- Do-it-yourself well cleaning and repair work

- cleaner's equipment

- cleaning and making necessary repairs

- what is the best way to strengthen and seal the seams

- Seat selection ↑

- Oak staining technology ↑

- Carrying out repairs in cement wells

- Sealing joints

- Displacement of cement rings

- Well deepening

- Cleaning the sewer well

- Well log assembly technology

- The purpose of the pumping station

- Roll and coating waterproofing materials

- Making a well ring with your own hands

- stone finish

- Tips

- Rationale for ongoing work

- Seam technology

- Preliminary work

- Repair of dry seams and cracks

- Repair of leaking seams

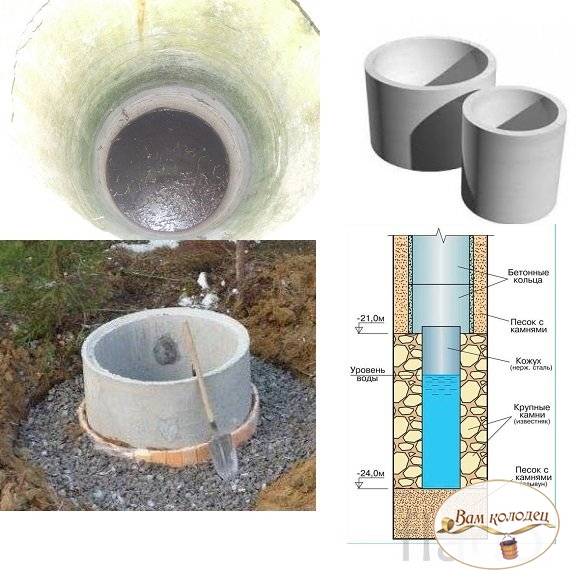

- The main structural elements of the sewer well

- Concrete well

- Brick repair work

- Conclusion

- Conclusions and useful video on the topic

Do-it-yourself well cleaning and repair work

At present, it is difficult to find a specialist or a team that will competently carry out the necessary measures. Therefore, you will have to learn in detail how to clean the well with your own hands.

cleaner's equipment

Recall that the "cleaning" work is laborious and unsafe.Only a daredevil and his friends dare to scoop up buckets of dirty water, standing on a slippery staircase in a stuffy tunnel of a well.

It is preferable to work during daylight hours with a team of three people. By the way, as a "climbing" equipment you will need:

• safety rope and rope

• comfortable stairs

• support rods

• wooden swing with a hook

• platforms on cables

• hunting rubber boots

Dressed in a canvas suit, wearing boots and a helmet, you can gradually descend into the well shaft, attaching a safety cable to your belt. A prerequisite for descent and ascent is the presence of a surface insurer and a signal rope.

Helpful Hints

If the cleaning equipment causes a smile and ridicule of others, then these are vain emotions - you cannot do without reliable insurance. Tested by time and work on the descent and ascent of mine mine rescuers. Safety equipment can be rented.

Having plunged into the well shaft, the cleaner, by visual examination, becomes clear how to clean the well and what needs to be repaired inside.

cleaning and making necessary repairs

When cleaning a well, it may be necessary to do the following:

• strengthening and sealing of seams of concrete rings

• cleaning of bottom filters

• repair of wooden structures

what is the best way to strengthen and seal the seams

To strengthen and seal damaged seams of rings, cracks or potholes, a waterproof sealant is used. The simplest type of reinforcement is also a traditional concrete mortar.But as the practice of cleaning the well shows, it is preferable to carry out strengthening work with a more reliable material, such as Fasi RM concrete surface restorer or water-repellent impregnations with a waterproof effect.

The restorer of the concrete surface of wells is a traditional cement mortar, which is applied to the working surface with a spatula. In addition, there are materials for filling cracks and joints: Penetron, Peneplag and Penekrit.

Seat selection ↑

Determining the place of digging is of great importance, since both the quality of the water and the integrity of neighboring buildings depend on it. In order to prevent subsidence of the soil and the destruction of the foundations of capital structures, the well must be placed at least five meters from these objects. And to prevent contamination of groundwater with runoff, the drain pit should be located 20 meters from the intended digging site.

The most reliable way to determine the depth of an aquifer, apart from expensive geological exploration, is to take information from the nearest neighbors. If one of them already has a well, then you can do without calling specialists

The layout of the well on the site

Oak staining technology ↑

Having decided to make a wooden well from oak, you need to be aware of one unpleasant feature - oak wood gives the water a bitter taste. And although it disappears over time, it should take at least a couple of years for this to happen. In order to prevent the appearance of bitterness, before the arrangement of the mine, the oak is subjected to a staining process, which is carried out according to the following technology.

- The bark is removed from the wood and the knots are cut. The tree is cut into the desired size, for which you first need to calculate the dimensions of the future well. The frame is assembled and adjusted, with each log numbered to prevent confusion in the future. suitable, since the water must be running). After 2 years, the blanks are taken out of the water and dried under a canopy. After complete drying, you can start digging and arranging the mine.

The process of staining oak takes a lot of time, but the result is a really high-quality building with good drinking water.

Carrying out repairs in cement wells

Sealing joints

Work on sealing the joints between reinforced concrete rings is the most common type of minor damage and is easily repaired, therefore, anyone can carry out such a repair of the well with their own hands, without having special skills, but following the basic safety rules.

Cracks in the rings appear as a result of shrinkage of the soil and its displacement. This is the usual behavior of the soil in different seasons. To eliminate cracks, it is possible to use a simple cement mortar mixed with a simple PVC adhesive.

It is possible to use ready-made mixtures for sealing, but their price will be significantly higher than the components for cement mortar.

To seal cracks at the joints of the plates, you will need:

- putty knife;

- cement mortar;

- metal brush;

- a hammer.

If large cracks are found through which soil and perched water enter, then repair of the well from cement rings in such cases is carried out from the outside of the mine.To do this, a hole is dug from the side of the crack to the desired depth, the seam is processed from the outside, and the hole is dug back.

Displacement of cement rings

Repair: displacing the rings in the well is a rather complicated operation that requires partial disassembly of the entire well shaft. The displacement in most cases occurs as a result of soil movement, if during the construction of the mine the rings were not fixed to each other or a pillow of sand and crushed stone was not installed near the walls of the mine.

The technology for repairing wells in such cases provides for the dismantling of all cement rings above the displacement point, their secondary installation in the required place and fastening together with special iron brackets. On the outer part of the mine, an additional layer of large crushed stone is laid, which softens the pressure of the soil on the mine when it moves.

Well deepening

Deepening also applies to repair work. With incorrect initial calculations of the depth of the well or as a result of a number of other circumstances, the water level in the source may significantly decrease or even fall through the ground. In such cases, measures will be required to deepen the shaft, where repair rings for the well are used.

When carrying out deepening work, it will not be possible to use already installed rings, because after the expiration of time, they are well clamped by the ground due to small seasonal movements. You should not try to lower the installed cement products by force, this can lead to great damage and, as a result, more complex repairs will be required with partial dismantling of the well, which will inevitably entail additional financial costs.

Before you repair the well with your own hands, you need to clearly assess your capabilities, the availability of special knowledge and the right tool. In many cases, carrying out any work on your own can not only harm the source itself, but also harm your health. Based on this, if you doubt your own abilities, it is better to ask for help from a specialized company and hire a team of qualified workers.

Cleaning the sewer well

Repairing a sewer well is not much different from similar troubleshooting work in fresh water sources, where the same cement rings are used to build a shaft and head.

The difference is that these wells perform different functions, but the technical device for all is actually the same and the types of malfunctions are the same.

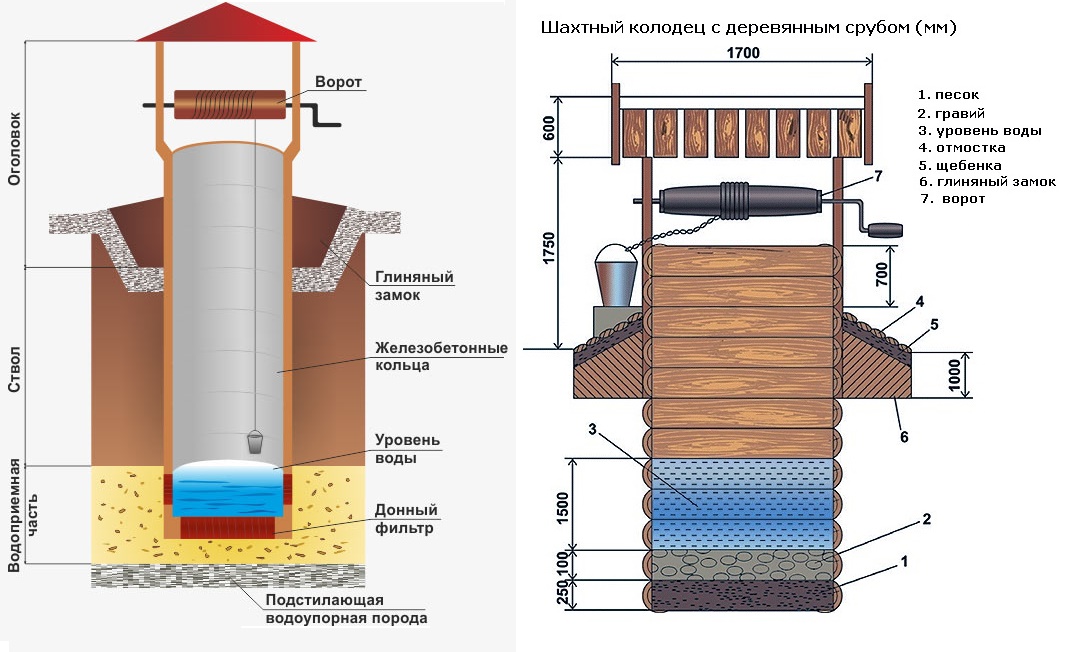

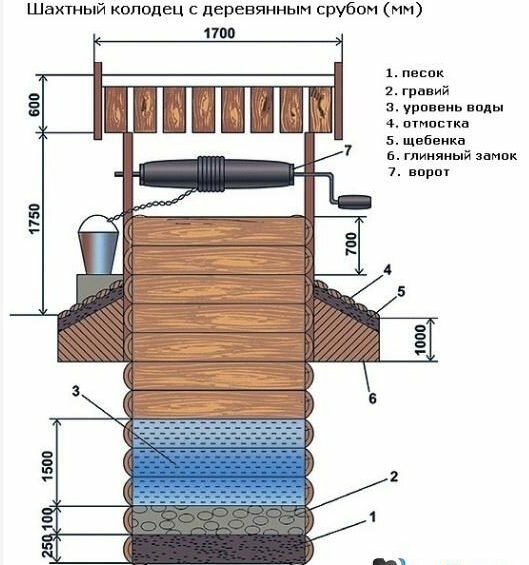

Well log assembly technology

Scheme of connecting the corner of the log house into the paw.

To assemble the log house, you should prepare the tools:

- petrol or electric saw, hacksaw; axe, chisel, hammer; scraper and adze; plumb line, tape measure and level.

The log house is erected in a square shape, more often 1 × 1 m. The wood for the log house is selected based on the location of the logs relative to the water. Material that is above water is more prone to rotting than drowned in it.

It is better to combine the use of different types of wood. Underwater parts should be made of pine, willow or aspen, hanging over a layer of water - from larch, elm, alder or bog oak. With this combination of material, the well can last more than 20 years.

Oak logs that have passed the staining process in the underwater part of the well may not collapse for more than a century.But without this treatment, the wood will give the water a bitter taste and change color to brown. Other types of wood are less durable and affect water quality.

Timber must be straight, not dry.

The logs used must be free of rot or insect infestation. The bark is peeled off before assembling the log house. It is not recommended to treat the material with antiseptics or other protective compounds.

Scheme of the gate for a wooden well.

To equip the well, logs with a diameter of 18-20 cm are used, larger trunks are sawn along.

The saw cut is placed inside the log house. The assembly of the log house is first made on the surface. If installation is planned inside the shaft, the crowns are prepared and marked in advance.

In the corners of the log house, the elements are connected into a paw without a trace. Fastening is carried out with pins measuring 10 cm apart vertically.

For structural strength, adjacent crowns are fastened with brackets, tied with bars in the corners. Boards are nailed in the middle of each wall during installation. The logs are adjusted carefully, since it is not allowed to caulk the cracks, the tow will affect the quality of the water.

The purpose of the pumping station

What is the purpose of water supply systems? This is the pumping of water to the consumer from a water supply source (well, river, reservoir), and this requires a special pumping booster device.

It is the pumping unit that takes water through the suction pipelines and transfers it to a residential building or industrial building through pressure pipelines. No water supply system will work without pumping units.

Pumps are needed for supplying water for drinking purposes, for extinguishing fires, pumping domestic and industrial wastewater, draining mines and basements, borehole and sand pumps. There are pumps for pumping solutions, feces, clean water, oil products. The selection of the type and brand of the pump is made for each specific case.

Popular models: al ko (alco), grundfos, gardena 3000 4, grundfos, gilex jumbo 60 35, marina, whirlwind, etc.

Roll and coating waterproofing materials

Often, when waterproofing various surfaces, bituminous mastics and polymer compositions are used. They are usually used for outdoor waterproofing. It is worth remembering that if the well is drinking, it is not worth treating it with such materials from the inside. This is due to the fact that with prolonged use of the well, elements that are harmful to the body can penetrate into the water.

Waterproofing with the help of such compositions is carried out in several layers. At the same time, reinforcing meshes consisting of polyester fibers are used during such work.

It should be noted that mastic, compositions based on liquid rubber and paint contribute to additional sealing of concrete rings. The use of such materials prevents the gradual penetration of moisture through the concrete.

Also, for processing the well, you can use roll materials on a soft frame. They can be used alone or together with mastics. Fixing such materials is quite simple, so many owners of suburban areas choose them.

Making a well ring with your own hands

If a cap or canopy is made, the gray concrete ring remains visible. The view is not the most attractive, and I want to decorate it.

stone finish

The most popular way to decorate a well is to finish it with stone - pebbles or medium-sized rubble. If everything is more or less clear with the finishing material - to buy or assemble, then the question of what to cling to it remains. There are several recipes:

-

A bag of glue for tiles and natural stone 25 kg + a bag of dry mix 300 - 50 kg. We mix everything, in a dry form, we dilute to a pasty state with water. Stones are soaked in water. We apply a thin layer on the ring - a vertical strip from top to bottom, select and place the stones, sinking them into the solution. When a piece is made, before the solution has dried up, the stones are cleaned, the seams are overwritten.

- M500 cement - 1 part, sifted medium-grained sand - 3 parts, PVA glue - 1/3 part, water - about 1 part. Work at approx. +20°C, wearing thick rubber gloves: corrosive to hands. Knead immediately a small batch of the solution: 1 part is a 500 ml jar. Such an amount can be worked out before the solution sets. The technology is similar: stones are soaked, but the well ring is also wetted. Then a layer of mortar is applied to it, stones are pressed in.

We offer the third recipe for how to line a well with stone in video format. The composition of the mixture here is very similar, but before applying the solution, a mesh is fixed on the ring. With this technology, nothing will definitely fall off.

An interesting variant of the hinged cover on the well is proposed in the following video: it leans back almost completely, but whether such a device is needed is up to you.

Tips

If a source of water is required, for example, in a country house, then installing a well will be a simpler solution, since there is much less work with it, and the well requires more serious technological research.At the same time, the water from the well will be significantly cleaner, and the risk of jamming the inflow of water will be less due to the greater depth and remoteness of water from various infrastructure that can cause pollution.

At the same time, the water level in the well does not fluctuate from season to season, as is the case with a well. Also, the well, despite its durability, requires constant care and maintenance. At the same time, the well does not require such serious maintenance and frequent maintenance.

From a financial point of view, a well is a more affordable option than a well. Moreover, sometimes the cost of a well exceeds the cost of a well. But the reason here is simple - the complexity of drilling and the need to attract specialized drilling equipment.

You can make sure that repairing wells and wells with your own hands is quite realistic. Before carrying out work, you should clearly understand the algorithm of the necessary actions and know what exactly you have to deal with, as well as what result you want to get. But even a person who has not previously encountered such work without any special difficulty can do the repair of a well or a well with his own hands.

From the video below you can learn how to clean the well from sand.

Rationale for ongoing work

Particular attention should be paid to the issues of the validity of the repair work. According to p

6 art. 55.24 of the Civil Code of the Russian Federation, in order to ensure the safety of buildings and structures during their operation, institutions must provide maintenance of buildings, structures, their operational control and current repairs.

Operational control over the technical condition of buildings, structures is carried out during their operation through periodic inspections, control checks and (or) monitoring of the condition of foundations, building structures, engineering and technical support systems and engineering networks in order to assess the state of structural and other reliability characteristics and safety of buildings, structures, systems and networks of engineering and technical support and compliance of the specified characteristics with the requirements of technical regulations, project documentation.

During general inspections, the technical condition of the building or the object as a whole, its systems and external improvement are monitored, with partial inspections, the technical condition of individual structures of the premises, elements of external improvement. Unscheduled inspections should be carried out after earthquakes, mudflows, heavy rains, hurricane winds, heavy snowfalls, floods and other natural phenomena that can cause damage to individual elements of buildings and facilities, after accidents in heat, water, power supply systems and when deformations are detected grounds.

To conduct these inspections, the institution should create a commission, and their results should be reflected in the documents on the registration of the technical condition of the building or object (registers of the technical condition, special cards, etc.). These documents should contain an assessment of the technical condition of the building or facility and its elements, identified faults, their location, the causes that caused these faults, as well as information on the repair work performed during the inspections.Generalized information about the state of a building or object should be reflected annually in its technical passport.

The basis for carrying out repair work should be acts of inspection of property and defective statements (defective acts) (Letter of the Ministry of Finance of the Russian Federation dated 04.12.2008 No. 03-03-06 / 4/94). In order to conduct inspections in the institution, it is necessary to form a commission or appoint responsible persons. It is advisable to show the following information in the defective statement:

- identification data of the fixed asset object (inventory number, brief description of the object, its location, etc.);

- identified defects and shortcomings;

- a list of necessary works to bring the fixed asset object into working condition;

- signatures of the members of the commission conducting the inspection.

At the same time, in our opinion, it is advisable to approve the forms of documents in the accounting policy of the institution. As an example, you can use an act on detected equipment defects, which is drawn up in the form OS-16, approved by the Decree of the State Statistics Committee of the Russian Federation dated January 21, 2003 No. 7.

Repair work can be carried out both by the employees of the institution (as part of the performance of their official duties), and with the involvement of third-party organizations. Recall that the involvement of a third-party organization must be carried out in accordance with the procedures provided for by federal laws dated April 5, 2013 No. 44-FZ “On the contract system in the field of procurement of goods, works, services to meet state and municipal needs” (hereinafter referred to as the Law on the contract system ) and dated July 18, 2011 No. 223-FZ “On the procurement of goods, works, services by certain types of legal entities”.

Seam technology

To decide how and with what to seal the seams in the well, you need to see if water is flowing from them, since the technology for repairing dry and wet seams is different.

Preliminary work

Before sealing the seams between the rings in the well, some preparatory measures should be taken:

Clean the walls of the shaft from dirt, algae and other deposits using mechanical cleaning methods or a jet of water under strong pressure;

Cleaning with a Karcher high-pressure device

- Remove the destroyed concrete from the joints, beat it off where it is cracked and does not hold well;

- Expand and deepen the seams, clean them.

In a word, the repaired surface must be clean and durable.

The photo shows the brackets fixing the concrete rings

Repair of dry seams and cracks

The seams in the well are sealed with dry mixtures mixed with water. The most affordable option is cement and sand. But such a composition, under the influence of moisture and frost, will not last long, and will begin to collapse again. To prevent this from happening, liquid glass is introduced into the mixture.

When working with it, you should remember that it hardens very quickly, so the seams must be prepared in advance for sealing, and the mortar should be made exactly as much as you can use in 5-10 minutes. The process itself consists in covering the joints with mortar with a spatula, as is done when plastering walls.

Sealing joints with cement mortar

When deciding how best to seal the seams in the well, do not try to simplify your work and use various sealants, mounting foam or epoxy for this purpose. At best, you will not achieve the desired effect, at worst, you will harm the quality of drinking water, make it unsafe for consumption.

Repair of leaking seams

If a top water seeps through the cracks and potholes in the walls of the well, it is pointless to seal them with cement mortar - it will wash out without having time to set and harden. How to cover the seams in the well in this case?

To do this, quickly hardening expanding materials are used - the so-called hydraulic seals (HydroStop, Waterplug, Peneplug and others). They harden very quickly, without forming cracks and reliably sealing the leak.

Fast setting waterproofing compound

Hydraulic seals are absolutely waterproof, resistant to temperature changes, thawing salts and other aggressive influences. Their only drawback is their high price. A three-kilogram package costs an average of 800-1000 rubles.

Waterproofing seams in a well using a hydraulic seal is possible in two ways:

Just a solution. It is prepared according to the manufacturer's instructions - most often it is diluted in a clean dish with water heated to 20 degrees in a ratio of 5: 1. the proportion may vary depending on the size of the defect. The solution is kneaded in a small amount, as it quickly hardens, stirs very quickly and is pressed into a pre-embroidered hole with your own hands. Then it is held manually for 2-3 minutes.

If the groundwater behind the walls of the well is under pressure, and the flow between the rings is very strong, you can try the following method. Drill one or two holes with a puncher 15-20 cm below the leaking seam.

Water will rush into them, the pressure between the rings will weaken or disappear altogether, and sealing the seams in the well will be easier. When the mortar sets, the holes can be filled with fitted wooden chopsticks and also covered.

When working with a perforator, remember the close proximity of water and electricity, follow safety precautions

Unfortunately, even the highest quality well repairs cannot guarantee that leaks will not appear over time in other places. Therefore, it is necessary not only to waterproof the seams of the well, but also to treat the entire inner surface of the shaft with special elastic compounds.

After drying, they create a continuous film, sealing all small cracks and preventing them from growing. The composition adheres well to the surface, resistant to water and frost.

If the upper seams constantly leak and diverge, it makes sense to close them up not only from the inside, but also from the outside, by digging the soil around the well. After the repair work is completed, it is advisable to arrange a clay castle around the source or make a blind area.

This is interesting: How to break through a blockage in washbasin without cable?

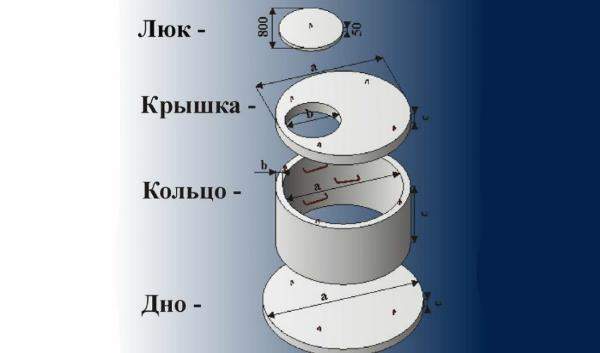

The main structural elements of the sewer well

To begin with, attention should be paid to what structural elements the sewer well has. The main ones are:

- Working tank.

- Mine.

- Neck.

- Bottom.

- Observation hatch.

Also, in the case of using reinforced concrete rings, a waterproofing layer is created, which can be represented by a tape or waterproofing plastic materials. In the case of a plastic well, almost all structural elements are of the same design due to the seamless production.

This image shows parts of a sewer well: Manhole - cover - concrete ring - bottom (base) of the well.

Concrete well

A well made of reinforced concrete rings.

The most common causes of repair behavior concrete wells are the appearance of cracks or displacement rings. Such consequences are caused by the use of low-quality cement during the construction of the well or the features of the soil surrounding the well. In some cases, the seams between the rings are washed away by flood waters that oversaturate the soil with moisture.

The cracks formed on the surface are sealed with mastic.

The degree of complexity of repair work is related to the degree of destruction of the sealing coating. Minor damage noticed in time in the form of gaps formed can be repaired from the inside, and you can do it yourself. The crack is tapped before processing, all unreliably fastened pieces of concrete are removed.

With the help of waterproof mastic for concrete, defects are carefully covered, and at the end you can install and use a filter

It is important to ensure that the composition of the mastic is safe for humans, as it will interact with drinking water.

More serious damage should be repaired both inside and outside the well. For this purpose, a ditch is dug along the perimeter of the structure, which should reach the structural defect. The width of the trench should be chosen so that it allows repair work to be carried out even if the filter needs to be replaced.

Having reached the crack, it is cleaned of dirt and carefully sealed with mastic. On top of the composition, it is desirable to treat the seam with a special waterproofing composition, which will prevent erosion of the material.

The displacement of concrete rings requires partial dismantling of the well structure. The most time-consuming repair will be in case of displacement of concrete well rings.In this case, the entire damaged area will have to be dug up and dismantled. Then it will have to be assembled again, while installing additional connecting rings and brackets. All seams are carefully sealed, after which the well structure is sealed and a new blind area is mounted.

Brick repair work

Brick-lined wells are the easiest to repair. The elements of their lining are small and easily replaceable. First of all, the walls must be thoroughly cleaned of dirt, otherwise it is easy not to notice the damage. If through cracks have formed between the bricks, they should be repaired with high quality from the outside of the structure. We are preparing a repair trench. Having reached the defect, we clear it up to 10 cm in depth.

After that, we thoroughly coat the gap with clay, deepening at least 5 cm. Inside the well, work boils down to replacing spoiled bricks and restoring crumbling plaster. Defective brick or its remains are carefully hollowed out of the wall. We take a new part and insert it in place of the old one, laying it on the cement mortar.

Brick-lined wells are quite easy to repair. The damaged brick is carefully hollowed out and replaced with a new one.

Before plastering, carefully prepare the base. With a steel brush, we clean it from dirt and mucus, otherwise a sinus will form under the solution, in which water can accumulate. And this will lead to the rapid destruction of the new plaster. We carefully tap the old coating and remove all unreliable areas and crumbled fragments. After that, once again we clean the base and proceed to plastering.

Conclusion

For carrying out any work in deep mines, there is a special safety instruction, which provides for the availability of personal protective equipment and safety elements, as well as certain rules for the use and composition of the building material used in the implementation of repair work.

In order to pass without excesses, be sure to watch the video in this article.

For houses in the private sector or those located in rural areas, timely and competent do-it-yourself repair of the well remains relevant. The well in this case is often the only available source of water supply in the absence of a centralized system. Therefore, maintaining it in working condition, ensuring the supply of clean water is a prerequisite for comfort.

Quite often, in a well that has recently been regularly supplying clean water, the liquid acquires an unpleasant taste and smell, it has a color that indicates the presence of impurities. Such water should not be used for drinking or culinary purposes. In addition, the increased amount of impurities can ruin plumbing, household appliances, and quickly render filter cartridges unusable. Will repairs be required wells in the country with your own hands - in each case, you can decide after careful design inspection

, but cleaning and eliminating the causes of pollution is always required. There can be several reasons for the appearance of dirt.

- Natural silt deposits on the walls and bottom of the channel, which are a mixture of unicellular algae, microparticles of organic matter, bacteria, etc. that have entered the water. Like any organic matter, such a mixture begins to decompose, giving the water an unpleasant odor and taste.

- Large pollution that accidentally fell into the well - leaves carried by the wind through the upper part that was not closed with a lid, a small animal that fell and drowned, etc.

- Soil particles and organic matter from the soil that enter through the walls in case of violation of their tightness.

If in the first two cases you can limit yourself to cleaning and sanitizing the structure, in the latter you will have to think about how to repair the well.

Conclusions and useful video on the topic

The video will introduce the procedure and technological stages of sealing joints in a concrete well:

Detailed video instruction on fixing a pressure leak using the Peneplag hydraulic seal:

Competent production of hand-made seals and the use of industrial compounds guarantees an excellent result, eliminates leaks and cracks in a reinforced concrete well shaft.

We are interested in your personal experience in fixing leaks in a concrete well shaft. Please write comments in the block under the article submitted for review. Ask questions here, share useful information and photos of the process of sealing cracks and weak spots in the wellbore.