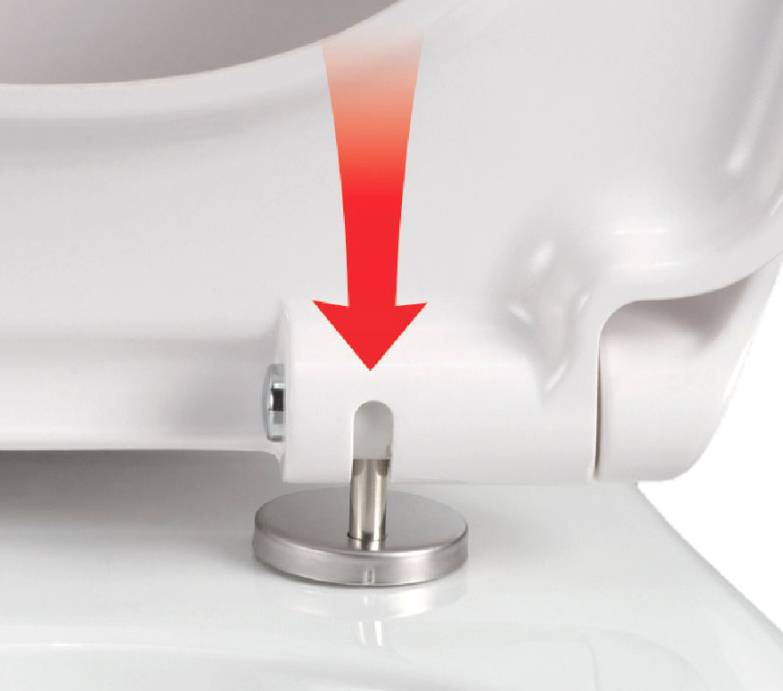

Pulling loose supports

To tighten one of the iron supports that secure the seat cover to the toilet body, it is necessary to remove the caps on each fastening leg.They are equipped with holes for the hex, although in some models these caps do not have holes.

To disassemble the structure on the left fastening leg, the cap is removed by turning to the right, and on the right - to the left. After that, it remains only, without applying excessive force, to remove the seat with the cover. To do this, it is simply gently lifted up in an open form.

Under the extracted structure, a second pair of shiny caps will open to the eye. Under them, a screw will already be noticeable, which will need to be screwed with a Phillips screwdriver. You just need to thoroughly tighten it and assemble the structure in the reverse order.

Elimination of other breakdowns

There are situations when, for some reason, the toilet lid itself breaks. If desired, you can try to glue it. Liquid nails do an excellent job with this task. If cracks have formed on the plastic seat, they can be repaired with dichloroethane or acetone. To do this, a little liquid is dripped onto the accident site and the edges are joined, fixing the cover in a stationary position for several minutes.

If the cause of the failure was the accumulation of lubricant, which is a viscous and transparent substance, in one zone of the cylinder, then to eliminate the defect, you need to carefully pick it out and then evenly distribute it throughout the system.

If, however, when closing / opening the lid makes a prolonged creaking sound, this indicates that the lubricating gel-like materials have been used up.

The cause of the malfunction lies in the breakdown of the spring? In this case, it will not be possible to repair it so that the device works fully.Microlifts in the bulk are non-separable structures, and it is almost impossible to choose a spring that is suitable in length and diameter.

Problems with the stem are also unlikely to be corrected on their own. It’s great if you can find a similar failed mechanism in which the stem functions properly. In other cases, the only correct way out of the situation is to replace the structure with a new one.

The nuances of the correct painting on glass

Do not think that painting on glass with stained glass paints is an expensive pleasure. You can save on the purchase of paints. To do this, do not purchase individual containers with paints, but the whole set.

By purchasing a set of paints right away, you get the opportunity to save money, as well as diversify the pattern.

To make the drawing process safe, do not forget about some precautions. Avoid contact of the paint and the painting itself with food and drinks

Paint should not get into the oral cavity. Therefore, when decorating glasses, glasses and saucers, they should not be used for their intended purpose in the future. Their main current function is to serve as a decor item. This is if you want to be completely safe. However, it is quite acceptable to paint “acting” tableware, subject to a minimum indent from the top cut of a cup or glass of 1.5 cm. That is, your lips and nose should not directly contact the paint.

Proper application of stained glass paints on glasses for permanent use

Modern man is increasingly striving for beauty, the desire to create beauty in everything, gives rise to a large number of exclusive handmade things. You can always decorate your home, give it a touch of perfection, give zest and originality, especially if you master painting with stained glass paints. Drawings on glass will help make any room exclusive, and if you paint it yourself, then the house will have a lot of light and joy.

Innovations in plumbing: we disassemble and repair the microlift

A modern modification of a conventional toilet lid, called a microlift, has its own features that are easy to appreciate as soon as you start using them. The main purpose of this design is the smooth raising and lowering of the lid, completely eliminating the possibility of sharp blows to the sanitary ware from which the toilet bowl is made. This will prevent its preliminary spoilage, which can significantly reduce costs from the family budget.

Design features and benefits

The principle of operation of a toilet bowl with a lid that has a built-in micro-elevator is akin to a conventional door closer, which is so familiar to most modern people. The microlift is usually already pre-installed in the lid, so it is hardly possible to purchase it separately. They make a microlift from durable plastic or its analogue, a material called duroplast. It is completely a polymer, although in appearance it can be confused with metal or even with ceramics, and in terms of properties it is closer to it.

Such a mechanism implies a rigid fixation to the toilet, but the designers did not forget about air cushioning either. On the cover there are necessarily compartments with shock-absorbing silicone.

- Polymeric sitting and cover for a toilet bowl.

- A special rod that fixes the lid on the toilet bowl.

- A metal or duraplast spring that regulates and balances the weight of the entire structure.

- Microlift, that is, a hinged mechanism, which ensures a smooth change in the positions of the cover.

You need to know that in more expensive designs, instead of rods and springs, pistons and cylinders of special design can be used in which they go. Such models are generally considered non-separable, they operate on the basis of pneumatics or hydraulics, and are only subject to replacement, not repair.

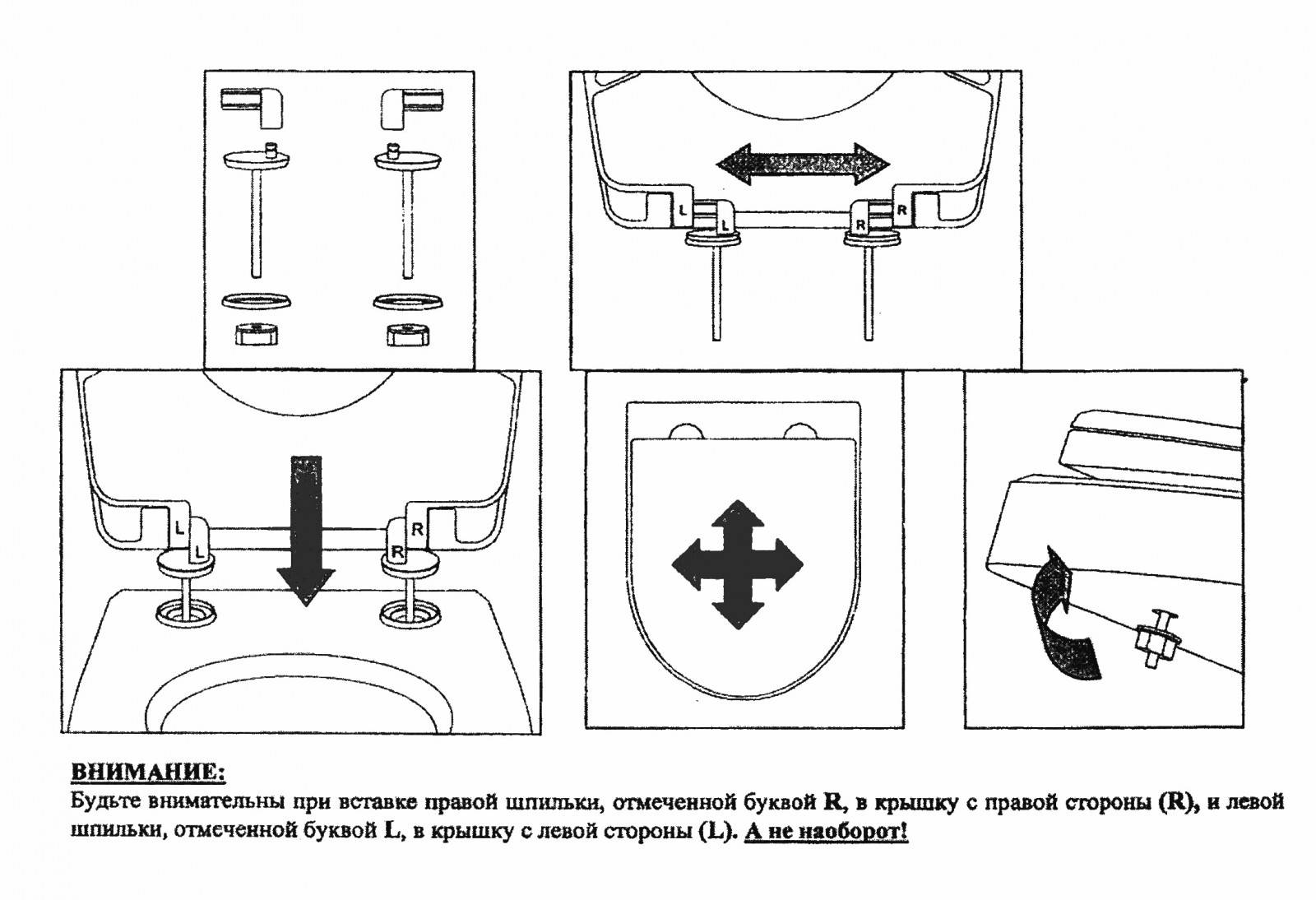

Just remove the toilet lid with microlift

Contrary to expectations, almost all toilet lids are equipped with conventional, standard fasteners, which makes it easy to remove them from their place and replace them. The design can be sky-high complex and even equipped with electronics, but the fasteners remain traditional.

- Raise the toilet lid as if you are going to use it. That is, the lid must be raised, while the toilet seat remains in place.

- On the left and right bottom of the bowl rim there are special fasteners, which can be plastic, metal or also duroplat. Unscrew the fastening nuts, first on one side, and then on the other side.

- Gently pull the toilet seat towards you to release the pins from the holes and remove the lid.

As you can see, removing the toilet lid with a microlift is not at all difficult, at least not more difficult than a regular one, so even a complete novice in plumbing can handle it. In the same way, but in reverse order, you can easily install a new toilet lid, with or without a closer.

Seat cover replacement

One of the significant reasons for the fatal breakdown of the mechanism is the wrong choice of model and errors during its installation. Therefore, when purchasing a new cover, you should be guided by the following rules:

take into account the dimensions of plumbing;

pay attention to the shape and configuration of the toilet;

give preference to products of trusted manufacturers.

The seats offered for sale with a lid equipped with a closer are suitable for toilet bowls of any design: floor-mounted, attached, suspended.

When choosing a new model, it is important to take into account the features of the plumbing fixture and pay attention to the fact that the distances between the fasteners of the system coincide with the seat attachment points.

To replace a broken lid with a closer with a new one, you will need a set of tools:

- hacksaw;

- pliers;

- end key.

Of the materials, silicone or oil will also be required to process the dried elements. Ideally, it is better to use a special lubricant that, penetrating into the cracks, freezes the rust.

Traditionally, the lid with the toilet seat is fixed with two bolts. But in some models, a metal stud may be used instead. For dismantling, you only need to lift the cover, and then unscrew the pins.

If the cover has been used for quite a long period, it is likely that the bolts are clogged, and the attachment points are coated and “soldered” to the body.

To provide easier unscrewing, simplifying your task, the bolts will have to be pre-coated with oil or silicone, but this is not always effective.

Using pliers, carefully, trying not to damage the decorative surface of the toilet bowl, unscrew the clamp and bolts.To protect plumbing from possible damage when working with pliers, it is better to cover the surface with rags or pieces of cardboard. This recommendation should not be ignored. Otherwise, at the slightest oversight, you will have to change not only the lid, but also the toilet bowl.

In extreme cases, if the processing did not give the desired result and the bolts do not lend themselves, they can be sawn with a hacksaw or cut off with a hot knife blade. Do not be afraid that the melted plastic will stain the plumbing. After hardening, it will not be difficult to remove it from the surface.

Having dismantled the old lid, in the grooves on the toilet, remove the remnants of dirt, accumulations of rust and limescale, after which bolts are inserted into the attachment points and the structure is fixed

Installation of a new cover is performed in the following sequence:

- 4 rubber inserts are inserted into the new seat cover. They will ensure a soft fit of the product to the seat.

- Fasteners are installed in the cast holes on the toilet bowl. They are screwed using rubberized seals, supplemented with a clamp or by means of a bolted connection.

- Seals are mounted in the seat, connected to the mounts on the toilet.

- The cover is fixed to the seat with a bolt, a plastic sleeve and a cup, which will be responsible for adjusting the height.

- Perform centering of the structure and check the seat for fixation strength.

Since the key cause of failure of the mechanism can be the incorrect position of the cover and seat, it is so important to accurately adjust the system when installing the structure.The adjustment process to ensure a uniform fit of the device over the entire surface of the sanitary ware is carried out by rotating the cups screwed onto the bolt

An important point: adjustment and centering is performed at the stage when the fixing nuts are only baited, but not yet firmly tightened

The adjustment process to ensure a uniform fit of the device over the entire surface of the sanitary ware is carried out by rotating the cups screwed onto the bolt. An important point: adjustment and centering are performed at the stage when the fixing nuts are only baited, but not yet firmly tightened.

To consolidate knowledge and better present the process of repairing and installing a toilet lid, we offer useful and interesting videos.

Repair of toilet mounts:

How to install the system correctly:

In the future, in order to reduce the risk of premature failure, it is important to periodically check the position of the device and adjust it during operation. And remember: a seat with an elevator device is a “smart” mechanism that requires careful handling.

The microlift in the toilet is like a door closer. Thanks to this element, you can really smoothly lower or raise the lid along with the seat.

If you want to purchase similar toilet equipment, be sure to pay attention to its advantages, disadvantages and selection criteria.

Cover selection

To choose a toilet lid, you need to rely on the following parameters:

- material of manufacture;

- shape and size;

- additional options;

- manufacturing company.

What are lids made from?

The lid-seat for the toilet bowl can be made:

plastic. The most commonly used polyethylene, polyvinyl chloride or polypropylene.Plastic lids are inexpensive and come in a variety of shapes and colors. Negative qualities are poor thermal conductivity and susceptibility to mechanical stress;

duroplast. A more expensive, but also more advanced material for the production of caps. Most often, child seats are made from duroplast, since the composition of the material includes an antibacterial component that prevents the growth of bacteria on the surface of the device. Lids are also available in different shapes and colors;

wood (MDF, chipboard). Covers made of these materials are characterized by high cost and high weight. In case of accidental sharp lowering, chips may appear on the surface. A positive aspect is the environmental friendliness of the material used.

The optimal material for home use, according to experts, is duroplast.

Variety of shapes and sizes

The toilet lid should completely repeat the shape of the bowl. Only in this case it is able to serve for a long time.

If small children live in the house, then you can install a multi-colored cover in the shape of an animal.

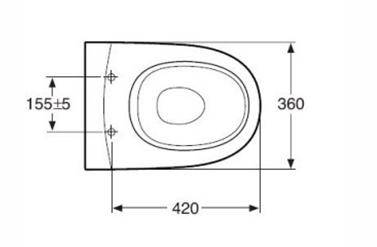

To determine the dimensions of the cover, you need to know:

- the distance between the holes for attaching the device to the toilet bowl;

- the width of the toilet (measured in the largest part of the plumbing equipment);

- the length of the toilet bowl (measured from the center line of the location of the fasteners to the edge of the bowl.

Availability of additional functions

Recently, lids with additional functions have become very popular:

bidet cover. Allows you to install one plumbing fixture instead of two, which saves space in the toilet room.Depending on the model and cost, the function of autonomous water heating can be provided on the lid. The lid is controlled from the panel located nearby or from the remote control;

cover with microlift. After using the toilet, the lid slowly lowers onto the seat, eliminating the possibility of a sharp fall that could cause damage to plumbing and noise;

The heated seat cover ensures maximum comfort even in the cold season. With the help of a temperature sensor on the seat surface, the temperature is constantly maintained at 35ºС - 36ºС;

cover for an adult and a child, complemented by two seats of different sizes. For the comfort of small toilet users, special lids have been developed that do not require the installation of additional equipment in the form of a lining.

All additional functions can be installed both separately and together with each other. For example, a cover with a child seat, supplemented by a heating function and a microlift.

Separately, you can highlight the "smart" cover, which is equipped with a sensor that reacts to the approach of a person. When the user enters the toilet, the lid opens, and when the user leaves, it closes. "Smart" covers can be supplemented with any functions.

Cap manufacturers

When choosing a cover, you should also pay attention to the manufacturer, on which the quality and durability of products depend. The most popular are the lids issued:

- Spanish company Roca. Toilet lids are suitable for sanitary products of this brand, as well as for other modifications. Lids are available in different sizes, colors and with various additional features.The product warranty is 3-5 years;

- Polish company Cersanit. The company's products are recommended by experts as the most durable and reliable. A wide range of models allows you to choose devices of different shapes and sizes;

- Jika company (Czech Republic). The company has been introduced to the Russian market relatively recently, but, according to users, the lids are reliable products;

- by Gustavsberg (Sweden). The company specializes in the production of caps with additional options.

Among Russian companies, one can single out the company Suntec, which produces high-quality covers of various configurations, colors and sizes.